Page 1

MODEL W1830

4005867

HANGING 3-SPEED

AIR FILTER

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 04/15)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © MARCH, 2012 BY WOODSTOCK INTERNATIONAL, INC. REVISED APRIL, 2015 (ST)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#14736TS Printed in China

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Contents

INTRODUCTION .....................................2

Woodstock Technical Support .................. 2

Machine Specifications .......................... 3

SAFETY ............................................... 5

Standard Machinery Safety Instructions ...... 5

Additional Safety for Air Filters ................7

ELECTRICAL .........................................8

Circuit Requirements ............................8

Grounding Requirements ........................ 9

Extension Cords .................................. 9

SETUP .............................................. 10

Unpacking ....................................... 10

Inventory ........................................ 10

Power Connection .............................. 11

Test Run .......................................... 12

Site Planning .................................... 13

Mounting to Ceiling ............................ 14

OPERATIONS....................................... 16

General .......................................... 16

Machine Storage ................................ 16

Filtering Performance ......................... 16

ACCESSORIES ...................................... 17

Air Filter Accessories .......................... 17

MAINTENANCE .................................... 18

Cleaning Filters ................................. 18

SERVICE ............................................ 19

General .......................................... 19

Replacing Fuse .................................. 19

Remote Control Battery Replacement ...... 19

Electrical Safety Instructions ................. 20

Electrical Wiring Diagram ..................... 21

Troubleshooting ................................. 22

PARTS .............................................. 23

Cabinet & Remote Control .................... 23

Control Panel ................................... 24

Motor & Impeller ............................... 25

Label Placement ............................... 26

WARRANTY ........................................ 29

SAFETYINTRODUCTION

SET UPELECTRICAL MAINTENANCE

OPERATIONS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

SERVICE PARTS

Page 4

Model W1830 (For Machines Mfd. Since 4/15)

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

This machine has been specially designed to provide many years of trouble-free service. Close attention

to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

-2-

Page 5

Model W1830 (For Machines Mfd. Since 4/15)

MODEL W1830

SHOP FOX® HANGING AIR FILTER

Product Dimensions

Weight........................................................................................................... 31 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................ 20 x 17 x 10 in.

Footprint (Length x Width).............................................................................. 20 x 17 in.

Shipping Dimensions

Type.................................................................................................... Cardboard Box

Content........................................................................................................ Machine

Weight........................................................................................................... 34 lbs.

Length x Width x Height........................................................................... 24 x 20 x 13 in.

INTRODUCTION

Motors

Main

Type......................................................................... ODP Permanent-Split Capacitor

Horsepower.............................................................................................. 1/8 HP

Phase.............................................................................................. Single-Phase

Amps........................................................................................................... 1A

Speed................................................................................... 1200, 1400, 1750 RPM

Bearings................................................................. Sealed & Permanently Lubricated

Main Specifications

Operation

Dust Collector Type.................................................................................. Air Filter

Approved Dust Types.............................................................................. Particulate

Filter Type................................................................................ Pleated/Bag Panels

Airflow Capacity.......................................................................... 260, 362, 409 CFM

Filtration Rating...................................................................................... 1 Micron

Impeller Information

Impeller Type.................................................................................... Squirrel Cage

Impeller Size................................................................................. 5-1/2 – 5-1/5 in.

Construction

Frame....................................................................................................... Steel

Impeller.................................................................................................... Steel

Paint Type/Finish............................................................................. Powder Coated

Blower Housing............................................................................................ Steel

-3-

Page 6

INTRODUCTION

Model W1830 (For Machines Mfd. Since 4/15)

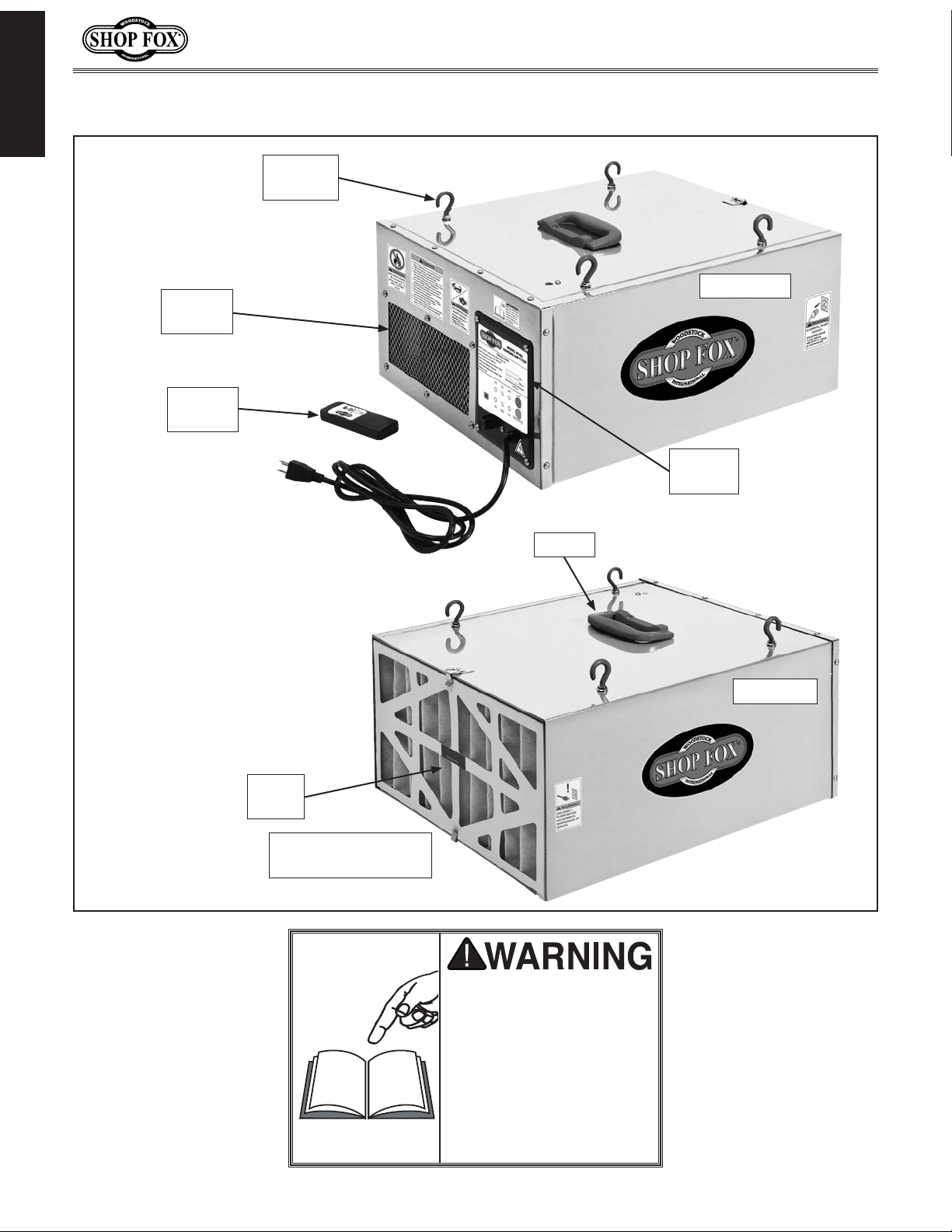

Controls and Features

Machine

Hook

Exhaust

Port

Remote

Control

Front View

Control

Panel

Handle

Rear View

Outer

Filter

Inner Filter

(Behind Outer Filter

READ and understand this

entire manual before using

this machine. Serious personal injury may occur

if safety and operational

information is not understood and followed. DO

NOT risk your safety by

not reading!

-4-

Page 7

Model W1830 (For Machines Mfd. Since 4/15)

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

injury hazards to untrained users.

SAFETY

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday eye-

glasses only have impact resistant lenses—they are NOT safety glasses.

3. ALWAYS WEAR A NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT PRODUCES

DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which may

get caught in moving parts. Wear protective hair covering to contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-5-

Page 8

Model W1830 (For Machines Mfd. Since 4/15)

APPROVED OPERATION. Untrained operators

ONLY USE AS INTENDED

USE RECOMMENDED ACCESSORIES

CHILDREN & BYSTANDERS.

REMOV

SECURING WORKPIECE.

FEED DIRECTION.

GUARDS & COVERS.

NEVER STAND ON MACHINE.

STABLE MACHINE. Unexpected movement during

will do the job safer and better at the rate for

positions that make workpiece control difficult

can be seriously hurt by machinery. Only

allow trained or properly supervised people

to use machine. When machine is not being

used, disconnect power, remove switch keys,

or lock-out machine to prevent unauthorized

use—especially around children. Make

workshop kid proof!

SAFETY

. Only use machine for

its intended purpose. Never modify or alter

machine for a purpose not intended by the

manufacturer or serious injury may result!

. Consult

this owner’s manual or the manufacturer for

recommended accessories. Using improper

accessories will increase the risk of serious

injury.

Keep children and

bystanders a safe distance away from work

area. Stop using machine if children or

bystanders become a distraction.

E ADJUSTING TOOLS. Never leave

adjustment tools, chuck keys, wrenches, etc.

in or on machine—especially near moving

parts. Verify removal before starting!

When required, use

clamps or vises to secure workpiece. A secured

workpiece protects hands and frees both of

them to operate the machine.

operations greatly increases the risk of injury

and loss of control. Verify machines are

stable/secure and mobile bases (if used) are

locked before starting.

FORCING MACHINERY. Do not force machine. It

which it was designed.

AWKWARD POSITIONS. Keep proper footing and

balance at all times when operating machine.

Do not overreach! Avoid awkward hand

or increase the risk of accidental injury.

UNATTENDED OPERATION. Never leave machine

running while unattended. Turn machine off

and ensure all moving parts completely stop

before walking away.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to

keep machine in good working condition. An

improperly maintained machine may increase

the risk of serious injury.

CHECK DAMAGED PARTS. Regularly inspect

machine for damaged parts, loose bolts,

mis-adjusted or mis-aligned parts, binding,

or any other conditions that may affect safe

operation. Always repair or replace damaged

parts, wires, cords, or plugs before operating

machine.

Unless otherwise noted, feed

work against the rotation of blades or cutters.

Feeding in the same direction of rotation may

pull your hand into the cut.

protect you from accidental contact with

moving parts or flying debris. Make sure

they are properly installed, undamaged, and

working correctly before using machine.

accidental contact with cutting tool may

occur if machine is tipped. Machine may be

damaged.

Guards and covers can

Serious injury or

MAINTAIN POWER CORDS. When disconnecting

cord-connected machines from power, grab

and pull the plug—NOT the cord. Pulling the

cord may damage the wires inside. Do not

handle the cord/plug with wet hands. Avoid

cord damage by keeping it away from heated

surfaces, high traffic areas, harsh chemicals,

and wet or damp locations.

EXPERIENCING DIFFICULTIES. If at any time you

are experiencing difficulties performing the

intended operation, stop using the machine!

Contact our Technical Support for help at

(360) 734-3482.

-6-

Page 9

Model W1830 (For Machines Mfd. Since 4/15)

Additional Safety for Air Filters

INTENDED USE. This air filter is designed

to capture dust from ambient air in a

woodworking shop for a short time after

cutting or sanding operations. DO NOT use

this air filter to collect particles of silica,

metal, lead paint, asbestos, or hazardous

bacterium. DO NOT allow this filter to collect

liquids, combustible fumes, burning or

smoking material, or toxic fumes.

HAZARDOUS DUST. Dust exposure may cause

cancer, birth defects, or long-term respiratory

damage. Be aware of the dust hazards

associated with each workpiece material, and

always wear a NIOSH-approved respirator to

reduce your risk.

LEAD PAINT DUST AND ASBESTOS FIBERS. DO

NOT try to collect lead paint or asbestos

fibers with this machine. Due to the high

hazard to human health, these materials must

be collected with special equipment.

DISCONNECTING POWER SUPPLY. Turn the

switch OFF, disconnect the air filter from the

power supply, and allow the impeller to come

to a complete stop before leaving the machine

unattended or doing any service, cleaning,

maintenance, or adjustments.

REGULAR CLEANING. For best performance,

regularly check/clean the filters to avoid the

buildup of fine dust. Make sure to regularly

clean the surrounding area where the machine

is operated—excessive dust buildup on

overhead lights, heaters, electrical panels,

or other heat sources will increase the risk of

fire.

SUSPENDED DUST PARTICLES AND IGNITION

SOURCES. DO NOT operate the air filter in

areas where explosion risks are high. Areas

of high risk include, but are not limited to,

areas near pilot lights, open flames, or other

ignition sources.

SAFETY

DUST ALLERGIES. Dust from certain woods

may cause an allergic reaction in people and

animals. Make sure you know what type of

wood dust you will be exposed to in case

there is a possibility of an allergic reaction.

WEAR RESPIRATOR. Fine dust that is too small

to be caught in the filter will be blown into

the ambient air during operation. Wearing a

NIOSH approved respirator during this time

will reduce your risk of permanent respiratory

damage.

EMPTYING DUST. When removing dust from the

filters, turn OFF the switch, disconnect power,

and wear a respirator and safety glasses.

Empty dust away from ignition sources and

into an approved container.

USE this and other machinery with caution and respect. Always consider safety first, as it applies

to your individual working conditions. No list of safety guidelines can be complete—every shop

environment is different. Failure to follow guidelines could result in serious personal injury, damage to equipment or poor work results.

FIRE SUPPRESSION. Only operate the air filter

in locations that contain a fire suppression

system or have a fire extinguisher nearby.

IMPELLER HAZARDS. DO NOT place your hands

or tools inside the air filter housing during

operation for any reason. The powerful

suction could easily cause accidental contact

with the impeller which could cause serious

personal injury or damage to the machine.

OPERATING LOCATION. DO NOT operate the air

filter in rainy or wet locations—exposure to

water may create a shock hazard or decrease

the life of the machine.

-7-

Page 10

Model W1830 (For Machines Mfd. Since 4/15)

This machine must be connected to the correct size and

type of power supply circuit, or fire or electrical damage

may occur. Read through this section to determine if an

adequate power supply circuit is available. If a correct

circuit is not available, a qualified electrician MUST install

one before you can connect the machine to power.

A power supply circuit includes all electrical equipment

between the breaker box or fuse panel in the building

and the machine. The power supply circuit used for

this machine must be sized to safely handle the fullload current drawn from the machine for an extended

period of time. (If this machine is connected to a circuit

protected by fuses, use a time delay fuse marked D.)

The full-load current rating is the amperage a machine

draws at 100% of the rated output power. On machines

with multiple motors, this is the amperage drawn by the

largest motor or sum of all motors and electrical devices

that might operate at one time during normal operations.

or machine damage. To reduce this risk,

where only one machine will be running

ELECTRICAL

Circuit Requirements

The machine must be properly set up

before it is safe to operate. DO NOT

connect this machine to the power

source until instructed to do later in

this manual.

ELECTRICAL

Full-Load Current Rating

Full-Load Current Rating at 120V .....................1 Amp

Circuit Requirements for 120V

This machine is prewired to operate on a 120V power

supply circuit that has a verified ground and meets the

following requirements:

Circuit Type ...................... 120V, 60 Hz, Single-Phase

Circuit Size ............................................. 15 Amps

Plug/Receptacle .................................... NEMA 5-15

Incorrectly wiring or grounding this

machine can cause electrocution, fire,

only an electrician or qualified service

personnel should do any required

electrical work on this machine.

NOTICE

The circuit requirements listed in this

manual apply to a dedicated circuit—

at a time. If this machine will be

connected to a shared circuit where

multiple machines will be running at

the same time, consult a qualified

electrician to ensure that the circuit is

properly sized for safe operation.

-8-

Page 11

Model W1830 (For Machines Mfd. Since 4/15)

This machine MUST be grounded. In the event of certain

types of

a path of least resistance for electric current

order

Improper connection of the equipment-grounding

will

increase

insulation

grounding

cord or plug is necessary, do not connect the equipmentgrounding

Check with a qualified electrician or service personnel

if

or if

properly grounded.

plug is damaged or worn, disconnect it from power, and

immediately replace it with a new one.

electrician install the proper receptacle

We do not recommend using an extension cord with

Any extension cord used with this machine must contain a

plug and receptacle, and

meet the following requirements:

This machine is equipped with a power cord that has an

equipment-grounding

The plug

receptacle

(

accordance with local codes and ordinances.

Grounding Requirements

malfunctions or breakdowns, grounding provides

to travel—in

to reduce the risk of electric shock.

wire

the risk of electric shock. The wire with green

(with/without yellow stripes) is the equipment-

wire. If repair or replacement of the power

wire to a live (current carrying) terminal.

you do not understand these grounding requirements,

you are in doubt about whether the tool is

If you ever notice that a cord or

ELECTRICAL

For 120V Connection

wire and NE M A 5-15 grounding plug.

must only be inserted into a matching

see Figure) that is properly installed and grounded in

Extension Cords

this machine. Extension cords cause voltage drop, which

may damage electrical components and shorten motor

life. Voltage drop increases with longer extension cords

and smaller gauge sizes (higher gauge numbers indicate

smaller sizes).

ground wire

Minimum Gauge Size at 120V ...................... 14 AWG

Maximum Length (Shorter is Better) ................50 ft.

, match the required

-9-

120V

5-15 PLUG

Figure 1. NEMA 5-15 plug & receptacle.

DO NOT modify the provided plug or

use an adapter if the plug will not

fit the receptacle. Instead, have an

on a power supply circuit that meets

the requirements for this machine.

GROUNDED

5-15 RECEPTACLE

Grounding Prong

Neutral Hot

Page 12

SETUP

Unpacking

This machine has been carefully packaged for safe

transportation. If you notice the machine has been

damaged during shipping, please contact your authorized

Shop Fox dealer immediately.

Inventory

The following is a description of the main components

shipped with the Model W1830. Lay the components out

to inventory them.

Note: If you can't find an item on this list, check the

mounting location on the machine or examine the

packaging materials carefully. Occasionally we pre-install

certain components for safer shipping.

Model W1830 (For Machines Mfd. Since 4/15)

Keep machine disconnected from

power until instructed otherwise.

B

A

C

Shipping Inventory: (Figure 2) Qty

SETUP

A. Air Filter Unit ..............................................1

B. Hanging Chains .............................................4

C. Ceiling Hooks ...............................................4

D. Machine Hooks .............................................4

E. Remote Control w/Batteries .............................1

Installed & Not Shown Qty

• Outer Filter .................................................1

• Inner Filter .................................................1

D

E

Figure 2. Shipping inventory.

-10-

Page 13

Model W1830 (For Machines Mfd. Since 4/15)

Power Connection

To avoid unexpected startups or property damage, use

the following steps whenever connecting or disconnecting

the machine.

Connecting Power

Insert the power cord plug into a matching power supply

receptacle. The machine is now connected to the power

source.

Disconnecting Power

Grasp the molded plug and pull it completely out of the

receptacle. Do not pull by the cord as this may damage

the wires inside.

Figure 3. Connecting power.

Figure 4. Disconnecting power.

SETUP

-11-

Page 14

Test Run

Once you have unpacked the machine, perform a test

run before mounting to the ceiling to make sure it runs

prope rly.

If, during the test run, you cannot easily locate the source

of an unusual noise or vibration, stop using the machine

immediately, then review the Troubleshooting on Page

20.

If you still cannot remedy a problem, contact our Tech

Support at (360) 734-3482 for assistance.

To test run the machine, do these steps:

1. Make sure you have read the safety instructions at

the beginning of the manual.

2. Place the air filter on a workbench or similar stable

surface that can support the load.

Model W1830 (For Machines Mfd. Since 4/15)

3. Connect the air filter to power.

SETUP

4. Press the ON SPEED button on the control panel of

the air filter (see Figure 5) to turn the unit ON. The

machine should begin to operate.

— Strange or unusual noises should be investigated

and corrected before operating the machine

further. Always disconnect the machine from

power when investigating or correcting potential

problems.

Note: Do not be alarmed if you notice a small

amount of vibration during the Test Run. It is

normal for all air filters to produce a small

amount of vibration during operation. This

vibration is much more noticeable when operating

on a hard surface, such as a workbench, compared

to when operating in a suspended position, as

designed.

5. Push the ON SPEED button repeatedly to cycle

through the three air flow speed options. The lights

on the control panel should display the selected

speed.

Figure 5. Air filter control panel.

8. Push the remote control ON SPEED

button (see Figure 6) repeatedly to

cycle through the air flow options.

The lights on the control panel should

display the selected speed.

9. Push the remote control TIME button

repeatedly to cycle through the three

time options. The lights on the control

panel should display the amount of

time the air filter will run before

automatically turning OFF.

10. Press the remote control OFF button

to turn the air filter OFF.

6. Press the OFF button to turn the machine OFF.

7. Point the remote control directly at the control

panel, and press the remote control ON SPEED

button to turn the machine ON.

-12-

Figure 6. Remote control.

Page 15

Model W1830 (For Machines Mfd. Since 4/15)

Site Planning

Site planning is an important step to maximize the

effectiveness of the hanging air filter. Air circulation

must be thought out and all obstructions to the air path

considered.

Think of air circulation in terms of the circular motion of

the air before and after the air filter. The air exiting the

filter is exhausted at a higher velocity than that entering

it. Consequently, exhaust being vented inside a building

can have an effect on the pattern of air circulation.

Air

Filter

Air circulation patterns will vary depending upon which

air flow speed is used and according to your specific shop

setup. Figure 7 shows an example of good air circulation.

Figure 8 shows an example of poor air circulation, where

the air filter is placed too close to obstructions. In this

situation, the velocity of the air is lost and circulation is

diminished.

Below is a list of things to keep in mind when selecting

a spot for the air filter:

• Study your shop layout and try to determine the best

location for the hanging air filter. Air flow that is

obstructed will cause a short cycle effect, producing

unsatisfactory results. There must be a clearance of

at least 3 ft. from any obstructions in front and back

of the unit.

• Try to place the air filter in front of high dust

producers like sanders or near areas where sanding

will take place.

Figure 7. The air filter placement

promotes GOOD circular air motion.

SETUP

Air

Filter

Figure 8. The air filter placement is too

close to the walls and leaves much of the

room unfiltered.

• Make sure that an electrical outlet

with a properly grounded receptacle is

available at the location you choose.

• Do not place the hanging air filter where garage

doors may pass closely or where it may impede

transport or movement of any other object.

• Try to place the unit where it is easy to access for

turning it on, cleaning and maintenance.

It is very important that the hanging air filter be

supported properly. Please follow these guidelines

when planning where to mount the unit:

• Where the mounting brackets attach is the top of

the unit. The hanging air filter can only be secured

by the machine hooks on its top.

-13-

• The hanging air filter must be

supported by wood joists that are

capable of supporting at least 100 lbs

each. DO NOT attach the hanging air

filter to only sheet rock, press board

or paneling. These materials cannot

support the filter, and it may fall.

• Avoid hitting your head on the hanging

air filter. Make sure there is enough

clearance between the unit and the

ground, especially important in a

basement. If possible, position the air

filter in an area that has little foot

traffic but still offers easy access to

the switch and filters.

Page 16

Mounting to Ceiling

The Model W1830 performs best when hung from the

ceiling.

Model W1830 (For Machines Mfd. Since 4/15)

The advantage of having the air filter mounted to the

ceiling is that the air circulation pattern is not blocked by

equipment and obstacles closer to the floor.

When choosing a location to mount the air filter to the

ceiling, keep in mind the clearance necessary underneath

the machine for foot traffic or other operations. The

mounting chains can be used at full length, which will

bring the bottom of the air filter to approximately 25

from the ceiling, or the chains can be doubled-up, which

will bring the unit approximately 19

Important: The ceiling hooks must only be screwed into

solid wood. Otherwise, they may pull out under load and

cause the air filter to fall.

To mount the air filter to the ceiling, do these steps:

SETUP

1. Replace the four Phillips head screws shown in

Figure 9 with the four provided machine hooks (see

Figure 10).

1

⁄2" below the ceiling.

1

⁄2"

ONLY mount the air filter unit to joists

or table that can hold at least 100

lbs. DO NOT mount the unit only to

sheet rock, pressboard, paneling, or

honeycomb wall panels with expansiontype fasteners. The fasteners can tear

out and the air filter can fall. Ignoring

this caution can result in injury or

property damage.

2. Tighten each hex nut on the hooks against the air

filter body to secure them in place.

Phillips Head Screws

Figure 9. Remove these Phillips head

screws.

Hook

-14-

Hex Nut

Figure 10. Machine hook installed.

Page 17

Model W1830 (For Machines Mfd. Since 4/15)

Note: Some positions for the ceiling hooks may be

slightly uneven from each another. To make up for

this, minor adjustments can be made to the length

of the hanging assembly by adjusting the amount

that the machine hook is threaded into the air filter

housing (see Figure 11). After adjusting the hook

height, tighten the hex nut to secure the hook.

3

3. Drill a

⁄32" pilot hole into the center of the joists at

the mounting locations, then fully thread the ceiling

hooks into the joists (see Figure 12).

Hex Nut

Important: If the joists are covered with sheet rock

or paneling, use a stud finder or other device to

locate the center of the joists.

4. Attach the provided chains to the ceiling hooks.

5. With the help of another person to hold the air

filter up, attach the other end of the chains to the

machine hooks.

Figure 11. Machine hook partially

threaded to adjust the hanging length.

Ceiling

Joist

Hook

Machine

Hook

SETUP

-15-

Figure 12. Air filter mounted to the joists.

THIS AIR FILTER IS TO BE USED FOR

WOOD DUST ONLY. Do not use it to

filter toxic fumes, paint spray, or

dissipate smoke or fumes, which could

damage the filters.

Page 18

Model W1830 (For Machines Mfd. Since 4/15)

20' x 20' x 8'

3200 ft

3

409 CFM 409 CFM

= =

3200 ft

3

7.8 Minutes

60 Min.

7.8 Min.

OPERATIONS

General

Turning ON & OFF

When the air filter is connected to power, press

the ON SPEED button on the air filter control

panel or the remote control to turn the unit ON.

Note: The remote control communicates with

the air filter using infrared (IR) and must be

pointed directly at the air filter control panel to

work properly.

Changing Air Flow Speeds

The air filter can be set to operate in three air

flow speeds—260 (LO), 362 (MED), and 409 CFM

(HI). CFM is the acronym for Cubic Feet per

Minute of air flow that is generated through the

air filter.

To cycle through the available speeds, press the

ON SPEED button on the control panel or remote

control repeatedly. This will illuminate the

corresponding lights on the control panel.

Setting Timer

The air filter can be set for a timed performance

of 1, 2, or 4 hours. At the end of this time, the

OPERATIONS

air filter will automatically turn OFF.

Filtering Performance

When used in conjunction with an efficient

dust collection system, the Model W1830

removes most fine wood particles up to 1

micron from the air. This air filter is capable of

recirculating the air in a room measuring 20'

x 20' x 8' approximately 7.7 times an hour. We

recommend that the volume of air in your room

be recirculated 6–9 times an hour for the best

filtering effect.

Therefore, rooms with a larger volume may

require two or more air filters to achieve proper

filtering.

To calculate the recirculating rate for your

shop space, do these steps:

1. Calculate the volume of air in your shop by

multiplying the length x width x height of

the room (see the example below). Then,

divide the volume by the speed (CFM) you

have chosen to operate the air filter. This

will give you how many minutes it takes to

recirculate the air in the room.

Example: The room measures 20' x 20' x 8'

and you are operating the air filter at 409

CFM (HI).

To cycle through the available time settings,

press the TIME button on the remote

control repeatedly. This will illuminate the

corresponding lights on the control panel.

Machine Storage

When the air filter is not in use, unplug the

power cord from the power source. Secure the

power cord away from potential hazards, such as

high traffic areas, sharp objects, heat sources,

harsh chemicals or fumes, damp areas, etc.

= =

2. Calculate how many times per hour the

room volume is recirculated through the

air filter by dividing 60 minutes by the

circulating time from Step 1. This will give

you how many times an hour the air in the

room is recirculated through the air filter.

=

7.7 Times per Hour

-16-

7.8 Minutes

Page 19

Model W1830 (For Machines Mfd. Since 4/15)

ACCESSORIES

Air Filter Accessories

The following Air Filter accessories may be available through your local Woodstock International Inc.

Dealer. If you do not have a dealer in your area, these products are also available through online dealers.

Please call or e-mail Woodstock International Inc. Customer Service to get a current listing of dealers at:

1-800-840-8420 or at sales@woodstockint.com.

D3834—Inner Filter for Model W1830

D3835—Outer Filter for Model W1830

We recommend that you keep a set of filters on hand to ensure

uninterrupted service of your air filter.

D3834

The Shop Fox Model W1746 is one machine that will sit in the shop

and gather dust—fine dust that is! With its three speed fan, automatic

shut-off and 0.3 micron filter, this fine dust air filter circulates shop

air and captures the fine dust that otherwise stays suspended. Even

with an efficient dust collector, if other machines are making dust, you

need this fine air filter.

D3835

OPERATIONS

-17-

Page 20

MAINTENANCE

Cleaning Filters

The amount of air filter operation has a direct bearing on

when you must clean or replace the filters.

To maintain efficient operation, check the filters

approximately every 40 hours of use in light or moderately

dusty environments. In very dusty environments, check

the filters every eight hours of use. Always wear a

respirator when checking the filters.

To change and service the filters, do these steps:

1. DISCONNECT MACHINE FROM POWER!

2. Un-latch the filter retaining clips from the top and

bottom of the unit, as shown in Figure 13, and

remove the outer filter. Place the filter in a trash

bag and shake it gently to remove the bulk of the

dust.

Model W1830 (For Machines Mfd. Since 4/15)

Keep the air filter unit unplugged

during all maintenance procedures.

Ignoring this warning may result in

laceration or amputation injuries from

accidental startup!

If you choose to use compressed air to further clean

the filter, do so outdoors and in an appropriate

environment where people are not in the immediate

vicinity.

3. Remove the inner filter, place it inside a trash bag

and gently shake the dust from the inside of the

filter.

Optional: Wash the inner filter with water to remove

the remaining dust, then let it air dry completely.

4. Re-install the inner filter, then re-install the outer

filter with the wire mesh facing to the inside.

5. Re-latch the retaining clips to secure the filters.

MAINTENANCE

Note: During regular use the filters can be cleaned

several times before replacement becomes necessary. To

determine whether the filters need to be replaced, hold

them up to the sunlight and visually inspect them. If you

cannot see through the filters due to caked dust and

grim, replace them before putting air filter back into

operation.

Always wear a respirator and safety

glasses when cleaning the filters.

Sawdust may cause allergic reactions

or respiratory problems.

Retaining Clip (1 of 2)

Inner

Filter

Outer

Filter

Figure 13. Filters exposed for cleaning.

-18-

Page 21

Model W1830 (For Machines Mfd. Since 4/15)

SERVICE

General

This section covers the most common service adjustments

or procedures that may need to be made during the life

of your machine.

If you require additional machine service not included

in this section, please contact Woodstock International

Technical Support at (360) 734-3482 or send e-mail to:

tech-support@shopfox.biz.

Replacing Fuse

The fuse on the control panel will blow in the case of a

thermal overload.

MAKE SURE that your machine is

unplugged during all service procedures! If this warning is ignored, serious personal injury may occur.

Replace the fuse only with a fast-acting, 2 amp, 250V fuse

(Part Number X1830055).

Tool Needed Qty

Phillips Screwdriver #2 .........................................1

To replace the machine fuse, do these steps:

1. DISCONNECT MACHINE FROM POWER!

2. Unthread the fuse holder cap from the control panel

(see Figure 14) and remove it. The fuse will come

out with it.

3. Replace the fuse and fully thread the cap in to

secure it.

Remote Control Battery

Replacement

The remote control uses two AA batteries. To replace

them, slide the battery compartment cover down and off

the remote (see Figure 15). Insert the batteries in the

proper direction and replace the cover.

Fuse

Holder Cap

Figure 14. Fuse holder cap on the control

panel.

Batteries

SERVICE

Cover

-19-

Figure 15. Remote control battery

compartment cover removed.

Page 22

Model W1830 (For Machines Mfd. Since 4/15)

Troubleshooting

This section covers the most common problems and corrections with this type of

machine. WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Machine does not start or a

breaker trips.

Machine stalls or is underpowered.

Machine has vibration or

noisy operation.

Loud, repetitious noise, or

excessive vibration coming

from air filter.

Air filter does not adequately collect dust; poor

performance.

1. Power supply switched OFF or is at

fault.

2. Remote control not working or batteries are dead.

3. Infrared transmission is blocked or

remote too far away.

4. Wall circuit breaker tripped.

5. Control panel fuse blown.

6. Wiring is open/has high resistance.

7. Infrared receiver at fault.

8. Control panel ON SPEED button at

fault.

9. Motor at fault.

1. Motor overheated.

2. Run capacitor at fault.

3. Motor at fault.

1. Motor or component loose.

2. Motor fan rubbing on fan cover.

3. Motor bearings at fault.

1. Air filter is not mounted properly

and wobbles.

2. Impeller fan is damaged, loose, or

severely unbalanced.

3. The motor mounting is loose.

4. Motor fan housing is dented, causing the motor fan blade to hit the

housing while spinning.

1. The filters are dirty. 1. Clean the filters.

1. Ensure power supply is ON/has correct voltage.

2. Replace batteries; point remote control directly at

control panel.

3. Make sure the infrared receiver on the control panel

is not blocked; try using the remote closer to the

filter.

4. Ensure circuit size is correct/replace weak breaker.

5. Check filters/resolve reason for blown fuse; replace

fuse (see Page 19).

6. Check/fix broken, disconnected, or corroded wires.

7. Inspect/replace if faulty.

8. Replace faulty ON SPEED button.

9. Test/repair/replace.

1. Clean filters to reduce load on motor.

2. Test/repair/replace.

3. Test/repair/replace.

1. Inspect/replace damaged bolts/nuts, and re-tighten

with thread locking fluid.

2. Fix/replace fan cover; replace loose/damaged fan.

3. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

1. Stabilize the air filter.

2. Unplug air filter, and inspect the impeller for dents,

bends, loose fins. Replace impeller if any damage is

found.

3. Make sure all fasteners on the air filter are tight.

4. Replace motor fan housing.

SERVICE

-20-

Page 23

Model W1830 (For Machines Mfd. Since 4/15)

SHOCK HAZARD.

QUALIFIED ELECTRICIAN

WIRE CONNECTIONS.

WIRE/COMPONENT DAMAGE

. The motor wiring shown in these

shocked, wait at least this long before working

Electrical Safety Instructions

These pages are current at the time of printing. However, in the spirit of improvement, we may

make changes to the electrical systems of future machines. Study this diagram carefully. If you notice

differences between your machine and these wiring diagrams, call Woodstock International Technical

Support at (360) 734-3482.

connected to a power source is extremely

dangerous. Touching electrified parts will

result in personal injury including but not

limited to severe burns, electrocution,

or death. Disconnect the power from

the machine before servicing electrical

components!

hazards of electricity, only a qualified

electrician should perform wiring tasks on this

machine. If you are not a qualified electrician,

get help from one before attempting any kind

of wiring job.

tight to prevent wires from loosening during

machine operation. Double-check all wires

disconnected or connected during any wiring

task to ensure tight connections.

or components increase the risk of serious

personal injury, fire, or machine damage.

If you notice that any wires or components

are damaged while performing a wiring task,

replace those wires or components before

completing the task.

Working on wiring that is

. Due to the inherent

All connections must be

. Damaged wires

MOTOR WIRING

diagrams is current at the time of printing,

but it may not match your machine. Always

use the wiring diagram inside the motor

junction box.

MODIFICATIONS. Using aftermarket parts or

modifying the wiring beyond what is shown

in the diagram may lead to unpredictable

results, including serious injury or fire.

CAPACITORS/INVERTERS. Some capacitors and

power inverters store an electrical charge for

up to five minutes after being disconnected

from the power source. To avoid being

on these components.

ELECTRICAL REQUIREMENTS. You MUST follow

the electrical requirements at the beginning

of this manual when connecting your machine

to a power source.

EXPERIENCING DIFFICULTIES. If you are

experiencing difficulties understanding the

information included in this section, contact

our Technical Support at (360) 734-3482.

The photos and diagrams

included in this section are

best viewed in color. You

can view these pages in

color at www.shopfox.biz.

BLACK

WHITE

GREEN

RED

WIRING DIAGRAM COLOR KEY

BLUE

BROWN

GRAY

ORANGE

-21-

YELLOW

YELLOW

GREEN

PURPLE

PINK

LIGHT

BLUE

BLUE

WHITE

TURQUOISE

SERVICE

Page 24

Read

Page 21

Model W1830 (For Machines Mfd. Since 4/15)

Electrical Wiring Diagram

STOP

Before

Wiring

Neutral

Hot

110VAC 5-15 Plug

(As Recommended)

Ground

Power

Cord

Ground

Fuse

F2A250V

Control

Panel

Ground

8MFD 375VAC

Run Capacitor

Motor

Ground

Cabinet

Impeller

Housing

SERVICE

-22-

Page 25

Model W1830 (For Machines Mfd. Since 4/15)

PARTS

Cabinet & Remote Control

102

101

103

108

106

107

108

109

109

107

104

110

111

112

105

258

113

257

101

259

114

116

115

250

251

256

REF PART # DESCRIPTION REF PART # DESCRIPTION

101 XPHTEK15M TAP SCREW M4 X 10 112 X1830112 GROUND WIRE 18AWG 335MM

102 X1830102 CABINET 113 X1830113 WIRE MESH 251 X 528MM

103 XPS14M PHLP HD SCR M6-1 X 12 114 D3834 INNER FILTER 421 X 241 X 160MM

104 X1830104 CABINET HANDLE 115 D3835 OUTER FILTER 421 X 241 X 45MM

105 X1830105 HANDLE BRACKET 116 X1830116 RUBBER FOOT

106 XPS40M PHLP HD SCR M5-.8 X 16 250 X1830250 REMOTE CONTROL UNIT

107 XPW02M FLAT WASHER 5MM 251 XPBATTAA BATTERY AA

108 XPLW01M LOCK WASHER 5MM 256 X1830256 THREADED HOOK M6-1 X 35

109 XPN06M HEX NUT M5-.8 257 X1830257 HANGING CHAIN 11-1/2"

110 XPS08M PHLP HD SCR M5-.8 X 12 258 X1830258 HOOK SCREW M6 X 25

111 XPTLW02M EXT TOOTH WASHER 5MM 259 XPFN02M FLANGE NUT M6-1

PARTS

-23-

Page 26

156

155

Model W1830 (For Machines Mfd. Since 4/15)

Control Panel

158

157

161

159

160

162

164

165

163

166

154

150

153

151

152

109

167

112

REF PART # DESCRIPTION REF PART # DESCRIPTION

109 XPN06M HEX NUT M5-.8 158 X1830158 CONTROL PANEL PLATE

112 X1830112 GROUND WIRE 18AWG 335MM 159 X1830159 INSULATED FLAT WASHER 3MM

150 X1830150 POWER CORD 18G 3W 72" 5-15 160 XPHTEK31M TAP SCREW M4 X 14

151 X1830151 STRAIN RELIEF 6P-4 161 X1830161 PRINTED CIRCUIT BOARD

152 XPS06M PHLP HD SCR M5-.8 X 20 162 X1830162 CONTROL PANEL BOX

153 X1830153 FUSE HOLDER CFH052S CR3-13 163 XPW07M FLAT WASHER 3MM

154 X1830154 FUSE HOLDER CAP 164 XPLW09M LOCK WASHER 3MM

155 X1830155 FUSE F2A250V 165 XPN07M HEX NUT M3-.5

156 X1830156 CONTROL PANEL LABEL 166 X1830166 WIRE NUT 18G

157 XPFH85M FLAT HD SCR M3-.5 X 30 167 X1830167 WIRE 18G 6-3/4"

PARTS

-24-

Page 27

Model W1830 (For Machines Mfd. Since 4/15)

Motor & Impeller

207*

101

202

208*

209

210

211

206

201

208A Includes

*

204, 207, & 208

205

167

213

204*

203

202

211

101

200

212

REF PART # DESCRIPTION REF PART # DESCRIPTION

101 XPHTEK15M TAP SCREW M4 X 10 207 X1830207 REAR IMPELLER HOUSING COVER

167 X1830167 WIRE 18G 6-3/4" 208A X1830208A IMPELLER HOUSING ASSEMBLY

200 X1830200 CAPACITOR COVER 208 X1830208 IMPELLER HOUSING

201 XPTLW01M EXT TOOTH WASHER 4MM 209 X1830209 RUBBER SPACER

202 XPW02M FLAT WASHER 5MM 210 XPWF05M FENDER WASHER 5MM

203 X1830203 R CAPACITOR 8M 375V 1-1/4 X 2-1/2 211 XPLN02M LOCK NUT M5-.8

204 X1830204 FRONT IMPELLER HOUSING COVER 212 X1830212 MOTOR 1/8HP 120V 60HZ

205 XPB94M HEX BOLT M5-.8 X 25 213 XPS02M PHLP HD SCR M4-.7 X 12

206 X1830206 SQUIRREL CAGE IMPELLER

-25-

PARTS

Page 28

Model W1830 (For Machines Mfd. Since 4/15)

Label Placement

Safety labels warn about machine hazards and how to prevent serious personal injury. The owner

of this machine MUST maintain the original location and readability of all labels on this machine.

If any label is removed or becomes unreadable, REPLACE that label before allowing machine to be

operated again. Contact us at (360) 734-3482 or www.shopfoxtools.com to order new labels.

300

307

301

306V2

303

302

309

302

304

305

REF PART # DESCRIPTION REF PART # DESCRIPTION

300 X1830300 EXPLOSION HAZARD LABEL 305 XLABEL-04 ELECTRICITY LABEL

301 X1830301 GENERAL WARNINGS LABEL 306V2 X1830306V2 CONTROL PANEL LABEL ETL V2.07.14

302 XLABEL-24 DISCONNECT LABEL 307 X1830307 REMOTE CONTROL LABEL

303 XLABEL-06 EYE/LUNG HAZARD LABEL 309 X1830309 SHOP FOX LABEL

304 XLABEL-08A READ MANUAL LABEL

PARTS

-26-

Page 29

Model W1830 (For Machines Mfg. Since 1/12)

Page 30

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

Place

Stamp

Here

Woodstock international inc.

p.o. box 2309

bellingham, Wa 98227-2309

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Page 31

WARRANTY

WARRANTY

Woodstock International, Inc. warrants all Shop Fox machinery to be free of defects from workmanship

and materials for a period of two years from the date of original purchase by the original owner.

This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or

accidents, lack of maintenance, or reimbursement of third party expenses incurred.

Woodstock International, Inc. will repair, replace, or arrange for a dealer refund at its expense and

at its option, the Shop Fox machine or machine part, which in proper and intended use has proven to

be defective, provided that the original owner returns the product prepaid to an authorized warranty

or repair facility as designated by our Bellingham, Washington office with proof of their purchase of

the product within two years, and provides Woodstock International, Inc. reasonable opportunity to

verify the alleged defect through inspection. If it is determined there is no defect, or that the defect

resulted from causes not within the scope of Woodstock International Inc.'s warranty, then the original

owner must bear the cost of storing and returning the product.

This is Woodstock International, Inc.’s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that Shop Fox machinery complies with

the provisions of any law, acts or electrical codes. We do not reimburse for third party repairs. In no

event shall Woodstock International, Inc.’s liability under this limited warranty exceed the purchase

price paid for the product, and any legal actions brought against Woodstock International, Inc. shall be

tried in the State of Washington, County of Whatcom. We shall in no event be liable for death, injuries

to persons or property or for incidental, contingent, special or consequential damages arising from the

use of our products.

Every effort has been made to ensure that all Shop Fox machinery meets high quality and durability

standards. We reserve the right to change specifications at any time because of our commitment to

continuously improve the quality of our products.

Page 32

High Quality Machines and Tools

Woodstock International, Inc. carries thousands of products designed

to meet the needs of today's woodworkers and metalworkers.

Ask your dealer about these fine products:

Loading...

Loading...