Page 1

THE

PREMIER

MODEL

FAMILY

M75-6s

EASY-MOUNT

222 HARTREY AVE.. EVANSTON.

-

~--

~--

TWX: 910-231 0048 TELEX: 72-4381

OF STEREO

SOUND

STEREO DYNETIC@

PHONOGRAPH CARTRIDGE

IL.

60204

REPRODUCERS

CARTRIDGE AND STYLI SPECIFICATIONS

20

N75-6

15 microns

(.00ffi in.)

Spherical

--

N75-37

64

microns

LO025 in.)

Spherical

?Optional 78 rpm Stylus for V15 Type II and M75 Series Cartridges:

'Output voltages given {or stereo cut record. For MONO cut record,

**Tracking forces greater than maximum indicated should not be used.

Beige

6.2

mV

Dark

6.2 mV

Green

amplifier

Set

output voltage at both left channel and right channel cartridge terminals

will

to "MONO" or "AtB."

be

71%

of figures above.

20 to

20,000

Hz

20 to

20,000

Hz

within

2 dB

-

NET WEIGHT: 5.6 grams

INDUCTANCE: 720 millihenries

DC

RESISTANCE: 630 ohms

OPTIMUM LOAD: 47,000 ohms resistance in parallel with 400 to 500

plcof-rads total

70,000 ohms with almost no audible change in frequency response. Total

capacitance includes both tone arm wiring and amplifier input circuit.

FOUR-CHANNEL:

four-channel matrix systems

MONOPHONIC OPERATION: Set function switch on amplifier to "MONO"

or

"A+B." If amplif~er is not equipped with this switch, connect left and

right channels in parallel.

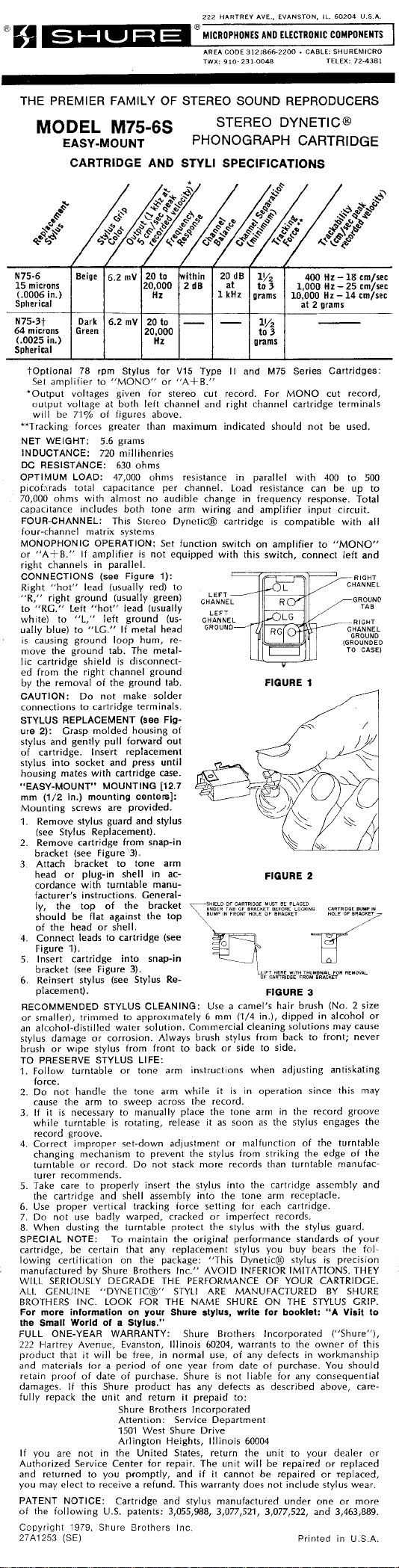

CONNECTIONS (see Figure

Right "hot" lead (usually red) to

"R," right ground (usually green)

to "RG." Left "hot" lead (usually

whlte) to

ually blue) to "LC." If metal head

1s causing ground loop hum, remove the ground tab. The metallic cartridge shield is

ed from the right channel ground

by the removal of the ground tab.

CAUTION: Do not make solder

connections to cartridge terminals.

STYLUS REPLACEMENT (see

ure

2):

stylus and gently pull forward out

of cartridge. Insert replacement

stylus into socket and press until

housing mates with cartridge case.

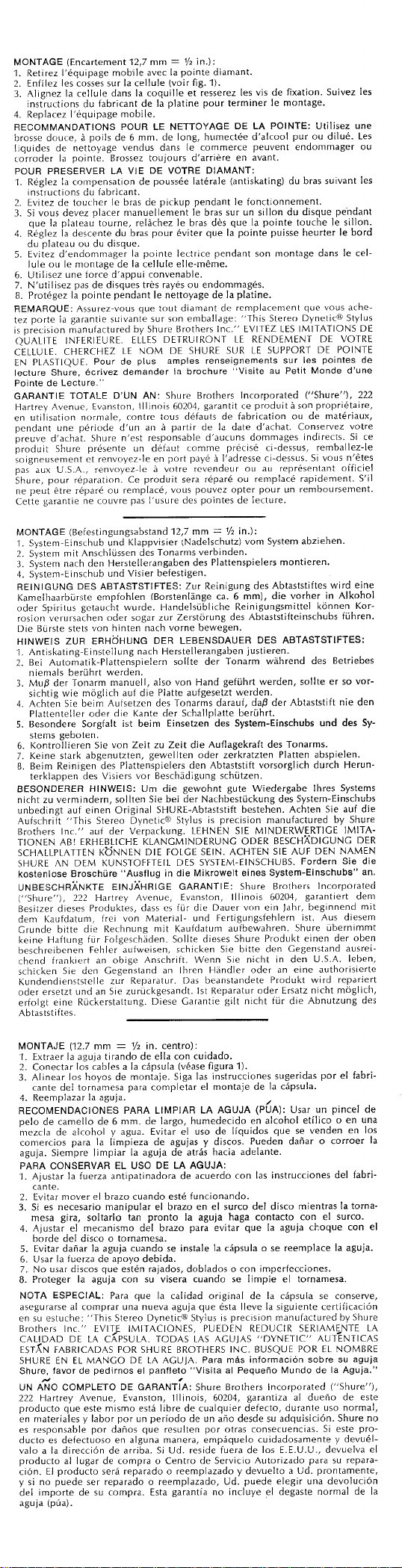

"EASY-MOUNT" MOUNTING

mm (1/2 in.) mounting centers]:

Mounting screws are provided.

1. Remove stylus guard and stylus

(see Stylus Replacement).

2. Remove cartridge from snap-in

bracket (see Figure

3 Attach bracket to tone arm

head or plug-in shell in ac- FIGURE

cordance with turntable manufacturer's instructions. General-

ly:

the

should be flat

of the head or shell.

4. Connect leads to cartridge (see

Figure

5. Insert cartridge into snap-in

bracket (see Figure

6.

Reinsert stylus (see Stylus Re-

placement). FIGURE

RECOMMENDED STYLUS CLEANING: Use a camel's hair brush (No. 2 size

or smaller),

an alcohol-distilled water solution. Commercial cleaning solutions may cause

stylus damage or corrosion. Always brush stylus from back to front; never

brush or

TO PRESERVE STYLUS LIFE:

1.

Follow turntable or tone arm instructions when adjusting antiskating

force.

2. Do not handle the tone arm while it is in operation since this may

cause the arm to sweep across the record.

3. If it is necessary to manually place the tone arm in the record groove

while turntable is rotating, release it as soon as the stylus engages the

record groove.

4. Correct improper set-down adjustment or malfunction of the turntable

changing mechanism to prevent the stylus from

turntable or record. Do not stack more records than turntable manufacturer recommends.

5. Take care to properly insert the stylus into the cartr~dge assembly and

the cartridge and shell

6. Use proper

7. Do not use bad!y warped, cracked or imperfect records.

8. When dusting the turntable protect the stylus with the stylus guard.

SPECIAL NOTE:

cartridge, be certain that any replacement stylus you buy bears the following certification on the package: "This

manufactured by Shure Brothers Inc."

WILL SERIOUSLY DEGRADE THE PERFORMANCE OF YOUR CARTRIDGE.

ALL GENUINE

BROTHERS INC. LOOK FOR THE NAME SHURE ON THE STYLUS GRIP.

For more information on your Shure stylus, write for booklet:

the Small World of a Stylus."

FULL ONE-YEAR WARRANTY: Shure Brothers lncorporated

222 Hartrey Avenue, Evanston, Illinois 60204, warrants to the owner of this

product that

and materials tor a period of one year from date of purchase. You should

retain proof of date of purchase. Shure is not liable for any consequential

damages.

fully repack the unit and return it prepaid to:

If you are not in the United States, return the unit to your dealer or

Authorized Service Center for repair. The unit will be repaired or replaced

and returned to you promptly, and if it cannot be repaired or replaced,

you may elect to receive a refund. This warranty does not include stylus wear.

PATENT NOTICE:

of the following U.S. patents: 3,055,988, 3,077,521, 3,077,522, and 3,463,889.

Copyright

27A1253 (SE) Prlnted in U.S.A.

capacitance

per channel. Load resistance can be up to

Thls Stereo Dynetic@ cartridge

1):

"L,"

left ground (us-

dlsconnect-

Grasp molded housing of

Fig-

[12.7

3).

top

of

the bracket

against

the top

1).

3).

trlmmed to

wlpe stylus from front to back or side to side.

it will be free, in normal use, of any defects in workmanship

If this Shure product has any defects as described above, care-

1979,

approximately

vertlcal tracking force setting for each cartridge.

assembly into the tone arm receptacle.

To maintain the original performance standards of your

"DYNETIC@" STYLI ARE MANUFACTURED BY SHURE

Shure Brothers lncorporated

Attention:

1501 West Shure Drive

Arlington Heights, Illinois 60004

Cartridge

Service Department

and stylus manufactured under one or more

Shure Brothers Inc.

at

1

kHz

-

dB

1%

to

grams

1%

to

grams

400

Hz

1,000

Hz

Hz

at 2 grams

-

-

-

3

10,000

3

IS

compatible with all

,::{&

CHANNEL

2

$WELD

OF

C4-T-DGE

MUST

81

YNDLR

Tiis

LUMP

Or

IN

FRONT

6 mm

(1/4

Dynetic@ stylus is precision

AVOID INFERIOR IMITATIONS. THEY

PLACED

BRACKET

BEFORE

LOCIINe

CbRTRlD6E

W1TH

TWUMBH&IL

FROM

HOLE

BRACKET

TON

"OLE

LLFT

OF BRlCILT

HERE

OF

CiiRTllDDE

3

in.), dipped in alcohol or

str~king the edge of the

"A

("Shure"),

OFBRaCKET

Visit to

U.S

18 cm/sec

25 cm/sec

14

cm/sec

BUWIN

7

REMOVAL

A

Page 2

Loading...

Loading...