Shurflo 357-102-00 Installation Manual

CORRECT POSITION

Bait & Livewell Pump Installation & Operation

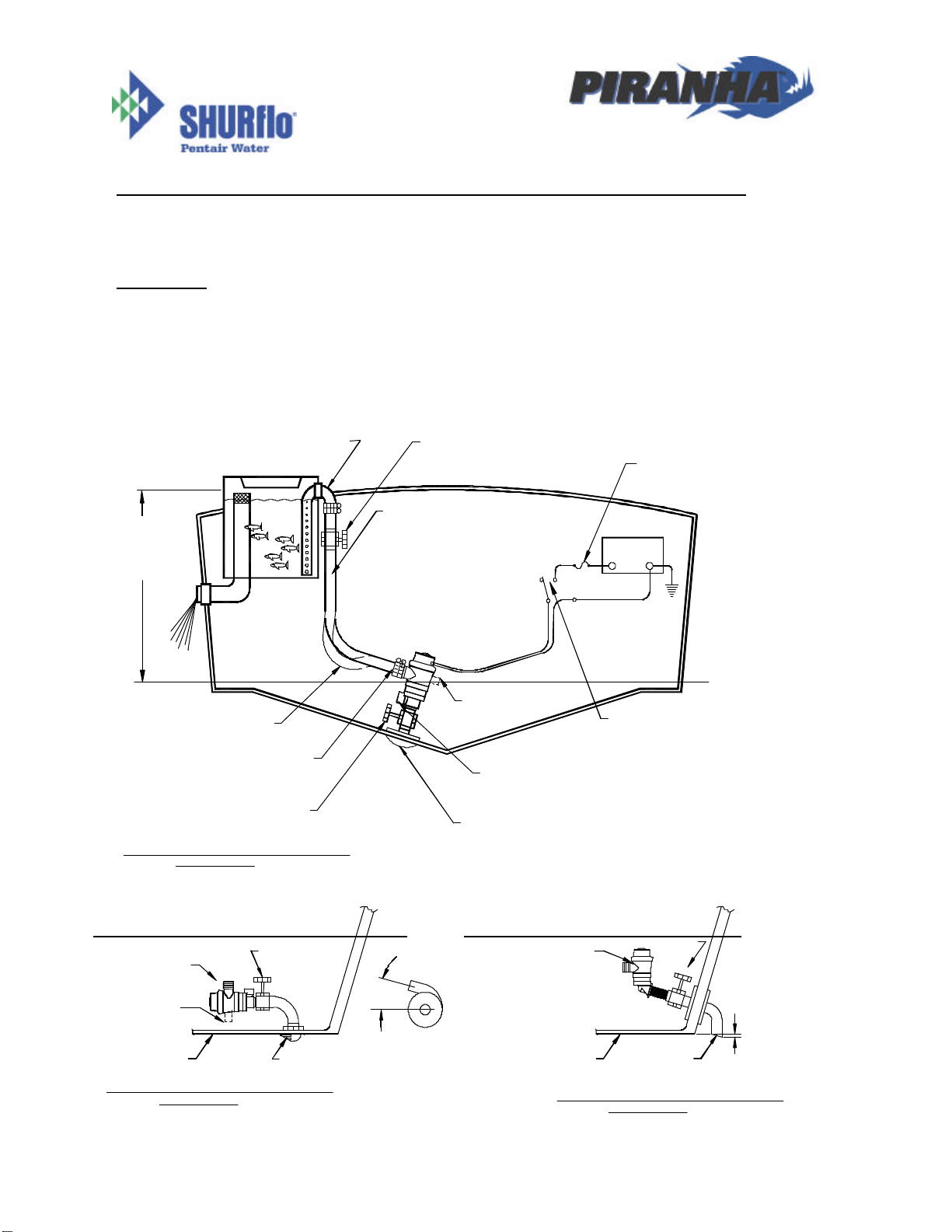

MOUNTING (Suggested installation & operation only. Your installation may vary)

Mount scoop-type thru-hull [high speed pick-up] to hull. Do not drive screws through hull! Below water

level thru-hull fittings must have a seacock shut-off valve. Mount ¾” NPT-M pump inlet port directly to

seacock. For extended inlet ports cut to desired length to fit.

PLUMBING

Use smooth I.D. discharge tubing or hose. Tubing & hose should be rated for below water line use.

Always use double clamps for connections below the water line. Tubing should enter tank at top to

avoid tank draining while pump is off. See illustration for recommended installation.

Avoid airlock & maximize performance: Avoid any sagging or loops in the tubing. Tubing must go up

from pump to tank. Use full-flow style valves only. Valve is used to regulate flow to tank while at rest and

while under way (2 different settings).

MUST "ENTER" AT

TOP OF TANK

MAX. "HEAD"

BASED UPON

TANK SIZE/DISTANCE

DRAIN

WATER

LINE

DO NOT ALLOW TUBING TO SAG.

ALWAYS USE DOUBLE STAINLESS STEEL

CLAMPS FOR PLUMBING BELOW WATER LINE.

SEA-COCK SAFETY VALVE REQUIRED.

BE SURE VALVE OPENING IS AS LARGE AS BAIT

PUMP DISCHARGE PORT I.D.

WARNING!! SEA-COCK MUST BE CLOSED BEFORE

SERVICING PUMP

FLOW-ADJUST VALVE

VALVE OPENING SHOULD BE THE

SAME AS PUMP DISCHARGE PORT I.D.

TUBING MUST TRAVEL UPWARD

FROM PUMP TO BAIT TANK.

IF TUBING SAGS BELOW HORIZONTAL

PUMP MAY BECOME AIR-LOCKED.

(OFF)

PUMP IMPELLER MUST BE

BELOW WATER-LEVEL

WRONG POSITION

FOR DISCHARGE PORT

BROWN (+)

½" NPT PORT FOR CONNECTION TO A WASH-DOWN PUMP.

REF. S/B #1066 FOR SUGGESTED INTEGRATED PLUMBING ARRANGEMENT.

LOCATE A SCOOP OR CLAMSHELL STYLE THRU-HULL FITTING

APPROX. 6 IN. [15CM] OFF KEEL, TO THE STERN.

RED

(ON)

SEE PUMP LABEL FOR FUSE SIZE

12 VDC BATT.

_

+

BLACK

U/L MARINE APPROVED, IGNITION

PROTECTED ON/OFF SWITCH.

10 AMP RATING (MINIMUM).

WRONG POSITION

FOR DISCHARGE PORT

HORIZONTAL MOUNT

FOR DISCHARGE PORT

KEEL

WARNING!! SEA-COCK MUST BE CLOSED BEFORE

SERVICING PUMP

VALVE

THRU-HULL

(SCOOP OR CLAM SHELL)

UP 15°

(OR MORE)

WATER-LINE

DISCHARGE

PORT

PUMP END VIEW

CORRECT POSITIONSEA-COCK

FOR DISCHARGE PORT

TRANSOM MOUNT

SEA-COCK

VALVE

1

/

" [3MM]

8

KEEL

WARNING!! SEA-COCK MUST BE CLOSED BEFORE

RAW WATER

PICK-UP

SERVICING PUMP

911-611 Rev G 11/08 ECO#: 16079 Page 1 of 2

ELECTRICAL

Use 16GA wire for all circuits. If installation is over 20 feet, use 14GA wire. Brown pump wire must be connected to positive

power. Use waterproof connectors and splices. Attach all wires to UL Marine approved duty switch rated at or above 10 amps.

Wire connections should be made above water level at the highest possible position. Seal wire connections to prevent corrosion

and electrolysis.

WARNING

Always use fuse with amps rating specified on pump label. Failure to do so may result in

serious personal injury or fire hazards.

OPERATION

Never operate equipment if gasoline fumes are present. Always test pump before leaving dock. Open sea cock before running

pump, do not run pump dry. Tank fill time should be tested at rest and under way. Pump will fill tank faster while boat is running at

higher speeds. General tank fill times are between 7 minutes [warmer water] and 10 minutes [colder water]. Measure tank fill time from

empty while at rest and adjust valve position for desired time. Measure tank fill time at normal cruising speed and adjust valve to

desired time. Refer to tank size chart for optimal pump size. Note position for later reference. Always remember to adjust valve when

at rest or under way. Flow should be circular and slightly upward so debris clears from bottom of tank. Flow should not be too fast that

fish get tired.

WARNING

Do not disassemble base from pump body. Warranty will be voided upon disassembly. SHURflo is not responsible for problems

due to disassembly of base from pump body. Do not pump oil, diesel fuel, gasoline or other flammable liquids with this pump.

Always disconnect power before servicing pump. Always use fuse size specified in specification.

Seacock MUST be closed before removing cartridge from pump housing.

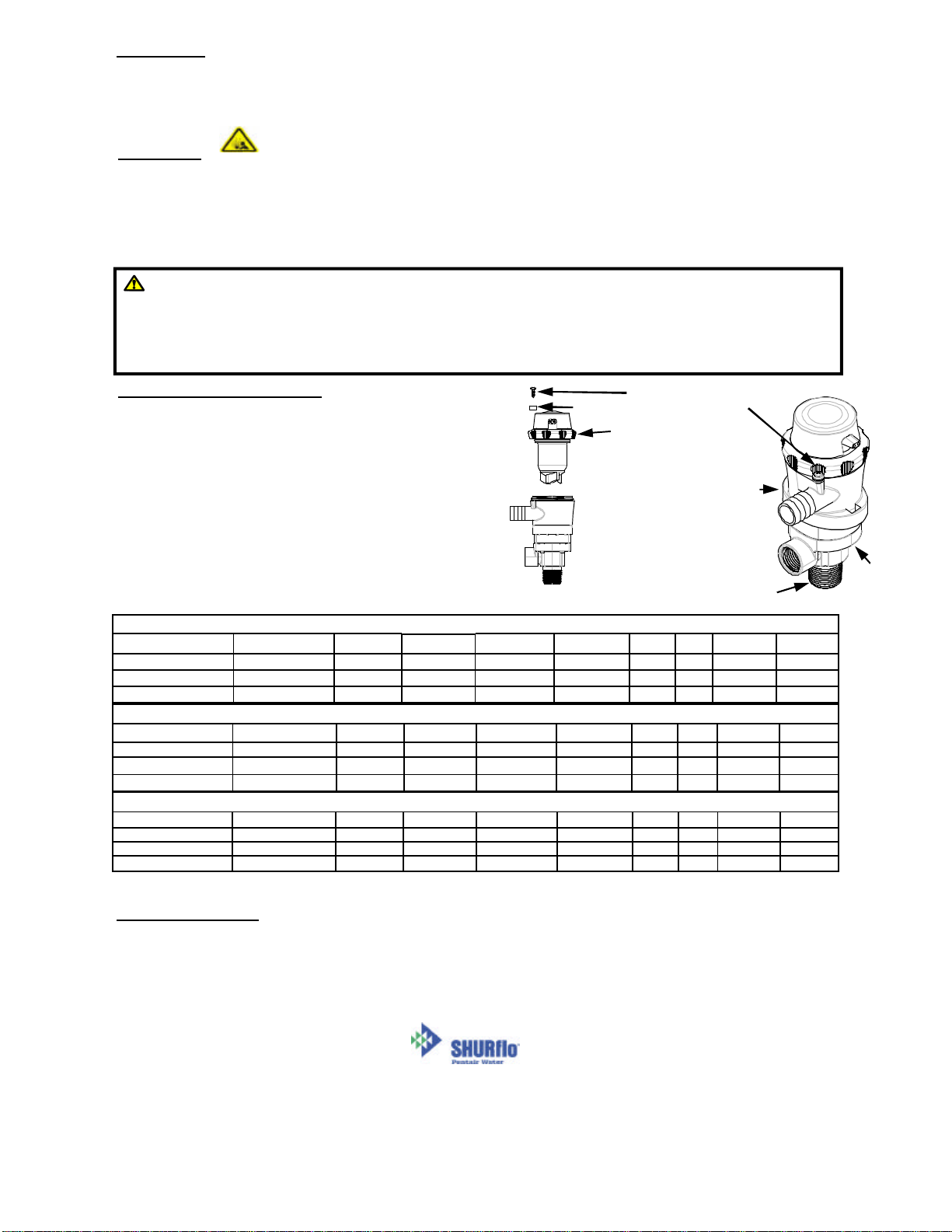

MAITENANCE AND CLEANING

Impeller and Motor Cartridge:

First and most important, close seacock valve. Remove motor

cartridge by removing locking screw and then unscrewing the

blue-collar nut. Remove motor cartridge. Clean out debris and press

Spacer

Remove screw and spacer

prior to replacing cartridge

Blue Motor Cartridge Collar Nut

unscrews ccw for easy impeller

cleaning and cartridge change.

motor cartridge firmly into housing, then hand-tighten blue collar nut

to housing. Make sure to align the finger holes on blue collar nut to

allow room for locking screw. Align spacer and locking screw.

Pump Body

Assemble screw and spacer into existing hole. CAUTION: MAKE

SURE NOT TO OVER TIGHTEN SCREW, SNUG IS FINE. Always

check for leaks/cracks and all connections regularly. Repair or

replace as needed. Keep valve closed when system is not in use.

When not using livewell, remove or drain all water from the system.

When removing boat from the water, open seacock valve. When

boat is in water and livewell is not in use, close seacock valve.

Dual Port Housing

*Dual Port Model Gallons [Liters] Tank Size

1 Ft [.3 M] 2 Ft [.6 M] 3 Ft [.9 M] 4 Ft [1.3 M]

600 GPH [2271 LPH] 31 [117] 23 [87] 12 [45] 5 [19]

800 GPH [3028 LPH] 42 [159] 36 [136] 30 [114] 21 [79]

1100 GPH [4163 LPH] 54 [204] 44 [166] 35 [132] 24 [91]

*Aerator Straight Gallons [Liters] Tank Size

1 Ft [.3 M] 2 Ft [.6 M] 3 Ft [.9 M] 4 Ft [ 1.3M ]

600 GPH [2271 LPH] 33 [125] 27 [102] 21 [79] 15 [57]

800 GPH [3028 LPH] 38 [144] 32 [121] 27 [102] 18 [68]

1100 GPH [4163 LPH] 53 [201] 41 [155] 32 [121] 21 [79]

*Aerator Angled Gallons [Liters] Tank Size

5 Ft [1.6 M]

13 [49]

14 [53]

5 Ft [1.6M]

9 [34]

12 [45]

13 [49]

Amps Fuse Inlet Outlet

3.0 A 4 A 3/4” NPT-M 3/4” Barb

4.5 A 6 A 3/4” NPT-M 3/4” Barb

4.5 A 6 A 3/4” NPT-M 1-1/8” Barb

Amps Fuse Inlet Outlet

3.0 A 4 A 3/4” NPT-M 3/4” Barb

4.5 A 6 A 3/4” NPT-M 3/4” Barb

4.5 A 6 A 3/4” NPT-M 1-1/8” Barb

Inlet

1 Ft [.3 M] 2 Ft [.6 M] 3 Ft [.9 M] 4 Ft [ 1.3 M ] 5 Ft [1.6 M] Amps Fuse Inlet Outlet

600 GPH [2271 LPH] 27 [102] 21 [79] 12 [45] 6 [23] 3.0 A 4 A 3/4” NPT-M 3/4” Barb

800 GPH [3028 LPH] 38 [144] 32 [121] 27 [102] 18 [68] 14 [53] 4.5 A 6 A 3/4” NPT-M 3/4” Barb

1100 GPH [4163 LPH] 44 [166] 35 [132] 28 [106] 21 [79]

12 [45]

4.5 A 6 A 3/4” NPT-M 1-1/8” Barb

*Specifications given at design voltage of 13.6V DC per ABYC recommendations.

Base

LIMITED WARRANTY

SHURflo warrants its Piranha™ series bait pumps to be free of defects in material and workmanship under normal use for a period

of two (2) years from the date of manufacture, as indicated on the pump label. SHURflo is not responsible for problems due to

improper installation or maintenance. Returns are to be shipped prepaid to SHURflo. For complete Limited Warranty details

contact SHURflo.

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo, LLC Headquarters

Mailing Address: 5900 Katella Avenue

Cypress, California 90630

Shipping Address/UPS: 5900 Katella Avenue

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218 Ÿ Fax (562) 795-7564

Cypress, California 90630

911-611 Rev G

© 2008 SHURflo, LLC All Rights Reserved

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218 Ÿ Fax (574) 264-2169

Patent # 6715994 / 5833437

SHURflo, LLC East

52748 Park Six Court

Elkhart, Indiana 46514-5427

Loading...

Loading...