Page 1

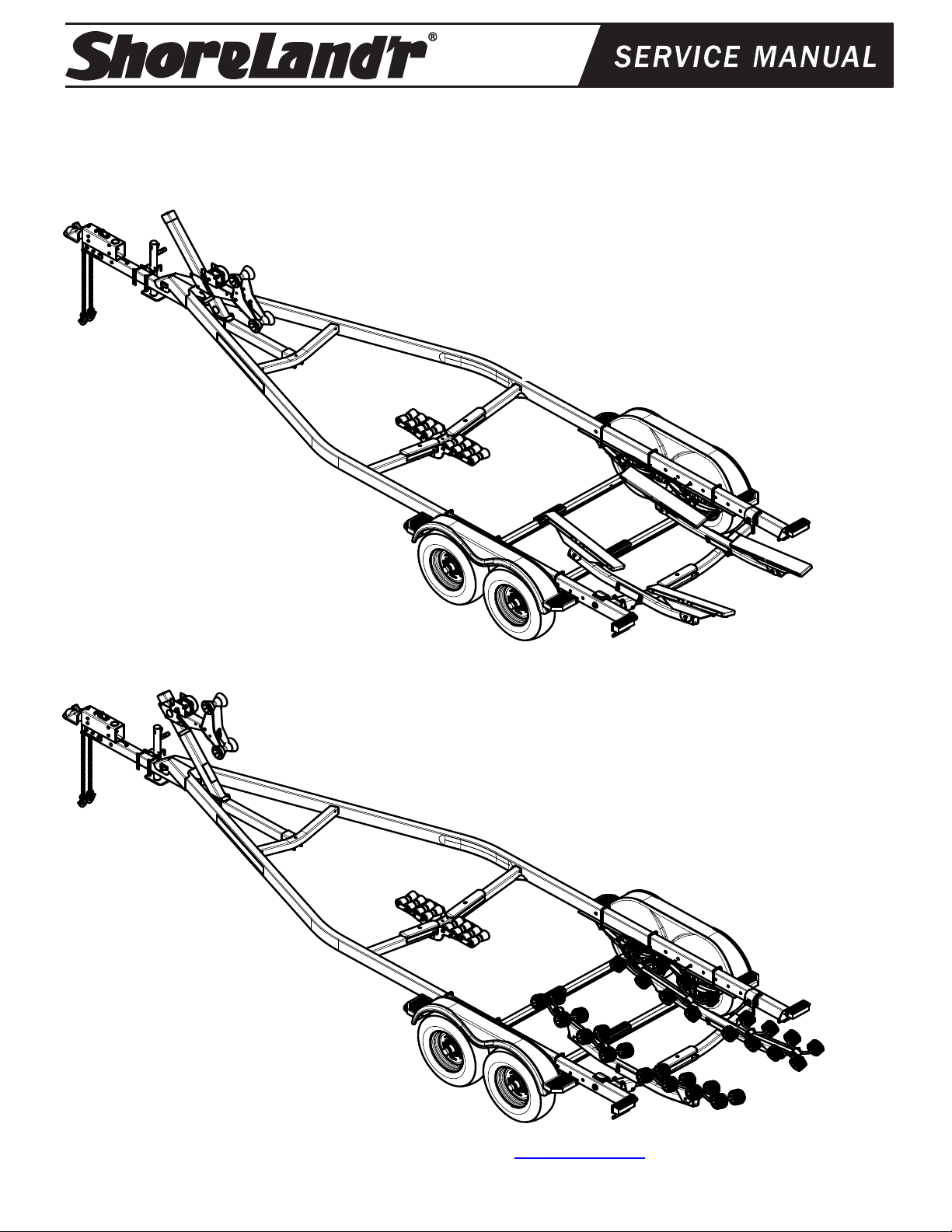

SRB68TCBB__ & SRR68TCBB__

ShoreLand’r

When ordering parts, it is important that you specify the

finish or color you have on your product. The 5-digit

number along with a 2-digit space _ _, note that the

parts can be purchased in various finishes.

00……...Galvanized w/ White Plastic Components

01 .........White

offers its product line in painted finishes.

SRB68TCBB (All Colors) Bundles Required:

* ST205/75R15-D Tire/T-Silver Dir Rim..............4

69082 Literature Bag – Brake Trailers ........................1

80835_ _ Frame Bundle – SRB68TCBB..........................1

70750 Brake Kit 3X5/Alum Tandem Brake..................1

61778_ _ Bunk Assy 36IN W/Brkts 3X8...........................4

62466_ _ Support Tube Assy for 3X5..............................1

69976_ _ Tongue Wment 58/68/80 Steel ........................1

4510658 Actuator – 16000# UFP GDC160.....................1

3310052 Jack 1250LB Pad W/Mtg Hdwe .......................1

*Check with your dealer/customer service representative for current

SRR68TCBB (All Colors) Bundles Required:

* ST205/75R15-D Tire/T-Silver Dir Rim..............4

69082 Literature Bag – Brake Trailers ........................1

80748_ _ Frame Bundle – SRR68TCBB .........................1

70750 Brake Kit 3X5/Alum Tandem Brake..................1

60617_ _ Roller arm Assy 24 1/2IN Galv.........................4

62466_ _ Support Tube Assy for 3X5..............................1

69976_ _ Tongue Wment 58/68/80 Steel ........................1

4510658 Actuator – 16000# UFP GDC160.....................1

3310052 Jack 1250LB Pad W/Mtg Hdwe .......................1

*Check with your dealer/customer service representative for current

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 1 of 14 4/29/2011

Page 2

Recommended carrying capacity is based on

shipping weight of the trailer with standard

equipment. Adding optional equipment may decrease

the trailer’s carrying capacity.

Tire Size and Carrying Capacity Chart

Tire Size

GVWR

Carrying Capacity

Axle

Refer to the tire side wall for correct tire pressure.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 2 of 14 4/29/2011

ST205/75R15-D

8480 lb.

6800 lb.

2 Standard (Disc-Brake)

Page 3

FINAL ASSEMBLY INSTRUCTIONS

Remove the hardware bag from the frame, remove

parts and sort by size.

Consumer / Owner:

Your

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com

Page 3 of 14 4/29/2011

Sea Ray

adjusted to fit your boat. If properly maintained it will give

your boat maximum support and many years of care free

service.

Follow these instructions before using your trailer:

Read your

decals on the trailer.

trailer is designed, assembled and pre-

Shoreland’r Owner’s Guide

and all safety

Wash and wax your trailer regularly. Always rinse your trailer after

each use, especially when boating in salt or brackish water.

Re-check all fasteners for tightness before towing.

Contact your authorized

problem with your trailer. To locate a dealer, please use

www.shorelandr.com

For further information or assistance, contact

800-859-3028 or visit

Shoreland’r

- dealer locator feature.

www.shorelandr.com

0004361

dealer if you experience a

Shoreland’r

.

at 1-

Page 4

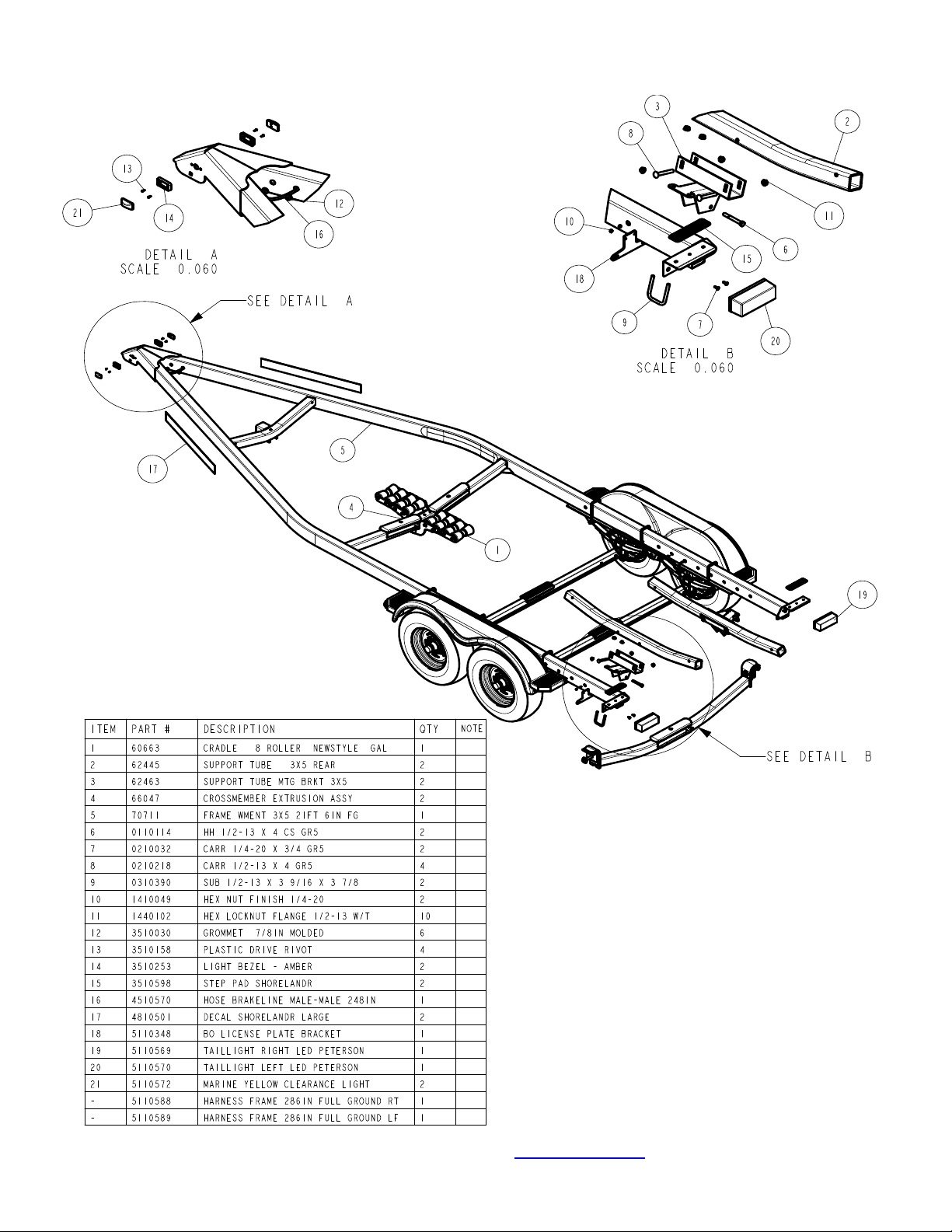

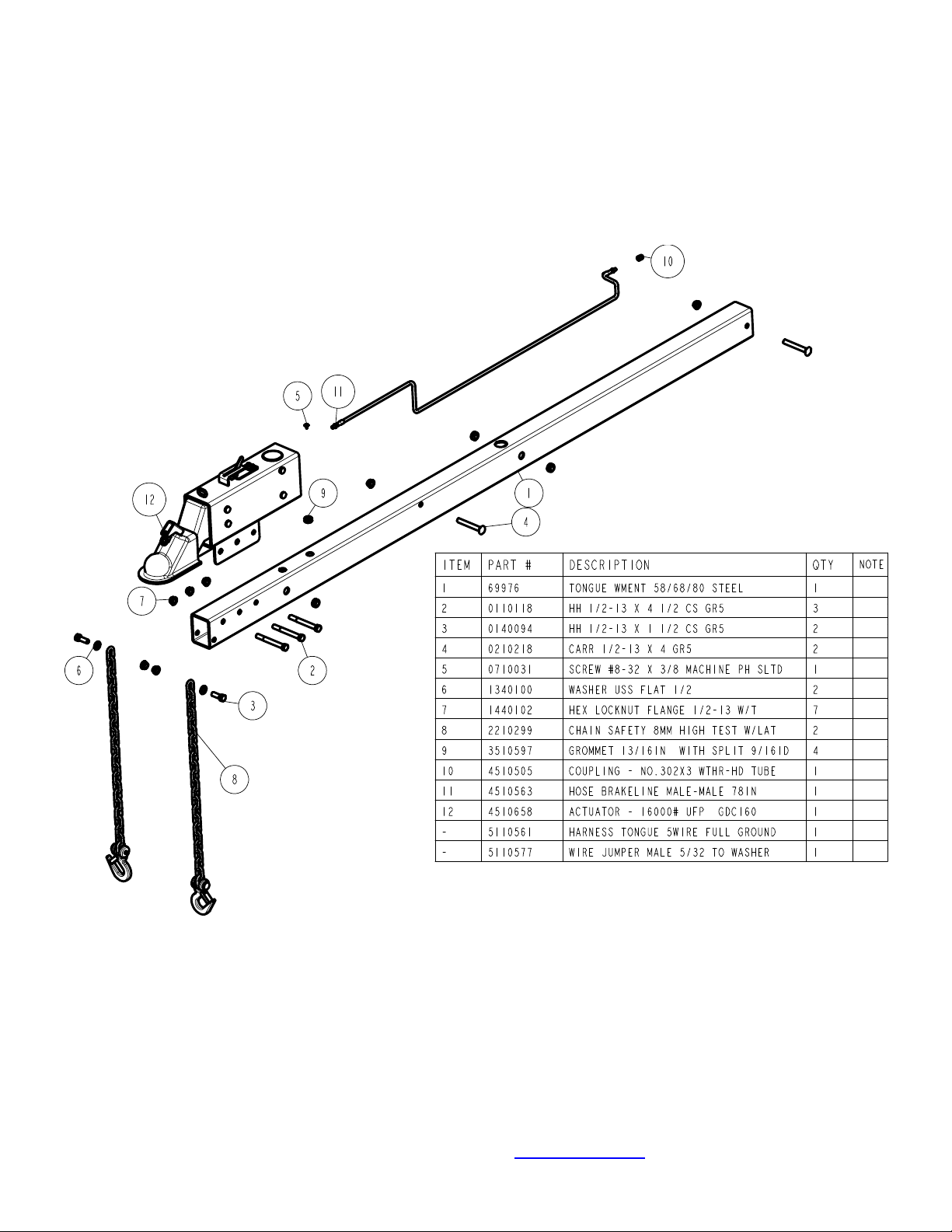

Tongue

The tongue comes shipped separately. Locate and install

under the frames front tongue channel and in the channel

welded to the front cross member which will support the

rear of the tongue.

Align the hole in the tongue with the hole in the tongue

channel. Install the 1/2” x 4” carriage bolt in the front hole

and secure with a 1/2” lock nut. Secure the rear of the

tongue to the frame with a 1/2” x 4” carriage bolt and lock

nut. Tighten.

Tongue Wire Harness

Locate the tongue wire harness. Place the end of the wire

remove the grommet in the side frame and place the extra

wire in the side frame. Place grommets into all the wire

holes. Replace grommets just removed from the side

frames.

Safety Chains

Mount the safety chains to the front of the tongue by

placing a 1/2” flat washer onto a 1/2” x 1 1/2” hex bolt, and

then insert the bolt through the last link on one of the

safety chains provided. Insert the bolt through the hole

harness with the two three wire triangular plugs into the

hole in the top of the tongue. Pull backwards through the

tongue until they can be fished through the holes in each

side of the tongue. Note that the brown, white, and yellow

harness must go to the left side of the trailer and the

brown, white, and green harness must go to the right side

of the trailer.

Plug the tongue wire harness ends into the frame

harnesses by matching colors and ends. Push the extra

wire provided, either into the hole in the tongue or else

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 4 of 14 4/29/2011

provided in the front of the tongue as shown. Secure with

a 1/2” hex flange lock nut. Repeat the process on the

other chain. Tighten.

Actuator

Locate the actuator, and position it on the front of the

tongue as shown. Look into the back end of the actuator

and locate the solenoid. Note there is a wire harness

coiled around the round solenoid. Uncoil the wire and

plug it into the bullet plug on the end of the blue wire of

the tongue harness. Remove the plastic plug from the

port in the rear of the solenoid. Thread the fitting on the

Page 5

end of the tongue brake hose into the port of the

solenoid. Tighten.

Align the holes in the actuator with the holes in the

tongue. Secure the actuator to the tongue using three

(3) 1/2” x 4 1/2” hex bolts and lock nuts. Tighten.

Thread the brass coupling provided on the other end

of the brake hose just installed. Align so it can be

mated to the brake hose from the side frame. Once

aligned thread the side frame brake hose into the

other end of the coupling. Tighten both hoses into the

coupling.

This 42” winch post assembly will be

used on the bunk trailer only.

Winch Post Assembly (Will be used on

both assemblies.)

Mount the winch post assembly to the

tongue in a location that will best fit your

boat. Secure the winch post base weldment

(Ref. 2) to the tongue using (2) 1/2” x 3-9/16’

x 5” U-bolts and hex lock nuts. Attach the

winch post tube weldment to the base just

installed with a 1/2” x 4-1/2” hex bolt and hex

lock nut. Tighten only enough to hold the

assembly in position until the boat is

positioned on the trailer. Snap the winch

handle on the winch by compressing the

spring loaded clip incorporated in the handle.

Once in position, release the clip. Handle is

secure.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 5 of 14 4/29/2011

Page 6

This 52” post assembly will be used on the

roller trailer.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 6 of 14 4/29/2011

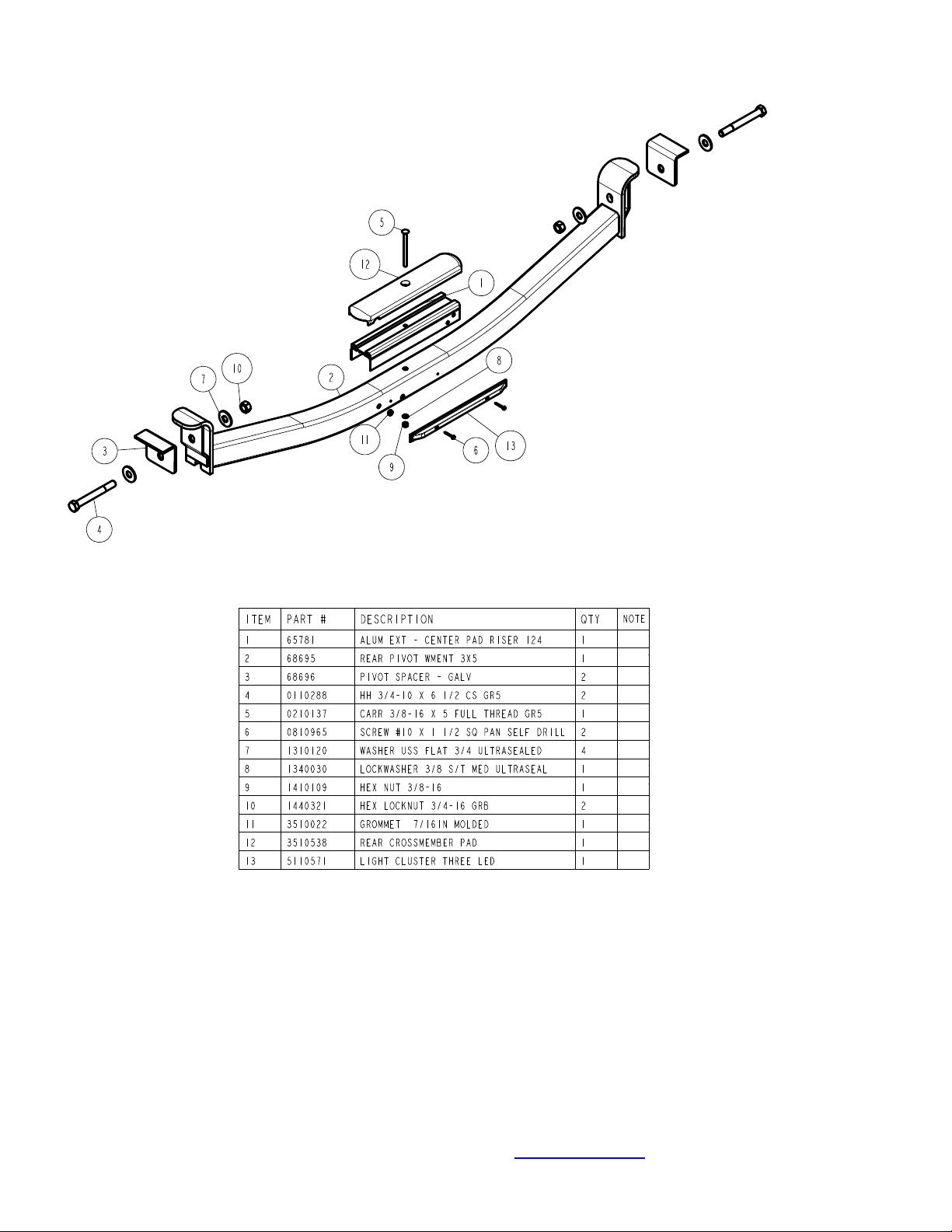

Page 7

RB Bunk Assembly

Locate the support arms bundle. Place

one of the arms into the factory installed

mounting bracket on the rear pivot with the

ends curved up as shown. Secure in the

bracket with two (2) 1/2” x 4” carriage bolts

and hex lock nuts. See Detail B. Tighten.

Place one of the bunk assemblies on the

end of the support arms just installed. Line

up the top hole in the mounting bracket

with the hole in the support arm and

secure with a 1/2” x 4-1/2” hex bolts and

hex lock nuts. Tighten. Repeat on the

other end of this support arm. Repeat this

complete process on the other support

arm.

Note that the bunk assemblies have two

height adjustments. The instructions are to

install them in the lowest position to keep

the center of gravity as low as possible for

towing. If required for fender clearance,

the bunks can be installed in the raised

position by mounting the bunk assemblies

to the bunk support arms using the lower

mounting hole.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 7 of 14 4/29/2011

Page 8

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 8 of 14 4/29/2011

Page 9

Roller Arm Assembly

Locate the support arms bundle. Place one of the

arms into the factory installed mounting bracket on

the rear pivot with the ends curved up as shown

on page 2. Secure in the bracket with two (2) 1/2”

x 4” carriage bolts and hex lock nuts. Tighten.

Place one of the roller assemblies on the end of

the support arms just installed. Line up the hole in

the mounting bracket with the hole in the support

arm and secure with a 1/2” x 4-1/2” hex bolts and

of this support arm. Repeat this complete process

on the other support arm.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 9 of 14 4/29/2011

Page 10

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 10 of 14 4/29/2011

Page 11

ROCKER ARMS

Locate the rocker arms (Ref. No. 1 of the chassis

schematic). Note that the center bushing has a grease

zerk in it. Position a rocker arm up into the center channel

welded in the center of the tandem spring bracket so that

the grease zerk is pointing down. Align the holes in the

channel with the rocker arm. Insert a 3/4” x 4-1/2” hex bolt

from the outside in and secure in place with 3/4” lock nut.

Tighten. Repeat this process on the other rocker arm and

spring bracket. Grease the rocker at this time by applying

grease through the zerk just discussed.

NOTE: THE GREASE ZERK IS POSITIONED DOWN

SO THAT IT IS ACCESIBLE FOR SERVICING WHEN

NEEDED.

SPRINGS

Position the axles so they are properly aligned with the

trailer. The axles must be positioned so that the disc brake

calipers are on the back side of the axle.

Place the springs on the topside of the spring pads welded

to the axle. (See chassis diagram). Note that the hook end

of the spring must be to the rear of the trailer. Place a

spring clamp on the top center of the spring as shown.

Next place the 1/2” x 6-1/2” U-bolts down over the top of

the spring clamp, spring and axle as shown

Place the spring and axle U-bolt plate onto the ends of the

two U-bolts just installed on the bottom side of the axle.

Secure in place with 1/2” lock nuts. Thread the nuts onto

the U-bolts but do not tighten securely until the complete

unit is mounted in position on the trailer. Repeat on the

other spring and the other axle.

AXLE

Place one of the spring bracket bushings into the rear of

the spring bracket and secure with a 9/16” x 3 1/4” hex bolt

and hex lock nut. Repeat on other spring bracket.

Position the rear axle under the frame, then hook the hook

loop of the spring around the bushings just installed. Note

that if the axle is positioned too low when trying to hook

the springs on the bushings, the hooks will not hook

around the bushings.

Raise the front of the springs up so they align with the

rear hole in the axle rocker arm. Secure in place with

9/16” x 3-1/4” hex bolts and lock nuts.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 11 of 14 4/29/2011

Next install another spring bracket bushing in the front

hole on the rock arm assembly. Secure with a 9/16” x

3-1/4” hex bolt and lock nut. Tighten.

Hook the hook end of the springs mounted to the front

axle over the bushing just installed in the rocker arm

Page 12

assembly.

Then swing the front of the spring up and attach to the

front mounting hole in the spring bracket with another

9/16” x 3-1/4” hex bolt and lock nut.

Tighten all axle U-bolts and spring bolts not tightened

at this time.

Brake Line Installation

Locate line clamps and 1/4” self tapping screws

provided in the kit. Thread the hose into the hole on

the bottom of the brass block on the right brake

calipers. Form the hose so that it can be placed in a

clip and attached to the spring plate with a #10-32 X1

machine screw, washers and a 10-32 hex nut to keep

it up in place under the leaf springs.

Route the hose along the back side of the axle and secure to

the axle with the five (5) clamps and self tapping screws. Note

that the axle is pre-drilled for the mounting screws.

Remove the plastic plug from the port in the brass block on

the left brake caliper. Thread the brake hose fitting into this

port place in a clip and attached to the spring plate with #1032 X1 machine screw, washers and a 10-32 hex nut to hold

the hose in position making sure that it does not rub or touch

the spring. Tighten all fittings.

Repeat this process on the second axle.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 12 of 14 4/29/2011

Page 13

fittings. Note that the coil in the line will absorb the vibration

created during towing.

Bleeding the Brake System

Bleed the brake system as specified in the brake manual.

The bleeding process is necessary to remove ALL air

entrapped in the system in order for the brake system to

function properly.

Trailer Adjustments

The adjustment of the trailer to your boat is very important

not only for the trailer, but also the boat. Failure to do so

may lead to potential failure or damage to either the trailer

or boat.

Adjust as follows:

Axle Adjustment

The amount of tongue weight on your trailer can be

adjusted as follows:

To lower the tongue weight, adjust the axle assembly

forward. To increase the tongue weight, adjust the axle

assembly backward.

The distance that the axle assembly has to be moved will

vary because it is directly related to the weight and center

of gravity of the boat place on it.

Tire and Wheel Assemblies

Mount the tire and wheel assemblies using the 1/2” fine

threaded tapered lug nuts provided. Tighten to 80-90 ft/lb.

of torque using the rotation pattern as shown in the

ShoreLandr’s Owners Manual. Re-torque the lug nuts

after 50 miles of driving and then periodically

Connecting the Two Axles Together and To the

Actuator

Locate the brass tee and the 18” brake hose. Thread the

male port of the tee into the female end of the brake hose

route the hose thru the clip on the back of the spring

bracket to the rear axle. Tighten.

Remove the plastic cap from the end of the frame brake

line coming out of the side frame by the axle. Carefully

pull the brake hose enough so that it will reach the port of

the tee just threaded into the brake hose. Thread the

brake hose fitting into the top port of

the tee and tighten.

Locate the 60” brake hose. Thread one end of the hose

into the remaining port of the tee installed in the previous

step. Route the hose thru the front brake line clip and

insert into the caliper on the second axle. Place a coil in

the line to use up any excess line and then connect the

hose to the side frame using clips and self tapping

screws to keep the hose from being damaged. Tighten all

Best towing is achieved when the tongue weight is 5- 7% of

the total gross load of the complete unit.

To move the axle assembly, loosen the U-bolts that secure

the assembly to the side frames. Move the assembly to the

desired location then re-tighten the U-bolts.

Note: The brake line and wire harness will need care when

moving the assembly.

Rear Support System

Place the boat on the trailer so that the transom is located

at the rear of the support system. On an RB bunk trailer, the

transom of the boat should be within 1-2” of the end of the

bunk. The center of the rear rollers on the roller rack should

be approximately 4” from the transom. This gives you

maximum support on the transom. The rear pivot is

adjustable forward and backward to assist in adjusting the

trailer to various length boats. This is accomplished by

removing the pivot bolt that attaches the rear pivot to the

side frame and then sliding the assembly to the desired

position and re-attaching with the pivot bolt just removed.

The wire harness for the three-light identification light will

have to be rerouted as well.

RB Bunks

Make sure the bunks are positioned far enough apart to

give your boat as much stability as possible while

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 13 of 14 4/29/2011

Page 14

transporting. Position the bunks so they are located

just to the outside of a strake that your boat may have.

This will help center your boat and assist when loading.

The bunks need to be adjusted up high enough to keep

the keel from resting on the center pads. A minimum of

one to two inches of clearance is desirable.

Rollers

Position the roller racks so they are far enough apart to

give your boat stability while transporting. When the

desired width is achieved, move the roller rack system

so that one set of the rollers are just to the outside of a

strake if possible. The rollers need to be adjusted so

that you have a minimum of one to two inches of

clearance between the keel of the boat and the center

cross member pads. This will help center the boat

when loading and unloading.

When the desired position is determined, tighten only

enough to hold the bunks or rollers from moving while

the other adjustments are being made. Final tightening

will be done at the end of the adjusting process.

Front Support System

RB and Roller

The keel of the boat must rest on the center of the front

keel roller system creating a three-point support

system. The keel roller system is designed to fit most

boats without needing any further adjustment.

Once the boat is positioned on the front roller system,

the stabilizer pads can be adjusted. This is

accomplished by sliding the pad up against the boat

bottom by hand. It is not necessary that they carry

much weight. They are designed to give your boat

added stability while being towed. It may be necessary

to adjust the assembly up so that they can be moved

further apart giving additional support. Pull the

assembly away from the boat. Place the U-bolt that

holds the assembly to the cross member in a lower

hole in the bracket. Then push the assembly back

against the boat. Tighten in position.

Winch Post

Now that all other adjustments are complete the winch

post can be adjusted. Slide the winch post base

backward on the tongue until the bow roller comes in

contact with the boat. This bow roller needs to be

positioned directly above the boat bow eye to prevent

your boat from moving forward in the event of a sudden

stop. Loosen the three 1/2” hex bolts that clamp the

winch holder channel to the winch post. Attach the

winch strap into the bow eye and slide the winch holder

channel up or down to the desired position as you

crank the winch tight. Once the bow roller is located

just above the bow eye, tighten the three 1/2” hex bolts that

clamp the winch holder channel to the winch post. Tighten

the U-bolts that secure the winch post assembly to the

tongue. Attach the bow eye safety chain into the bow eye of

the boat as well. The chain is another level of unit the event

of an accident. It may also be used to keep your boat on the

trailer while loading and unloading at the ramp; especially

with a roller trailer.

Adjustments are now complete. Double check your boat for

fit. If desired fit has been achieved, tighten all fasteners that

may have either been left loose or have been loosened to do

the adjusting.

Re-check all fasteners on the complete trailer to make sure

they are all tight and ready for towing. All fasteners should

be periodically checked before towing. The law requires that

the white ground wire on both the tongue wire harness and

vehicle harness be properly grounded to respective trailer

and vehicle frames.

See your ShoreLand’r Owner’s Guide for further technical

information regarding your trailer and its components.

Midwest Industries, Inc. Ida Grove, IA 51445 800.859.3028 www.shorelandr.com 0004361

Page 14 of 14 4/29/2011

Loading...

Loading...