Shure M75-6 User Guide

222

HARTREY

AVE..

EVANSTON.

IL.

60204

U.S.A.

MODEL

M75-6

/7WT#3AACK

Model Diamond Stylus

Number Replacement

M75-6 N75-6 Radius:

M75E N75E Elliptical

M75G N75G Radius:

M75 Series N75-3,* Radius:

V-15 Type

.0006” (.015 mm)

Side Contact

Radius

:

.0002“ (.005 mm)

Frontal Radius:

,0007’’

(.OX3

,0006“ (.015 mm)

I1

,0025’’ (.064 nlm)

AREACODE312/328.9000

PHONOGRAPH CARTRIDGE

Output Voltage Stylus

(I

,000

Hr.

5

cm/sec)

6.2 millivolts

6.2 millivolts

mm)

6.2 millivolts

6.2 millivolts Green

.

CABLE:

SHUR5MICRO

DATA

SHEET

STEREO DYNETICO

Grip Tracking

at

Color

Beige

Yellow

Dark

Gray

(Grams)

1%

3/4

3/4

1%

to

to

to

1%

1%

to 3

3

Higher stylus forces within specified range greatly improve

trackability.

FREQUENCY RESPONSE:

CHANNEL SEPARATION:

RECOMMENDED LOAD IMPEDANCE:

INDUCTANCE:

D.C. RESISTANCE:

MOUNTING:

WEIGHT:

TERMINALS:

GENERAL:

graph cartridges has been developed for use with all high fidelity

amplifiers having magsetic and constant velocity inputs.

SHURE-SME MOUNTING INSTRUCTIONS:

in the Shure-SME Precision Pickup Arm, Model

refer to the aarapraphs on Cartridge Installation and Balancing

in the instruction-Manual supplied with the pickup arms.

OPERATION

are listed under “Specifications.” Forces greater than the indi-

cated “maximum” should not be used.

4-LEAD STEREO CONNECTION:

ahannel

L

-. . . . . .

nel to terminal “RG.”-Connect ”hot” lgad

minal

“L”

To prevent “ground loops” ar

should be used at cartridge terminals

MONAURAL CONNECTION:

Monaural

and “L” terminals and ynnect ground or shield lead to both

ground terminals marked

720 millihenries

Standard

6 grams

4

terminals

The M75 Series

:

Recommended needle forces

tn

terminal

. . .

. ..-.

and shield or ground lead of left channel to LG.

or

Stereo recordings, connect “hot” !ead to both

From 20 to 20,000 Hz. (cps)

More than 25 db at

1,000

Hz. (cps)

47,000 ohms per channel

630 ohms

%”

(12.7 mm) mounting center

of

High Trackability Dynetic phono-

To mount the M75

3009

for

optimum results

CON N ECTl 0 N

“R”

and shield or eround lead of rieht chan-

S

Connect “hot” lead of right

of

left channsl

id hum, no common connection

For single channel reproduction

RG” and “LG.”

and 3012,

<?

ter;;

“R”

of

Suggestions

To clean the stylus, use a camel's-hair

smaller) dinDed liehtlv in

Always

brush the stylus with a forward movement from the rear

(terminal end of the cartridge) to the front. Never brush or wipe

the stylus from front to back

CAUTION:

Make all solder connections to terminal jacks provided before slipping them over the terminals.

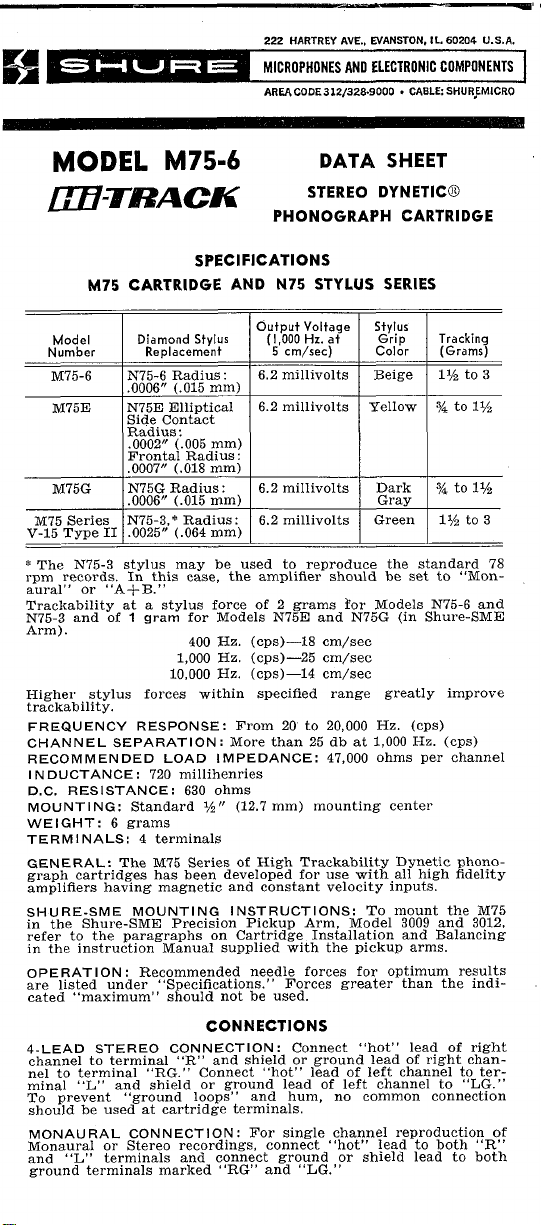

I

FFT

LEFT

Do not make solder connection to cartridge terminaJs.

.

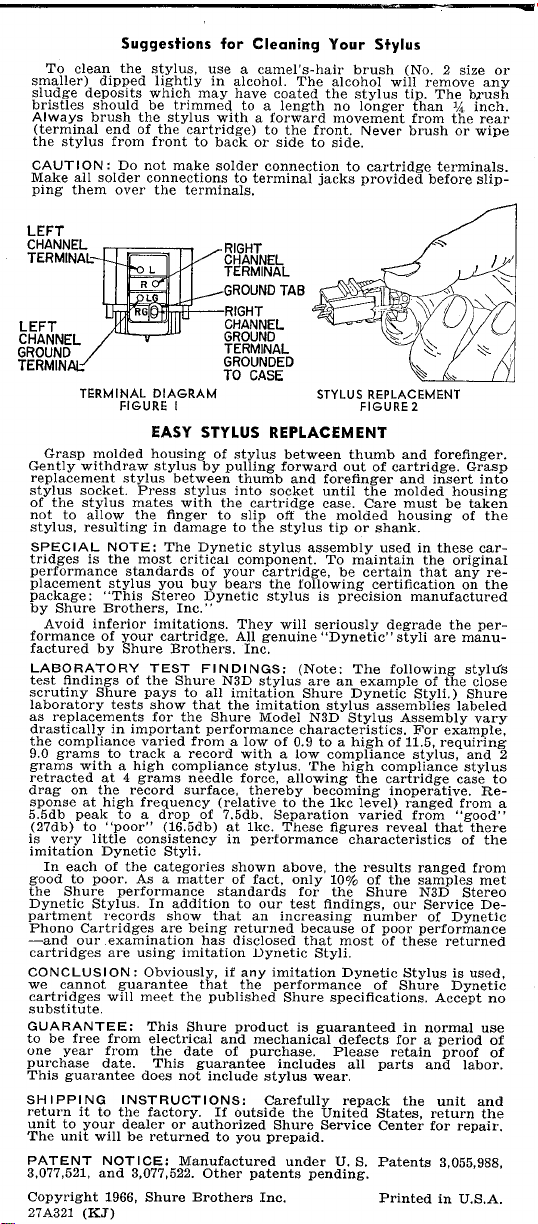

TERMINAL DIAGRAM STYLUS REPLACEMENT

FIGURE

EASY STYLUS

Grasp molded housing of stylus between thumb and forefinger.

Gently withdraw stylus by pulling forward out of cartridge. Grasp

replacement stylus between thumb and forefinger and insert into

stylus socket. Press stylus into socket until the molded housing

of the stylus mates with the cartridge case. Care must be taken

not to allow the, finger to slip

stylus, resulting in damage to the stylus tip

SPECIAL NOTE:

tridges is the most critical component. To maintain the original

performance standards of your cartridge, be certain that any replacement stylus you buy bears the following certification on the

package

by Shure Brothers, Inc.

formance of your cartridge. All genuine "Dynetic" styli are manufactured by Shure Brothers. Inc.

LABORATORY TEST FINDINGS:

"This Stereo Dynetic stylus is precision manufactured

:

Avoid inferior imitations. They will seriously degrade the per-

for

I

Cleaning

alrnhnl

or

RIGHT

RIGHT

CHANNEL

CHANNEL

TERMINAL

TERMINAL

GROUND TAB

GROUND TAB

RIGHT

RIGHT

CHANNEL

CHANNEL

GROUND

GROUND

TERMINAL

TERMINAL

GROUNDED

GROUNDED

TO

CASE

TO

CASE

Your

Thp

side to side.

Stylus

hriish

FIGURE

INn

7:

qim

2

REPLACEMENT

oft

the molded housing of the

or

shank.

The .Dynetic stylus assembly used in these car-

(Note: The followinc stvlds

nr

For

drastically in important performance charactefistics

the compliance varied from a low of 0.9 to a high of'i1.5, requiring

9.0 grams to track a record with a low compliance stylus, and

grams with a high compliance stylus. The high compliance stylus

retracted at

drag

sponse at high frequency (relative to the ikc level) ranzed from a

5.5db peak to a drop of 7.5db.

(27rlh) to "noor" (ifi.FiBh) at

In each of the categories shown above, the results ranged from

good to poor. As a matter of fact, only 10% of the samples met

the Shure performance standards for the Shure N3D Stereo

Dynetic Stylus.

partment records show that an increasing number of Dynetic

Phono Cartridges are being returned because of poor performance

-and

cartridges are using imitation Uynetic Styli.

CONCLUSION:

we cannot guarantee that the performance,

cartridges will meet the published Shure specifications. Accept no

substitute.

GUARANTEE:

to be free from electrical and mechanical defects for a period

one year from the date of purchase. Please retain proof

purchase date. This guarantee includes all parts and labor.

This guarantee does not include stylus wear.

PATENT

3,077,521, and 3,077,522. Other patents pending.

Copyright 1966, Shure Brothers Inc.

278321 (KJ)

4

on

grams needle force, allowing the cartridge case to

the record surface, thereby becoming inoperative. Re-

In addition to our test findings, our Service De-

our

examination has disclosed that most of these returned

Obviously, if

any

imitation Dynetic Stylus is used

of

This Shure product is guaranteed in normal use

Shure Service Center for repair.

nmn"iA

NOTICE:

Manufactured under

U.

S.

Patents 3,055,988,

Printed in

example

Shure Dyneti;

U.S.A.

of

of

2

Loading...

Loading...