Shop fox M1012 User Manual

MODEL M1012

48" PAN AND BOX

BRAKE

INSTRUCTION MANUAL

Phone: 1-360-734-3482 • On-Line Technical Support: tech-support@shopfox.biz

COPYRIGHT © NOVEMBER, 2004 BY WOODSTOCK INTERNATIONAL, INC. REVISED OCTOBER, 2007 (BL)

WARNI NG: NO PO RTION OF THI S MANUA L MAY B E REPRO DUCED IN ANY S HAPE OR F ORM WITHOU T

#6744 BL

THE WRI TTEN AP PROVAL OF WO ODSTO CK INTERNATIONA L, INC.

Print ed in Chi na

Contents

INTRODUCTION ..................................................................................................2

Woodstock Technical Support ............................................................................ 2

About Your New Pan and Box Brake ...................................................................

Specifications ............................................................................................... 3

Controls and Features .....................................................................................

SAFETY ............................................................................................................5

Standard Safety Instructions ............................................................................. 5

Safety Instructions for Pan and Box Brakes ............................................................

SET UP ............................................................................................................

Unpacking ................................................................................................... 8

Items Needed for Set Up ..................................................................................

Inventory .................................................................................................... 9

Lifting .......................................................................................................10

Machine Placement .......................................................................................10

Cleaning Machine .........................................................................................11

Mounting Main Body to Supports ........................................................................

Attaching Handles and Handlebar ......................................................................13

Installing Counterweights ................................................................................

Mounting Stop Rod ........................................................................................

Mounting to Floor .........................................................................................

Aligning Fingers ............................................................................................

OPERATIONS ................................................................................................... 17

General .....................................................................................................17

Adjusting Setback .........................................................................................

Spacing Fingers ............................................................................................

Adjusting Clamping Pressure ............................................................................

Setting Stop Collar ........................................................................................

Basic Bending ..............................................................................................

Adjusting Counterweights ...............................................................................

MAINTENANCE ................................................................................................. 22

Lubrication .................................................................................................22

Maintenance Schedule ....................................................................................

Maintenance Notes ........................................................................................

SERVICE ......................................................................................................... 24

General .....................................................................................................24

Aligning Bending Wing ....................................................................................24

PARTS ........................................................................................................... 26

Parts List ...................................................................................................27

WARRANTY ..................................................................................................... 30

Warranty Registration ....................................................................................31

12

13

14

15

16

17

18

19

20

20

21

23

23

2

4

7

8

8

OPERATIONSSETUP

MAINTENANCESAFETYINTRODUCTION

SERVICE

PARTS

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

WARRANTY

M1012 48" Pan and Box Brake

INTRODUCTION

INTRODUCTION

Woodstock Technical Support

We stand behind our machines! In the event that questions arise about your machine, parts are missing, or a defect is found, please contact Woodstock International Technical Support at 1-360-734-3482 or

send e-mail to: tech-support@shopfox.biz. Our knowledgeable staff will help you troubleshoot prob

lems and send out parts for warranty.

If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.

If you still have questions after reading the latest manual, or if you have comments please contact us at:

Woodstock International, Inc.

Attn: Technical Support Department

P.O. Box 2309

Bellingham, WA 98227

-

About Your New Pan and Box Brake

Your new SHOP FOX® 48" Pan and Box Brake has been specially designed to provide many years of trouble-free service. Close attention to detail, ruggedly built parts and a rigid quality control program assure

safe and reliable operation.

This pan and box brake is an indispensable tool if you need to increase the strength of sheet metal

plates with bends, or you intend on fabricating more complicated brackets, gussets, boxes, and fixtures. When bolted to a concrete floor, your pan and box brake allows you easily bend 48" wide mild

steels up to 12 gauge thick in a range of angles from 0˚ to 135˚. The removable and adjustable fingers

can be installed in a variety of positions to accommodate for varying widths of metal.

Woodstock International, Inc. is committed to customer satisfaction in providing this manual. It is our

intent to make sure all the information necessary for safety, ease of assembly, practical use and durabil

ity of this product be included.

-

-2-

M1012 48" Pan and Box Brake

Specifications

Height w/o Counterweight Attached ....................................................................... 48"

Height with Counterweight Attached ...................................................................... 69"

Finger Sizes ....................................................................... (6) 3", (2) 4", (1) 25", Steel

Shipping Weight ........................................................................................ 1300 Lbs.

Footprint ............................................................................................. 56

Crate Size ....................................................................... 69

Brake Range .............................................................................................. 0°-135°

Maximum Width ................................................................................................ 48''

Maximum Size of Pan/Box Sides ...............................................................................6"

Material Gauge Capacities:

Mild Steel .................................................. 12 gauge at half width, 14 gauge at full width

Aluminum ................................................................................................. 6 gauge

Soft Brass ................................................................................................ 10 gauge

Annealed Phosphor Bronze ............................................................................ 11 gauge

Soft Copper .............................................................................................. 10 gauge

Hard Copper ............................................................................................. 11 gauge

ABS Plastic ................................................................................................ 3 gauge

3

⁄4" L x 29 1⁄2" W x 37 1⁄2" H

1

⁄2'' x 29''

INTRODUCTION

-3-

INTRODUCTION

M1012 48" Pan and Box Brake

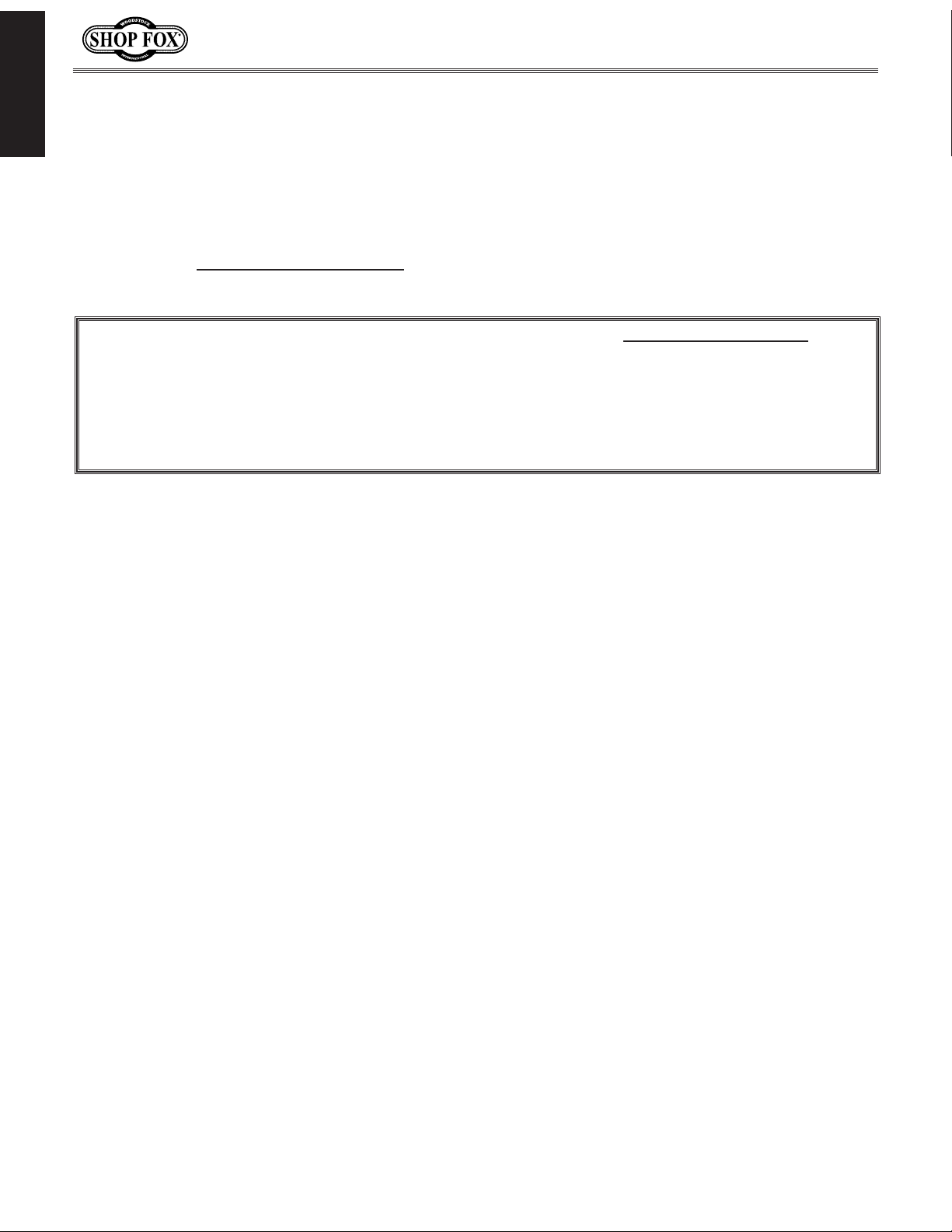

Controls and Features

3

5

4

1

6

2

8

7

Figure 1. Main features of the Model M1012.

1. Bending Leaf

2. Clamping Leaf

3. Counterweight

4. Finger Blocks

5. Clamping Handles

6. Operating Handles

7. Bending Wing

8. Clamp Block

-4-

M1012 48" Pan and Box Brake

SAFETY

READ MANUAL BEFORE OPERATING MACHINE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW WILL

RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

This symbol is used to alert the user to useful information about proper

NOTICE

operation of the equipment, and/or a situation that may cause damage

to the machinery.

Standard Safety Instructions

SAFETY

1. Read and understand the Instruction Manual before operating this tool. Learn the applications,

limitations and potential hazards of this tool. Keep the manual in a safe and convenient place for

future reference.

2. Keep work area clean and well lighted. Clutter and inadequate lighting invite potential hazards.

3. Wear eye protection at all times. Use safety glasses with side shields or safety goggles that meet

the appropriate standards of the American National Standards Institute (ANSI).

4. Make sure all safety guards are securely in place and in working condition.

6. Keep children and visitors away. Visitors must be kept at a safe distance while operating unit.

7. Childproof your workshop and dangerous tools. Use padlocks, master switches or remove starter

keys where applicable.

8. Do not force machinery. Work at the speed for which the machine or accessory was designed.

9. Use the correct tool. Do not force the tool or attachment to do a job for which it was not

designed.

10. Wear proper apparel. Do not wear loose clothing, neck ties, gloves, jewelry, and secure long hair

away from moving parts.

11. Keep proper footing and balance.

12.

Perform tool maintenance and care. Follow lubrication and pre-use inspections listed in the manual.

-5-

M1012 48" Pan and Box Brake

13. Experiencing difficulties. If at any time you are experiencing difficulties performing the intended

operation, stop using the tool! Then contact our Technical Support Department or ask a qualified

expert how the operation should be performed.

14. Develop good habits. Develop good habits in your shop and safety will become second-nature to

you.

15. DO NOT over-reach. Keep proper footing and balance at all times.

SAFETY

16. Maintain tools and machinery with care. Keep tools sharp and clean for best and safest perfor-

mance. Follow instructions for lubricating and changing accessories.

17. Use recommended accessories. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause risk of injury.

18. Check damaged parts. Before further use of the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part that is damaged should be

properly repaired or replaced.

19. Be aware of hazardous chemicals. Some coolants/lubricants used for machining may contain haz-

ardous chemicals

20. Never operate when tired, or under the influence of drugs or alcohol. Full mental alertness is

required at all times when using metalworking equipment.

. Read and understand all user information and protect yourself accordingly.

-6-

M1012 48" Pan and Box Brake

Safety Instructions for Pan and Box Brakes

READ and understand this

entire instruction manual

before using this machine.

Serious personal injury

may occur if safety and

operational information is

not understood and fol

lowed. DO NOT risk your

safety by not reading!

1. OVERLOADING PAN AND BOX BRAKE. Overloading this tool can cause injury from flying parts. Bend

12 gauge or thinner metal.

2. USING TORCHES. Heating metal with a torch while the metal is in the pan and box brake will weaken

the fingers.

-

USE this and other machinery with caution

and respect. Always consider safety first,

as it applies to your individual working

conditions. No list of safety guidelines can

be complete—every shop environment is

different. Failure to follow guidelines could

result in serious personal injury, damage

to equipment or poor work results.

3. METAL EDGES. Always chamfer and de-burr sharp sheet metal edges. Sharp edges on sheet metal

can cut your fingers to the bone. Always chamfer and de-burr sheet metal before bending in the pan

and box brake.

4. GLOVES AND GLASSES. Always wear leather gloves and approved safety glasses when using this

tool.

SAFETY

5. EXPERIENCING DIFFICULTIES. If at any time you are experiencing difficulties performing the intend-

ed operation,

expert how the operation should be performed.

6. TOOLS IN POOR CONDITION. Inspect the pan and box brake for any cracked linkage, levers, or loose

fasteners. Correct any problems before use.

STOP using the tool and contact our Technical Support Department, or ask a qualified

-7-

SET UP

Unpacking

The SHOP FOX® Model M1012 has been carefully packaged for safe transporting. If you notice the machine has

been damaged, please contact Woodstock International

Technical Support at 1-360-734-3482 or send e-mail to:

tech-support@shopfox.biz

SUFFOCATION HAZARD!

SETUP

Items Needed for Set Up

Immediately discard all plastic bags

and packing materials to eliminate

a choking and suffocation hazard

for children and animals.

M1012 48" Pan and Box Brake

READ and understand this entire instruction manual before using this machine.

Serious personal injury may occur if

safety and operational information is not

understood and followed. DO NOT risk

your safety by not reading!

The following items are needed, but not included, to

setup your machine:

Description

• Hammer Drill .............................................. 1

• Punch

• Hammer Drill Bit

• Hammer ....................................................

• Wrench or Socket

• Lag Shield Anchors

• Lag Bolts

• Lock Washers

• Flat Washers

1

⁄2" ..................................................1

5

⁄16" x 2 1⁄2" .....................................4

1

⁄2" ......................................1

1

⁄2" ....................................1

5

⁄16" x 1 3⁄4" .........................4

5

⁄16" ........................................4

5

⁄16" .........................................4

1

-8-

M1012 48" Pan and Box Brake

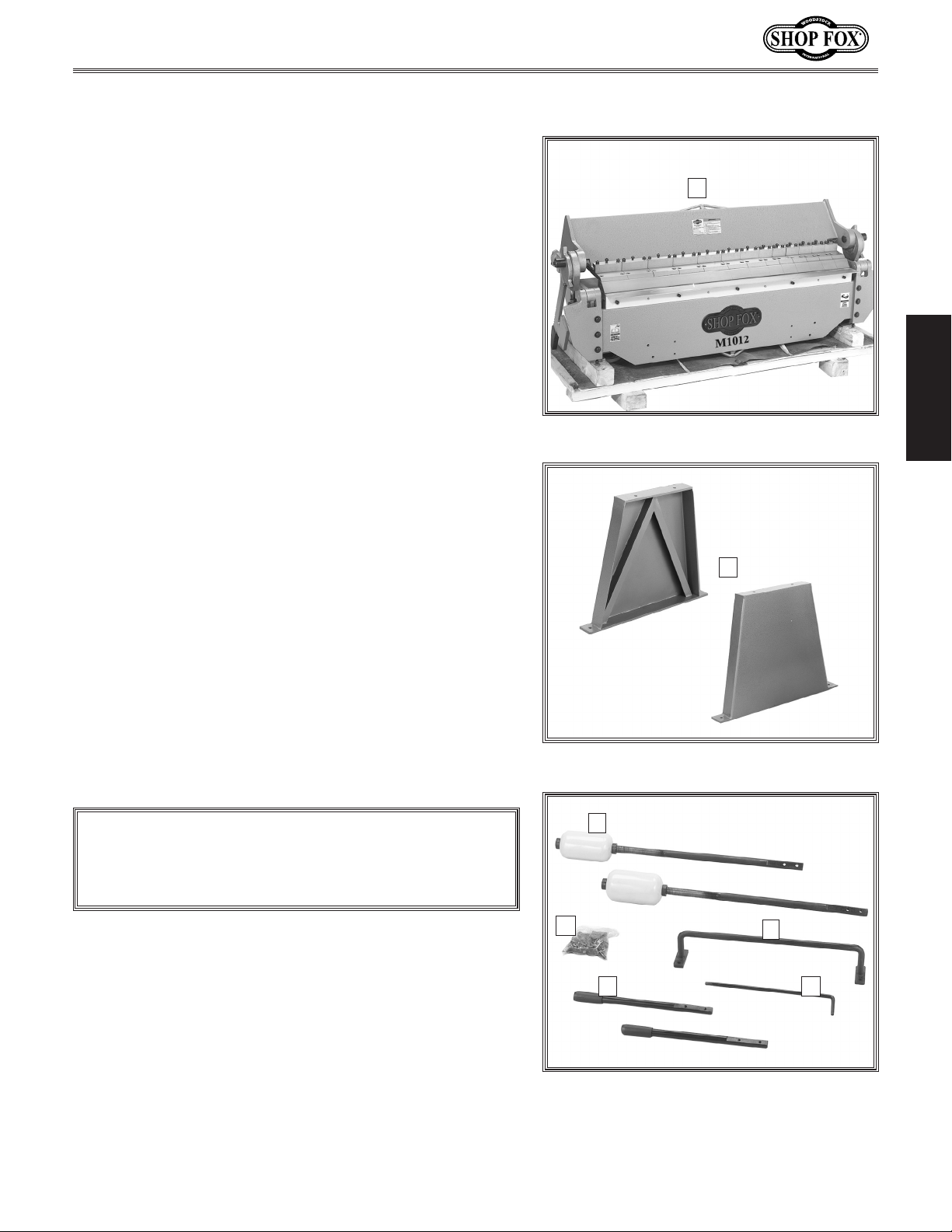

Inventory

The following is a description of the main components

shipped with the SHOP FOX

components out to inventory

CONTENTS (Figures 2-4) Qty

A. Pan and Box Brake Main Body ..........................1

B. Supports ....................................................2

C. Counterweight Assemblies ...............................2

D. Handlebar ...................................................1

E. Stop Rod ....................................................1

F. Operating Handles ........................................2

G. Hardware Bag: .............................................1

• Hex Bolts M10-1.5 x 40 ..............................

• Flat Washers 10MM ...................................8

• Lock Washers 10MM ...................................8

• Hex Bolts M12-1.75 x 40 .............................8

• Flat Washers 12MM ...................................8

• Lock Washers 12MM ...................................8

• Hex Nut M10-1.5 ......................................1

• Hex Nut M16-2 .........................................2

• Stop Hub ................................................1

• Stop Collar .............................................1

• T-Bolt ...................................................1

• Flat Washer 16MM ....................................1

• Hex Nuts M12-1.75 ....................................4

®

Model M1012. Lay the

them.

8

A

SETUP

Figure 2. Pan and box brake main body.

B

If any parts appear to be missing, examine the packaging carefully to be sure those parts are not among the

packing materials. If any parts are missing, find the

part number in the back of this manual and contact

Woodstock International, Inc. at 360-734-3482 or at

tech-support@shopfox.biz

NOTICE

When ordering replacement parts, refer to the parts

list and diagram in the back of the manual.

Figure 3. Supports.

C

G

F

Figure 4. Contents of box.

D

E

-9-

Loading...

Loading...