Shurflo 4901-4292 Installation Manual

INSTALLATION AND OPERATION MANUAL

The Pro Blaster wash down pump delivers water on demand. With the spray nozzle off (output

side closed) the pump will turn off. As the nozzle is opened, the pressure within the hose

(output side) drops. Once the pressure drops below a predetermined point, the pumps

pressure switch closes and the pump operates. With the nozzle set at a fine mist the pump will

cycle, as it is able to pressurize the hose faster than water being released. If the spray nozzle

is held wide open the pump may operate continually. The pump may momentarily operate

even after the nozzle is closed, as it pressurizes the hose. Once the pressure setting is

reached the switch opens and the pump stops.

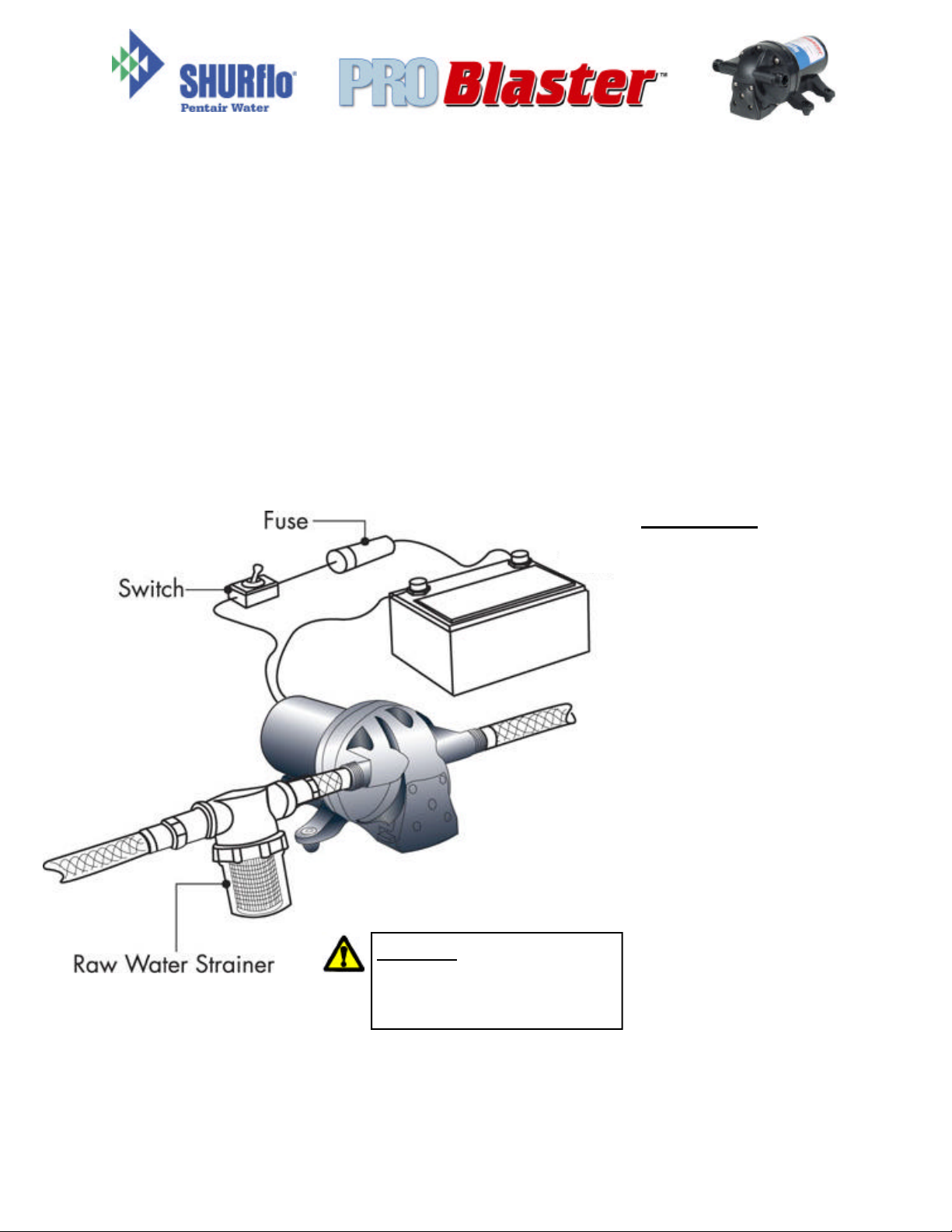

ELECTRICAL

+

CAUTION:

Use of "open" type switches

(not ignition protected) may cause

an explosion of fuel vapors.

• The pump should be on a

dedicated (individual) circuit

protected by the specified

fuse indicated on the motor

label.

• A U/L approved marine duty

(ignition protected) switch rated

at or above 15 amps is recommended, and must interrupt

current flow on the positive (+

red) lead.

• Wire size (gauge/Mm2) is based

on the distance from the power

source to the pump. The

minimum recommended wire

size is #14 gauge [2.5Mm2]. For

lengths of 20-50 ft. [6-15M] use

#12 gauge [4Mm2]. The pump

must be grounded to a "known

ground" (battery). The ground

wire must be the same size as

the positive wire.

911-741 Rev F 12/08 ECO #: 16135 Page 1 of 4

MOUNTING

• Consider a dry location that allows easy access if maintenance is required. The pump should not

be located in an area of less than one cubic foot unless adequate ventilation is provided.

Excessive heat may trigger the integral thermal breaker and interrupt operation. When the

temperature drops the breaker will automatically reset and start operation.

• Mount higher than the outside water (sea) level. The pump is capable of a 6 ft. [2M] vertical

prime above the outside water level. The pump can be mounted in any position. If mounting

the pump vertically, the pump head should be in the down position.

CAUTION: Do not drive screws through the vessel's hull. Use #8 stainless steel hardware to

fasten the pump. Choose a solid surface (bulkhead or stringer) that will not amplify pump sound.

The mounting feet are intended to isolate the pump from the mounting surface; over-tightening,

flattening, or oversized screws will reduce the mounting pads ability to isolate vibration and noise.

Plumbing

· SHURflo recommends at least 1ft. [.3M] of ½"[13mm] I.D. flexible high pressure tubing to both ports. Ideally

the pump's ports/strainer should not be connected to plastic or rigid pipe. The pump's normal

oscillation may transmit through rigid plumbing causing noise, and possibly loosen or crack

components.

· Installation of a 50 mesh strainer such as SHURflo 253 series is recommended to prevent foreign debris from

entering the pump.

SHURflo hex/swivel barb fittings provide easy removal if maintenance or access is required. The

fittings are designed with a "taper-seal", creating a water tight connection when hand-tightened.

Always secure barb tubing connections with properly sized stainless steel clamps to prevent leaks. Never use

Teflon tape or sealing compounds on threads. Sealer may enter the pump causing a failure. Failure due to

foreign debris is not covered under warranty.

· Rapid cycling may be caused by excessive back pressure created by one or more of the following within a

plumbing system:

Water filters and purifiers not on separate feed lines, Flow restrictors in faucets and shower heads, Small ID lines

Pipe/tubing should be at least 1/2” [13mm] for main lines, Restrictive fittings and connections (elbows, “T”’s, feeder

lines to faucets, etc).

NOTES:

• To prevent cavitation, through hull fittings should be located at least 12 in. off the centerline of the

water pick-up for the motor.

• The through hull fitting must have a seacock valve to shut-off in case of an emergency.

• Always use high quality non-corrosive fittings, valves and hardware to assure long-term reliability.

• Properly seal all pipe threads before the strainer to prevent unforeseen leaks. Never use Teflon tape

or sealing compounds on SHURflo pump threads or fittings. Sealer may enter the pump causing a

failure not covered under warranty.

STRAINER / FILTRATION

Installation of a 50-mesh minimum strainer, such as SHURflo series 253, is recommended to prevent

debris from entering the pump. SHURflo recommends at least 1ft. (.3 M) of 1/2” or 3/4” (13mm) I.D.

flexible high-pressure tubing on both ports. Ideally, the pump ports and strainers should not be

connected to plastic or rigid pipe. The pump’s normal oscillation may transmit through rigid plumbing

causing noise, and possible loosen or cracking components.

CAUTION:

The strainer must be mounted above the outside water line to prevent water from siphoning during

cleaning. Mount the strainer where it can be inspected an cleaned easily without closing the

seacock valve.

911-741 Rev F Page 2 of 4