Page 1

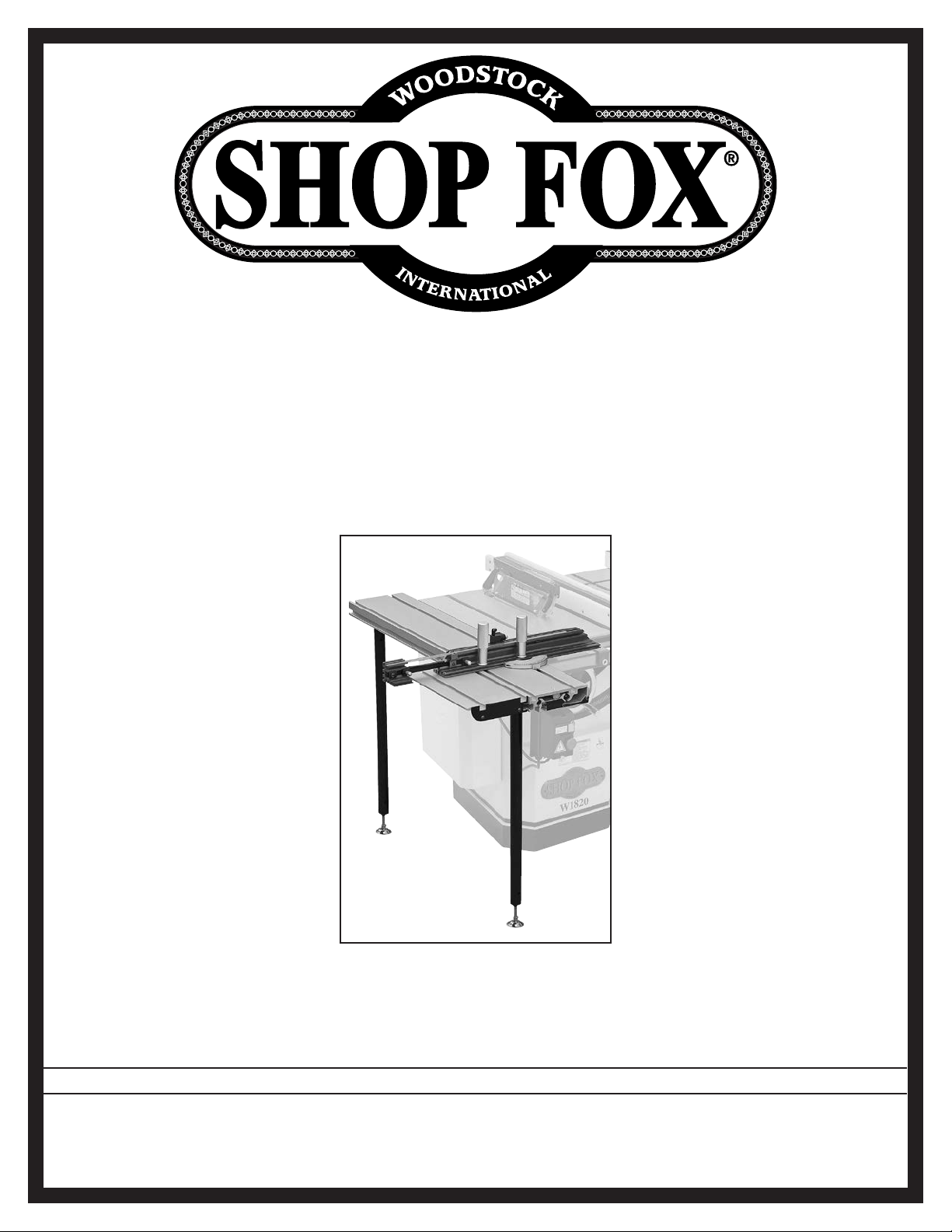

MODEL W1822

SLIDING TABLE

ATTACHMENT

#12868TS

OWNER'S MANUAL

(FOR MODELS MANUFACTURED SINCE 3/16)

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JULY, 2010 BY WOODSTOCK INTERNATIONAL, INC., REVISED APRIL, 2016 (BL)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property

damage from negligence, improper training, machine modifications or

misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Contents

INTRODUCTION .....................................2

Important Notice! ................................ 2

Woodstock Technical Support .................. 3

Specifications ..................................... 3

SAFETY ............................................... 4

Standard Machinery Safety ..................... 4

Additional Safety for Sliding Table Saws ..... 6

SETUP ................................................ 7

Unpacking ......................................... 7

Inventory .......................................... 7

Assembly ........................................... 8

OPERATIONS....................................... 13

Operation Overview ........................... 13

Crosscut Fence ................................. 14

Extension Fence ................................ 14

Extension Table ................................. 14

Flip Stop ......................................... 15

Crosscutting ..................................... 15

Miter Cutting .................................... 16

PARTS .............................................. 17

Table ............................................. 17

Fence ............................................. 18

WARRANTY ........................................ 21

Important Notice!

Table Saw Modifications Required for Installation

The Model W1822 can be installed on a wide range of table saw brands and sizes; however, installation

usually requires permanent modification to your table saw or its parts. This modification can include

cutting, grinding, drilling, and tapping threads in metal surfaces. Read the following to determine what

type of modification may be required for your saw:

SAFETYINTRODUCTION

SETUP ACCESSORIES

OPERATIONS

• If your saw table does not have mounting holes that match those in the Model W1822, you will

need to drill (and possibly tap) new holes in the saw table.

• If the fence rails on your saw prevent installation of the Model W1822, then you will need to

either:

— Cut off the ends of the rails (this is the easiest and fastest option).

— Re-mount the rails farther to the right, which may also require you to drill (and possibly tap)

new holes in your table and cut small notches into your rails for access to T-slots in your saw’s

table.

• If the power switch on your saw is mounted on the left, you may need to re-mount it to a new

location, such as the non-moving base portion of the Model W1822 or a new location on your fence

rails. Remounting the switch may require drilling and tapping new holes.

Before beginning any modification to your table saw or its parts, read the entire assembly section in this

manual to make sure the person making the modification is capable of performing the required tasks,

and to make sure the Model W1822 will fit your saw.

PARTS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

Page 4

Model W1822 (For Machines Mfd. Since 3/16)

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

The Model W1822 has been specially designed to provide many years of trouble-free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure safe and reliable operation.

Woodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is to

include the basic information for safety, setup, operation, maintenance, and service of this product.

We stand behind our machines! In the event that questions arise about your machine, please contact

Woodstock International Technical Support at (360) 734-3482 or send e-mail to: tech-support@shopfox.

biz. Our knowledgeable staff will help you troubleshoot problems and process warranty claims.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you have comments about this manual, please contact us at:

Woodstock International, Inc.

Attn: Technical Documentation Manager

P.O. Box 2309

Bellingham, WA 98227

Email: manuals@woodstockint.com

Specifications

Sliding Table Size .......................................9" x 47"

Extension Table Size ................................ 9" x 13

Maximum Table Travel ...................................... 55"

Maximum Crosscutting Length ............................. 48"

Fence Length ......................................... 30

Weight .....................................................70 lbs.

Fits the following Shop Fox Model table saws: W1677, W1703, W1711, W1714, W1725, W1726, W1748,

W1817, W1818, W1819, W1820 (may fit additional models as they are released).

1

3

⁄4"–37"

⁄4"

-2-

Page 5

Model W1822 (For Machines Mfd. Since 3/16)

SAFETY

SAFETY

Standard

Machinery Safety

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY. Machinery presents serious

injury hazards to untrained users.

SAFETY

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY. Everyday eye-

glasses only have impact resistant lenses—they are NOT safety glasses.

3. ALWAYS WEAR A NIOSH APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT PRODUCES

DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY. Machinery noise can cause

permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry which may

get caught in moving parts. Wear protective hair covering to contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR ALCOHOL.

Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make

sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch keys.

-3-

Page 6

Model W1822 (For Machines Mfd. Since 3/16)

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power OFF and allow all moving parts to come to

a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet locations, or

where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE. Undersized cords over-

SAFETY

heat and lose power. Replace extension cords if they become damaged. DO NOT use extension cords

for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make sure switch is

in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING MACHINERY.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and adjusting

wrenches before turning machinery ON.

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and alignment of

parts, broken parts, part mounting, loose bolts, and any other conditions that may affect machine

operation. Repair or replace damaged parts.

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended accessories.

The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR. Know and avoid condi-

tions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN DUST MAY BE HAZARDOUS to the respiratory systems of people and

animals, especially fine dust. Make sure you know the hazards associated with the type of dust you

will be exposed to and always wear a respirator approved for that type of dust.

-4-

Page 7

Model W1822 (For Machines Mfd. Since 3/16)

Additional Safety for Sliding Table Saws

READ and understand this

entire manual AND the

table saw owner's manual

before using this attachment. Serious personal

injury may occur if safety

and operational information is not understood and

followed. DO NOT risk your

safety by not reading!

KICKBACK. Kickback happens when the workpiece is thrown back toward the operator at a high rate of

speed. Until you have a clear understanding of kickback, how it occurs, and how to prevent it, DO NOT

operate the table saw with this sliding table attachment!

CLEARANCE. To prevent flying metal debris causing serious injuries, always make sure the sliding table

crosscut fence will not contact the blade before starting the table saw.

WORKPIECE CONTROL. If the workpiece should unexpectedly move and bind with the blade, kickback

could occur. Always make sure the workpiece is placed in a stable position on the tables and is either

supported by the rip fence or the crosscut fence during cutting operations.

OPERATOR POSITION. If kickback occurs, the workpiece will be ejected in a path that is in-line with the

blade. Never have any part of your body in-line with the cutting path of the blade during operation.

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

SAFETY

AWKWARD POSITIONS. Avoid awkward body and hand positions where a sudden slip could cause your

hands to move into the spinning blade.

REACHING OVER SAW BLADE. To prevent your hands or arms accidently contacting the spinning blade,

never reach behind or over the blade during cutting operations.

USING RIP FENCE WITH SLIDING TABLE CROSSCUT FENCE. When using the rip fence as a stop block

for the crosscut fence, the rip fence must be in front of the blade. Otherwise, the workpiece could bind

against the rip fence and kickback could occur.

REMOVING WORKPIECES. To avoid accidental contact with the spinning blade, always turn the saw OFF

and wait until the blade is completely stopped before removing any part of the workpiece from the

table.

-5-

Page 8

SETUP

Unpacking

The Model W1822 has been carefully packaged for safe

transportation. If you notice the machine has been

damaged during shipping, please contact your authorized

Shop Fox dealer immediately.

Inventory

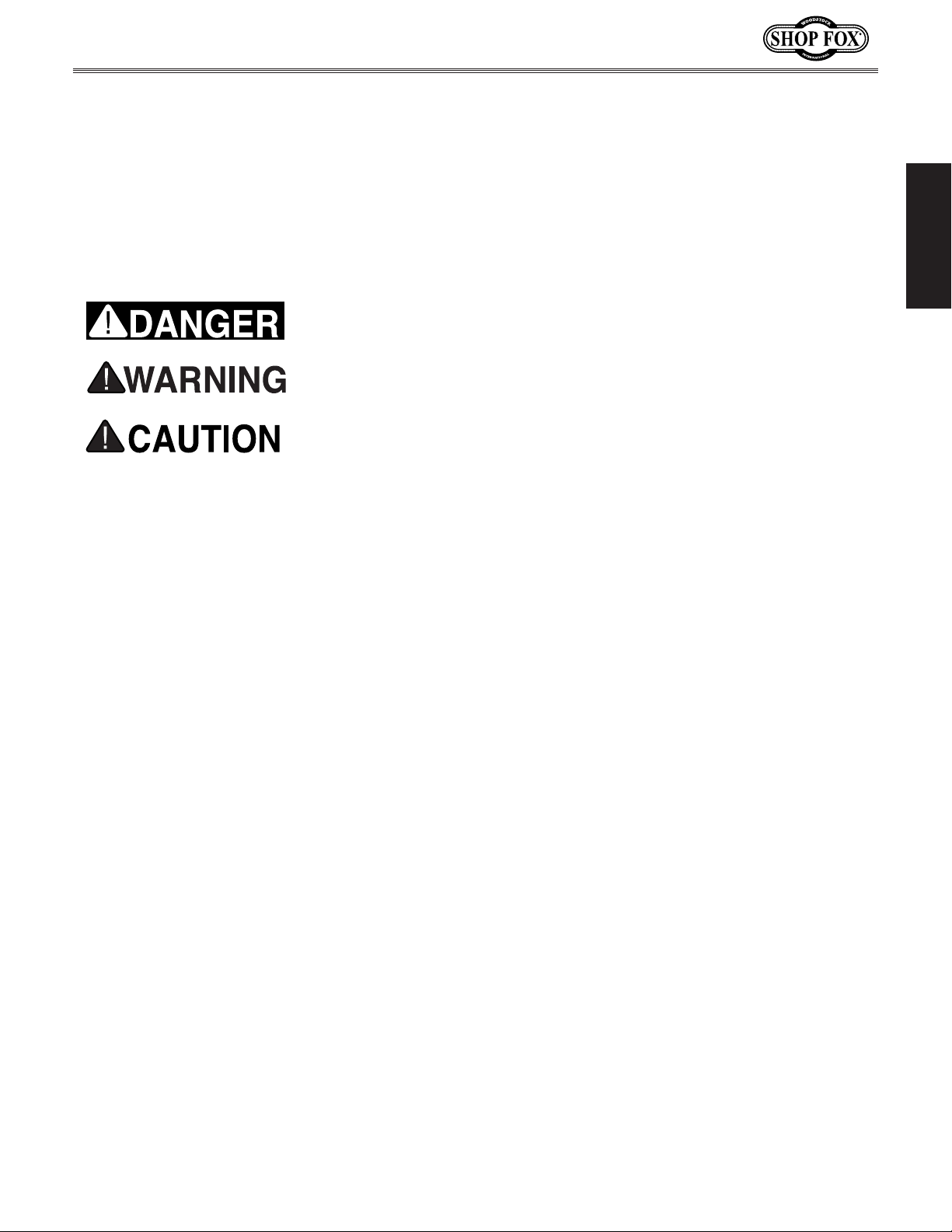

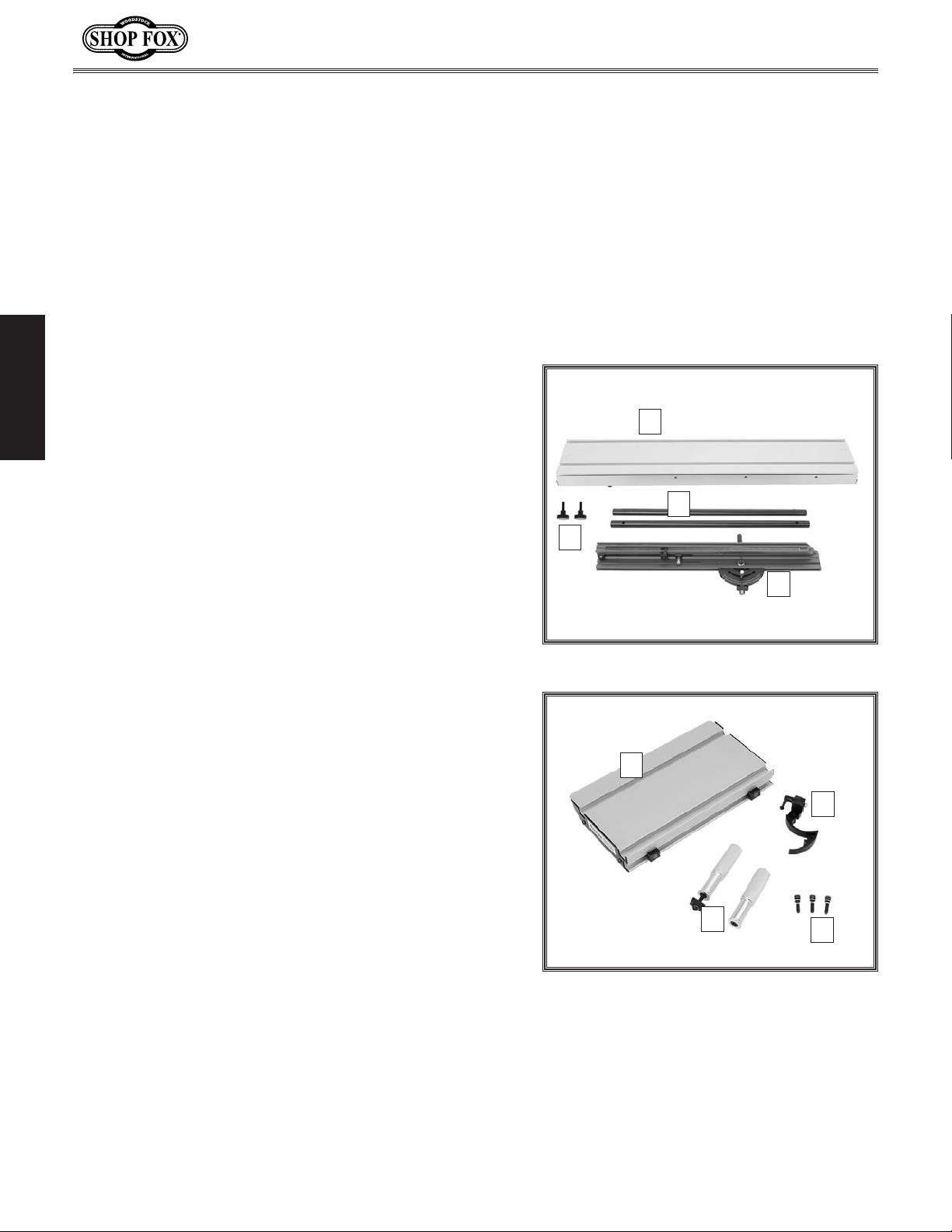

Refer to Figures 1–2 and the listing below to inventory

the contents of the shipping box.

SETUP

Note: If you can't find an item on this list, check the

mounting locations or examine the packaging materials

carefully. Occasionally we pre-install certain components

for shipping purposes.

Model W1822 (For Machines Mfd. Since 3/16)

A

B

Description Qty

A. Sliding Table Assembly ....................................1

B. Support Legs................................................2

C. Support Leg Foot Pad Assemblies .......................2

D. Fence Assembly ............................................1

E. Extension Table ............................................1

F. Flip Stop Assembly ........................................1

G. Knurled Pivot Handles ....................................2

H. Mounting Screw Assemblies ..............................3

— Cap Screws M8-1.25 x 30 ..............................3

— Lock Washers 8mm ................................ ......3

— Flat Washers 8mm.......................................3

If any nonproprietary parts are missing (e.g. a nut or a

washer), we will gladly replace them; or for the sake of

expediency, replacements can be obtained at your local

hardware store.

C

D

Figure 1. Shipping inventory items A–D.

E

F

G

H

-6-

Figure 2. Shipping inventory items E–H.

Page 9

Model W1822 (For Machines Mfd. Since 3/16)

Assembly

The assembly process typically requires modifications to

your table saw. To make the process easier, we strongly

recommend that you have another person help you. Also,

if you have to drill new holes, we recommend clamping

the components in place when marking or drilling; this

will ensure accurate final results.

Tools Needed Qty

Another Person For Lifting ....................................1

Wrench 13mm ...................................................1

Hex Wrenches 4mm & 6mm ............................ 1 Each

Marker ............................................................1

Precision Straightedge .........................................1

Adjustable Square ..............................................1

Feeler Gauges ..............................................1 Set

Masking Tape ......................................... As Needed

To assemble and install your sliding table attachment,

do these steps:

NOTICE

Additional tools will be needed for

cutting, grinding, drilling, and tapping

threads in metal surfaces

Table T-Slot

SETUP

Fence Rail

Cut-Out

Figure 3. Illustrated example of a fence

modification.

1. DISCONNECT SAW FROM POWER!

2. Attach the sliding table to the left side of the saw

table so that the sliding table top is 0.010"–0.020"

higher than the top of the table saw to prevent the

workpiece from dragging on the saw table.

— If the fence rails on your saw prevent installation

of the Model W1822, then you will need to either

cut off the ends of the rails, or re-mount the rails

farther to the right, which may also require you

to drill (and possibly tap) new holes in your table

and cut small notches into your rails for access to

T-slots in your saw’s table (see Figure 3).

— If the power switch on your saw is mounted on

the left, you may need to re-mount it to a new

location, such as the non-moving base portion of

the Model W1822 (see Figure 4 for an example) or

a new location on your fence rails. Remounting the

switch may require drilling and tapping new holes.

— If you have a wing attached to the left side of the

saw table, remove it.

Figure 4. Example of relocating the power

switch.

Sliding Table

Mounting Holes

— If you do not have a wing attached to the left side

of the table or do not have the correct mounting

holes for the sliding table, you will need to drill

and tap three M8-1.25 holes into the saw table in

a layout that matches those in the sliding table

(see Figure 5).

-7-

Saw Table

Figure 5. Mounting hole locations.

Page 10

3. Thread a foot pad assembly into the bottom of each

support leg, as shown in Figure 6. For now, do not

tighten the jam nuts against the legs so the leg

height can be adjusted in a later step.

Model W1822 (For Machines Mfd. Since 3/16)

Foot

Pad

NOTICE

If you are using a mobile base with the table saw, use

one of the options above when moving the saw and

the sliding table attachment:

• Attach an extension to the mobile base that

will provide support for the sliding table legs.

• Install locking casters onto the bottom of the

sliding table legs.

SETUP

• Adjust the sliding table feet up, move the

unit, then re-adjust the feet to provide proper

support to the sliding table.

Support

Leg

Jam

Nut

Figure 6. Example of foot pad assembly

threaded into the support leg.

T-Nut

4. Turn the sliding table upside down, slide the support

leg T-nuts into the sliding table miter gauge slot (see

Figure 7), then hand-tighten the legs clockwise to

secure them in place.

Note: For the best support, position the support

legs near each end of the sliding table, as shown in

Figure 7.

5. With the help of at least one other person to support

the weight, turn the sliding table assembly over,

then position it against the side of the saw table.

6. Pull out the locking pin that is underneath the

sliding table, then slide the top part to left to

expose two of the mounting holes, as shown in

Figure 8.

Figure 7. Support legs installed.

x 3

Figure 8. Mounting fasteners (2 of 3).

-8-

Page 11

Model W1822 (For Machines Mfd. Since 3/16)

7. Align the mounting holes, then thread (2) M8-1.25

x 30 cap screws, 8mm lock washers, and 8mm flat

washers through the sliding table into the mounting

holes of the saw table.

8. Move the sliding table to the right and install the

remaining M8-1.25 x 30 cap screw, 8mm lock washer,

and 8mm flat washer.

9. Place the straightedge across the saw table and

the sliding table at each end to make sure that the

combined table surface is flat.

— If the combined table surface is flat, skip to the

next step.

— If the outside edge of the sliding table tilts down,

use strips of masking tape along the bottom edge

of the saw table to shim the sliding table up and

even with the saw table from side to side (see

Figure 9).

— If the outside edge of the sliding table tilts up,

use strips of masking tape along the top edge

of the saw table to shim the sliding table down

and even with the saw table from side to side

(see Figure 10).

Note: After reinstalling the sliding table, remove all

excess masking tape with a razor blade.

10. Adjust the leg feet until they are firmly on the floor

but not affecting the alignment between the saw

and sliding tables, then tighten the feet jam nuts

against the legs to secure the settings.

SETUP

Tape

Figure 9. Using tape to shim the sliding

table up.

Tape

11. Make sure the miter gauge slots of the saw table are

parallel to the saw blade according to the table saw

owner's manual.

In the next steps, you will align the sliding table

parallel with the saw blade. This is necessary to

ensure straight cutting operations and to prevent

workpieces from binding and kicking back.

12. Tilt the main saw blade to 0° and raise it all the way

up.

-9-

Figure 10. Positioning the tape to shim

the sliding table down.

Page 12

13. Mark the right blade edge that is even with the

table, then move the sliding table all the way

toward the table saw front.

14. Use the adjustable square and feeler gauges to

measure the distance between the sliding table

miter gauge slot and the main saw blade at the mark

you made in Step 13. This is distance "A" shown in

Figure 11.

15. Move the sliding table all the way toward the rear

of the table saw, rotate the saw blade so the mark

you made in Step 13 is at location "B", then take the

measurement of "B".

Model W1822 (For Machines Mfd. Since 3/16)

If the sliding table does not travel

exactly parallel to the saw blade, the

workpiece could bind and kickback

toward the operator, causing serious

personal injury. You MUST make sure

that the sliding table travels parallel

with the saw blade before beginning

operation to avoid kickback injuries.

SETUP

— If the difference is equal to or less than 0.004"

between the "A" and "B" measurements, the sliding

table parallelism is acceptable. Continue with

Step 16.

— If the difference between the "A" and "B"

measurements is greater than 0.004", place

masking tape between the sliding table and saw

table on one end or the other to make the sliding

table parallel with the saw blade.

Repeat Steps 13–15 until the difference between

the "A" and "B" measurements is equal to or less

than 0.004".

16. Insert the T-nuts of the extension table into the

T-slot on the outside edge of the sliding table, then

tighten the lock levers to secure the extension table

to the sliding table, as shown in Figure 12.

Note: The extension table provides additional

workpiece support and should be positioned as

needed during operation.

Saw Blade

AB

Sliding Table T-Slot

Figure 11. Measuring the distance

between the sliding table miter gauge slot

and the saw blade.

Tip: Instead of rotating the lock levers to secure the

extension table, you can pull outward on the levers

to disengage them, then use a 4mm hex wrench to

tighten the cap screws in the center of the levers.

-10-

Lock Levers

Figure 12. Locations of the extension

table lock levers.

Page 13

Model W1822 (For Machines Mfd. Since 3/16)

17. Remove the T-bolt from the knurled pivot handle

of the crosscut fence and set it aside for use in the

next steps.

Forward

Set Screw

18. Slide the miter gauge bar into the sliding table miter

gauge slot, as shown in Figure 13.

19. While holding the crosscut fence in position, rotate

it slightly so that you can insert the T-bolt you

removed from the handle in Step 17 into the fence

slot and into the sliding table miter gauge slot, as

shown in Figure 13.

20. Position the fence along the table, then tighten the

forward miter gauge bar set screw (see Figure 13)

and the miter gauge lock knob (see Figure 14) to

secure the fence in place.

21. Use a square to position the fence exactly 90° to the

saw blade, then thread and tighten the two knurled

pivot handles with a plastic washer onto the fence

bolts, as shown in Figure 14.

T-Bolt

Figure 13. Installing the fence T-bolts into

the sliding table miter gauge slots.

Pivot

Handles

Lock Knob

Point Cap Screws

Figure 14. Pivot handles installed.

SETUP

Note: The handles have different thread sizes and

each will only fit a specific bolt.

-11-

Page 14

OPERATIONS

Operation Overview

The purpose of this overview is to provide the novice

woodworker with a basic understanding of how the sliding

table attachment is used during a typical operation, so

they can more easily understand how to use it.

Note: Due to the generic nature of this overview, it is not

intended to be an instruction guide for performing actual

machine operations. To learn more about specific operations and woodworking techniques, seek training from

people experienced with this type of saw, and do additional research outside of this manual by reading "how-to"

books, trade magazines, or web sites.

To complete a typical operation, the operator does the

following:

Model W1822 (For Machines Mfd. Since 3/16)

READ and understand this entire instruction manual before using this machine.

Serious personal injury may occur if

safety and operational information is not

understood and followed. DO NOT risk

your safety by not reading!

1. Examines the workpiece to make sure it is suitable

for cutting.

2. Adjusts the angle and position of the crosscut fence

OPERATIONS

to the blade for the operation, then locks it in

place. If required, positions the extension fence for

additional support.

3. Positions the extension table to support the

workpiece.

4. Makes sure the sliding table lock knob is disengaged

so the table can move.

5. Makes sure the crosscut fence will not contact the

blade as the sliding table is moved forward.

6. Wears safety glasses and a respirator, holds the

workpiece firmly and flatly against the fence, turns

the table saw ON, and then pushes the crosscut

fence and workpiece forward and completely past

the blade to complete the cut.

DO NOT investigate problems or

adjustments while the table saw is

running. Wait until the table saw is

turned OFF, unplugged and all work-

ing parts have come to a complete

stop before proceeding!

The operator is very careful to keep the workpiece

firmly against the table and crosscut fence during

the entire cut.

7. Stops the table saw.

-12-

Always wear safety glasses when operating this machine. Failure to comply

may result in serious personal injury.

Page 15

Model W1822 (For Machines Mfd. Since 3/16)

Crosscut Fence

The crosscut fence can be positioned anywhere along the

sliding table and at angle between 50° left and 50° right.

To position the fence along the sliding table, loosen the

two pivot handles, the set screw on the forward end

of the miter gauge bar, and the miter gauge lock knob

(see Figure 15). Then, move the fence to the desired

location and re-tighten the set screw, lock knob, and pivot

handles.

To adjust the fence angle, loosen the two pivot handles

and rotate the fence to the desired angle. Then,

re-tighten the pivot handles to secure the setting.

Pivot

Handles

Lock Knob

Figure 15. Pivot handles and miter gauge

lock knob.

Extension Fence

Use the extension fence to expand the support for long

workpieces.

To pull out the extension fence from the crosscut fence,

loosen lock knob shown in Figure 16, position the

extension fence for your operation, then re-tighten the

lock knob.

The extension fence scale can be positioned to display the

actual distance from the blade by loosening the thumb

screw shown in Figure 16, match the reading of the scale

with the distance from the blade as shown with a tape

measure, then re-tighten the thumb screw.

Extension Table

The extension table is used to give the optimum

horizontal support for the workpiece to the side of the

sliding table.

Thumb

Scale

Extension

Fence

Figure 16. Extension fence controls.

Screw

Lock Knob

OPERATIONS

To position the extension table, loosen the two lock levers

shown in Figure 17, slide the extension table along the

sliding table to the desired location, make sure the tables

are even with each other to fully support the workpiece,

then re-tighten the lock levers.

-13-

Lock Levers

Figure 17. Locations of the extension

table lock levers.

Page 16

Flip Stop

Use the flip stop to make repetitive cuts of the same

dimension.

Slide the flip stop T-nut into the fence top T-slot, then

secure the assembly in place with the lock lever, as shown

in Figure 18.

Model W1822 (For Machines Mfd. Since 3/16)

Lock Lever

Figure 18. Flip stop installed.

Crosscutting

The Model W1822 enables you to use your table saw to

crosscut large panels, as shown in Figure 19.

To make a crosscut with the sliding table, do these

OPERATIONS

steps:

1. DISCONNECT SAW FROM POWER!

2. Position the crosscut fence to the rear of the sliding

table, as illustrated in Figure 19, adjust it to be 90°

to the blade, then lock it in place.

Make sure the fence will not contact the blade as

the sliding table moves through its entire range of

motion.

3. Position the extension table just forward of the

crosscut fence to provide maximum table support for

the workpiece, then lock it in place.

4. If necessary, pull the extension fence out to give

additional vertical support to the workpiece.

Blade

Workpiece

Crosscut

Fence

Figure 19. Example of large panel rip

cutting.

5. Mount the workpiece flat on the tables and firmly

against the crosscut fence.

6. Turn the saw ON, firmly hold the workpiece on the

tables and against the fence, then push the fence

and sliding table forward to pass the workpiece all

the way through the blade to make the cut.

7. Turn the saw OFF, then remove the workpieces.

-14-

Page 17

Model W1822 (For Machines Mfd. Since 3/16)

Miter Cutting

The crosscut fence can be positioned for miter cuts

between 50° the left and 50° right.

To perform a miter cut, do these steps:

1. DISCONNECT SAW FROM POWER!

2. Position the fence at the rear of the sliding table

and at the correct angle, then lock it in place (see

the example illustrations in Figures 20– 21).

3. Position and secure the extension table and

extension fence to provide the optimum support for

the workpiece.

4. Mount the workpiece flat on the tables and firmly

against the crosscut fence.

5. Turn the saw ON, firmly hold the workpiece on the

tables and against the fence, then push the fence

and sliding table forward to pass the workpiece all

the way through the blade to make the cut.

6. Turn the saw OFF, then remove the workpieces.

Blade

Workpiece

Figure 20. Example of miter cutting with

the fence positioned 45° to the right.

Blade

OPERATIONS

-15-

Workpiece

Figure 21. Example of miter cutting with

the fence positioned 45° to the left.

Page 18

Model W1822 (For Machines Mfd. Since 3/16)

ACCESSORIES

Sliding Table Saw Accessories

The following sliding table saw accessories may be available through your local Woodstock International

Inc. Dealer. If you do not have a dealer in your area, these products are also available through online

dealers. Please call or e-mail Woodstock International Inc. Customer Service to get a current listing of

dealers at: 1-800-840-8420 or at sales@woodstockint.com.

1

W1685—Shop Fox 1

W1666—Shop Fox 2 HP Dust Collector

Specifications: 110V, single-phase motors, 21

3

bag capacity, heavy-duty 12" balanced steel, radial fin impeller,

5.4 ft

6" inlet with a removable two 4" opening "Y" fitting, and 30-micron bag

filtration Approximately 108 lbs. shipping weight.

⁄2 HP Dust Collector

1

⁄2" x 33 1⁄2" portable base,

OPERATIONS

Use the versatile D2271 Shop Fox Roller Table wherever you need

extra workpiece support. Features all-steel welded construction and

measures 19" wide x 65" long. Comes with 9 ball bearing rollers and

has four independently adjustable legs for any leveling requirement.

Height adjustable from 26

1

⁄2" to 44". 1000 lb. capacity.

-16-

Page 19

Model W1822 (For Machines Mfd. Since 3/16)

PARTS

101

103

104

112

105

172

171

170

Table

108

107

106

104

103

101

171

172

117

109

112

101

102

103

118

119

168

113

173

172

171

170

114V2

115

115

116V2

REF PART # DESCRIPTION REF PART # DESCRIPTION

101 XPBHS09M BUTTON HD CAP SCR M6-1 X 12 114V2 X1822114V2 SUPPORT LEG (ALUMINUM) V2.03.16

102 XPLW03M LOCK WASHER 6MM 115 XPN03M HEX NUT M8-1.25

103 XPW03M FLAT WASHER 6MM 116V2 X1822116V2 FOOT PAD M8-1.25 (RUBBER) V2.03.16

104 X1822104 SLIDING TABLE SIDE COVER 117 X1822117 LOCK LEVER FLAT WASHER 8MM

105 X1822105 SLIDING TABLE ASSEMBLY 118 X1822118 STOP PLATE

106 XPCAP31M CAP SCREW M8-1.25 X 25 119 X1822119 STOP PIN ASSEMBLY

107 XPLW04M LOCK WASHER 8MM 168 X1822168 MACHINE ID LABEL

108 XPW01M FLAT WASHER 8MM 170 XPBHS06M BUTTON HD CAP SCR M5-.8 X 12

109 X1822109 FRONT TABLE SIDE COVER 171 XPLW01M LOCK WASHER 5MM

111 X1822111 EXTENSION TABLE 172 XPW02M FLAT WASHER 5MM

112 X1822112 T-BOLT M8-1.25 X 35 173 X1822173 REAR TABLE SIDE COVER

113 X1822113 LOCK LEVER M8-1.25

111

170

172

171

170

PARTS

-17-

Page 20

150

144

149

148

Fence

152

147

142

Model W1822 (For Machines Mfd. Since 3/16)

151

121

121

134

122

157

133

172

158

130V2

125

163

162

169

124

129

128

159

127V2

141

156V2

154

142

143

144

145

139

136

140

139

144

136

137

138

140

155

135

131

165

146

162

164

126

134

123

132

REF PART # DESCRIPTION REF PART # DESCRIPTION

121 X1822121 KNURLED HANDLE M8-1.25 145 XPCAP01M CAP SCREW M6-1 X 16

122 X1822122 LONG CROSSCUT FENCE 146 XPSS03M SET SCREW M6-1 X 8

123 X1822123 KNOB BOLT M6-1 X 35 147 X1822147 FLIP STOP BRACKET

124 X1822124 HANDLE SCREW M6-1 X 8 148 X1822148 FLIP STOP PIVOT PIN

125 X1822125 SQUARE NUT M5-.8 149 X1822149 FLIP STOP

126 X1822126 MITER GUAGE BODY 150 XPLN03M LOCK NUT M6-1

127V2 X1822127V2 T-SLOT BLOCK V2.09.10 151 X1822151 LOCK LEVER M6-1 X 32

128 XPLW01M LOCK WASHER 5MM 152 X1822152 TEFLON FLAT WASHER 6MM

129 XPCAP15M CAP SCREW M5-.8 X 20 153 X1822153 SCALE MOUNTING PLATE

PARTS

130V2 X1822130V2 STOP PIN BRACKET V2.09.10 154 X1822154 CROSSCUT FENCE EXTENSION BAR

131 X1822131 MITER GUAGE T-SLOT BAR 155 X1822155 PVC PAD

132 X1822132 MITER GUAGE PIVOT PIN 156V2 X1822156V2 SCALE STRIP INCH/METRIC V2.09.10

133 X1822133 THREADED HANDLE BUSHING 157 X1822157 MITER GUAGE STOP PIN

134 X1822134 TEFLON FLAT WASHER 8MM 158 X1822158 COMPRESSION SPRING

135 X1822135 T-BOLT M8-1.25 X 40 159 X1822159 STOP PIN KNOB

136 X1822136 T-SLOT NUT M6-1 160 XPSS51M SET SCREW M4-.7 X 8

137 X1822137 POINTER BRACKET KNOB BOLT M6-1 161 XPBHS26M BUTTON HD CAP SCR M4-.7 X 12

138 X1822138 POINTER 162 XPLW02M LOCK WASHER 4MM

139 XPLW03M LOCK WASHER 6MM 163 XPW05M FLAT WASHER 4MM

140 XPBHS05M BUTTON HD CAP SCR M6-1 X 20 164 XPBHS27M BUTTON HD CAP SCR M4-.7 X 8

141 X1822141 SHORT CROSSCUT FENCE 165 X1822165 SPRING STRIP

142 X1822142 SQUARE NUT M6-1 169 XPBHS26M BUTTON HD CAP SCR M4-.7 X 12

143 X1822143 CROSSCUT SUPPORT PLATE 172 XPW02M FLAT WASHER 5MM

144 XPW03M FLAT WASHER 6MM

161

162

163

160

-18-

Page 21

Page 22

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

Place

Stamp

Here

Woodstock international inc.

p.o. box 2309

bellingham, Wa 98227-2309

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Page 23

WARRANTY

WARRANTY

Woodstock International, Inc. warrants all Shop Fox machinery to be free of defects from workmanship

and materials for a period of two years from the date of original purchase by the original owner.

This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or

accidents, lack of maintenance, or reimbursement of third party expenses incurred.

Woodstock International, Inc. will repair, replace, or arrange for a dealer refund at its expense and

at its option, the Shop Fox machine or machine part, which in proper and intended use has proven to

be defective, provided that the original owner returns the product prepaid to an authorized warranty

or repair facility as designated by our Bellingham, Washington office with proof of their purchase of

the product within two years, and provides Woodstock International, Inc. reasonable opportunity to

verify the alleged defect through inspection. If it is determined there is no defect, or that the defect

resulted from causes not within the scope of Woodstock International Inc.'s warranty, then the original

owner must bear the cost of storing and returning the product.

This is Woodstock International, Inc.’s sole written warranty and any and all warranties that may be

implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant that Shop Fox machinery complies with

the provisions of any law, acts or electrical codes. We do not reimburse for third party repairs. In no

event shall Woodstock International, Inc.’s liability under this limited warranty exceed the purchase

price paid for the product, and any legal actions brought against Woodstock International, Inc. shall be

tried in the State of Washington, County of Whatcom. We shall in no event be liable for death, injuries

to persons or property or for incidental, contingent, special or consequential damages arising from the

use of our products.

Every effort has been made to ensure that all Shop Fox machinery meets high quality and durability

Page 24

High Quality Machines and Tools

Woodstock International, Inc. carries thousands of products designed

to meet the needs of today's woodworkers and metalworkers.

Ask your dealer about these fine products:

Loading...

Loading...