Page 1

I

222 HARTREY AVE EVANSTON. ILL CABLE SHUREMICRO

I

EVANSTON PHONE DA 8-9000 CHICAGO PHONE SH 3-1600.

MODEL M8D STEREO STANDARD PHONO CARTRIDGE

The M8D Cartridge has standard

mounting centers. Two #3-48 x

machine screws are supplied with each cartridge for

mounting purposes. By using

cartridge can be mounted on

centers. It is

line on the front of the cartridge be perpendicular to

the turntable or record surface. If no

avoiloble to do this, a paper or metal shim can be used

on one mounting post to adjust angle of cartridge.

The recommended needle point force for optimum

results is

ridges, adjustment is generally

it be necessary, adiustment

adjusting the counter

arm. Forces

to provide

GENERAL

The Model M8D Stereo Standard

Cartridge has been developed for use in all high

fidelity applications.

~nto magnetic and constant velocity inputs.

The Model M8D

words. the Model M8D will

phonically, Monaurol Discs 'Monaurally, and Stereo

Discs Monaurally without excessive wear and without distortion.

The Model

principle employed in both the Studio, Professional and

Dynetic Phono Cartridges and offers the same

Custom

important features, such as:

High needle compliance.

Low needle talk. For single channel reproduction of Monaural or

Low tracking forces.

Wide range frequency response.

Magnetic induction from external fields is reduced

to a minimum.

No magnetic attraction to steel turntables.

ResPMIm

c.p.1.

Output

Channel Separation: More than

Recommended Load Impedance: 47,000 ohms (per

channel) for Stereo.

values will produce a slight increase in high frequency

response.

Stylur: Number N8D

Compliant*:

Tracking Force:

Inductance 420 millihenries

D.C.

Terminals: 4 terminals. An independent ground term-

inal far each channel.

:$:;ti?

mounting centers using #2 machine screws.

Wmight: 9.0 grams (32 0s.)

Fnquency

Voltage 5 millivolts per channel.

Radius

Resistance: 330 ohms.

:

Standard

3 or

It has been designed to connect

is completely compatible.

M8D utilizes the same moving magnet

SPECIFICATIONS ground

.0007" (0.018 mm.) Diamond

VERTICAL per dyne

HORIZONTAL

5

to 8 grams

#4 machine screws. .437" (1l.lmm.)

plav Stereo Discs Stereo-

CharachrisBcc

22,000

ohms for monaural. Higher

(

3.0 x 10-6 centimeters

(See Fig.

V2"

(12.7 mm.) mounting centers

Dynetic Phono

From

3O

20db at 1000 c.p.8.

(6

grams optimum)

I).

In other

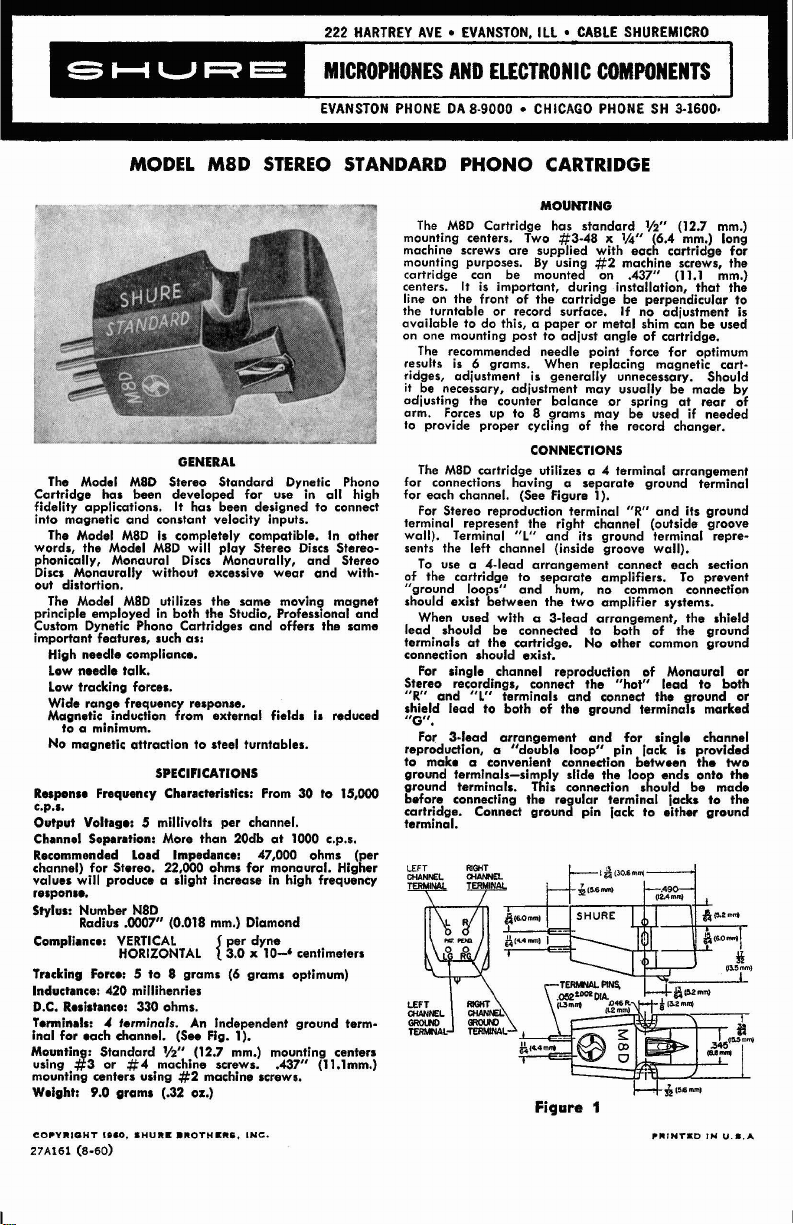

for connections having

for each channel. (See Figure 1).

terminal represent the right channel (outside groove

wall). Terminal

sents the left channel

of the cortridge to seporate amplifiers. To prevent

"ground loops" and hum, no common connection

should exist between the two amplifier systems.

lead should be connected to both of ;he ground

terminals at the cartridge. No

connection should exist.

Stereo recordings, connect the "hot" lead to both

"R"

?$$!d

reproduction, a "double loop" pin jack is provided

to make

ground terminals.

before connecting the re ular terminal lacks to the

cartridge. Connect

terminal.

y=~~~

,w

77

6

The

M8D cartridge utilizes a 4 terminal arrangement

For Stereo reproduction terminal

To use a 4-lead arrangement connect each section

When used with a 3-lead arrangement

and

"1"

lead

-.

Mead arrangement and for single channel

For

a

termlnals-sim ly slide the loo ends onto the

&

,,,,,

MOUNTING

1h''

#2

machine screws, the

important, during installation, that the

grams. When replacing magnetic cart-

UP

roper

balance or spring at rear of

to 8 srams may be used if needed

cyclTng of the record changer.

CONNECTIONS

o seporate ground terminal

.437" (11.1 mm.)

unnecesrory. Should

may usually be made by

"R"

"L" and its ground terminal repre-

(inside aroove wall).

-

other common ground

terminals and connect the ground or

to

of

tho

ground

convenient connection between the two

TL

connection stou~d be made

grounl pin jack to either ground

J--+&I-J-

Figure

1

1/2"

(12.7 mm.)

(6.4 mm.) long

odiustment is

and its ground

the shield

terminals

marked

Page 2

Do not

inals. Make all solder connections to

provided.

Ieudspeakers. Although the hosing of the M8D

cartrid e is carefully controlred, there are many

possibfitie. where a particular High Fidelity ryrhm

can wurs opposite phasing of the sound from the

speakers. The hasing can be easily checked by a

listening test.

Reverse the connections of the wires to one speaker.

This can be done at the amplifier or the speaker,

which ever is more convenient. When the sound a

pears to come from a point halfway between

speokers, they are in phase. Also, bass reproduction

will be much fuller when speakers are correctly

phased.

SPECIAL NOTE:

plays such an extremely important part in the overall

performance

Reptoducer, be certain that any replacement stylus is

a genuine Shun

is practically immune to damage during

However, care should be token to avoid bending or

distorting

removed.

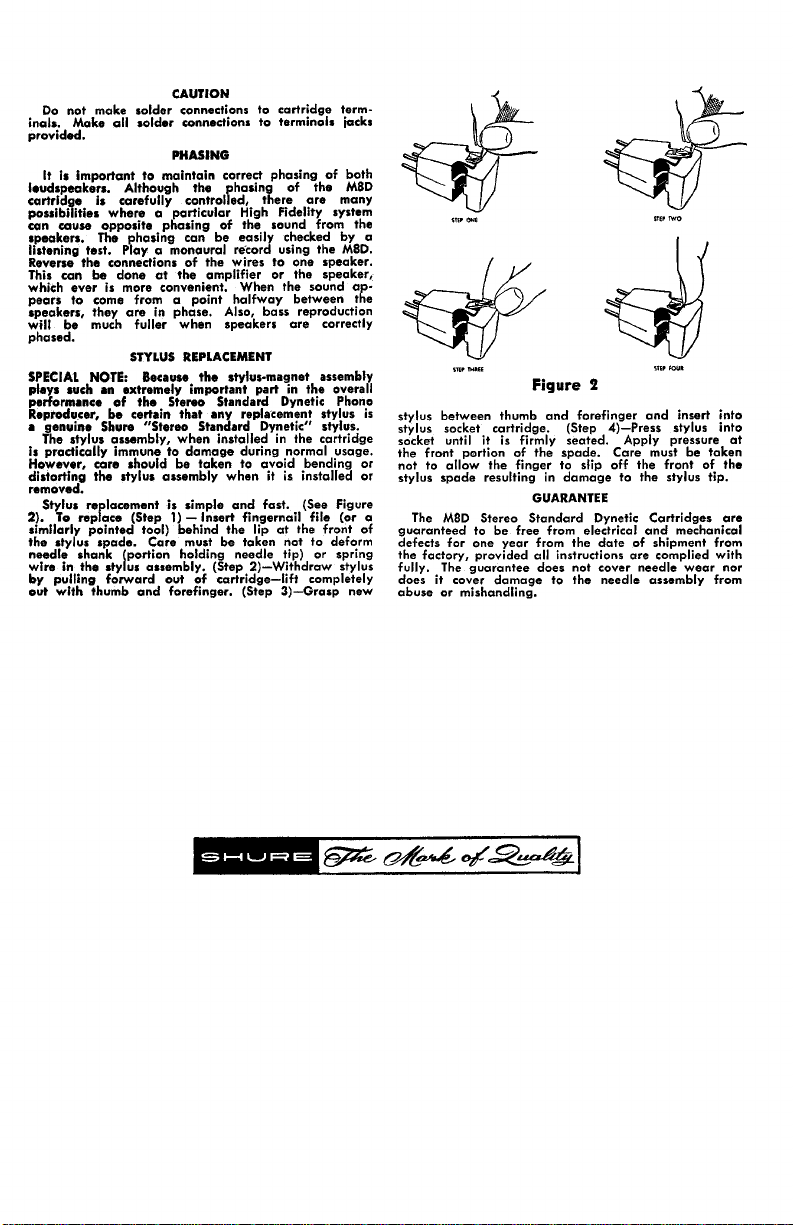

2).

simllarly pointed tool) behind the lip at the front of

the stylus spade. Care must be taken not to deform

needle shank portion holding needle tip) or spring

wire in the stylus assembly. (Step

by pulling

out with thumb and forefinger. (Step 3)-Grasp new

make solder connections to cartridge term-

It

is important to maintain correct phasing of both

The stylus assembly, when installed in the cortridge

the stylus assembly when it is installed or

Stylus re

lacement is simple and fast.

Ta repkce (Step

forward out of cartridge-lift completely

CAUTION

terminals

PHASING

pray a monaural record using the M8D.

STYLUS REPLACEMENT

Because the stylur-magnet assembly

of the Steno Standard Dynetic Phona

"Sterea Standard Dynetic" stylus.

1)

-

Insert fingernail file (or a

2)-Withdraw stylus

bcks

tli

norm01 usage.

(See Figure

ITB

Mlt

stylus between thumb ond forefinger ond insert into

stylus socket cortridge. (Step 4)-Press stylus into

socket until it is firmly seated. Apply pressure at

the front portion of the spade. Care must be token

not to allow the finger to slip off the front of the

stylus spade resulting in damage to the stylus tip.

The

M8D Stereo Standard Dynetic Cartridges are

guaranteed to be free from electrical and

defects for one yeor from the date of shipment from

the factory, provided all instructions ore complied with

fully. The guarantee does not cover needle wear nor

does it cover domage to the needle assembly from

abuse or mishandling.

Figure

GUARANTEE

2

mechanical

Loading...

Loading...