Shop fox D4144 User Manual

Model D4144

Drill Grinding Attachment

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

To reduce risk of serious personal injury when using

this tool:

• Make sure the drill bit is firmly held in the

grinder attachment, and the attachment is

securely fastened to the workbench before

starting the operation.

• Always wear ANSI approved eye protection when

grinding.

• Read and follow the grinder manufacturer's

safety precautions.

Figure 1. Model D4144 secured to a

• When side-grinding, always use a grinding wheel

that is specifically designed and approved for

that purpose.

A B

workbench.

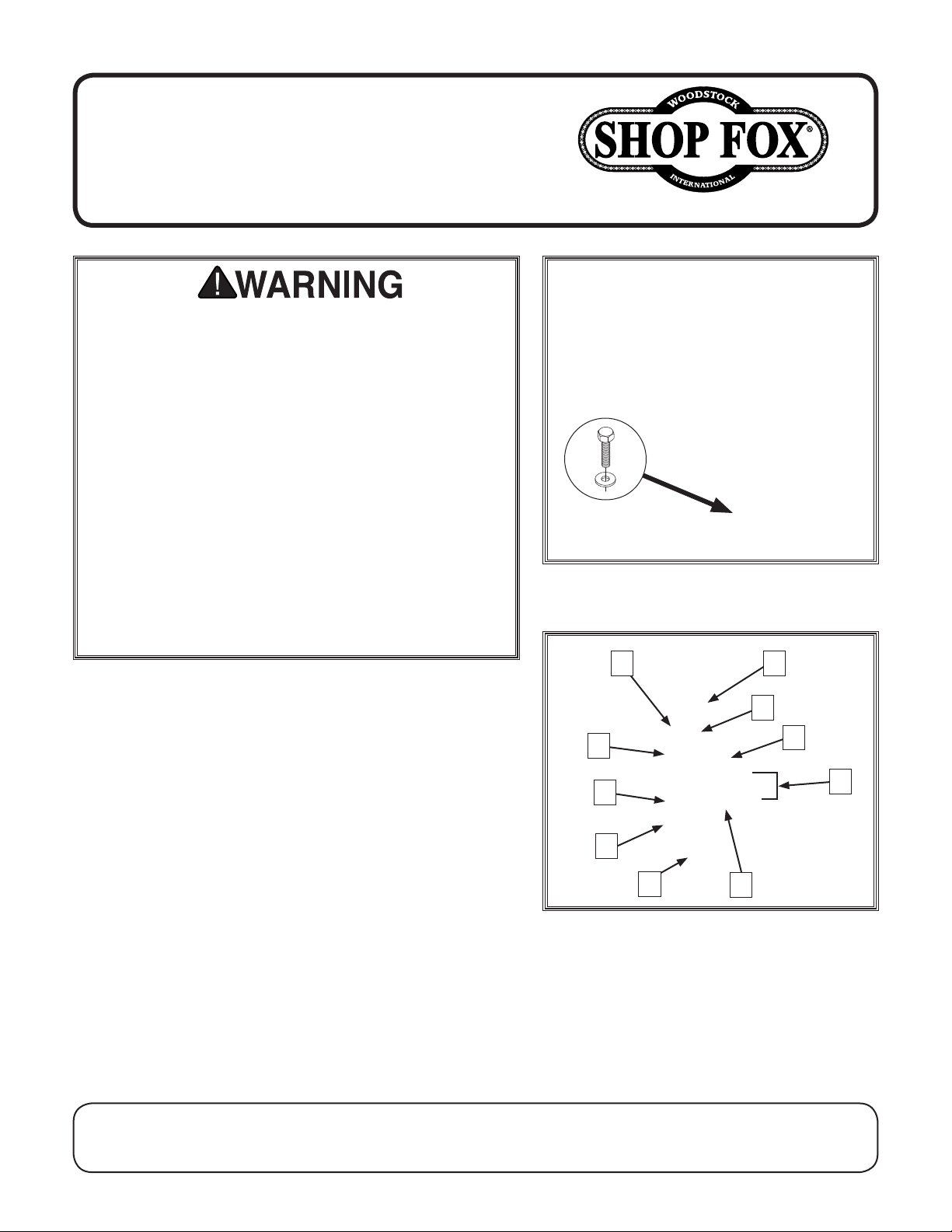

Identification (see Figure 2)

A. Lip Rest: Keeps the drill bit from rotating during the

operation.

B. Clamp: Secures the drill bit in place against the

trough.

C. Trough: Keeps the drill bit in position relative to the

grinding wheel.

D. Feed Screw: Supports the bottom of the drill bit.

E. Feed Wheel & Lock Wheel: Fine tunes the position

of the feed screw and drill bit.

F. Adjustable Slide Bracket: Provides initial positioning

of the drill bit to the grinding wheel.

G. Mounting Base: Allows the tool to be mounted to a

workbench with

H. Pivot Tension Plate: Controls the tension on the

pivot stud.

I. Pivot Stud: Allows the drill bit to turn in an arc

against the grinding wheel.

COPYRIGHT © OCTOBER, 2010 BY WOODSTOCK INTERNATIONAL, INC. REVISED MAY, 2016 (TR)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

3

⁄8" fasteners.

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

C

J

I

H

G

Figure 2. Model D4144 identification.

J. Angle Adjustment: Adjusts the angle

of the trough to 1 of 5 available angles

relative to the grinding wheel. This

setting will produce the drill bit point

angle.

F

D

E

Printed in Taiwan#13330TS

D4144 Drill Grinding Attachment

Mounting

Mount the drill grinding attachment firmly to the workbench at a distance from the grinding wheel that will

allow you to properly sharpen the drill bit as instructed

below.

3

Typically, using a

⁄8" x 1 1⁄2" lag screw and 3⁄8" flat washer

works well for most workbenches (see Figure 1 on the

5

previous page). Predrill the hole with a

⁄16" drill bit, then

hand-tighten the lag screw to avoid cracking the tool

base.

Operation

1. DISCONNECT GRINDER FROM POWER!

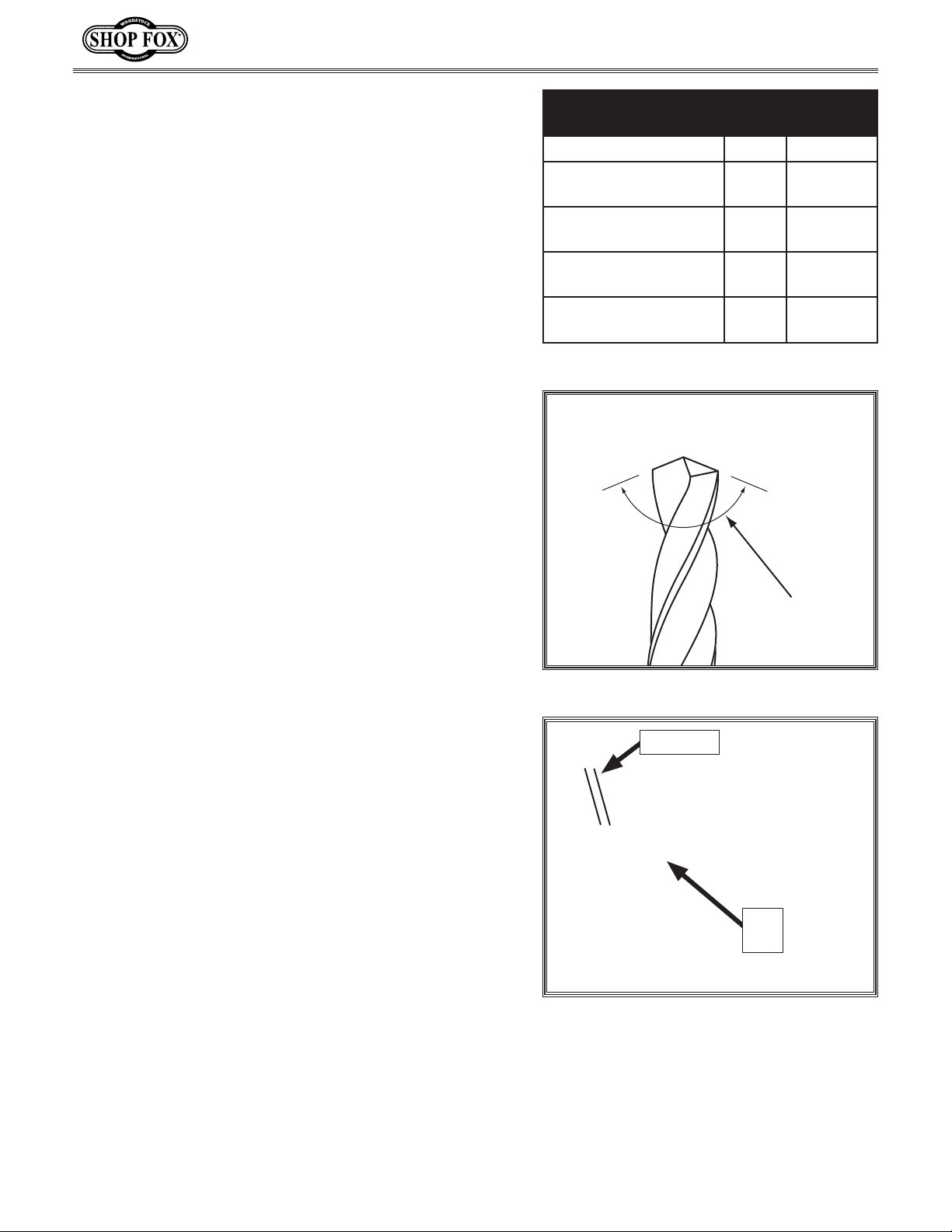

2. Refer to the chart in Figure 3 and select the correct

point angle setting for the drill bit application, then

use the angle adjustment wing nut and angle scale

below it to set the trough to the selected angle. This

angle will provide the point angle of the bit (see

Figure 4).

Application

Thin Sheets 88°

Hard Materials 68°

General Purpose 59°

Soft Materials 49°

Countersinks 41°

Point

Angle

Overhang

1

⁄16"

50% Drill

Diameter

50% Drill

Diameter

50% Drill

Diameter

As

Needed

Figure 3. Point angle and overhang chart.

(Side View)

3. Loosen the clamp thumb screw and place the drill

bit in the trough.

4. Use the adjustable slide bracket to position the end

of the drill bit past the lip rest by the correct overhang amount as directed in the chart (see Figure 5

for an example). This will provide an adequate bit

length for sharpening.

5. Move the lip rest up against the inside flute of the

bit, then tighten the two screws to secure it in

place. The lip rest will keep the bit from rotating

when grinding.

6. Use the feed wheel to fine tune the position of the

drill bit, then tighten the feed lock wheel and the

clamp thumb screw to hold the bit in place.

Point Angle

Figure 4. Drill bit point angle.

Overhang

Lip

Rest

Figure 5. Drill pit positioned past the lip

rest by the proper overhang amount.

-2-

Loading...

Loading...