Shurflo 8050-305-226, 8050-305-526 Installation Manual

UTILITY PUMP INSTALLATION INSTRUCTIONS

WARNING

Explosions hazard. DO NOT PUMP

FLAMMABLE LIQUIDS WITH THIS UNIT.

Never operate the pump in an explosive

environment. Arcing from the motor brushes,

switch or excessive heat from an improperly

cycle motor may cause an explosion.

FEATURES:

Suitable for Pumping: Engine oil, transmission fluids, anti-freeze solutions and low viscosity

gear lubes

Dry Run Capabilities: Yes

Pump Body: Polypropylene

Diaphragm: Geolast, oil resistant

Valves: Buna-n

Motor: 12V DC with internal thermal protector

Battery Leads: 8 feet [ 2.4m ] with alligator clips (Premium Only)

Duty Cycle: Intermittent Duty

Open Flow: 1.5 GPM [5.8 L]

Current Draw: 4.5 Amps Max.

Ports: 3/8” Female NPT

Control: Internal By-Pass 35 PSI

MOUNTING:

• Consider a location that allows for easy access if maintenance is required. The pump should not be

located in an area less than one cubic foot unless adequate ventillation is provided. Excessive heat

may trigger the integral thermal breaker and interrupt operation. When the motor temperature drops,

the breaker will automatically reset and the pump will start.

• The pump may be mounted in any position. If mounted the vertically pump head should be in the

down position so that in the unlikely event of a leak, fluid will not enter the motor.

• The pump can be positioned above the liquid tank if needed, as it is capable of 6ft [1.82M] vertical

prime (with water).

• Use #8 hardware to fasten the pump. Choose a solid surface that will not amplify pump operation.

The mounting feet are intended to isolate the pump from the mounting surface; over-tightening,

flattering, or use of oversized screws will reduce the ability to isolate noise and vibration.

PLUMBING:

• SHURflo recommeds 3/8” [9.5mm] or 1/2” [13mm] I.D. flexible high pressure tubing to both ports.

Ideally, the pump ports/strainer should not be connected directly to rigid pipe. The pump’s normal

oscillation may trasmit through rigid plumbing causing noise, and possibly loosening or cracking

components.

• Installation of a SHURflo 255 series strainer on the inlet side is recommeded to prevent foreign

debris from entering the pump. Failure due to debris is not covered under the SHURflo limited

warranty.

ELECTRICAL:

• The pump should be on a dedicated (individual) circuit, protected by the fuse indicated on the motor

label.

• An “ON/OFF” switch rated at or above 15 amps is recommended. The switch must interrupt current

flow on the positive (+ red) lead. Marine applications should use U/L approved marine duty (ignition

protected) switches and wiring standards.

• The black lead (-) must be connected to a “known ground”. The ground wire must be the same size

(gauge/Mm²) as the positive wire.

• Wire size (gauge/Mm²) is based on the distance from the power source to the pump. The minimum

recommended is # 14 gauge [2.5 Mm²]. Lenghts of 20-50 ft. [6-15M] use # 12 gauge [4 Mm²].

• The total current draw on the circuit must not exceed 15 amps. If the pump is used in conjunction

with other components, overload current protection (fuse or circuit breaker) and wire size must be

for the total amp requirement of all devices on the circuit.

911-714 Rev E 12/08 ECO#: 16135 Page 1 of 2

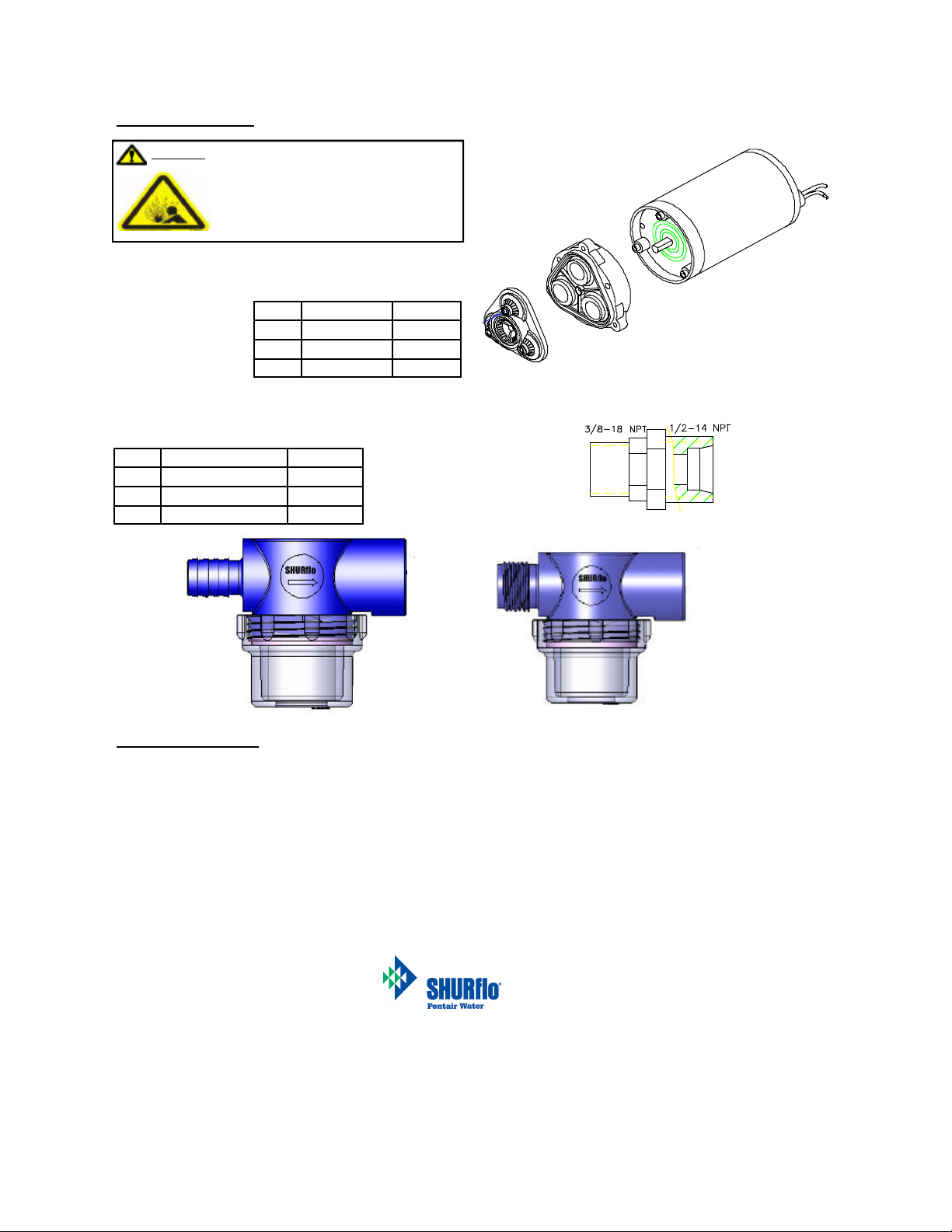

PREMIUM PUMPS:

WARNING

STRAINERS AVAILABLE:

Number Components Part Number

1 1/2” NPT-F x 1/2” BARB 255-113

2 1/2” NPT-M x 1/2” NPT-F 255-213

3 3/8” NPT-M x 1/2” NPT-M 8-145

Explosions hazard. Motor switch MUST be in

“OFF” position when connecting and

disconnecting alligator clips to battery

terminals and ground. The switch in an “ON”

position can cause an electrical spark which

can result in explosion. Injury or death can

occur.

PART KITS AVAILABLE:

Number Components Parts Kits

1 Motor 11-148-06

2 Drive Assembly 94-385-42

8 Valve Assembly 94-391-12

1

2

3

Use adapter fitting when connecting a 255 strainer (included)

LIMITED WARRANTY

SHURflo warrants Diaphragm Pumps to be free from material and workmanship defects under normal use and

service for a period of one (1) year from the data of manufacture or one (1) year of use with proof of purchase, not

to exceed (2) years in any event. The limited warranty will not apply to pumps that were run dry, misapplied, or are

incompatible with components not manufactured by SHURflo. Pump failure due to debris or chemical incompatibility

is not covered under the terms of this limited warranty. SHURflo will not warrant any pump that is physically

damaged, or altered outside the SHURflo factory. Warranty claims may be resolved by an authorized dealer service

center, or by SHURflo. For complete warranty details, please call your closest SHURflo office.

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo, LLC Headquarters

5900 Katella Avenue

Cypress, California 90630

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (562) 795-7564

911-714 Rev E

© 2008 SHURflo, LLC All Rights Reserved

SHURflo, LLC East

52748 Park Six Court

Elkhart, Indiana 46514-5427

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (574) 264-2169

SHURflo Europe, Middle East, Africa

Pentair Water Belgium bvba,

Industriepark Wolfstee, Toekomstlaan 30

B-2200 Herentals, Belgium

Phone +32-14-283500Ÿ Fax +32-14-283505

Patent #: 6623245 Page 2 of 2

Loading...

Loading...