222

HARTREY

AVE.,

EVANSTON,

li.

60204

U.S.A.

AREACODE312/328.9000 . CA8LE:SHUREMICRO

MODEL

EASY-MOUNT

M71C

DATA SHEET

STEREO DYNETIC@

PHONOGRAPH CARTRIDGE

SPECIFICATIONS

M71 AND M73 CARTRIDGE SERIES

N71 AND N73

Model Diamond Stylus

Number Replacement

Side Contact Radius:

.0004" (.010 mm)

Frontal Radius

.0007" (.018 mm)

M71-6 NB71-6 Radius:

/

,0006"

I

M71C

*The N75-3 stylus may be used to reproduce the standard

rpm records. In this case, the amplifler should be set to "Monaural" or

TRACKABI LITY:

NC71 Radius

,0006'' (.OX mm)

"A+B."

~

(.OX mm)

:

M71EB at a stylus force of 1% grams

400 Hz.

M71-6 at a stylus force of 1% grams

M71C at a stylus force of 3 grams

M73G at a stylus force of 1 gram

-

-

400 Hz.

400 Hz.

-

400

Hz. - 14.3 cm/sec.

Higher stylus forces within specified range improve trackability.

FREQUENCY

CHANNEL SEPARATION:

RECOMMENDED LOAD IMPEDANCE:

INDUCTANCE:

D.C. RESISTANCE:

MOUNTING:

WEIGHT:

TERM I NALS:

GENERAL:

tridges has been developed for use with all high fidelity amplifiers

having magnetic and constant

MOUNTING:

centers. Hardware is provided for mounting purposes. (The brass

screws have British threads.)

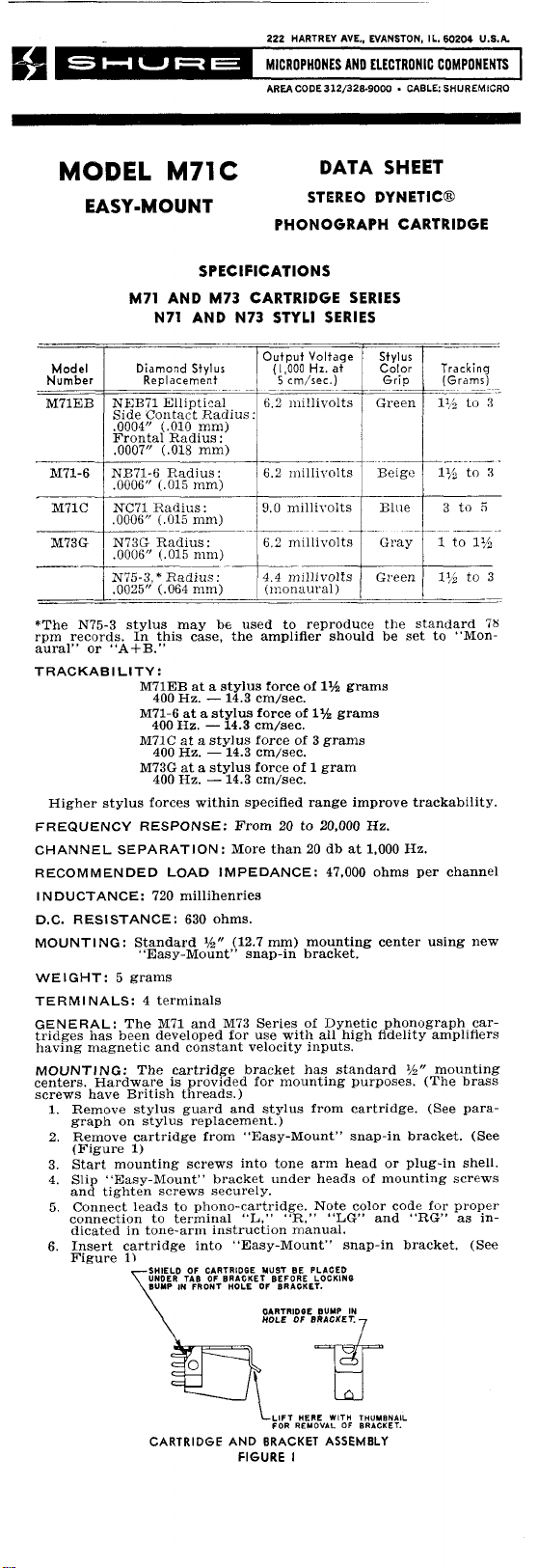

1.

Remove stylus guard and stylus from cartridge. (See paragraph on stylus replacement.)

-.

2. Remove cartridge from "Easy-Mount" snap-in bracket. (See

(Figure 1)

3. Start mounting screws into tone arm head or plug-in shell.

4. Slip "Easy-Mount" bracket under heads of mounting screws

and tighten screws securely.

5. Connect leads to

connection to

dicated in tone-arm

~~

6. Insert cartridge into "Easy-Mount" snap-in bracket. (See

Figure

RESPONSE:

720 millihenries

630 ohms.

Standard

"Easy-Mount" snap-in bracket.

5

grams

'/z"

4 terminals

The M71 and M73 Series of Dynetic phonograph car-

The cartridge bracket has standard

phono-$artridge. Note color code for proper

termlnal

-...-~

~

1)

SHIELD OF CARTRIDGE

~B~~l;~~~~~;F~::I;:E+p~~~~~

instruct~on manual.

\

STYLI SERIES

5

cm/sec.)

~~-

:

/

6.2 ~nillivolts 1 Beige

I

9.0

milli.io1ts

I

14.3 cm/sec.

14.3 cm/sec.

14.3 cm/sec.

From

20

to 20,000 Hz.

More than 20 db at 1,000 Hz.

47,000 ohms per channel

(12.7 mm) mounting center using new

velocity

inputs.

L,:'

"R," "LG" and "RG" as in-

MUST

BE PLACED

OARTRIDQE

BUMP

OF

BRACKET.

IN

7

HOLE

Blue

1

I

1/2"

l?b

3

mounting

to

to

.5

3

-

78

\--LIFT HERE WITH THuwNAlL

CARTRIDGE AND BRACKET

FOR REMOVAL OF BRACKET.

FIGURE

I

ASSEMBLY

7. The top of the "Easy-Mount" bracket should be ,flu=\ aga!nSi

the top of the tone arm head for proper playing

unless other mounting

changer/tone arm manufacturer

8.

Reinsert stylus.

SHURE-SME MOUNTING INSTRUCTIONS: TO mount the cartridge in the Shure-SME Precision Pickup Arm, Model

3012,

refer to the paragraphs on Cartridge Installation and Balanc-

In the Instruction Manual supplied with the pickup arms.

ing

OPERATION: Recommended needle forces for optimum results

are listed under "Speciflcations." Forces greater than the indi-

cated "maximum" should not be used.

instructions

are suppl~ed

by

the record

3009

position,

and

CONNECTIONS

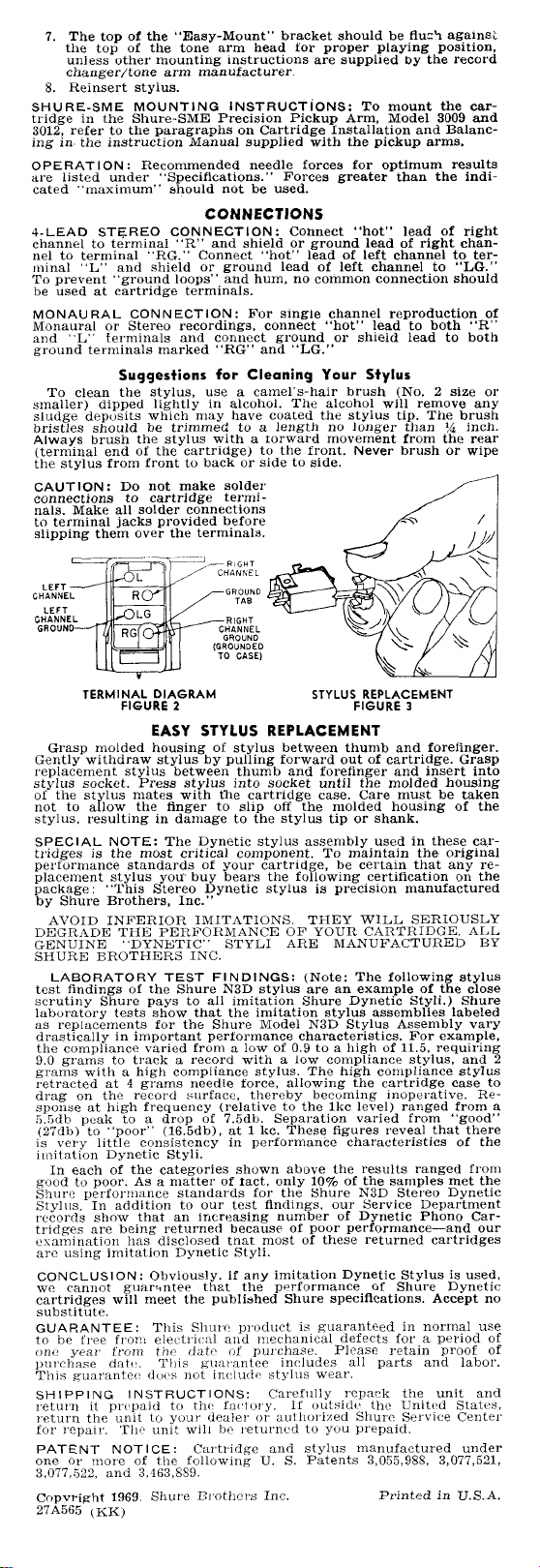

4-LEAD STSREO CONNECTION: Connect "hot" lead of right

channel to terminal "R" and shield or ground lead of

nel to terminal

ininal

L"

To prevent "ground loops" and hum, no common connectlon should

be used at cartridge terminals.

MONAURAL CONNECTION: For

Monaural or Stereo recordings, connect "hot" lead to both

and

"L"

ground terminals marked

"RG."

and shield or ground lead of left channel ,to

Connect "hot" lead of left channel to ter-

slngle channel reproduction of

terminals and connect ground or shleld lead to both

"RG"

and

"LG."

rlght chan-

"LG."

"R"

Suggestions for Cleaning Your Stylus

To clean the stylus, use a camel's-hair brush (No. 2 size or

smaller) dipped lightly in alcohol. The alcohol will remove any

sludge depvsits which

bristles should be trimmed to a length no longer

Always brush the stylus with a rorward movement from the rear

(terminal end of the cartridge)

the stylus from front to back or

CAUTION: Do not make solder

connections to cartridge termi-

nals. Make all solder connections

to terminal jacks provided before

slipping them over the

may have coated the stylus tip. The brush

tv the front. Never brush or wipe

s~de to side.

than % inch.

terminals.

TERMINAL DIAGRAM

FIGURE

2

STYLUS

FIGURE

REPLACEMENT

3

EASY STYLUS REPLACEMENT

of the stylus mates with the cartridge case. Care must be taken

not to allow the finger to slip off the molded housing of the

stylus, resulting in damage to the stylus tip or shank.

SPECIAL NOTE:

tl.~clgcs

13

LI~~I~I~I~III:~~~~~ ~I:ill(li~~~d~

placement stylus

package: "This Stereo

by Shure Brothers, Inc."

AVOID INFERIOR

DEGRADE THE PERFORMANCE OF YOUR CARTRIDGE

GENUINE "DYNETIC" STYLI

SHURE BROTHERS INC.

LABORATORY TEST FINDINGS: (Note: The following

test findines of the Shure N3D stvlus are an exam~le of the close

9

~rnrils

6:6db pcak 'io a drop

(27db) to,"poorM (16.5db), at 1 kc: These figures reveal ,that there

is very

inlitation Dynetic Styli.

good

Shnre periorni:lnce standards for the Shure N3D Stereo Dynetic

Stylr~s. In addition to our test findings, our Service Department

~,ecords show that an Increasing number of Dynetic Phono Cartridges are being returned because of poor performance-and our

esarninntion has disclosed tnat most of these returned cartridges

arc

CONCLUSION: Obviously. if any imitation

we

cartridges will meet the publijhed Shure speciflcations. Accept no

substitute.

GUARANTEE: This

to be free

onc year, froni ttic clatl'

purch:rse dntt,. Tills gri;rt.antee in(:ludes all parts and labor.

This

SHIPPING INSTRUCTIONS:

t.eturn it pt.i,~miti

return the un~t

for

PATENT NOTICE:

one or

3,077,522,

Copvright

27A565

l~ttle consistency in pertormance character~stlcs of the

In each of the categories shown above the results ranged from

to

poor. As a matter of tact, only

using imitation Dynetic Styli.

cannot gltar~ntee that the performance of Shure Dynetic

guarantc('

r'5patr.

more of the following U. S. Patents 3,055,988, 3,077,521,

and

(KK)

Tltt* Ijynt.tic sty111.3 :i~:il~~~lt)ly

tllc lllust cr~rrcsl C!,III~)UIIC.I~~. TI) ~~~:iilil:~in the (8riglnal

of

you. buy bears the foilowing certification on the

YULII. v:irt~~tdx~,

Dynetic stylus is precision manufactured

IhTITATIONS. THEY WILL SERIOUSLY

ARE

to

trark a record with a low comwiiance stvlus.'and

of

7.5dlr. Separation varied from "good"

10%

fr.oni electi.i(~;~l and rliechariical defects for a pt3riod of

Tiit, unit will

S~LIIY' p~,oduct is guaranteed in normal use

of

pu~.chase. Plcasc retain proof of

dor.s

nut int,lu(l<. stylirs wear.

to

ti-i(. f:rt,to~y.

to

your dealer or, autlio~~ized Shur.c Ser.vice Center

Carefnlly repark the unit and

If

oulsidt, the 1Jnitt.d Statt's,

bc

~,eturntd to you prepaid.

C:~rt~,idge and stylus manufactured under

3,463,889.

1969

Sliul'e GI otliers Inc. Printed in

USV~

ill

tllr.ie Cii1.-

ltc

ct~lla111 tl~at ally re-

MANUFACTURED BY

ALL

stylus

of the samples met the

Dynetic Stylus is used.

U.S.A.

2

Loading...

Loading...