Page 1

I@.--

DESCRIPTION

The Shure Model 703 PRO MASTERTM is a compact,

rugged, heavy-duty, two-way loudspeaker system with

a high-frequency horn. The unit is designed for highpower, localized sound coverage in on-stage monitor

(foldback) applications. The 703 is recommended for use

with virtually any power amplifier capable of delivering

up to 100 watts to an 8-ohm load. The Speaker can be

placed in either of two slanted positions facing the

performer.

Two 8-inch heavy-duty speakers and a high-frequency

driver coupled to a 120" radial horn provide excellent

sound reproduction. The 703 is supplied with two highfrequency focusing wedges which, when inserted in the

radial horn, narrow the horn coverage from 120" to 60"

and increase the high-frequency response by approximately 5 dB.

The 703 is constructed of 15.9 mm

covered in scuff-resistant black vinyl. The attractive black

sculptured fabric grille is rugged, cleanable and replaceable if damaged. A retractile handle and balanced design

contribute to ease of transporting. The corners of the 703

are equipped with steel protectors. Rubber feet on two

surfaces provide protection and offer the option of positioning at either a

In addition to the high-frequency focusing wedges, the

703 is supplied with a rugged vinyl snap-on protective

cover.

jacketed connecting cable with phone plugs is available

as Shure Model

A

222 HARTREY AVE.. EVANSTON, IL. 60204 U.S.A.

-

@,

MICROPHONES

AREA CODE 3121866-2200 . CABLE: SHUREMICRO

TWX: 910- 231-0048 TELEX: 72-4381

AND

ELECTRONIC

COMPONENTS

OPERATION AND SERVICE MANUAL

(%

in.) plywood and

30" or 60" angle to the stage.

heavy-duty, 15m (50 ft), 18-gauge, rubber-

RKC4.

MODEL

703

WGijilhlST@Lji3

STAGE MONITOR

SPEAKER SYSTEM

FREQUENCY IN HERTZ

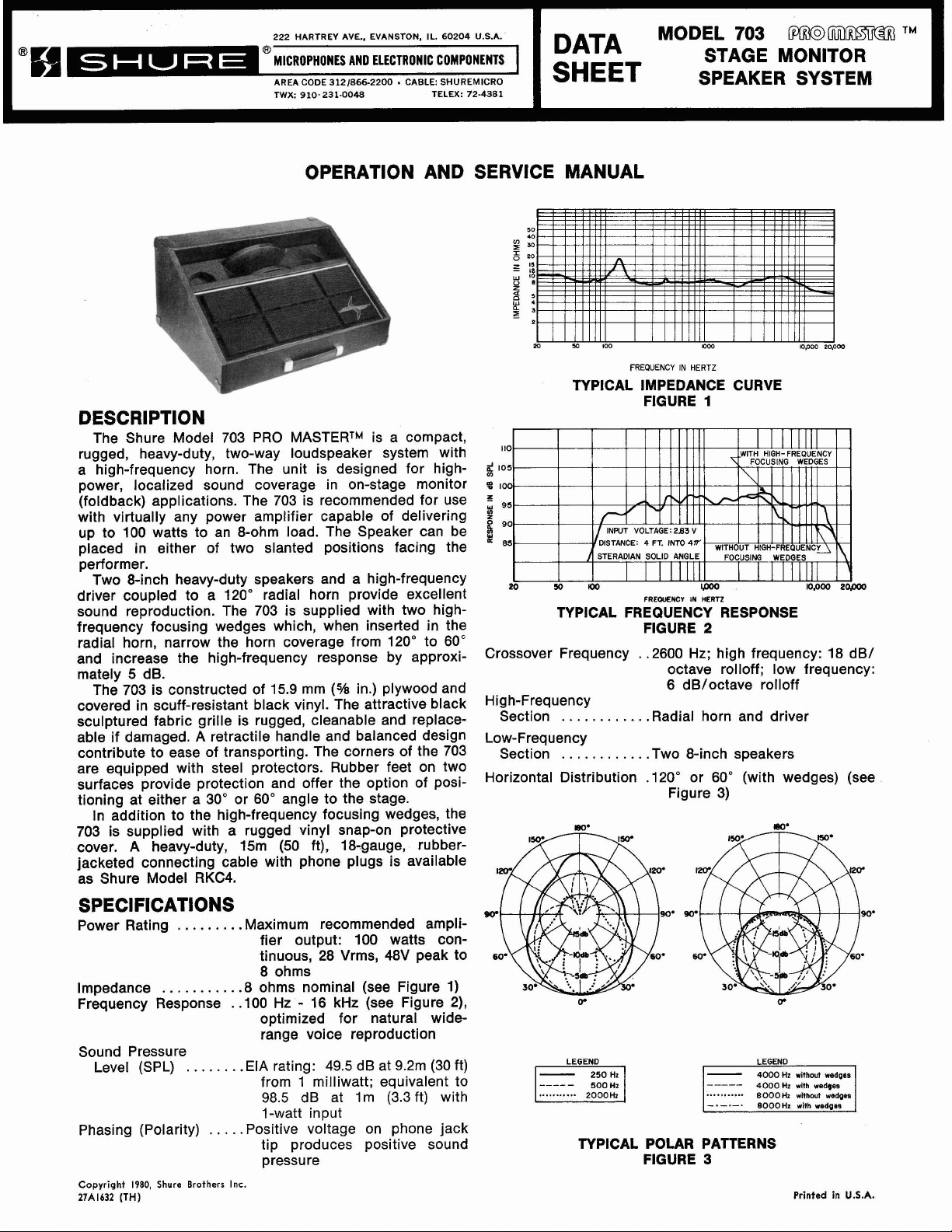

TYPICAL IMPEDANCE CURVE

FIGURE

110

g

I05

0

I00

Z

Y

95

6

90

P

85 DISTANCE: 4 FT.

20

TYPICAL FREQUENCY RESPONSE

Crossover Frequency . .2600 Hz; high frequency: 18 dB1

High-Frequency

Section

Low-Frequency

Section

Horizontal Distribution

...........

...........

FREOUENCY IN

FIGURE

.Radial horn and driver

.Two 8-inch speakers

.12O0 or 60" (with wedges) (see

1

INTO

48

lpoo

HERTZ

2

octave rolloff; low frequency:

6

dB/octave rolloff

Figure 3)

TM

I

SPECIFICATIONS

Power Rating

Impedance

Frequency Response

Sound Pressure

Level (SPL)

Phasing (Polarity)

Copyright

27A1632

1980,

(TH)

........

..........

.......

.....

Shure Brothers Inc.

.Maximum recommended ampli-

fier output: 100 watts continuous, 28 Vrms, 48V peak to

8 ohms

.8 ohms nominal (see Figure 1)

.

.I00 Hz - 16 kHz (see Figure 2),

optimized for natural widerange voice reproduction

.EIA rating:

from 1

98.5

I-watt input

Positive voltage on phone jack

tip produces positive sound

pressure

49.5

dB at

9.2m

milliwatt; equivalent to

dB at

lm

(30 ft)

(3.3ft) with

LEGEND LEGEND

...........

TYPICAL POLAR PATTERNS

FIGURE

...........

-.-.-.

3

4000 Hz

4

000

Hz

8000Hz

BOOOHz

without wedges

with wedges

without wedges

with wedgns

Printed

in

U.S.A.

Page 2

Vertical Distribution

Directivity Factor

R,

(Q)

.

. .

.

Environmental Resistance:

Operating

Temperature

Storage

Temperature

Connectors

Overall Dimensions

Weight

Construction

Supplied Accessories

Optional Accessory

. . . . . . .

. . . . . . . . . . . . .

.

. . . .

.

. .

.

.

.85" with wedges

80" without wedges

.

.

.

.7.9 at 1 kHz full octave measure-

ment

7.9 at 4 kHz with wedges

4.2 at 4 kHz without wedges

.

. . .

.

-7" to 43°C (20" to 110°F)

. . .

.

.

-29" to 71°C (-20" to 160°F)

.

.

.Two parallel-wired phone jacks

.

.

.283 mm H x 587 mm W x 438

mm D (11% in.

17% in.)

.14.3 kg (31 Ib 8 oz)

.

. . .

.

.15.9 mm

vinyl covering, black fabric

grille, retractile handle, steel

corner protectors, rubber feet

.

.Snap-on protective cover; high-

frequency focusing wedges

.

.

.

RKC4 15m (50 ft) cable with

phone plugs

(%

x

in.) wood, black

23% in.

INSTALLATION

Position the 703 at the front of the stage in front of the

performer's microphone, with the speaker grille aimed

approximately at the back of the microphone. Note that

the 703 may be used at either a

horizontal. The angle chosen should be that which pro-

vides the most direct line-of-sight to the performer and

also provides minimal visual interference with the

audience.

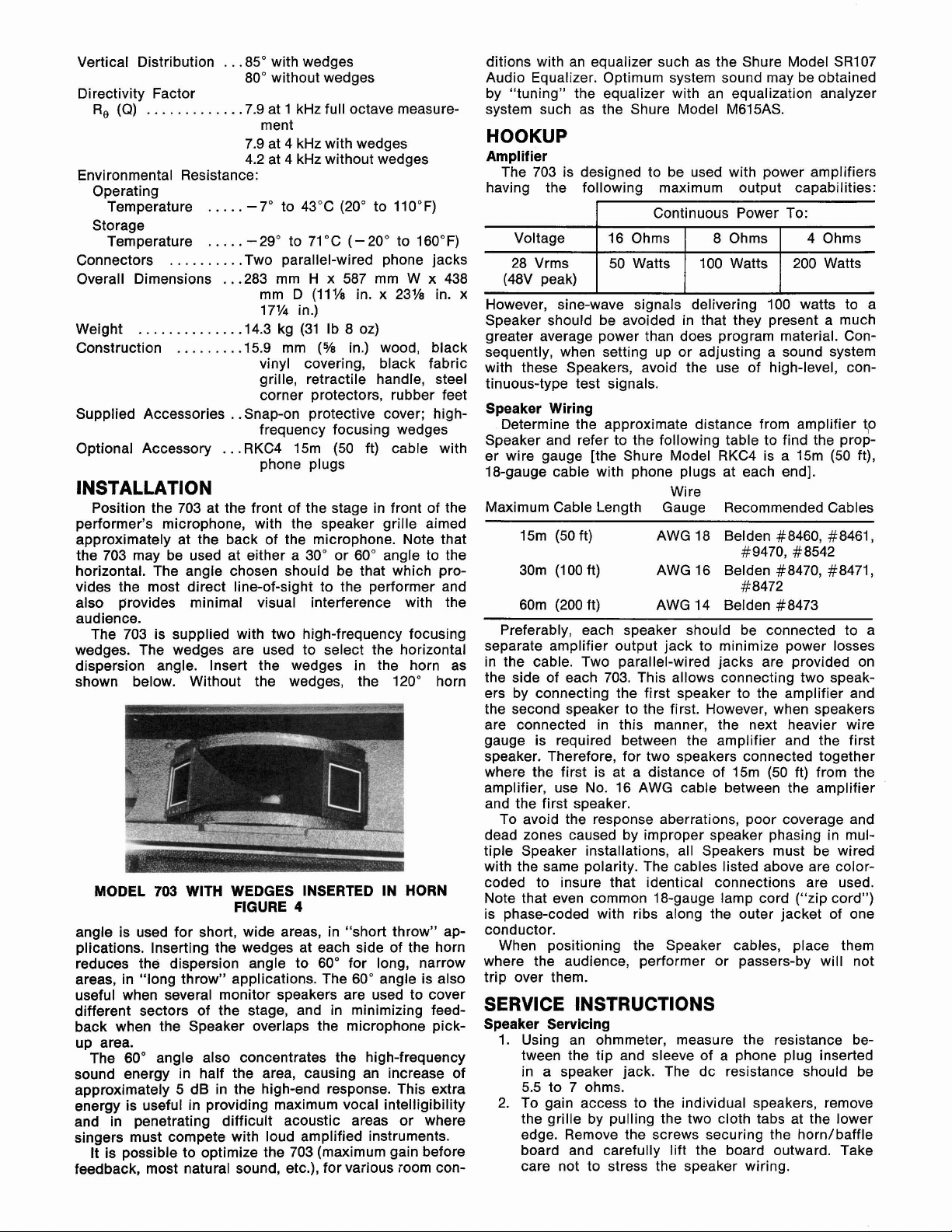

The 703 is supplied with two high-frequency focusing

wedges. The wedges are used to select the horizontal

dispersion angle. Insert the wedges in the horn as

shown below. Without the wedges, the 120" horn

703

MODEL

angle is used for short, wide areas, in "short throw" applications. Inserting the wedges at each side of the horn

reduces the dispersion angle to 60" for long, narrow

areas, in "long throw" applications. The

useful when several monitor speakers are used to cover

different sectors of the stage, and in minimizing feedback when the Speaker overlaps the microphone pickup area.

sound energy in half the area, causing an increase of

approximately 5 dB in the high-end response. This extra

energy is useful in providing maximum vocal intelligibility

and in penetrating difficult acoustic areas or where

singers must compete with loud amplified instruments.

feedback, most natural sound, etc.), for various room con-

60" angle also concentrates the high-frequency

The

It is possible to optimize the 703 (maximum gain before

WITH WEDGES INSERTED IN HORN

FIGURE

30" or 60" angle to the

4

60" angle is also

ditions with an equalizer such as the Shure Model

Audio Equalizer. Optimum system sound may be obtained

by "tuning" the equalizer with an equalization analyzer

system such as the Shure Model

M615AS.

HOOKUP

Amplifier

The 703 is designed to be used with power amplifiers

having the following maximum output capabilities:

28 Vrms

x

However, sine-wave signals delivering 100 watts to a

Speaker should be avoided in that they present a much

greater average power than does program material. Consequently, when setting up or adjusting a sound system

with these Speakers, avoid the use of high-level, continuous-type test signals.

Speaker Wiring

Determine the approximate distance from amplifier

Speaker and refer to the following table to find the proper wire gauge [the Shure Model RKC4 is a 15m (50 ft),

18-gauge cable with phone plugs at each end].

Maximum Cable Length Gauge Recommended Cables

15m (50 ft) AWG 18 Belden #8460, #8461,

30m (1 00 ft) AWG 16 Belden #8470, #8471,

60m (200 ft) AWG 14 Belden #8473

Preferably, each speaker should be connected to a

separate amplifier output jack to minimize power losses

in the cable. Two parallel-wired jacks are provided on

the side of each 703. This allows connecting two speakers by connecting the first speaker to the amplifier and

the second speaker to the first. However, when speakers

are connected in this manner, the next heavier wire

gauge is required between the amplifier and the first

speaker. Therefore, for two speakers connected together

where the first is at a distance of

amplifier, use No. 16 AWG cable between the amplifier

and the first speaker.

To avoid the response aberrations, poor coverage and

dead zones caused by improper speaker phasing in multiple Speaker installations, all Speakers must be wired

with the same polarity. The cables listed above are

coded to insure that identical connections are used.

Note that even common 18-gauge

is phase-coded with ribs along the outer jacket of one

conductor.

When positioning the Speaker cables, place them

where the audience, performer or passers-by will not

trip over them.

Wire

#9470, #8542

#8472

15m (50 ft) from the

lamp cord ("zip cord")

SERVICE INSTRUCTIONS

Speaker Servicing

1. Using an ohmmeter, measure the resistance between the tip and sleeve of a phone plug inserted

in a speaker jack. The dc resistance should be

5.5 to 7 ohms.

2. To gain access to the individual speakers, remove

the grille by pulling the two cloth tabs at the lower

edge. Remove the screws securing the

board and carefully lift the board outward. Take

care not to stress the speaker wiring.

horn/baffle

SR107

40

color-

Page 3

3.

Using an ohmmeter, measure the resistance of each

speaker voice coil. A clicking sound will be made

by a "good" speaker when an ohmmeter is connected or disconnected. Note that the resistance of

&inch speaker cannot be measured without

each

disconnecting a lead from one of its terminals. Each

8-inch speaker should measure between 11 and

13 ohms. The high-frequency driver should measure

7.7

between 6.7 and

ohms with its leads discon-

nected.

4. If the above tests do not locate the problem, apply

a small ac voltage from an oscillator and amplifier

to each speaker individually (approximately

4V,

50 Hz to 5 kHz for &inch speakers; approximately

2V,

3

kHz to 15 kHz for high-frequency driver).

ing plate to

mounting plate and driver from

4.

Replace driver diaphragm and voice coil assembly

as described in High-Frequency Diaphragm and Coil

instruction sheet.

5. For earlier production units, carefully place repaired

or new high-frequency driver in position over

baffle board, taking care to line up holes in driver

over holes in

terminals are positioned toward low-frequency

speakers. Replace three No. 6-32 x

and tighten high-frequency driver assembly.

6. For later production units, carefully place repaired

or new high-frequency driver in position over

baffle board with driver terminals toward low-

horn/baffle board. Remove driver

horn/baffle board.

horn/baffle board. Be sure that driver

1% in. screws,

frequency speakers and three screw heads of driver

seated in three cutouts in rear of horn. Position

WARNING

Sound pressure levels generated by this test may

be damaging to your hearing. Aim speakers away

from listeners and toward sound-absorbent material

(curtains, blanket, etc.). Carefully adjust test signal

amplitude to avoid unnecessarily high sound pressure levels for prolonged periods.

driver mounting plate over driver, lining up holes

in mounting plate over threaded bosses. Replace

two No. 10-16 x 1 in. screws, and tighten securely.

7. Replace driver leads. Note polarity marking or:

driver.

8. Reassemble

horn/baffle board to enclosure and

fasten securely to avoid rattles. Replace grille,

GUARANTEE

This Shure product is guaranteed in normal use to be

free from electrical and mechanical defects for a period

As the test signal frequency is varied, any erratic

buzzes or rattles indicate possible failure.

5. After servicing, replace the speakers and

horn/

baffle board, and tighten all hardware to avoid

rattles. Replace the grille.

High-Frequency Driver Replacement

To replace the high-frequency driver, follow these steps:

1. Remove grille and horn/baffle board as described

in Speaker Servicing.

2.

Remove leads from driver terminals. Note color Attention: Service Department

coding of speaker wires.

3.

For earlier oroduction units. remove three No. 6-32

x 1% in. sdrews securing high-frequency driver to

of one year from date of purchase. Please retain proof of

purchase date. This guarantee includes all parts and

labor. This guarantee is in lieu of any and all other guarantees or warranties, express or implied, and there shall

be no recovery for any consequential or incidental

damages.

SHIPPING INSTRUCTIONS

Carefully repack the unit and return

it

prepaid

Shure Brothers Incorporated

1501 West Shure Drive

Arlington Heights, Illinois 60004

If outside the United States, return the unit to your

horn/baffle board. For later production units, remove dealer or Authorized Shure Service Center for repair.

two No. 10-16 x 1 in. screws holding driver mount-

The unit will be returned to you prepaid.

horn/

horn/

NOTES

(.ALL

RESISTORS

OTHERWISE

TO

SPECIFIED.

BE

10%

,

UNLE55

CIRCUIT DIAGRAM

FIGURE

5

Page 4

REPLACEMENT PARTS LIST

Reference

Designation

A1

A2

C101

C102

C103

J1, J2

L101

L102

LSl, LS2

LS3

PI

M

M P2

M P3

M P4

MP5

M P6

M P7

M P8

M

P9

MP10

MP11

MP12

MP13

MP14

MP15

MP16

MP17

R101, R102

R103

Replacement

Kit

No."

-

RKC153*

RKC156*

*

*

-

A

-

-

-

-

-

-

-

A

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Qty.

-

1

1

-

-

-

-

-

-

-

-

A

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Part No.

90A2753

80231 6

80Y316

50G71

50E71

50F71

90BA2600

95A647

95A823

80A356

80A316

80B316*

80C316*

60A65

66A158

65A1338A

39A463

90A2756

53A1711

90BH2600

53A1656B

30A1002B

30L903C

30H903C

30A882B

30A1115A

95A889

90A2862

53A1775

30F1154A

45HC320E

45EC200G

*

*

*

Replacement Kit Consists

Crossover Network Assembly

High-Frequency Diaphragm and Coil

Capacitor, Mylar, 3.3

Capacitor, Mylar, 4.4 lo%, 250 WVdc*

Capacitor, Mylar, 9.4 ELF, lo%, 250 WVdc*

Connector, Phone Jack, 2-Conductor, Open

Circuit

Inductor, 0.5

Inductor, 0.3

8-inch Loudspeaker

High-Frequency Driver (see A2 for

replacement diaphragm and coil assembly)

703 Speaker Enclosure Assembly

Handle, Feet, Corner Protectors;

Speakers, Crossover Network, Horn/Baffle

Board, Grille Assembly)

Foot, Rubber

HornlBaffle Board

Nameplate

Grille Assembly (with Nameplate)

Connector Plate (without Connectors)

Retractile Handle Assembly

Corner Protector

Carriage Bolt, Aluminum, 2" (Crossover

Network)

Phillips Round Head Machine Screw,

#lo-32UNF-2A, 1

Phillips Round Head Machine

#

10-32, % (Feet)

Phillips Flat Head Wood Screw, #6,

1

%I"

(Horn/Baffle Board)

Threaded Nail, #6,

5h"

(Corner Protectors)

Front Cover

High-Frequency Focusing Wedge

Driver Mounting Plate

Phillips Pan Head Thread Forming Screw,

#lo-16, 1" (Driver)

Resistor, Wirewound, 32 ohms,

Resistor, Wirewound, 20 ohms,

mH, 0.45 ohms

mH, 0.33 ohms

Of:

Description

ELF, lo%, 250 WVdc*

VE

"

(Horn/Baffle Board)

(including

Screw,

15W, 10%

22W, 10%

*

*

* *

*

*

without

*

Parts listed as RKC Kits should be ordered by that kit number. Any orders received for piece parts where RKC Kit number

is shown will be shipped in RKC quantities.

**

Replacement diaphragm and coil assemblies

RKC156. Inspect driver for part number.

*"

Selected for low dissipation factor.

not

interchangeable: 80A316 driver uses RKC153; 80B316 and 80C316 use

Loading...

Loading...