Shurflo 5900 Installation Manual

CAUTION

MOUNTING

• Mount pump within 6 feet of tank for best performance.

• Mount pump in a space of two cubic foot for adequate

ventilation.

• The pump may be mounted in any position. If mounting the

pump vertically, the pump head should face down.

• Choose a solid surface. Do not insulate the baseplate

heat sink. Heat sink must be free and have air

flowing across.

• Do not over-tighten mounting feet.

ELECTRICAL

• The pump should be on an individual circuit, protected by

the specified size fuse or circuit breaker on the label.

• A 15 amp or higher switch is recommended, and must

be on the positive (+ red) lead.

• TEST INCOMING POWER WITH MULTIMETER TO

TEST POLARITY ( RED = + and BLACK = -- ).

• Pump draws 15 milliamps when pump is powered on,

even when the pump is not running.

SHUT OFF POWER TO PUMP WHEN LEAVING COACH.

PLUMBING

• Installation of a strainer (SHURflo model 254 or larger) is

required to prevent debris from entering the pump.

• For noise and vibration reduction we recommend at least

18 in. [.5 M] of _" [13mm] I.D. flexible high-pressure tubing

to both ports. The pump ports and strainer should not

be connected to plastic or rigid pipe.

• SHURflo quick-connect fittings provide easy installation

and removal if required. The fittings are designed with

dual o-rings, creating a seal when snapped into place.

Lubricate o-rings with silicone-based grease.

• NOTE: Remove clips completely from pump during

maintenance and storage to avoid distortion.

ISO Certified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions

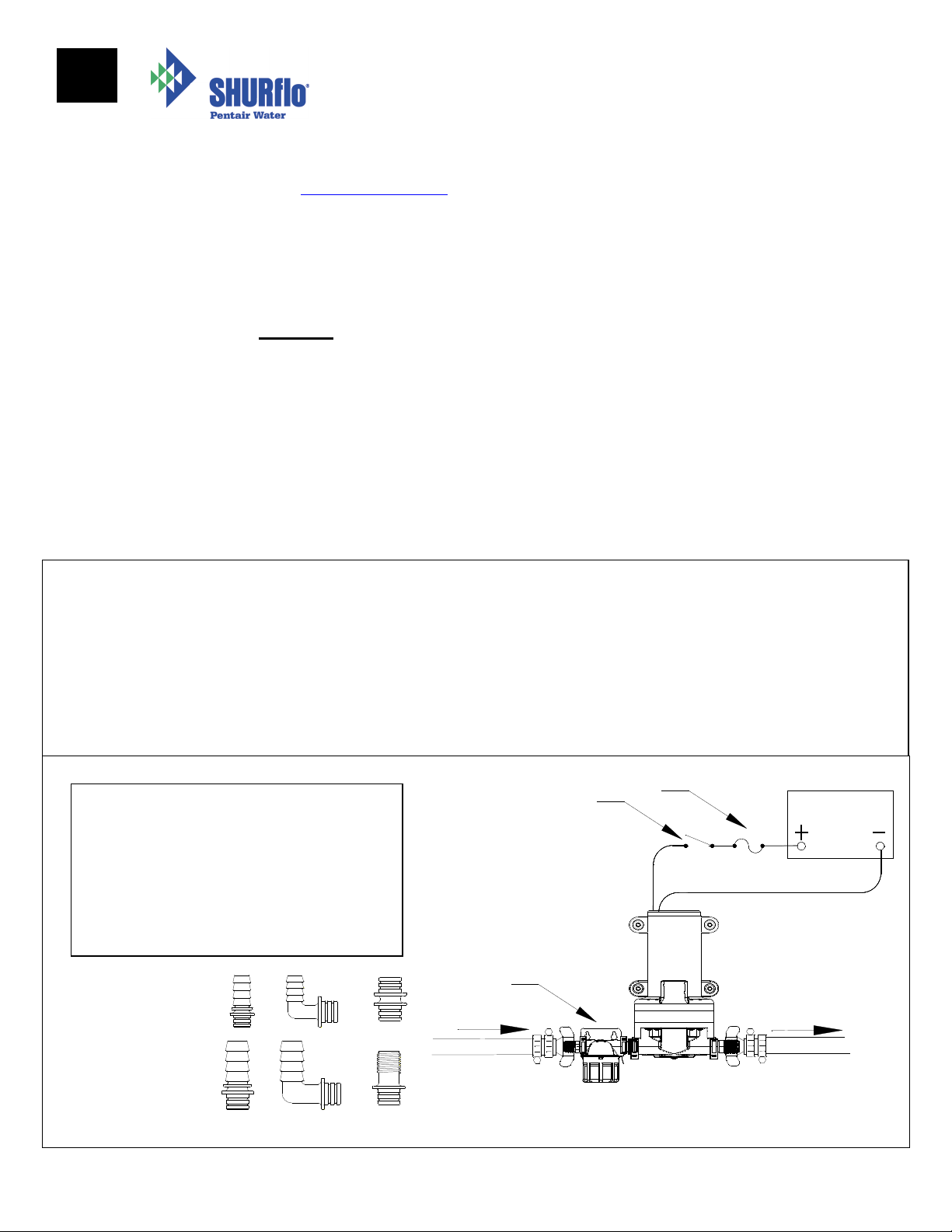

To Insert Fittings:

Clips have the word ‘FITTING’ on them

1. Hold fitting with _” wrench and tighten

plumbing to fitting.

2. Make sure o-rings are lubricated

3. Insert fitting into quick-connect port.

4. Snap lock clip over fitting and lock tab

with ‘fitting’ facing out toward fitting.

To Remove Fittings:

1. Pry up edge of lock clip over lock tab one

at a time.

2. Remove clip and slide fitting out of port.

Fully install clips or remove

completely during maintenance and

storage.

RED PUMP WIRE MUST BE CONNECTED

TO POSITIVE POWER OR CONTROLLER

WILL BE DAMAGED!!!

Electrical Connection with 10 Amp or 15 Amp Controller

Disconnect wires from current pump and connect to Smart

Sensor Pump. Make sure wires are at least 14GA [2.5mm2].

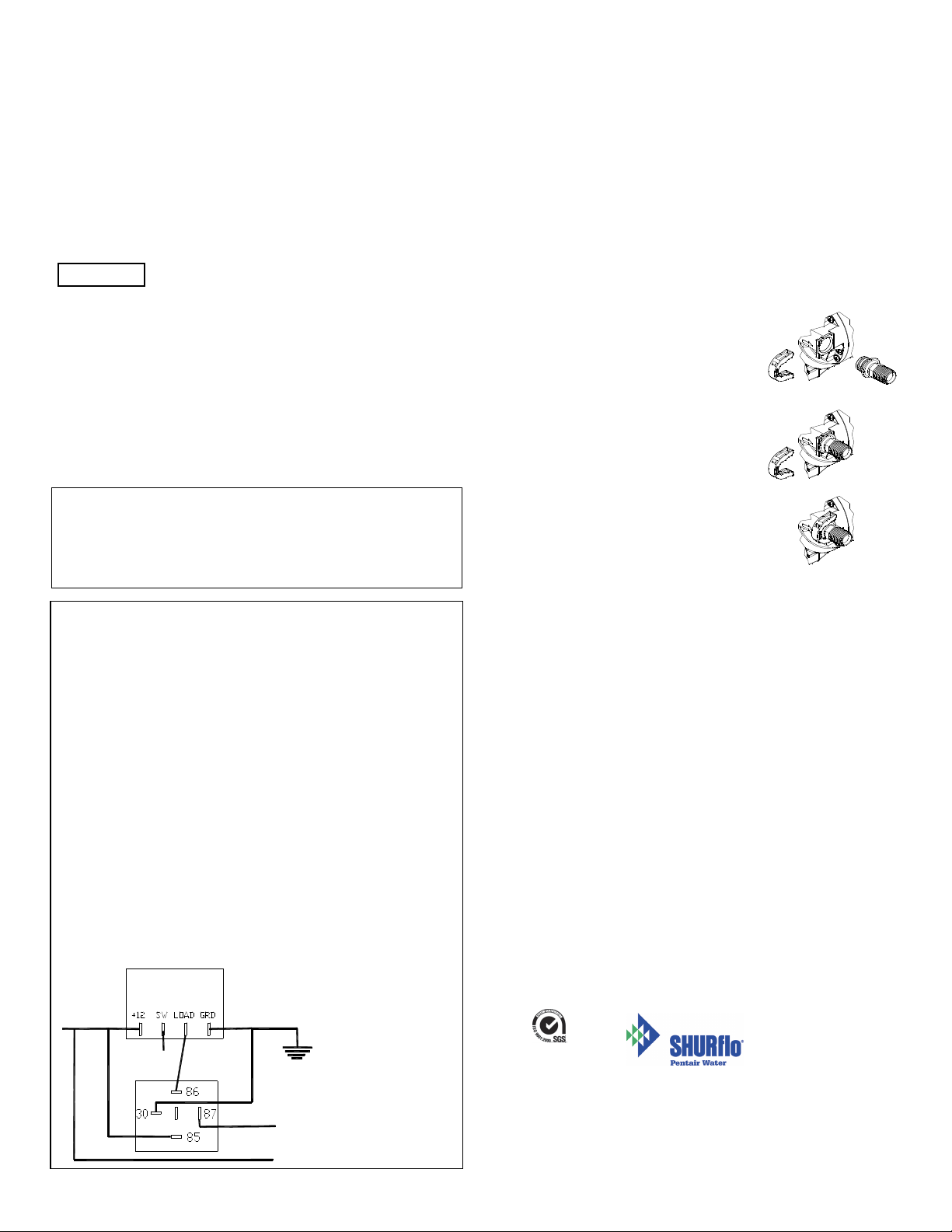

Electrical Hook-Up with 7Amp Intellitec Controller

Replace 7 Amp controller with 10 Amp or 15 Amp Controller,

or install relay as shown below. The purpose of the relay is to

allow the 7 amp controller to close the circuit on the relay

allowing a higher amp circuit to run the pump. Common name

for the relay is a Bosch 30-Amp automotive-type relay. Turn

off all power before electrical work.

Relay Installation

1. Splice 2 red wires into the incoming power line to +12V.

2. Connect one red wire to the red fused pump wire.

3. Connect one red wire to relay terminal 85.

4. Remove wire from the controller LOAD terminal to the

black (-) pump wire and connect it to relay terminal 87.

5. Make a jumper wire from LOAD to relay terminal 86.

6. Splice ground wire from relay terminal 30 to controller

GND terminal and circuit ground.

7. Leave wire to SW terminal connected to switches.

A

B

D

C

F

E

G

+12VDC

(+)

(-)

Wire Size for a 10% voltage drop on a 12VDC, 15 Amp Circuit

Length is distance from power source to pump and back to ground

0–20 Ft [0-6M] = 14GA [2.5mm2]

20–50 Ft [6-15M] = 12GA [4mm2]

50–70 Ft [15-21M] = 10GA [6mm2]

70–100 Ft [21-30M] = 8GA [10mm2]

LIMITED WARRANTY

SHURflo warrants The Extreme series RV pump to be free from material and

workmanship defects under normal use and service for a period of (3) three

years from the date of purchase. In the absence of proof of purchase the

warranty is (3) three years from the date of manufacture indicated on the

motor nameplate. SHURflo is not responsible nor will it reimburse for labor

necessary to remove and reinstall a pump, if found defective. Contact

TROUBLESHOOTING & MAINTENANCE

Regularly check all fittings/screws/connections

PUMP WILL NOT START/ BLOWS CIRCUIT

Electrical connections, fuse, breaker, main switch, and ground connection.

Is the motor hot? Self-resetting thermal breaker may have triggered.

WILL NOT PRIME/SPUTTERS (No discharge/Motor runs)

Is the strainer clogged with debris?

Is there water in the tank, or air in the hot water heater?

Is the inlet plumbing sucking in air at connections (vacuum leak)?

Is inlet/outlet plumbing severely restricted or kinked?

PUMP WILL NOT SHUT OFF/RUNS WHEN FAUCET IS CLOSED

Output side plumbing for leaks, and inspect for leaky valves or toilet.

For air trapped in outlet side (water heater) or pump head.

NOISY OR ROUGH OPERATION

For plumbing which may have vibrated loose.

Is pump plumbed with rigid pipe?

Does the mounting surface amplify noise?

For mounting feet that are loose or compressed too tight.

For air in system.

Sanitizing: SHURflo recommends sanitizing your system every year or as

needed for maintenance. Follow your manufacturer’s recommended

procedures.

Winterizing: Follow your manufacturer’s recommendations. Do not allow

A +12VDC Power

B 7-Amp Controller

C - Ground

D To coach switches

E 30-Amp Relay

F Wire moved from

‘LOAD’ Terminal

-Black Wire to Pump

G + Red Wire to

Pump

SHURflo , LLC

5900A Katella Ave.

Cypress, CA 90630

(800) 854-3218

(562) 795-5200

FAX (562) 795-7564

SHURflo, LLC East

52748 Park Six Court

Elkhart, IN 46514-5427

(800) 762-8094

(574) 262-0478

FAX (574) 264-2169

www.shurflo.com

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

IMPORTANT

READ INSTRUCTIONS ENTIRELY BEFORE INSTALLING THE SMART SENSOR 5.7

These are generalized instructions. For detailed installation, maintenance and troubleshooting and limited warranty

information, contact SHURflo or visit http://www.shurflo.com.

For smooth, maximized flow and less noise and vibration, we offer these suggestions:

•Use a minimum _” [13mm] diameter tubing. Eliminate any unnecessary restrictive elbow fittings and valves

•Mount pump on solid surface. Do not over-tighten rubber feet.

•Use flexible high-pressure hose on pump inlet and outlet.

Use Optional SHURflo Pump Silencing Kit, Model 94-591-01.

•Use an Extreme Series High-Flow water strainer [Model # 254-266].

•Wire Size: 14GA [2.5mm2] minimum, 12GA [4mm2] recommended. See chart on page 2.

•Bleed all air from system.

• Reducing restrictions on the inlet side will allow the pump to run freely, reducing cavitation (starving & noise).

• Reducing restrictions to pump outlet side will minimize backpressure, allowing the pump to run freely.

• Minimum suggested requirement is 2 ft3 [.06M3] of space around pump. Less area around pump can cause

the thermal overload to turn off pump at about 20 minutes of operation. More airflow is better for cooling pump.

• Pump is designed for intermittent duty only.

• Minimum power requirement is 15 AMPS.

• If coach has an Intellitec latching pump controller, see wire diagram on page 2.

• Pump shut-off pressure is 65 PSI [4.5 Bar]. System must be designed to handle 65 PSI [4.5 Bar].

•Pump draws 15 milliamps continuously when pump switch is on, even when pump is not running.

ALWAYS SHUT OFF POWER TO PUMP WHEN LEAVING COACH.

OPERATION

THIS PUMP IS NOT DESIGNED FOR CONTINUOUS DUTY OR FOR USE AS A REVERSE OSMOSIS (RO) PUMP.

PLEASE CONTACT SHURFLO, OR VISIT WWW.SHURFLO.COM FOR YOUR INDIVIDUAL NEEDS.

In a high flow application, the pump will function normally. In a low flow application, the pump will sense a build-up in

pressure, send a signal to the motor and slow down, with virtually no cycling and very low noise. When the fixture is

closed, pressure will build up and the pump will shut off. Pump draws 15 milliamps continually when pump switch is on.

Always turn pump off when not in use for long periods of time, or when leaving your coach.

The pump fully breaks in after a few hours on time. The diaphragm and valves better seat themselves and the motor

brushes will make full contact. What this means for you is a little higher flow and lower amp consumption. Make sure you

purge all of the air in your system.

G

F

H

I

B

E

C

D

A

Pump Dimensions (with fittings and strainer):

9-1/2” [24cm] x 12-1/2” [32cm] x 6” [16cm]

Extreme

Extreme

TM

TM

Series Smart Sensor

Series Smart Sensor

TM

TM

5.7

5.7

5900 Installation & Operation Manual

911-594-D 06/05 Page 1 of 2

94-615-05

94-615-04

94-615-06*

94-615-01

94-615-00

94-615-03

*2 supplied with pump

A Battery

B Fuse. See label for proper size.

C 15 Amp [minimum] switch

D Red (+) wire. See chart for size.

E Black (- Ground) wire. See chart for size.

F Pump

G Model 254 series strainer

H Pump inlet flex line

I Pump outlet flex line

Fittings

94-615-01 - 1/2”

94-615-00 - 1/2”

94-615-03 - Coupler

94-615-04 - 3/4”

94-615-05 - 3/4”

94-615-06 - 1/2” NPS-M

EN

Loading...

Loading...