Shurflo 8050-305-426 Installation Manual

SHURflo Oil Change System

INSTALLATION AND OPERATION INSTRUCTIONS

PRODUCT MODEL 8050-305-426

FEATURES:

Suitable for Pumping: Engine oil, automatic transmission fluids,

anti-freeze solutions and low viscosity gear

lubes

Dry Run Capabilities: Yes

Pump Body: Polypropylene

Diaphragm: Geolast, oil resistant

Valves: Buna-n

Motor: 12V DC with internal thermal protector

Receiver: Plastic with 3 Gallon [11.4 Liter]

Battery Leads: 8 feet [ 2.4m ] with alligator clips

Suction Tube: 8 feet [ 2.4m ], 1/4” OD, oil and heat resistant

Dimensions: 15 1/2” [ 393mm ] high

Weight: 6.4 lb [ 2.9kg ]

WARNING

WARNING

Explosions hazard. DO NOT PUMP GASOLINE

OR DIESEL FUEL. Take necessary

precautions to rid area around battery of

potential explosive gases. Run your bilge

blower motor for additional protection.

Continue ventilation during oil changing

procedure. Failure to do so can result in

explosion. Injury or death can occur.

Explosions hazard. Motor switch MUST be in

“OFF” position when connecting and

disconnecting alligator clips to battery

terminals and ground. The switch in an “ON”

position can cause an electrical spark which

can result in explosion. Injury or death can

occur.

OPERATING INSTRUCTIONS:

1. Vent bilge area. Run the engine for 5 to 10 minutes to heat up and thin oil. Oil should be

140°F-160° F [60°-71°C]. Turn off engine prior to removing oil.

2. Remove dipstick and insert the oil probe tube making certain it is at the bottom of the oil pan. It

may help to measure the probe against the dipstick, add an inch and mark the probe.

3. Check that pump switch is in OFF position. Connect red (+) clip to battery (+) terminal. Connect

black (-) clip to (-) ground terminal.

4. Energize the pump by turning switch, located on the motor rear end-bell to the “ON” position.

Turn off pump when oil removal is completed. It will be easy to detect through the clear tube.

Do not worry about running pump dry, pump has run dry capabilities.

5. Remove probe from dipstick tube while wiping with a rag to prevent oil spills.

6. To empty the container, pull up the retractable pour spout and pour the oil.

7. Please recycle or dispose of used oil and fluid in a responsible manner that is friendly to our

environment. Please check the laws of your state and follow all USCG regulations.

8. To store, wrap tubing around pump loosely and insert oil probe tube into the small hole in the lid.

NOTE: This pump is suitable for engine oil, automatic transmission fluids, anti-freeze solutions, and low

viscosity gear lubes.

CAUTION

Oil may be HOT! When performing oil change

procedure use adequate eye protection,

appropriate gloves and clothing.

CAUTION

Pump is equipped with an automatic thermal

breaker. In the event of overload or high

temperature, the circuit will “open”. Once the

motor temperature is within proper limits, it will

automatically reset and the pump will start

operation without warning.

911-672 Rev F 12/08 ECO #: 16135 Page 1 of 2

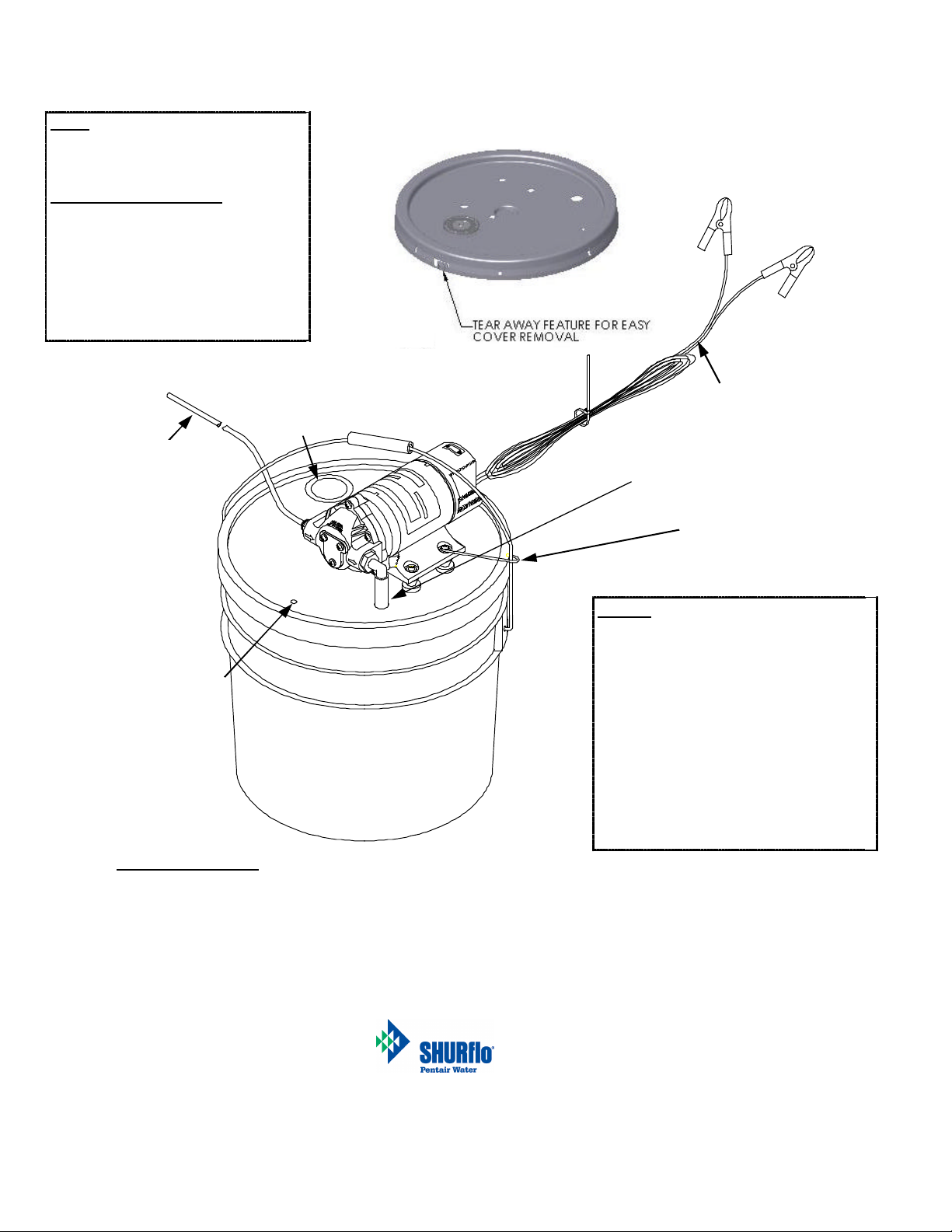

NOTE:

© 2008 SHURflo, LLC All Rights Reserved

Page 2 of 2

MAKE SURE LID IS SECURELY FASTENED

TO BUCKET BEFORE TRANSFERING

LIQUID.

TO SECURE LID TO BUCKET:

LUBRICATE THE SEALING LIP OF THE

BUCKET AND LID. START A SECTION OF

THE LID SEAL TO THE BUCKET BY

KNEELING ON IT. USE A MALLET TO SNAP

THE LID TO THE BUCKET WHILE

KNEELING ON IT MAINTAIN THE SNAP.

STARTING NEXT TO YOUR KNEE WORK

AROUND THE LID UNTIL FULLY SEATED/

SEALED.

8’ x 1/4 O.D. Oil Probe Tube

(Insert to Bottom of Engine Oil

Pan).

TO REMOVE LID FROM BUCKET:

TEAR STRIP AS SHOWN BELOW

Red (+)

Black (-)

8’ x #16 Gauge Battery

Clips

Drain Spout

Before securing bucket lid, push

16” x 3/8” I.D. tube thru underside of

lid and onto the elbow barb fitting.

IMPORTANT:

Make sure to attach wire hook

to the bucket when pumping

and transferring fluid.

NOTES:

• ALWAYS VENT BILGE AREA

Oil Probe Storage

• OIL MUST BE 140-160°F [60-71°C]

• SOLIDS/PARTICULATES IN THE

FLUID MAY DAMAGE PUMP

• PUMP PORTS ARE 3/8” F-NPT

• FLOW RATE DEPENDS UPON OIL/

FLUID VISCOSITY AND

TEMPERATURE

LIMITED WARRANTY

SHURflo warrants Diaphragm Pumps to be free from material and workmanship defects under normal use and

service for a period of one (1) year from the data of manufacture or one (1) year of use with proof of purchase, not

to exceed (2) years in any event. The limited warranty will not apply to pumps that were run dry, misapplied, or are

incompatible with components not manufactured by SHURflo. Pump failure due to debris or chemical incompatibility

is not covered under the terms of this limited warranty. SHURflo will not warrant any pump that is physically

damaged, or altered outside the SHURflo factory. Warranty claims may be resolved by an authorized dealer service

center, or by SHURflo. For complete warranty details, please call your closest SHURflo office.

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo, LLC Headquarters

5900 Katella Avenue

Cypress, California 90630

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (562) 795-7564

911-672 Rev F

SHURflo, LLC East

52748 Park Six Court

Elkhart, Indiana 46514-5427

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (574) 264-2169

SHURflo Europe, Middle East, Africa

Pentair Water Belgium bvba,

Industriepark Wolfstee, Toekomstlaan 30

B-2200 Herentals, Belgium

Phone +32-14-283500Ÿ Fax +32-14-283505

Loading...

Loading...