Shurflo 94-260-01 Installation Manual

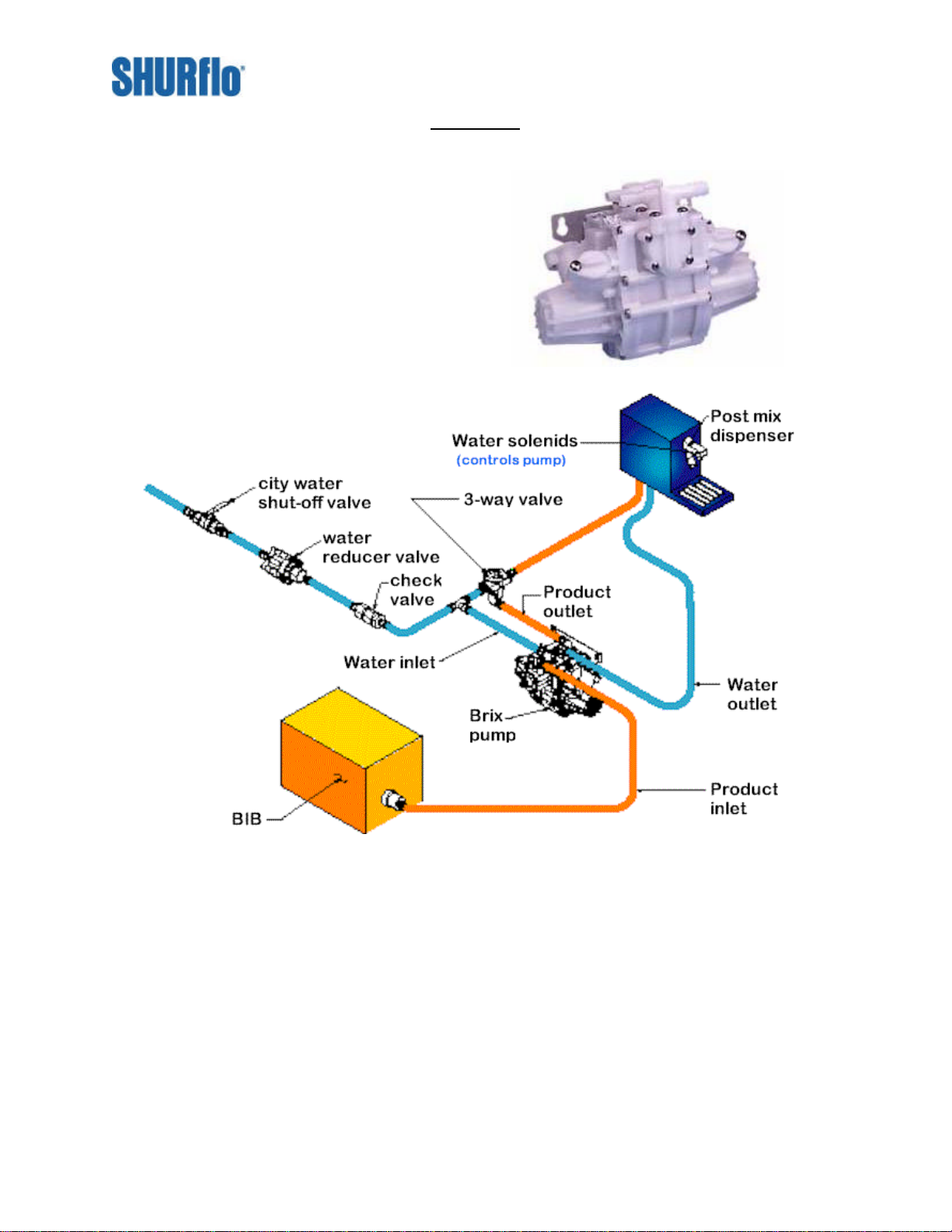

The Brix pump is a proportioning device,

which pumps two liquids (e.g. water and

concentrate) in an exact ratio. The particular

ratio is determined by the pump design, and

is thereby maintained precisely, independent

of system flow or pressure changes, with no

need to regularly readjust brix at the

dispensing valve.

The pump operates on the source pressure of

one of the proportioned liquids; typically the

incoming water eliminating the need for CO2

or electric power.

Brix Pump

The Brix pump is designed with a vacuum shut off. The vacuum shut-off will automatically stop

operation of the brix pump, when the concentrate BIB container is completely evacuated, by closing

off the water inlet. When a new BIB is installed, the pump will automatically resume operation without

the need to prime the system.

The Brix pump is ideally suited to premium juice applications, and incorporates a valve design suitable

for use with syrups containing "stringy" pulp.

stic or Stainless Steel;

The table below shows brix pump ratios currently available. The brix pump is shipped with the 3- way

sanitizing valve.

Model Ratio Qty./Box

94-260-01 3:1 pump 8

94-260-03 4:1 pump 8

94-260-05 5:1pump 8

94-260-06 5.3:1 pump (6:1 APR FOR FCB) 8

94-260-07 7.7:1 pump 8

94-260-17 4.2:1 pump w/o sold out feature 8

Technical Specs

DESIGN: Positive Displacement; Fix Ratio (non-adjustable)

POWER SOURCE: Potable Water

MATERIALS OF

CONSTRUCTION:

TEMPERATURE LIMITS:

DIMENSIONS 7.6" x 5.2" x 5.7" [19.3 x 13.2 x 14.47 cm]

WEIGHT: 2.2 lbs. [1 kgs]

OPERATING PRESSURE: 50 PSI. [3.4 bar] MAX. / 25 PSI. [1.7 bar] MIN.

ACCURACY: ± 3% of available ratio

SOLD OUT: Automatic B-I-B Vacuum Shut-off @ 18-22 in. Hg. [48-61 kPa]

AVAILABLE FITTINGS:

Acetal Copolymer, EPDM, Santoprene, Silicone, 316 Stainless Steel -FDA sanctioned,

NSF listed

34 - 120 °F [2-45°C]

3/8" [10mm] Barb, Plastic 90 ° Std. Configuration,

1/4" [6mm] , 3/8" [10mm], and 1/2" [13mm] barb, Pla

Straight and/or 90° configurations

Operations Manual

BRIX PUMP 5000-2XX-XX

Installation and Operation Instruction Manual

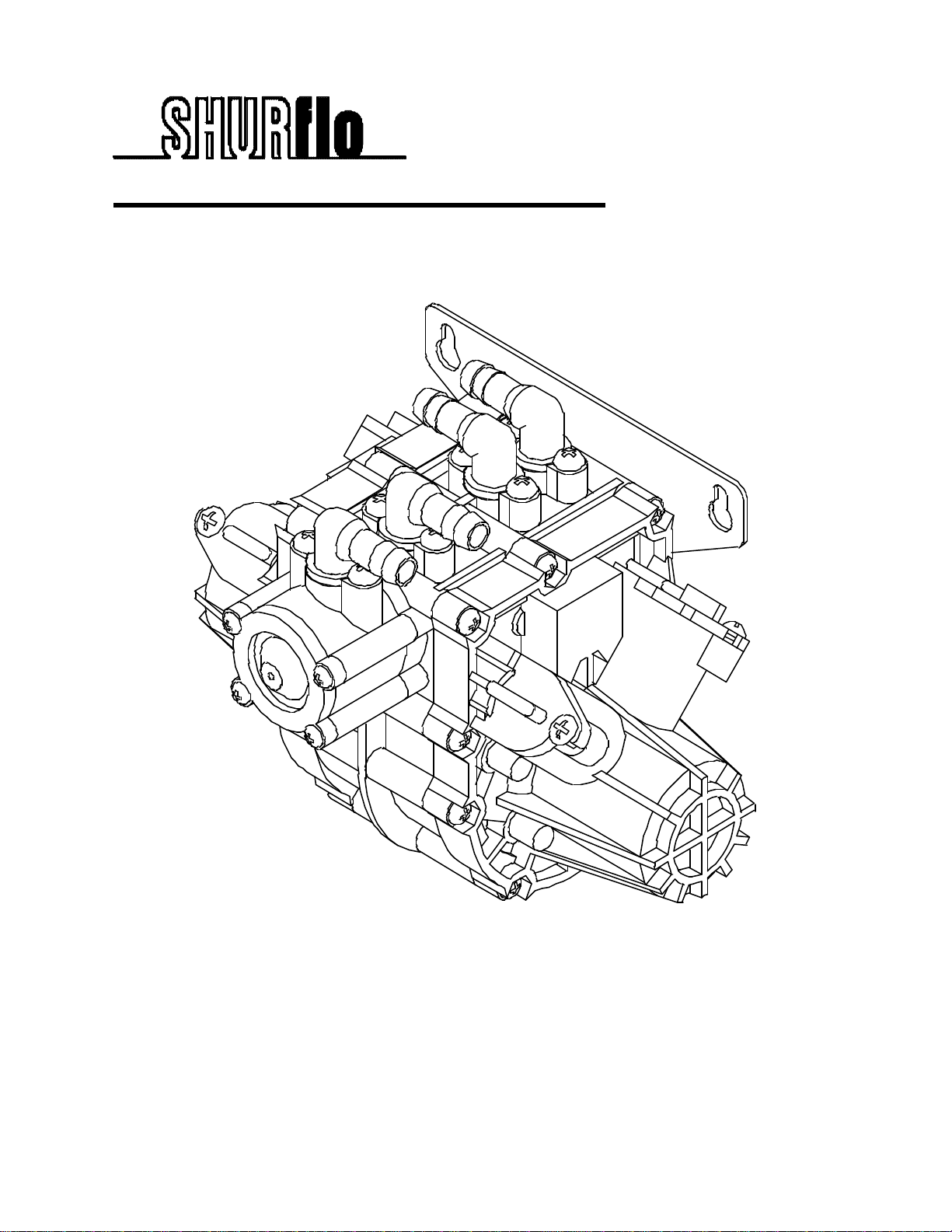

SHURflo has applied its expertise and years of experience in pump

technology to provide a safe and reliable proportioning pump. Every SHURflo

pump is 100% tested for proper flow, pressure, and performance before it

leaves the factory. Although this tested design will provide years of troublefree and economical operation, you should use care in installing your system.

911-332 Rev. K 4/03

DESCRIPTION

The SHURflo BRIX proportioning pump is driven by pressurized water, allowing the water and product to

be delivered at an exact ratio. The pump operates whenever there is a differential in pressure between

the inlet and outlet watersides of the pump. The design incorporates large "duck bill" style valves that

easily allow concentrates with pulp or particulates to flow through. When your customers demand a

quality drink, you are assured that SHURflo technology will deliver accurate repeatable brix without the

need for expensive metering devices.

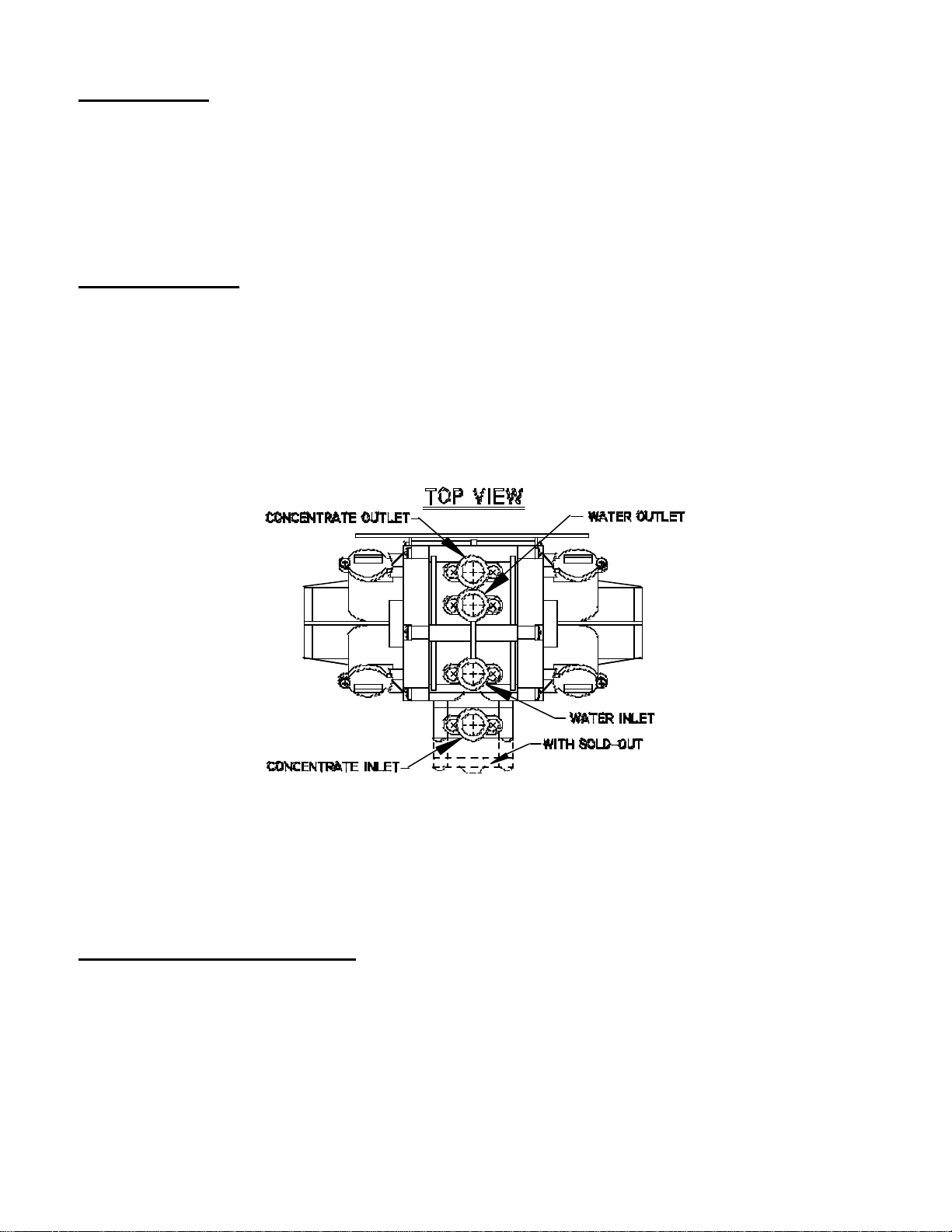

MODEL OPTIONS

The BRIX pump is offered in two basic configurations, with or without a vacuum shut-off. The last two

numbers of the model indicate the use (-02), or deletion (-01) of the shut-off. The type of conc entrate

container being used determines if the shut-off should be applied.

When a Bag-in-Box (B-I -B) container is used, a vacuum shut-off is needed. The pump will automatically

stop operation, when the concentrate bag is completely evacuated, by closing off the inlet water. When a

new B-I -B is installed, the pump will automatically resume operation without the need to prime the

system. BRIX pumps without a vacuum shut-off option should be used with rigid sided containers like

tanks or jugs. Containers of this type must be vented.

Dashed lines indicate position of vacuum shut-off when ordered.

The BRIX pump is available in exact ratios, which properly proportion various concentrate types. Pump

ratios are indicated on the part number label. The ratio of a pump is preset and is not adjustable in any

way.

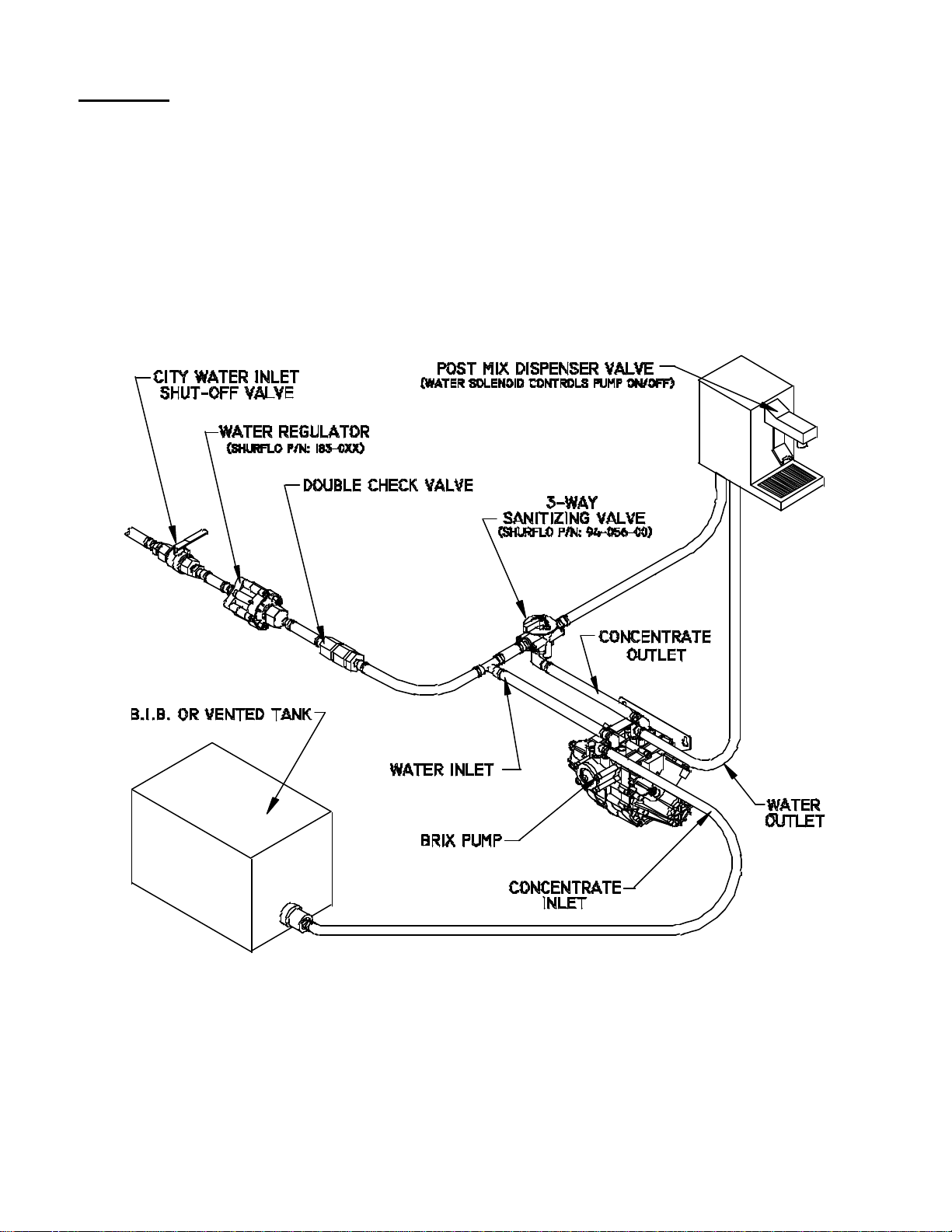

DISPENSER CONFIGURATION

The dispenser valve is an important component to the BRIX pump system and contributes heavily to the

final performance. When developing the system, the type of dispenser depends on the customers

requirements, concentrate properties, backpressure created within the lines, and the dispensers ability to

flow. A BRIX pump is designed to deliver to one dispenser valve at a time. If other valves are on line, it is

acceptable only when a lockout device prevents simultaneous operation. Depending on the system

design and the concentrate, finished drink flow rates are generally 1½ - 3 ounce [45-90 cc] per second.

2.

POST MIX

Dispenser valves, which have separate water and concentrate lines, will typically exhibit good

performance. Mixing the drink at the nozzle reduces backpressure, allowing longer outlet tubing lengths.

Pump operation is controlled by opening or closing the water outlet line of the pump. The concentrate line

must not be closed off while the water outlet line is open and the pump is cycling, or damage to the pump

may occur. When multiple concentrates are plumbed to a post-mix dispenser, each pump's water outlet

must have an individual line, valve to open when that flavor is selected.

"Bar Guns" (generally) are restrictive; therefore, it is recommended that special "Juice Guns" be used.

Concentrate passages of standard bar guns are small and may become plugged with pulp or solids

contained in some concentrates. Concentrates with pulps or solids may require sanitizing more

frequently to prevent build-up in the system, causing poor performance.

Standard post-mix system plumbing with 3-way sanitizing

3.

Loading...

Loading...