Shop fox D4088 User Manual

Model D4088 Drill Press

Lathe Attachment

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

Introduction

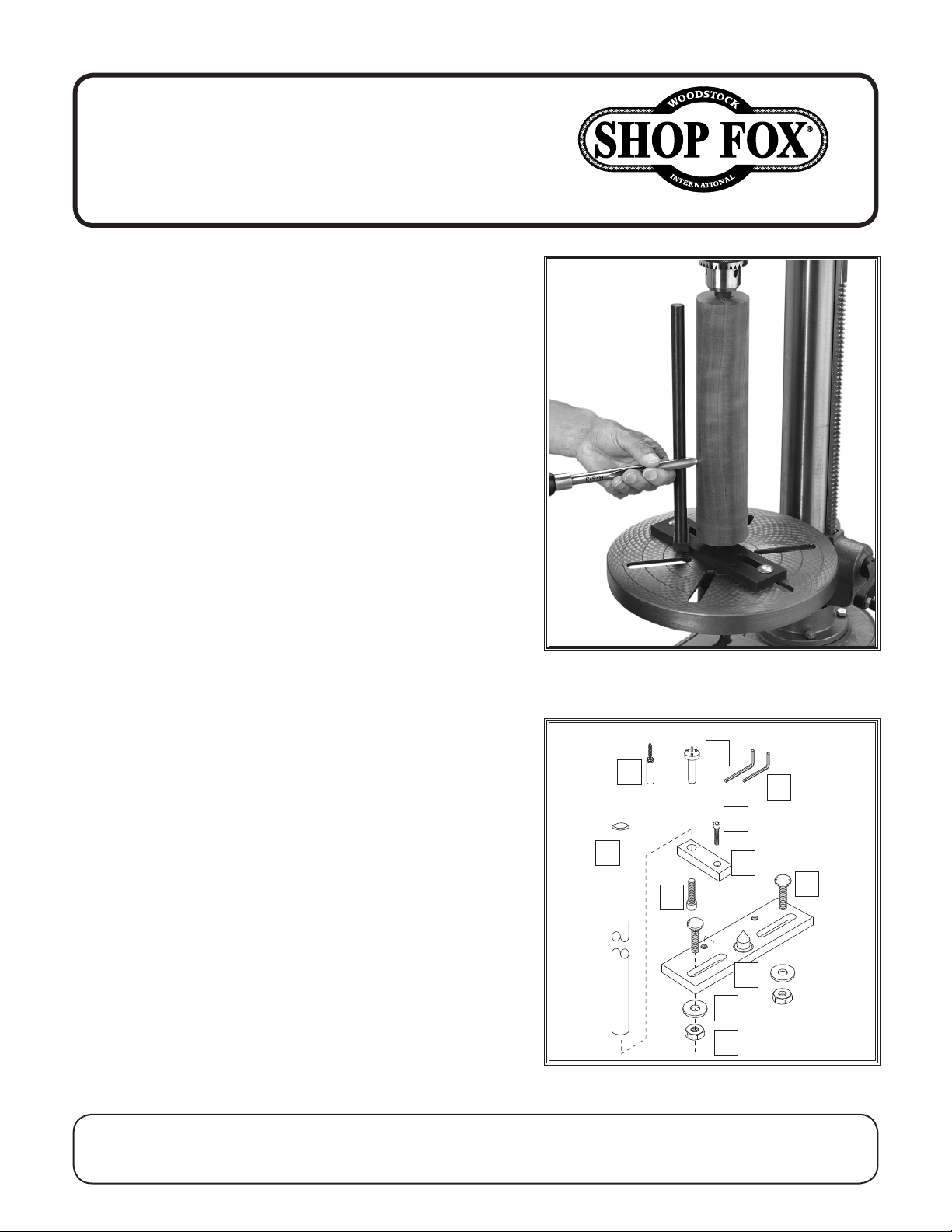

The Model D4088 Drill Press Lathe Attachment allows

wooden workpieces to be turned on a drill press in the

same manner as a wood lathe. Items like small pickets,

legs, spindles, handles, dowels, and pins can be made.

Fits drill press tables with T-nut slots or with slotted

through holes as shown in Figure 1.

Specifications

Tool Rest Length ............................................. 12"

Maximum Workpiece Length (if reversed) ............... 24"

Maximum Workpiece Diameter ..............................6"

Shank Diameter of Screw and Spur Center ..............

Construction Material .....................................Steel

Shipping Weight .........................................3.5 lbs.

3

⁄8"

Inventory

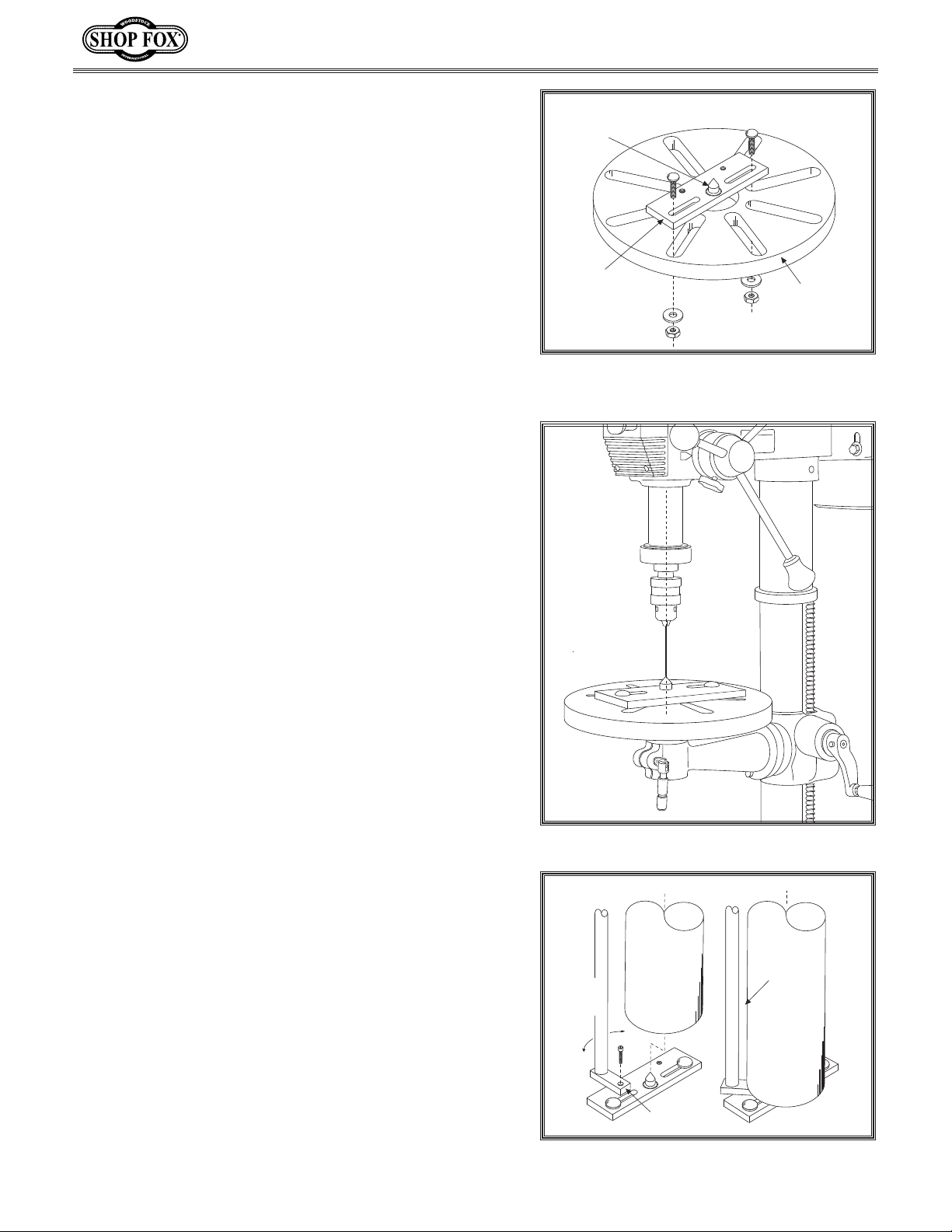

Refer to the list and Figure 2 to inventory your package.

If you can't find an item on this list, check the mounting

locations or examine the packaging materials carefully.

Occasionally we pre-install certain components for

shipping purposes.

If any nonproprietary parts are missing (e.g. a nut or a

washer), we will gladly replace them; or for the sake of

expediency, replacements can be obtained at your local

hardware store.

Description .................................................. Qty

A. Tool Rest ....................................................1

B. Screw Center ...............................................1

C. Spur Center .................................................1

D. Hex Wrenches 5, 6mm ................................1 Ea

E. Cap Screw M6-1 x 20 ......................................1

F. Tool Rest Foot ..............................................1

G. Carriage Bolt M10-1.5 x 40 ...............................2

H. Cap Screw M8-1.25 x 20 ..................................1

I. Base and Live Center Assembly .........................1

J. Flat Washer 10mm.........................................2

K. Hex Nut M10-1.5 ...........................................2

Figure 1. D4088 Drill Press Lathe

Attachment

C

B

A

H

J

K

Figure 2. I nventor y.

D

E

F

G

I

COPYRIGHT © JULY, 2010 BY WOODSTOCK INTERNATIONAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

Printed in China#13043CR

Setup

Base

Drill Press

Table

Live

Center

Spindle

Centerline

and

Live Center

Aligned

to

Gap

Foot

Tool

Rest

1

8

⁄

1

2

⁄

""

Workpiece

If you need help with your new drill press lathe attachment, call our Tech Support at: (360) 734-3482.

Tools Needed ................................................ Qty

Wrench 17mm ...................................................1

To setup the drill press lathe attachment, do these

steps:

1

1. At each end of the workpiece, drill a

5

⁄8" deep.

⁄8" pilot hole

D4088 Lathe Attachment Instructions

2. DISCONNECT DRILL PRESS FROM POWER!

3. Verify that the drill press table is properly leveled,

and adjust as required.

4. Place the base so the live center is located in the

center of the drill press table, as shown in Figure 3.

5. Fasten the base to the table with the carriage bolts,

flat washers, and hex nuts, but do not fully tighten

the hex nuts yet.

6. Install a drill bit or dowel in the chuck, lower the

chuck so the tip of the drill bit or dowel just touches

the point of the live center.

7. Move the base so the tip of the live center is aligned

with the spindle centerline, as shown in Figure 4.

Next, tighten the base hex nuts.

8. Retract the drill press spindle, and fasten the tool

rest foot onto the base with the cap screw, as shown

in Figure 5. Later, use the workpiece to estimate

where to tighten the tool rest in place to achieve

1

a gap of

⁄8" to 1⁄2" between the workpiece and the

tool rest.

Figure 3. Mounting base to drill press

table.

Figure 4. Live center to spindle alignment.

9. Double check that all fasteners are tight.

Figure 5. Tool rest installation and

adjustment.

-2-

Loading...

Loading...