Shurflo 804 Installation Manual

Winterizing

g g

Follow manufacturers recommendations for

winterizing.

Option: Drain system of water. Unhook pump

and blow system with air. Leave faucets open.

LIMITED WARRANTY PROCEDURE

SHURflo warrants its 804 Series to be free from material and workmanship defects under normal use and

service for a period of one (1) year from the date of manufacture or one (1) year of use with proof of

purchase, not to exceed (2) two years in any event.

The limited warranty will not apply to pumps that were improperly installed, misapplied, or are

incompatible with components not manufactured by SHURflo. Pump failure due to foreign debris is not

covered under the terms of this limited warranty. SHURflo will not warrant any pump that is physically

damaged, or altered outside SHURflo.

Warranty claims may be resolved by an authorized dealer service center, or by a SHURflo service center.

Returns are to be shipped with charges pre-paid.

Package all returns carefully. SHURflo will not be responsible for freight damage incurred during shipping

to a service center.

SHURflo is not responsible nor will it reimburse for labor necessary to remove and reinstall a pump, if

found defective.

This limited warranty is in lieu of all other warranties, expressed or implied, and no other person is

authorized to give any other warranty or assume obligation or liability on SHURflo's behalf. SHURflo shall

not be liable for any labor, damage or other expense, nor shall SHURflo be liable for any indirect, incidental

or consequential damages of any kind incurred by the use or sale of any defective product or part. This

limited warranty covers products distributed within the United States of America. Other world market areas

should consult with the distributor for any deviation from this document.

SHURflo's obligation under this warranty policy is limited to the repair or replacement of the pump. Pumps

found not defective (under the terms of this limited warranty) are subject to charges to be paid by the returnee

for the testing and packaging of "tested good" units. Warranty returns will be shipped on a freight allowed

basis. SHURflo reserves the right to choose the method of transportation.

!

ISO Certified Fac ility

Shipping/UPS:

911-558, Rev A 10/00 page 4 of 4

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo

12650 Westminster Ave.

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

FAX (714) 554-4721

Garden Grove, CA 92843

!!!!

12650 Westminster Ave.

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

(800) 762-8094 (219) 262-0478

FAX (219) 264-2169

http://www.shurflo.com

Sanitizing

Mix a solution of 3 tablespoons of sodium

hypochlorite [bleach] per 10 gallon tank capacity.

Pour solution into tank. Fill tank. Run all fixtures.

Allow to sit 4 hours minimum. Flush system.

To shorten time to 1 hour, double the bleach

concentration.

© 2000

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

SHURflo has supplied pumps to the manufacturers

of RV's for over 30 years. Our patented Tri-afram® line of potable water pumps deliver smooth,

consistent flow at al l ranges of operation, while

drawing low current. The balanced diaphragm

design incorporates two precision ball bearings

for long life. SHURflo pumps are 100% tested

for proper operation before they leave the factory.

GENERAL INFORMATION

SHURflo realizes that in many instances our pump is being installed as a replacement pump within an existing system.

The followin

ELECTRICAL

CAUTION:

•

•

•

Model 804 Series Pump/Accumulator Combination

INSTALLATION AND OPERATION MANUAL

When installed correctly, SHURflo water

pumps will provide years of quiet operation.

A SHURflo pump in combination with a low

backpressure water system can exceed all

expectations. For unmatched reliability and

trouble-free performance request SHURflo's

complete line of water system products.

uidelines should be considered to achieve optimum pump operation.

MOUNTING

Electrical wiring should be performed by

a qualified electrician, in accordance with

all local electrical codes.

The pump should be on a dedicated

circuit, controlled with a double pole switch

UL certified)

higher than the fuse ampere indicated

(individual)

(UL/C-

by the pump motor label. Depending on distance of

the power source from the pump and ampere load on

the circuit, wire size may need to be heavier than

indicated by the chart.

Improper duty cycle and/or rapid start & stop

conditions may result in premature motor failure

due to excessive heat. Refer to the Product Data

Sheet.

For the pump to meet

circuit

MUST be protected with a fuse

UL/C-UL

requirements, the

or a UL/C-UL

certified or equivalent circuit breaker as indicated on

the motor label.

Wire sizing for 10% Voltage Drop

VOLTAGE WIRE LEADS WIRE SIZE FUSE RATI NG

12 VDC

CAUTION:

ULTRAflo

24 VDC

ULTRAflo &

12 VDC Std.

Circuit protection is dependent on the individual application requirements. Failure to provide proper

15 Amps

Red (positive +)

Black (negative – )

9 Amps

( Distance from pump to Voltage Source and

overload/thermal devices may result in a motor failure, which will not be covered under warranty.

911-558, Rev A 10/00 page 1 of 4

The unit should be located in an area that is dry and

provides adequate ventilation. If mounted within an

enclosure, provisions to cool the motor may be

necessary.

The unit may be mounted in any position. However,

if mounting the pump vertically, the pump head with

the pressure switch should be in the "

that in the event of a leak, fluid will not enter the

switch. If mounted vertical, make sure wall will hold

weight.

The 804 series can be mounted using four proper

length 3/8” (9.5mm) bolts. Be certain there is no

excess stress on plumbing connections.

All tanks should be securely mounted to a solid

foundation. Pump can be mounted on top of tank or

beside it.

#

14 max of 25 ft

#

12 max of 40 ft

#

10 max of 60 ft

#

8 max of 110 ft

#

16 max of 25 ft

#

14 max of 40 ft

#

12 max of 60 ft

#

10 max of 100 ft

[7.6 M]

[12.1 M]

[18.2 M]

[33.5 M]

[7.6 M]

[12.1 M]

[18.2 M]

[30.4 M]

Back

See pump

motor label

UP

" position so

)

PLUMBING

•

Dual-head pumps have two (each) inlet and outlet ports. They must be plumbed together.

CAUTION

: NEVER

stop or reduce output flow of the non-controlled

(no P/S)

pump head end to pressures higher than

indicated on motor nameplate. Failure of components will occur that are not covered under the standard

SHURflo Limited Warranty.

•

Maximum flow rating achieved through the inlet/outlet manifolds when 5/8"

•

Flexible

should be at least 18 in.

tubing route and avoid sharp bends that may kink over time.

• ½"-

internal taper when

ft/lb

NOTE:

high-pressure tubing compatible with the fluid should be used to connect the inlet/ outlet ports. Flexible tubing

[46 cm]

long to minimize stress on the fitting/ ports and reduce noise. Allow for the shortest possible

14 male threaded models:

hand-tightened

(45 in/lb) [5•Nm]

.

SHURflo does not recommend the use of metal fittings or rigid pipe to plumb the inlet/outlet ports. Standard

Are intended to be used with SHURflo Swivel Barb Fittings which seal with an

. Standard ½"-14 fittings may be used when tightened to a maximum torque of 3.7

[15.8 mm]

tubing is utilized.

plastic male and female threaded fittings can be acquired at commercial plumbing supply stores. SHURflo also

distributes Swivel Barb Fittings and special fittings through its dealers.

CAUTION

: Teflon tape or sealers may act as lubricant causing stripped threads or broken housings due to

overtightening. Care should be used whe n applying s ealers. S ealers may en ter the pu mp inhibiti ng valve

action, causing no prime or no shut-off.

•

Installation of a 50 mesh strainer is required to prevent foreign debris from entering the pump.

Failure due to foreign debris is not covered under warranty.

Inlet port[s]: 1/2”-14 NPSM Outlet port[s]: 1/2”-14 NPSM

Aftermarket kits include:

!

Dual-Head: 3/4” Barb outlet fitting

5/8” Barb manifold (2) Strainer (1)

!

Standard: 3/4” Barb outlet fitting

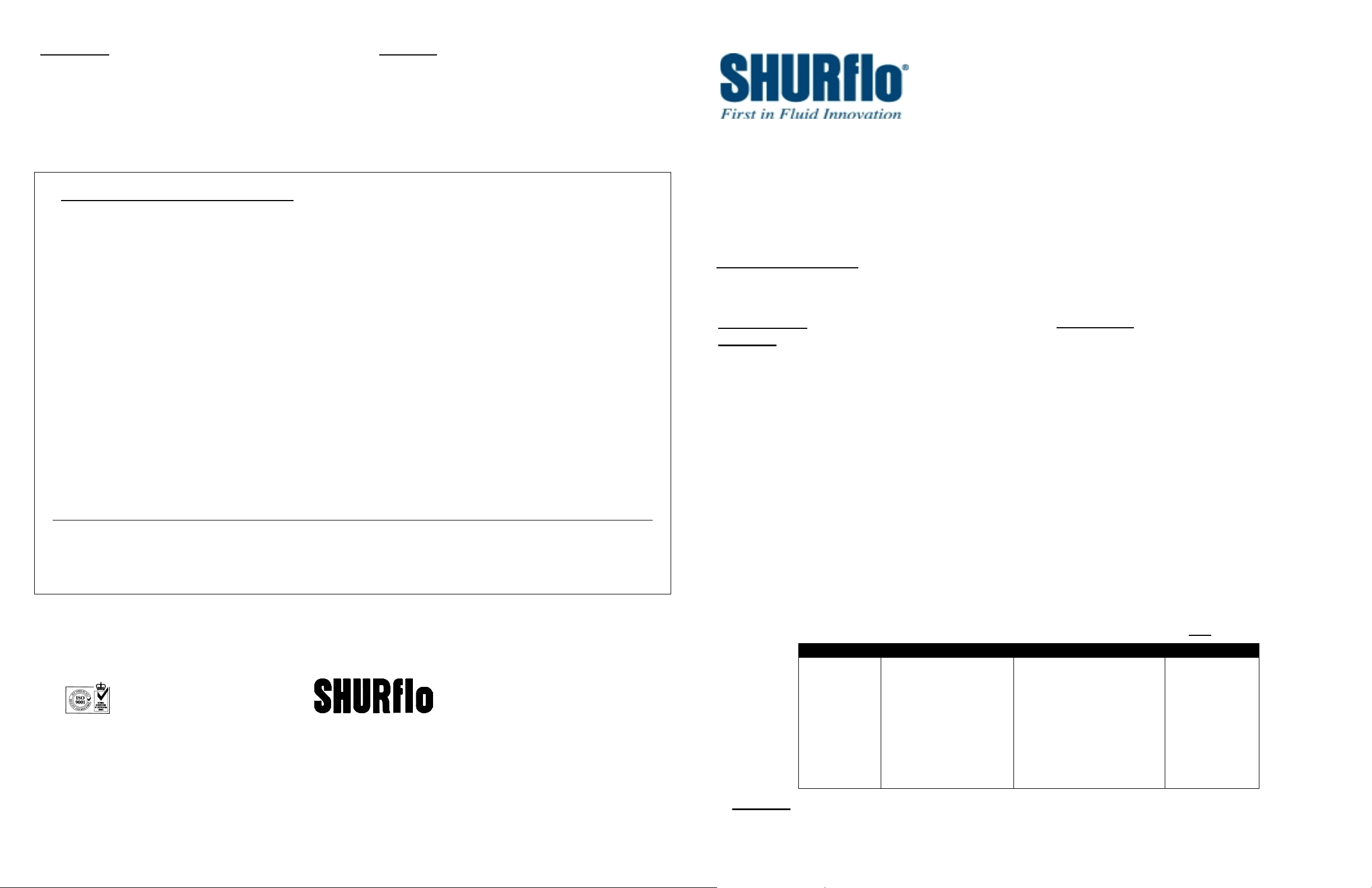

Front View of Pump/Accumulator Combination Unit with Standard Pump

SPECIFICATIONS Dual-Head Standard Head

12

Voltage:

Maximum Amps:

Fuse Size

Open Flow, H20:

Pressure Switch:

Inlet Port Configuration

Outlet Port Configuration

Duty Cycle:

Ambient Temp. Range:

Maximum Inlet Pressure:

Ignition Protect ed:

Approx. Size ( L x W x H )

*with hose

Baseplate Mounting Holes

VDC

15 amps 9 amps 9 amps

25 amp 15 amp 15 amps

5.6

OFF

GPM

[21 lt/m]

= 45

5/8” B

1/2”-14 NPSM 1/2”-14 NPSM

Intermittent Continuous

33°—120° F

30

PSI

UL Marine/ISO 8846 UL Marine/ISO 8846

14” x 13”* x 14-1/2” 14” x 13”* x 14-1/2”

35.5cm x 33cm* x 36.8cm 35.5cm x 33cm* x 36.8cm

4-13/16” x 8-5/8”

12.2cm x 21.9cm 12.2cm x 21.9cm

24

VDC

6.5

[3.1 bar]

PSI

ARB

[0.5°—49° C]

[2.0 bar]

center to center

GPM

[24 lt/m]

3.8

33°—120° F

30

4-13/16” x 8-5/8”

12

GPM

= 45

OFF

1/2”-14 NPSM

PSI

VDC

[14.3 lt/m]

PSI

[3.1 bar]

[0.5°—49° C]

[2.0 bar]

center to center

SERVICE KITS

Kits are available to repair standard dual-head pumps. Repair kits include simple illustrated instructions allowing

easy installation. To insure that the correct kit is received, the model number and all nameplate data

must

be

included with the order. Contact a SHURflo distributor or SHURflo directly to order the necessary.

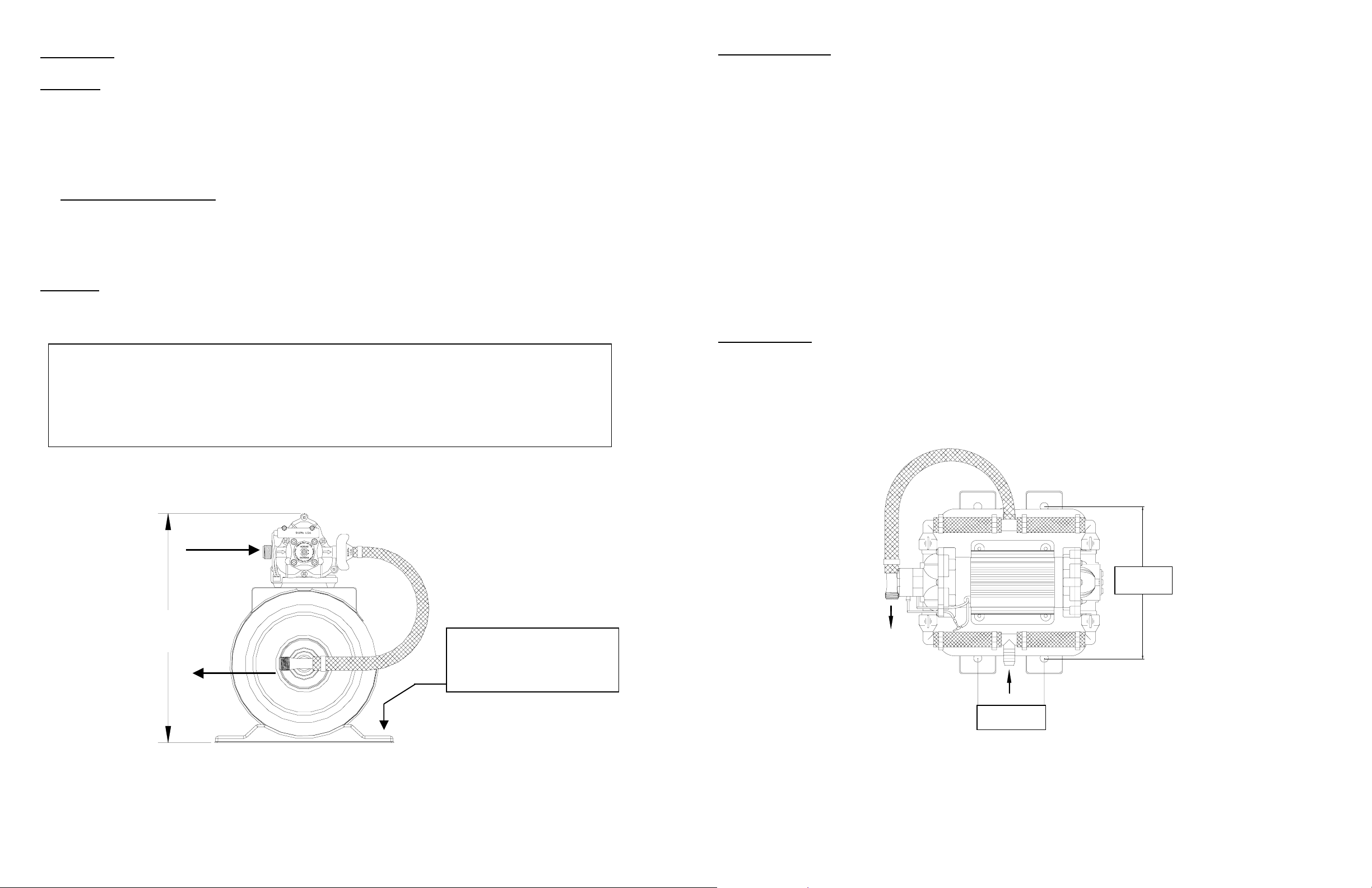

Top View of Pump/Accumulator Combination with Dual-Head Pump

In

14-1/2”

Mounting: 3/8” [9.5mm]

bolts (4 plcs)

Out

911-558, Rev A 10/00 page 2 of 4

8-5/8”

OUT

IN

4-13/16”

911-558, Rev A 10/00 page 3 of 4

Loading...

Loading...