Page 1

OD1000

Displacement measurement sensor

O P E R A T I N G I N S T R U C T I O N S

Page 2

Product described

OD1000

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Information on the operating instructions.............................................. 6

1.2 Explanation of symbols............................................................................ 6

1.3 Scope of delivery....................................................................................... 6

1.4 Customer service...................................................................................... 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Improper use............................................................................................. 8

2.3 Limitation of liability................................................................................. 8

2.4 Modifications and conversions................................................................ 8

2.5 Requirements for skilled persons and operating personnel.................. 9

2.6 Operational safety and particular hazards.............................................. 9

2.6.1 Laser radiation......................................................................... 9

2.7 Warning signs on the device.................................................................... 10

3 Product description........................................................................... 11

3.1 Product characteristics............................................................................ 11

3.2 Setup and dimensions............................................................................. 12

3.3 Product ID.................................................................................................. 12

4 Transport and storage....................................................................... 14

4.1 Transport................................................................................................... 14

4.2 Unpacking.................................................................................................. 14

4.3 Transport inspection................................................................................. 14

4.4 Storage...................................................................................................... 14

5 Mounting............................................................................................. 15

5.1 Mounting instructions............................................................................... 15

5.2 Mounting device....................................................................................... 15

6 Electrical installation........................................................................ 16

6.1 Safety......................................................................................................... 16

6.2 Wiring notes.............................................................................................. 16

6.3 Connecting the device electrically........................................................... 18

7 Operation............................................................................................ 20

7.1 General notes............................................................................................ 20

7.2 Control elements and status indicators.................................................. 20

7.2.1 Indicator lights......................................................................... 20

7.2.2 Operating buttons.................................................................... 21

7.3 Operating concept.................................................................................... 21

8 Operation via display........................................................................ 22

8.1 Menu structure and parameter description............................................ 22

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

3

Page 4

CONTENTS

8.1.1 Main display level and main menu......................................... 22

8.1.2 Measurement menu group..................................................... 23

8.1.3 I/O interface menu group: Q1 output..................................... 24

8.1.4 I/O interface menu group: Q2/Qa output, In1 input............. 25

8.1.5 Device menu group.................................................................. 26

8.1.6 Communication menu group.................................................. 26

8.1.7 Info menu group...................................................................... 26

8.2 Main display level..................................................................................... 26

8.3 Measurement............................................................................................ 27

8.3.1 Application settings................................................................. 27

8.3.2 Default settings........................................................................ 32

8.4 I/O interface.............................................................................................. 37

8.4.1 Q1 output................................................................................. 37

8.4.2 Q2/Qa output............................................................................

8.4.3 In1 input................................................................................... 46

8.5 Device........................................................................................................ 51

8.5.1 User level.................................................................................. 51

8.5.2 Reset........................................................................................ 51

8.5.3 Saving customer settings........................................................ 51

8.5.4 Language.................................................................................. 52

8.5.5 Display settings........................................................................ 52

8.5.6 Measurement laser................................................................. 52

8.6 Communication......................................................................................... 53

8.7 Info............................................................................................................. 53

8.7.1 Firmware verification............................................................... 53

8.7.2 Serial number.......................................................................... 53

8.7.3 Sensor operating hours........................................................... 53

8.7.4 Laser operating hours............................................................. 54

8.7.5 Sensor status........................................................................... 54

8.7.6 Part number............................................................................. 54

43

9 Operation via IO-Link........................................................................ 55

9.1 Process data............................................................................................. 55

9.2 Device data............................................................................................... 55

10 Operation via SOPAS ET................................................................... 56

11 Maintenance...................................................................................... 58

11.1 Cleaning..................................................................................................... 58

11.2 Maintenance............................................................................................. 58

12 Troubleshooting................................................................................. 59

12.1 General faults, warnings, and errors....................................................... 59

12.2 Detecting and displaying errors............................................................... 59

12.3 Information for service cases.................................................................. 60

12.4 Returns...................................................................................................... 60

4

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 5

CONTENTS

12.5 Repairs...................................................................................................... 60

12.6 Disposal..................................................................................................... 60

13 Technical data.................................................................................... 62

13.1 Performance............................................................................................. 62

13.2 Interfaces.................................................................................................. 63

13.3 Mechanics/electronics............................................................................. 63

13.4 Ambient data............................................................................................. 64

14 Accessories........................................................................................ 65

14.1 Accessories............................................................................................... 65

15 Annex.................................................................................................. 66

15.1 EU declaration of conformity / Certificates............................................. 66

15.2 Licenses.................................................................................................... 66

15.2.1 .................................................................................................. 66

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to handle the prod‐

uct from SICK AG. Adherence to all the specified safety notes and guidelines is a pre‐

requisite for working safely. You must also comply with any local work safety regulations

and general safety specifications applicable to the use of the product.

Ensure that you read through these operating instructions carefully before starting any

work. They constitute an integral part of the product and should be stored in the direct

vicinity of the product so they remain accessible to personnel at all times. If the product

is passed on to a third party, these operating instructions should be handed over with

it.

These operating instructions do not provide information on operating the machine in

which the product is integrated. For information about this, refer to the operating

instructions of the particular machine.

1.2 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious inju‐

ries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.3 Scope of delivery

Supplied documentation:

■

SafetyNotes

6

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 7

NOTE

All available documentation can be found online at

www.sick.com/OD1000

b

1.4 Customer service

If you require any technical information, our customer service department will be happy

to help. To find your representative, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.,

to ensure faster processing.

ABOUT THIS DOCUMENT 1

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The displacement measurement sensor is an opto-electronic measuring device and is

used for optical, non-contact distance measurement between the displacement meas‐

urement sensor and an object.

The required optical properties of the object that will be detected are specified in the

technical data section of this document.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

The device does not constitute a safety-relevant device according to the EC Machi‐

•

nery Directive (2006/42/EC).

The device must not be used in explosion-hazardous areas, in corrosive environ‐

•

ments or under extreme environmental conditions.

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

Device should be used only in accordance with its intended use.

■

All information in these operating instructions must be strictly observed.

2.3 Limitation of liability

Applicable standards and regulations, the latest state of technological development,

and our many years of knowledge and experience have all been taken into account

when assembling the data and information contained in these operating instructions.

The manufacturer accepts no liability for damage caused by:

■

Failing to observe the operating instructions

■

Incorrect use

■

Use by untrained personnel

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

2.4 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dangers.

8

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 9

Interrupting or modifying the device or SICK software will invalidate any warranty claims

against SICK AG. This applies in particular to opening the housing, even as part of

mounting and electrical installation.

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualification requirements for the various

areas of work:

■

Instructed personnel have been briefed by the operator about the tasks assigned

to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g. Master Electrician). Other relevant regulations applicable in other

countries must be observed.

SAFETY INFORMATION 2

The following qualifications are required for various activities:

Table 1: Activities and technical requirements

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Commissioning, configura‐

tion

Operation of the device for

the particular application

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in

■

their particular application

Basic knowledge of the WindowsTM operating system in use

■

Basic knowledge of the design and setup of the described

■

connections and interfaces

Basic knowledge of data transmission

■

Knowledge of the operation and control of the devices in

■

their particular application

Knowledge of the software and hardware environment for

■

the particular application

2.6 Operational safety and particular hazards

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan‐

gerous situations.

2.6.1 Laser radiation

The device is equipped with a laser source:

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

■

Measurement laser (red, visible to the human eye)

CAUTION

Optical radiation: Laser class 1

The accessible radiation does not pose a danger when viewed directly for up to

100 seconds. It may pose a danger to the eyes and skin in the event of incorrect

use.

■

Do not open the housing. Opening the housing will not switch off the laser.

Opening the housing may increase the level of risk.

■

Current national regulations regarding laser protection must be observed.

The laser qualifies as a class 1 laser based on standard IEC 60825-1: 2014

(Safety of laser products - Part 1: Equipment classification and requirements,

Edition 3).

2.7 Warning signs on the device

A visible red laser is installed in the device. The laser corresponds to laser class 1. The

housing is labeled with a warning sign.

10

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 11

3 Product description

3.1 Product characteristics

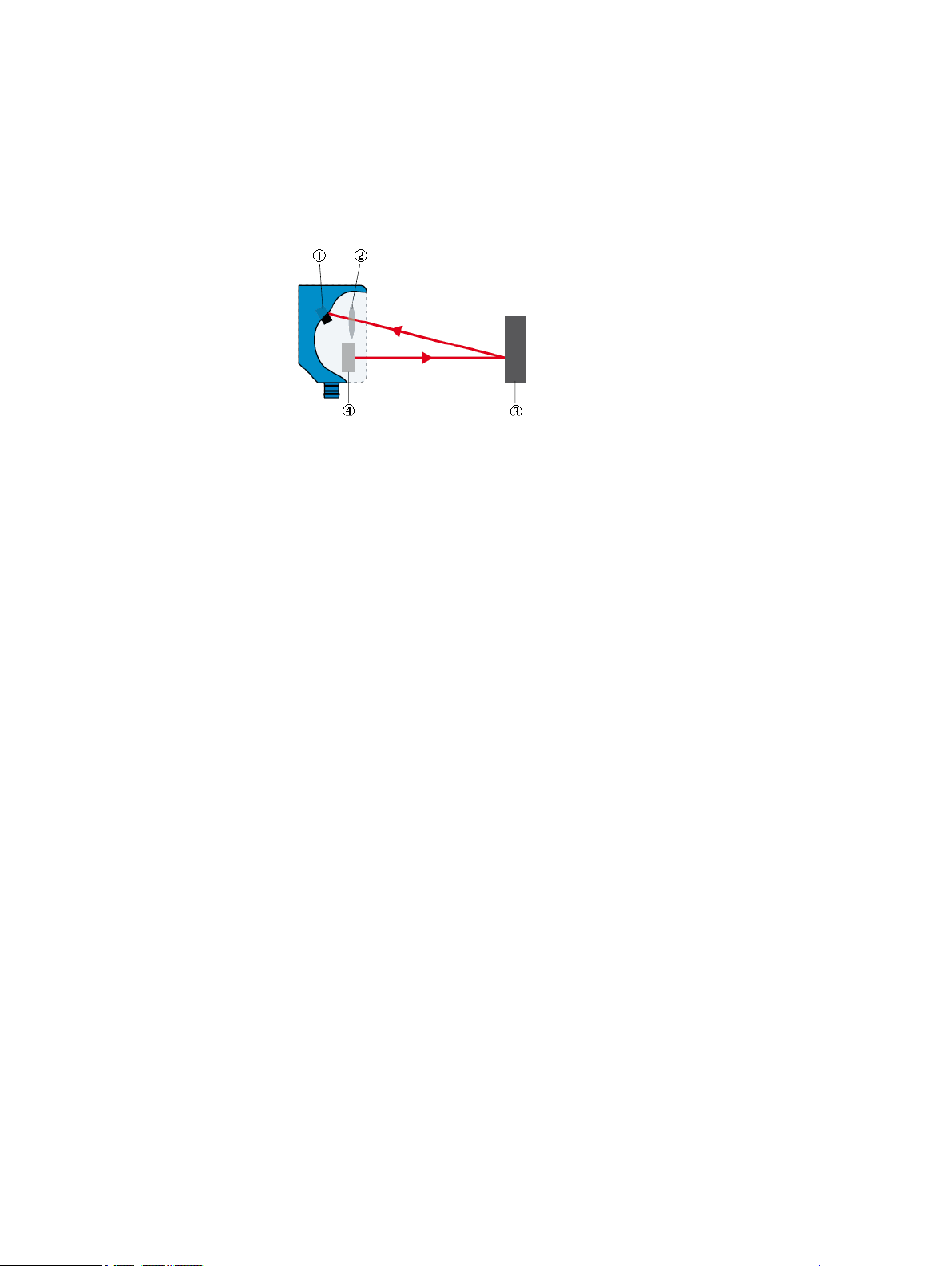

The displacement measurement sensor uses the triangulation principle for distance

measurement. This technology makes it possible to measure the distance between the

displacement measurement sensor and an object.

Figure 1: Triangulation principle

Receiver

1

Lens

2

Object

3

Laser

4

PRODUCT DESCRIPTION

3

A point of light is projected onto the measuring object. The light reflected is captured by

a light-sensitive receiver at a specific angle. Based on the angle between the send and

receive direction, the position of the object is triangulated (lat. Triangulum: triangle).

The distance determined is transmitted via the IO-Link interface. The analog signal out‐

put converts the distance value into an output signal proportional to the distance

(switchable: mA/V).

Digital switching outputs can be used to monitor when configured thresholds/distance

values have been reached. The “Distance to the object”, “Window”, and “ObSB” switch‐

ing functions are supported.

Measured distance values can be visualized and parameter settings can be made

using the graphical OLED display. Alternatively, the displacement measurement sensor

can be configured via the IO-Link interface in conjunction with an IO-Link master. The

SOPAS user interface can be used for configuration as well. This process also takes

place via the IO-Link interface in conjunction with an IO-Link master. For more informa‐

tion visit:

www.sick.com/SOPAS_ET

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

11

Page 12

71.5 (2.81)

60.7 (2.39)

58.55 (2.31)

22.5

(0.89)

53.2 (2.09)

11.95

(0.47)

∅ 4.5 (0.18)

4.5 (0.18)

3 (0.12)

15.2

(0.60)

PWR

Q1

Q2

M12 x 1

2

1

6

9

78

4

5

2

25.9

(1.02)

3

3 PRODUCT DESCRIPTION

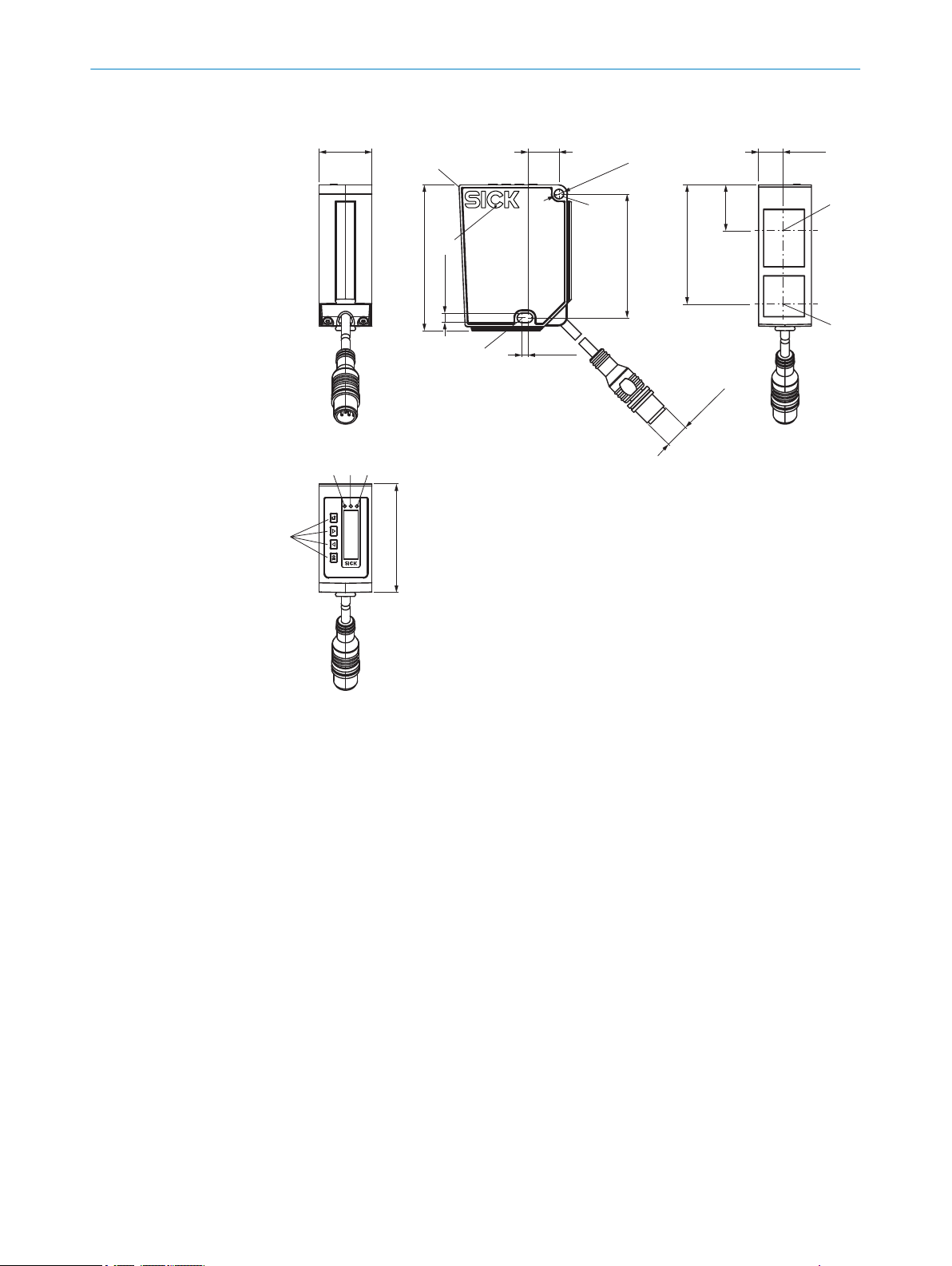

3.2 Setup and dimensions

3.3 Product ID

Figure 2: Setup and dimensions

Device zero point (distance = 0 mm)

1

Fixing holes (for M4)

2

Ventilation opening – do not cover!

3

Center of optical axis, receiver

4

Center of optical axis, sender

5

Display LED, green

6

7

8

9

Display LED, yellow

Display LED, yellow

Display operating elements

Type label

The following information can be read off the device from the type label:

12

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 13

1

6

8

2

9

ß

à

á

ã

â

7

ä

SICK AG

D-791 83 Waldkirc h

Made in Germa ny

OD1000

OD1000-6001R15

1 075 638

SN16100001

MAR 2016

EN/IEC 60825-1:2014

Complies with 21 CFR

1040.10 and 1040.11

except for deviations

pursuant to laser

notice No. 50, dated

June 24, 2007

CLASS 1 LASER PRODUCT

DC 18 - 30 Vdc class 2

Qout: < 100 mA

QAout: 4 - 20 mA/0 - 10 V

Amb. Temp.: < 50 °C

Power Con.: < 2.5 W

Enclosure Type: 1

brown

blue

black

white

gray

1

3

4

2

5

LASER APERTURE

L+

M

Q1/C

Q2/Q

A

In1

LASER

1

5

25

3

4

PRODUCT DESCRIPTION 3

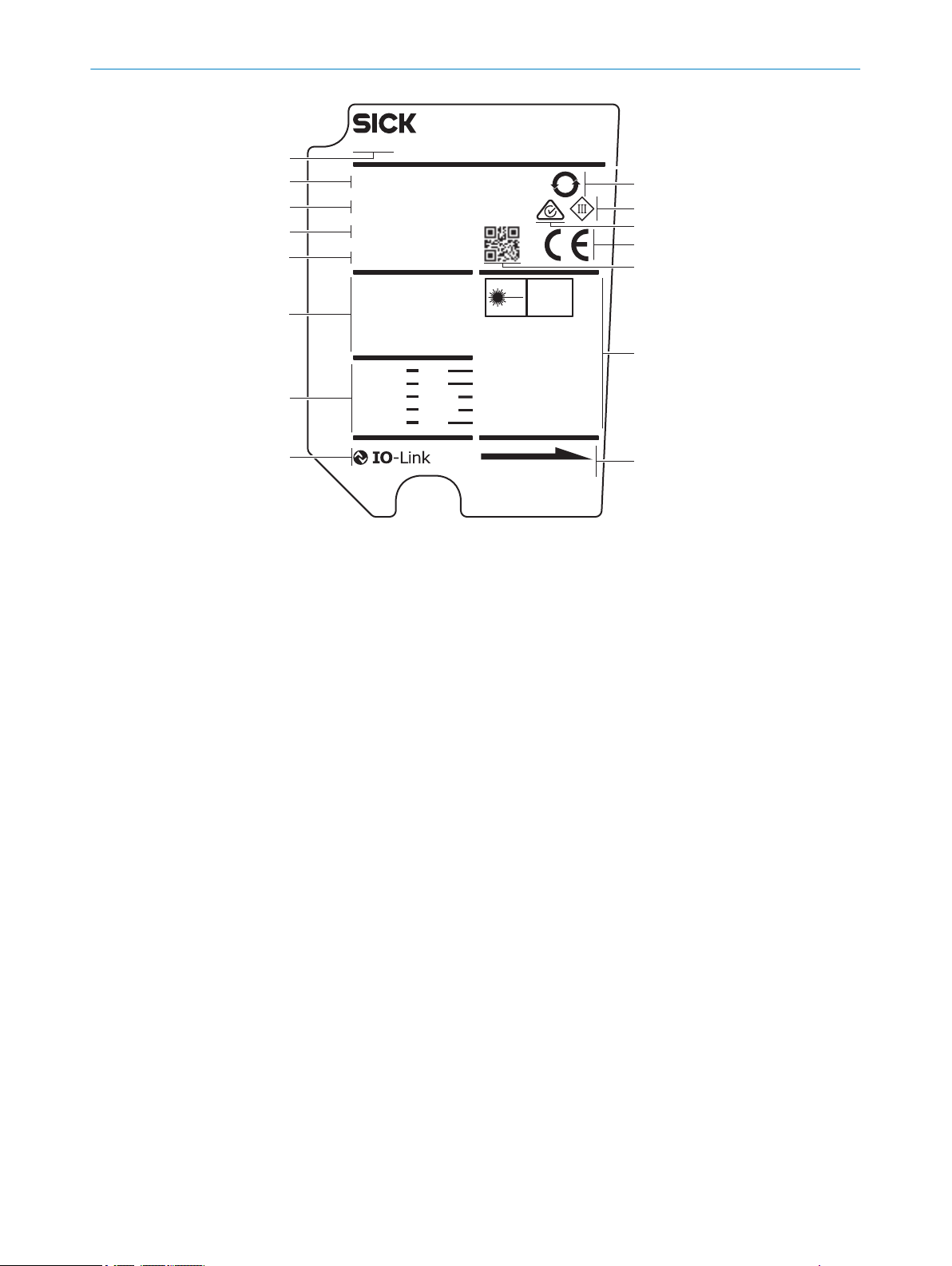

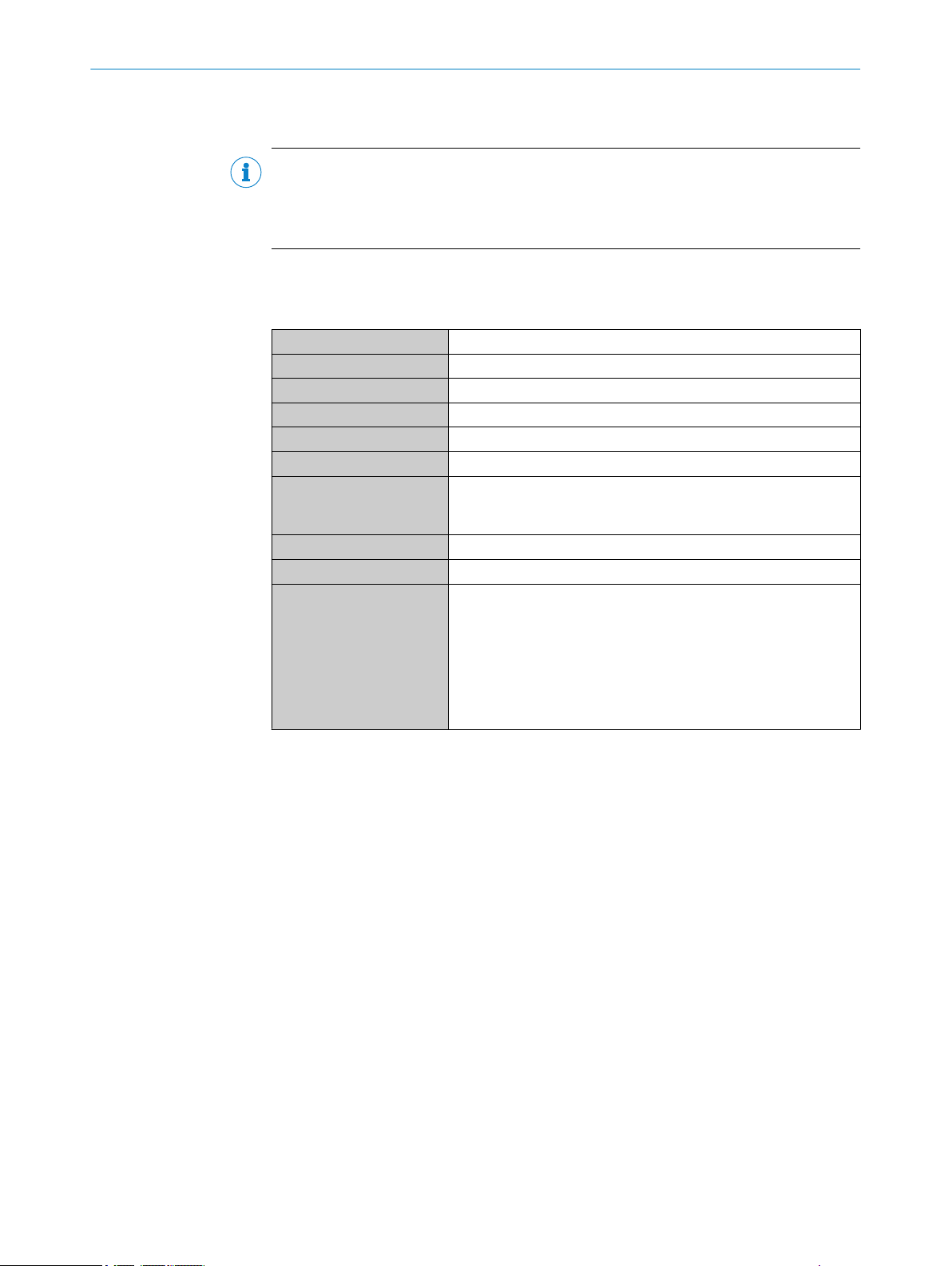

Figure 3: OD1000 type label

1

2

3

4

5

6

7

8

9

ß

à

á

â

ã

ä

Device display

The following information can be called up using the info menu on the device display:

Firmware verification

•

Serial number

•

Sensor operating hours

•

Laser operating hours

•

Sensor status (error history)

•

Part number

•

EFUP information for China

Protection class

RCM conformity mark

EU conformity mark

2D code with part number and serial number

Laser information

Laser radiation direction

IO-Link symbol

Pin assignment

Electrical data and environmental data

Month and year of manufacture

Serial number

Part number

Type code

Device family

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

13

Page 14

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

4.2

Unpacking

■

Before unpacking, it may be necessary to equalize the temperature to protect the

device from condensation.

■

Handle the device with care and protect it from mechanical damage.

4.3 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport compa‐

ny's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

4.4 Storage

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 62.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

14

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 15

5 Mounting

5.1 Mounting instructions

Observe the technical data.

•

Protect the sensor from direct sunlight.

•

To prevent condensation, avoid exposing the sensor to rapid changes in tempera‐

•

ture.

The mounting site has to be designed for the weight of the device.

•

To avoid inaccurate measurements when installing multiple devices: Make sure

•

that the laser light spot of one device is not in the visible range of another device.

Only commission the device 30 minutes after switching it on. Measured values

•

which are taken immediately after the device is switched on are not reliable.

5.2 Mounting device

1. Mount the displacement measurement sensor using the designated fixing holes,

see "Setup and dimensions", page 12.

2. Make the electrical connection. Attach and tighten a voltage-free cable, see "Con‐

necting the device electrically", page 18.

3. Switch on the supply voltage.

✓

The green operating LED lights up.

The device needs around 10 seconds of initialization time before it is ready for

operation.

4. Align the light spot so that the desired object is measured.

MOUNTING 5

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

15

Page 16

6 ELE

CTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

WARNING

P

ersonal injury due to incorrect supply voltage.

An incorrect supply voltage may result in personal injury.

■

Only operate the device using safety extra-low voltage and safe electrical insula‐

tion as per protection class III.

NOTICE

E

quipment damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

■

Only carry out wiring work when the power is off.

■

Only connect and disconnect electrical connections when the power is off.

6.2 Wiring notes

NOTICE

aults due to incorrect wiring.

F

Incorrect wiring may result in operational faults.

■

Follow the wiring notes precisely.

NOTE

Preassembled cables can be found online at:

www.sick.com/OD1000

b

The electrical connection of the device is configured as an M12 round connector. The

otection class stated in the technical data is achieved only with a screwed plug con‐

pr

nector or cover cap.

Please observe the following wiring notes:

■

A correct and complete cable shielding design is required for trouble-free data

transmission.

■

The cable shield must be connected at both ends in the control cabinet and at the

device. The cable shield of the pre-assembled cables is connected to the knurled

nut and thus also to a large area of the device housing.

■

The cable shield in the control cabinet must be connected to a large area of the

signal ground, see figure 7.

■

Appropriate measures must be taken to prevent equipotential bonding currents

flowing through the cable shield.

■

During installation, pay attention to the different cable groups. The cables are

grouped into the following 4 groups according to their sensitivity to interference or

radiated emissions.

16

Group 1: Cables very sensitive to interference, such as analog measuring

°

cables

Group 2: Cables sensitive to interference, such as device cables, communica‐

°

tion signals, bus signals

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 17

1

2

4

3

1

2

4

3

90

90

1

2

3

4

1

2

3

4

ELECTRICAL INSTALLATION

Group 3: Cables which are a source of interference such as control cables for

°

inductive loads, motor brakes

Group 4: Cables which are powerful sources of interference, such as output

°

cables from frequency inverters, welding system power supplies, power

cables

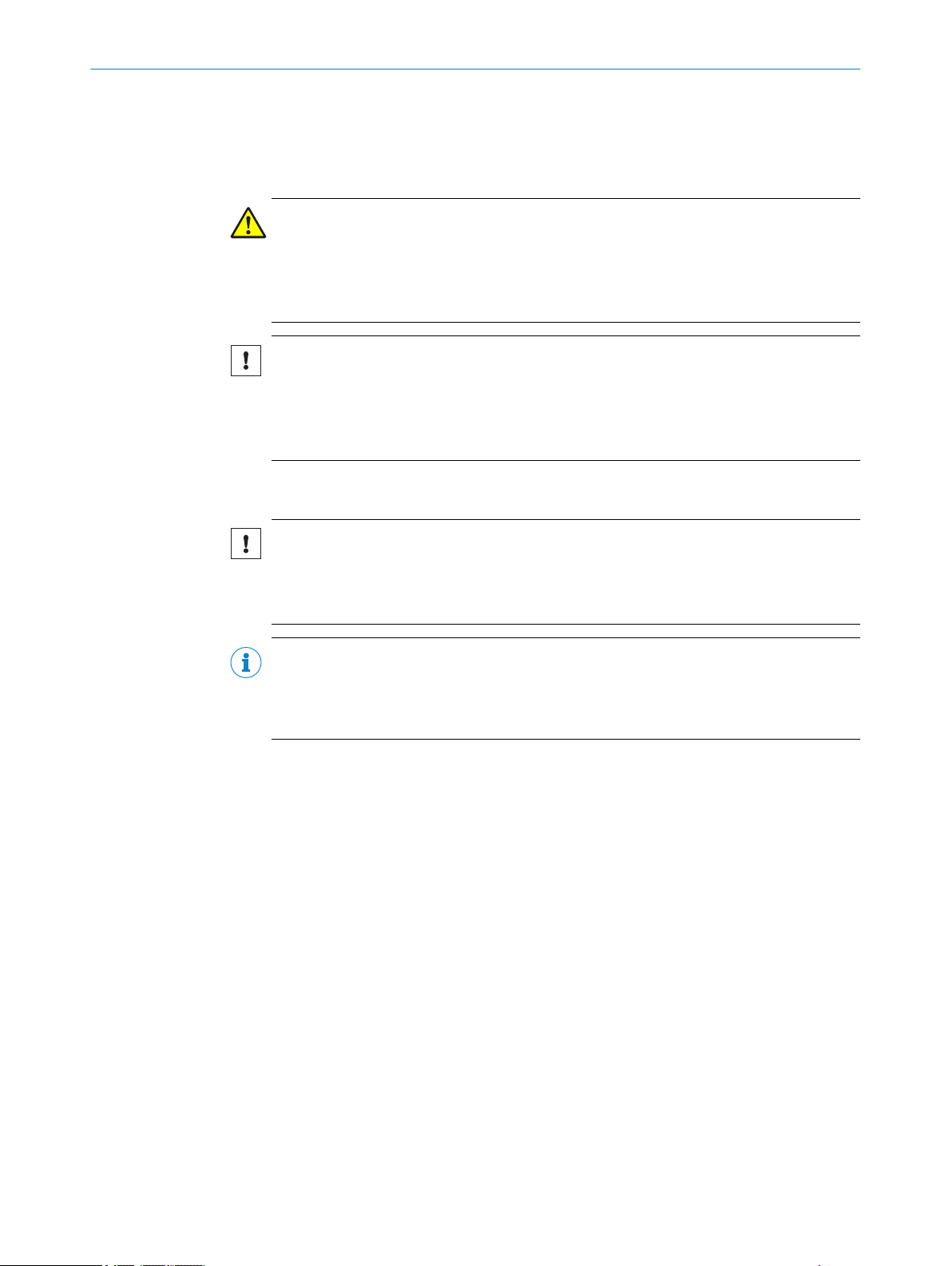

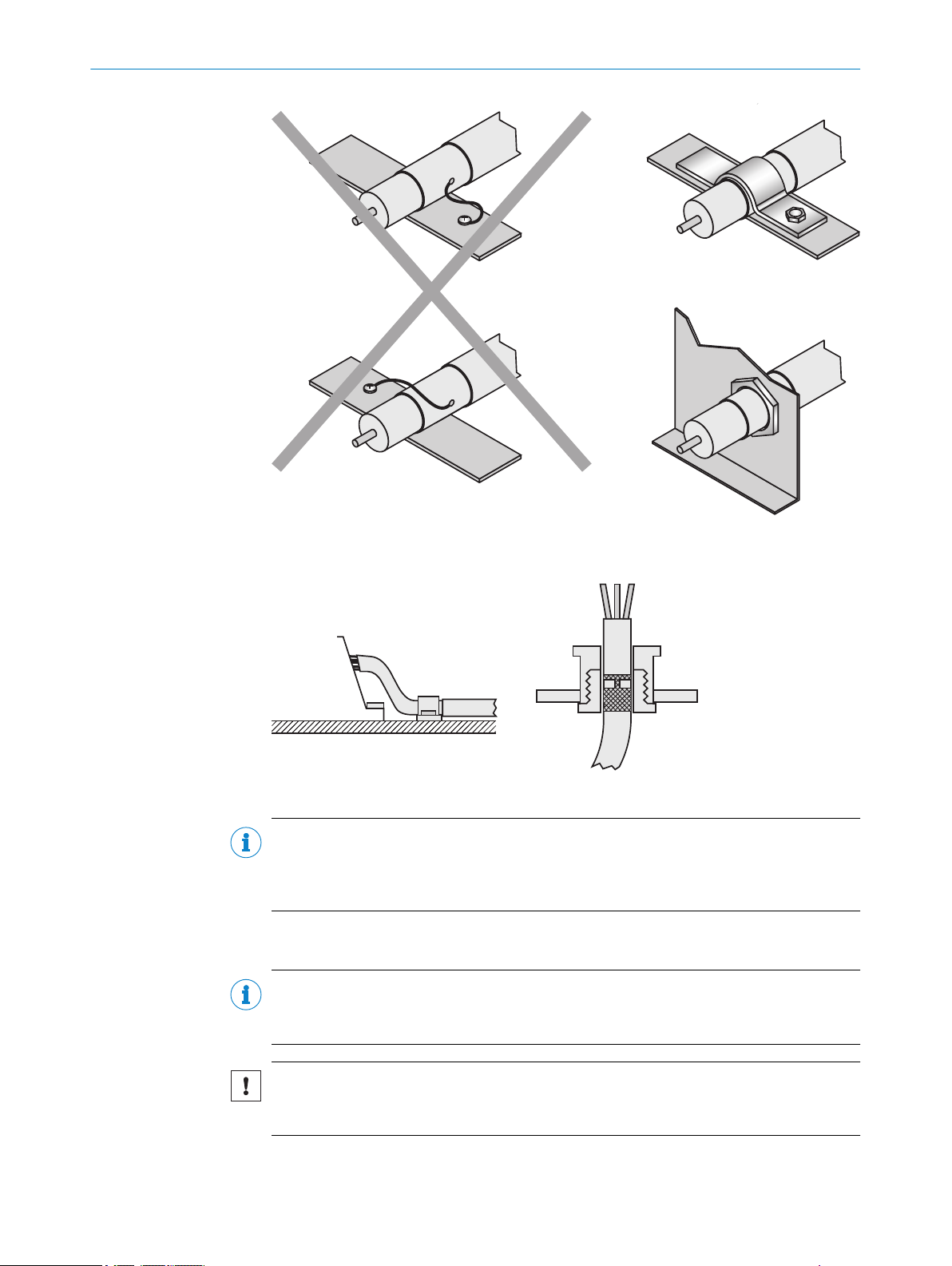

Cables in groups 1, 2 and 3, 4 must be crossed at right angles (see figure 4).

w

Route the cables in groups 1, 2 and 3, 4 in different cable channels or use

w

metallic separators (see figure 5 and see figure 6). This applies particularly if

cables of devices with a high level of radiated emission, such as frequency

converters, are laid parallel to device cables.

6

Figure 4: Cross cables at right angles

Figure 5: Ideal laying ‑ Place cables in different cable channels

Figure 6: Alternative laying – Separate cables with metallic separators

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

17

Page 18

6 ELECTRICAL INSTALLATION

Figure 7: Make an extensive and low-impedance ground connection of the cable shield in the

control cabinet.

Figure 8: Shield connection in plastic housings

NOTE

Prevent equipotential bonding currents via the cable shield with a suitable grounding

concept. If necessary, ground currents on the EtherNet/IP cabling can be prevented by

the use of an EtherNet/IP adapter (part number 2044264).

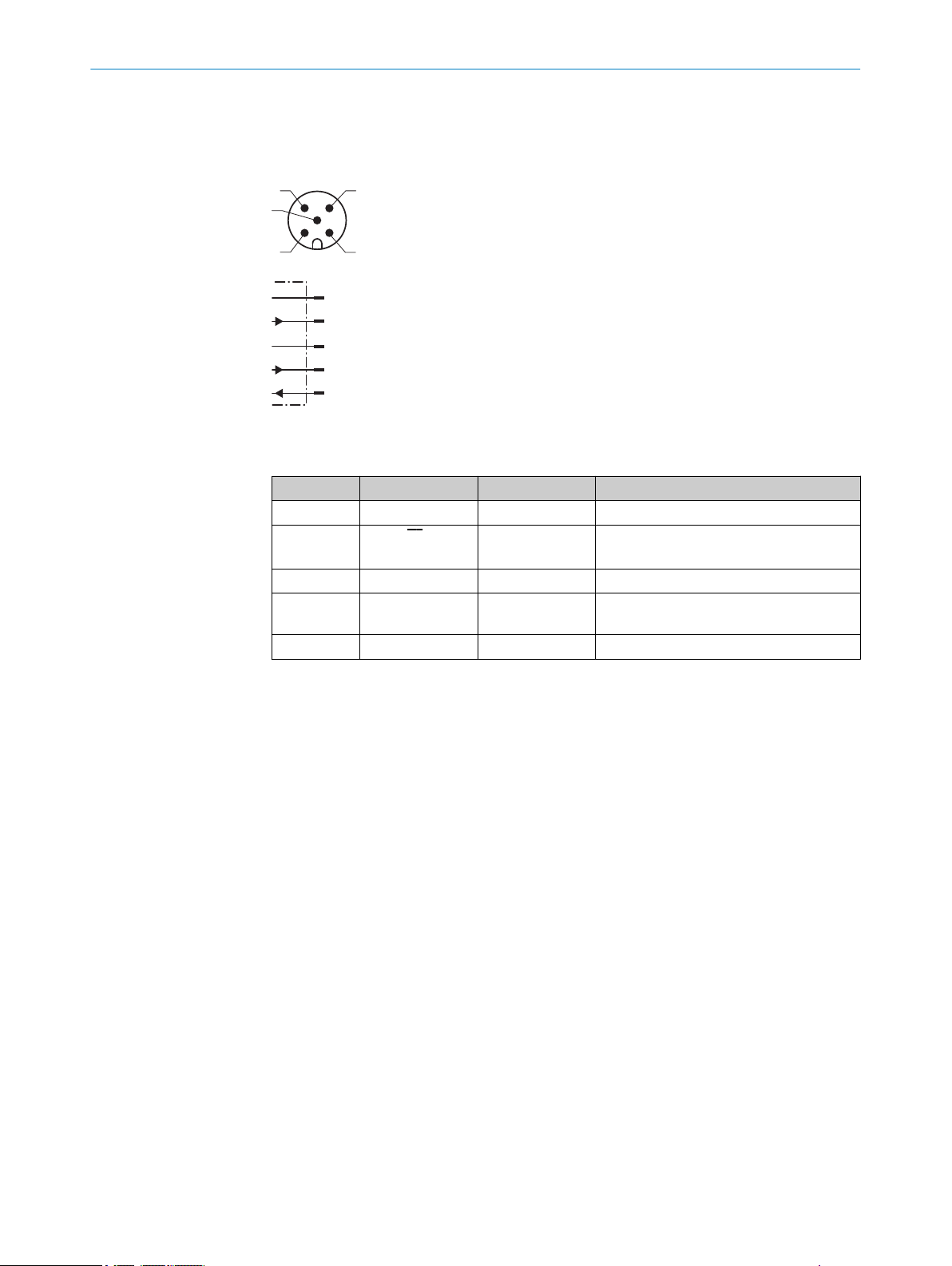

6.3 Connecting the device electrically

NOTE

The connection diagram, and information on inputs and outputs, can be found on the

side plate on the device.

18

NOTICE

All electrical circuits must be connected to the device with safety extra-low voltage

(SELV or PELV).

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 19

1

4 3

5

2

L+

1

brn

M

3

blu

Q1/C

4

blk

QA/Q2/¯Q1

2

wht

In1

5

gra

ELECTRICAL INSTALLATION 6

1. Ensure that the voltage supply is not connected.

2. Connect the device according to the connection diagram.

3. Observe the wiring instructions, see "Wiring notes", page 16.

Figure 9: Connection diagram, 5-pin male connector

Table 2: Legend for connection diagram

Contact Identification Wire color Description

1 L+ Brown Supply voltage: +18 ... +30 V DC

2 QA/Q2/Q

1

3 M Blue Supply voltage: 0 V

4 Q1/C Black Output 1: switching output 1 (push-pull

5 In1 Gray Input 1

White Output 2: analog output / switching out‐

put 2 (push-pull stage) / Q1 not

stage) / IO-Link

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

19

Page 20

PWR

Q1

Q2

1

4

2

3

7 OPERATION

7 Operation

7.1 General notes

If the device is not able to perform a measurement even though the measuring object is

within the specified measuring range, the alignment should be checked and optimized

if necessary. In general, adjusting the measuring rate can increase the measuring abil‐

ity for very dark objects, for example.

For a successful teach operation, the device must be able to measure. The distance to

the teach object must not change during the teach operation. The object must be in the

measuring range, and the distance values taught in for the distance near to the sensor

and the distance far from the sensor must not be exactly the same during a switching

window or the analog scaling.

To prevent EMC interference, observe the wiring instructions. If an environment is dis‐

rupted by EMC interference, data output via IO-Link is the preferred solution. If the

application requires an output of the measured values in such an environment via the

analog output, an analog current output should also be preferred to using the voltage

output, because this is significantly less susceptible to EMC interference.

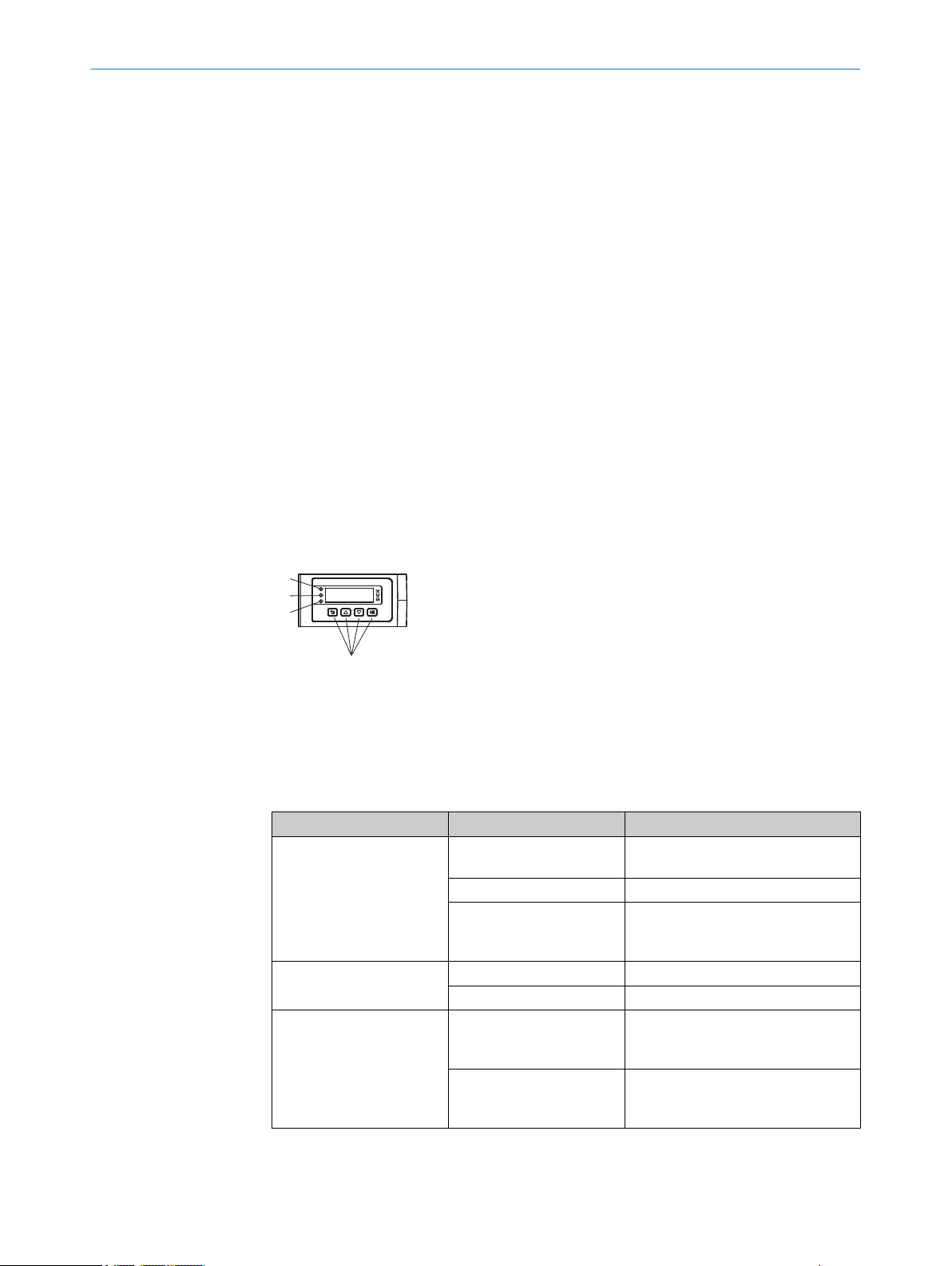

7.2 Control elements and status indicators

7.2.1 Indicator lights

Status-LED PWR (grün)

1

Status-LED Q1 (orange)

2

Status-LED Q2 (orange)

3

Bedientasten

4

Table 3: Meaning of the indicator lights

Display Status Meaning

PWR status indicator

Output display Q

Output display Q

1

2

O

o

Ö

O

o

O

o

Voltage supply available, device

ready for use

Voltage supply not available

Voltage supply available, device

ready for use, connection to an IOLink master available

Switching output active

Switching output not active

Switching output active or measured

value within the scaling range for the

analog output

Switching output not active or meas‐

ured value outside the scaling range

for the analog output

20

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 21

Display Status Meaning

Output displays Q

o

Ö

O

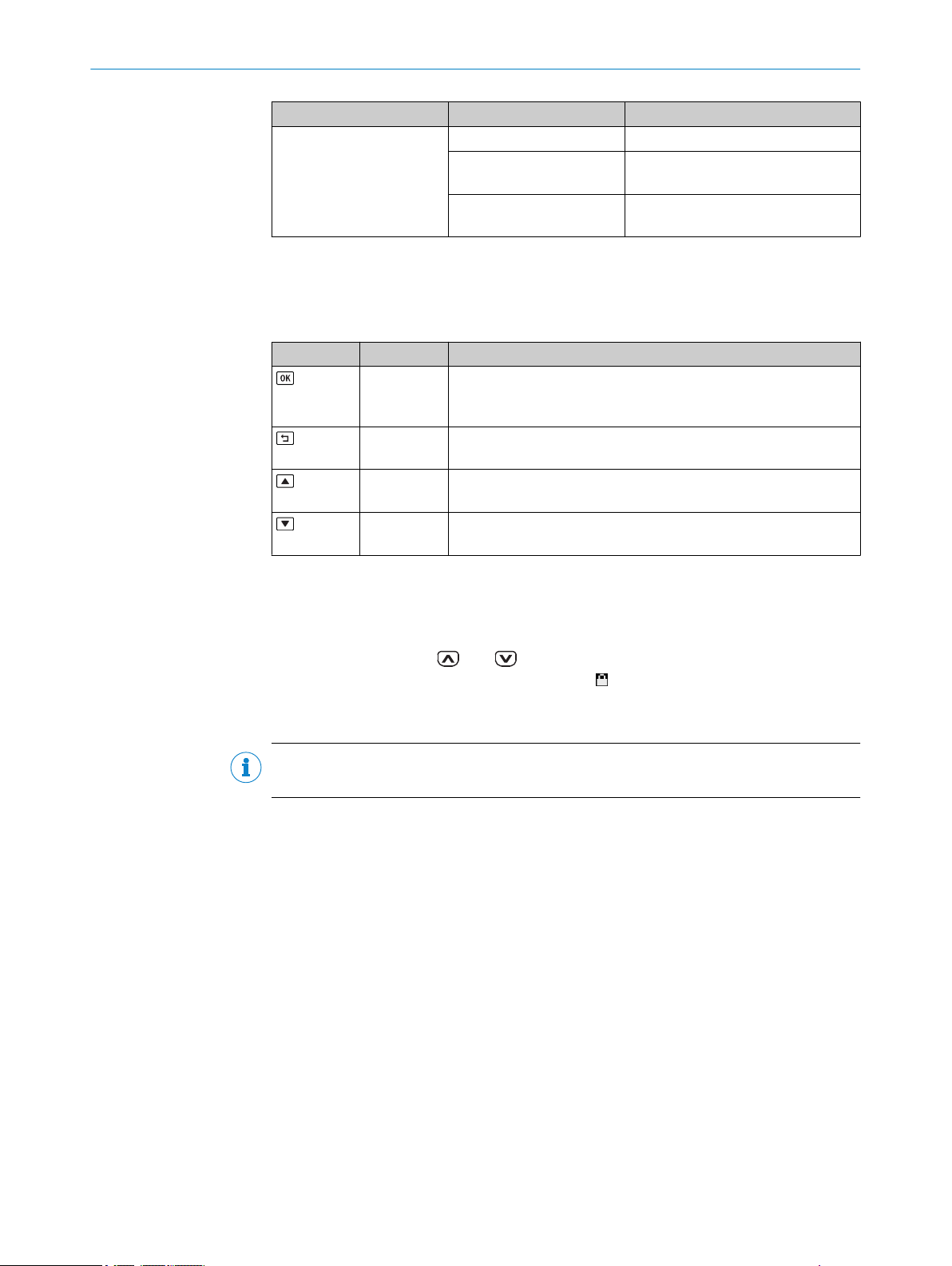

7.2.2 Operating buttons

Pushbutton Function Description

Does not light up

Flashing

Permanently on

Open menu/

confirm

Cancel Switches to the previous menu level.

Navigate Switches between multiple screens on one menu level.

Navigate Switches between multiple screens on one menu level.

OPERATION 7

1

Ö Ö Simultaneous

Ö Ö 5 seconds in alter‐

nation

Ö Ö Permanently in

alternation

Opens the menu, confirms entries, or switches to the next menu

level of a selected element.

Moves the cursor to the right when entering numbers.

Moves the cursor to the left when entering numbers.

Increases the value when entering numbers.

Reduces the value when entering numbers.

Teach-in operation is carried out

Teach-in operation has failed

There is a fault

Activating / Deactivating the operating button lock

The operating buttons can be locked / unlocked using a shortcut in order to prevent

accidental operation:

b

Press and hold the and pushbuttons simultaneously for > 3 seconds.

✓

When the pushbutton lock is activated, the padlock symbol appears in the dis‐

play. When the pushbutton lock is deactivated, the padlock symbol is not dis‐

played.

NOTE

The operating button lock can also be activated / deactivated via SOPAS ET or IO-Link.

7.3 Operating concept

The device can be operated using the following methods:

Display and operating buttons on the device, see "Operation via display",

•

page 22.

SOPAS ET user interface (PC), see "Operation via SOPAS ET", page 56.

•

IO-Link, see "Operation via IO-Link", page 55.

•

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

21

Page 22

8 OPERATION VIA DISPLAY

8 Operation via display

NOTE

Only certain functions are available depending on the user level set (see see "User

level", page 51):

Easy: frequently required functions (factory setting)

•

Advanced: all available functions

•

8.1 Menu structure and parameter description

8.1.1 Main display level and main menu

22

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 23

8.1.2 Measurement menu group

OPERATION VIA DISPLAY 8

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

23

Page 24

8 OPERATION VIA DISPLAY

8.1.3 I/O interface menu group: Q1 output

24

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 25

8.1.4 I/O interface menu group: Q2/Qa output, In1 input

OPERATION VIA DISPLAY 8

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

25

Page 26

8 OPERATION VIA DISPLAY

8.1.5 Device menu group

8.1.6 Communication menu group

8.1.7 Info menu group

8.2 Main display level

As soon as voltage is supplied to the device, the display shows the main display level

and a measured value is displayed.

26

The / pushbuttons can be used to switch between the following displays:

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 27

OPERATION VIA DISPLAY 8

Relative distance measured value:

•

The (relative) distance value always takes into account the set measured value off‐

set.

Absolute and relative distance measured value:

•

Simultaneous display of the distance without (absolute) and with (relative) the set

measured value offset.

Scaled analog value:

•

The current output value is only displayed when the analog output is activated.

Signal level:

•

NOTE

The signal level corresponds to the amount of light received by the device's

receiver optics. This is a dimensionless value. It essentially depends on the dis‐

tance from the measuring object, the surface of the measuring object (color,

roughness/gloss, angle to the optical axis), and the cycle time set on the device.

To enable the device to measure the distance correctly, the signal level must not

drop below a lower limit value. The dynamics of the device normally regulate the

level to ensure an optimized value. Depending on the set cycle time, object proper‐

ties, and object distance, the signal level may drop below the lower limit value and

make it impossible to carry out a measurement. It may be possible to improve the

measuring behavior by increasing the cycle time, optimizing the alignment of the

device with the object, or reducing the distance to the measuring object.

Distance visualization:

•

The cursor gives a qualitative indication of the position within the maximum meas‐

uring range.

Temperature:

•

The value displays the temperature inside the device and is not relevant for the

specified operating temperature range.

8.3 Measurement

8.3.1 Application settings

The functions are only available in the Advanced user level, see "Device", page 51.

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

27

Page 28

Max. measuring range

Transparent

screen

Distance rangeNear limit Far limit

15 mm

Tolerance window

15 mm

Tolerance window

Reliable detectionReliable blanking Reliable

blanking

Measuring object

OPERATION VIA DISPLAY

8

8.3.1.1 Distance range

The “Distance range” function can be used to define an evaluation range in which the

device measures object distances. All surrounding ranges are blanked. A typical appli‐

cation is the blanking of a transparent protective screen fitted between the object and

the device.

During configuration, please note that the application must take into account a toler‐

ance range of 15 mm outside the set limits of the distance range. Reliable blanking

and detection of objects cannot be guaranteed within this tolerance range.

Figure 10: Blanking of a transparent protective screen by establishing the near limit and far limit

of the distance range, taking into account the tolerance ranges

Near limit / Far limit

The near limit / far limit values are the distances in mm which define the limits of the

evaluation range.

NOTE

As there are limited discretization steps, the device transfers the limit values entered to

the next possible distance values (mm). The recalculated value is adopted by the device

and is also shown on the display.

Simple configuration of the distance range is also possible via the SOPAS_ET software,

see "Operation via SOPAS ET", page 56.

> Measurement >

> Measurement > > Application settings > > Distance range > > Far limit >

> Application settings > > Distance range > > Near limit >

28

The near limit and far limit parameters are device-dependent and are set to the physi‐

cal limit in the factory settings. The functionality and linear behavior are available in the

valid measuring range of 200 to 1,000 mm.

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 29

8.3.1.2 Edge height change

The edge height change function supplies a switching signal at the set device output as

soon as there is a change in value between two measured values. A typical application

for this function is counting shingles in printing applications. The device takes on the

complex evaluation tasks carried out by the control system.

The following settings must be configured on the device in order to use the edge height

change function:

•

•

•

•

•

•

Min. / max. height change

The min. / max. height change values define the smallest and largest difference in mm

by which the two measured values must differ in order for there to be an edge height

change. The function only takes into account the difference between two measured val‐

ues and is independent of the absolute distance of the object.

OPERATION VIA DISPLAY 8

Select the function on the switching output, see "Edge height change", page 43

Set a fixed cycle time (recommended), see "Cycle time", page 32

Set the minimum and maximum height change, see "Edge height change",

page 29

Set the hysteresis (if necessary), see "Edge height change", page 29

Set the change direction (if necessary), see "Edge height change", page 29

Set the cycle offset (if necessary), see "Cycle time", page 32

> Measurement > > Application settings > > Edge height change > > Min. height change >

> Measurement > > Application settings > > Edge height change > > Max. height change >

Parameter Factory setting

Min. height change:

-9,999.9 mm ... +9,999.9 mm

Max. height change:

-9,999.9 mm ... +9,999.9 mm

10 mm

100 mm

Hysteresis

Hysteresis is the difference in distance between the switch-on and switch-off points.

This is necessary for stable switching when the measured distance fluctuates around

the switching point that has been set. Hysteresis can be configured freely with most dis‐

tance sensors and is stated in mm. More precise logic can be achieved by setting a

lower value. Choose a higher value to ensure more stable switching or reduce the prob‐

ability of a faulty switch.

> Measurement > > Application settings > > Edge height change > > Hysteresis >

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

29

Page 30

8 OPERATION VIA DISPLAY

Parameter Factory setting

0 mm ... +100 mm 0.5 mm

Change direction

The change direction value defines whether changes in measured values which result

in smaller or larger distances are detected in both directions.

•

•

•

> Measurement > > Application settings > > Edge height change > > Change direction >

Parameter Factory setting

Both, positive, negative Both

Both: All changes in measured values within the set limits are detected

Positive: Only changes in measured values within the set limits which result in

larger distances are detected (description applies to factory setting).

Negative: Only changes in measured values within the set limits which result in

smaller distances are detected (description applies to factory setting).

Cycle offset

The cycle offset value specifies which previous output value is compared with the value

currently measured.

NOTE

We recommend using the edge height change operating mode with a fixed cycle time,

see "Cycle time", page 32. This ensures time consistency for the output of measured

values. In the Auto operating mode, fluctuating remission values of the object surface

can change the cycle time of the device, which means that reliable detection cannot be

guaranteed in the case of high detection speeds or small structures.

> Measurement > > Application settings > > Edge height change > > Cycle offset >

Parameter Factory setting

1 ... 256 8

30

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 31

1

2

9

ß

à

4

5

8

6

6

7

1234 0

1234 0

1234 0

1234 0

t

3

OPERATION VIA DISPLAY 8

Examples of the digital output for the edge height change function

Figure 11: Edge height change – duration of the change in measured value is longer than the

time span of the cycle offset

Cycle offset: 4, without measured value filter

1

Cycle time fixed, e.g. 1 ms

2

Signal diagram for real distance

3

Max. limit value for edge height change (mm)

4

Min. limit value for edge height change (mm)

5

Change in measured value, from large to small distance

6

Change in measured value, from small to large distance

7

Signal diagram for digital output

8

“Change direction: both” parameter

9

“Change direction: negative” parameter

ß

“Change direction: positive” parameter

à

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

31

Page 32

9

ß

à

2

t

1

1234 0

1234 0

1234 0

1234 0

4

5

3

8

7

6

7

6 6

7

8 OPERATION VIA DISPLAY

8.3.2 Default settings

8.3.2.1 Cycle time

Figure 12: Edge height change – duration of the change in measured value is shorter than the

time span of the cycle offset

Cycle offset: 4, without measured value filter

1

Cycle time fixed, e.g. 1 ms

2

Signal diagram for real distance

3

Max. limit value for edge height change (mm)

4

Min. limit value for edge height change (mm)

5

Change in measured value, from large to small distance

6

Change in measured value, from small to large distance

7

Signal diagram for digital output

8

“Change direction: both” parameter

9

“Change direction: negative” parameter

ß

“Change direction: positive” parameter

à

The cycle time defines the interval in which the device performs a measurement and

essentially corresponds to the output rate of the measured values.

There are 2 modes available:

Auto mode: The device adjusts itself to the maximum speed at which a stable

•

measurement can be achieved, depending on the object surface.

32

NOTE

In the Auto operating mode, the cycle time is adjusted dynamically so the output

rate of the measured values can vary over time.

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 33

Fixed setting: The device uses the set cycle time as a maximum, regardless of the

•

object surface. The output rate of the measured values corresponds to the set

value and remains constant.

NOTE

If the remission properties of the object are not sufficient to perform a valid meas‐

urement, the device outputs the value of an incorrect measurement, see "Action in

case of incorrect measurements", page 36.

> Measurement > > Default settings > > Cycle time >

Parameter Factory setting

Auto, 0.3 ms, 0.5 ms, 1 ms, 5 ms, 10 ms Auto

8.3.2.2 Measured value filter

The measured value filters are used to optimize the signal diagram in order to simplify

the evaluation by the control system, e.g., for regulation tasks.

OPERATION VIA DISPLAY 8

Averaging filter: The averaging filter carries out a moving averaging of the meas‐

•

ured values. This filter is suitable for smoothing a noisy signal diagram. This

improves the reproducibility of the device.

Median filter: The moving median filter sorts the measured values according to

•

their size and selects the middle value from a sequence. This filter is suitable for

excluding individual outliers from the calculation of an average value.

Both types of filter affect the response time of the distance sensor.

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

33

Page 34

Real distance

Measured value without averaging (Avg: OFF)

Output signal

Time t

1

Measured value with median (Avg: 63)

2

4

Measured value with averaging (Avg: 64)

3

4

3

21

8 OPERATION VIA DISPLAY

8.3.2.3 Bit filter

> Measurement > > Default settings > > Measured value filter >

Parameter Factory setting

Do not use a filter x

Averaging filter:

4, 8, 16, 32, 64, 512

Median filter:

3, 7, 15, 31, 63, 511

The bit filter for switching outputs determines how often an identical output state has to

recur consecutively before the signal at the switching output changes accordingly.

If the defined number is not reached, the switching output remains unchanged. This

may increase the reliability in the application if the distance value fluctuates around the

selected switching point. This will not affect the cycle time or the output rate.

> Measurement > > Default settings > > Bit filter >

-

-

34

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 35

Parameter Factory setting

On: 1 ... 32, off 2

8.3.2.4 Measuring direction

The function changes the plus/minus sign of the relative distance value depending on

the direction from the center of the measuring range.

•

•

> Measurement > > Default settings > > Measuring direction >

OPERATION VIA DISPLAY 8

Positive: Distances which are larger than the set zero position of the device are

assigned a plus sign. Smaller distances are assigned a minus sign accordingly.

Negative: Distances which are larger than the set zero position of the device are

assigned a minus sign. Smaller distances are assigned a plus sign accordingly.

Parameter Factory setting

Positive, negative Positive

8.3.2.5 Measured value offset

The measured value offset moves the zero point of the device within the maximum

measuring range. This makes it possible to measure absolute distance changes in rela‐

tion to an individual reference distance.

NOTE

In the case of all offset settings, the current gradient of the analog characteristic curve

remains unchanged.

Setting the measured value offset

A manual measured value offset may be set. The distance value that the distance sen‐

sor outputs and that is evaluated in the switching functions takes into account the set

offset. Only absolute measured values are transferred via IO-Link communication.

Table 4: Example of measured value offset

In factory setting 600.0 mm 12.00 mA -600.0 mm

With offset input

+100.0 mm

Distance (absolute) Analog output Set offset

600.0 mm 14.00 mA -500.0 mm

> Measurement > > Default settings > > Measured value offset > > Set measured value

offset >

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

35

Page 36

8 OPERATION VIA DISPLAY

Parameter Factory setting

-1,000.0 m ... +1,000.0 m -600.0 m

Teaching in the zero point

The current distance is taught in as a new zero point (reference point). When the analog

output is activated, the analog value is set to the center of the measuring range at this

distance (12 mA / 5 V).

> Measurement > > Default settings > > Measured value offset > > Teach in zero point >

NOTE

This function can also be executed using a shortcut:

b

In the main display level, press and hold the pushbutton for > 3 seconds until

the relative distance value is set to 0.0 mm

Resetting the zero point

This resets the zero point to the center of the measuring range according to the factory

setting.

> Measurement > > Default settings > > Measured value offset > > Reset zero point >

NOTE

This function can also be executed using a shortcut:

b

In the main display level, press and hold the pushbutton for > 6 seconds until

the relative distance value is set to the factory setting.

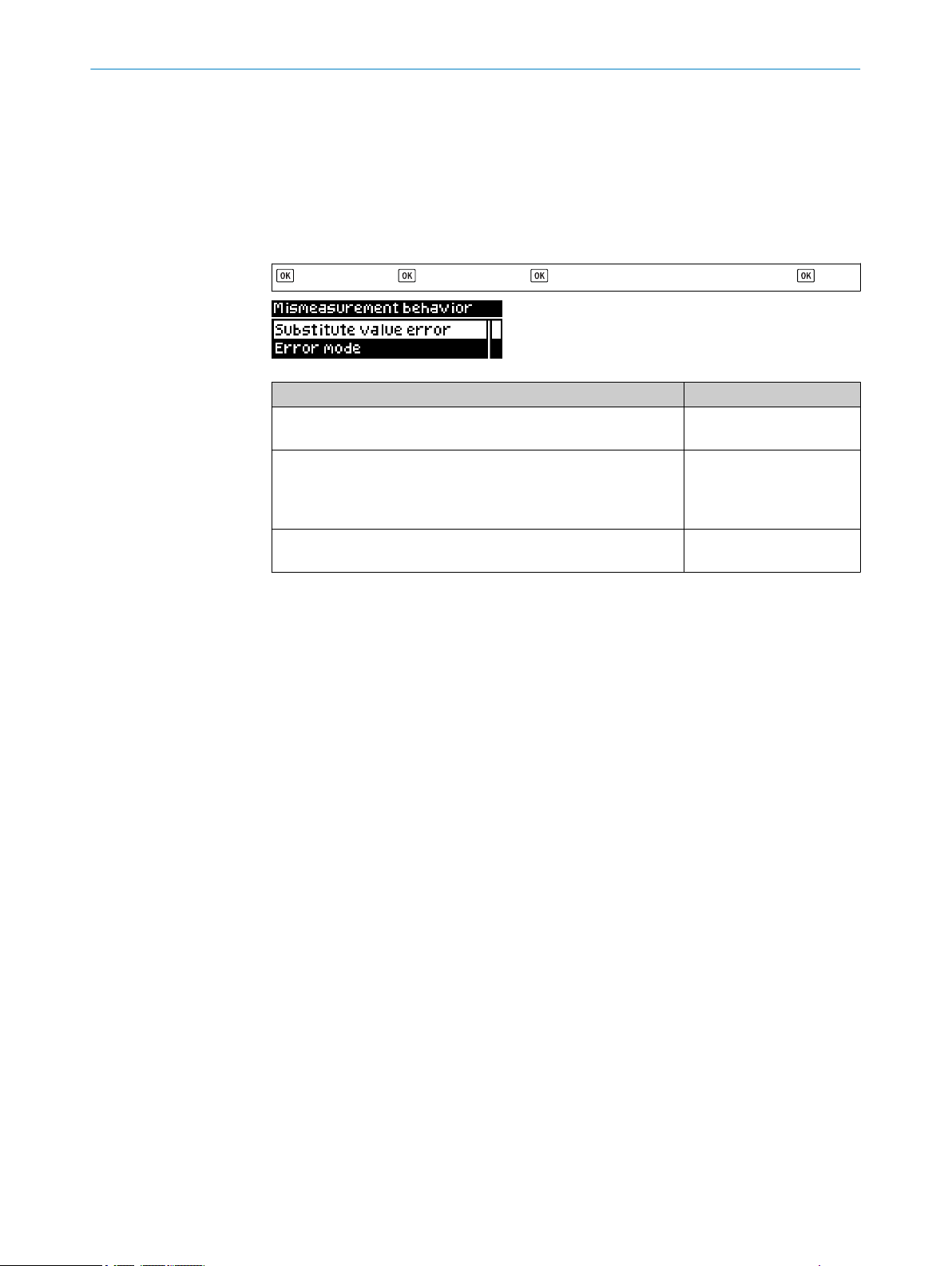

8.3.2.6 Action in case of incorrect measurements

If a distance measurement cannot be run, an error is output. Possible causes of the

error:

The measuring object is outside of the measuring range.

•

The light signal received by the device is not strong enough.

•

The laser is switched off.

•

You can configure the device behavior for the event that no measurement is possible.

The following options are available:

36

Substitute value in the event of an error: A numerical value can be entered which

•

is output when no measurement is possible.

Error mode > User-defined values: If no measurement is possible, the set Substi‐

•

tute value in the event of an error (see above) is displayed and held until a valid

measured value is available again.

Error mode > Hold last value: If no measurement is possible, the last valid meas‐

•

ured value is displayed and held until a valid measured value is available again.

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 37

OPERATION VIA DISPLAY 8

Error mode > Hold last value for a defined time: If no measurement is possible,

•

the last valid measured value is displayed and held for the time set under Error

suppression time (see below). Once this time has elapsed, the set Substitute

value in the event of an error (see above) is displayed and held until a valid meas‐

ured value is available again.

Error suppression time: It is possible to set a time for which the last valid meas‐

•

ured value is displayed and held if the error mode Hold last value for a defined

time (see above) is activated.

> Measurement > > Default settings > > Action in case of incorrect measurements >

Parameter Factory setting

Substitute value in the event of an error:

-3,276.8 m ... +3,276.7 m

Error mode:

User-defined values

Hold last value

Hold last value for a defined time

Error suppression time:

0001 ms ... 9,999 ms

+3,276.7 m

✓

-

-

1 ms

8.4 I/O interface

8.4.1 Q1 output

The Q1 output is purely a switching output. In addition, the output serves as a commu‐

nication line for bidirectional data transmission when using the IO-Link interface.

The Q1 output of the OD 1000 provides the following switching modes:

DtO, distance to object (1-point), one switching point

•

Window, two switching points

•

ObSB, object between sensor (device) and background, one switching point

•

Alarm (only in Advanced user level)

•

Signal level warning (only in Advanced user level)

•

Edge height change (only in Advanced user level)

•

The switching modes are explained in the subsequent chapters.

8.4.1.1 Notes on the measuring and setting functions

The following functions can be set independently from each other on both outputs

depending on the selected output function.

Delay mode

Delay mode is used to output the output state change with a time delay or as a short

switching pulse (1 shot).

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

37

Page 38

1 2 3

0,5 s

4

0,5 s

t

5

0,5 s0,5 s

High

Low

8 OPERATION VIA DISPLAY

1

2

3

4

5

Off: Right after the measured distance has exceeded the specified switching point, the

state of the switching output changes (factory setting).

Switch-on delay: The changeover of the switching output from an inactive to an active state

is time-delayed. The delay time is adjustable. The changeover from an active to an inac‐

tive state is not delayed.

Switch-off delay: The changeover of the switching output from an active to an inactive state

is time-delayed. The delay time is adjustable. The changeover from an inactive to an

active state is not delayed.

Switch-on/switch-off delay: The changeover from an inactive to an active state and vice

versa is time-delayed. The delay time is adjustable.

1 shot: Once the switching condition has been met, the switching output changes from an

inactive to an active state. The output state remains in an active state for a specified

period regardless of how long the switching condition is met. It does not switch back to an

inactive state until this time has elapsed. Any additional changes made to the switching

condition during this period are still not taken into account.

NOTE

For a combination of switch-on delay and switch-off delay, the following conditions

must be met:

Equidistant measuring frequency

•

Min. 2x measuring frequency

•

Cycle time must not be set to AUTO.

•

Active status

The active status describes the relationship between the output state (active or inac‐

tive) and the potential present on the switching output (high or low).

> I/O interface > > Q1 output > > Distance to object >

If the Distance to object switching mode is selected, the required settings can be taught

in or set manually. These are described in the following.

8.4.1.2 Distance to object, DtO, single switching point

A signal is output if the measured distance value has undershot (normally open – High

Active) or exceeded (normally closed – Low Active) the switching point.

38

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

Subject to change without notice

Page 39

Min Max

1

1

0

Min Max

1

1

0

OPERATION VIA DISPLAY 8

Figure 13: Distance to object or single switching point (normally open – High Active, PNP)

Switching point

1

Figure 14: Distance to object or inverted single switching point (normally closed – Low Active,

PNP)

Switching point

1

If the “Distance to object” switching mode is selected, the required settings can be

taught in or set manually.

In the “Distance to object” operating mode, the following settings can be configured:

Teach-in

•

Manual teach-in

•

Active status

•

Hysteresis

•

Delay mode

•

Time for delay mode

•

The possible settings are described below.

Teach-in: A single switching point can be taught in. The switching point is set to the cur‐

rent distance at the time the button is pressed.

Q1: A signal is output if the switching point that has been taught in is undershot.

•

Thus the output acts as a normally open contact (“High” active status).

Q1not: A signal is output if the switching point that has been taught in is

•

exceeded. Thus the output acts as a normally closed contact (“Low” active status).

Manual teach-in: The distance of the switching point can be set manually in 1/10 mm.

Q1 active status: The active status specifies the functionality of the switching output, see

"Notes on the measuring and setting functions", page 37.

High: The switching output acts as a normally open contact. A signal is output if

•

the switching point that has been taught in is undershot.

Low: The switching output acts as a normally closed contact. A signal is output if

•

the switching point that has been taught in is exceeded.

Delay mode

see "Notes on the measuring and setting functions", page 37 .

•

Time for delay mode

The time for the delay mode can be set manually in ms.

•

I/O interface > > Q1 output > > Distance to object >

>

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

39

Page 40

Min Max

1

1

0

2

Min Max

1

1

0

2

8 OPERATION VIA DISPLAY

Parameter Factory setting

Q1 teach-in:

Q1, Q1 not

Manual Q1 teach-in:

-1,000.0 mm ... +1,000.0 mm

Q1 active status:

High, Low

Q1 hysteresis:

0000.0 mm ... +0100.0 mm

Delay mode:

Off

Switch-on delay

Switch-off delay

Switch-on/switch-off delay

1 shot

Time for delay mode:

0000 ms ... 9,999 ms

8.4.1.3 Window

-

+400 mm

High

+1.0 mm

✓

-

-

-

-

100 ms

Window mode: An upper and a lower switching threshold are set for the switching out‐

put. A switching signal is output when the measured value is between the two switching

thresholds (in the window).

Figure 15: Normally open switching window (High Active, PNP)

Switching point near

1

Switching point far

2

Figure 16: Normally closed switching window (Low Active, PNP)

Switching point near

1

Switching point far

2

> I/O interface > > Q1 output > > Window >

Parameter Factory settings

Q1 teach-in:

Switching point 1, switching point 2

40

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

-

Subject to change without notice

Page 41

Parameter Factory settings

Min Max

1

1

0

2

Min Max

1

1

0

2

Manual Q1 teach-in:

Switching point 1: -1,000.0 mm ... +1,000.0 mm

Switching point 2: -1,000.0 mm ... +1,000.0 mm

Q1 active status:

High, Low

Q1 hysteresis:

0000.0 mm ... +0100.0 mm +1.0 mm

Delay mode:

Off

Switch-on delay

Switch-off delay

Switch-on/switch-off delay

1 shot

Time for delay mode:

0 ms ... 9,999 ms

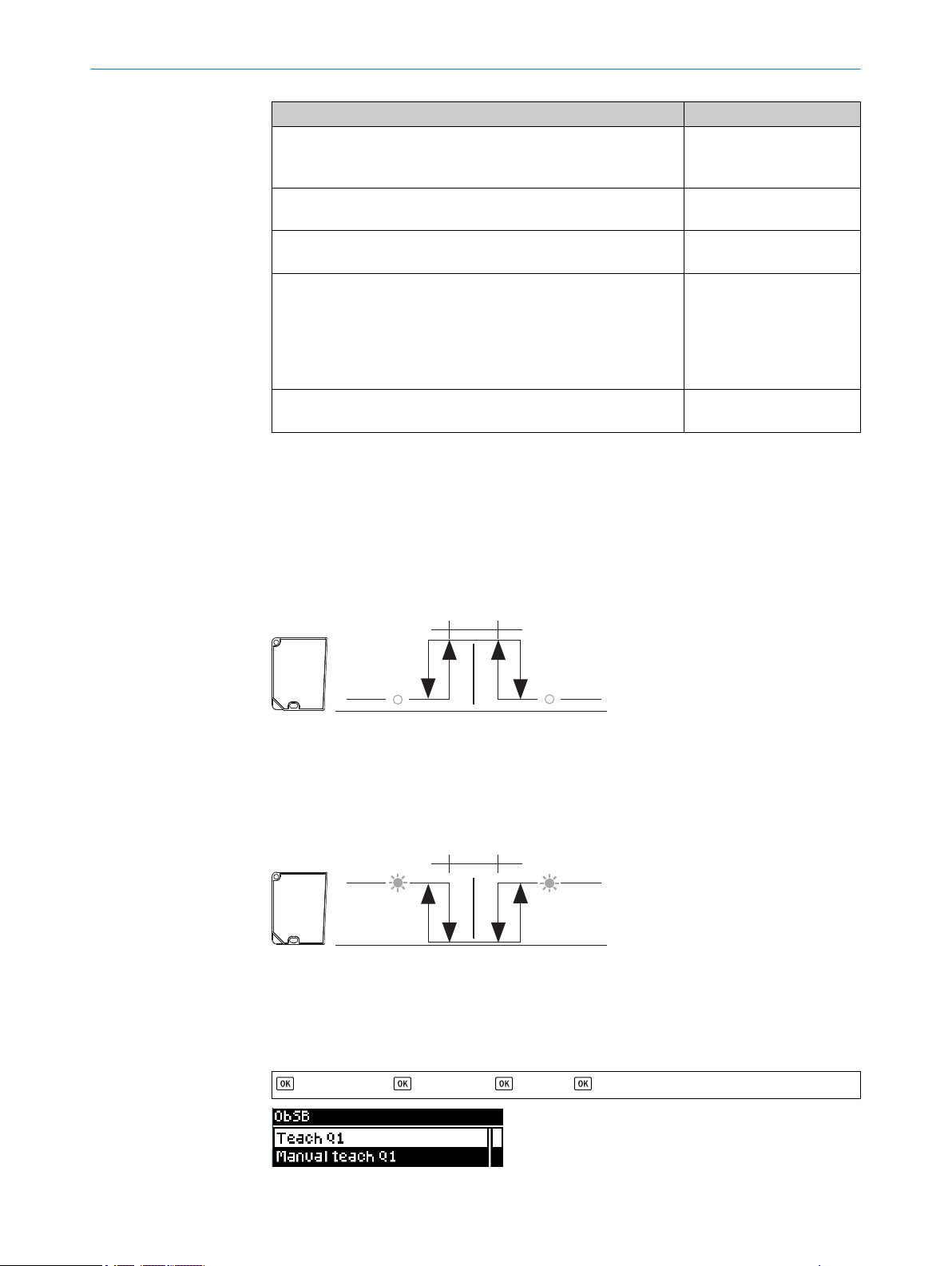

8.4.1.4 ObSB (object between sensor and background)

Object between device and background: In this switching mode, any background can be

taught in as a reference. If an object obscures the background or the distance to the

background changes significantly, this causes the device to switch. This switching mode

is primarily suited to the reliable detection of high-gloss or extremely dark materials.

This makes it possible to detect even painted vehicle parts with large approach angles,

for example.

OPERATION VIA DISPLAY 8

+400.0 mm

-400.0 mm

High

✓

-

-

-

-

100 ms

Figure 17: Object between device and background (normally open – High Active, PNP)

Switching point (reference background)

1

Tolerance around teach point: ± 4.0 mm

2

Figure 18: Object between device and background (normally closed – Low Active, PNP)

Switching point (reference background)

1

Tolerance around switching point: ± 4.0 mm

2

> I/O interface > > Q1 output > > ObSB >

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

41

Page 42

8 OPERATION VIA DISPLAY

Parameter Factory setting

Q1 teach-in:

Q1, Q1 not

Manual Q1 teach-in:

-1,000.0 mm ... +1,000.0 mm

Q1 active status:

High, Low

Q1 hysteresis:

0000.0 mm ... +0100.0 mm

Q1 ObSB tolerance

-1,000.0 mm ... +1,000.0 mm

Delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

Time for delay mode:

0000 ms ... 9,999 ms

8.4.1.5 Alarm

The alarm function is only available in the Advanced user level. A constant switching sig‐

nal is output at the output of the device while no measurement is possible. This func‐

tion can be used to evaluate the measured value at the analog output, for example.

-

+400 mm

High

+1.0 mm

+4.0 mm

Off

100 ms

> I/O interface > > Q1 output > > Alarm >

Parameter Factory settings

Alarm Off

8.4.1.6 Signal level warning

The signal level warning function is only available in the Advanced user level.

A warning can be output via the Q1 and Q2 switching outputs if the signal level drops

below a certain value. This value can either be specified as a number value or deter‐

mined by the Teach-in function. When the Teach-in function is used, the threshold value

for outputting the warning is calculated by reducing the measured signal level value by

about 12%. Then the warning will not be output until the signal level is about 12% lower

than it was at the time it was taught in.

The level warning threshold or signal level switching point can be set manually using a

signal level within the value range of 0 to 5,000. The signal level is a sensor-specific,

unitless value. We recommend configuring the setting using application-specific test

measurements.

In automatic mode, the device automatically regulates the reception level to around

1000. In the case of very critical object surfaces, an abrupt loss of signal can therefore

occur as soon as a readjustment is no longer possible. In settings other than Auto, there

is no automatic adjustment, which makes it easier to define thresholds for the signal

level warning.

42

> I/O interface >

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

> Q1 output > > Signal level warning >

Subject to change without notice

Page 43

OPERATION VIA DISPLAY 8

Parameter Factory settings

Q1 teach-in:

Switching point 1, switching point 2

Manual Q1 teach-in:

-0 ... 5,000

Q1 active status:

High, Low

Q1 hysteresis:

0 ... 10,000

Delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

Time for delay mode:

0000 ms ... 9,999 ms

-

112

High

10

Off

100 ms

8.4.1.7 Edge height change

The edge height change function is only available in the Advanced user level, see

"Device", page 51.

> I/O interface > > Q1 output > > Edge height change >

Parameter Factory settings

Q1 active status:

High, Low High

Delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

Time for delay mode:

0000 ms ... 9,999 ms 100 ms

8.4.2 Q2/Qa output

The output Q2/Qa can be configured either as an analog output or a switching output.

8.4.2.1 Notes on the output functions

Off

8.4.2.1.1 4-20 mA output function

If the 4-20 mA setting is selected, output 2 functions as an analog current output. The

measured value of the device is output as a proportional-linear current value that corre‐

sponds to the other device settings.

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

43

Page 44

8 OPERATION VIA DISPLAY

8.4.2.1.2 0-10 V output function

If the 0-10 V setting is selected, output 2 functions as an analog voltage output. The

measured value of the device is output as a proportional-linear voltage value that corre‐

sponds to the other device settings.

8.4.2.1.3 Digital output function

In the case of the digital output function, output 2 functions as a switching output.

Since output 1 is used exclusively for switching, this setting corresponds to the behavior

of output 1. A switching signal that corresponds to the other device settings is output

based on the current measured value.

8.4.2.1.4 Off output function

When the Off output function is activated, output 2 does not have any function and is

therefore deactivated.

8.4.2.2 4-20 mA analog output

> I/O interface > > Q2/Qa output > > 4-20 mA analog output >

Parameter Factory setting

Qa teach-in:

Distance (4 mA)

Distance (20 mA)

Manual Qa teach-in:

Distance (4 mA): -1,000.0 mm ... +1,000.0 mm

Distance (20 mA): -1,000.0 mm ... +1,000.0 mm

8.4.2.3 0-10 V analog output

> I/O interface > > Q2/Qa output > > 0-10 V analog output >

Parameter Factory setting

Qa teach-in:

Distance (0 V)

Distance (10 V)

Manual Qa teach-in:

Distance (0 V): -1,000.0 mm ... +1,000.0 mm

Distance (10 V): -1,000.0 mm ... +1,000.0 mm

-

-

-400.0 mm

+400.0 mm

-

-

-400.0 mm

+400.0 mm

8.4.2.4 Digital output

44

O PE R AT I NG IN S TR U CT I ON S | OD1000 8019642/ZJW1/2017-04-03 | SICK

The Q2 digital output provides the following switching modes:

DtO, distance to object (1-point), one switching point

•

Window, two switching points

•

ObSB, object between sensor (device) and background, one switching point

•

Q2 = Q1 not

•

Subject to change without notice

Page 45

OPERATION VIA DISPLAY 8

Alarm (only in Advanced user level)

•

Signal level warning (only in Advanced user level)

•

Edge height change (only in Advanced user level)

•

> I/O interface > > Q2/Qa output > > Digital output >

Parameter Factory setting

Distance to object > Q2 teach-in:

Q2, Q2 not

Distance to object > manual Q2 teach-in:

-1,000.0 mm ... +1,000.0 mm

Distance to object > Q2 active status:

High, Low

Distance to object > Q2 hysteresis:

0000.0 mm ... +0100.0 mm

Distance to object > delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

Distance to object > time for delay mode:

0000 ms ... 9,999 ms

Window > Q2 teach-in:

Switching point 1, switching point 2

Window > manual Q2 teach-in:

Switching point 1, switching point 2

Window > Q2 active status:

High, Low

Window > Q2 hysteresis:

0000.0 mm ... +0100.0 mm

Window > delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

Window > time for delay mode:

0000 ms ... 9,999 ms

ObSB > Q2 teach-in:

Q2, Q2 not

ObSB > manual Q2 teach-in:

-1,000.0 mm ... +1,000.0 mm

ObSB > Q2 active status:

High, Low

ObSB > Q2 hysteresis:

0000.0 mm ... +0100.0 mm

ObSB > Q2 ObSB tolerance

-1,000.0 mm ... +1,000.0 mm

ObSB > delay mode:

Off, switch-on delay, switch-off delay, switch-on/switch-off delay, 1

shot

ObSB > time for delay mode:

0000 ms ... 9,999 ms

-

+400.0 mm

High

+1.0 mm

Off

100 ms

-

-

High

+1.0 mm

Off

100 ms

-

+400.0 mm

High

+1.0 mm

+4.0 mm

Off

100 ms

8019642/ZJW1/2017-04-03 | SICK OP E RA T IN G I N ST R UC T IO N S | OD1000

Subject to change without notice

45

Page 46

ON

OFF

1

2

HOLD

8 OPERATION VIA DISPLAY

8.4.2.5 Off

When the Off output function is activated, output 2 does not have any function and is

therefore deactivated.

8.4.3 In1 input

8.4.3.1 Notes on the input functions

8.4.3.1.1 Description

The In1 input is used for the following tasks:

■

Configuration of various device parameters, see "Teach-in", page 48

■

Switching the laser on or off at defined times

If the function is set to Teach (factory setting), the specific parameters or different meas‐