Shurflo 5902 Installation Manual

Model 5902 Extreme Series Pump/Accumulator Combination

INSTALLATION AND OPERATION MANUAL

The most advanced system available. This fully-automatic potable and raw water system delivers smooth,

consistent flow at all ranges of operation, while drawing low current. The balanced diaphragm design

incorporates two precision ball bearings for long life. SHURflo pumps are 100% tested before leaving the

factory.

GENERAL SAFETY PRECAUTIONS

To prevent possible serious or fatal injury.

Do not exceed 50 PSI [3.4 bar] working pressure

on the tank.

MOUNTING

• All tanks should be securely mounted horizontally to a solid foundation with the pre-charge valve “out” for maintenance and

convenience. Pump can be mounted on top of tank or beside it.

• The unit should be located in an area that is dry and provides adequate ventilation. If mounted with in an enclosure, a provision to cool

the motor may be necessary.

• System is not rated for below waterline installation. The strainer and pump must be mounted above the outside water line.

• The pump is capable of a 6 ft. [2M] vertical prime.

PLUMBING:

• SHURflo recommends that the pump inlet and outlet ports be plumbed with at least 1 ft. [.3M] of flexible tubing. Inlet tubing

1/2” I.D. min [mm] from the tank to the pump should be rated for vacuum. Standard garden hose is not suitable as inlet tubing

will collapse under vacuum, reducing water flow and possibly damaging the pump. The system outlet port should not be

connected to rigid (plastic) pipe. Normal oscillation of the system may transmit through rigid plumbing causing noise and

possibly loosen or crack components.

• Avoid any sharp radius in tubing that may kink over time. Route tubing away from heat (exhaust manifolds etc.) and fasten

securely. See your tubing manufacturer for recommendations.

• Always use high quality non-corrosive fittings, valves and hardware to assure long-term reliability.

• The through hull fitting must have a sea-cock valve to shut-off in case of an emergency.

• Properly seal all pipe threads before the strainer to prevent unforeseen leaks, Never use Teflon tape or sealing compounds

on SHURflo fittings. Sealant may enter the pump causing a failure not covered under warranty.

• If fuel vapor is detected, never operate the engine

or electrical equipment until the source is located

and/or properly vented.

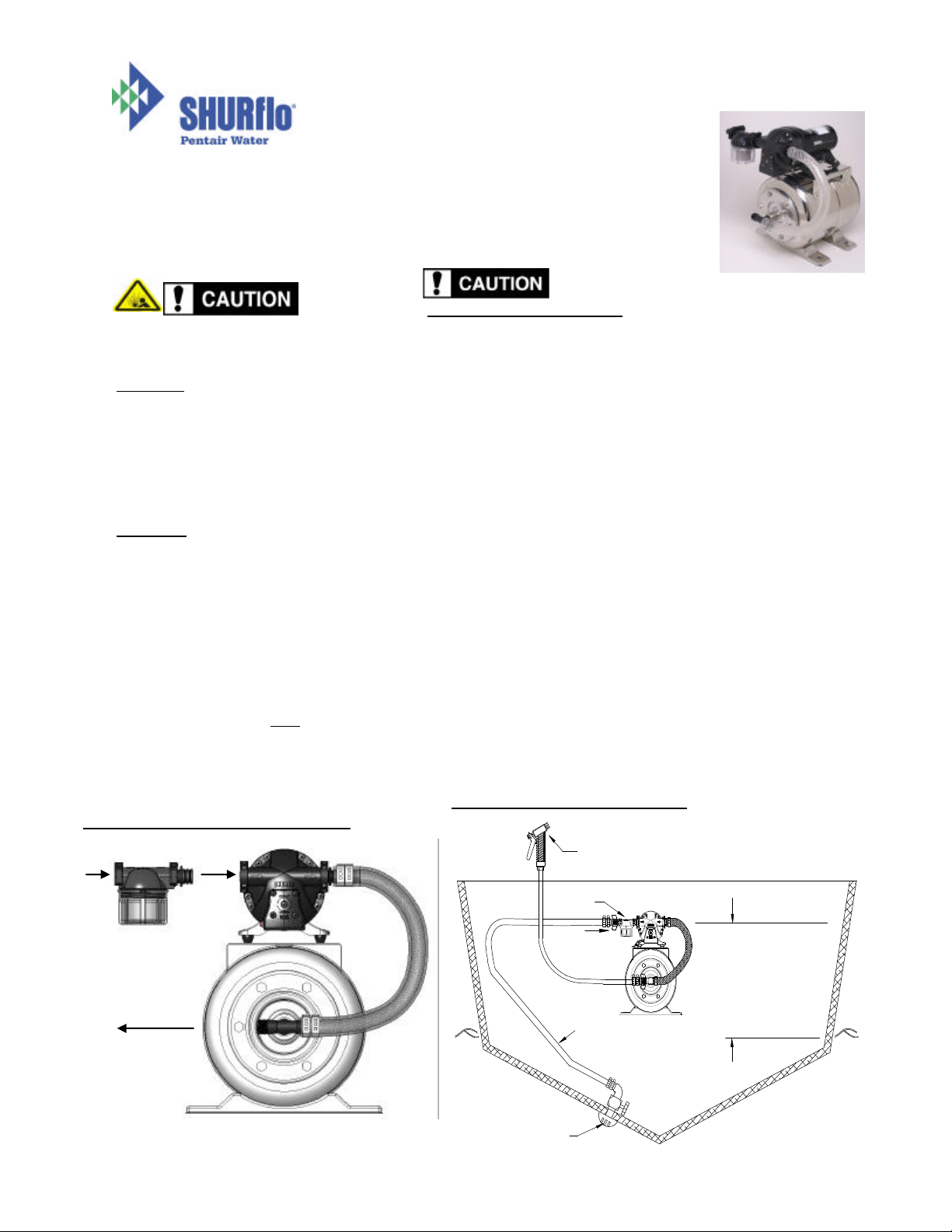

TYPICAL WASHDOWN INSTALLATION:

TYPICAL POTABLE WATER INSTALLATION:

spray nozzle or

water valve (optional)

shurflo

254 series

strainer

inlet

6 FT. max [2.7 m]

vertical lift from

outside water level

to pump inlet port

use flexible high pressure tubing

from thru-hull fitting, strainer,

and pump. tubing should be rated

for below water line use.

sea-cock

valve

through

hull fitting

911-670 Rev K 12/08 ECO#:16135 Page 1 of 4

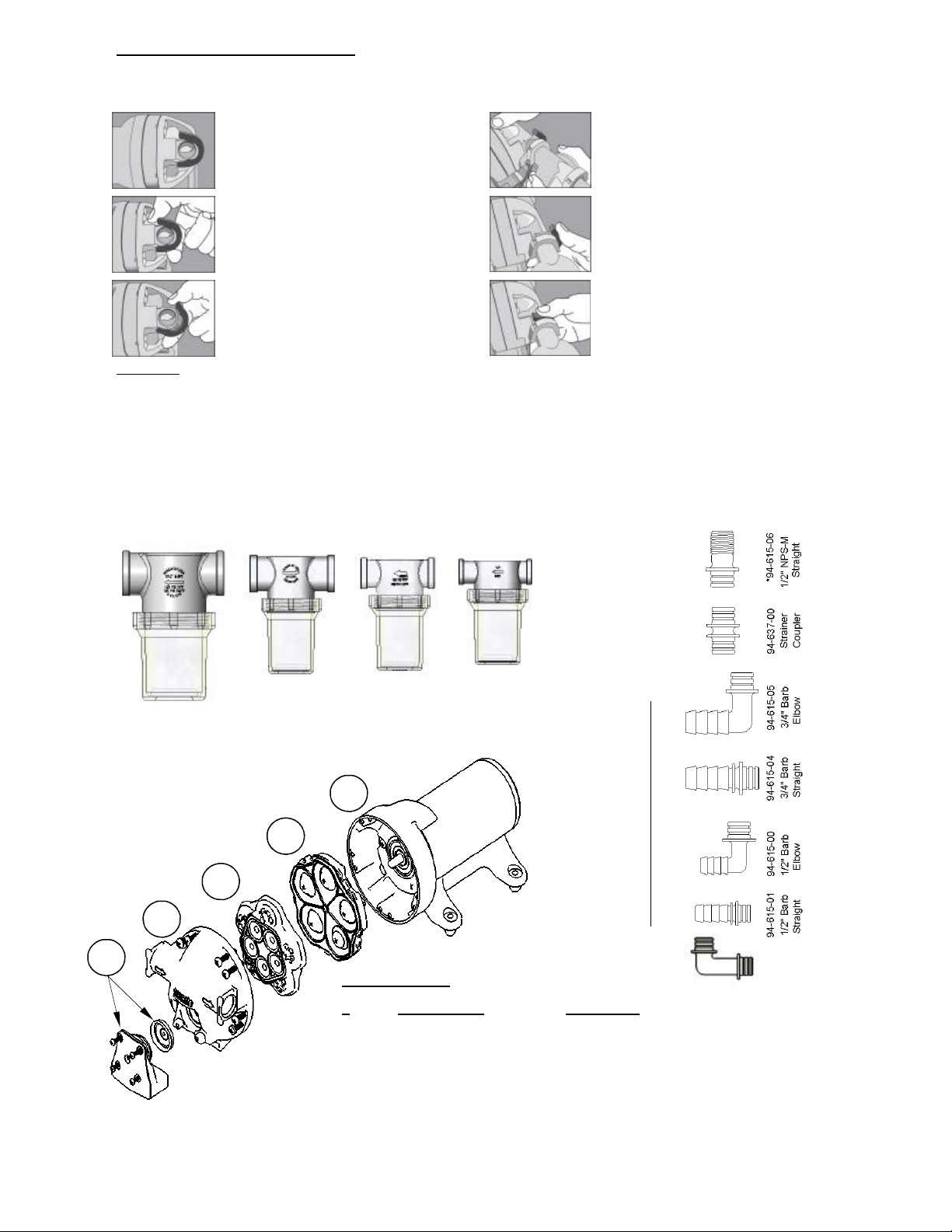

FITTINGS INTALLATION INSTRUCTIONS

SHURflo quick connect fittings provide easy installation and removal if required. The fittings are designed with dual o-rings,

creating a seal when snapped into place.

Step #3:

Pump clip original stage.

Insert strainer or fitting into quick

connect port, push all the way until

stops.

Step #1:

Place your thumb at the edge of

the clip as shown.

Step #2:

Using your thumb, pry up edge of

lock clip over lock tab. (as shown)

STRAINER

Installation of a 40-mesh minimum strainer such as SHURflo series 254 (included with system) is necessary to prevent debris

entering the pump. System failure due to debris is not covered by SHURflo warranty.

Step #4:

Place your thumb on top of the

clip as shown.

Step #5:

Snap lock clip over fitting and lock.

Pull fitting to make sure is locked in.

to place.

• The strainer MUST be mounted on the inlet side of the pump. The directional flow for the water inlet is marked with an arrow on the

pump head and on the strainer.

• Mount the strainer where it can be inspected and cleaned easily. The strainer can be mounted directly on the pump inlet port or it can

also be mounted away from the pump by using the bracket and fittings supplied (see figure below).

• System is not rated for below waterline installation. The strainer and pump must be mounted above the outside water line.

Raw Water Strainers Available (Sold Separately)

1

253-400-01

1 1/4” Strainer

2

3

253-320-01

1” Strainer

4

253-220-01

3/4” Strainer

253-120-01

1/2” Strainer

5

SERVICE KITS

# Component Part Kit #:

1 Pressure Switch 94-069-00

2 Upper Housing 94-670-02

3 Valve Assembly 94-030-01

4 Drive Assembly 94-030-02

5 Motor 12V DC 77-007-17

5 Motor 24V DC 77-009-17

5 Motor 32V DC 77-010-17

* Included with Aftermarket Extreme Pro Blaster pump kits.

FITTING KITS (Sold Separately)

Elbow

Adapter

94-689-00

911-670 Rev K Page 2 of 4

Loading...

Loading...