SHURflo 3400-002,3400-006,3400 series Installation Instructions Manual

3400 SERIES ACCUMULATOR TANK

GENNERAL INSTALLATION INSTRUCTIONS

This manual does not address water boost applications. For help, please contact SHURflo.

Read this manual carefully. Failure to follow instructions could cause serious bodily injury and/or property

damage. Do not exceed 100 psi [6.8 bar] on the 3400 series.

WARNING: Hazardous pressure. To prevent possible serious or fatal injury and/or damage to equipment,

system pressure MUST BE LESS THAN 100 pounds per square inch (psi) [6.8 bar] under any

circumstances. Failure to follow instruction can result in tank blowup. If system discharge pressure can

exceed 100 psi [6.8 bar], install a relief valve capable of passing the full pump volume at 100 psi [6.8

bar]. Install relief valve in pump supply line to tank, as close to tank as possible. Consult installer or

licensed plumber for correct relief valve. Install system according to local codes.

The SHURflo Accumulator tank is a bag-type pressure storage vessel and/or a pulsation dampening device.

The accumulator is precharged to 20 psi [1.4 bar] for shipping. Do not exceed this pressure for long-term

storage, shipping or system non-use.

An accumulator placed in the pressurized side of a potable water or reverse osmosis system (with a

demand pump), can minimize pump cycling. The accumulator contributes to longer pump life, less noise,

less amperage draw, and reduced water pulsation. The most efficient use of the accumulator occurs with

the precharge pressure set at the SAME pressure as the pumps' pressure switch "turn ON" setting.

Typically, a 40 psi [2.7 bar] pump will "turn ON" at 20 psi [1.4 bar]. Therefore, the precharge should also be

20 psi [1.4 bar]. The precharge must be set in a "static" condition (pump off and at least one water fixture

opened to atmosphere).

NOTE: If the accumulator precharge exceeds the pump "turn ON" pressure by "a couple of psi," the

volume of pressurized liquid within the accumulator will be reduced.

• The precharge valve stem cap MUST be tight to prevent a leak down of pressure. It is recommended the

precharge be checked on a monthly basis.

• The accumulator may be mounted anywhere in the pressurized cold water side of the plumbing. The port

is non-directional in flow, allowing mounting in any position.

• CAUTION: Do not freeze or mount near a high heat source. Extreme temperatures may lead to tank

explosion and serious injury.

GENERAL INFORMATION

• Keep safety labels in good condition. Replace missing or damaged safety labels.

• When servicing tank, BE SURE the pump (power source) is disconnected. Release all water pressure before

working on tank or system. Release all precharge pressure by depressing the valve core.

• In areas where temperature is high for long periods of time, tank precharge may increase. This may

reduce tank drawdown (amount of stored water at pressure). If this occurs, reduce precharge pressure 2

psi [14kPa] below pump "turn ON" pressure. Cold temperatures may require more air pressure.

TO CHECK TANK AIR CHARGE

If drawdown decreases significantly, check as follows:

1. Shut off electric power to pump, open faucet near tank, and drain completely.

2. At air valve, check precharge with tire gauge. Precharge should be at pump "turn ON" pressure setting.

3. If precharge is more than 2 psi [14kPa] below the "turn ON" pressure, add air to tank. Use air compressor or

portable air storage tank. If precharge is above "turn ON" pressure, bleed off the appropriate amount.

4. Use soap or liquid detergent to check for air leaks around air valve. Continuous bubbling indicates leak.

If necessary, install new core in air valve (same as used for automobile tires).

5. If tank is filled with water (waterlogged), the bladder is leaking. Replace bladder.

911-481 Rev. F 10/04 Page: 1 of 2

MOUNTING

The Two Gallon (7.6ltr) and Six Gallon (22.7ltr) Accumulator Tank can be mounted using four proper length

3/8” (9.5mm) bolts. Be certain there is no excess stress on plumbing connections. All tanks should be

securely mounted to a solid foundation. Pump can be mounted on top of tank or beside it.

OPTIONAL APPLICATIONS

When used as a dampening device/water hammer or noise suppresser, the precharge should be set at the operating

(dynamic) pressure. Place a gauge in the offending plumbing where the accumulator can be mounted. Adjust the valve

so the noise is generated and read the pressure. Set the precharge to the observed pressure, remove the gauge, and

install the accumulator.

For applications requiring an intermittent flow rate at a given pressure, the proper precharge is the minimum pressure

required at the dispense valve. For example, if a system requires a minimum pressure of 30 psi [2.0 bar] (for correct

brix, etc.) the correct precharge should be set at 30 psi [2.0 bar] to permit the most reserve storage capacity. If the

precharge is higher than pump "turn ON", the liquid volume can be significantly less.

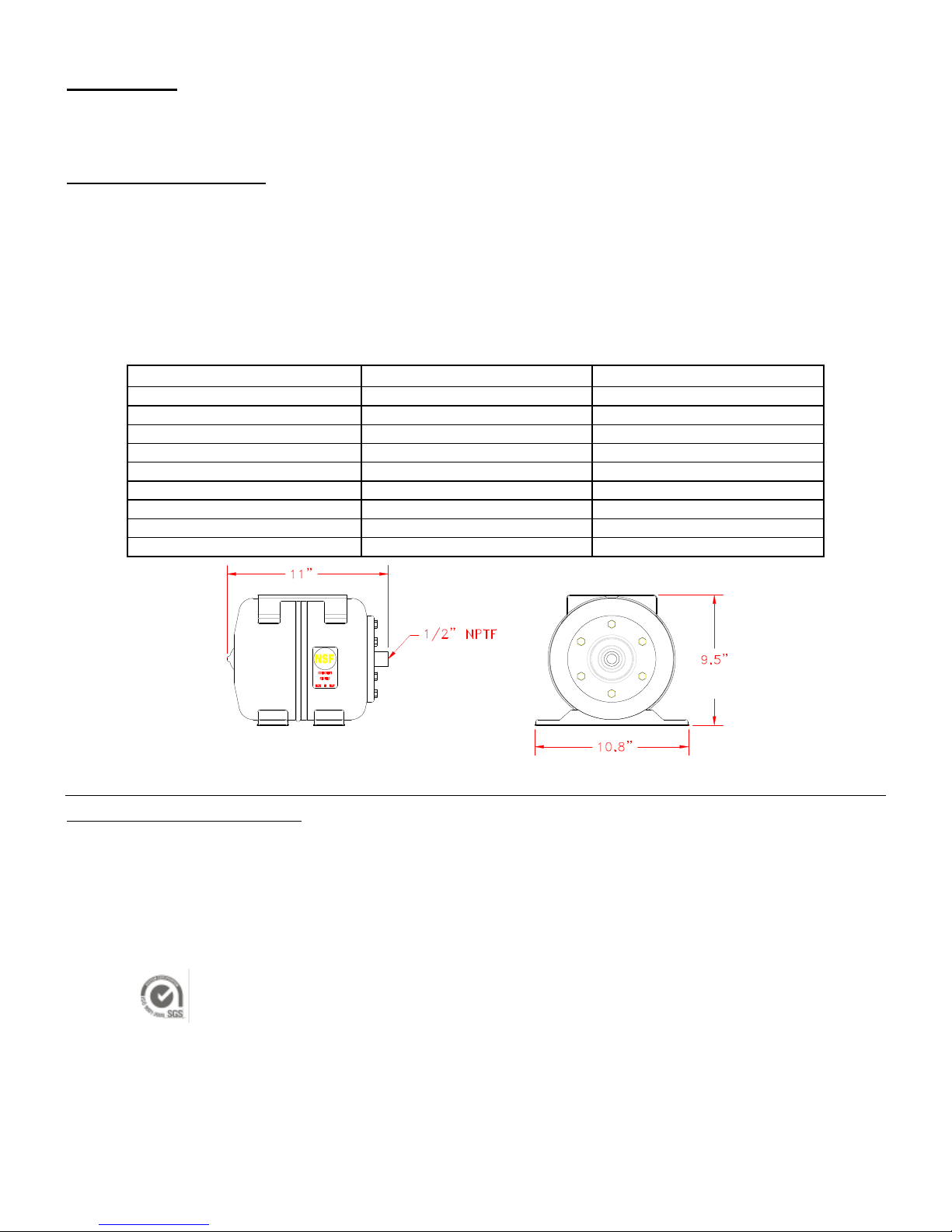

3400-002 SPECIFICATIONS 3400-006 SPECIFICATIONS

Maximum Pressure 100 psi [6.8 bar] - O2 or N2 100 psi [6.8 bar] - O2 or N2

Total Volume (gas/liquid) 2 gal. [7.6 lt] 6 gal. [22.7 lt]

Liquid Volume @ 20 psi charge .7 gal [2.2 lt] 2.2 gal [9.8 lt]

Temperature Range 34-1200 F [1/490C] 34-1200 F [1/490C]

Threaded Port 1/2" FNPT 3/4” MNPT

Tank Material Stainless Steel Stainless Steel

Bladder Material Butyl Butyl

Width 11" [28 cm] 11" [28 cm]

Length 12" [31 cm] 18" [46 cm]

Listing NSF Standard 18 NSF Standard 18

[28cm]

.

[24cm]

[28cm]

Typical Dimensions of 3400-002, 2 Gallon [7.6 Liter]

LIMITED WARRANTY PROCEDURE

SHURflo warrants the accumulator to be free from material and workmanship defects (under normal use and service) for a period of one (1) year from the

date of manufacture or one (1) year use, with proof of purchase, not to exceed two (2) years in any event.

The limited warranty will not apply to accumulators that were improperly installed, misapplied, or are incompatible with components or liquid not manufactured

by SHURflo. Failure due to chemical incompatibility or foreign debris is not covered under the terms of this limited warranty. SHURflo will not warrant any

accumulator that is physically damaged or altered outside the SHURflo factory.

Warranty claims may be resolved by an authorized dealer service center, or by SHURflo. Returns are to be shipped with charges pre-paid. Package all returns

carefully. SHURflo will not be responsible for freight damage incurred during shipping to a service center.

For complete limited warranty information contact SHURflo.

«ISO Certified Facility

SHURflo «

5900A Katella Ave.

Cypress, CA 90630

(562) 795-5200

(800) 854-3218

FAX (562) 795-7564

Shipping: 5900C Katella Ave.

Cypress, CA 90630

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

(574) 262-0478

(800) 762-8094

FAX (574) 264-2169

© 2004 All Rights Reserved

www.shurflo.com

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

911-481 Rev. F 10/04 Page: 1 of 2

Loading...

Loading...