Page 1

Model D4074

Multipurpose Vise

Instruction Sheet

Phone #: (360) 734-3482 • Online Tech Support: tech-support@shopfox.biz • Web: www.shopfox.biz

Specifications

Flat Jaw Size ........................................... 5" x 7⁄8"

Maximum Jaw Opening .......................................5"

Pipe Jaw Maximum Diameter ................................2"

Maximum Throat Depth ....................................2

Mounting Pattern ......................... 4

Base Swivel Capability .................................... 360°

Jaw Rotation Capability .................................. 360°

Weight .....................................................44 lbs.

This vise is not a toy. DO NOT use as a crushing tool

and never clamp a container with compressed or

explosive contents. Serious injury may occur if this

vise is used incorrectly.

7

⁄8"/4-hole square

7

⁄8"

Figure 1. Model D4074.

Placement Location

Consider the existing and anticipated needs, the size of

the material to be held in the vise, and the space for

auxiliary stands, work tables or other machinery when

establishing a location for your new vise. See Figure 2 for

the minimum working clearances.

Workbench Load

The D4074 Multipurpose Vise weighs 44 lbs. Some

workbenches may require additional reinforcement to

support both the vise, the workpiece, and any hammering

or prying forces that may be applied to each.

COPYRIGHT © JULY, 2010 BY WOODSTOCK INTERNATIONAL, INC., REVISED JUNE, 2014 (TS)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

17½"

Figure 2. Minimum Clearances.

Printed in China#13033JB

28"

Page 2

Mounting

The multipurpose vise must be mounted to a workbench

to avoid accidental tipping. If you intend to use the vise

for portable applications, mount it to a heavy metal or

plywood base (at least 1" thick) that is wide enough to

prevent tipping or rocking during use, then clamp the

base to a workbench or table.

D4074 - For Models Manufactured Since 12/13

Bolt

Flat Washer

Machine Base

To mount the multipurpose vise, do these steps:

1. Place the vise in its chosen location, making sure

that all four corners of the vise sit flat on the

mounting surface.

2. Transfer the mounting pattern directly from the

vice to the workbench by marking through the vice

mounting holes.

3. Attach the vise to the workbench using one of the

methods outlined below.

Note: DO NOT overtighten the mounting bolts or you

may crack the vise base.

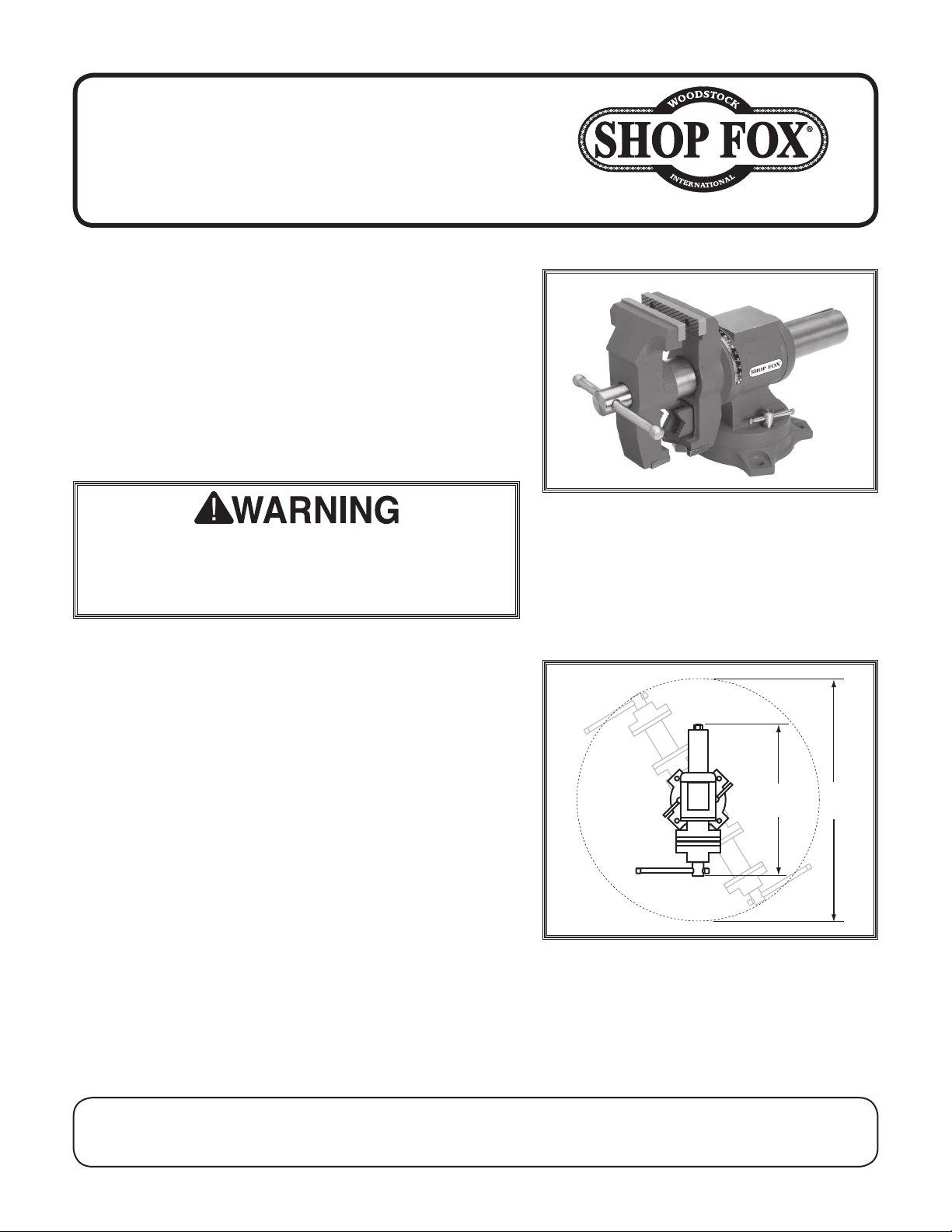

The strongest mounting option is a "Through Mount"

(Figure 3) where holes are drilled all the way

through the workbench, and hex bolts, washers, and

hex nuts are used to secure the vise to the workbench.

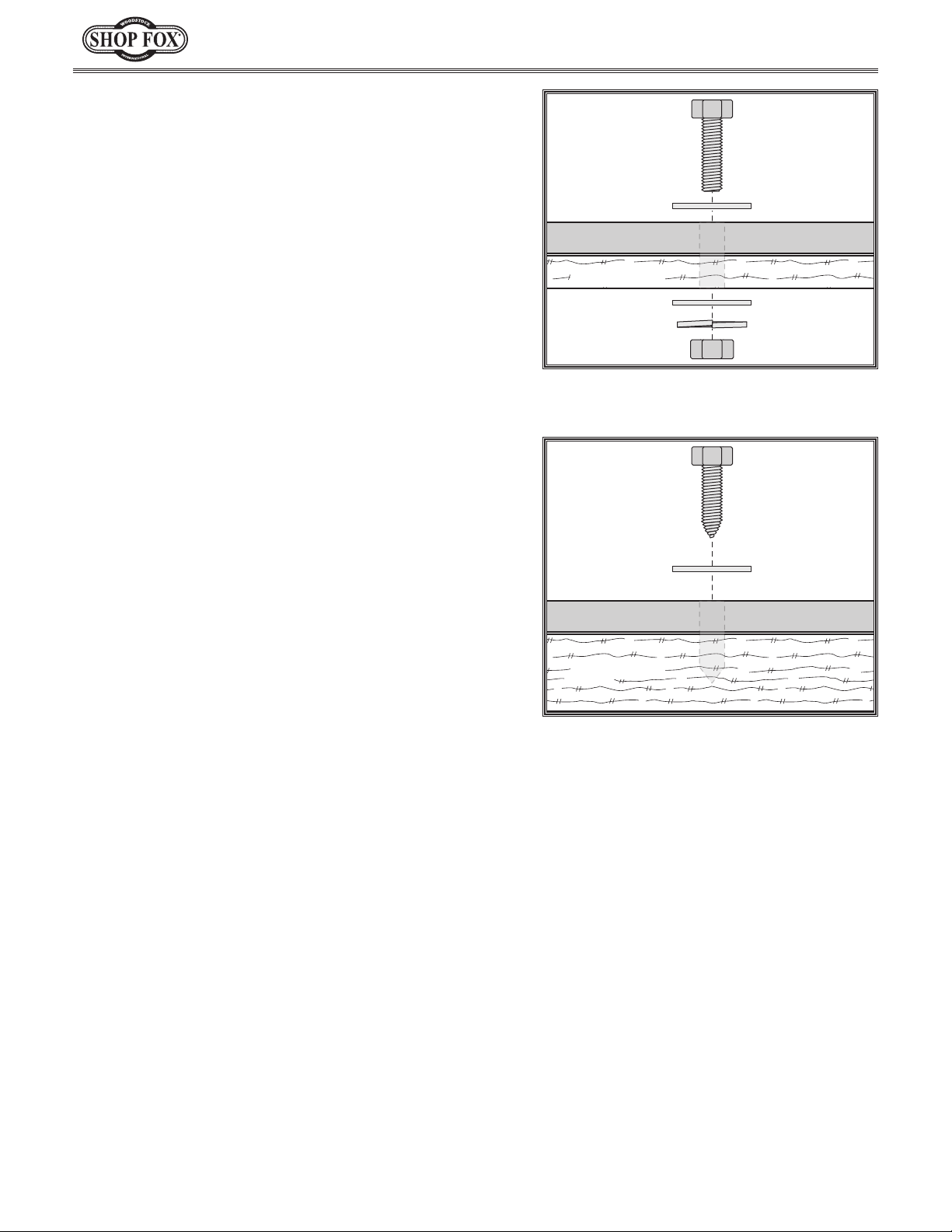

Another option for mounting is a "Direct Mount"

(Figure 4) where the vise is simply secured to the

workbench with a lag screw.

Workbench

Flat Washer

Lock Washer

Hex Nut

Figure 3. Example of a through-mount

setup.

Lag Screw

Flat Washer

Machine Base

Workbench

Figure 4. Example of a direct-mount

setup.

4. Check the stability of the mounted vise to make sure

it can be used safely.

Operations

To maximize the life of your vise, follow this advice:

• Do not use cheater pipes on the handles or hammer

the levers to increase tightening force.

• Do not heat or weld on the vise.

• Do not store the vise in wet or damp locations.

• Only use the anvil for light tapping and workpiece

shaping. Do not use large hammers and avoid

hammering directly on the jaws.

-2-

• Do not pry on clamped materials in

such a way that may bend or break

the vise.

• When loosening the jaws, make sure

your hands will not hit the workpiece,

workbench or vise when the handle

breaks free.

• Every few years, disassemble, clean,

and lubricate the vise using lithium

grease. Otherwise, lubricate as

necessary.

Page 3

D4074 - For Models Manufactured Since 12/13

Features Overview

C

D

H

B

G

A

E

F

Figure 5. Features overview.

A. Anvil Face: Provides a strong and stable

surface for hammering malleable materials

with a small hammer.

B. Rotating Jaws: Allow 360° of movement

and are locked by tightening the jaw.

Scale provides approximate angle readings

through 180°.

C. Standard Jaws: Clamp flat-edged work-

pieces.

D. Main Vise Handle: Used to clamp and lock

the jaws.

E. Base Locking Levers: Allow the base to be

swiveled 360° for maximum flexibility and

locked for stability.

F. Mounting Base: Used to attach the vise to

a workbench or other suitable surface.

G. Pipe Jaws: Clamp pipes and other

cylindrical workpieces. For easier access,

they can be positioned at the top by

rotating the main jaws.

H. Cut Jaws: Clamp irregularly shaped objects

or pieces of pipe that are too short to be

clamped in the pipe jaws.

-3-

Page 4

Parts

D4074 - For Models Manufactured Since 12/13

19

5

4

7

20

21

17

4

2

3

16

5

6

18

17

9V2

23V2

10

24

11

12

13

14V2

6

8

6

22

REF PART # DESCRIPTION REF PART # DESCRIPTION

2 XD4074002 LEADSCREW ASSEMBLY 13 XD4074013 PHLP HD SCR M5-.8 X 30

3 XD4074003 ADJUSTABLE JAW 14V2 XD4074014V2 LOCK NUT M16-2

4 XD4074004 JAW FACEPLATE 16 XD4074016 OUTER V-JAW

5 XD4074005 PHLP HD SCR M6-1 X 14 17 XD4074017 PHLP HD SCR M5-.8 x 10

6 XD4074006 RIVET 2 X 4MM NAMEPLATE, STEEL 18 XD4074018 EXTENTION SCALE

7 XD4074007 BACK JAW 19 XD4074019 CAP SCREW M5-.8 X 12

8 XD4074008 ROTATION SCALE 20 XD4074020 INNER PIPE JAW

9V2 XD4074009V2 LOCK HANDLE V2.12.13 21 XD4074021 INNER V-JAW

10 XD4074010 MAIN HOUSING 22 XD4074022 BASE

11 XD4074011 END CAP 23V2 XD4074023V2 ROTATION PLATE V2.12.13

12 XD4074012 END CAP WASHER 24 XD4074024 CARRIAGE BOLT M10-1.5 X 50

-4-

Loading...

Loading...