SICK OD5000 Series, OD5000-C85W20, OD5000-C85T20, OD5000-C150T40, OD5000-C150W40 Operating Instructions Manual

Page 1

OD5000

Displacement measurement sensor

O P E R A T I N G I N S T R U C T I O N S

Page 2

Product described

OD5000

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Information on the operating instructions.............................................. 7

1.2 Explanation of symbols............................................................................ 7

1.3 Customer service...................................................................................... 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Improper use............................................................................................. 8

2.3 Limitation of liability................................................................................. 8

2.4 Modifications and conversions................................................................ 8

2.5 Requirements for skilled persons and operating personnel.................. 9

2.6 Operational safety and particular hazards.............................................. 9

2.6.1 Laser radiation......................................................................... 10

2.7 Warning signs on the device.................................................................... 11

3 Product description........................................................................... 12

3.1 Product characteristics............................................................................ 12

3.2 Setup and dimensions............................................................................. 12

3.2.1 Light spot size.......................................................................... 14

3.3 Product identification............................................................................... 15

4 Transport and storage....................................................................... 17

4.1 Transport................................................................................................... 17

4.2 Unpacking.................................................................................................. 17

4.3 Transport inspection................................................................................. 17

4.4 Storage...................................................................................................... 17

5 Mounting............................................................................................. 18

5.1 Scope of delivery....................................................................................... 18

5.2 Facilities for connecting........................................................................... 19

5.3 Mounting instructions............................................................................... 20

5.4 Mounting device....................................................................................... 20

5.4.1 Mounting the device depending on application.................... 21

6 Electrical installation........................................................................ 24

6.1 Safety......................................................................................................... 24

6.2 Wiring notes.............................................................................................. 24

6.3 Pin assignment of the connections......................................................... 24

6.4 Connecting the device electrically........................................................... 27

7 Operation............................................................................................ 28

7.1 General notes............................................................................................ 28

7.2 Control elements and status indicators.................................................. 28

7.2.1 Indicator lights......................................................................... 28

7.2.2 Operating elements................................................................. 29

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

3

Page 4

CONTENTS

7.3 Operation via web browser (SOPASair).................................................... 29

7.3.1 Determining the device IP address......................................... 29

7.3.2 Connecting via the web browser............................................. 29

7.3.3 Overview of SOPASair.............................................................. 30

7.3.4 Monitoring................................................................................ 31

7.3.5 Measurement........................................................................... 31

7.3.5.1 Setting diffuse or specular reflection.................... 32

7.3.5.2 Determining the measurement type..................... 32

7.3.5.3 Teaching in the zero point...................................... 33

7.3.5.4 Setting the sampling duration............................... 33

7.3.5.5 Synchronizing several OD5000 sensors............... 34

7.3.5.6 Determining the direction of detection................. 34

7.3.5.7 Checking the light distribution curve and peaks.. 35

7.3.6 Settings for channels A–D...................................................... 36

7.3.6.1 Setting the measurement value filter.................... 36

7.3.6.2 Setting the Hold function....................................... 38

7.3.6.3 Setting the alarm (action in case of incorrect

measurements)....................................................... 41

7.3.7 I/O channels............................................................................. 42

7.3.7.1 Setting limits........................................................... 42

7.3.7.2 Setting the hysteresis............................................. 42

7.3.7.3 Setting the switch-on delay (On Delay).................. 43

7.3.7.4 Setting the switch-off delay (Off Delay)................. 43

7.3.7.5 Setting the calibration............................................ 44

7.3.7.6 Setting One shot..................................................... 45

7.3.8 I/O settings input (MF)............................................................ 46

7.3.8.1 Setting the polarity................................................. 46

7.3.8.2 Setting the switching function................................ 46

7.3.8.3 Setting the debounce............................................. 47

7.3.9 Device....................................................................................... 47

7.3.9.1 Deactivating the measurement laser.................... 47

7.3.9.2 Resetting the device to factory settings................ 47

7.3.9.3 Setting the sensor time.......................................... 47

7.3.9.4 Device identification............................................... 47

7.3.9.5 Saving the configuration........................................ 47

7.3.9.6 Loading the configuration...................................... 48

7.3.10 Communication........................................................................ 48

7.3.10.1 Communication settings........................................ 48

7.3.10.2 Network settings..................................................... 49

7.3.11 Recording................................................................................. 50

7.3.11.1 Formatting settings................................................. 50

7.3.11.2 Starting and testing the recording......................... 50

7.3.11.3 Determining the allocation..................................... 51

7.3.11.4 Setting the interval................................................. 51

7.3.11.5 Setting the start conditions................................... 51

7.3.11.6 Defining the threshold............................................ 51

4

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 5

CONTENTS

7.3.11.7 Defining the trigger channel................................... 51

7.3.11.8 Setting the start position........................................ 51

7.3.11.9 View process........................................................... 52

7.3.12 Info............................................................................................ 52

7.3.13 Expert....................................................................................... 53

7.3.14 Settings.................................................................................... 53

7.3.14.1 Selecting a language.............................................. 53

7.3.14.2 Selecting the display mode.................................... 53

7.4 Operation via Ethernet.............................................................................. 53

7.4.1 Reading and writing data........................................................ 53

7.4.2 Command list........................................................................... 54

7.4.2.1 Outputting measured values.................................. 55

7.4.3 Measurement........................................................................... 56

7.4.3.1 Selecting default settings....................................... 56

7.4.3.2 Making the settings for channels A–D.................. 59

7.4.4 I/O settings.............................................................................. 60

7.4.4.1 Configuring channels A–D...................................... 60

7.4.4.2 Configuring MF input.............................................. 62

7.4.5 Device settings......................................................................... 62

7.4.6 Communication........................................................................ 63

7.4.7 Saving data.............................................................................. 63

7.4.8 Info............................................................................................ 64

7.4.9 Determining measured values using time specifications..... 64

7.4.10 Obtaining data continuously................................................... 64

7.4.11 Error messages........................................................................ 67

8 Maintenance...................................................................................... 68

8.1 Maintenance............................................................................................. 68

8.2 Cleaning..................................................................................................... 68

9 Troubleshooting................................................................................. 69

9.1 General faults, warnings, and errors....................................................... 69

9.2 Detecting and displaying errors............................................................... 69

9.3 Information for service cases.................................................................. 70

9.4 Returns...................................................................................................... 70

9.5 Repairs...................................................................................................... 70

10 Decommissioning............................................................................. 71

10.1 Disposal..................................................................................................... 71

11 Technical data.................................................................................... 72

11.1 Performance............................................................................................. 72

11.2 Interfaces.................................................................................................. 72

11.3 Mechanics and electronics...................................................................... 72

11.4 Ambient data............................................................................................. 73

11.5 Linearity diagram...................................................................................... 73

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

5

Page 6

CONTENTS

12 Accessories........................................................................................ 75

12.1 Recommended accessories..................................................................... 75

13 Annex.................................................................................................. 76

13.1 EU declaration of conformity / Certificates............................................. 76

13.2 Licenses.................................................................................................... 76

13.2.1 .................................................................................................. 76

6

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 7

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to handle the prod‐

uct from SICK AG. Adherence to all the specified safety notes and guidelines is a pre‐

requisite for working safely. You must also comply with any local work safety regulations

and general safety specifications applicable to the use of the product.

Ensure that you read through these operating instructions carefully before starting any

work. They constitute an integral part of the product and should be stored in the direct

vicinity of the product so they remain accessible to personnel at all times. If the product

is passed on to a third party, these operating instructions should be handed over with

it.

These operating instructions do not provide information on operating the machine in

which the product is integrated. For information about this, refer to the operating

instructions of the particular machine.

1.2 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

ABOUT THIS DOCUMENT 1

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious inju‐

ries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.3 Customer service

If you require any technical information, our customer service department will be happy

to help. To find your representative, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.,

to ensure faster processing.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The displacement measurement sensor is an opto-electronic measuring device and is

used for optical, non-contact distance measurement of objects.

The required optical properties of the object that will be detected are specified in the

technical data section of this document.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

The device does not constitute a safety component in accordance with the respec‐

•

tive applicable safety standards for machines.

The device must not be used in explosion-hazardous areas, in corrosive environ‐

•

ments or under extreme environmental conditions.

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

Device should be used only in accordance with its intended use.

■

All information in these operating instructions must be strictly observed.

2.3 Limitation of liability

Applicable standards and regulations, the latest state of technological development,

and our many years of knowledge and experience have all been taken into account

when assembling the data and information contained in these operating instructions.

The manufacturer accepts no liability for damage caused by:

■

Failing to observe the operating instructions

■

Incorrect use

■

Use by untrained personnel

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

2.4 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dangers.

8

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 9

Interrupting or modifying the device or SICK software will invalidate any warranty claims

against SICK AG. This applies in particular to opening the housing, even as part of

mounting and electrical installation.

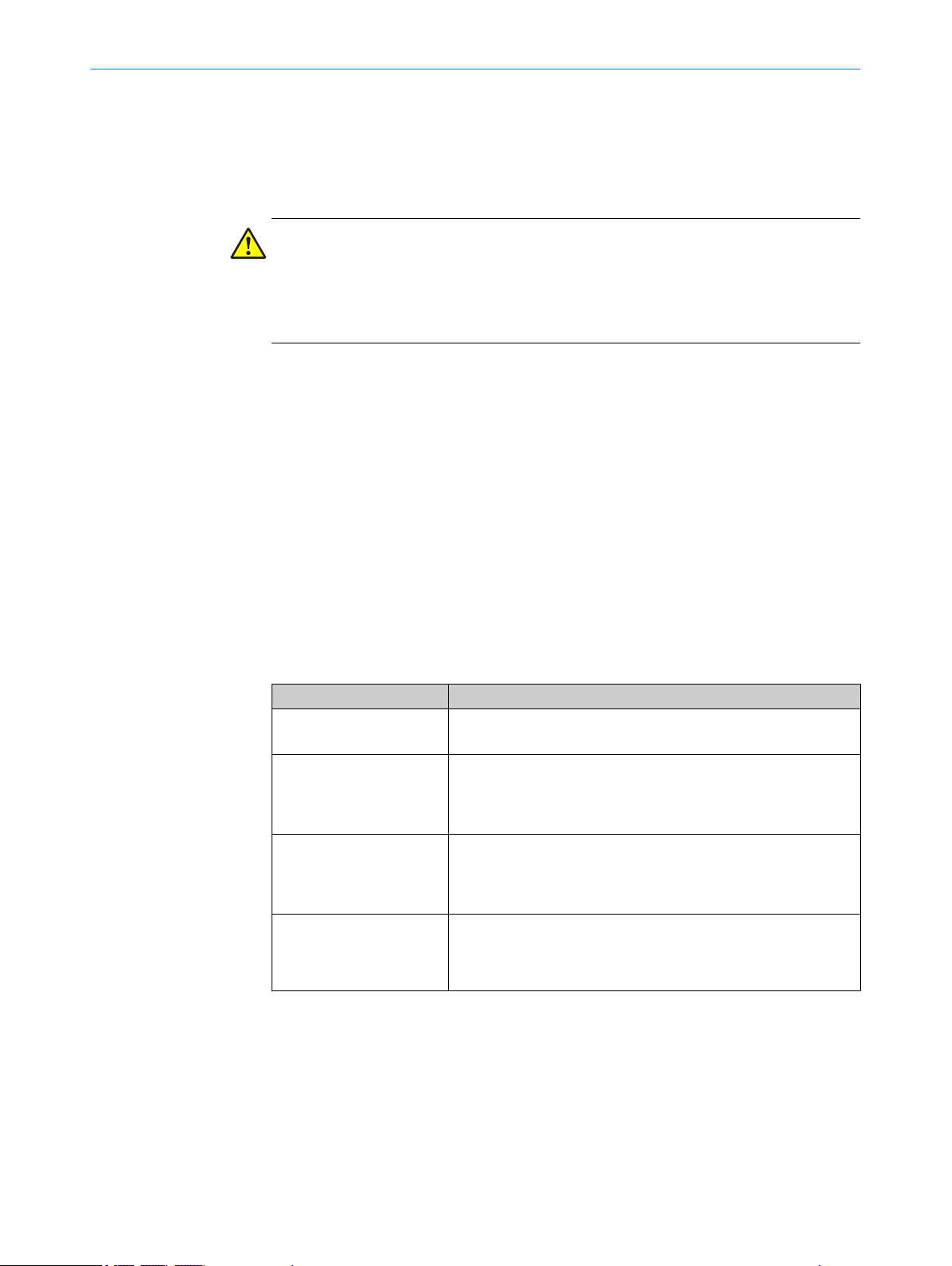

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualification requirements for the various

areas of work:

■

Instructed personnel have been briefed by the operator about the tasks assigned

to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g. Master Electrician). Other relevant regulations applicable in other

countries must be observed.

SAFETY INFORMATION 2

The following qualifications are required for various activities:

Table 1: Activities and technical requirements

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in

■

their particular application

Commissioning, configura‐

tion

Basic knowledge of the WindowsTM operating system in use

■

Basic knowledge of the design and setup of the described

■

connections and interfaces

Basic knowledge of data transmission

■

Operation of the device for

the particular application

Knowledge of the operation and control of the devices in

■

their particular application

Knowledge of the software and hardware environment for

■

the particular application

2.6 Operational safety and particular hazards

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan‐

gerous situations.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

CAUTION

Optical radiation: Laser class 1

The accessible radiation does not pose a danger when viewed directly for up to 100

seconds. It may pose a danger to the eyes and skin in the event of incorrect use.

■

■

WARNING

Electrical voltage!

Electrical voltage can cause severe injury or death.

b

b

b

b

b

Do not open the housing. Opening the housing will not switch off the laser. Open‐

ing the housing may increase the level of risk.

Current national regulations regarding laser protection must be observed.

Work on electrical systems must only be performed by qualified electricians.

The power supply must be disconnected when attaching and detaching electrical

connections.

The sensor must only be connected to a voltage source as set out in the require‐

ments in the operating instructions.

National and regional regulations must be complied with.

Safety requirements relating to work on electrical systems must be complied with.

2.6.1 Laser radiation

WARNING

Dangerous equipotential bonding currents!

Improper grounding can lead to dangerous equipotential bonding currents, which may

in turn lead to dangerous voltages on metallic surfaces, such as the housing. Electrical

voltage can cause severe injury or death.

Work on electrical systems must only be performed by qualified electricians.

b

Follow the notes in the operating instructions.

b

Install the grounding for the sensor and the system in accordance with national

b

and regional regulations.

The device is equipped with a laser source:

■

Measurement laser (red, visible to the human eye)

CAUTION

Optical radiation: Laser class 1

The accessible radiation does not pose a danger when viewed directly for up to

100 seconds. It may pose a danger to the eyes and skin in the event of incorrect

use.

■

Do not open the housing. Opening the housing will not switch off the laser.

Opening the housing may increase the level of risk.

■

Current national regulations regarding laser protection must be observed.

10

The laser qualifies as a class 1 laser based on standard IEC 60825-1: 2014

(Safety of laser products - Part 1: Equipment classification and requirements,

Edition 3).

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 11

2.7 Warning signs on the device

A visible red laser is installed in the device. The laser corresponds to laser class 1

based on IEC 60825-1:2007 (second edition) and IEC 60825-1:2014 (third edition).

The housing is labeled with a warning sign.

SAFETY INFORMATION 2

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

11

Page 12

1 2

4 3

3 PRODUCT DESCRIPTION

3 Product description

3.1 Product characteristics

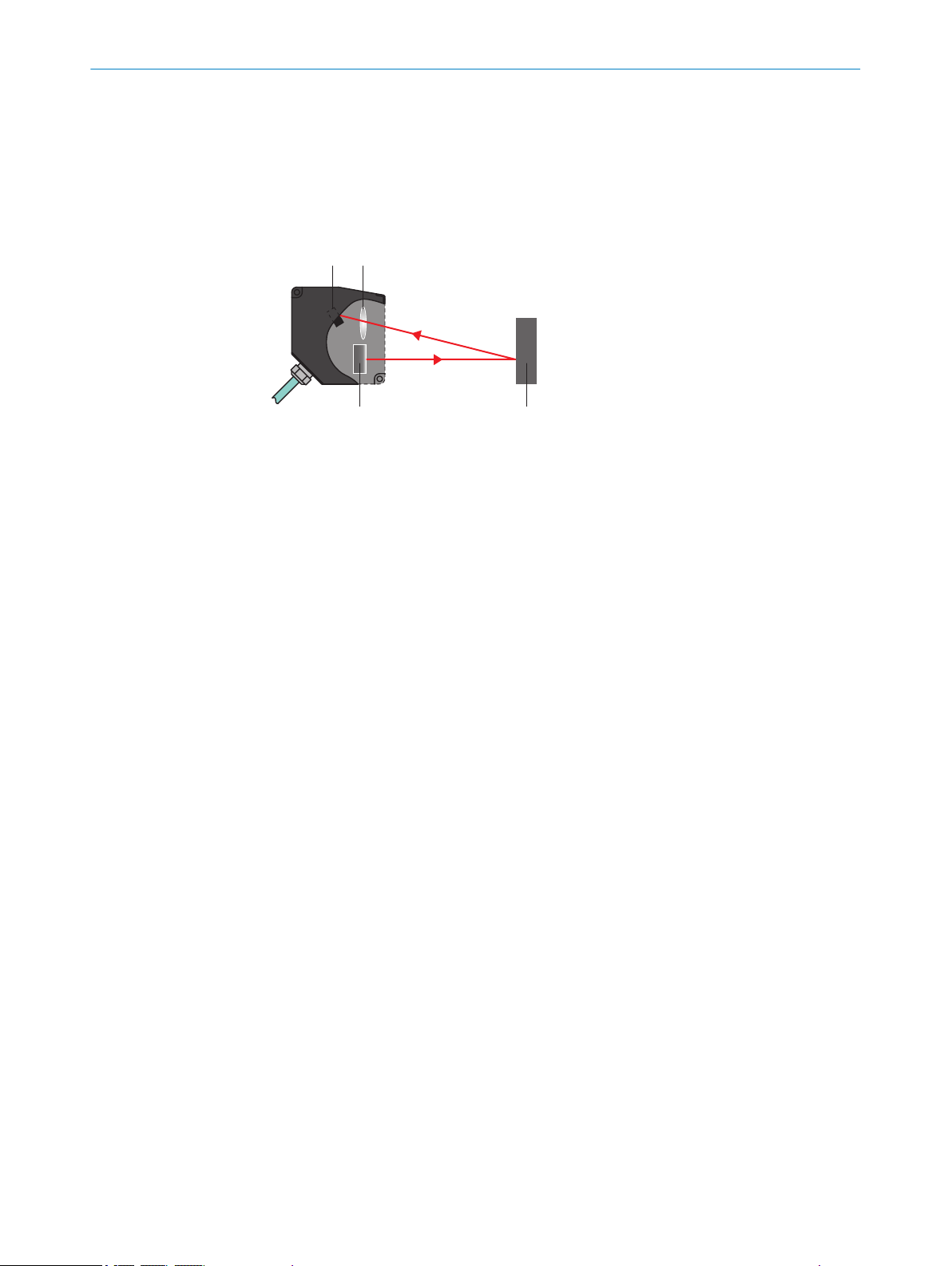

The displacement measurement sensor uses the triangulation principle for distance

measurement. This technology makes it possible to measure the distance between the

displacement measurement sensor and an object.

Figure 1: Triangulation principle

Receiver

1

Lens

2

Object

3

Laser

4

3.2

A point of light is projected onto the measuring object. The light reflected is captured by

a light-sensitive receiver at a specific angle. Based on the angle between the send and

receive direction, the position of the object is triangulated (lat. Triangulum: triangle).

The displacement measurement sensor can be configured via the SOPASair user inter‐

face. For more information visit:

www.sick.com/SOPASair

b

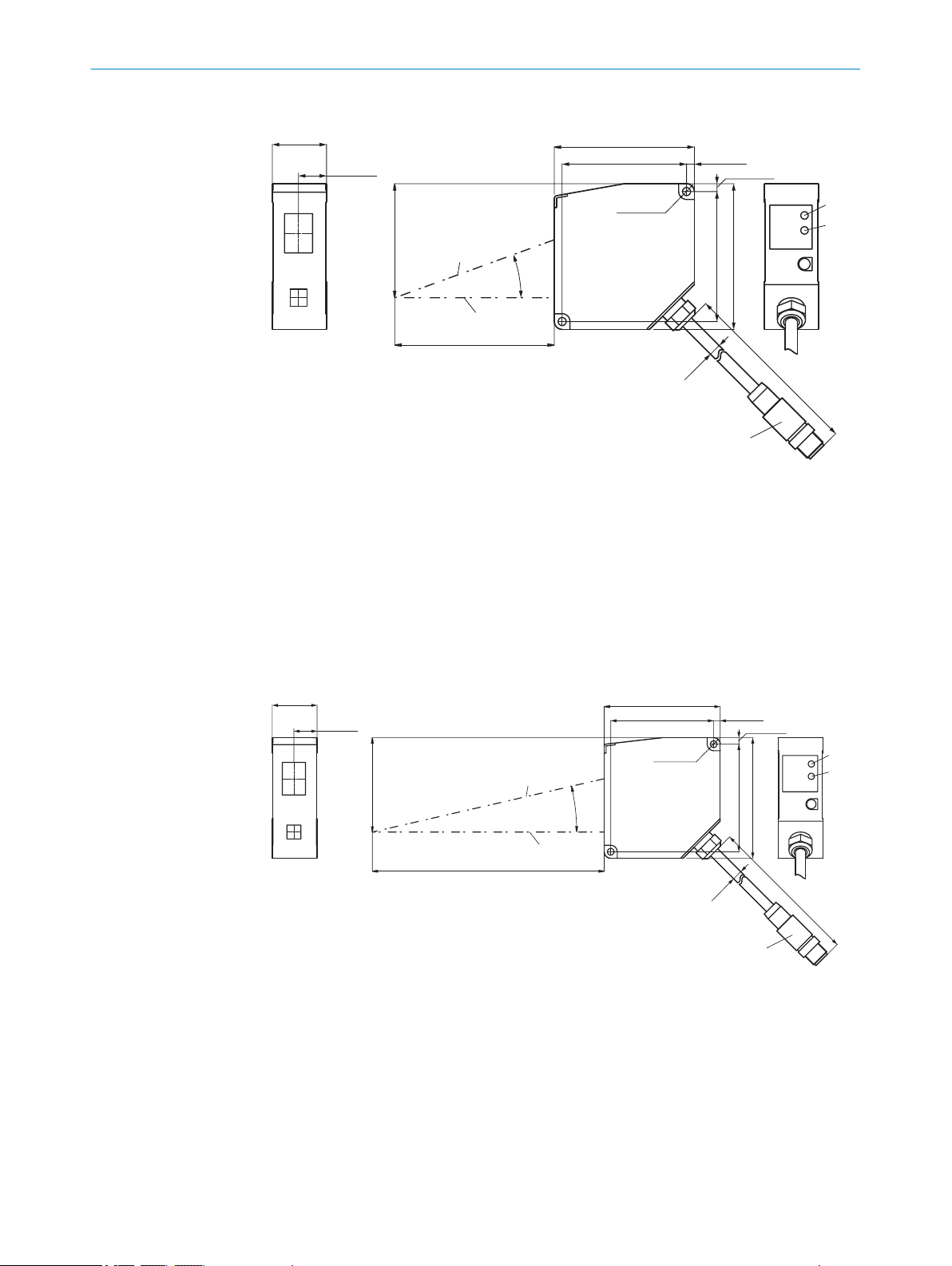

Setup and dimensions

All measurements in mm (inch).

12

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 13

OD5000-C85xxx

20°

85 (3.35) ±20

61

2 - Ø 4.3

(0.17)

Ø

6.5

(0.26)

29

(1.14)

15 (0.59)

75 (2.95)

66.6 (2.62)

4.2 (0.17)

4.2 (0.17)

69.6 (2.74)

78 (3.07)

500

(19.69)

61 (2.40)

2

3

4

5

6

7

1

2 - Ø 4.3

(0.17)

Ø

6.5

(0.26)

29

(1.14)

15 (0.59)

13°

150 (5.91) ±40

75 (2.95)

66.6 (2.62)

4.2 (0.17)

4.2 (0.17)

69.6 (2.74)

78 (3.07)

500

(19.69)

61 (2.40)

2

3

4

5

6

7

1

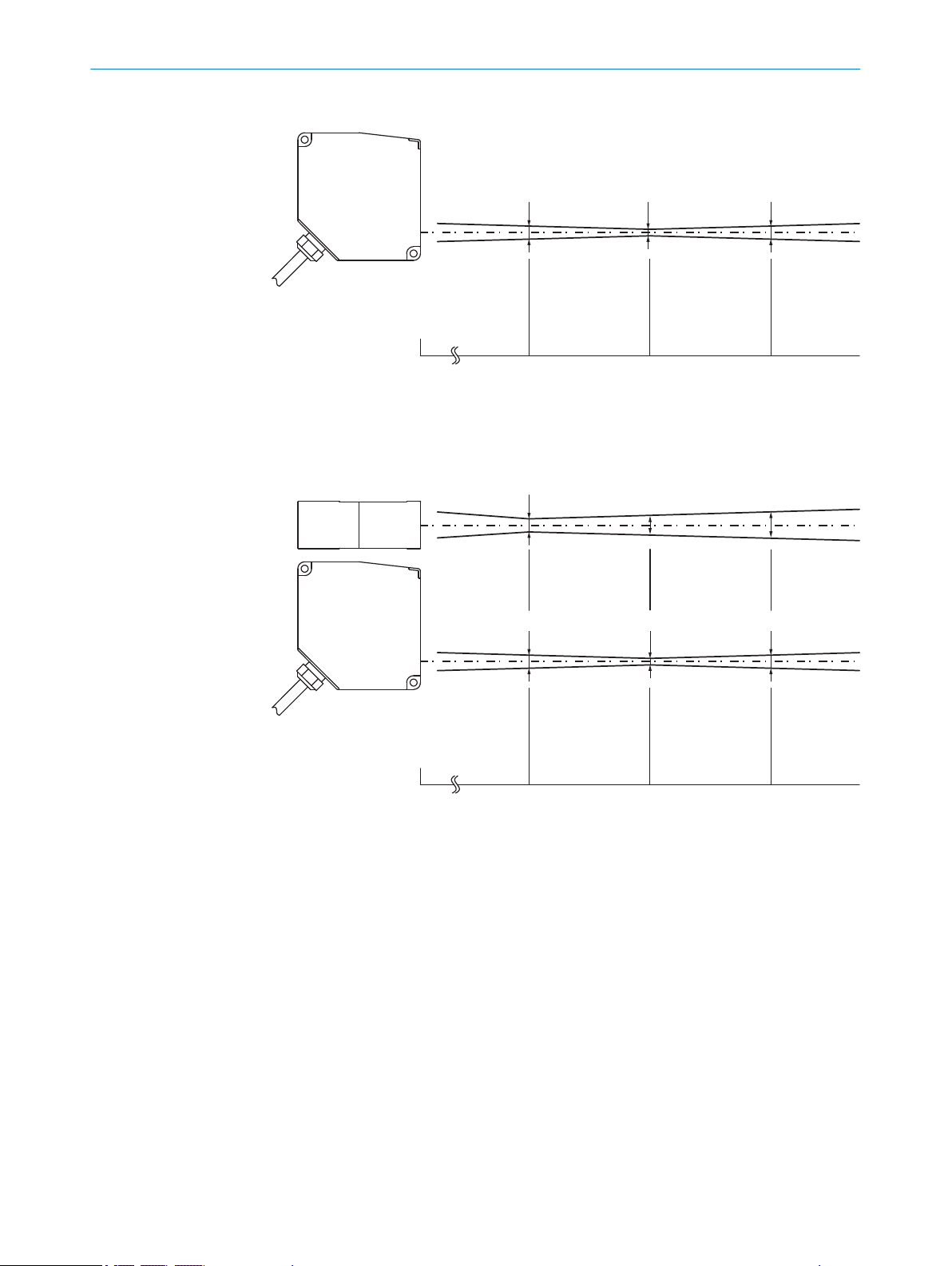

Figure 2: Setup and dimensions

Reference plane

1

Optical axis, receiver

2

Optical axis, sender

3

Measuring range

4

Link LED

5

Status LED

6

Plug connector, M12, 8-pin

7

PRODUCT DESCRIPTION 3

OD5000-C150xxx

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

Figure 3: Setup and dimensions

1

2

3

4

5

6

7

Reference plane

Optical axis of the receiver

Optical axis of the sender

Measuring range

Link LED

Status LED

Plug connector, M12, 8-pin

13

Page 14

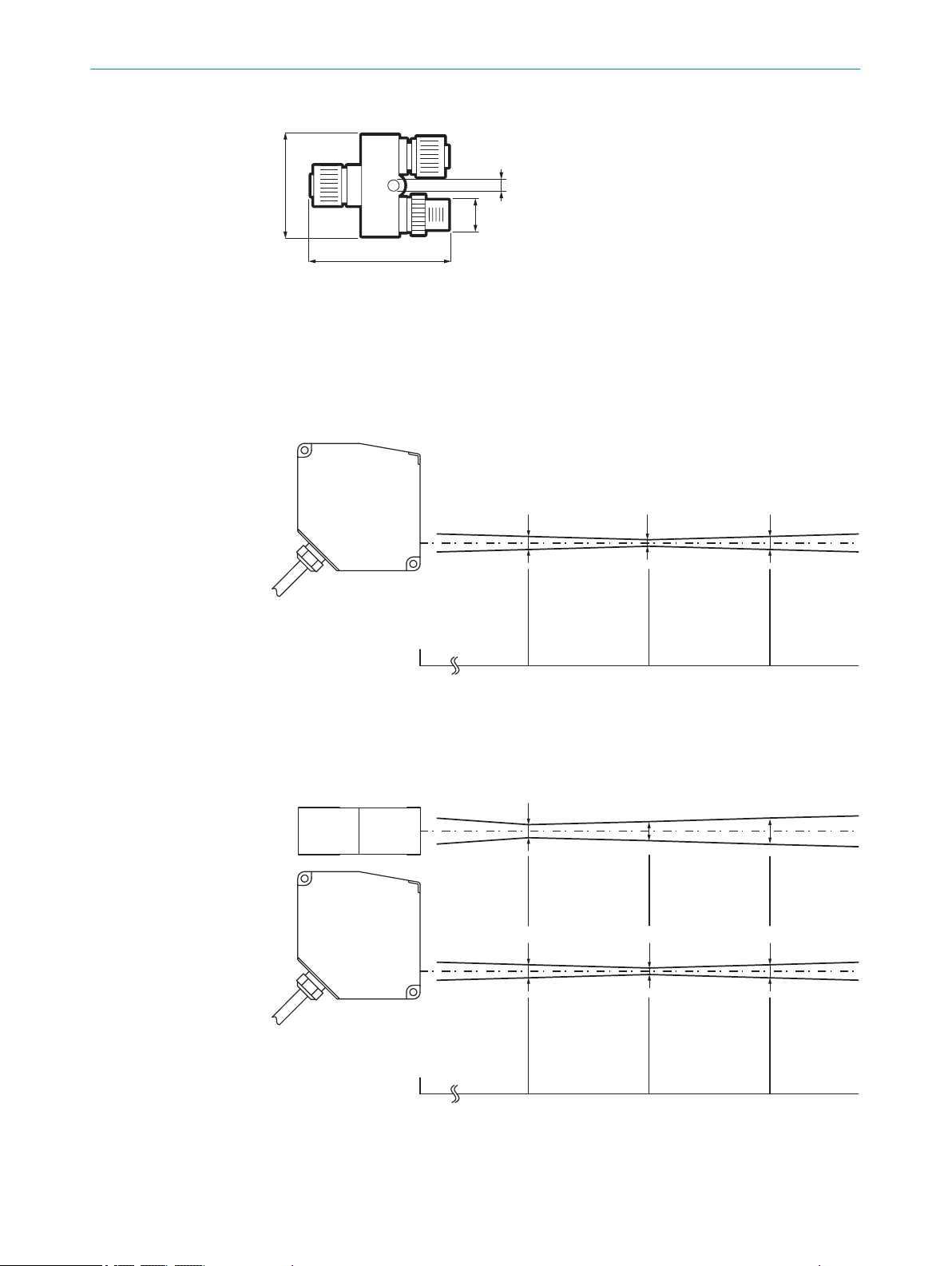

51,7

39

39

M12

3

2

1

Ø 120 μm

0 65

(2.56)

85

(3.35)

105

(4.13)

Ø 120 μmØ 70 μm

Distance (mm)

Ø 120 μm

0 65 85 105

Ø 120 μmØ 70 μm

Distance (mm)

1500 μm 2500 μm2000 μm

3 PRODUCT DESCRIPTION

Y-distribution

Figure 4: Setup and dimensions

1

2

3

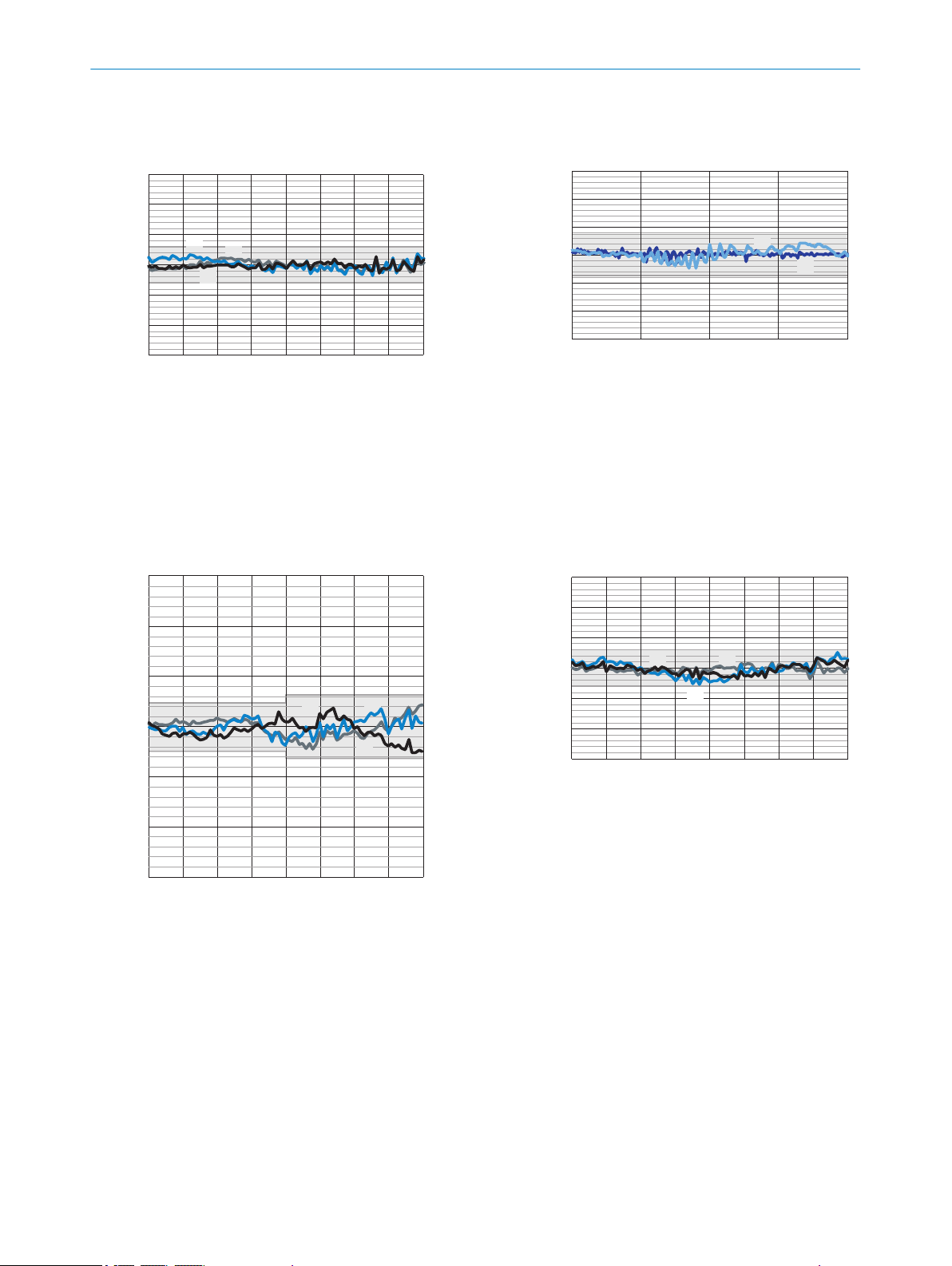

3.2.1 Light spot size

OD5000-C85T20

M12, 4-pin, A-coded

M12, 5-pin, D-coded

M12, 8-pin, A-coded

Figure 5: Typical light spot size of OD5000-C85T20

OD5000-C85W20

Figure 6: Typical light spot size of OD5000-C85W20

14

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 15

OD5000-C150T40

Ø 120 μmØ 300 μm Ø 300 μm

Distance (mm)

0 110

(4.33)

150

(5.91)

195

(7.68)

Ø 120 μmØ 300 μm Ø 300 μm

Distance (mm)

0 10 150 195

4000 μm2000 μm 6000 μm

Figure 7: Typical light spot size of OD5000-C150T40

OD5000-C150W40

PRODUCT DESCRIPTION 3

Figure 8: Typical light spot size of OD5000-C150W40

3.3 Product identification

Type label

The following information can be read from the type label on the device:

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

15

Page 16

à

8

7

6

2

1

4

5

3

9

ß

3 PRODUCT DESCRIPTION

Figure 9: OD5000 type label

Type code

1

Part number

2

Serial number

3

MAC address

4

Version number

5

EFUP information for China

6

RCM mark of compliance

7

Place of manufacture

8

EU conformity mark

9

Bar code

ß

US and Canada conformity marks

à

16

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 17

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

TRANSPORT AND STORAGE 4

4.2

Unpacking

■

Before unpacking, it may be necessary to equalize the temperature to protect the

device from condensation.

■

Handle the device with care and protect it from mechanical damage.

4.3 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport compa‐

ny's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

4.4 Storage

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 72.

■

Relative humidity: see "Technical data", page 72.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

17

Page 18

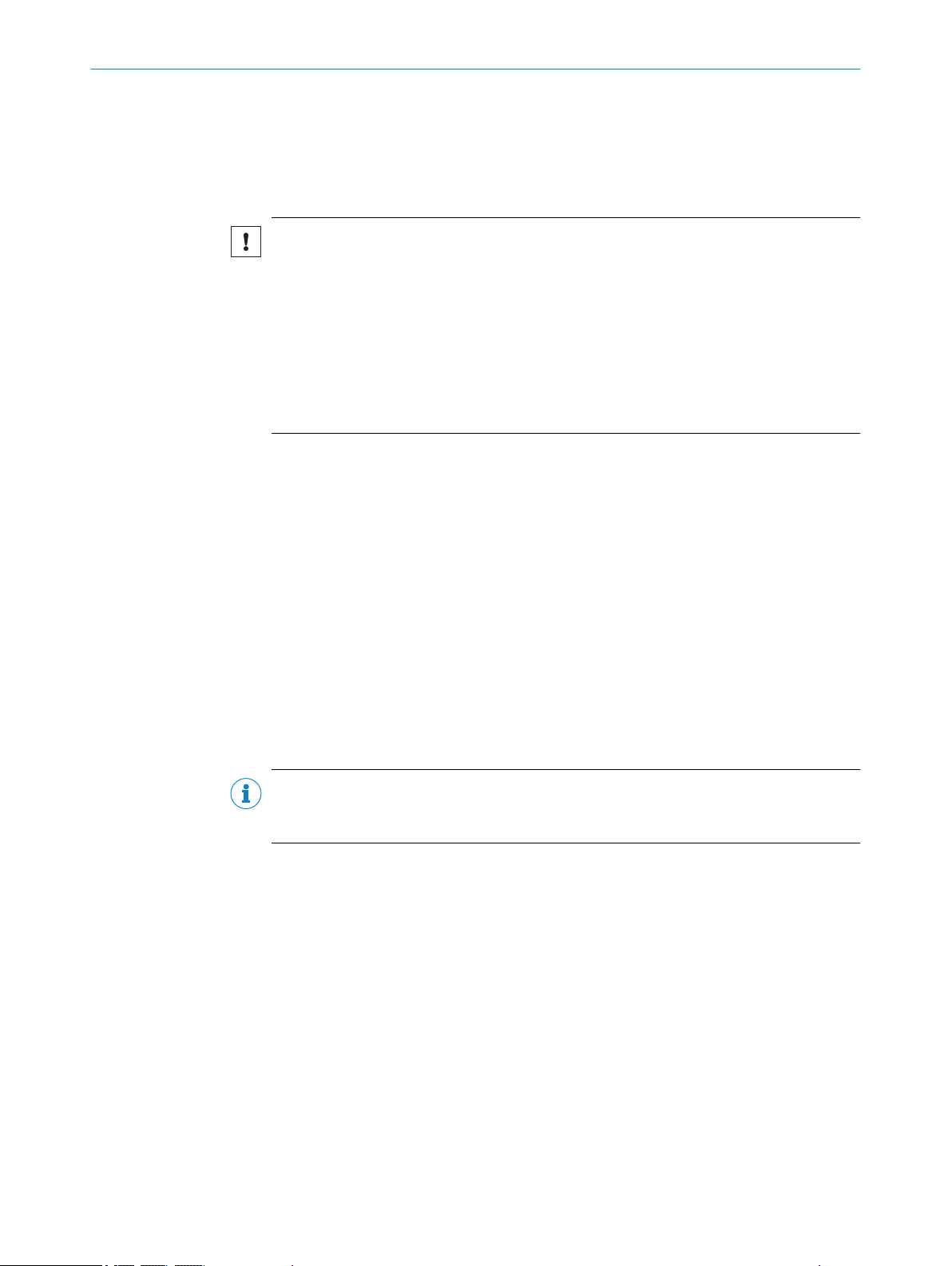

1 2 3

4 5 6

5 MOUNTING

5 Mounting

5.1 Scope of delivery

Included with delivery

Figure 10: Scope of delivery

OD5000

1

Y-distribution

2

Protective cap for Y-distribution

3

2 x screws, each M4 x 50 mm

4

2 x M4 nuts and 2 x washers

5

Safety notes

6

Optional: Accessories

Supplied documentation:

■

Safety notes

NOTE

All available documentation can be found online at:

www.sick.com/OD5000

b

18

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 19

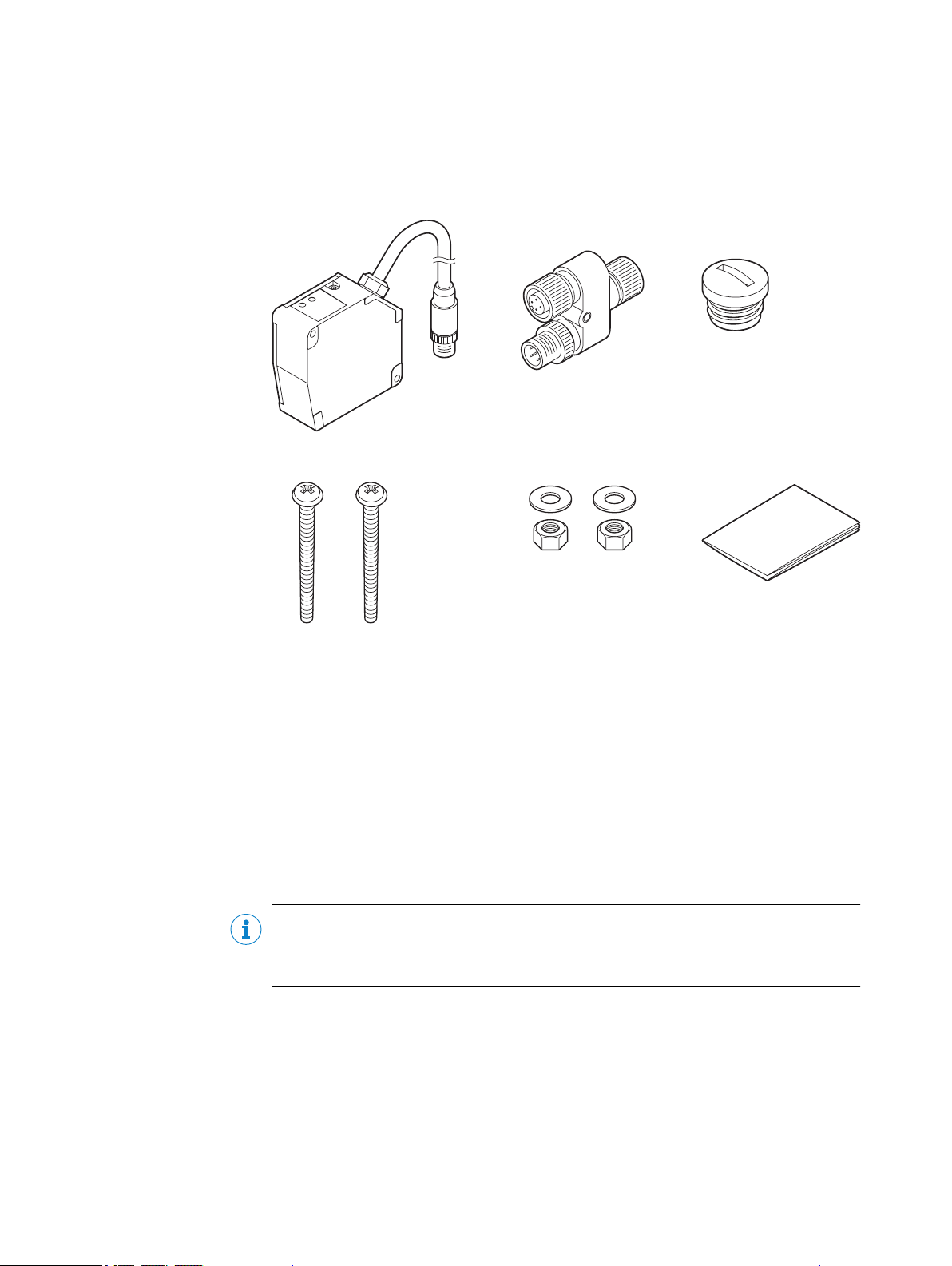

5.2 Facilities for connecting

1

2

3

4 5

7

8

9

ß6

MOUNTING 5

Figure 11: Facilities for connecting

1

2

3

4

5

6

7

8

9

ß

OD5000

Sensor head extension cable (e.g., DSC-1208-G02MA, part number 6064004)

Y-distribution

Cable with open ends (e.g., DOL-1204-G02MAC, part number 2088079)

Ethernet cable (e.g., SSL-2J04-G02ME, part number 6034414)

M12 AOD1 connection cable, 4-pin on M8, 4-pin (e.g., DSL-2804-G02MC, part num‐

ber 6039180)

AOD1

PC

PLC

Switch

1)

1)

We do not recommend using a standard cable. This connection cable is designed as a twisted pair.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

19

Page 20

2x

1

2

5 MOUNTING

5.3 Mounting instructions

Observe the technical data.

•

Protect the sensor from direct sunlight.

•

To prevent condensation, avoid exposing the sensor to rapid changes in tempera‐

•

ture.

The mounting site has to be designed for the weight of the device.

•

To avoid inaccurate measurements when installing multiple devices: Make sure

•

that the laser light spot of one device is not in the visible range of another device.

Take into account the device warm-up time of 10 minutes. During the device

•

warm-up phase, the measured values are subject to an increased variance (tem‐

perature drift).

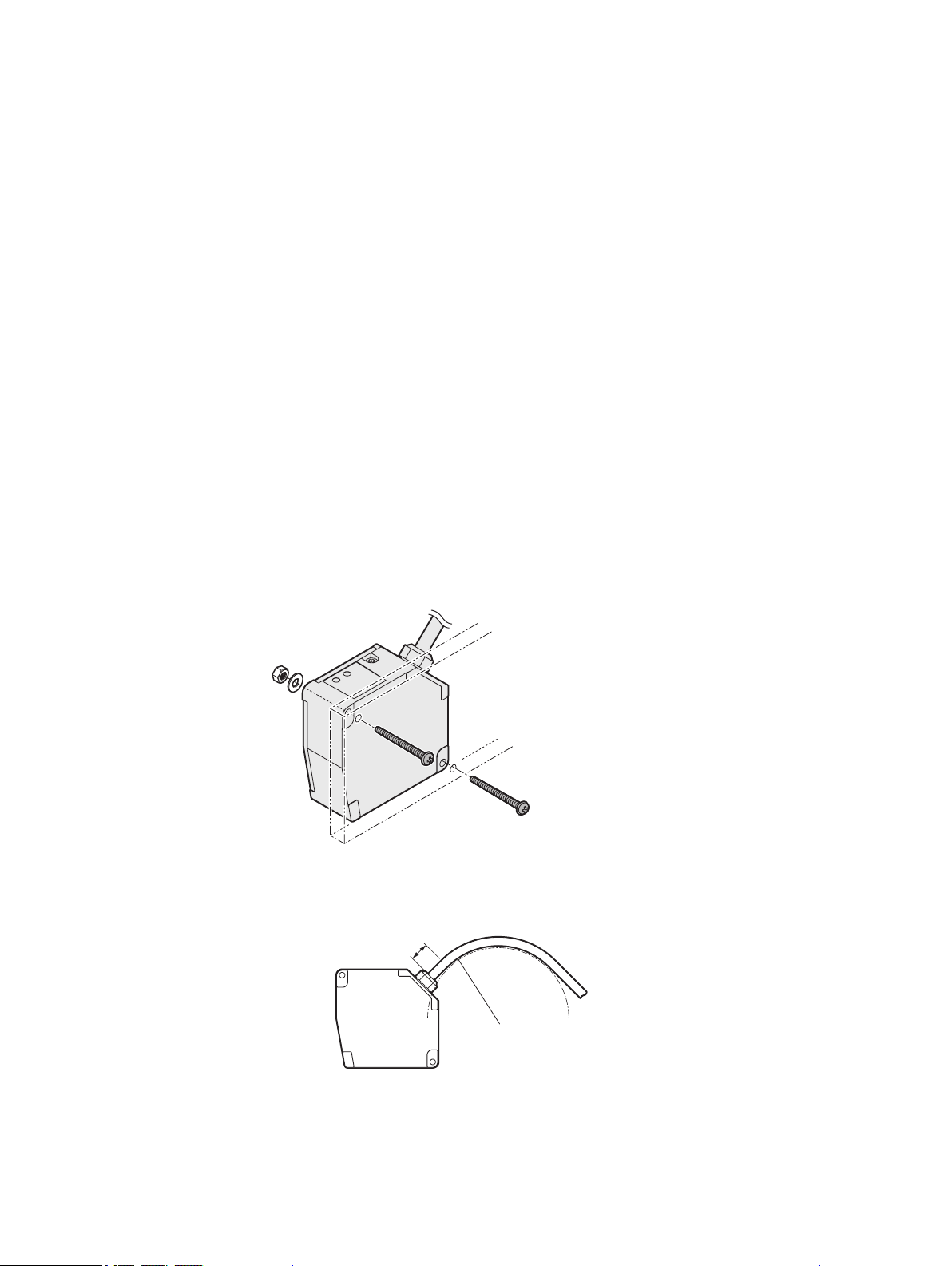

5.4 Mounting device

1. Mount the displacement measurement sensor using the designated fixing holes,

see "Setup and dimensions", page 12.

2. Make the electrical connection. Attach and tighten a voltage-free cable, see "Con‐

necting the device electrically", page 27.

3. Switch on the supply voltage.

✓

The status LED lights up green.

The device needs around 10 seconds of initialization time before it is ready for

operation.

4. Align the light spot so that the desired object is measured.

Mounting on the wall

Figure 12: Mounting on the wall

Permissible bend radii of the connection cable

20

Figure 13: Permissible bend radius

At least 10 mm

1

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Radius of at least 60 mm

2

Subject to change without notice

Page 21

1 2

m m X

MOUNTING 5

NOTICE

■

Do not bend the cable less than 10 mm from the sensor head.

■

Do not bend the cable with a radius of more than 60 mm.

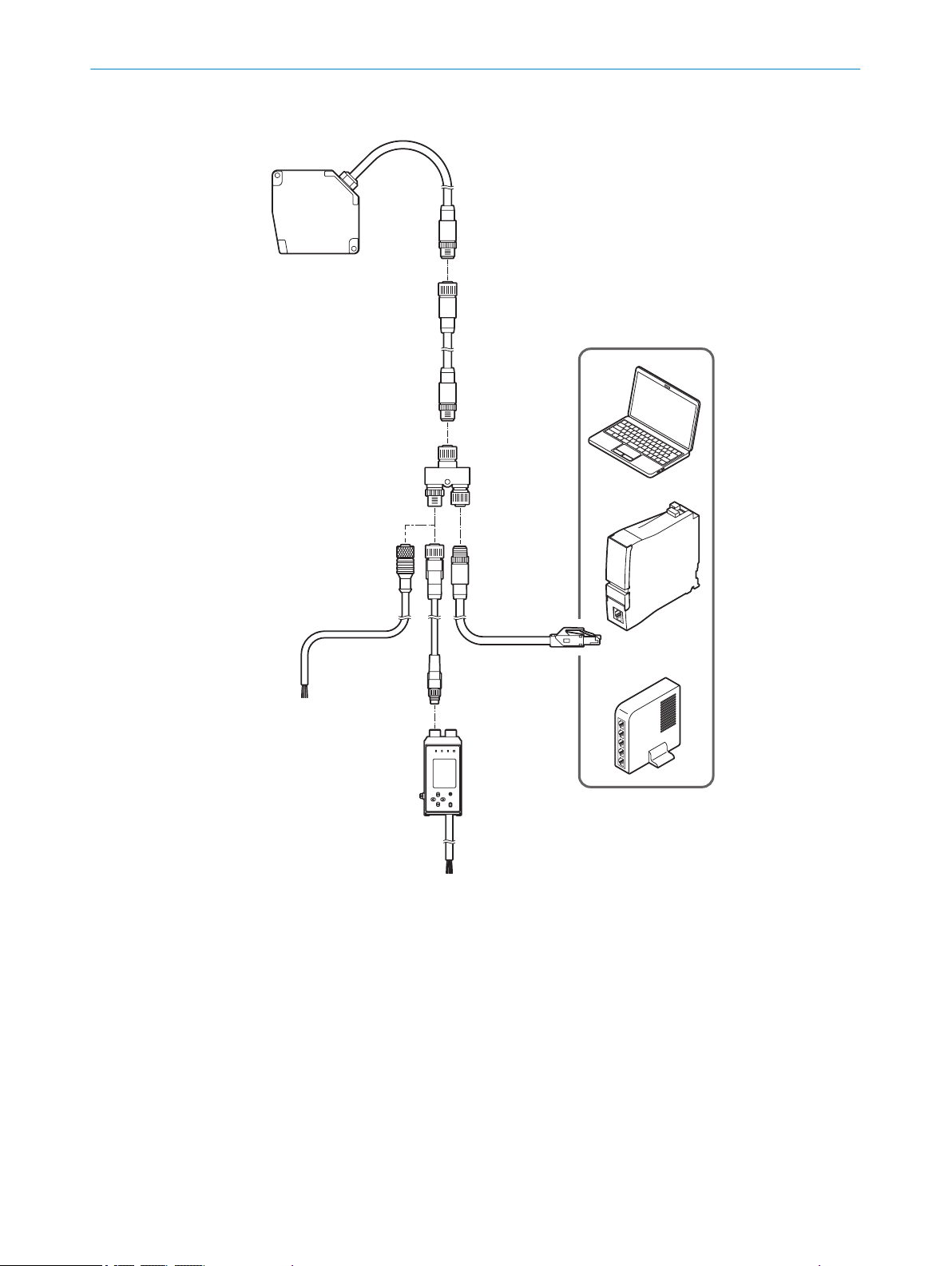

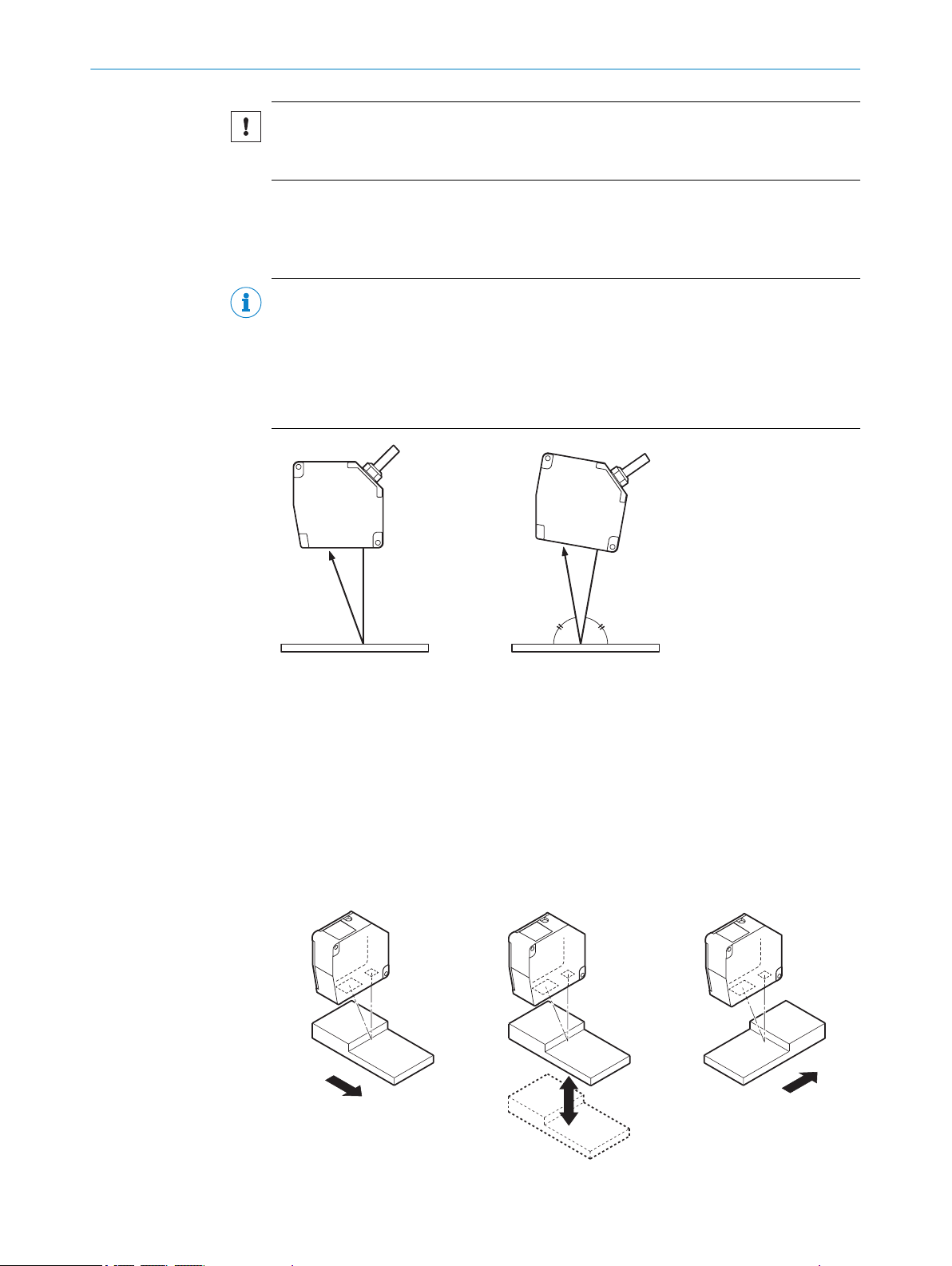

Mounting variations

There are two mounting variations for the device. Typically, diffuse reflection is used.

Specular reflection is used when transparent or reflective surfaces are to be registered.

NOTE

The housing form for the device indicates the orientation of the correct mounting

method. When mounting the device for the measurement of reflective objects, the

device must be mounted so that it is slightly tilted. In doing so, the slanted edge of the

housing must be positioned so that it is perpendicular to the measuring object. In this

mounting variation, only a reduced measuring range is available, see "Technical data",

page 72.

Figure 14: Mounting variations

Diffuse reflection

1

Specular reflection

2

5.4.1 Mounting the device depending on application

With height differences

The preferred direction must be taken into account during mounting in order to prevent

shadows.

Figure 15: Mounting with height differences

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

21

Page 22

m X

m X

m X

5 MOUNTING

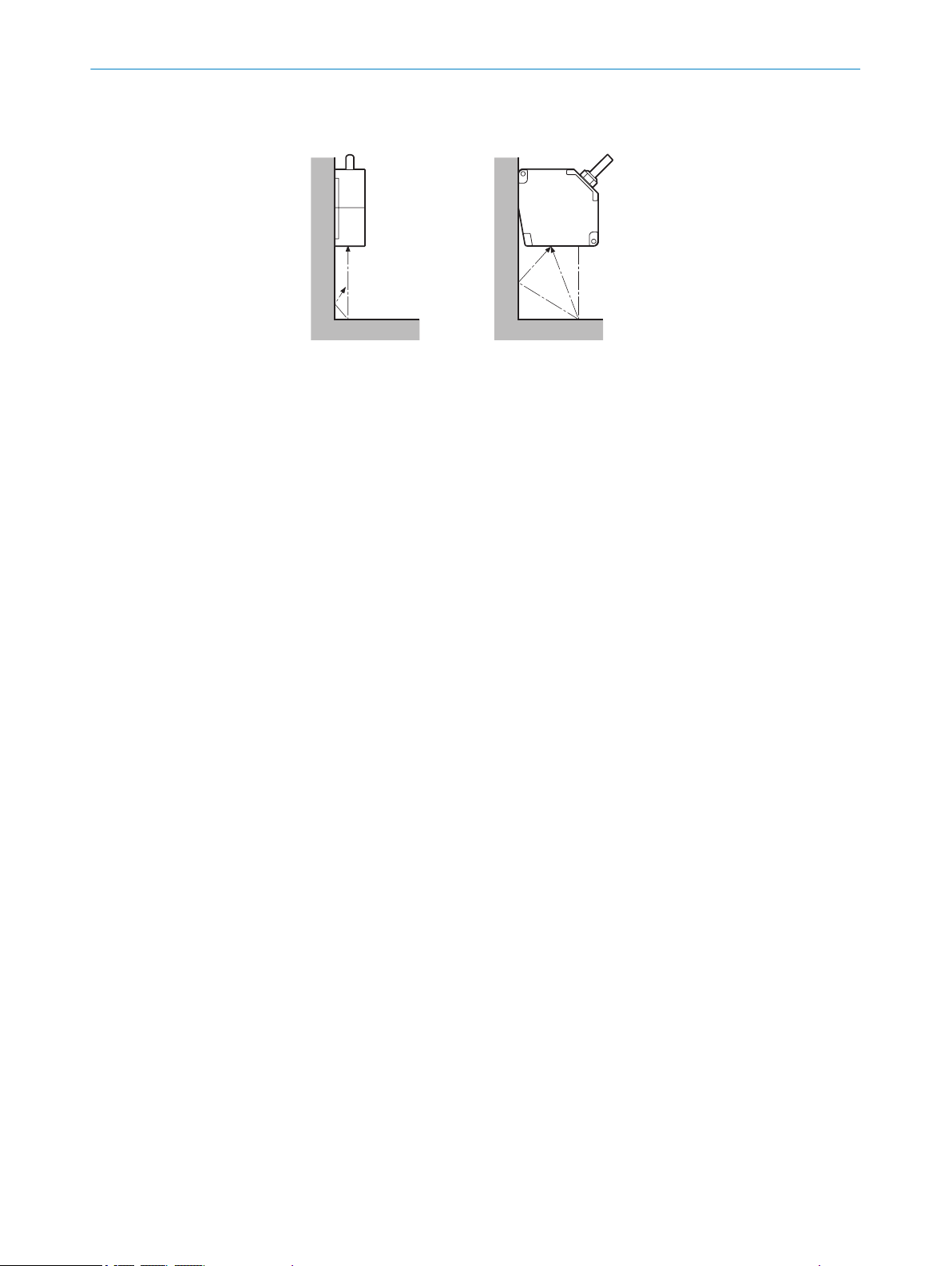

With different material or colors

Figure 16: Mounting with different material or colors

With rotating surfaces

Figure 17: Mounting with rotating surfaces

With holes or recesses

Figure 18: Mounting with holes or recesses

22

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 23

Mounting on the wall

m X

Figure 19: Mounting on the wall

MOUNTING 5

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

23

Page 24

3

2

1

1

4 3

2

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

WARNING

Personal injury due to incorrect supply voltage.

An incorrect supply voltage may result in personal injury.

■

Only operate the device using safety extra-low voltage and safe electrical insula‐

tion as per protection class III.

NOTICE

Equipment damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

■

Only carry out wiring work when the power is off.

■

Only connect and disconnect electrical connections when the power is off.

6.2 Wiring notes

NOTICE

Faults due to incorrect wiring.

Incorrect wiring may result in operational faults.

■

Follow the wiring notes precisely.

NOTE

Preassembled cables can be found online at:

www.sick.com/OD5000

•

6.3 Pin assignment of the connections

Y-distribution

Figure 20: Y-distribution connections

M12, 4-pin, A-coded

1

M12, 5-pin, D-coded

2

M12, 8-pin, A-coded

3

The Y-distribution is only intended for use as a distributor and not as an amplifier.

Figure 21: Male connector, M12, 4-pin, A-coded

24

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 25

1

43

5

2

1

7

2

6

3

4

5

8

ELECTRICAL INSTALLATION 6

Connection 1 to the Y-distribution

Table 2: Pin assignment on 4-pin M12 male connector

Pin Signal Function

1 24 V Voltage supply

2 Input (MF) / RS485+ Input MF (NPN) / Reserved

3 0 V Voltage supply

4 Input (MF) / RS485- Input MF (PNP) / Reserved

- Shield -

Figure 22: Female connector, M12, 5-pin, D-coded

Connection 2 to the Y-distribution

Table 3: Pin assignment on 5-pin M12 female connector

Pin Signal Function

1 TxD+ Network interface

2 RxD+ Network interface

3 TxD- Network interface

4 RxD- Network interface

5 NC Not connected

- Shield -

Figure 23: Female connector, M12, 8-pin, A-coded

Connection 3 to the Y-distribution

Table 4: Pin assignment on 8-pin M12 female connector

Pin Signal Function

1 Input (MF) / RS485+ Input MF (NPN) / Reserved

2 0 V Voltage supply

3 24 V Voltage supply

4 TxD- Network interface

5 RxD+ Network interface

6 TxD+ Network interface

7 Input (MF) / RS485- Input MF (PNP) / Reserved

8 RxD- Network interface

- Shield -

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

25

Page 26

1

4 3

2

1

43

2

6 ELECTRICAL INSTALLATION

Pin assignment of the connections for M12 converter, RJ45

Figure 24: Male connector, M12, 4-pin, D-coded

Table 5: Pin assignment on 4-pin M12 male connector

Pin Signal Function

1 TxD+ Network interface

2 RxD+ Network interface

3 TxD- Network interface

4 RxD- Network interface

- Shield -

Pin assignment for M12 voltage supply, 4-pin (based on DOL-1204-G02MAC, part num‐

ber 2088079, can be used for OD5000 standalone operation)

Figure 25: Male connector, RJ45

Table 6: Pin assignment on male connector, RJ45

Pin Signal Function

1 TxD+ Network interface

2 TxD- Network interface

3 RxD+ Network interface

4 NC Not connected

5 NC Not connected

6 RxD- Network interface

7 NC Not connected

8 NC Not connected

- Shield -

Figure 26: Male connector, M12, 4-pin, A-coded

Table 7: Pin assignment on 4-pin M12 female connector

Pin Signal Function

1 24 V Voltage supply

2 Input (MF) / RS485+ Input MF (NPN) / Reserved

3 0 V Voltage supply

4 Input (MF) / RS485- Input MF (PNP) / Reserved

- Shield -

26

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 27

6.4 Connecting the device electrically

NOTE

The connection diagram, and information on inputs and outputs, can be found on the

side plate on the device.

NOTICE

All electrical circuits must be connected to the device with safety extra-low voltage

(SELV or PELV).

1. Ensure that the voltage supply is not connected.

2. Observe the wiring instructions, see "Wiring notes", page 24.

3. Connect the device according to the connection diagram.

ELECTRICAL INSTALLATION 6

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

27

Page 28

12 3

7 OPERATION

7 Operation

7.1 General notes

If the device is not able to perform a measurement even though the measuring object is

within the specified measuring range, the alignment should be checked and optimized

if necessary see "Mounting the device depending on application", page 21. In general,

adjusting the measuring rate can increase the measuring ability for very dark objects,

for example.

To prevent EMC interference, please observe the wiring instructions.

7.2 Control elements and status indicators

7.2.1 Indicator lights

Figure 27: OD5000 control panel

Communication LED (link)

1

Status LED (power)

2

Cover screw for reset pushbutton

3

Table 8: Meaning of the indicator lights

Indicator Status Color State

Communication LED (link)

Status LED (power)

Ö

Flashing

O

Permanently on

Ö

Ö

Ö

O

O

O

Ö

Green Ethernet communication is

active

Blue Laser off

Red Invalid measurement

Red Measured value is in the

positive value range

Orange Measured value is in the

negative value range

Green All active outputs have a

high signal / no output

active

White “Find me” is active

28

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 29

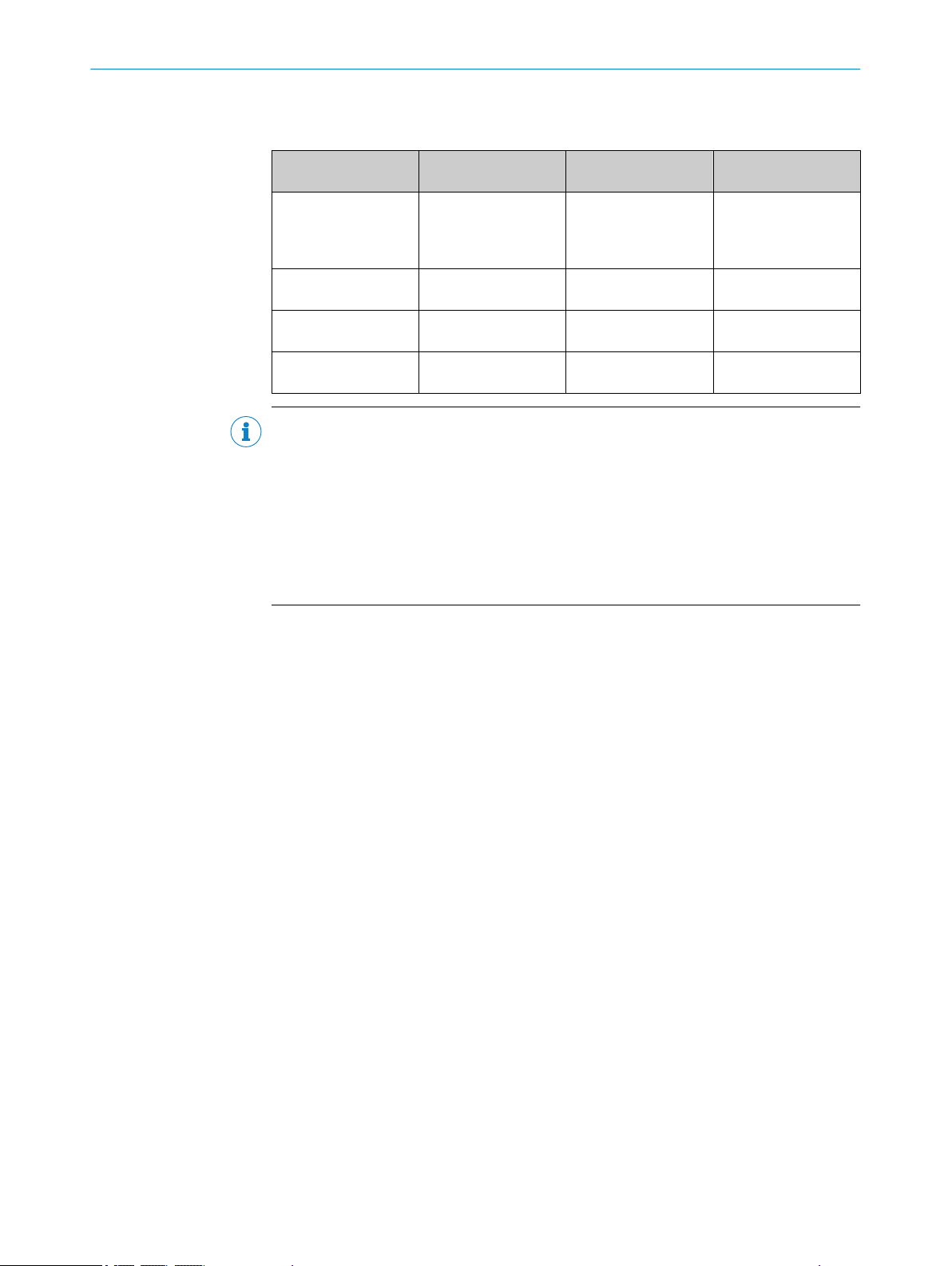

7.2.2 Operating elements

Table 9: Functions of the reset pushbutton

Hold down pushbut‐

ton for

< 1 s None Unchanged Changes are not

1 to 5 s IP address is initial‐

5 to 10 s IP address is changed

> 10 sec All settings are initial‐

NOTE

■

The reset pushbutton is only accessible once the screw has been removed.

■

■

■

Function LED status Description

adopted if pushbutton

is not pressed for long

enough

ized (static IP)

(DHCP)

ized

Flashing orange

(slowly)

Flashing green (slowly) IP address is obtained

Flashing green

(quickly)

IP address is changed

to 192.168.0.01

and set to DHCP

All settings are reset

to the factory settings

Press reset pushbutton to reset all settings to factory settings.

Always remove and store the screw together with the sealing ring.

Refit the screw and sealing ring.

Observe the maximum torque of 0.08 Nm ±20%.

OPERATION 7

The IP67 enclosure rating is only ensured with a proper screw connection and intact

sealing ring.

7.3

Operation via web browser (SOPASair)

7.3.1 Determining the device IP address

DHCP is preset on the device as standard meaning that the IP address is obtained

automatically.

In order to ascertain the IP address assigned to the device, please contact the relevant

network administrator or use SOPAS ET.

The device IP address can also be verified and adjusted by a device-specific search in

SOPAS ET.

The most up-to-date version of the software is available at:

www.sick.com/OD5000

b

7.3.2 Connecting via the web browser

The following browsers are supported:

Internet Explorer (version 11 or higher)

•

Google Chrome (version 49 or higher)

•

1. Start browser.

2. Enter the device IP address.

✓

The SOPASair settings screen is displayed.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

29

Page 30

OPERATION

7

Logging in

Figure 28: Log-in screen

The Maintenance and Expert user levels are available for choosing settings.

Maintenance user name: Maintenance

Maintenance password: main

The Expert user level is for the exclusive use of trained and authorized service personnel

at SICK AG, see "Expert", page 53.

NOTE

After logging in, the "pencil" button may need to be clicked to allow editing.

7.3.3 Overview of SOPASair

Figure 29: Overview of SOPASair

The following menu items are available when viewed online:

Monitoring

•

Measurement

•

I/O channels

•

Device

•

Communication

•

Recording

•

Info

•

Expert

•

30

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 31

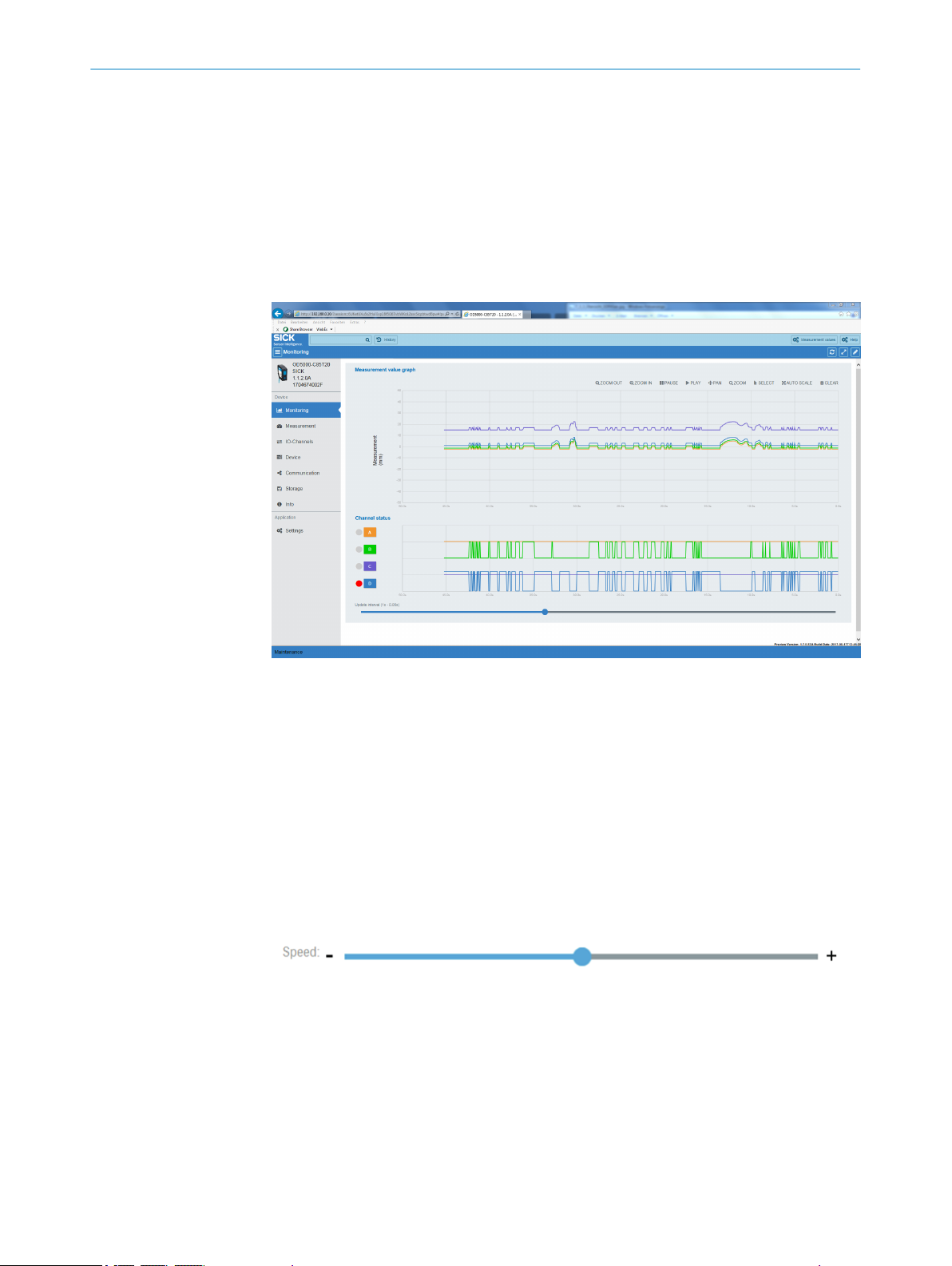

7.3.4 Monitoring

OPERATION 7

The left-hand navigation screen can be viewed as standard but can be hidden by click‐

ing on the upper right-hand buttons with three bars.

Two buttons can be seen on each bar at the top:

Measured values: Displays the current measured values. The display of the measured

value can be adapted using two buttons.

Help: Displays help texts on the current settings.

7.3.5 Measurement

Figure 30: Overview of the Monitoring tab

The measured value plotter displays the current measured values (distance/thickness).

Current measured values can be hidden or displayed at any time using the Measured val‐

ues button in the bar at the top of the screen. The color corresponds to the respective

channel.

The display of the individual channels can be activated and deactivated using buttons A

to D.

The digital plotter displays the statuses of the output signals for channels A to D.

The status of the outputs is displayed by LEDs to the left of the buttons:

Red = output active

•

Grey = output inactive

•

The speed at which the measured values and the digital plotter are output is adjusted

equally by sliding the controller on the speed bar.

Measurement settings can be made in the Measurement tab.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

31

Page 32

7 OPERATION

Figure 31: Overview of the Measurement tab

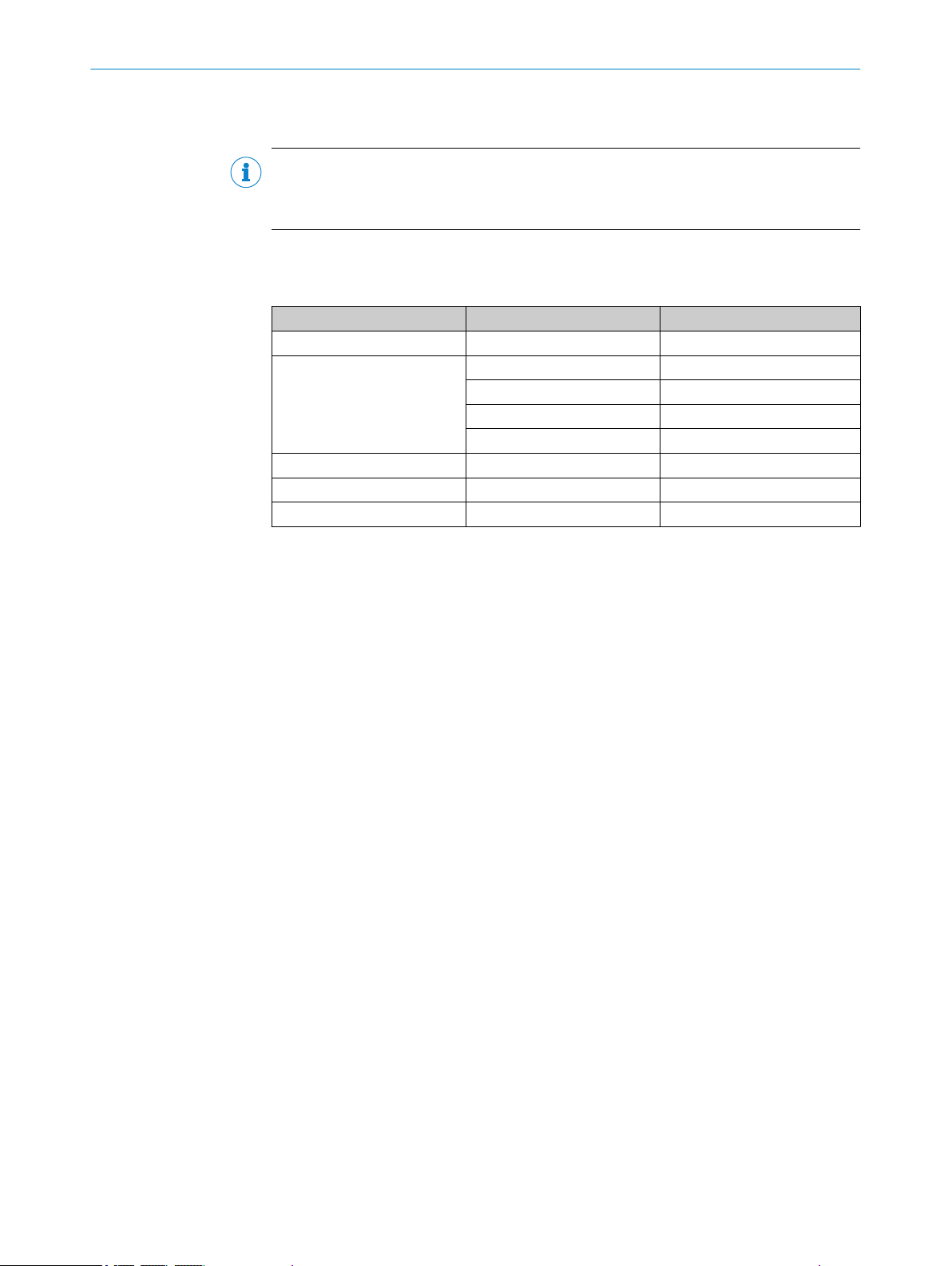

7.3.5.1 Setting diffuse or specular reflection

One of two options can be selected depending on the measuring object and the mount‐

ing method, see "Mounting device", page 20.

NOTE

Some device variants only support one mode.

The OD5000-C150xxx only supports diffuse reflection.

Part number Device Diffuse Specular

6063623 OD5000-C85T20 x x

6063624 OD5000-C85W20 x x

6063625 OD5000-C150T40 x Not supported

6063626 OD5000-C150TW0 x Not supported

NOTE

The measuring range is reduced if the OD5000-C85xxx is reflected specularly, see

"Technical data", page 72.

7.3.5.2 Determining the measurement type

This function determines which measurement is used via the respective channel.

Table 10: Adjustments for the measurement type

Setting Meaning

Distance Measures the distance between the zero point and a defined peak

Thickness Measures the distance between two peaks, e.g., a transparent

(object surface)

object with several reflective surfaces (e.g., layers of glass)

32

Depending on the selected measurement type, it is possible to determine on which

peak or between which peaks the measurement is to be taken.

With the distance measurement type, up to eight peaks can be selected. Peak 1 (P1) is

activated by default.

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 33

With the thickness measurement type (for measuring a transparent object), a selection

must also be made of the peaks between which the measurement is to be taken. If the

selected peak does not exist then a measurement is not taken. If the same peak is

selected twice in this case, 0 is output as the measured value.

NOTE

The thickness may only be measured with specular reflection mounting. This mode is not

available for all devices in the OD5000 series, see "Setting diffuse or specular reflec‐

tion", page 32.

7.3.5.3 Teaching in the zero point

The current distance is taught in as a new zero point (reference point) or reset to the

output value.

7.3.5.4 Setting the sampling duration

The following settings are possible:

12.5 μs

•

25 μs

•

50 μs (default value)

•

100 μs

•

500 μs

•

1,000 μs

•

AUTO (selects the sampling rate for the quickest possible measurement depending

•

on the measuring object)

OPERATION 7

NOTE

If the sampling duration is set to the shortest time of 12.5 μs then the measuring range

is reduced.

■

Select the required range (near, medium, far) via the configuration interface.

For a sampling duration of 12.5 μs

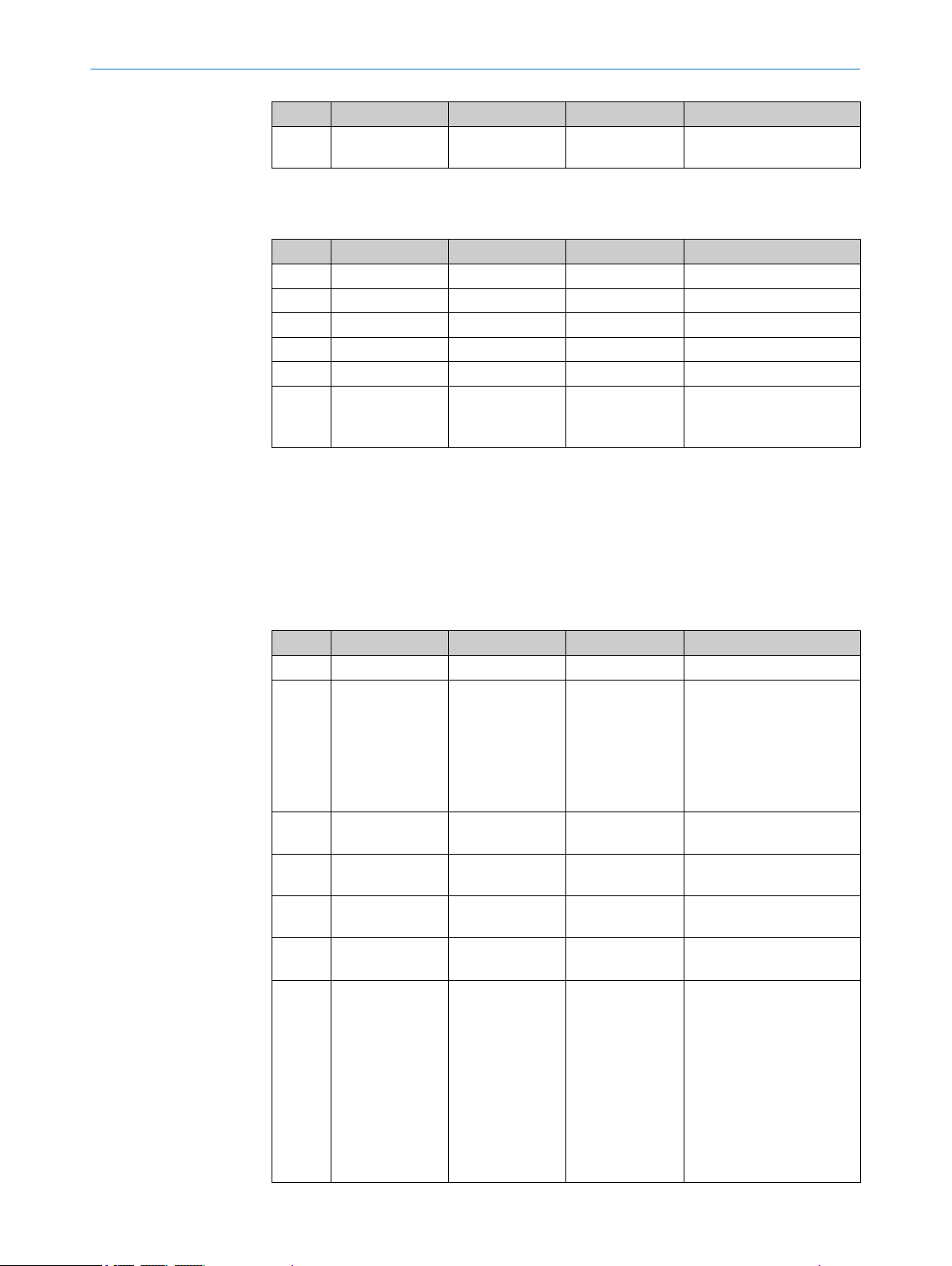

Table 11: Measuring range for a sampling duration of 12.5 μs

OD5000C85W20

Near 65.0 mm to 77.7 mm

71.5 mm to 74.3 mm (for spec‐

ular reflection)

Medium (starting value) 73.5 mm to 90.8 mm

70.6 mm to 86.9 mm (for spec‐

ular reflection)

Far 84.8 mm to 105.0 mm

81.0 mm to 91.5 mm (for spec‐

ular reflection)

OD5000C85T20

OD5000C150W40

110.0 mm to 134.4 mm

124.8 mm to 166.3 mm

150.2 mm to 190.0 mm

OD5000C150T40

An upper and lower limit must be set for the auto setting. The actual sampling duration

is automatically adjusted within these limits.

Table 12: Adjustments for the upper and lower limit

Lower limit Upper limit

25 μs (default value) 25 μs

50 μs 50 μs

100 μs 100 μs

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

33

Page 34

1 2

3

4

5

0 mm 0 mm

7 OPERATION

Lower limit Upper limit

200 μs 200 μs

500 μs 500 μs (default value)

1,000 μs 1,000 μs

7.3.5.5 Synchronizing several OD5000 sensors

If several sensor heads are used in the application, they may be synchronized using the

following settings. One sensor head is selected by default. To use two sensor heads, a

drop-down menu is displayed with the following request:

Table 13: Adjustments for synchronization mode

Setting Meaning

Synchronous Synchronizes several sensor heads

Anti interference 1/2 Switches between two sensor heads

The following should be considered when using these modes:

In synchronization mode, the measurement results from two sensor heads are recorded

simultaneously. An application possibility is measuring the thickness of non-transpar‐

ent objects using two sensor heads, for example. The individual results from the sensor

heads must be accounted for using special control software, which is not possible with

the SOPASair configuration software.

In Anti interference mode, the measurement results from several sensor heads are

recorded one after the other. This increases the measurement time to double the sam‐

pling duration for that measurement. This can be in used, for example, in an application

in which the laser beams overlap a pair of sensor heads.

To use this mode, the following settings must be made:

1. Define one device as a master and the others as slaves, see "Network settings",

page 49.

2. Set Anti interference 1 for the master.

3. Set Anti interference 2 for the slave.

✓

The devices will now take measurements one after the other.

7.3.5.6 Determining the direction of detection

The direction of detection determines whether the measured value increases (posi‐

tive) or decreases (negative) when the distance between the device and measuring

object increases.

34

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Figure 32: Direction of detection

Set to positive

1

Set to negative

2

Sensor

3

Center point of the measurement

4

Subject to change without notice

Page 35

Measuring object

Peak 4

Peak 3

Peak 2

Peak 1

1

2

3

4

1

2

3

45

6

5

To determine the order of the peaks, see "Checking the light distribution curve and

peaks", page 35.

7.3.5.7 Checking the light distribution curve and peaks

In this settings display, the user can check the light waveform which is displayed on the

receiver. The peak displays the distance to the measuring object. If the device detects

peaks then these are displayed in the corresponding light waveform and labeled P1 to

P8.

OPERATION

7

Figure 33: Light distribution curve

Sensor

1

Laser

2

Reflective surface

3

Side close to the sensor head (depending on the Measuring direction setting)

4

Side far from the sensor head (depending on the Measuring direction setting)

5

Reflected light intensity

6

During the measurement, light can be reflected from several surfaces at the same

time; for example, from the front and rear of a transparent measuring object.

Direction of detection: The device assigns numbers to the scanned surfaces. This

means that the measurement can focus on individual reflection points (peaks). The

numbers are assigned (using the direction of detection: near/far) in such a way that

they either increase (near) or decrease (far) beginning on the side closest to the sensor.

Example based on four glass panes:

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

35

Page 36

1 ( 8) *

2 ( 7)

3 ( 6)

4 ( 5)

7 ( 2)

8 ( 1)

5 ( 4)

6 ( 3)

1

7 OPERATION

Figure 34: Peak detection

Laser

1

1 = Near

(8) = Far

Near is selected as the standard setting, i.e., the numbering increases from the side

closest to the sensor.

7.3.6 Settings for channels A–D

Figure 35: Overview of the settings tab for channels A–D

7.3.6.1 Setting the measurement value filter

36

The measurement value filters optimize the signal diagram in order to simplify the eval‐

uation by the control system (e.g., for regulation tasks). You can select from the follow‐

ing filters:

Mean filter

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

•

Median filter

•

By default, the mean filter is set to a filter depth of 256 measured values and the

median filter to a filter depth of 31 measured values.

Subject to change without notice

Page 37

Ausgangssignal

Zeit t

1

2

4

3

4

3

21

OPERATION 7

Mean filter

The mean filter carries out a moving averaging of the measured values. This filter is

suitable for smoothing a noisy signal diagram in order to ensure better repeatability.

Filter depth: 1 / 2 / 4 / 8 / 16 / 32 / 64 / 128 / 256 (default value) / 512 / 1024 /

2048 / 4096 / 8192 / 16384 / 32768 / 65536 (unit: measuring point)

The mean filter can be deactivated by selecting filter depth 1.

Median filter

The moving median filter sorts the measured values according to their size and selects

the middle value from a sequence. This filter is suitable for excluding individual outliers

from the calculation of an average value.

Filter depth: Off / 7 / 15 / 31 (default value)

Both types of filter affect the response time of the device.

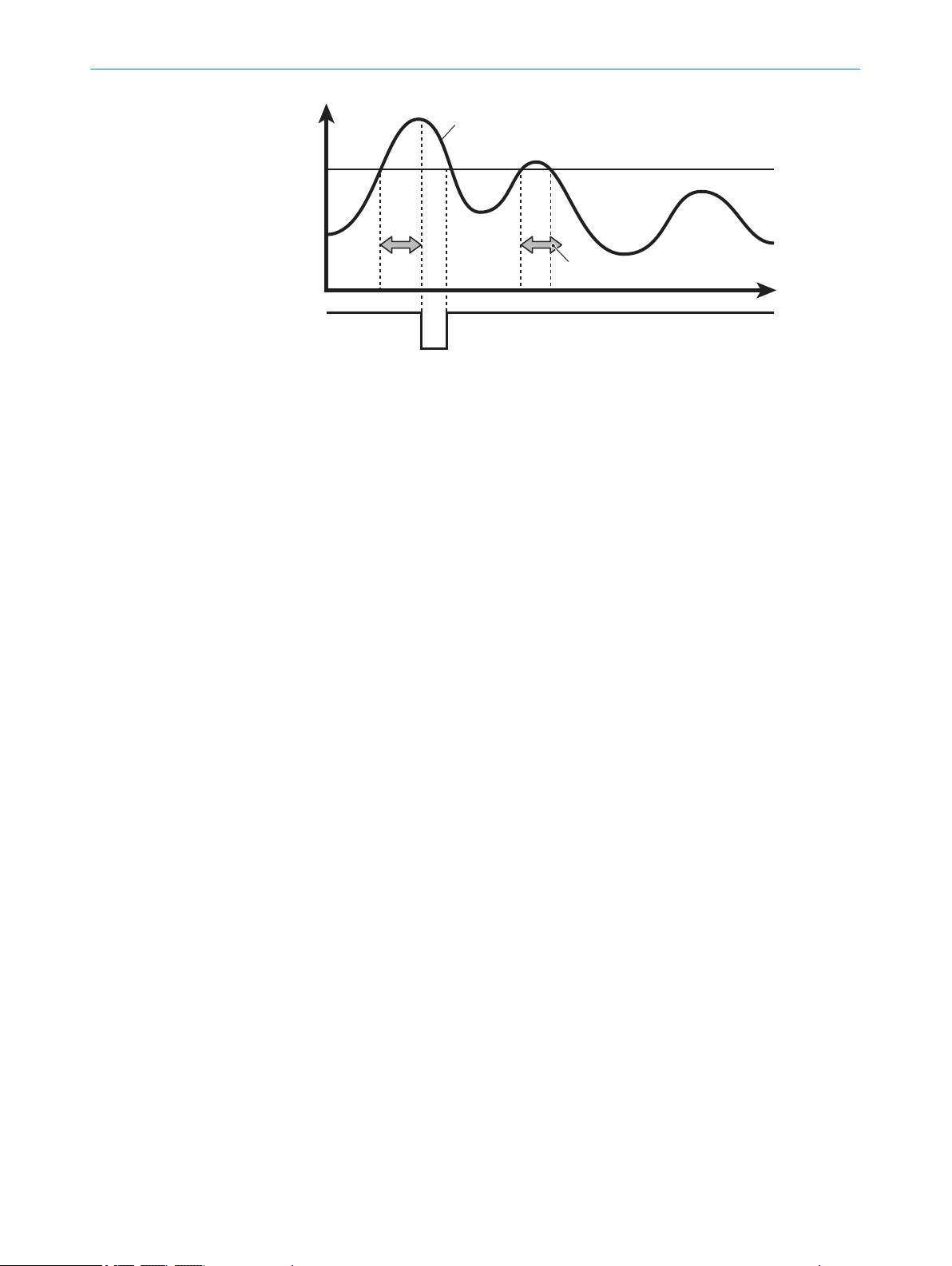

Figure 36: Median filter

1

2

3

4

True distance

Measured value with median

Measured value with averaging

Measured value without averaging

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

37

Page 38

ON

OFF

1

2

ON

OFF

1

2

3

4

5

7 OPERATION

7.3.6.2 Setting the Hold function

The Hold function extracts a specific value such as the maximum or minimum value

within a detection period. The value which was set under Hold Set is used as the holding

period.

Use this function after entering Hold Reset if Auto Peak or Auto Bottom is used.

•

Off

When the hold function is deactivated, the measurement result is output in an unedited

format and the Hold Input is ignored.

Figure 37: Hold function off

Measured value

1

Hold function

2

Peak

The highest value within the detection period is output.

Figure 38: Hold function peak

Measured value

1

Hold

2

Detection period

3

Internal measured value

4

Measured value for the hold function peak

5

38

Bottom

The lowest value within the detection period is output.

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 39

ON

OFF

1

2

3

4

5

Figure 39: Bottom hold function

ON

OFF

1

2

3

4

Measured value

1

Hold function

2

Detection period

3

Internal measured value

4

Measured value of the Bottom hold function

5

Sample Hold

OPERATION 7

The value detected within the detection period is output.

Figure 40: Sample Hold hold function

Measured value

1

Hold function

2

Internal measured value

3

Measured value of the Sample Hold hold function

4

Auto Peak

The highest value is recorded as soon as Hold Reset Input is detected.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

39

Page 40

ON

OFF

1

2

3

4

ON

OFF

1

2

3

4

P(2)

P(1)

B(1)

B(2)

P(1)-B(1)

P(2)-B(2)

ON

OFF

1

3

5

3

4

2

7 OPERATION

Figure 41: Auto Peak hold function

Measured value

1

Hold function

2

Internal measured value

3

Measured value of the Auto Peak hold function

4

Auto Bottom

The lowest value is recorded as soon as Hold Reset Input is detected.

Figure 42: Auto Bottom hold function

Measured value

1

Hold function

2

Measured value of the Auto Bottom hold function

3

Internal measured value

4

Peak to Peak

The value is maintained from peak to peak.

Figure 43: Peak to Peak hold function

1

Measured value

40

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 41

Hold function

2

Duration of measurement

3

Internal measured value

4

Output hold value

5

7.3.6.3 Setting the alarm (action in case of incorrect measurements)

This function allows you to determine the output when a measurement is not possible.

Table 14: Settings for action in case of incorrect measurements

Setting Meaning

User-defined value A defined value is displayed

Hold last value The most recently measured value is displayed

User-defined value at a set

time

Forces the output of a user-defined value at a set time during an

incorrect measurement

Action in case of incorrect measurements: User-defined value

The user-defined value is set in the section on Action in case of incorrect measurements.

Values ±2,147,483 mm are possible; the default value is 1.00 mm.

OPERATION 7

NOTICE

If the AOD1 setting is selected for Input terminal under Communication, the user-defined

value is automatically adjusted to the following value:

209.7152 mm

This value must not be modified.

Error suppression time

When User-defined value at a set time is selected, then the number of measuring points is

determined under Error suppression time, during which the most recently measured value

is displayed. If a measurement still cannot be taken after this period then the userdefined value is displayed.

Values are possible from 0 (default value) to 4,095.

Restoration period following an error

When User-defined value at a set time is selected, then the number of measuring points is

determined under Restoration period following an error. The user-defined value is continued

to be output although a measurement is possible again.

Values are possible from 0 (default value) to 4,095.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

41

Page 42

7 OPERATION

7.3.7 I/O channels

Figure 44: Overview of the I/O channels tab

In this view, the settings are made for the digital signal of each channel. Four channels

are available for this. Settings can be made for each channel individually.

An MF input is also available. The settings for this option can also be made under I/O

channels.

NOTE

The digital signals cannot be measured on the device pins but are made available via

the Ethernet interface as part of data transmission.

7.3.7.1 Setting limits

The threshold is set using limits. In doing so, the digital signal is set to ON or OFF.

Values ±2,000.00 mm are permissible for the upper limit; the default value is

+2.0 mm (for the 85 mm variant) or +4.0 mm (for the 150 mm variant).

Values ±2,000.00 mm are permissible for the lower limit; the default value is

-2.0 mm (for the 85 mm variant) or -4.0 mm (for the 150 mm variant).

7.3.7.2 Setting the hysteresis

If the measured value rises slightly above or drops slightly below the threshold, this can

lead to the input and output repeatedly switching on and off within a short space of

time. This can be prevented by assigning a defined tolerance to the measured value via

the hysteresis setting, beyond which the device switches.

42

NOTE

The limits and the hysteresis can also be set by moving the corresponding marker in the

graphic (blue: limits, yellow: hysteresis).

Values of ±2,000.000 mm are possible; the default value is 0.0000 mm.

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 43

Hysteresis

Upper

limit

ON

OFF

Figure 45: Hysteresis

1

2

34

Upper

limit

ON

OFF

7.3.7.3 Setting the switch-on delay (On Delay)

This setting is used to delay the switching on of the output by a set amount of time if

the measured value exceeds the threshold.

This setting prevents the input and output from repeatedly switching on and off within a

short period of time and enables the use of a slower PLC.

OPERATION 7

The delay is increased by the configured time by switching the switching output to ON.

Figure 46: On Delay

Measured value

1

Shorter than the defined time period

2

The measured value is of equal size or greater than the threshold

3

Output switches to OFF

The measured value is below the threshold

4

Output switches to ON

Values are possible from 0 ms (default value) to 100 ms.

7.3.7.4 Setting the switch-off delay (Off Delay)

This setting is used to delay the switching off of the output by a set amount of time if

the measured value falls below the threshold.

This function suppresses short signals (bursts) which prevents inaccurate measure‐

ments.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

43

Page 44

1

2

34

Upper

limit

ON

OFF

OPERATION

7

Figure 47: Off Delay

Measured value

1

Shorter than the defined time period

2

Output switches to OFF

3

Output switches to ON

4

Values are possible from 0 ms (default value) to 4,000 ms.

7.3.7.5 Setting the calibration

The display for setting the calibration will vary depending on the settings in the Measure‐

ment tab.

Distance

Shift

This setting is used to move the measured value to a fixed value. A corresponding cor‐

rection value (shift) is added to or subtracted from the measured value of the sensor

head.

Span

This value is selected according to the ratio of the measurement error to the measuring

range. It is used for:

compensating for a deviation caused by a tilted installation (distance)

•

measuring the thickness of glass (so that refraction may be taken into account)

•

In a distance measurement, both values must usually be adjusted. With the thickness

measurement type (for measuring the thickness of glass), it is important to set the cali‐

bration factor (span) to the correct value to ensure a precise measurement and to com‐

pensate for the refraction index of the measured material. Only the span value can be

set for the thickness measurement.

Teaching-in is a recommended process. For the distance measurement, two different

objects which are far apart must be placed in front of the sensor – the distances (refer‐

ence values) must be known.

Teaching-in the distance measurement

44

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 45

OPERATION 7

1. Position the first object.

2. Enter the reference value for the first object in Target value 1.

3. Click on the Teach-in point 1 button.

4. Position the second object.

5. Enter the reference value for the second object in Target value 2.

6. Click on the Teach-in point 2 button.

✓

The sensor calculates the suitable shift and span values and applies these to the

measurement.

Teaching-in for thickness measurement

1. Position object with a known reference thickness in front of the sensor.

2. Enter the reference thickness in the Reference thickness field.

3. Click on the Teach-in button.

✓

NOTE

The span and shift values can be adjusted manually at any time after the teach-in.

7.3.7.6 Setting One shot

If this function is activated, the output is only given once when the conditions for output

are met. The output is then switched off.

The sensor calculates the suitable span value and applies this to the measure‐

ment.

The output time is set via Off Delay.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

45

Page 46

7 OPERATION

7.3.8 I/O settings input (MF)

Figure 48: Tab showing the overview of the I/O settings of input (MF)

7.3.8.1 Setting the polarity

This is where the polarity is set for the external input terminal.

Table 15: Input terminal settings

Setting Meaning

High Switches on when input is detected

Low Switches off when input is detected

High (N.O.) is set by default.

7.3.8.2 Setting the switching function

This is where the function is set for the external input terminal.

Table 16: Switching function settings

Setting Meaning

None Input (MF) is not used (input is ignored)

Laser off Laser is switched off during input

Hold function ON/reset Used as hold input/reset input when the hold function is activated

Start process recording Used as a recording input

Measured value offset Used as an Offset or as an Offset Release Input

For Peak Hold/Bottom Sample Hold: Hold input

For Auto Peak Hold/Auto Bottom Hold: Reset input

Recording is carried out when activated. When the specified

amount of saved entries is reached, the recording is stopped and

a file is created.

If the input setting is set to OFF during the recording, the process

is paused and a file is created using the data saved up until that

point.

Less than 1 s: Offset

1 s or more: Offset compensation

46

The default mode is None.

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 47

7.3.8.3 Setting the debounce

Sets the delay time with which the external input is switched on until actual operation

begins. This prevents the external input from suddenly being switched on or off.

Values are possible from 0 ms to 32,767 ms, the standard value is 20,000 ms.

7.3.9 Device

OPERATION 7

Figure 49: Overview of the Device tab

General device settings can be made in this view. The following functions are available

here:

7.3.9.1 Deactivating the measurement laser

Checking or unchecking the box next to Deactivate measurement laser activates and deacti‐

vates the laser. If the laser is deactivated then measurement stops as a result. The

laser is activated as standard.

7.3.9.2 Resetting the device to factory settings

Selecting this function resets all device settings to their factory settings. This does not

include network settings (e.g., IP addresses). A subsequent device restart (power reset)

is recommended.

7.3.9.3 Setting the sensor time

This section displays the current time as well as the time at which the device was

started. Clicking on the Set current time button adjusts the device time to the time set on

the computer being used.

7.3.9.4 Device identification

When this function is selected, the status LED of the device in question flashes for 5 s.

7.3.9.5 Saving the configuration

When this function is selected, the entire device configuration is saved in a file and pre‐

pared for download. A save location must be selected for the file.

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

47

Page 48

7 OPERATION

NOTE

The default save location is normally the download folder (this depends on the individ‐

ual browser settings).

7.3.9.6 Loading the configuration

When this function is activated, a previously stored OD5000 configuration file must be

selected from the computer being used. This is then uploaded to the device and all set‐

tings are adopted accordingly.

7.3.10 Communication

Figure 50: Overview of the Communication tab

Settings which affect communication received from or sent to the device can be made

in this view. The following settings are available here:

7.3.10.1 Communication settings

Input settings

This is where the MF access is assigned a function.

The possible selection includes:

External Input: The MF access is used for the selected switching function, see "Set‐

•

ting the switching function", page 46.

AOD1: The OD5000 can be connected with an AOD1 evaluation unit via its pins

•

RS485+/RS485- (see "Pin assignment of the connections", page 24).

NOTE

Only one channel (A) can be used when AOD1 is selected.

AOD1 Baud rate

This is where the speed of communication with the AOD1 is set. The device automati‐

cally establishes a connection with the AOD1 by default and the settings are defined

autonomously.

48

O PE R AT I NG IN S TR U CT I ON S | OD5000 8021391//2017-10-06 | SICK

Subject to change without notice

Page 49

If the settings are not automatically defined then the same speed must be set as is set

for the AOD1. The following values are possible:

•

•

•

•

•

•

•

•

•

•

•

•

•

7.3.10.2 Network settings

Ethernet settings are also defined from the Communication tab.

MAC address

OPERATION 7

9.6

19.2

38.2

57.6

115.2

230.4

312.4

468.8

500.0

625.0

833.3

937.5

1,250 (default value)

The device-specific MAC address is displayed in this field.

IP address

The device IP address is defined in this field.

The default value is 192.168.0.01.

Addressing mode

The user can choose between a static IP address and DHCP (default value) in this field.

Subnet mask

The device subnet mask is defined in this field.

The default value is 255.255.255.0.

Standard gateway

The standard gateway of the device is defined in this field.

The default value is 0.0.0.0.

Accurate time synchronization

A device of the OD series is defined as a time server in this field. This allows the inter‐

nal clock within all the connected sensors to be synchronized precisely via the standar‐

dized precision time protocol (PTP). In this function, a device of the OD series must be

defined as a master; all additional sensors must be defined as a slave.

This procedure is necessary when Synchronous or Anti interference is set as the synchroni‐

zation mode.

Table 17: Accurate time synchronization modes

Mode Meaning

Off (default value) Function has been deactivated

Master Device is defined as master

Slave Device is defined as slave

8021391//2017-10-06 | SICK O PE R AT I NG IN S TR U CT I ON S | OD5000

Subject to change without notice

49

Page 50

7 OPERATION

7.3.11 Recording

NOTE

If a device on the network is already defined as a PTP time server then this must be

used and all OD devices must be defined as slaves. Otherwise, synchronization cannot

be executed properly.

Figure 51: Overview of the Recording tab

Recording is used to prepare measurement data for storage. Output is in the form of a

*.csv file. Saved data is listed and can be downloaded to the corresponding list entry at

the click of a button. The exact download process depends on the individual browser

settings.

Various functions are available via this display.

7.3.11.1 Formatting settings