Page 1

V15

l'ype

IV

Stereo Dyneticw

Phono Cartridges

Page 2

the

IV

does more...

The creation ofthe

V15

me N is something of a tour de

force in innovative engineering. The challenge was to

design a cartridge that would transcend all existing

cartridges in musical transparency, technical excellence,

and uniformity. The unprecedented research and design

disciplines that were brought to bear on this challenge over

aperiod of severalyean have resulted

in

an altogether new

pickup system that exceeds previous

performance levels

by a

significant degree - not merely in one parameter, but

in totality. In fact, this pickup system has prevailed

simultaneously over several extremely

difficult music

re-creation problems which, until now, have defied

practical solutions. Most of all, this is an eminently musical

cartridge which is a delight to the critical ear, regardless of

programmaterial, or the rigorous demands of today's most

technically advanced recordings.

Page 3

..An

elegant

solution

to many prevalent problems

The

V15

Type N is a Stabilized, Static-free, Super-Trackability cartridge-stylus

system. The next few pages will explain the following advantages of the

SUPER TRACK

NTY

system:

Demonstrably improved trackability

the record.

across the entire audible spectrum

-

h

effective dust and lint removal

especially in the critical mid- and

system.

high-frequency areas.

A

Hyperelliptical stylus tip

Dynamically stabilized tracking configuration dramatically reduces

overcomes record-warp caused

both harmonic and intermodulation

problems, such as fluctuating tracking

distortion.

force, varying tracking angle and wow.

Ultra-flat response - individually

Electrostatic neutralization of the

tested to meet all specifications.

record surface minimizes three

Reduced dynamic mechanical

separate problems: static discharge;

electrostatic attraction of the cartridge

to the record; and attraction of dust to

impedance

dlows superb

performance at ultra-light tracking

forces.

Contents:

..................................

Trackability

4-5

Warp

.........................

....

..........

..6

...................................................

Static

7

Dust

...................................................

8

Stylus Information

..........

9,

13, 15

Installation

...............................

10-12

Operation

.....................................

13

................

Care and Cleaning 13-14

Specifications and

Dimensions

.........................

14-15

Warranty

.........................................

16

READ

ON

...

Page 4

The new frontiers

of

trackability

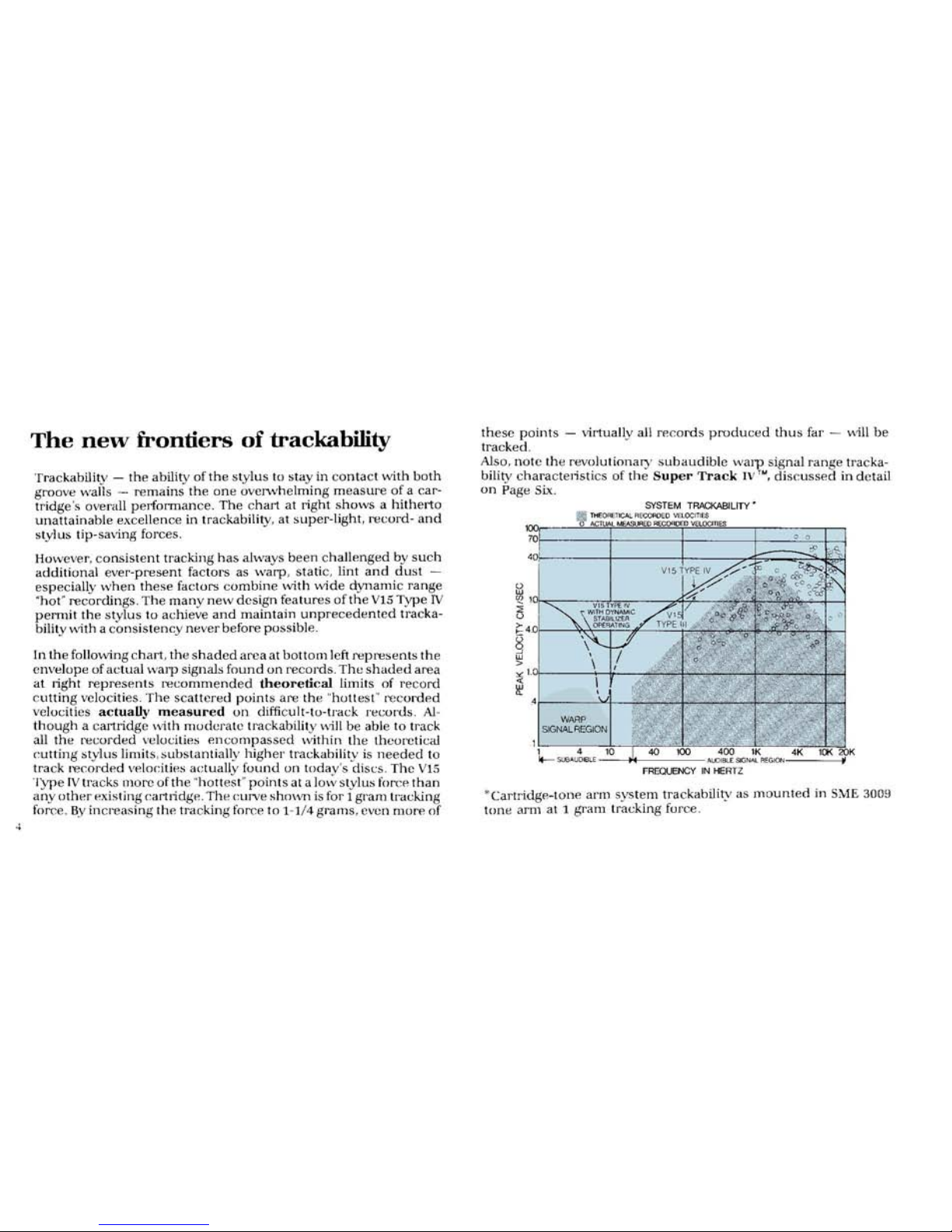

'Trackability - thr abilit>, of the stylus to stay in contact with both

groove

walls - remains the one ove~whelming measure of a car-

tridge's overall

performance. The chart at right shows a hitherto

unattainable excellence in

trackability, at super-light, record- and

stylus

tip-sa~ing forces.

However, consistent

tracking has always been challenged by such

additiunal ever-present factors as warp, static, lint and dust

-

especially when these factors combine with \vide dynamic range

"hot"

~cordings. The many new design features of the

Vl5

Type

N

permit the stylus to achieve and mainta~n unprecedented trackability with a cbnsistency never before possible.

In the following chart, the shaded

areaat bottom left =presents thr

en\~elooe

of actual Ivalv slenals found on records The shadrd area

.

L,

at right reprrsrnts recommended theoretical limits of rrcord

rutting velocities 'The scattered points are the "hottest' rrecordrd

velocities actuaUy measured on d~fficult-to-track records

Al-

though a cartridge nith rnodcratc. trackabllity \\ill be able to track

all the recorded velocities encornpassed

\\ithin the theoretical

rutting stylus limits, substantially higher trackability is needed to

track

~xrordrd vrloritirs actually found on tuday's

discs

The

V15

I>ve

IV

tracks more of the 'I~ottest" points at a lo\\, stylus f~rcp than

any othrr rxisting rart~idgp Thr run,r shonm is for 1 gram tracking

force.

By increasing thr tracking force to

1-1/4

grarns, evcri morr of

4

these polnts - xirtually all r~rords pruduced thus far - will be

tracked

Also, note the revolutionar) subaudible warp signal range trackahility charactelistics of the Super Track

IVTM,

discussrd in detail

on Page

Six.

SYSTEM

TRACKABILITY'

THEORETICAL RECORDED VELOCTES

'Cartndgr-ton? arrn system trarkahllity as rnounted In

SME

3009

tune

am

at 1 gram tracking furce

Page 5

Coping

with

"hot"

recorded

signals

...

The "hot" signal problem

The stylus cannot track the hea\ily modulated signals found on

Inany of the newest records

Its symptoms

The stylus mistracks and produces

dlstort~on and buzzlng sounds. While mistracking can occur at any

frequency. extreme mistracking occurs most at high frequencies.

Extreme

mistracking can ineparably damage the record groove.

The Super

Track

IVTM

total design solution

The

V15

Type

IV

has a

new stylus assembly

designed fnr dramati-

cally increased trackahility as

thr result of two significant im-

provements

A.

The effective stylus mass of the conventional moving system has

hrrn

lotvered hv utilizine

a telescooed shank structure

(No

1

in

figure at lefty and a

&w iightwkight high-energy

magnet

[No.

21

The reduced effective mass of the new structure helps

improve trackability in the critical mid-and

high-hquencies.

B.

Incorporating

a newly designed two-function bearing sys-

tem

(No.

3)

has bypassed prex<ously necessary design compromises. The new bearing system is independently optimized

for low frequencies and for high frequencies so that trackability

is enhanced across the entire audio spectrum.

The

V15

Type N has a

Hyperelliptical nude diamond tip

[No

4)

that results in an elongated tip-groove contact area The ne\v tip

provides as much as a

25%

reduction in distortion over a conven-

tional biradial (elliptical) stylus"

"See graph on Page Nine

Page 6

Our

war on warv...

o

I

HOK CIZR~RI~GF

TURNTABLE

CONSTINT

ONSTANCE-

17,

TURNTABLE

'

THE

V15

'TYPE

N

The warp problem

Suhaudible record warps and low-frequency arm-cartridge

resonance

Interfere \\ith the ability of the stylus to track audio

signals

Its ~ympfoms

Reactions ofthe playback system tovery

low frequency warps (between

0

5

and 8 Hz as shown in the

trackability chart on Page

Four) on the record surface can

result in gross changes in the distance between the cartridge

and the record The distance change

alte~s the stylus tracking

force and th? vertical tracking angle, illustrated in the sketches

above,

rhis can cause groove skipping, cartridge bottoming,

signal wow, and, occasionally, amplifier and/or speaker over-

load

6

Worst of all, trackabllity at

all

frequencies is dimin~shed by

these warp-caused changes in tracking force

At some very low frequency (typically from

5

to

15

Hz), the tone

am,-cartridge

cornbination has a resonance frequency. When

the

am-cartridge resonance frequency coincides with the

warp frequency, all the enumerated symptoms are exaggerated. In addition, there is a sudden, very large increase in

output at resonance.

The Super Track IVTMtotal design solution

A

viscous-damped Dynamic Stabilizer

combines with the

new

stylus assembly

described on Page five to raise the --cartridge

resonance frequency and attenuate the am-cartridge system re-

sonance effect. The following graph shows the output at resonance

with and without the Stabilizer

-

-8%

WITH

DYNAMIC

STABILIZER

Page 7

The Dynamic Stabilizer is viscous-damped to resist sudden

changes in motion, such as those caused by subaudible warp.

Instead, the damping ensures that the tone

arm

will

follow the

irregularities of the record surface, even at the frequency of armcartridge resonance. The original cartridge-to-record distance is

thus maintained, and vertical tracking angle and stylus

tracking

force remain constant! Stabilizing the distance, angle, and force

ensures that the full tracking capability of the cartridge is realized

at all times.

The double-faceted problem of

electrostatic charges

...

The static problem

A. Static electricity on

,,,,,,,,

FIBERS

the record surface at-

IUNO

tracts the cartridge to the

record.

B.

Static electricity on

the record surface is discharged through the

D

-

u

stylus.

RECORD

Its

s~II~P~o~s

A. Static charges on the record are omnipresent and unevenly distributed. Therefore, they attract the

cartridge unevenly and change the

ann-to-record distance, the

vertical

tracking angle, and stylus tracking force. The result is

undesirable wow and flutter.

B.

The static discharge through the stylus and amplifying system

can cause annoying pops and clicks.

The Super Track

IVTM

total design solution

The fibers in the Dynamic Stabilizer that look like an off-center dust

brush are actually electrically conductive. The fibers ride on the

surface of the record, pick up the static electricity and discharge it

to ground, much like a miniature lightning rod*. As a result, the

record surface is electrically neutralized.

Static charges on the record can be caused by contact

with the

record jacket, the turntable mat, or other records.

Duringplay, the

record-contact fibers continuously sweep the inner groove charge

just ahead of the stylus, preparing the groove about to be played.

The static charge is thus prevented

fmm affecting the am-torecord distance, or from causing static noise in the amplifier and

loudspeakers. [Clicks and pops due to other causes may mask

some of the reduction of static noise.) The removal of static charges

stabilizes tracking force during the entire record playing process.

"In

fact, the static

discharge

fcature

will

be

reahonably

rffertive

even when the

Dynamic Stabilizer

is

in the "Up'position and thrfihr~.~

arr

not

in aontactnith

the

record

suiiacc

Page 8

I

Cleaning

up

Dust

...

l

I

The dust problem

DUS~

particles on the surface of the

The ~uper'I'rack1~~~ totaldesign solution

record, or in the recordgmove result in an accumulated "dust ball"

~h, reco~-contact fibem in the vamic Stabilizer are

corn-

on the stylus tip which interferes with pickup of "clean" signals.

onsed

of more than

10,000

ultra-fine strands. Each strand has a

---- ~ --

~-~~~-

~

diameter of approxi&ateli

7.6

microns

1.0003

in.). These strands

Its sp toms

Faulty tracking, distorted signals, .%move

fit down into the groove, removing interfering dust and sweeping

jumping, anyultimate record damage can he caused when the

the record clean. And, dust is not ground into the gmove walls.

stvlus

collects the dust instead of tracking the record signals.

pkicles that accumulate and foul the tip accurate iracking and can cause loss of contact with the record surface, with

resulting gross distortion.

Impact

Protection...

7

The impact problem

When the arm is accidentally

The Super Track 1VM fofal design solution

dmpped onihe recokl, the delicate stylus assembly is subjected to

-

the full shock

at

contact,

Because

the stylus

is

it

can

In its mrmal operating position, the Dynamic Stabilizer is a

bounce

across

the record and

create

several

points

of

gmove

shock absorber which cushions the impact hom an accidental

arm drop. The Dynamic Stabilizer takes the force of the blow, and

aamage.

eliminates further bouncing of the stylus

Its sppt0ms

The stylus may be permanently damaged,

even inoperative. The record is

permanently impressed with sev-

eral audible "pop" points.

Page 9

The

Hyperelliptical

Stylus

tip

BIRADLAL IELLIPTlCALl STYLUS

HYPERELLIPTICAL

STYLUS

SUCH AS

IN

V15

TYPE

I11

OF THE

V15

TYPE

IV

The Hyperelliptical nude diamond tip

configuration of the

V15

Type Nrepresents a

significant advance in tip design for stereo

sound reproduction. As the above figures

show, its "footprint" (represented by black

oval1 is longer and narrower than the traditional Biradial

IElliptical) tip-gmove contact

area. Because the Hyperelliptical footprint

geometry is narrower than both the

Biradial

and long-contact shapes such as the Hyperbolic,it

is

preeminent forreproduction ofthe

Stereo-cut groove. In fact,

as

a result of the

optimized contact area of the

Hyperelliptical

tip, both harmonic distortion !white bars in

graph at

right) and intermodulation distor-

tion

(black bars1 are dramatically reduced.

2nd

harmonlc dlstortbon

Average both channels.

8

kHz. 5 cmisec peak recorded veloclty

Intermodulation distortton

Average both channels, 3 kHzil.5 kHz

4.0% 4.0%

2.4%

2.596

HERICAL

b

BOLlC BlRADlAL HYPERELLIPTICA

HARMONIC AND INTERMODULATION

DISTORTION FOR VARIOUS TIP SHAPES

Page 10

Step

1:

stylus removal and replacement

don't slip and damage the stylus tip

a>

shank

Step

2:

electrical connections

This cartridge has four temlnals wlth a separate ground terminal for each channel.

For

stereo, termma1

"L

and its gmund terminal

'LG"

represent the left channel [inside

groove wall1 Terminal

"R'

and its ground temlnal

'KG"

mpresent the right channrl

loutslde groove wall1

10

Connect the cartridge

as

show in the illustration below Note that,

in many tone arms, lead

wiring is color coded and rnatches thls

cartridge's color coded terminals

LEFT CHANNEL

WHITE

RIGHT CHANNEL

RED

LEFT CHANNEL

GROUND

BLUE

RIGHT CHANNEL

GROUND

GREEN

u

-GROUND TAB

Step

3:

mounting the cartridge

The cartridge has

12.7

mm

ill2

in I mountlng centen Mounting

hardware

1s

prumdrd,

iRef~r

to the tone

arm

manual

for

h~rth~r

spec~fir

details. such

as

the nerd for spacers

1

Page 11

DO VOI KLPL4CI. THF bYII.1'5 l'YlIl. LLLC IRIC \L (01\tC.TIO\S )\Kt \1-\DL .AYD

THF. \IOU\TISG IS (O\I~

PIELLU

Thr liio llnslc

mounting

mrth<~d\

di.~

1

\lountin;:

thp cartrldgr

In

a

lilrir

.rrn

she41 that has

un-

lhrcaded clcnrancc hulrs

e

\luunt,ng thc cnrtndge

tn

n

tun? arm

hrll (hit

h.th

lh~radcd niountln;: lholrs

L-sc

thr

thin

phallr

rrtalncrpru~ydrd

In

thp hardi\a~r

p.ic

klii

t,,,th

mrthr~d\

Ihr Iretalnci. holds the

screiis

phi

F

vlthcr-

mi

thc shell

mrthr~d

11

ur

on

thc cn~.tndgr

tmrthid

21

IklPORT~ST:

I\hcn

usng

mcthod

I

mounting

In

d

ihrll that has

unthr.r.tdrd

rlvarance holcsl splett

thp

CORRLC? SCR6\.\' LbhGTH IKCORRECT SCRL\\ LLXGill

MbTHOD

1

OF MOUKTING THE

CARTRIIJGE IS SHOb\'II BELObV

.

~

,-

,-:_____SpaCCRS

..

.

(IF

NECESSARY)

METHOD Z OF XfOI!.UIING THk.

CARTRIDGE 15 SHOWN BELOW

THREADED HOLES

iN

<AmNE

CASTiC RETAINER

PUSHONTOSCREWS

!-"

,*-,

uz,SPACBS

.

.i

IF NECESSARY

scniws THREAD

INTO

TONE

ARM

SHELL

Page 12

Step

4:

setling the tracking

and

antiskating force

DYNAMIC STABILIZER

To

notatrl

this

~orve

POSITIOKS

at

the

stylus tip

0

75

grams

1

'"UP

2

DYNAMIC STABILIZER

1

25

grains 175

grams

"OPERATING

\\hen

ualrig

an

cxtrrnnl gauge

wrh

as

thr Shurt,

bFG-2

Snlus

For?

Ldug,~

for

3

"GUARD

settmg

trarlang

fu1.c~

loch the D\n.%m~ Stdhll~~~r

in

lliv

up

positioll and

set

thr trn~hnp

torrr

as

iholtn

tor

th~

nnli

aho\r

I\hrn

Ihr Ll>~r.tiir~c Stnbllizcr

CONDUCTIVE

rlries

on

thc

~rccurrl

x\~th

111r < art~nclge In

iisc

the r\tr.~

O

5

gram, 1,111

tx

i>ff-,rt

I,?

tho Dyna~rilc Stalillirrr

.+nd

\iILL

\Or

IPPE.iR

-\TTHF

STl'l.l-b TIP

I'hr

tip

f<,~.rt,

ii~ll

hr

that sho\\n

In

thc firit roli~lllrl

I

with the

dynamic

stabilizer

up...

Rcplncc thc st>lus

In

the cartridge

sec

Stcp

11

TRACKI\(; FORCE

u<th the

dynamic stabilizer opcratin

g...

I

his c nrtndge

1..

rlc,\igned

ior

.i

\t>lus tlp 11.arhlrig

ir>ri.i,

rang?

ot

0

75 to

12.5

giarna

\\hen

thr ~~siui~s-d.~mpc~rl Ih~l~irrllr Strilnilw~

IS

171

tllc OPCI-atlng

posltlon

~PP

lllubli ittl~ri

.li~~\.vi

~t

~\i~t\

ii

tor??

011

the

wvordc~f

0

i

grrirn\

that

must .~lw I,? dr.r.r,mm<,<l.+lt.~il

In

thc tutnl tunr

a1.111

tl.ii.king fmir wttilig

Tllor.rlo~r

uat,

thr tollrli$illg Srttlllgs

SOTE

Do not

rxrr~d

the maximum trarkingforcrs of

1

75

grams iihrn

the cart~idgr

15

used

\\it11 the Dynamic Stabilizer

In

thc 'operating'

rlosltlon,

or

125

ararns

\\hen

usrd

\\~th lhr

U\n.imlc

Stnixlurr

in

th

4STISK\II\CI

TOKC5

Srt thi, ni~l~rkati ~nrr.l~;in~s~i~ .~rvol.dlngtu

ttlv

trillr

.I!

111

~rl.~nuf.ii

11111.1 s ill~i~

tii~ns

Cac

,in

.~ntl\k.!tlng

1rlr.r.r

rorrrspcrn~li~,;: lil tlir lol.11 toni.

.ir.!n

irarhlng

iul~

r

aptling

tCul~ltirli

2

irl

hart .ilru!i,

I

Page 13

Step

5:

operation

Beforr

playng thr fir51

rccurd.

ral.cfully plncp thr, pnam~c

Stabil~zrr

In

the opcl.atlilg'positian

50

that 11 floats helon thc

\&z,d/,"w

cmmplrl ,Uthr~ugh this cartildge i\,ll track

records

at a at\lus

t~p f<,rr~ of

0

75

grams, it

ma,"

he

dcsirablr.

In

som-

toiir

arrrla

'-

CUE

STRIPE

la

lilcrraac,

thr tracking

f0n.r

for

optinrum tresults

NOTE See further instructions under Cleanlng

1

NOTE ON COL1P~%,,21RlLITY \\'ITH V4RIOL'S

RECORD FOKXWTS

Step

6:

cleaning

CLEANING THE DYNhVIC STABILIZER

Use the supplied brush

"d~y".

Use

no

fluids.

Carefully clean

the dust out of the fibers

using a hack to front movement.

Brush the fibers long

enough70 remove the fine

particles

between the fibers as well as anv mat of lint on the surface.

Take care not to catch the

sty1us"shank or tip when clean~ng

the Dynamic Stahll~zer brush.

CLEANING THE STYLUS TIP

Use the

supplled brush Alwa s brush the stylus fmm back

to front; never brush

orwipe tiestylus from front to back, or

side to side. An alcohol

or

alcohol-distilled

water solution

can he used as

a

cleanin agent. Commercial cleaning so-

lutions may cause stylus

damage or corrosion.

NOTE.

Afler

installat~un

lor

a

prnlonged period

of

not

hav-

mg been usedl, make certain that no

foreign

matter

has

lodged between the cartridge body

and

the Dynamic

Stabilizer,

immoblllzlng 11 A simple method is to move the

Stabillrer carefully

from

"up" to

"guard"

several times This

Mill

ensure proper performance

Also

check the stylus tip

to make

cenaln that no foreign matter has accumulated If

it

has, follow the recommended htylus tip cleaning

method

Forbrst

prrfurmanrr,

rlean

bc>th thc st>lu\ tqi and thc fillr15

,if

Ill? Dynamic Stdt,illzcr rrgulnrly

Page 14

Shure

V15

me

IV

Dimens~ons

FRONT

ClOCV

presemg stylus life

1.

R~ilow turntable

or

tone arm instructions when adiusting

ant~skating

force in the suspension system of the tone arrn

2.

Do not handle the tone arm while it is In vperatlon since

thls may cause the arm to sbveep

across

the record.

3

If

11 is necessary to manually place the tone

arm

in the

record groove while turntable is rotating, release it as the

wnamic Stabilizer sets do- on the

record

or

as the stylus

pngages the record gmove

4.

Correct improper set-down adjustment or malfunction

of

the turntable changing mechanism to prevent the stvlus from

strik~ng

the

edge

of the turntable

or

cord

Do

not

siack

mom

records than turntable manufacturer recommends

5.

Take

care

to properly insert the stylus into the

cartridge

assembly and the cartridge and shell asssmhiy into the tone

arm

receptacle

6

Use

pmper vertical tracklng force setting A>r.rach cartr~dge

7

Do

not

use

damaged records

8.

When dusting th; turntable protect the stylus wlth the

Dynamic Stabdizer locked in thp guard position

Page 15

Shure

V15

l3q~

IV

and

V15

IV-G

I

Specifications

.

I

-

TYPICAL FREQUENCY RESPONSE ENVELOPE

I

pn

UI

5

-lo

n"

rmo

FRECGWX

IN

HERTZ

Frequency Response:

10 to 25,000

Hz

Typical Trackability

im

SME

Tone

Arm

at 1 gram tip tracklng

force,

in

cm/sec peak recorded velocity].

400 Hz

-

29

rmlser

Output Voltage

la1 1,000

Hz,

5 cm/sec peak recorded v~lo~ltyl: 4.0 mV per

channel

Channel Balance:

Within 2 dB

Channel Separation

lmin~mum!

25

dB

at 1,000

Hz,

15 dB at 10,000

Hz

Optimum Load:

47,000 ohms reslstancr in parallel with 200 to 300

picofarads capacitance per

channel

Load

resistance can be up to 70,000

ohms with almost no audible changp ~n frequency response Total capacitance includes both the

tone

ann

wiring and amplifier input circuit [Mast

amplifiers, tone arms and cables meet this requirement

!

Inductance:

500 m~llihennes

DC Resistance:

1380 ohms

Tracking Force:

Force at the Total tone arm setting with

stylus tip Dynamic Stabilizer "operating

Minimum 0 75 grams 125 grams

10 gram 15 grams

Maximum 1.25 grams 175 grams

Force Exerted by Dynamic Stabilizer:

0.5 grams

Output Terminals:

4

terminals

Mounting:

12.7 mm istandard 1/2 in ! mounting centers

Net

Weight:

6.4 grams

Vl5

Type

IV

Styli Available:

VN45HE Hyperellipt~cal Nude Diamond Tip, Black Grip, Black Name-

plate

VN4G

Spherical Nude Diamond Tip, 15 micmns i 0006 1n.1 radius,

Black Grip, Gray Nameplate

isupplied

In

V15 IV-G Cartridg~l.

VN478E

Biradial iEUlptical1 Nude Diamond Tip. For monophonic

78

rpm records. Tip Tracking Force Range: 0.75 to

1.25

grams. 13 x 63 microns 1.0005 in x 0025 in I.

15

Page 16

Fun

One

Year

Warranty

(-

Shure Brothers Incorporated i"Shure'i.221 Hartreyhenue

Ebanaton, lllinols

60204, warrants to the

owner

of this pro

duct that it

will be

free,

in normal use. of any defects ir.

workman\hip and materials for a period of onc year fmm

date of purchase You should retain proof af date of pur-

r-=

chase

Shure is not liable for any consequential damages

If

!=,

this Shure pmduct has any defects

as

described above.

p3

carefully repack the unit and =turn it prepaid to:

Shure Brothers Incorporated

Attrntion: SCMCB Department

1501 \Vest Shure Driw

Arlington Heights. Illinols

60004

Ifpu

are

not ~n th~ United Stat-, return the unit to your

dralcr

or

AuthurBpd

Senice

Center. for repair The unit \\ill

Quality

Assurance Certificate

Shure

V15

IV

Cartridges

The V15

Type

IV Stereo Dynetica Cartridge has been manufactured under the

Shure Master Quality Control

Pmgrarn. This pmgram embraces stringent

safeeuards and standards to assure you that your Vl5

'Wpe

N

is in perfect

.

.

operating condition.

Shure

qualitycontrol not only covers lncomingparts andthefinishedproducts,

but intermediate

subasjemblies as well. For example: every individual

car-

tndge body and every stylus-magnet assembly is tested and microscopically

examlned Each finished cartridge is indiidually sublected to exactinglistening tests, and tested electrically and mechanically against close tolerance

performance specifications seldom

achieved

in the High ndelity Industry.

r

SPECIAL

NmE

To

maintain the original petiomance standards of

"our

cartridge, be certain that any replacement stylus you bu beam

I

The follu\>inl certifiratlon an the

~ackag?:

'"This

Stereo Dweticiso/lus

PATENT NOTICE: Cartridge and stylus manufactured under one or

moreof the follow~ng U.S. Patents 3,055,988, 3,077,521,3,077,522,

16

3,463,889, and 4,194,744. Other patents pending.

is

precisionmanufactured

by

&re ~Fothen Inc:

AVOID

INFE~OR

IbfITATIONS THEY

M'lLL

SERIOUSLY DEGMDL THE PERFORMANCE

OF

YOUR

CARTRIDGE

ALL

GENUISE

''DWETIC"~'

STYLI

ARE

MAN-

UFACTURED BY SHURE BROTHERS INC

'

""Y

PC>"

TUF

MAMF

SHT'RF

L

ON

THE STYLlJS GRIP

Copyright 1980

SHURE

BROTHERS INC.

222 Hartrey Avenue, Evanston, Illinois 60204

27A1303 (TI) Printed in U.S.A.

Loading...

Loading...