Price

$1

0.00

700

AND

706

SERIES

SERVICE

MANUAL

Manufactured by

SHURE

BROTHERS

INC.

222

Hartrey Avenue

Evanston, Illinois

60204

U.S.A.

Copyright

1981,

Shure Brothers Inc.

AL663 (Al) 27A8027

Printed in

U.S.A.

SPECIFICATIONS*

Type

................

.Solid-state power console using

discrete components and integrated circuits

Inputs

...............

.Six input channels (high andlor

balanced low impedance), plus

two aux input channels (7

and

8)

lnput Channel Controls. VOLUME, INPUT ATTENUATOR,

A/B PAN

(700), LOW and HlGH

FREQUENCY EQUALIZATION,

EFFECTSIREVERB, MONITOR

Aux Channel Controls.

.

.VOLUME, A/B PAN (700)

Master Controls.

......

.MASTER, EFFECTS SEND, RE-

VERB LOW and HlGH EQUAL-

IZATION, REVERB RETURN,

MONITOR MASTER

Outputs

.............

.SPEAKER, MONITOR, EQ OUT,

MIX OUT, EFFECTS, HEADPHONES, AUX, MIC

Common Mix Buses

...

.MIX OUTPUT, EQ OUTPUT (A, B

in 700)

Reverb and Effects

.....

Built-in reverberation unit; provi-

sions for connection to remote

reverb on-off switch and external effects devices

Graphic Equalizers.

...

.lo-band, fully combining, mini-

mum-phase, octave type, normally connected to power amplifier input; 13 dB boost or cut

at 63, 125, 250, 500 Hz,

1, 2, 4,

8 and 16 kHz; BELOW 63 Hz 12

dB/octave cutoff filter (10 dB

down at 31 Hz)

LED Status Indicators.

..

INPUT CLIP, DB PEAKIfeedback

frequency, PA OVERLOAD,

POWER, TEMP WARNING,

SHUTDOWN

706;

700

with

700

with

both channels one channel

Power Output

driven driven

Per channel/4 ohms 200W min. 240W typical

Per

channel/8 ohms 125W min. 145W typical

Measured at 1 kHz, 120

Vac, 1 % THD

Distortion

...........

.THD typically less than 0.1% at

40 Hz and

1

kHz, 0.25% at 15

kHz;

IM distortion typically

less than 0.25% [One channel

driven, 180W or less to

4

ohms,

110W or less to 8 ohms, measured from low-impedance input with individual and master

controls at typical settings

(orange index marks)]

Low- and

High-

Frequency lnput

........

Equalization

?

13 dB at 100 Hz and 10 kHz

lnput Clipping

.........

Indicators

.Light

3

dB below input or equal-

izer clipping level

...

DB Peak Indicators.. Indicate power amplifier peak

voltage;

+6 dB LED indicates

100 watts sine-wave output to

4-ohm load. Rise time: 250

@ec

to full-scale indication; fall

time: 65 msec from full-scale to

no indication

PA Overload

.........

Indicators

.Light when power amplifier THD

exceeds 1

%

;

fully on at

5%

Temperature Warning

..........

Indicator .Lights when output transistor

temperature exceeds 70°C

(158°F)

Shutdown Indicator

....

Lights when power amplifier shut-

down occurs due to output

transistor temperature over

100°C

(212"F), air flow or fan

failure, or dc at speaker output

lnput Sensitivity

...

(full power output).

BAL LO

IMP

0.6 mV

HI

IMP

8

mV

AUX

21

5

mV (700)

106

mV (706)

EQ

INPUT

960 mV

PA INPUT

960 mV

SPECIFICATIONS*

(continued)

...

Input Clipping Level.

BAL LO IMP 700 mV to 21 mV

(INPUT ATTEN

-30 to 0)

HI IMP 10V to 335 mV (INPUT

ATTEN -30 to 0)

AUX 30V to 10V (VOLUME

from

0 to 10)

Voltage Gain

.........

.94 dB BAL LO IMP INPUT to

SPEAKER OUTPUTS

71 dB HI IMP INPUT to SPEAKER

OUTPUTS

43 dB AUX INPUT to SPEAKER

OUTPUTS (700; 706: 49 dB)

64 dB BAL LO IMP INPUT to MIX

OUTPUT

77 dB BAL LO IMP INPUT to

MONITOR OUTPUT

74 dB BAL LO IMP INPUT to

EFFECTS OUTPUT

16 dB BAL LO IMP INPUT to MIC

OUTPUT

58 dB BAL LO IMP INPUT to AUX

OUTPUT

81 dB BAL LO IMP INPUT to

HEADPHONE OUTPUT

0 dB EQ INPUT to EQ OUTPUT

30 dB PA INPUT to SPEAKER

OUTPUTS

Levels and Impedances

Nominal Maximum Actual Working

Circuit Level Level Impedance Impedance

BAL LO IMP INPUT 5 mV 700 mV lk 19-300 ohms

HI IMP INPUT 50

mV 10V 145k lOOk or less

AUX INPUT

0.5V 30V 50k 10k or less

MIX OUTPUT

1V 9V 2.4k 2k or more

EFFECTS OUTPUT

1V 9V 2.4k 2k or more

MONITOROUTPUT 1V 9V 2.4k 2k or more

EQ

INPUT 1V 1OV 50k 10k or less

EQ OUTPUT

1V 9V 2.4k 2k or more

AUX OUTPUT

1V 9V 5k 2k or more

MIC OUTPUT 5

mV 75 mV 70 ohms 19-300 ohms

PA INPUT

1V 1OV 50k 10k or less

SPEAKER OUTPUT

-

28.3V

-

4 ohms or more

HEADPHONES

-

1 OV 360 ohms 4 ohms or more

...

Frequency Response 22 dB, 40 to 20,000 Hz, BAL LO

IMP INPUT

to SPEAKER OUT-

PUTS

Hum and Noise

....

(20 Hz to 20 kHz).

-127

dBV equivalent input (BAL

LO IMP)

Noise

...

(300 Hz to 20 kHz).

-128

dBV equivalent input (BAL

LO IMP)

..

Signal-to-Noise Ratio .Greater than 80 dB (below full

output) at

typical control settings (orange marks, MASTER

at 5, INPUT

ATTEN at -12)

Mic

lnput Simplex

............

Power

.24 Vdc open-circuit,

1.8k series

resistance,

simplex onloff

switch

..

Power Requirements .Models 700 and 706: 120 Vac

f

lo%, 50160 Hz; 1100W (700),

600W (706) max. (Can be rewired for other

voltages; see

OPERATION AT OTHER VOLT-

AGES);

Models 700E6 and

706E6: 100, 120, 140, 200, 220

and 240

volts, 50160

Hz

(switch-

selectable).

Environmental

Conditions

Operating

.........

.-7" to 43°C (20" to 110°F)

Storage

...........

.-40" to 74°C (-40" to 165°F)

Overall Dimensions.

...

.l9O mm H x 584 mm W x 508 mm

D (7% in. x 23 in. x 20 in.)

Weight

..............

.700: 21.3 kg (47 Ib)

706: 17.9 kg

(39% Ib)

Construction

.........

.Molded construction with black

finish, carrying

handle, molded

rubber feet, line cord storage

Certifications

........

.Listed by Underwriters' Labora-

tories, Inc.; listed by Canadian

Standards Association as Certified (700, 706)

*Measurement Conditions (unless otherwise specified): All volume and gain

controls for measured channel at maximum; unused channel controls at

0;

equalization controls at 0. Measured input terminated as follows (unused

inputs unterminated): BAL

LO

IMP, 150 ohms; HI IMP, 33k; AUX. EQ and PA.

4.7k. All outputs terminated as follows: all high-level outputs. 47k; MIC,

150 ohms; SPEAKER,

4

ohms: HEADPHONES, 200 ohms.

TABLE OF CONTENTS

Section

Page

SPECIFICATIONS

...............................

ii

DESCRIPTION

..................................

vii

MAINTENANCE

.................................

1

TROUBLESHOOTING

............................

1

CIRCUIT OPERATION

............................

2

PA Overload LED Indicators

.....................

2

DB PeakIFeedback FinderTM LEDS

...............

3

Feedback Finder

..............................

3

...............

Power Amplifier Protection Circuits

3

SERVICE INSTRUCTIONS

........................

4

Replacement Parts

.............................

4

FuseReplacement

.............................

4

External Parts

.................................

4

Service Access

...............................

4

Reverb Pan Assembly

..........................

6

Printed Circuit Boards

..........................

6

DC Output Balance Adjustment

.................

7

DC Bias Current Adjustment

....................

7

DB Peak IndicatorsIFeedback Finder Frequency

Calibration

.................................

7

Full Wave Balance

.........................

7

DB Peak LED Calibration

...................

8

Feedback Finder Calibration

................

8

Small Signal and Driver Transistors and

Integrated Circuits

...........................

8

Driver Transistors

.............................

8

Output Transistors

.............................

8

Diode Bridge Rectifier

..........................

8

Transistor and Diode Removal

...................

8

Active Component Checking

....................

8

Printed Circuit Board Connectors

................

9

Ferrite Bead Rings

.............................

9

SERVICE ILLUSTRATIONS

.......................

9

OPTIONAL ACCESSORIES

.......................

9

...................................

GUARANTEE

9

SHIPPING INSTRUCTIONS

.......................

9

OPERATION AT OTHER VOLTAGES

...............

10

REPLACEMENT PARTS

LIST

.....................

11

NOTES TO SERVICE ILLUSTRATIONS

............

17

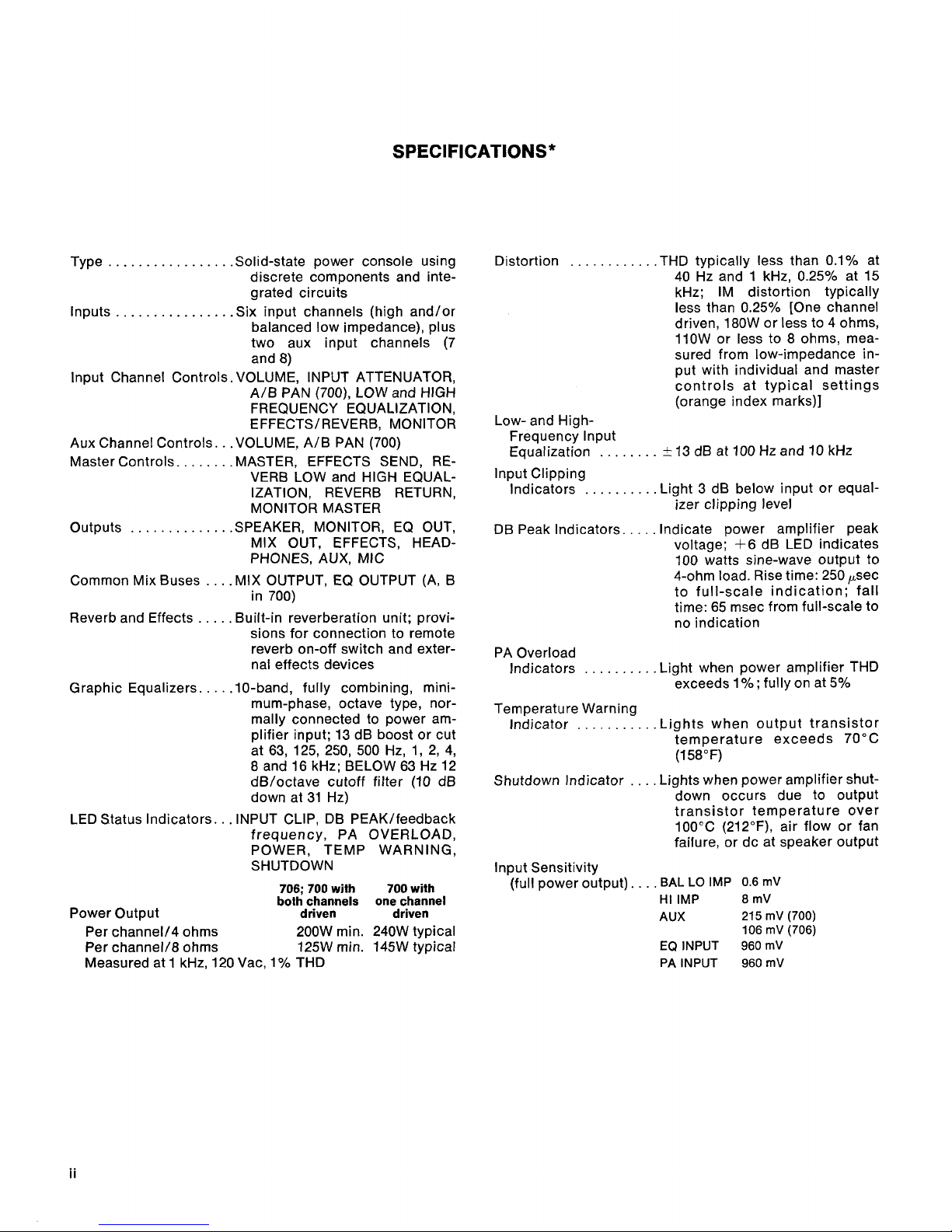

Model 700

DESCRIPTION

Model 706

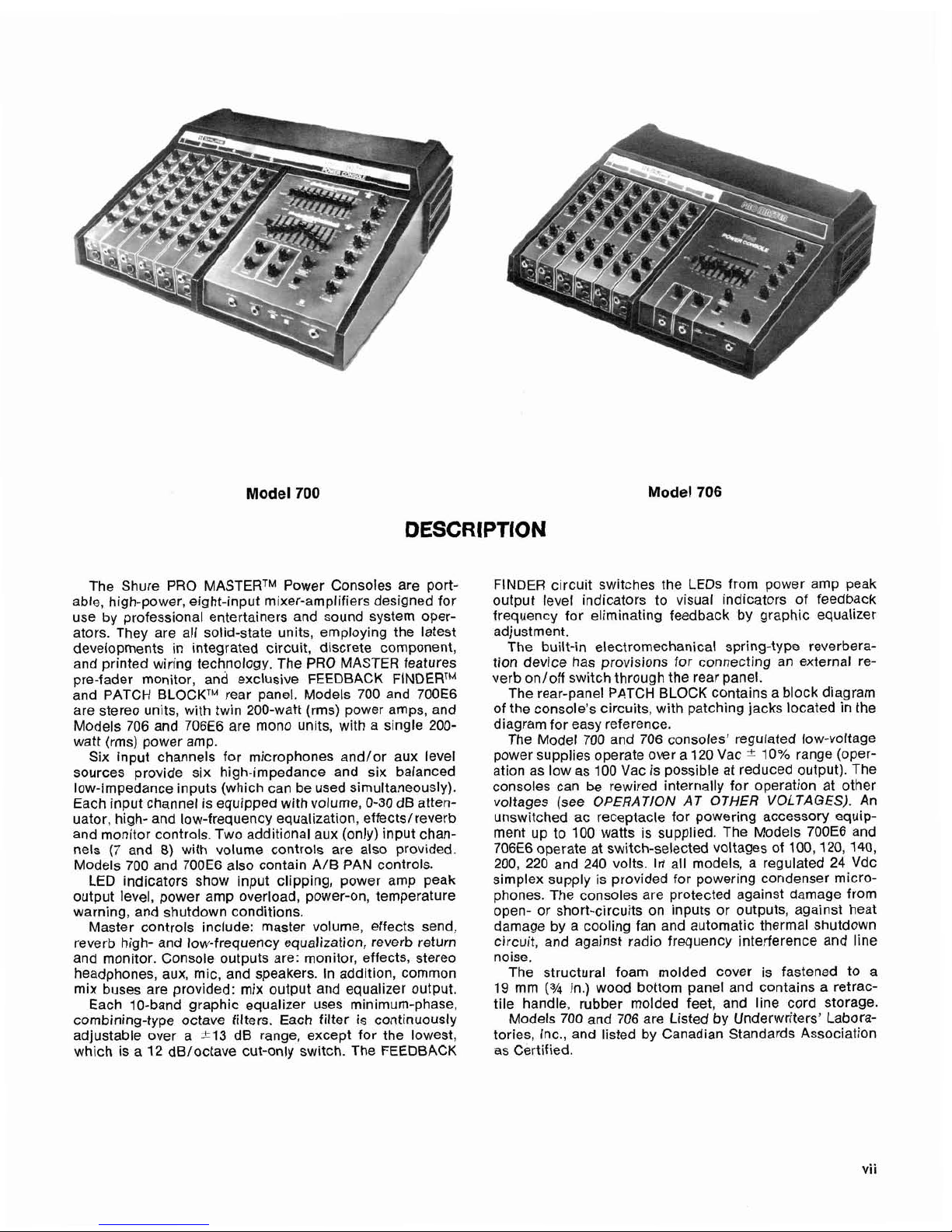

The Shure PRO MASTERTM Power Consoles are portable, high-power, eight-input mixer-amplifiers designed for

use by professional entertainers and sound system operators. They are all solid-state units, employing the latest

developments in integrated circuit, discrete component,

and printed wiring technology. The PRO MASTER features

pre-fader monitor, and exclusive FEEDBACK

FINDERTM

and PATCH BLOCKTM rear panel. Models 700 and 700E6

are stereo units, with twin

200-watt

(rms) power amps, and

Models 706 and

706E6 are mono units, with a single 200-

watt (rms) power amp.

Six input channels for microphones

andlor aux level

sources provide six high-impedance and six balanced

low-impedance inputs (which can be used simultaneously).

Each input channel is equipped with volume, 0-30 dB

attenuator, high- and low-frequency equalization, effectdreverb

and monitor controls. Two additional aux (only) input channels (7 and

8)

with volume controls are also provided.

Models 700 and

700E6 also contain AIB PAN controls.

LED indicators show input clipping, power amp peak

output level, power amp overload, power-on, temperature

warning, and shutdown conditions.

Master controls include: master volume, effects send,

reverb high- and low-frequency equalization, reverb return

and monitor. Console outputs are: monitor, effects, stereo

headphones, aux, mic, and speakers. In addition, common

mix buses are provided: mix output and equalizer output.

Each

10-band graphic equalizer uses minimum-phase,

combining-type octave filters. Each filter is continuously

adjustable over a

213 dB range, except for the lowest,

which is a 12

dB1octave cut-only switch. The FEEDBACK

FINDER circuit switches the

LEDs from power amp peak

output level indicators to visual indicators of feedback

frequency for eliminating feedback by graphic equalizer

adjustment.

The built-in electromechanical spring-type reverberation device has provisions for connecting an external reverb onloff switch through the rear panel.

The rear-panel PATCH BLOCK contains a block diagram

of the console's circuits, with patching jacks located in the

diagram for easy reference.

The Model 700 and 706 consoles' regulated low-voltage

power supplies operate over a 120

Vac * 10% range (oper-

ation as low as 100

Vac is possible at reduced output). The

consoles can be rewired internally for operation at other

voltages (see

OPERATION AT OTHER VOLTAGES).

An

unswitched ac receptacle for powering accessory equipment up to 100 watts is supplied. The Models

700E6 and

706E6 operate at switch-selected voltages of 100, 120, 140,

200, 220 and 240 volts.

Irf all models, a regulated 24 Vdc

simplex supply is provided for powering condenser micro-

phones. The consoles are protected against damage from

open- or short-circuits on inputs or outputs, against heat

damage by a cooling fan and automatic thermal shutdown

circuit, and against radio frequency interference and line

noise.

The structural foam molded cover is fastened to a

19 mm

(%

in.) wood bottom panel and contains a retrac-

tile handle, rubber molded feet, and line cord storage.

Models 700 and 706 are Listed by Underwriters' Laboratories, Inc., and listed by Canadian Standards Association

as Certified.

MAINTENANCE

The PRO MASTERTM is an exceptionally well-designed

unit. All components are of the highest quality, operating

well within their respective ratings to assure long life. The

following list of Do's and Don'ts describes minimal operat-

ing precautions and maintenance to provide years of dependable service.

DO clean the air filter every 100 hours of operation (more

frequently in dusty or dirty areas). Stand the console on

its rear bumpers, remove the screw securing the filter,

and slide it out of its slot. Rinse the filter in water or a

mild detergent solution, allow to dry, and replace.

DO unplug the console before cleaning. DO clean the

outer surfaces of the console with a clean, damp cloth

and mild detergent. DON'T use strong solvents or cleaning fluids.

DO use a l6AWG or larger (700, 700E6; 18 AWG for 706

or

706E6) heavy-duty extension cord when additional

line cord length is needed.

DON'T operate the console with air louvers blocked, or

placed on a radiator or heat-producing equipment. Avoid

operation in direct, hot sunlight.

DON'T replace the rear-panel fuse with a different size

or type. Use only

IOA, 250V (for Model 700, or 700E6

when operated at 100, 120 or 140 volts), or 5A, 250V,

slow blow (for Model 700E6 when operated at 200, 220

or 240 volts. For Model 706, use a 4A, 250V SLOW BLOW

fuse. For Model

706E6, use a 5A, 250V fuse when oper-

ated at 100, 120 or 140 volts, or a

3.15A, 250V SLOW

BLOW fuse when operated at 200, 220 or 240 volts.

DON'T connect the A and B speaker outputs together

(700 or

700E6). (See Instruction Manual for monophonic

setups.)

DON'T risk fire or shock hazard by operating the console

in rain.

DON'T use UNbalanced low-impedance microphones

with the SIMPLEX 24V switch on; turn off the switch

if not required for powering condenser microphones.

If simplex power is in use, connect unbalanced

low-

impedance microphones through a line matching trans-

former (Shure

A95FP) to a HI IMP INPUT.

TROUBLESHOOTING

Should any difficulty be encountered in console opera-

tion, the problem can often be traced to some simple

source such as an error in interconnection. The following

is offered as a basic guide to this type of problem.

PROBABLE CAUSE

SYMPTOM OR CORRECTION

1

Console appears to

be overheating (TEMP

WARNING LED on)

Console power

amplifiers turn off

and remain off

LED

On)

No signal at speaker

(all console functions

appear normal)

Console fuse blown

One of two inputs

on same channel not

working properly (both

%-inch and 3-pin

jacks in use)

INPUT

CLIP LED

flashing

PA OVERLOAD LED

flashes while DB PEAK

read

less

than

+6

1. Check air louvers for blockage

of proper air flow.

2. Check for proper speaker load

or shorted speaker cable.

3. Check air filter and clean if

necessary.

1. Check for proper air flow (fan

remains on during shutdown).

2. Check for hot air from left

louvers; console may have

overheated (see above). Wait

one minute to allow proper

cooling.

3. Turn console off for a few seconds and turn back on.

4. If shutdown persists, have console checked by qualified service personnel.

1. Check for defective or

improp-

erly connected speaker cables.

2. Check for improper

connec-

tions to EQ or PA INPUT.

3. Check settings of channel

VOLUME and MASTER volume

controls.

1. Replace with identical fuse.

2. If second fuse blows, have console checked by qualified service personnel.

1. Make sure similar micro-

phones are used on both

inputs, and microphone impedances match the inputs

used.

2. Make sure microphone is not

used with accessory equipment on other input.

3. Make sure both microphone

switches are on.

1. Adjust INPUT ATTEN to re-

duce channel input level.

2.

Reduce input signal level at

source.

1. Check for defective (shorted)

speaker cable.

2. Check that load impedance is

not too low (too many speakers

connected).

Console is "dead"

(no output,

POWER LED off)

1. Check that ac power source

is "live" and that console is

plugged in.

2. Check that power

ONIOFF

switch is on.

3.

Check that rear-panel fuse

is good.

Two simple methods of localizing problems without

opening the console are as follows. These methods can

be used to find the abnormal console section with or with-

out test equipment. (The methods are not needed

if

the

problem is obvious: SHUTDOWN, no POWER indication,

etc.)

With test equipment: Set all console controls to full

clockwise, REVERB RETURN control to full counterclock-

wise, and PAN (700) and EQ controls to center. Do not

connect a speaker or headphone load. Apply a 0.5

mV,

1 kHz test signal across pins 2 and 3 of one of the BAL LO

IMP input connectors. Normal voltmeter readings taken

at each speaker, rear-panel PATCH

BLOCKTM and front-

panel HEADPHONES connector are given in Table

1.

The top row of figures indicates the voltage in each stage

from input to output. Similarly, a 5

mV signal inserted in a

HI IMP input will check these same voltages. The other

listed inputs give voltage indications only for those circuits

following the inserted signal. Ac voltages may vary

t30%

from the values shown.

Without test equipment: Using only a microphone and

speaker, it is often possible to isolate problem areas using

the PATCH BLOCK rear panel. The ability to bypass cer-

tain circuits and interchange channel signals provides a

No DB

PEAK/frequency band LEDindicators

flashing (console

output normal)

No console output;

no DB PEAK LED

indicatorsflashing

Loud noise or

clicks when certain

microphones or

cables are used

No monitor output

(program output

normal)

Sound quality poor

(weak or thin)

simple but powerful tool for troubleshooting. For example,

in

a 700 console a suspected channel A equalizer

can

be

checked by patching between the A MIX OUTPUT and

A PA INPUT jacks. The signal bypasses the equalizer, and

a talk test will immediately indicate whether the problem

has been eliminated.

Similarly, a potentially defective channel B mix amplifier can be verified by patching the A MIX OUTPUT to the

B MIX OUTPUT. The presence of a "clean" signal from

channel A to the B speaker output indicates that the problem precedes the B MIX OUTPUT jack. Further patching

between the EFFECTS OUTPUT and B MIX OUTPUT jacks

will isolate the problem to the B MIX amplifier.

1.

Make certain FEEDBACK

FINDER switch is set to A, B,

ON or OFF (not between positions).

1. Check PATCH BLOCKTM rear

panel for improper patching.

2.

Check for improper connections to EQ or PA INPUT.

3. Check settings of channel

VOLUME and MASTER volume

controls.

1. SIMPLEX 24V switch is on

(when not needed).

2.

Unbalanced cable used when

SIMPLEX 24V switch is on.

3. Check for defective microphone cables.

1. Check MONITOR OUTPUT

connection to EQ or PA INPUT,

or external amplifier.

2. Make sure MONITOR and

MONITOR MASTER controls

are turned up.

3. Monitor speaker volume control (if present) may be turned

down.

1. Excessive equalization on

graphic equalizers.

2.

Defective input or patching

cables.

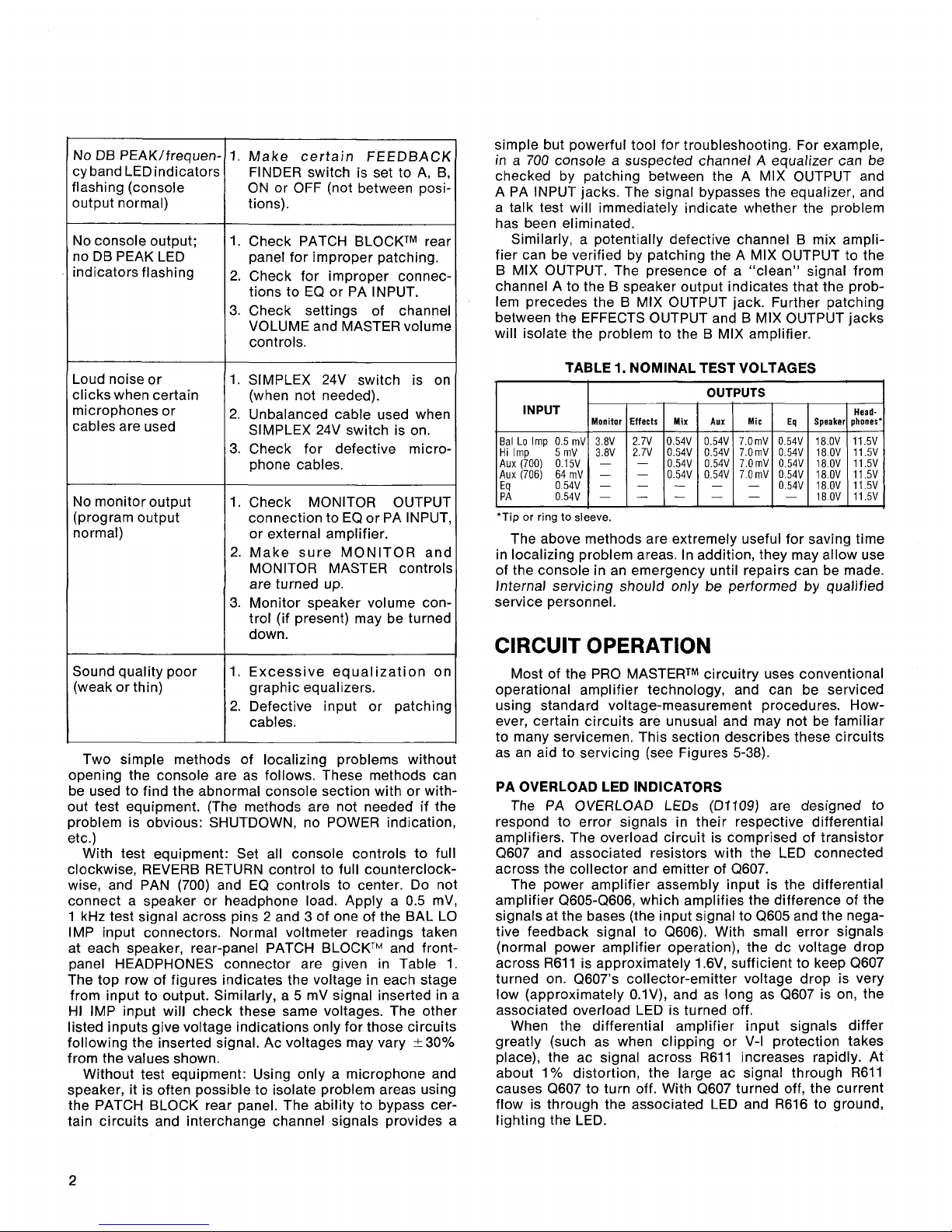

TABLE

1.

NOMINAL TEST VOLTAGES

I

7-

OUTPUTS

I

I

INPUT

I

Head-

'Tip

or

ring

to

sleeve.

Bal

Lo

Imp 0.5 mV

Hi

Imp 5 mV

Aux

(700) 0.15V

AUX

(706) 64 mV

Eq

0.54V

PA

0.54V

The above methods are extremely useful for saving time

in localizing problem areas. In addition, they may allow use

of the console in an emergency until repairs can be made.

Internal servicing should only be performed by qualified

service personnel.

Monitor

CIRCUIT

OPERATION

Effects

Mix

3.8V

3.8V

-

-

-

-

Most of the PRO MASTERTM circuitry uses conventional

operational amplifier technology, and can be serviced

using standard voltage-measurement procedures. However, certain circuits are unusual and may not be familiar

to many servicemen. This section describes these circuits

as an aid to servicing (see Figures 5-38).

PA

OVERLOAD LED INDICATORS

The PA OVERLOAD LEOS (01109) are designed to

respond to error signals in their respective differential

amplifiers. The overload circuit is comprised of transistor

Q607 and associated resistors with the LED connected

across the collector and emitter of

Q607.

The power amplifier assembly input is the differential

amplifier

Q605-Q606, which amplifies the difference of the

signals at the bases (the input signal to Q605 and the negative feedback signal to

Q606). With small error signals

(normal power amplifier operation), the dc voltage drop

across

R611 is approximately 1.6V, sufficient to keep Q607

turned on.

Q607's collector-emitter voltage drop is very

low (approximately

O.IV), and as long as Q607 is on, the

associated overload LED is turned off.

When the differential amplifier input signals differ

greatly (such as when clipping or

V-l protection takes

place), the ac signal across

R611 increases rapidly. At

about 1% distortion, the large ac signal through

R611

causes Q607 to turn off. With Q607 turned off, the current

flow is through the associated LED and R616 to ground,

lighting the LED.

Aux

2.7V

2.7V

-

-

-

-

Mic

0.54V

0.54V

0.54V

0.54V

-

-

Eq

0.54V

0.54V

0.54V

0.54V

-

-

Speaker

7.0mV

7.0mV

7.0mV

7.0mV

-

-

phones*

0.54V

0.54V

0.54V

0 54V

0.54V

-

18.OV

18.OV

18.OV

18.OV

18.0V

180V

11.5V

11.5V

11.5V

11.5V

11.5V

11.5V

Note that the circuit is sensitive to the actual power

supply voltages; if the ac line input voltage is less than

120V, clipping and overload indication will take place at

a lower output level. Note too that the LEDs remain on

during shutdown; this is a normal condition because the

power amplifiers are still partially powered during shutdown.

DB PEAK/FEEDBACK FINDERTM LEDS

With the FEEDBACK FINDER switch (S903) in the OFF

position, LED string

D1101-Dl108 indicates peak power

amplifier output voltage values corresponding to indications of -36 to

+6 dB at the SPEAKER OUTPUTS. A +6 dB

indication is calibrated through

R919 (or R916, Model 700)

for a 20

Vrms sinusoidal output (100 watts to a 4-ohm load).

The power amp assembly (A6) has a resistive voltage

divider at the power amp output that feeds the DB CAL

potentiometer

R919. The DB CAL potentiometer sets the

point at which the

$6 dB LED turns on. The ac signal is

then forwarded to a full-wave rectifier

(U920).

The rectifier is composed of two sections: a unity gain,

inverting precision half-wave rectifier formed by

U920A*

and its associated components, and an inverting summing

amplifier formed by

U920B, which has two inputs. The first

is via

R1045 and R1040, and exhibits a voltage gain of

approximately 1.5 times. The second input is from the output of the precision half-wave rectifier via

R1041. The gain

of this input is approximately 3 times.

When the input signal from the power amp is negative,

the output of the precision half-wave rectifier is zero; when

the input signal is positive, the rectifier output is negative.

When the summing amplifier adds the rectifier output and

the non-rectified signal together, the result is an output

voltage that is always positive 1.5

VIN.

The FULL WAVE BAL adjustment (R1045) is used to trim

the gain in one of the summing amplifier paths so that it

is exactly one-half the gain of the half-wave rectifier path.

The output of the full-wave rectifier is fed to the network

comprised of

D940, C925 and R1037, which produces the

desired fast attack, slower decay operation. The dc voltage

developed at C925 is fed to the LED comparator string via

the FEEDBACK FINDER switch

(S903).

The dc output voltages from U920 drive the comparators

U1101-U1102, which are referenced to a resistive voltage

divider. Each doubling of voltage on the input to the com-

parators turns on the next higher comparator, causing it

to light its associated LED, as well as keeping the LEDs

below it

lit.

For example,

an

input voltage of 1.OV to the

comparator lights the -18 dB LED, as well as the -24,

-30 and -36 LEDS.

Model 700: Note that when S903 is turned to A or B for

feedback determination, the corresponding LED string becomes a readout of frequency for that channel, and the

other channel retains its dB peak indicating function.

FEEDBACK FINDERTM

The Equalizer outputs are fed to the FEEDBACK FINDER

switch

(S903) on the Output Controls board (A9), which

selects the desired output channel (A or B in Model 700)

for display. The FEEDBACK

FINDER circuit senses the

frequency of the Equalizer signal and converts it to a dc

voltage for display on the selected channel LEDs.

Amplifier

U916B clips the input signal to establish a

square wave of approximately 1.2 Vpp.

U916B also con-

tains the FEEDBACK FINDER THRESHOLD control

(R999)

which is used to adjust the sensitivity of the circuit. U916B's

output is capacitively coupled to comparator U903A via an

RC filter

(R915, C909) that attenuates any ultrasonic noise

present in the signal. The first comparator

(U903A) is a

zero-crossing detector, with the operating threshold set

by the amount of hysteresis in the first stage.

The second comparator

(U903B) holds capacitor C910

discharged until the output of U903A goes high. The output of the third comparator

(U903C) goes high at the same

time as

U903A, and stays high until C910 charges to the

reference voltage of

7.5V. This time constant is adjustable

(through

R972, FBF CAL) about the nominal 20 ,&ec period

to calibrate the frequency-to-voltage converter. The resultant 20

@ec pulse from U903D is inverted by U903C and

switches a constant current source

(Q901) on and off.

Thus, the output of

U903D is a pulse train with a constant

pulse width of 20

~sec and a repetition rate equal to the

input frequency. The current pulses are integrated

by

capacitor C911 into a dc voltage which is directly proportional to the input frequency (approximately 12 Vdc output

with an input frequency of 11 kHz). The dc output voltage

is fed through switch S903 to the LED comparator strings

to indicate the frequency band. For example, a 1 kHz signal

will produce approximately 1 Vdc at

C911 and light the

LED above the 1 kHz graphic equalizer control (and all

lower frequency LEDs: 125, 250 and 500 Hz).

POWER AMPLIFIER PROTECTION CIRCUITS

Each power amplifier is protected by a voltage-current

(V-I) sensing circuit which limits the V-l conditions in the

output transistors to a safe level under overload conditions.

Transistors Q610 and Q611 conduct under overload conditions and remove the input signal from the driver transistors

(Q608 and Q609), thus limiting the dissipation of the output

transistors

(Q612-Q615). A single-slope boundary is de-

fined by the values of the resistor network on the bases of

Q610 and Q611.

Thermistors RT602 and RT603 (mounted on transistor

Q614 and Q615 heat sinks) monitor the transistor case tem-

peratures.

RT602 and RT603 decrease in resistance as the

case temperatures go up, causing the boundary to "pivot"

to a lower value. The benefit of this arrangement is that

under severe overload conditions, such as operating into

a short circuit, dissipation is limited to a safe value. However, under normal conditions the protection boundary

moves out to allow operation with more severe "normal"

loads than would otherwise be possible. Capacitors C609

and C610 insure stability during limiting.

Q603 provides pre-driver

(Q601) protection as follows.

When the current through

Q601 reaches a sufficiently high

level during overload, the increased voltage drop through

resistor

R614 is sensed by Q603, which then shorts out the

signal to

(2601, limiting its collector current to a safe value.

Diodes D609 and D608 are normally reverse-biased and

do not conduct. But with highly reactive amplifier loads, the

diodes will conduct to prevent reverse-voltage breakdown

of the output transistors.

Thermistor

RT601 is mounted on output transistor Q613.

Comparators U503A and U503B compare a constant refer-

'Channel 8 only: channel A components are shown In the Model

700 A9

Circuit

Diagram.

ence voltage of 0.73V to the voltage across RT601. When

an unusually high temperature of

70°C (158OF) is reached

on the heat sink,

RT6Ol's voltage will have dropped to the

reference voltage and

U503A or U503B will change state,

turning on

theTEMP WARNING LED (D801). If the tempera-

ture continues to rise to

100°C (212OF), RT6Ol's voltage

drops below

0.3V, U503C or U503D changes state, turning

off Q502 and

Q501, opening relay K1, and turning on the

SHUTDOWN LED

(D802). In this condition, the power amps

are partially powered but all other (low-level) circuits and

the fan

(BI) remain fully on. This condition remains until

the temperature on the heat sink drops to

70°C, when the

LEDs turn off and full power is restored to the power amps.

RT501 is a

positive-temperature-coeffic~ent

thermistor

with a threshold at

120°C (248OF). It is mounted on the

Power Supply board

(A5) in front of fan 61 in the path of the

air flow through the PC board-fan assembly. When air

motion is severely restricted,

RT501 heats and its resistance Increases (from 450 to approximately 1200 ohms).

The current through R502 is reduced and the voltage

drop across R502 is not enough to keep transistor

Q501

turned on. (2501 turns off, opening relay K1 and turning

on the SHUTDOWN LED. It is extremely important that

RT501 should be mounted in the path of the air flow, its

body perpendicular to the flow, approximately

%"

from

and not bent flat against the power supply board.,

The SPEAKER OUTPUTS dc sensor circuit is comprised

of comparator U504 and associated components. A portion

of the output voltage is derived from the divider network of

R640 and

R641 on the power amp board. It is fed to the

comparator inputs, and capacitors C509 and

C510 remove

the audio signal leaving only the dc component. When the

dc output at the SPEAKER OUTPUTS jacks exceeds

+

3QV,

U504 changes state, cutting off transistors Q501 and (2502,

opening relay K1, and turning on SHUTDOWN LED D802.

Note that, when the comparator outputs change state,

diode D509 and resistor

R518 cause "latching"; the power

switch must be turned off and back on to reactivate the

console. This feature is designed to call attention to the

presence of excessive dc at the output, which is an abnormal condition and probably requires servicing.

SERVICE

INSTRUCTIONS

Voltages in this equipment are hazardous to life.

Refer servicing to qualified service personnel.

REPLACEMENT PARTS

Parts that are readily available through local electronic

parts distributors are not shown on the accompanying Parts

List. Their values are shown on the Circuit Diagrams. Commercial parts not readily available and unique parts are

shown on the Parts List and may be ordered directly from

the factory.

The commercial alternates shown on the Parts List are

not necessarily equivalents, but may be used in the event

that direct factory replacements are not immediately available. To maintain the highest possible performance and

reliability Shure factory replacement parts should be used.

When ordering replacement parts, specify the Shure Re-

placement Kit Number (RKC) or part number, description,

product model number, and serial number.

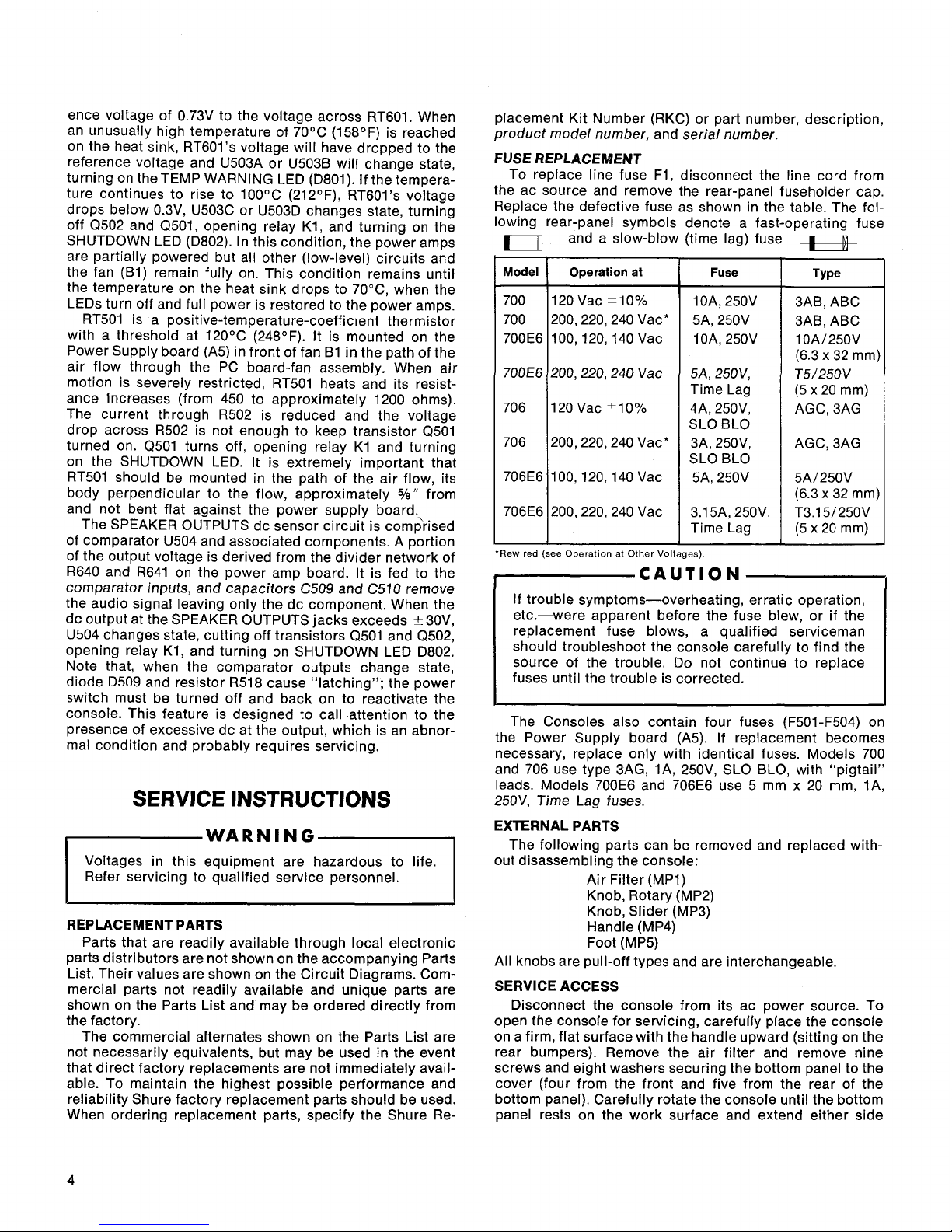

FUSE

REPLACEMENT

To replace line fuse F1, disconnect the line cord from

the ac source and remove the rear-panel fuseholder cap.

Replace the defective fuse as shown in the table. The following rear-panel symbols denote a fast-operating fuse

m~;

and a slow-blow (time lag) fuse

rT

'Rewired (see Operation at Other Voltages).

,-CAUTION

I

Model

700

700

700E6

700E6

706

706

706E6

706E6

If trouble symptoms-overheating, erratic operation,

etc.-were apparent before the fuse blew, or if the

replacement fuse blows, a qualified serviceman

should troubleshoot the console carefully to find the

source of the trouble.

Do not continue to replace

fuses until the trouble is corrected.

I

I

The Consoles also contain four fuses (F501-F504) on

the Power Supply board

(A5). If replacement becomes

necessary, replace only with identical fuses. Models 700

and 706 use type

3AG, IA, 250V, SLO BLO, with "pigtail"

Operation

at

120Vac~10%

200,220,240 Vac*

100,120,140 Vac

200,220,240 Vac

120 Vac " 10%

200,220,240

Vac*

100,120,140 Vac

200,220,240 Vac

leads. Models 700E6 and 706E6 use 5 mm x 20

mm,

lA,

250V, Time Lag fuses.

EXTERNAL PARTS

The following parts can be removed and replaced with-

out disassembling the console:

Air Filter

(MP1)

Knob, Rotary (MP2)

Knob, Slider (MP3)

Handle (MP4)

Foot (MP5)

All knobs are pull-off types and are interchangeable.

Fuse

IOA, 250V

5A, 250V

IOA, 250V

5A, 250V,

Time Lag

4A,

250V,

SLO BLO

3A, 250V,

SLO BLO

5A, 250V

3.1 5A,

250V,

Time Lag

SERVICE ACCESS

Disconnect the console from its ac power source. To

open the console for servicing, carefully place the console

on a firm, flat surface with the handle upward (sitting on the

rear bumpers). Remove the air filter and remove nine

screws and eight washers securing the bottom panel to the

cover (four from the front and five from the rear of the

bottom panel). Carefully rotate the console until the bottom

panel rests on the work surface and extend either side

Type

3AB, ABC

3AB, ABC

10A/250V

(6.3 x 32 mm)

T5/250V

(5 x 20 mm)

AGC, 3AG

AGC, 3AG

5A/250V

(6.3 x 32 mm)

T3.15/250V

(5 x 20 mm)

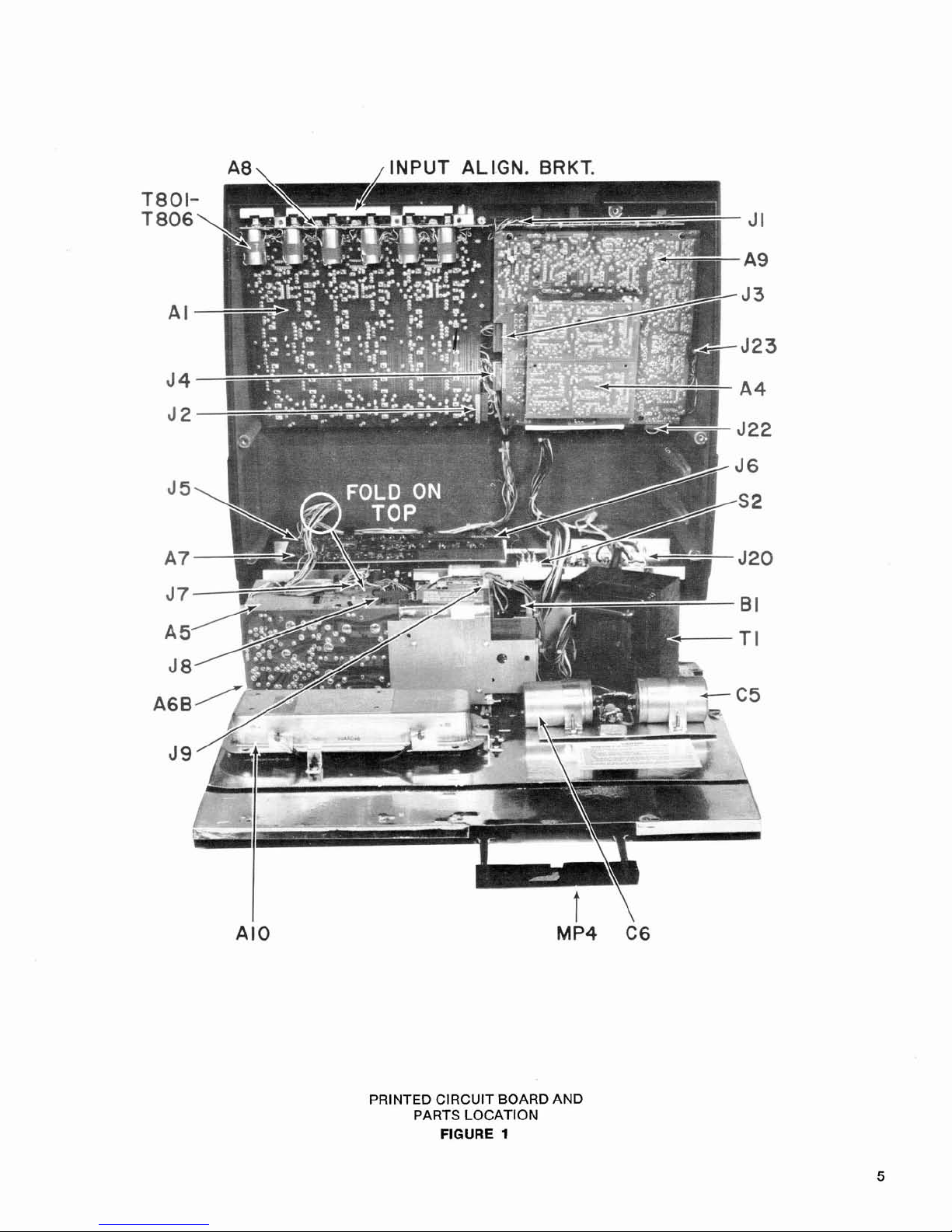

A8

\

/INPUT ALIGN. BRKT.

AIO

MP4

C6

PRINTED CIRCUIT BOARD AND

PARTS LOCATION

FIGURE

1

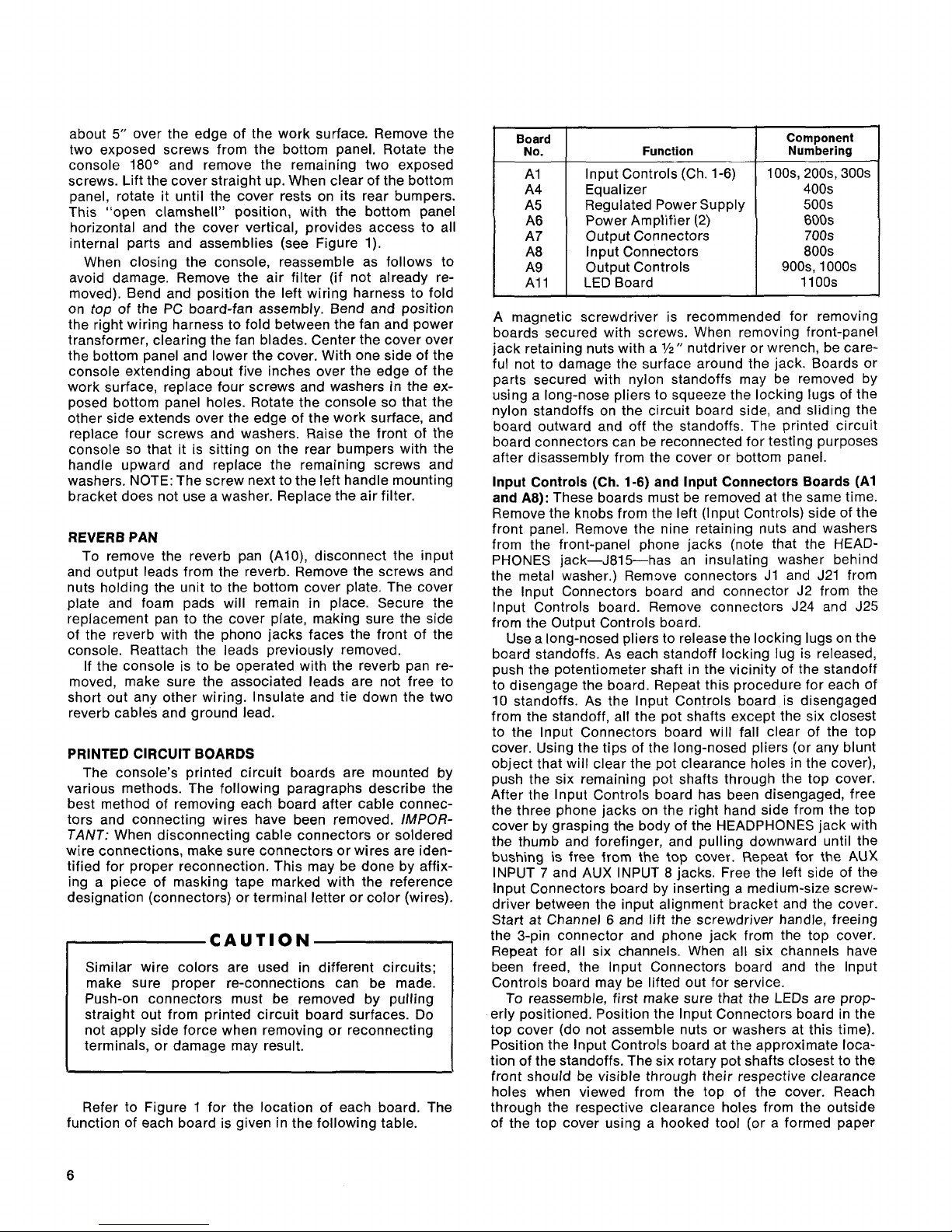

about 5" over the edge of the work surface. Remove the

two exposed screws from the bottom panel. Rotate the

console

180° and remove the remaining two exposed

screws. Lift the cover straight up. When clear of the bottom

panel, rotate it until the cover rests on its rear bumpers.

This

"open clamshell" position, with the bottom panel

horizontal and the cover vertical, provides access to all

internal parts and assemblies (see Figure

1).

When closing the console, reassemble as follows to

avoid damage. Remove the air filter (if not already removed). Bend and position the left wiring harness to fold

on top of the PC board-fan assembly. Bend and position

the right wiring harness to fold between the fan and power

transformer, clearing the fan blades. Center the cover over

the bottom panel and lower the cover. With one side of the

console extending about five inches over the edge of the

work surface, replace four screws and washers in the ex-

posed bottom panel holes. Rotate the console so that the

other side extends over the edge of the work surface, and

replace four screws and washers. Raise the front of the

console so that it is sitting on the rear bumpers with the

handle upward and replace the remaining screws and

washers. NOTE: The screw next to the left handle mounting

bracket does not use a washer. Replace the air filter.

REVERB PAN

To remove the reverb pan (AlO), disconnect the input

and output leads from the reverb. Remove the screws and

nuts holding the unit to the bottom cover plate. The cover

plate and foam pads will remain in place. Secure the

replacement pan to the cover plate, making sure the side

of the reverb with the phono jacks faces the front of the

console. Reattach the leads previously removed.

If the console is to be operated with the reverb pan re-

moved, make sure the associated leads are not free to

short out any other wiring. Insulate and tie down the two

reverb cables and ground lead.

PRINTED CIRCUIT BOARDS

The console's printed circuit boards are mounted by

various methods. The following paragraphs describe the

best method of removing each board after cable connectors and connecting wires have been removed.

IMPOR-

TANT:

When disconnecting cable connectors or soldered

wire connections, make sure connectors or wires are iden-

tified for proper reconnection. This may be done by affix-

ing a piece of masking tape marked with the reference

designation (connectors) or terminal letter or color (wires).

Similar wire colors are used in different circuits;

make sure proper re-connections can be made.

Push-on connectors must be removed by pulling

straight out from printed circuit board surfaces. Do

not apply side force when removing or reconnecting

terminals, or damage may result.

Refer to Figure 1 for the location of each board. The

function of each board is given in the following table.

A magnetic screwdriver is recommended for removing

boards secured with screws. When removing front-panel

jack retaining nuts with a

Y2"

nutdriver or wrench, be careful not to damage the surface around the jack. Boards or

parts secured with nylon standoffs may be removed by

using a long-nose pliers to squeeze the locking lugs of the

nylon standoffs on the circuit board side, and sliding the

board outward and off the standoffs. The printed circuit

board connectors can be reconnected for testing purposes

after disassembly from the cover or bottom panel.

lnput Controls (Ch.

1-6)

and lnput Connectors Boards (A1

and A8):

These boards must be removed at the same time.

Remove the knobs from the left (Input Controls) side of the

front panel. Remove the nine retaining nuts and washers

from the front-panel phone jacks (note that the

HEAD-

PHONES jack-J815-has an insulating washer behind

the metal washer.) Remove connectors

J1 and

J21

from

the lnput Connectors board and connector J2 from the

lnput Controls board. Remove connectors J24 and

J25

from the Output Controls board.

Use a long-nosed pliers to release the locking lugs on the

board standoffs. As each standoff locking lug is released,

push the potentiometer shaft in the vicinity of the standoff

to disengage the board. Repeat this procedure for each

of

10 standoffs. As the lnput Controls board is disengaged

from the standoff, all the pot shafts except the six closest

to the lnput Connectors board will fall clear of the top

cover. Using the tips of the long-nosed pliers (or any blunt

object that will clear the pot clearance holes in the cover),

push the six remaining pot shafts through the top cover.

After the lnput Controls board has been disengaged, free

the three phone jacks on the right hand side from the top

cover by grasping the body of the HEADPHONES jack with

the thumb and forefinger, and pulling downward until the

bushing is free from the top cover. Repeat for the

AUX

INPUT 7 and AUX INPUT 8 jacks. Free the left side of the

lnput Connectors board by inserting a medium-size screwdriver between the input alignment bracket and the cover.

Start at Channel 6 and lift the screwdriver handle, freeing

the

&pin connector and phone jack from the top cover.

Repeat for all six channels. When all six channels have

been freed, the lnput Connectors board and the lnput

Controls board may be lifted out for service.

To reassemble, first make sure that the

LEDs are properly positioned. Position the lnput Connectors board in the

top cover (do not assemble nuts or washers at this time).

Position the lnput Controls board at the approximate location of the standoffs. The six rotary pot shafts closest to the

front should be visible through their respective clearance

holes when viewed from the top of the cover. Reach

through the respective clearance holes from the outside

of the top cover using a hooked tool (or a formed paper

Component

Numbering

100s, 200s, 300s

400s

500s

600s

700s

800s

900s, 1000s

1

100s

Board

No.

A1

A4

A5

A6

A7

A8

A9

All

Function

Input Controls (Ch. 1-6)

Equalizer

Regulated Power Supply

Power Amplifier

(2)

Output Connectors

Input Connectors

Output Controls

LED Board

clipj and pop the rotary pot shafts into position. The remaining shafts will fall into position. Before snapping the

board into its locked position on the standoffs, check that

the LEDs are aligned with their respective holes. Seat the

board into its locked position. Assemble the washers and

nuts to the phone jacks on the Input Connectors board.

Make sure that the insulating washer is behind the metal

washer on the HEADPHONES jack. Check that the POWER,

TEMP WARNING, and SHUTDOWN LEDs are in their proper

locations. Replace all knobs.

Equalizer Board (A4):

This board is located at the center

of the foil side of the Output Controls board

(A9). Removal

requires releasing the nylon standoff locking lugs holding

the board in place and pulling the board straight out. Disconnect the wiring harness connectors from J401 and

J402.

Regulated Power Supply Board (AS):

Remove this board

by disconnecting connectors J7, J8, and

J9, and removing

six screws along the edges of the board.

Power Amplifier Boards (A6):

The two Power Amplifier

boards (Model 700) are identical except for mounting

brackets. Remove either board by first loosening the PC

board-fan assembly. This is accomplished by removing

four screws securing the boards to the bottom panel.

Select the power amplifier to be removed (channel B

amplifier is toward the front of the console and channel A

is toward the back).

Remove the electromagnetic shield (steel) and electrostatic shield (foil) by disconnecting the grounding lug and

disengaging the shields from the nylon standoffs. Disconnect connectors J13 and J14 (for channel B;

J10 and J11

for channel A). Remove three screws from the edge of the

Power Supply board and, using a small Phillips screwdriver, two screws from the fan.

Output Connectors Board (A7):

Remove all PATCH

BLOCKTM jack retaining nuts and washers, remove board

connectors J5 and J6 and unsolder three leads (yellow,

green and black) to the MIC OUTPUT jack

(PI). The board

lifts straight out of the rear of the cover.

Output Controls Board (A9):

Remove the knobs from the

right side of the front panel. Remove the four screws with

lockwashers and insulating washers, and disengage the

five nylon standoffs securing the board to the front panel.

Remove connectors J3, J4, J22, J23, J24 and J25.

LED Board (All):

This board (two boards in the Model 700)

can be removed after the Output Controls board

(A9) is

removed. The LED board is located directly below the

equalizer sliders, and can be removed by lifting upward.

DC OUTPUT BALANCE ADJUSTMENT

In order to eliminate dc offset at the output, a dc balance

control

(R601, blue) has been provided for each Power

Amplifier

(A6). This control is accessible from the lefthand side of the console. The dc balance should be

checked and adjusted as necessary whenever any Power

Amplifier circuit components are replaced. The dc output

balance adjustment should be made before making the dc

bias current adjustment.

The dc balance adjustment is made with all volume con-

trols down and no speaker load. Connect a dc voltmeter

(preferably with a 0.1 Vdc full-scale range) across a

SPEAKER OUTPUTS jack (J16-J17 for channel A,

J18-J19

for channel B).

Use a small screwdriver with an insulated shaft to

make this adjustment; hazardous voltages are present in the circuitry near

R601.

Carefully adjust the dc balance control for 0 Vdc -C20 mV

at the output. NOTE: The normal adjustment range of R601

is

+

1V. If the dc offset exceeds this value, other problems

exist in the circuit.

DC BIAS CURRENT ADJUSTMENT

Each Power Amplifier (A6) contains a dc bias current

adjustment control

(R617, orange) to set the dc idling

current through output transistors

Q612-Q615. This adjustment minimizes crossover distortion without drawing excessive idling power. The bias current should be checked

whenever any Power Amplifier circuit components are re-

placed. The adjustment should be made after the dc output

balance adjustment. Both dc bias current controls are

accessible from the left-hand side of the console.

The dc bias current adjustment is made with all volume

controls down and no speaker load. Remove the Power

Amplifier board shield and connect a dc voltmeter with a

floating ground across resistor R632 (0.3 ohms, 7W). See

Figures 28-31.

Use a small screwdriver with an insulated shaft to

make this adjustment; hazardous voltages are present in the circuitry near

R617.

Starting with the dc bias current control at full counter-

clockwise, adjust it for 6

f

2 mV across R632. The same

voltage should be present across resistors

R633, R638 and

R639.

DB PEAK INDICATORSIFEEDBACK FINDERTM

CALIBRATION

The following calibration procedures should be per-

formed when parts in the DB PEAK LED strings have been

replaced. The potentiometers involved on board A9 are the

A DB

(R916), B DB (R919), FULL WAVE CAL A (R1044),

FULL WAVE CAL B (R1045), and FBF (R972). The balance

and dB peak calibrations that follow are given for output

channel B; the identical steps for channel A use potentiometers R916 and

R1044. All procedures can be performed with the cover open and the Output Controls board

in place (see Figure 1). Note that the first two procedures

apply to the Model 706 and to channel B of the Model 700.

Full Wave Balance

1. Set the console controls to typical settings (orange

index marks), the INPUT

ATTENuators to 0, and the

MASTER controls to

5.

2. Feed a 1 kHz, 150 mV signal from a low-distortion

sine-wave signal generator to a channel input HI IMP

jack. With an audio voltmeter connected (without a

speaker load) to a B SPEAKER OUTPUT jack, adjust

the B MASTER or signal generator level control for a

10V output.

3. Connect an oscilloscope across test point TP B (right

center of

A9) and ground (see Figures 18 and 20).

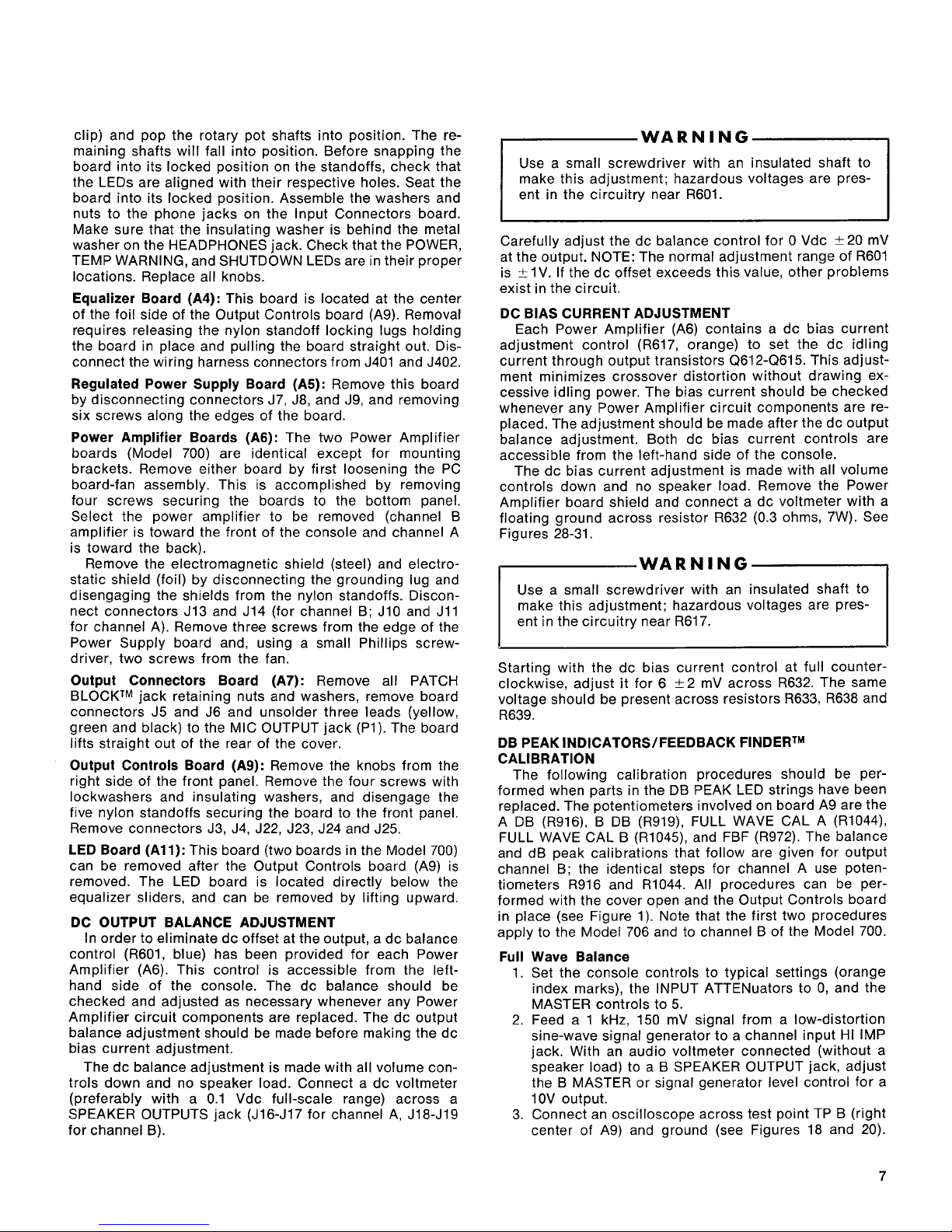

The scope display should appear as in Figure 2A or B

if the Full Wave is out of balance, or as in Figure 2C

if it is in balance.

4. If out of balance, adjust the FULL WAVE CAL B

(R1045) until the display looks like Figure 2C (alternate peaks have equal heights).

5. Repeat the above steps for channel A with the scope

on test point TP A.

DB Peak LED Calibration

1. With the console, signal generator and voltmeter set

up as for the Full Wave Balance procedure, vary

the signal generator level so that the output across

the B SPEAKER OUTPUT jack is 20V.

2. Adjust the B DB

(R919) until the channel B +6 DB

PEAK LED just barely turns on (dim or flickering).

3. Check for proper operation by decreasing the output

to

19V (the +6 LED should turn off) and increasing

it to 21V (the

+6 LED should be on brightly).

4. Repeat the above procedure for channel A.

Feedback

FinderTM Calibration

1. With the console, signal generator and voltmeter set

up as for the Full Wave Balance procedure, adjust

the signal generator for an 11.3 kHz signal.

2. Set the FEEDBACK FINDER switch to B or ON.

3. Adjust the FBF

(R972) so that the 16 kHz (+6) LED

barely turns on (dim or flickering).

4. Check for proper operation by decreasing the signal

generator frequency to

tl.O

kHz (the 16 kHz LED

should turn off) and increasing it to 11.5

kHz

(the 16

kHz LED should be on brightly).

BALANCE WAVEFORMS

FIGURE

2

SMALL SIGNAL AND PREDRIVER TRANSISTORS

AND INTEGRATED CIRCUITS

All transistors and integrated circuits are mounted on

printed circuit boards. When replacing these parts it is

imperative that proper lead configuration be followed. A

minimum of soldering heat (25W maximum iron) should be

used to avoid damage to the part or printed circuit board.

When replacing regulators U501 or

U502, apply Wakefield

Type 120 thermal joint compound to assure good heat

transfer. Refer to the

NOTES TO SERVICE ILLUSTRA-

TIONS

for transistor and integrated circuit lead codes.

DRIVER TRANSISTORS

Driver transistors Q608 and Q609 are mounted on heat

sink brackets located on the surface of the Power Amplifier boards.

Unsolder the transistor leads. When replacing

transistors, apply Wakefield Type 120 thermal joint com-

pound to the surface of the transistor to provide good heat

transfer from transistor to bracket. Be sure that these

transistors are not interchanged in the circuit; they are not

identical devices.

Q608 is an NPN transistor and Q609 is a

PNP transistor. Refer to the

NOTES TO SERVICE ILLUS-

TRATIONS

for transistor lead codes.

OUTPUT TRANSISTORS

Output transistors Q612 through

Q615 are located on the

black, finned heat sinks. The replacement procedure is the

same as that used for driver transistors Q608 and

Q609,

except make certain the two diodes mounted below the

heat sinks on Q612 and Q613 are thermally coupled (with

Wakefield Type 120 thermal joint compound) to the heat

sinks above them. Also, make sure that the thermistor

assemblies are replaced, and the output transistors are

replaced in the same orientation as when they were removed. Position the thermistor lead wires so that they are

not in contact with the heat sink or thermistor clip.

NOTE: When replacing output transistors, make certain

the replacement transistor matches the other output transistors in part number and beta code (A, B or C).

DIODE BRIDGE RECTIFIER

Silicon diode bridge rectifier

Dl is mounted on the bot-

tom panel adjacent to power transformer

TI.

When replac-

ing this component, apply Wakefield Type 120 thermal joint

compound between the heat sink base of the rectifier and

the bottom panel to provide heat transfer to the bottom

plate. Note that the base of the rectifier is provided with a

locating pin. A notch is provided in the bottom plate to

position the rectifier such that the locating pin fits into the

notch. The terminals are marked to indicate the ac connections to the power transformer and the

"+"

and

"-"

dc

output connections to filter capacitors

C5 and C6.

TRANSISTOR AND DIODE REMOVAL

Most transistors and all diodes used in the console are

mechanically supported by their leads. When replacing

these devices, proper lead configurations must be followed.

Minimum soldering heat (preferably with a low-wattage-

25W maximum-soldering iron) should be used to avoid

damage to the device. Be sure to place heat-shrinkable

tubing or "spaghetti" on leads where the original device

contained such tubing. Transistor lead codes are included

in the

NOTES TO SERVICE ILLUSTRATIONS

(Figure 4).

ACTIVE COMPONENT CHECKING

Integrated circuits can be checked without removing

them from their circuit board. Measure the input, output

and power supply voltages as shown on the applicable

circuit diagram.

Defective transistors and diodes can be located by use

of a standard ohmmeter such as a

Simpson 260. Polarity

of the ohmmeter must be verified before these checks

are made.

With a known diode orientation, measure the diode re-

sistance in the forward and reverse directions. The lowest

meter reading will establish the probe at the cathode end

(schematic symbol arrow points to cathode) as the "minus"

probe while the other probe will be "plus." Some ohm-

meters are not polarized in this manner with relation to

"volts plus probe" and "volts minus probe." With the ohmmeter "plus" probe on the anode end of a diode, and the

"minus" probe on the cathode end, the ohmmeter should

read approximately 2000 ohms or less. With the meter

probes reversed, a reading of about 10,000 ohms or more

should be obtained. If either of these conditions is not met,

the diode should be replaced.

To check LEDs, connect the cathode (notch or flat) of

the LED to the negative terminal of a

9V

transistor radio bat-

tery. Connect the positive battery terminal through a

4.7k

resistor to the LED anode. Replace any LED that does not

light.

CAUTION

Do not check LEDs with an ohmmeter. The LEDs may

be damaged or erroneous readings may be obtained.

To check transistors, the ohmmeter should be set to the

100- or 1,000-ohm scale. Transistors and diodes must be

removed from the circuit before testing. If all conditions

in the following table are met, the transistor may be considered free of any major defect; if any of the following

conditions are not met, the transistor should be replaced.

See

NOTES TO SERVICE ILLUSTRATIONS,

Figure

4,

for

transistor lead codes.

I

OHMMETER CONNECTIONS

I

OHMMETER READING

I

"PIYs" Lead I 64Minus" Lead I Transistor

NPN

I

Transistor

PNP

I

High

High

Low

Low

Collector

Emitter

Collector

Emitter

nection. Insert the new contact (with attached lead) in the

connector housing, pushing firmly to lock the contact.

Emitter

Collector

Base

Base

Base

Base

FERRITE BEAD RINGS

All input and output connectors in the console contain

ferrite bead rings

(L701-L711 and L801-L816). Be sure to

replace any ferrite bead rings removed during servicing.

High

High

High

SERVICE ILLUSTRATIONS

Immediately following the parts list on the pages that

follow are circuit diagrams, parts locating photographs,

and board foil drawings. Once a board has been located

through the parts location photo (Figure

I),

the components

on that board can be located from the corresponding parts

location photo. The function of the part is shown on the

adjacent circuit diagram. NOTE: Each circuit diagram

applies to all 700 Series consoles. Portions shown in

red

only apply to Models 700 and 700E6. Further differences

are shown in notes at the bottom of each diagram.

'Not

a significant measurement.

PRINTED CIRCUIT BOARD CONNECTORS

All printed circuit board connectors use the Molex

KK

Modular Interconnection System. To replace a lead and its

associated connector contact, proceed as follows. Using a

scribe or other pointed instrument, depress the contact

through the slot at the side of the connector housing. This

will free the contact and allow it to be removed from the

rear of the connector housing. Trim a new lead so that

inch of wire appears. lnsert the trimmed lead in a new

contact (Shure Part No.

56A235 or 56A251). Crimp the

wire to the contact and solder the wire to the crimped con-

Collector

Emitter

OPTIONAL ACCESSORIES

The following optional accessories are specially de-

signed for use with the Shure 700 Series Power Consoles:

A700C Protective Cover

A7S Console Stand

GUARANTEE

This Shure product is guaranteed in normal use to be

free from electrical and mechanical defects for a period of

one year from date of purchase. Please retain proof of

purchase date. This guarantee includes all parts and labor.

This guarantee is in lieu of any and all other guarantees or

warranties, express or implied, and there shall be no re-

covery for any consequential or incidental damages.

Low

Low

SHIPPING INSTRUCTIONS

Carefully repack the unit and return it prepaid to:

Shure Brothers Incorporated

Attention: Service Department

1501 West Shure Drive

Arlington Heights, Illinois 60004

If outside the United States, return the unit to your dealer

or Authorized Shure Service Center for repair. The unit

will be returned to you prepaid.

High

*

OPERATION AT OTHER VOLTAGES

The Model 700 and 706 consoles are supplied wired for

operation at an input of 120 Vac *10°/~, 50/60

Hz.

For oper-

ation at

240V, 220V, 200V, 140V or 100V, follow the steps

listed

below. Open the cover as described in

SERVICE

ACCESS.

Remove the screws securing the PC board-fan

assembly to the bottom panel and remove the assembly to

provide working room. For 240V, 220V or 200V operation,

unsolder and insulate the black lead from fuseholder XFl

to UNSWITCHED AC receptacle J20 (J20 will be inoperative at these voltages). NOTE: Fan

B1 is permanently

wired and will continue to operate at 120 Vac with the

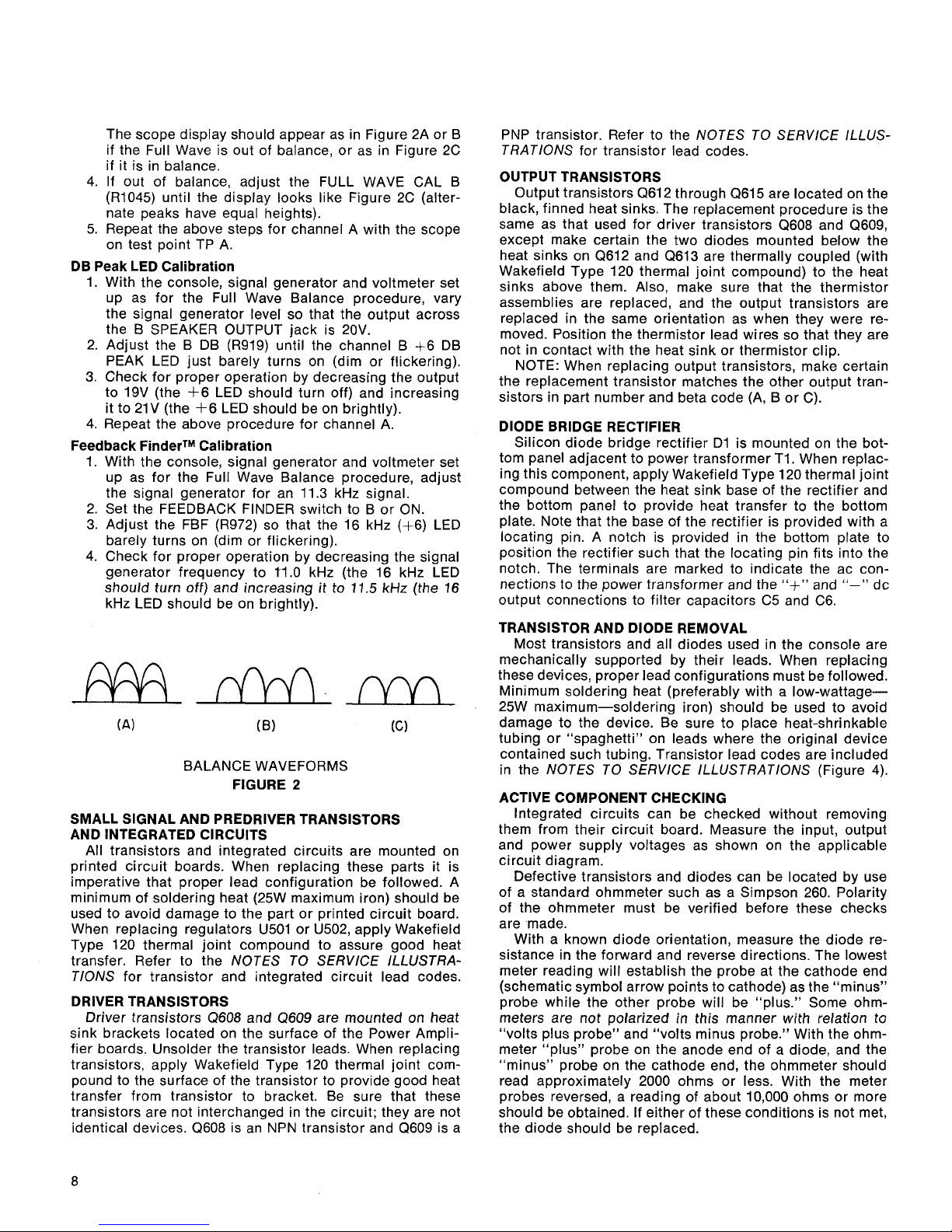

following wiring changes. (Figure 3 illustrates terminal

strip

TSl, located between transformer TI and fan B1,

and the jumper and transformer T1 leads which must be

moved.)

240V Operation:

1. Cut the bare jumper between the redlblack and blue1

white leads.

2.

Unsolder the yellowlblack lead and solder it to the

redlblack lead.

220V Operation:

1.

Perform the above steps for 240V operation.

2. Unsolder the white (AC) lead from the

bluelwhite lead

terminal and solder it to the terminal with blue and

yellow leads.

3.

Unsolder the white (AC) lead and solder it to the

terminal with blue and yellow leads.

140V Operation:

1. Cut the bare jumper between the red/black and blue/

white leads.

2. Unsolder the blue lead and solder it to the redlblack

lead.

3.

Unsolder the white transformer lead and solder it to

the yellow lead.

100V Operation:,

1. Unsolder the white (AC) lead and solder it to the white

transformer lead terminal.

2.

Solder a jumper wire between the white transformer

lead terminal and the terminal with blue and yellow

leads.

Reposition the power harness and mount the PC

boardfan assembly before testing the unit. For 240V, 220V and

200V operation, obtain a suitable ac plug and attach it to

the line cord. Obtain a 5A,

250V, type 3AB or ABC fuse

(for the 700 console), or a

3A, 250V, SLO BLO, type AGC

or 3AG fuse (for the 706 console), and insert it in place of

the present fuse. Check for proper operation by measuring

voltage across capacitor C5 or C6: Under no-signal conditions, the voltage should be 54V

t3V. Be sure to mark the

rear panel with the new operating voltage.

As supplied, Model

700E6 and 706E6 consoles are set to

200V Operation:

operate from 240 volts. To change operating voltages, dis-

1. Cut the bare jumper between the redlblack and blue/

connect the ac power (mains) cable, select the desired

white leads. operating voltage using the rear-panel VOLTAGE

SE-

2. Unsolder the yellowlblack lead and solder it to the

LECTOR switch, and make certain the fuse

(Fl) is of

white transformer lead.

the proper value.

TRANSFORMER REWIRING

FIGURE

3

REPLACEMENT PARTS LIST

This list describes parts for Models 700, 700E6, 706 and 706E6. Major differences between parts are shown by multiple

listings of the part with parenthetical notation of the models. When servicing 706 and

706E6 consoles, disregard refer-

ence designations given for parts not present in these models.

Qty.

Reference

Designation

A1

A 1

A4

A5

A5

A5

A5

A6A

A6B

A7

A7

A8

A8

A9

A9

A1 0

A1 1

B 1

C5, C6

C5, C6

C101, C103,

C111, C112,

C201, C203,

C211, C212,

C301, C303,

C311, C312,

C508, C513,

C904, C905,

C911, C918,

C930

'Parts listed as RKC K~ts

quantit~es.

at kit nun

Replacement

Kit No.*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

should be ordered by

lnput Controls (Ch. 1-6)

Board

(700,700E6)

lnput Controls (Ch. 1-6)

Board (706, 706E6)

Equalizer Board

Power Supply Board (700)

Power Supply Board

(700E6)

Power Supply Board (706)

Power Supply Board

(706E6)

Power Amplifier Board,

Ch. A (all models)

Power Amplifier Board,

Ch. B

(700,700E6)

Output Connectors Board

(700,

700E6)

Output Connectors Board

(706,

706E6)

lnput Connectors Board

(700, 700E6)

lnput Connectors Board

(706,

706E6)

Output Controls Board

(700,700E6)

Output Controls Board

(706, 706E6)

Reverb Pan

LED Board

Fan, Cooling, 70 CFM

Capacitor, Electrolytic,

800OPF, 60 WV~C (700,700E6)

Capacitor, Electrolytic,

4000

,uF,

60 WV~C (706,706E6)

Capacitor, Electrolytic,

4.7 or 5

,,.F, 35 Wvdc

None

Commercial

Alternate

Replacement Kit Consists Of:

None

Part No.

None

None

None

None

None

None

Description

None

None

None

None

None

None

None

None

None

Rotron

WR2HI

None

Sprague

36D252F075AC2A

Sprague, 30D-

TE1303; CDE

NLW-5-50

3er.

Any

orders received for piece parts where RKC

Kit

number is shown will be shipped in RKC

REPLACEMENT PARTS LIST

'Parts listed as RKC K~ts should be ordered

by

that kit number. Any orders rece~ved for piece parts where RKC Kit number is shown will be shipped in RKC

quantities.

12

Reference

Designation

C315, C316,

C605, C703,

C718, C928,

C929

C447, C448,

C915, C924,

C926, C927

C501, C502

C503

C504

C507

C819

C901, C902,

C908

D 1

D2,

D501 -D506,

D508, D601D603, D803,

D943, D944

Dl01, D102,

D201, D202,

D301, D302,

D801,D802,

D804, Dl 101

-

Dl109

Dl 03-Dl 06,

D203-D206,

D303-D306,

D509, D510,

D604, D605,

D701-D708,

D901 -D906,

D925-D936,

D938, D939,

D941, D942

D507

D606, D607

D608, D609

D937, D940

F1

Replacement

Kit No.*

-

-

-

-

-

-

-

-

-

RKC21

-

-

-

RKC50

RKC46

RKC19

-

Commercial

Alternate

Sprague 30DTE1211; Mallory

MTA-100F35; CDE

NLW-100-25

Sprague

503D475G025

Sprague TVA-1211

None

None

Mallory

TNT405U050POA

CDE BR250-50

Sprague 502D226G050CEl C;

Mallory MTV-25B35

Varo VT200/T

Motorola 1 N4002

Monsanto

MV5075C

TI or GE 1 N4148

Motorola 1 N5359A

Motorola 1 N4002

Motorola 1 N4721

RCA 1 N48,l N60

Littelfuse 314010

Qty.

-

-

-

-

-

-

-

4

-

-

-

2

4

4

-

Part No.

86N628

86F629

86A632

868632

86C629

86B636

86L628

86B629

86A640

86A404

86D422

86A415

86A428

86A410

86A406

86A405

80C323

Replacement Kit Consists

Of:

Description

Capacitor, Electrolytic,

100

,LF, 25 Wvdc

Capacitor, Electrolytic,

4.7

p.F, 25 WV~C

Capacitor, Electrolytic,

1000 ,LF, 25 WV~C

Capacitor, Electrolytic,

1000

,LF, 40 Wvdc

Capacitor, Electrolytic,

33

pF, 16 Wvdc

Capacitor, Electrolytic,

4

pF, 25 Wvdc

Capacitor, Electrolytic,

220 or 250

pF,

40 Wvdc

Capacitor, Electrolytic,

22

pF, 35 Wvdc

Silicon Rectifier,

200V,

25A

Silicon Rectifier,

IOOV,

1 /2A

Diode, Light-Emitting

Diode, Silicon, Computer, 75V

Silicon Zener Diode,

24V, 5W

Silicon Rectifier, IOOV, 1/2A

Diode, Silicon, 200V, 3A

Diode, Germanium, 30V

Fuse,

IOA, 250V (700)

REPLACEMENT PARTS LIST

Commercial

Alternate

Reference

Designation

F1

F1

F1

F501 -F504

F501 -F504

J1-J8, JIO,

J11, J13, J14,

J21-J25,

J401

-J402

J 9

J16-J19

J20

J 30

J30

J701-J705,

J707, J709,

J710, J801,

J803, J805,

J807, J809,

J811, J813,

J814

J707, J708,

J711, J712

J802, J804,

J806, J808,

J810, J812

J815

K1

L60 1

L701

-L711,

L801 -L816

MPI

MP2

M P3

MP4

MP5

M P6

PI

*Parts listed as RKC Klts

auantltles

Littelfuse 213005

Littelfuse 31 3004

Littelfuse 21303.15

Littelfuse 315001

Schurter 034.31 17

Replacement

Kit No.*

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

should be ordered by

None

None

Switchcraft 11

None

Otto Heil 161-6

Otto Heil 6061-3

None

Qty.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

that klt number

None

None

Part No.

80A380

80E159

808258

80A268

808380

56A251

56A235

90BA2600

95A8005

95A898

95A689

90BL2600

90BK2600

95A899

90BJ2600

55A145

95A8004

80A365

90BM2600

90A8101

90A2950

65A8013A

66A158

66A164

90E2232

Any orders

None

Replacement Kit Consists

Of:

Description

Fuse, Slo-Blo, 5A, 250V (700E6)

Fuse, Slo-Blo, 4A, 250V (706)

Fuse, Slo-Blo,

3.15A, 250V (706E6)

Fuse, Pigtail, Slo-Blo, 1 A, 250V

(700,706)

Fuse, Time Lag, 1 A, 250V

(700E6, 706E6)

Connector Contact (only)

Connector Contact (only)

Phone Jack, 2-Conductor

Outlet,

UNSWITCHED AC (700, 706)

Receptacle, AC Power Line

(700E6)

Receptacle, AC Power Line (706E6)

Phone Jack, 2-Conductor

Phone Jack, 3-Conductor

Connector, Receptacle,

3-Pin

Phone Jack, 3-Conductor,

HEADPHONES

Relay, DPDT

Choke Coil, 4.7

pH

Ferrite Bead Ring

Air Filter Assembly

Knob, Rotary

Knob, Slider

Handle

Foot

Rear Bumper

Connector, Plug, 3-Pin,

MIC OUTPUT

recelved for piece parts where RKC KII pumber

I

None

None

Stackpole 57-3425

None

None

None

None

None

None

Switchcraft D3M

shown will be shipped in

REPLACEMENT PARTS LIST

Commercial

Alternate

TI TIS93

TI TIS92

None

Motorola

MPS-A06

None

RCA

2N6263

Motorola 2N3741*

*

Motorola MPS-A20T

Motorola MPS-A70T

Motorola 2N3773tT

RCA TA8638ASt

Motorola 2N5087

Motorola MPS-UO2;

GE

D40D4

Motorola MPS-U52;

GE

D41 D4

Motorola

2N5458

IRC or Dale PW-5

IRC or Dale PW-5

None

None

None

shown will be shipped in RKC

tUse in emergency only. Select for high gain. May affect power output and reliability.

ttMust be matched for manufacturer and beta value.

Reference

Designation

Q501, Q603,

Q607

Q502

Q601

Q602, Q605,

Q606

(2604

Q608

(2609

(2610

Q611

Q612-Q615

Q901, (2905

Q902

Q903

(2904

R1, R2

R3

R102, R107,

R115, R116,

R148, R149,

R202, R207,

R215, R216,

R248, R249,

R302, R307,

R315, R316,

R348, R349,

R997

R118, R119,

R126, R127,

R218, R219,

R226, R227,

R318, R319,

R326, R327,

R995, R996

R131, R132,

R231, R232,

R331, R332,

R926, R939

**Parts listed as RKC

quantities.

"Selected for

120V

BV,.l.:o

Replacement

Kit No.*

RKC66

RKC65

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Kits should be ordered by

min.

Replacement Kit Consists

Of:

Description

Transistor, Silicon, PNP

Transistor, Silicon, NPN

Transistor, Silicon, Power, PNP

Transistor, Silicon, NPN

Transistor, Silicon, NPN

Transistor, Silicon, NPN

Transistor, Silicon, PNP

Transistor, Silicon, Power, NPN

Transistor, Silicon, PNP

Transistor, Silicon, Power, NPN

Transistor, Silicon, Power, NPN

Transistor, Silicon, PNP

Transistor, Silicon, Power, NPN

Transistor, Silicon, Power, PNP

Transistor, Silicon,

N-Channel, Field Effect

Resistor, 560,

5\N, 10%

Resistor,

2.5k, 5W, 10%

Potentiometer, Linear

Taper,

lOk

Potentiometer, Linear

Taper, 50k

Potentiometer, Linear

Taper,

lOk

received for piece parts where RKC Kit number is

Qty.

1

1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

that kit

Part No.

86A335

86A334

86A8301

86A355

86A8300

86A361

86A362

86A363

86A364

86A378

868378

86A348

86A352

86A353

86A329

45EC561B

45EC252B

46B82

46C82

46D82

number. Any orders

REPLACEMENT PARTS LIST

Reference

Designation

Replacement Kit Consists

Of:

part

NO.

1

Description

46F33

1

Potentiometer, IOk, Dc

Output Balance

46A82

45HC152B Resistor, 1.5k, 5W, 10%

I

Potentiometer, Audio

Taper,

1OOk

46G33

45HC561 B I Resistor, 560,5W, 10%

Potentiometer, 100, Dc

Bias Current

45HB309C

45HC220B Resistor, 22,5W, 10%

Resistor, 0.3,

7W, 5%

46B84

46B83

1

Potentiometer. Slide.

Potentiometer, Linear

Taper,

10k

46E82

45A43

I

Thermistor, PTC

Potentiometer, Audio

Taper,

100k

90A2790 1 Thermistor Assembly. NTC

86A904 Metal Oxide Varistor,

1

56V

55A141

1