Page 1

PM300 SERIES

OPERATING AND SERVICE MANUAL

Manufactured by

SHURE BROTHERS INC.

222 Hartrey Avenue

Evanston, Illinois 60204 U.S.A.

Copyright 1978, Shure Brothers Inc.

AL 407 (RE) 27A822

Printed in U.S.A.

Page 2

Page 3

PM300 SERIES SPECIFICATIONS

Amplifier Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Output . . . . . . . . . . . . . . . . .

Voltage Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 db (8 ohm load)

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

lnput lmpedance ............................................................. 40,000 ohms

Distortion............................................ 5% maximum at rated output at 1 KHz.

Hum and Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 db below rated output

Speaker Load Impedance

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight: PM300

PM300E and PM300E6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.45 kg (23 lb)

Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gray, black and bright metal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 kg (22 lb)

. . . . . . . . . .

100 watts continuous (RMS) to 8 ohm load (see Figure 3, Page 4)

Nominal 8 ohms (Operational 5.3 ohms minimum, see Page 4)

178 mm height x 429 mm width x 229 mm depth

All silicon transistor power amplifier

1.0 volt (8 ohm load, full rated output)

±0.3 db, 100 Hz. to 10,000 Hz. (typical)

±1.5 db, 35 Hz. to 25,000 Hz. (typical)

(7 in. x 16-7/8 in. x 9 in.)

Ambient Temperature Range

Power Supply: PM300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 volts, 60 Hz.

PM300E

PM300E6

Power Consumption . . . . . . . . . . . . . . . .40 watts with no signal; 160 watts with 1 KHz. signal and 100

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120/240 volts, 50/60 Hz.

. . . . . . . . . .

100, 120, 140, 200, 220, or 240 volts, 50/60 Hz. switch selectable

-7° C. to 43° C. (20° F. to 110° F.) without derating

watts output. 400 watts maximum.

Page 4

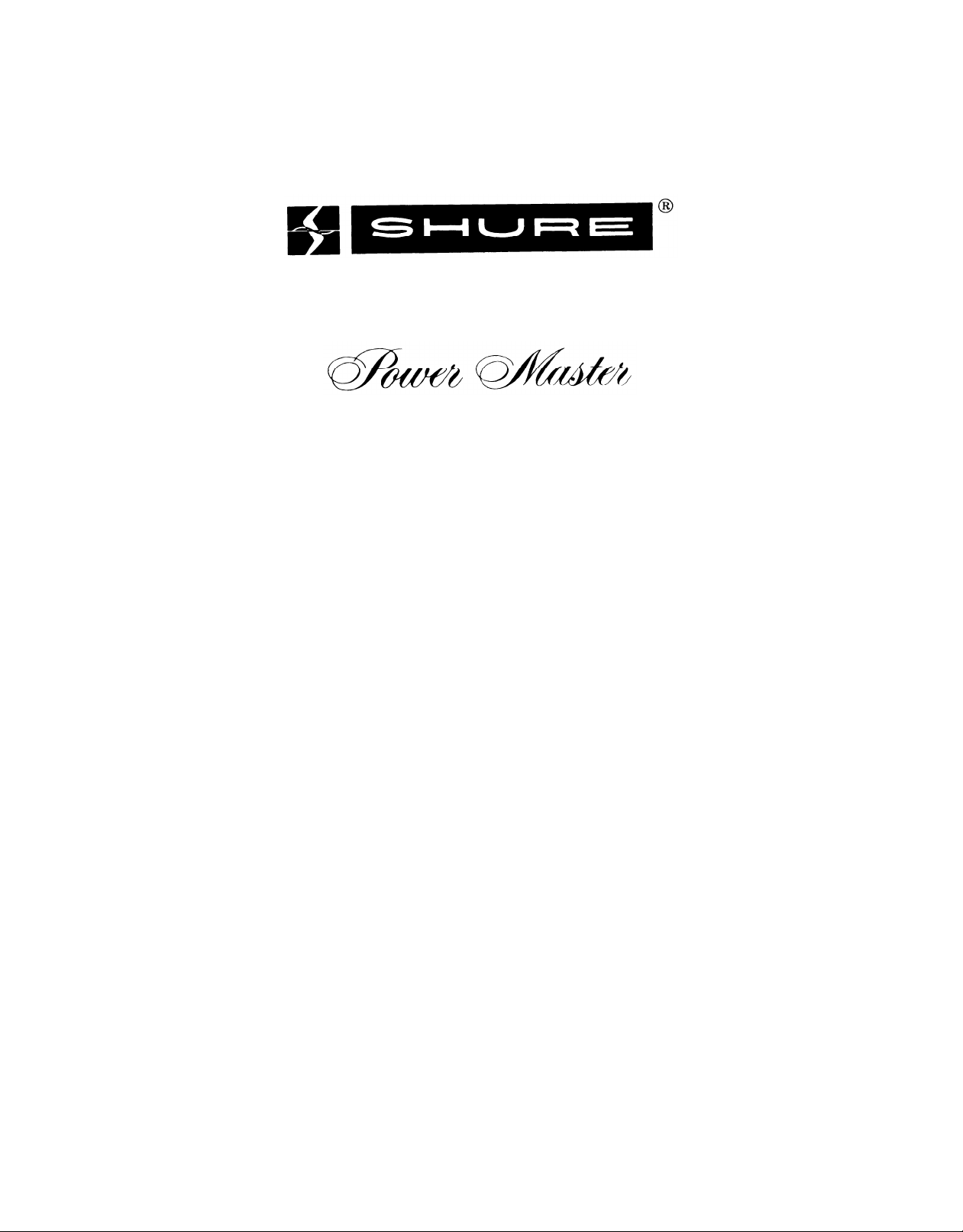

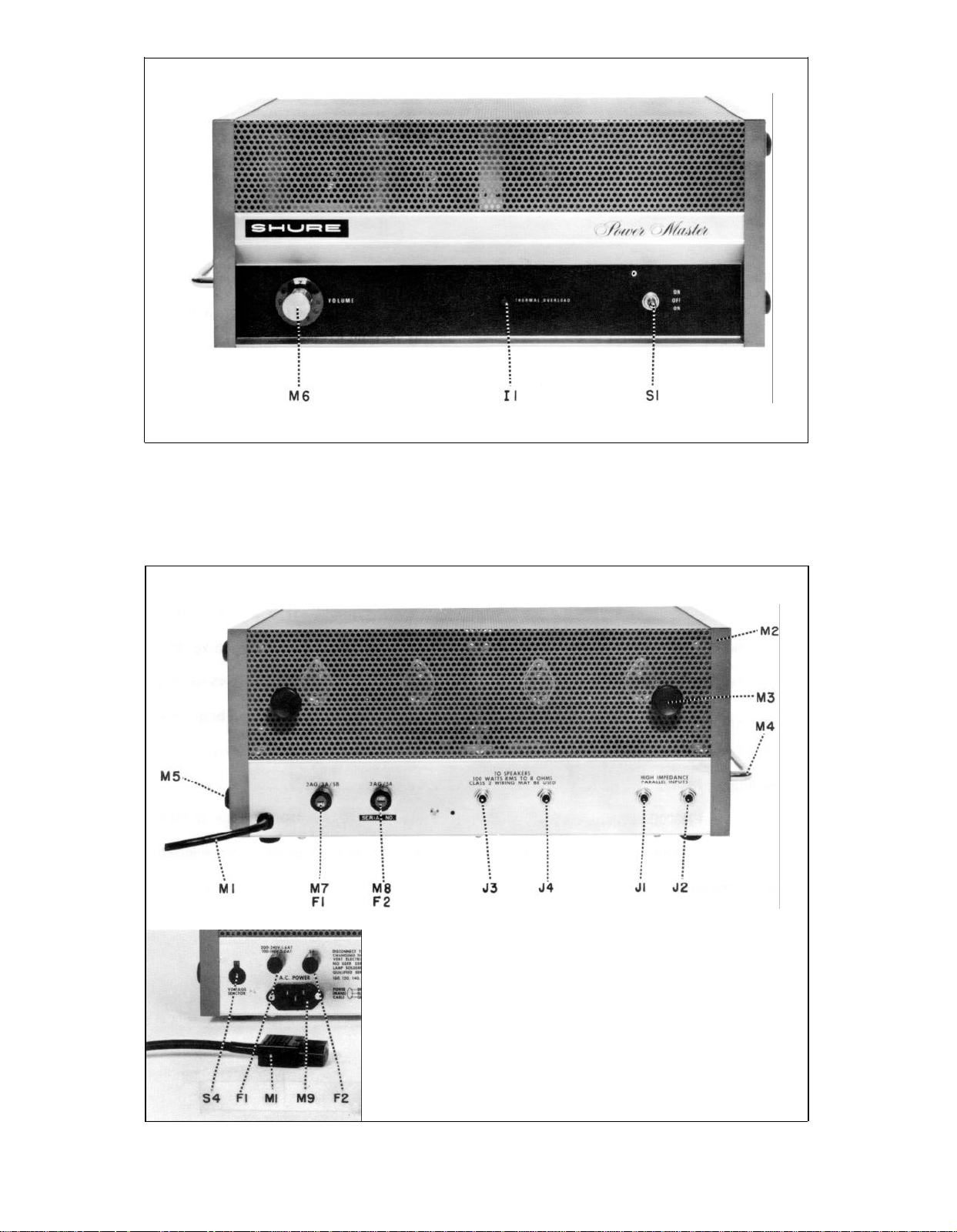

FIGURE 1.

2

FIGURE 2.

Page 5

DESCRIPTION

The Shure Power Master is a solid state booster power

amplifier capable of delivering 100 watts RMS to an 8-ohm

load. It has been designed specifically for use in conjunc-

tion with the Shure VA300-C and VA302-C Series Vocal

Master Amplifiers.

When used as a booster amplifier in conjunction with

the Shure Vocal Master Amplifier, the Power Master will

effectively increase area coverage, provide higher sound

levels and increase reserve power. Several Power Master

Amplifiers may be interconnected to provide even greater

power when required. This unit is ideally suited for use in

theatres, auditoriums, stadiums, college field houses, hotel

ballrooms, convention halls and wherever maximum coverage with reserve power is required.

Silicon transistors and similar solid-state devices are

used throughout the unit. The circuitry design protects the

solid-state components and eliminates the need for special

operating precautions. All components are of the highest

quality and are operated well within their respective tolerances to assure maximum stability under normal use

conditions.

The PM300 is listed by Underwriters’ Laboratories, Inc.,

and CSA Testing Laboratories listed as certified.

EQUIPMENT DESIGNED FOR USE WITH THE PM300

SERIES POWER MASTER AMPLIFIERS

VA300-C

VA302-C

VA302E-C

VA302E6-C

VA300-S

VA301-S

P300R

GUARANTEE: This Shure product is guaranteed in normal

use to be free from electrical and mechanical defects for a

period of one year from the date of purchase. Please retain

proof of purchase date. This guarantee includes all parts

and labor.

SHIPPING INSTRUCTIONS: Carefully repack the unit and

return it prepaid to the factory. If outside the United

States, return the unit to your authorized Shure Service

Center for repair. The unit will be returned to you prepaid.

SERVICE: If information or service should be required,

contact your local Shure Vocal Master dealer explaining

your difficulty in detail. In addition, the Shure factory

service department will be ready to assist you immediately upon request.

Vocal Master Console

Vocal Master Console

Vocal Master Console

Vocal Master Console

Vocal Master Speaker Column

Vocal Master Monitor Speaker

Rack Panel Mount Accessory

PM300 Series

Operating Instructions

Input Connections:

Two parallel-wired input connectors are provided on the

rear panel of the Power Master. These connectors are

standard phone jacks (J1 and J2).

The Power Master may be driven to full rated output, to

an 8-ohm load, by any control-center amplifier, preamplifier, or microphone mixer which is capable of delivering

one volt across a 40,000-ohm load.

When using a Shure VA300-C or VA302 Series Vocal

Master Console as the control amplifier, connect the cable

supplied with the Power Master to the jack marked “To

Tape Recorder” on the VA300-C,* or to the jack marked

“Aux. Hi Level Output” on the VA302 Series Console, connect the other end of the cable to one of the jacks marked

“High Impedance Parallel Inputs” on the Power Master.

Since the two input jacks of the Power Master are wired

in parallel, one jack may be used as an auxiliary, high level,

output to feed the signal to another Power Master or other

booster amplifier. Tape recorders may also be fed from

one of the input jacks of the Power Master to the recorder’s

high impedance auxiliary input. (When used in this manner, the inputs are serving as a junction or “Y” connector

for the Power Master source.)

Additional Power Master Amplifiers may be added to the

system by interconnection from an input jack on one Power

Master to an input jack on another Power Master.

When used in conjunction with a Shure VA300-C or

VA302 Series Vocal Master Console, a setting of approximately “7” on the volume control (M6) of the Power Master

will provide equal output from the Vocal Master Console

and the Power Master when each is connected to equivalent speaker loads.

Power Master

Up to a total of 15m (50 ft) of single conductor, shielded,

low capacitance cable (such as Belden #8401, 8410, or

8411) may be used to interconnect the Power Master

Amplifiers and the preamplifier. Where longer cable

lengths are required, it is suggested that the Power Master Amplifiers be driven by a 600-ohm line from a mixer

or control center amplifier, such as the Shure M67 or

M63, to avoid high frequency signal loss.

Output Connections:

Two parallel-wired output connectors are provided on

the rear panel of the Power Master. These connectors are

standard phone jacks (J3 and J4).

Full rated output of the amplifier is obtained when the

speaker load is 8 ohms (two VA300-S Speakers). Speaker

loads of less than 5.3 ohms (more than three VA300-S

Speakers) should not be used with this amplifier. No damage to the speakers or amplifier will occur, but thermal

shutoff of the amplifier may result. NOTE: With the am-

plifier driven at or near full power, pilot lamp will dim

or vary in brightness; this is a normal condition.

It should be noted that various speaker loads will affect

the output power of the amplifier. See Figure 3, Page 4 to

determine amplifier output power for the given speaker

load.

WARNING: Do not interconnect the speaker output jacks

or the speaker cables between two Power Master

Amplifiers or the Power Master and any other amplifier. This may result in damage to one or both amplifiers, and is not covered by the Guarantee.

*NOTE: Although most VA300-C Vocal Master Consoles have a “phone-

type” “To Tape Recorder” jack, a limited number of early production Consoles have a “phono-type” jack for this function.

If an early Vocal Master Console is used, an adapter (such as

the Switchcraft No. 336A) should be added, or one end of the

connecting cable rewired with a phono plug (such as a Switchcraft No. 3502).

3

Page 6

The Power Master does not use speaker output match-

ing transformers and thus avoids the distortion, power loss

and added weight inherent in such transformers. The

speaker output voltage is 28.3 volts, to an 8-ohm load, for

100 watts. This allows long speaker lines with wiring practices consistent with those used for 25-volt speaker lines.

Up to 30 m (100 ft) of #18 gauge two-conductor cable

(such as Belden #8452, 8478, 8460, or 8461) may be used

to connect from the Power Master to each 16-ohm

(VA300-S) speaker. Greater cable lengths require heavier

gauge wire to avoid appreciable power loss in the speak-

er cable. For 30 to 51 m (100 to 170 ft), use #16 gauge;

51 to 81 m (170 to 270 ft), use #14 gauge; and 81 to 128 m

(270 to 425 ft), use #12 gauge wire. To maximize the

power to each speaker, a separate cable should be used

to connect each speaker to the Power Master.

Speakers:

Selection of speakers for use in a vocal music system is

most critical. The factors which most significantly contribute to an outstanding vocal speaker system are correct

frequency range, distortion-free reproduction, and enough

sound power to fully penetrate the audience area.

The Shure VA300-S Speaker Column has been designed

to provide all of these features. It is recommended that

VA300-S Speaker Columns be used in pairs, each column

having a nominal impedance of 16 ohms, which provides

an impedance of 8 ohms when two are used. Each column

utilizes two special 10-inch speakers and four special 8-

inch speakers, and has a total speaker cone area of

2,310 cm² (358 in²) per column. The VA300-S Speaker

Column delivers virtually uniform penetrating power over

a 140° angle in the horizontal plane and a 65° angle in

the vertical plane. The rear-ported enclosure of the

VA300-S contributes to its highly directional pattern,

which is critical in achieving maximum audience penetration and reduction of feedback.

The Shure VA301-S Speaker Column is intended pri-

marily for use as an “on-stage monitor.” While this speaker

meets all of the criteria for an excellent vocal system

speaker, its area of coverage is more localized than that

of the VA300-S. The nominal impedance of the VA301-S is

32 ohms, so that when used in conjunction with two

VA300-S Speaker Columns, the total system impedance

becomes 6.4 ohms. An integral volume control on the

VA301-S permits its use on-stage as a monitor at the highest possible sound level without feedback.

The following list shows various speaker combinations

and the resultant impedance loads which are suitable for

use with the Power Master:

QUANTITY and SPEAKER MODEL

1 VA300-S

2 VA300-S

3 VA300-S

1 VA301-S

2 VA301-S

3 VA301-S

4 VA301-S

5 VA301-S

6 VA301-S

1 VA300-S and 1 VA301-S

1 VA300-S and 2 VA301-S

1 VA300-S and 3 VA301-S

1 VA300-S and 4 VA301-S

2 VA300-S and 1 VA301-S

2 VA300-S and 2 VA301-S

4

IMPEDANCE

OHMS (NOMINAL)

16

8

5.3

32

16

10.6

8

6.4

5.3

10.6

8

6.4

5.3

6.4

5.3

FIGURE 3. Typical output power vs. speaker load impedance for the

Power Master

PM300 Power Requirements:

The PM300 Power Master is furnished with a three conductor power cable and three-prong plug. Connect the

power cable to an outlet which supplies 120 ±10% volts

A.C., 60 Hz power. The three-position toggle switch on

the front panel controls power to the amplifier. This

switch (S1) is also used to reverse line polarity, for mini-

mum hum. If extension cords are required to supply

power to the PM300, a high quality #18 gauge or larger

cord should be used.

PM300E Power Requirements:

The PM300E Power Master is furnished with a threeconductor power cable without a plug. To connect a plug

to the power cable, attach the brown lead to the live (+)

terminal of the plug, attach the blue lead to the neutral (-)

terminal of the plug, and attach the green-yellow lead to

the earth-ground terminal of the plug.

The PM300E is factory wired for operation from a nominal 240 volt power supply. Connect the power cable to an

outlet which supplies 240 ±10% volts A.C., 50 to 60 Hz

power. The three-position toggle switch on the front panel

controls power to the amplifier. This switch (S1) is also

used to reverse line polarity, for minimum hum. If exten-

sion cords are required to supply power to the PM300E,

a high quality cable with conductors of 0.75 square millimeters cross-section or larger should be used.

An internal modification performed by competent personnel will allow the PM300E to be used with 120 volt, 50

to 60 Hz power. To change the power supply wiring for

120 volt operation, do the following:

UNPLUG THE AMPLIFIER POWER (MAINS) CABLE.

1.

Remove the bottom plate as described on page 6.

2.

With the amplifier upside down, note the six wires

3.

from the power transformer T1.

Unsolder the yellow-black transformer lead wire and

4.

the red-black transformer lead wire from their solderlug.

Resolder the yellow-black lead wire to the solder-lug

5.

to which the all-black transformer lead wire is already

attached.

Page 7

6. Resolder the red-black lead wire to the solder-lug

to which the green-black transformer lead wire is

already attached.

7. Reinstall the bottom plate.

8. Remove the four screws from the nameplate on the

handle end of the amplifier. Turn the nameplate over

and reinstall. The nameplate nomenclature will now

be suitable for 120 volt use.

To change the PM300E back for use with 240 volt power,

reverse the above steps. Be careful to reconnect the yellowblack and red-black transformer lead wires to an UNUSEDUNGROUNDED solder-lug. A pictorial diagram of the trans-

former lead wire connections is located on the inside of

the bottom cover. The circuit diagram for both 120 volt and

240 volt operation is shown on page 10 of this manual.

PM300E6 Power Requirements:

The Model PM300E6 is supplied with a detachable three-

conductor A.C. power (mains) cable without a connector

on the “mains” end. To attach a connector, connect the

brown conductor of the cable to the “live” terminal of the

connector, the blue conductor to the “neutral” terminal,

and the green-yellow conductor to the “earth” ( ) terminal.

The PM300E6 is designed to operate from 100, 120, 140,

200, 220, or 240 volts, 50 to 60 Hertz power (mains). An integral voltage-selector switch, located on the rear panel,

allows selection of the proper voltage.

As shipped from the factory, the PM300E6 is set to operate from 240 volts.

The A.C. fuseholder, located nearest the voltage-selector

switch, contains a 1.6 ampere slow-blow fuse (1.6 AT)

which should be used when the unit is operated from 200

through 240 volts. When operated from 100 through 140

volts, this fuse should be changed to a 3 ampere slow-blow

type (3.0 AT). The fuseholder located farthest from the

voltage-selector switch contains a 5 ampere (5.0 A) fuse

which should not be replaced by other values under any

circumstances. Each of the three fuses mentioned is a

5mm x 20mm type, and two of each value are supplied with

the unit.

CAUTION - DO NOT CHANGE VOLTAGE-SELECTOR

SWITCH SETTING OR ATTEMPT TO REPLACE FUSES WITHOUT FIRST DISCONNECTING THE A.C. POWER (MAINS)

CABLE.

Ventilation:

The Power Master has been designed to operate in a

horizontal position and minimum heat rise in the amplifier

will occur when mounted in this manner. Forty-four and

one-half millimeters (1¾ in.) minimum clearance should

be provided on front, back, and the top of the amplifier

to insure adequate air circulation. The Power Master may

be operated in an ambient temperature range from -7°C

to 43°C (20°F to 110°F) for continuous duty without derating.

Thermal Overload:

The Power Master is equipped with thermal sensing

switches on the heat-sinks of the output transistors. The

thermal switches are set to shut off AC power to the amplifier when a temperature of 90°C (194°F) is attained on the

heat-sinks; the switches will automatically recycle and

return AC power when the heat-sink temperature reaches

73°C (164°F). A thermal overload light (II), located on

the front panel of the Power Master, will indicate if thermal cycling has occurred. Thermal cycling may occur if

air is not allowed to circulate through the grilles of the

amplifier or if there is a prolonged short-circuit on the

speaker output.

Rack Mounting:

The accessory Rack Panel Kit, Model P300R, allows the

Power Master to be rack mounted in standard 19-inch audio

equipment cabinet racks. To insure adequate air circulation, a 44.5 mm (1¾ in.) space should be provided at the

top of the amplifier. The rack mounted Power Master

requires seven inches of height plus the air space. The

Rack Panel Kit is to be installed by qualified service

personnel only.

Connecting a VU Meter:

An external VU meter may be connected to the speaker

wires of the Power Master with a resistor attenuator (see.

Figure 4, Page 5). Use a true VU meter (such as Simpson

Model No. 1349) and three resistors connected as shown.

The resistors should be ½-watt carbon 5%, or 1% if avail-

able.

With an 8-ohm speaker load (two VA300-S) zero VU is

50 watts. Output power for other VU readings is shown in

the table below.

VU

+3

0

-3

-7

-10

Power to 8-ohm load

100 watts

50

25

10

5

FIGURE 4.

PM300 Series Power Master

Service Instructions

Amplifier Service (See Guarantee):

The Power Master uses components of the highest

quality, operating well within their respective ratings to

assure long life. CAUTION: There are no user serviceable

parts inside. Refer servicing to qualified service personnel.

Replacement Parts:

Parts that are readily

parts distributors are not

available through local electronic

shown on the accompanying Parts

List. Their values are shown on the circuit diagram. The

special custom made parts are shown on the Parts List.

The commercial alternates shown on the Parts List are

not necessarily equivalents, but may be used in the event

that direct factory replacements are not immediately available. To maintain the highest possible performance and

reliability, Shure factory replacement parts should be used.

When ordering replacement parts, specify the Shure Re-

placement Kit Number, description, product model number

and serial numbers.

5

Page 8

Bottom Removal:

To remove the chassis bottom plate, turn the amplifier

upside down and remove the ten screws located at the

edges of the chassis.

Cover Removal:

For servicing of the components on the top of the chassis, remove the two screws on the handle end of the cover,

and the two screws within the plastic feet nearest the bottom on the other end of the cover. Uncoil the A.C. line

cord from the storage spindles and slide off the cover.

Small Signal and Predriver Transistors:

Transistors Q1 through Q3, Figure 6, Page 7, are mechanically supported by their leads. When replacing these

transistors, it is imperative that proper lead configuration

be followed. A minimum of soldering heat should be used

to avoid damage to the transistor. Refer to the lower right

corner of the circuit diagram, Figure 7, Page 9 for lead

code.

Driver Transistors:

The driver transistors Q4 and Q5, Figure 5, Page 6, are

located on the amplifier chassis. Before removing these

transistors, write down the lead color and location at each

transistor solder junction. If replacing transistors, apply

type 120 Wakefield thermal joint compound to each side

of the insulating wafer to provide good thermal transfer

from transistor to chassis. After replacement and before

connecting transistor leads, check transistors with an ohmmeter between case and chassis; there should be no continuity. Be sure that these transistors are not inverted in

the circuit; they are not identical devices. Q4 is an NPN

transistor, while Q5 is a PNP transistor. Refer to the lower

right corner of the circuit diagram, Figure 7, Page 9 for

terminal code. NOTE: When replacing driver transistors,

perform the following modification (if not already performed): place insulated tubing over the leads of a 3.3k,

½W resistor and solder it across the terminals to which

the white and black leads of transformer T2 are con-

nected. Solder a .01 µF, 100V disc capacitor from termi-

nal “A” (see Figure 6, Page 7) to the terminal strip

chassis mounting lug next to terminal “A”.

Output Transistors:

The output transistors Q6 through Q9, Figure 5, Page 6,

are located on the black finned heat sinks. Replacement

procedure is the same as that used for the driver tran-

sistors, Q4 and Q5.

NOTE: The output transistors, Q6 through Q9 must be

matched for current gain. When replacing output

transistors be sure to replace with devices which

have the same gain code and part number as the

original transistors. Shure transistors are coded

either by a color dot or a letter stamped on the top

of the transistor.

Blue Dot

Red Dot =B Pink Dot

Orange Dot = C Violet Dot

Yellow Dot =D Black Dot

=A Brown Dot

=F

=G

=H

=J

Green Dot =E White Dot =K

FIGURE 5.

6

Page 9

Diodes:

Diodes D5 and D6, see Figure 5, Page 6, are located on

the black finned sinks with the output transistors. Special

care is required to insulate these diodes from the heat

sink while providing good thermal transfer from sink to

diode. Heat shrinkable tubing or “spaghetti” should be

placed over the diode and connecting leads; the diode

should be securely clamped to the heat sink with the clamp

provided.

Check Transistors and Diodes:

Defective transistors and diodes may be located by use

of an ohmmeter. Polarity of the ohmmeter must be verified

before these checks are made.

With a known diode orientation, measure the diode re-

sistance in the forward and reverse directions. The lowest

meter reading will establish the probe at the cathode end

(schematic symbol arrow points to cathode) as the “minus”

probe while the other probe will be “plus.” Some ohmmeters are not polarized in this manner with relation to

“volts plus probe” and “volts minus probe.”

To check transistors, the ohmmeter should be set to the

100-ohm or 1,000-ohm scale. Small signal transistors (Q1

through Q3) must be removed from the circuit before testing. Transistors mounted with screws (Q4 through Q9) may

be tested in place; however, the base and emitter leads to

these transistors must be removed.

Ohmmeter Connections

---

“Plus” Lead “Minus” Lead

Collector Emitter

Emitter Collector

Collector

Emitter

Base

Base

Base

Base

Collector

Emitter

Ohmmeter Reading

N.P.N. P.N.P.

Transistor Transistor

High High

High

High

Low

Low -

High

Low

Low

High

If all conditions in the above table are met, the transistor may be considered free of any gross defect; if any

of the following conditions are not met, the transistor

should be replaced. See lower right corner of circuit dia-

gram, Figure 7, Page 9 for transistor terminal code,

With the ohmmeter “plus” probe on the anode end of a

diode, and the “minus”

probe on the cathode end, the

ohmmeter should read approximately 2,000 ohms or less.

With the meter probes reversed, a reading of about 10,000

ohms or more should occur. If either of these conditions

is not met, the diode should be replaced.

Power Drain Resistor (R

SEL

):

The following condition may occur after replacement

of driver transistors Q4 and Q5, output transistors Q6

through Q9, or diodes D5 and D6. If the unit appears to

operate at an excessively high temperature or thermally

recycles after about 10 minutes with no signal input, the

“cold” standby power drain may be excessive (up to 20

watts higher than normal; a higher power drain indicates

further circuitry problems). The nominal power drain under

these conditions should be 40 watts; if the measured figure

exceeds 55 watts, insert a resistor (R

) in parallel with the

SEL

56-ohm resistor between the base of transistor Q4 and the

junction of diodes D5, D7 and D8 (figure 7, page 9). R

SEL

(½ W, 10%) should be either 180 ohms to decrease the

power consumption by 20 watts, or 82 ohms to decrease the

power consumption by 30 watts.

Lamp Replacement:

The lamp 12, Figure 6, Page 7, which provides illumination of the front panel controls, is soldered and epoxied

into the molded plastic lamp socket in order to meet Un-

derwriters’ Laboratories requirements. The assembly may

be removed by unsoldering the lamp leads at the terminal

strip and removing the screw that holds the socket to the

chassis.

FIGURE 6.

7

Page 10

Item

C1

C2

D1-D4

D5, D6

D7, D8

F1

F1

F1

F2

F2

F3

I1

I1

I2

J1-J4

M1

M1

M1

M2

M3

M4

M5

M6

M7, M8

M7, M8

M9

M10

Q1-Q2

Q3

Q4

Q5

Q6-Q9

R1

R2

R3-R6

R7

R8

S1

S1

S2, S3

S4

T1

T1

T2

**

Repl.

Kit No.

RKC26

RKC27

RKC46

RKC50

RKC23

RKC62

---

--RKC62

---

--RKC45

RKC78

RKC34

RKC68

RKC82

RKC88

---

RKC69

RKC70

---

RKC39

RKC49

RKC72

---

---

---

RKC9

RKC53

RKC55

RKC54

---

RKC47

RKC73

---

---

--RKC61

--RKC37

--RKC35

RKC147

RKC28

REPLACEMENT PARTS LIST FOR PM300 SERIES AMPLIFIERS

Replacement Kit Consists of:

Qty. Part No.

86A631

1

1

86B631

4

86A406

2

86A410

1

86A409

5

80A159

-

80A258

Capacitor, 2500 x 100

Capacitor, 4000 x 60

Silicon Rectifier, 3A., 200 V.

Silicon Rectifier, ½A., 100 V.

Zener Diode, 3.6 V., 1 W., 5%

A.C. Fuse (PM300 and PM300E)

A.C. Fuse (PM300E6 only)

Description

None

None

Motorola No. 1N4721

Motorola No. 1N4002

Motorola No. 1N4729A

Littelfuse 3AG/3A/SB (Slo-Blo)

Wickmann 5 x 20mm 1.6 AT, 250 V.

for 200-240 volts

-

80B258

A.C. Fuse (PM300E6 only)

Wickmann 5 x 20mm 3.0 AT, 250 V.

for 100-140 volts

5

-

1

1

2

1

1

80A160

80A259

80A269

80A79

80Z251

90A1463

95B446

95A510

D.C. Fuse (PM300 and PM300E)

D.C. Fuse (PM300E6 only)

Wired in A.C. Fuse (PM300 only)

Pilot Lamp (PM300 only)

Pilot Lamp (PM300E and PM300E6)

Lamp Assembly

Phone Jack

3 Wire A.C. Line Cord and Plug

Littelfuse 3AG/5A

Wickmann 5 x 20mm 5.0 A, 250 V.

Bussmann MDV/5A/SB (Slo-Blo)

Leecraft No. 36N1311-6

Leecraft No. 36HN-1311-7W

None

Switchcraft No. 11

None

(PM300 only)

1

-

70A3071

90A1888

Line Cord (PM300E only)

Line Cord and Connector

None

None

(PM300E6 only)

1

90A1681

Housing Assembly (Cover and

None

Spindle)

1

32A627

Knob and Screw (Line Cord

None

Storage Spindle)

1

4

3

1

-

-

4

90BC2600

65A685

90B2285

95A500

95A604

95A568

90A1522

86A349

Handle and Nuts

Bumper (Plastic Foot)

Volume Control Knob Assembly

Fuse Holder (PM300 and PM300E)

Fuse Holder 5x20 mm (PM300E6

only)

A.C. Chassis Power Connector

(PM300E6 only)

Input Interconnecting Cable

Transistor (Replaces 86A327)

Bud No. H9115

None

None

Littelfuse No. 341001

Schurter Type FEB

Switchcraft No. EAC-301

None

Motorola No. MPS-6521,

Texas Inst. No. 2N3711

1

1

1

1

1

-

-

1

86A333

86A338

86A339

86B339

86A332*

86B332*

45A38

46A025

45EC439B

45EC209B

45EC129B

55A72

Transistor 110 V. BV

Transistor 110 V. BV

Transistor 105 V. BV

CEO

CEO

CEO

Min.

Min.

Min.

(Mutually Interchangeable)

Transistor 110 V. BV

CEO

Min.

150 W.

Resistor

Potentiometer, 50K.

Resistor, 0.43 ohms, 5 W.

Resistor, 0.20 ohms, 5 W.

Resistor, 0.12 ohms, 5 W.

Toggle Switch (PM300 and

RCA No. 40349

RCA No. 2N3441

Motorola No. 2N3741 Selected

RCA No. 2N3773

Workman No. FRT-2

None

None

None

None

Cutler-Hammer No. 7563K5

PM300E)

-

55A98

Toggle Switch, 2 position

Marquardt Type No. 0132

(PM300E6 only)

95A551

1

-

55A99

Thermostat

Voltage-Selector Switch

None

None

(PM300E6 only)

1

1

51A215

51A241

Power Transformer (PM300 only)

Power Transformer (PM300E and

None

None

PM300E6)

1

51A217

Feed back Transformer

None

Commercial Alternate

Pig-Tail

NOTE:

The Commercial Alternates shown above are not necessarily equivalents, but may be used in the event that direct factory replacements are not

immediately available. To maintain the highest possible performance and reliability, Shure Factory Replacement Parts should be used.

*When ordering 86A332 or 86B332, specify current gain code. See page 6.

**Parts listed as RKC Kits should be ordered by that kit number. Any orders received for piece parts where RKC Kit number is shown will be shipped in RKC quantities.

8

Page 11

NOTES TO THE CIRCUIT DIAGRAM

D.C. Voltage Measurements:

Check the DC voltages before checking AC voltages because transistors Q2 through Q9 are direct coupled and

any deviation from the nominal voltages will affect the AC

voltages. The four key DC voltages are +94, +20, the

emitter of Q1, and the split voltage at the junction of R3,

R5, R7, and R8. If these four key DC voltages are correct,

then proceed with the AC voltage measurements.

The numbers within the symbol on the circuit dia-

gram denote the DC voltage at that point with the follow-

ing test condition:

1.

Voltages measured at points indicated with respect to

chassis, unless otherwise specified.

2.

Line voltage PM300: 120 V. 60 Hz.; PM300E: 120/240 V.

50/60 Hz.; PM300E6: 100, 120, 140, 200, 220, or 240 V.

50/60 Hz.

3.

No input signal applied.

4.

DC voltage measurements may vary ±20% from the

values shown.

5.

Measured with a VTVM of 11-megohms input impedance.

A.C. Voltage Measurements:

The numbers within the symbols on the circuit

diagram denote the AC voltage at that point with the following test conditions:

1.

Voltages measured at points indicated with respect to

chassis, unless otherwise specified.

2.

Line voltage as specified above.

3.

1,000 Hz. signal applied to one of the high impedance

parallel inputs at 300 millivolts (.3 volts).

4.

Measured with an AC VTVM of 1.0 megohms or greater

input impedance.

5.

Noninductive load of 8 ohms, 200 watts connected to

speaker output jack.

6.

Volume control set to maximum.

7.

AC voltage measurements may vary ±20% from the

values shown.

Shure part numbers are not shown in the Parts List, ac-

companying the circuit diagram, if parts are readily available through local electronic parts supply distributors. In

these instances, the circuit diagram will show the values of

the standard parts.

All capacitor values are shown in microfarads. All non-

electrolytic capacitors are to be 100 volts or more unless

otherwise specified in the circuit diagram. Electrolytic

capacitors are shown in microfarads and volts.

All resistor values are shown in ohms. Resistors are all

to be 10% tolerance unless specifically noted on the circuit diagram.

All resistors are ½ watt unless otherwise specified.

The following ground symbol

denotes chassis ground:

Ohmmeter Measurements:

With the A.C. line cord unplugged and the power switch

in the “OFF” position, the following ohmmeter measurements may be made.

1.

B+ to ground approximately 100 ohms.

2.

Ohmmeter plus probe to the junction of R3, R5, R7, and

R8, ohmmeter minus probe to ground; greater than 120

ohms.

3.

Ohmmeter plus probe to B+, ohmmeter minus probe to

the junction of R3, R5, R7, and R8: greater than 120

ohms.

4.

To test transistors and diodes, see page 7.

NOTES:

1.

ALL CAPACITORS IN MFD AND 100 VOLTS OR MORE

UNLESS SHOWN. ELECTROLYTIC CAPACITORS SHOWN

IN MFD x VOLTS.

2.

ALL RESISTORS 10%, ½ WATT, UNLESS OTHERWISE

INDICATED. R3 THRU R8 10%, 5 WATT.

3. THE FOLLOWING SYMBOLS DENOTE:

DC VOLTAGE

WITH RESPECT TO CHASSIS UNLESS OTHERWISE

SHOWN.

4. R

MAY BE 180 OR 82 OHMS, OR NOT USED, DEPENDING

SEL

ON POWER

DRAIN

(SEE PAGE 7).

AC VOLTAGE

PM300 CIRCUIT DIAGRAM

FIGURE 7.

9

Page 12

PM300E POWER SUPPLY CIRCUIT DIAGRAM

FIGURE 8.

PM300E6 POWER SUPPLY CIRCUIT DIAGRAM

10

FIGURE 9.

Loading...

Loading...