Shindaiwa X7506720300, GP344 User Manual

English

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

GP344 WATER PUMP

X7506720300

07/10

WARNING!

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with its

contents! Always wear eye and hearing protection

when operating this unit.

Introduction

HOT SURFACE

This Shindaiwa GP344 water pump has

been designed and built to deliver superior performance and reliability without compromise to quality, comfort, or

durability.

Shindaiwa high performance engines

represent the leading edge of 4-cycle

engine technology, delivering exceptionally high power at remarkably low displacement and weight. As an owner/

operator, you’ll soon discover why Shindaiwa is simply in a class by itself!

IMPORTANT!

The information contained in this manual

describes units available at the time of

production. While every attempt has

been made to give you the very latest

information about your Shindaiwa GP344

water pump, there may be some differences between your pump and what is

described here.Shindaiwa Inc. reserves

the right to make changes in production

without prior notice, and without obligation to make alterations to units previously manufactured.

Echo, Inc. reserves the right to make

changes to products without prior

notice, and without obligation to

make alterations to units previously

manufactured.

IMPORTANT!

The information contained in these

instructions describes units available at

the time of publication.

WARNING!

The engine exhaust from

this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

Contents

PAGE PAGE

Safety .............................................3

Unit Description .............................. 4

Specications ................................. 4

Assembly ........................................ 5

Mixing fuel ...................................... 6

Filling the fuel tank.......................... 6

Starting the Engine ......................... 7

Adjusting Engine Idle ...................... 8

Operation ........................................ 9

Maintenance ................................. 10

Long Term Storage ....................... 13

Troubleshooting Guide ................. 13

Emission System Warranty .......... 17

PAGE

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit as well as to protect

you and others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to

replace any safety rules and/or laws that may be in force in your area. If you have questions regarding your H4 series hand-held

power equipment, or if you do not understand something in this manual, contact Shindaiwa Inc. at the address printed on the

back of this Manual.

Attention Statements

Throughout this manual are special

“attention statements”.

DANGER!

A statement preceded by

the triangular attention symbol and

the word “DANGER” contains information that should be acted upon

to prevent serious injury or death.

the triangular attention symbol and

the word “WARNING” contains information that should be acted upon to

prevent serious bodily injury.

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

WARNING!

A statement preceded by

IMPORTANT!

CAUTION!

A statement preceded by the

word “CAUTION” contains information that should be acted upon

to prevent mechanical damage.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

Operational and warning labels

Read and follow this Owner’s/

Operator’s Manual. Failure to do

so could result in serious injury.

Wear eye and hearing protection at all times during

the operation of this unit.

2

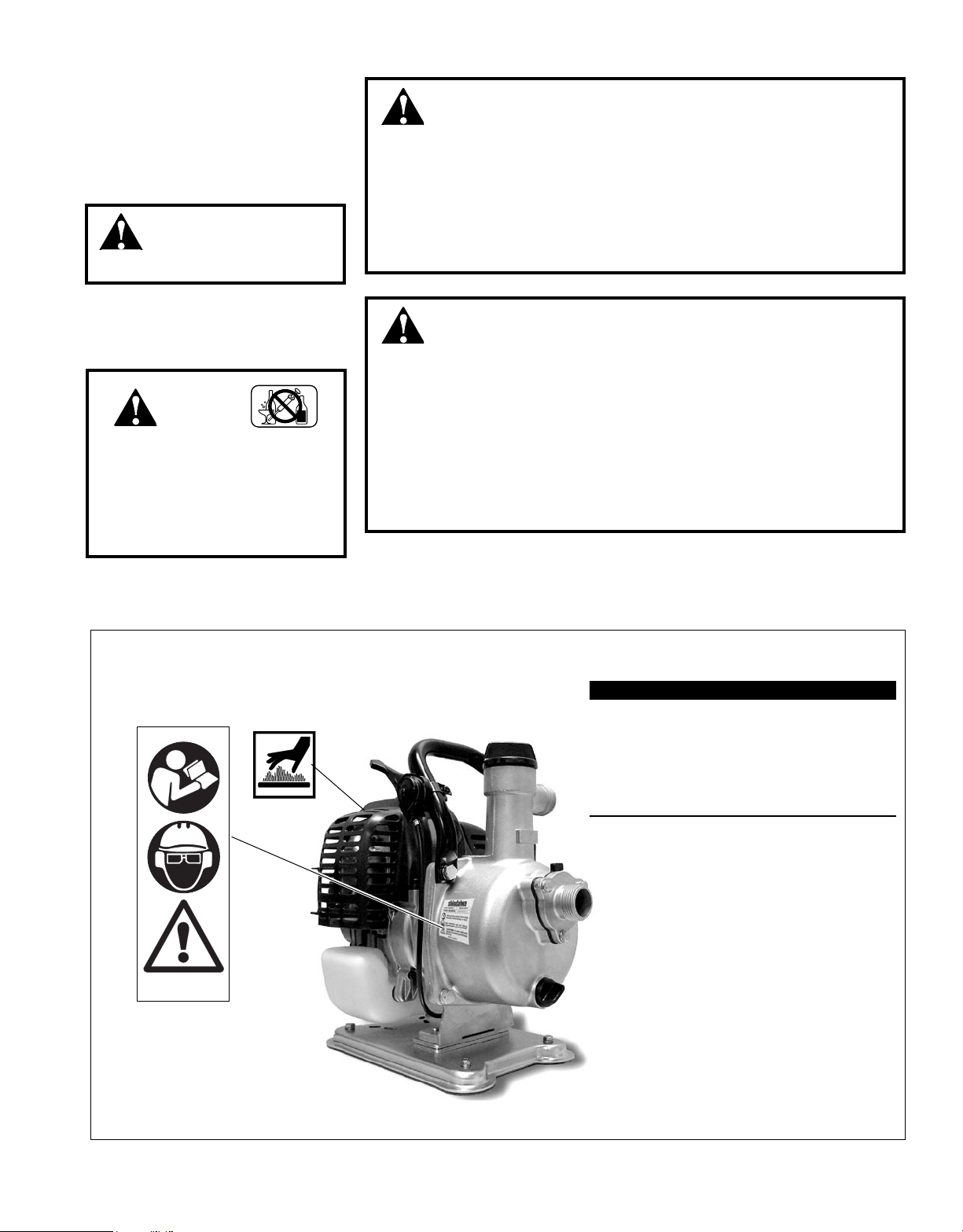

To avoid water pump

damage, ll priming port

with water before use.

WARNING: Surface can

be hot. Always wear gloves

when handling this unit.

Safety

HOT SURFACE

Work Safely

Pumps operate at very high speeds

and can do serious damage or injury

if they are misused or abused. Never

allow a person without training or

instruction to operate this unit!

WARNING!

Never make unauthorized

attachment installations.

WARNING!

Use Good Judgment

NEVER operate the engine when

transporting the unit.

NEVER operate the engine indoors!

Make sure there is always good ventilation. Fumes from engine exhaust

can cause serious injury or death.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly installed parts.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation, mud, etc.

ALWAYS disconnect the spark plug wire

before performing any maintenance

work.

Stay Alert

You must be physically and mentally t

to operate this unit safely.

WARNING!

Never operate power equipment

of any kind if you are tired or if you

are under the inuence of alcohol,

drugs, medication or any other substance that could affect your ability

or judgement.

Safety labels

WARNING!

Minimize the Risk of Fire

NEVER smoke or light res near the

unit.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid

overlling and wipe off any fuel that

may have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

rell, check that no fuel leaks from

Caution, Danger, Warning, and Operation

Information Labels: Make sure all information

labels are undamaged and readable. Immediately replace damaged or missing information labels. New labels are available from your

local authorized Shindaiwa dealer.

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using

the unit immediately. Fuel leaks must

be repaired before using the unit.

ALWAYS move the unit to a place

well away from a fuel storage area

or other readily ammable materials

before starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER run the engine without the

spark arrester screen in place.

IMPORTANT!

3

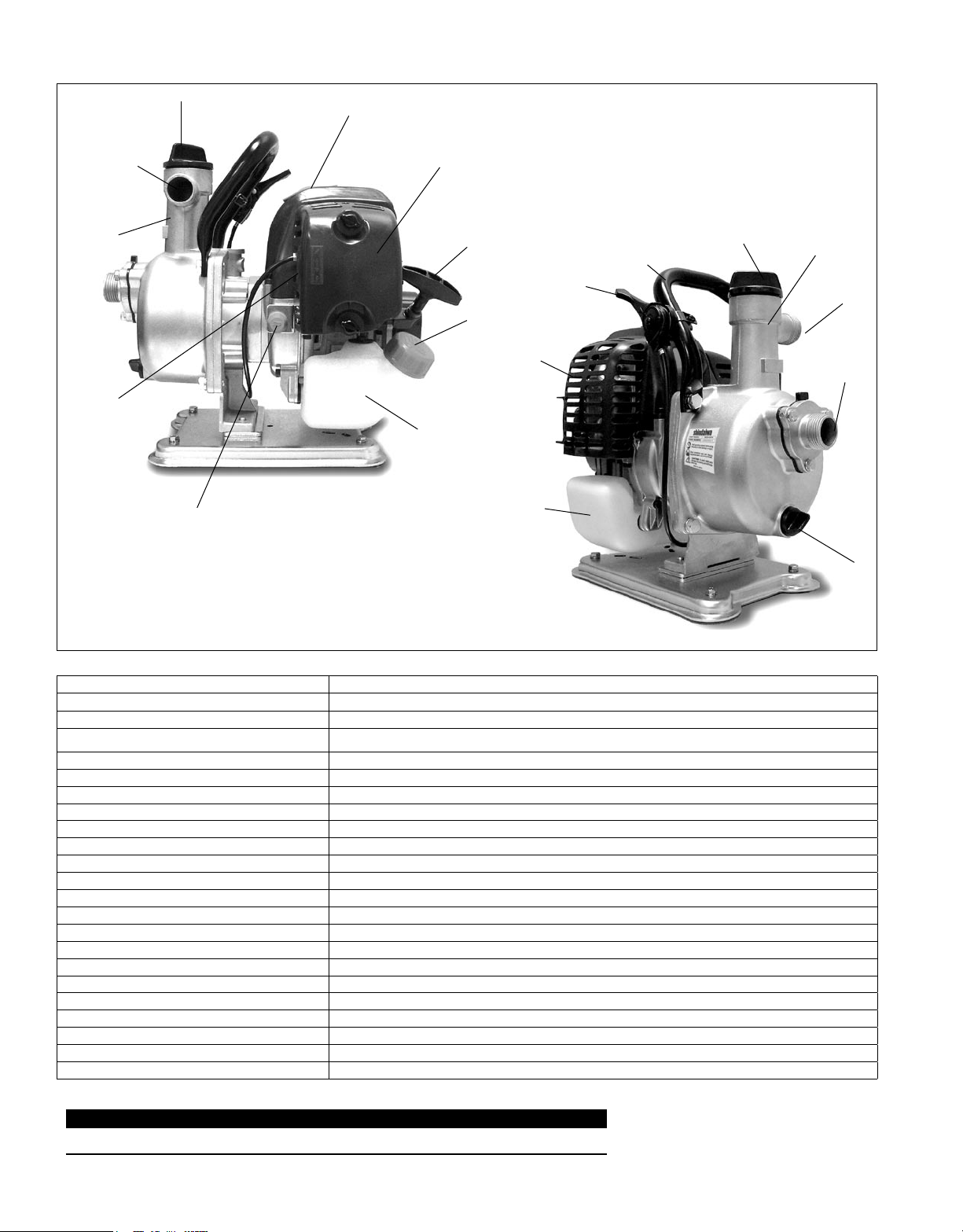

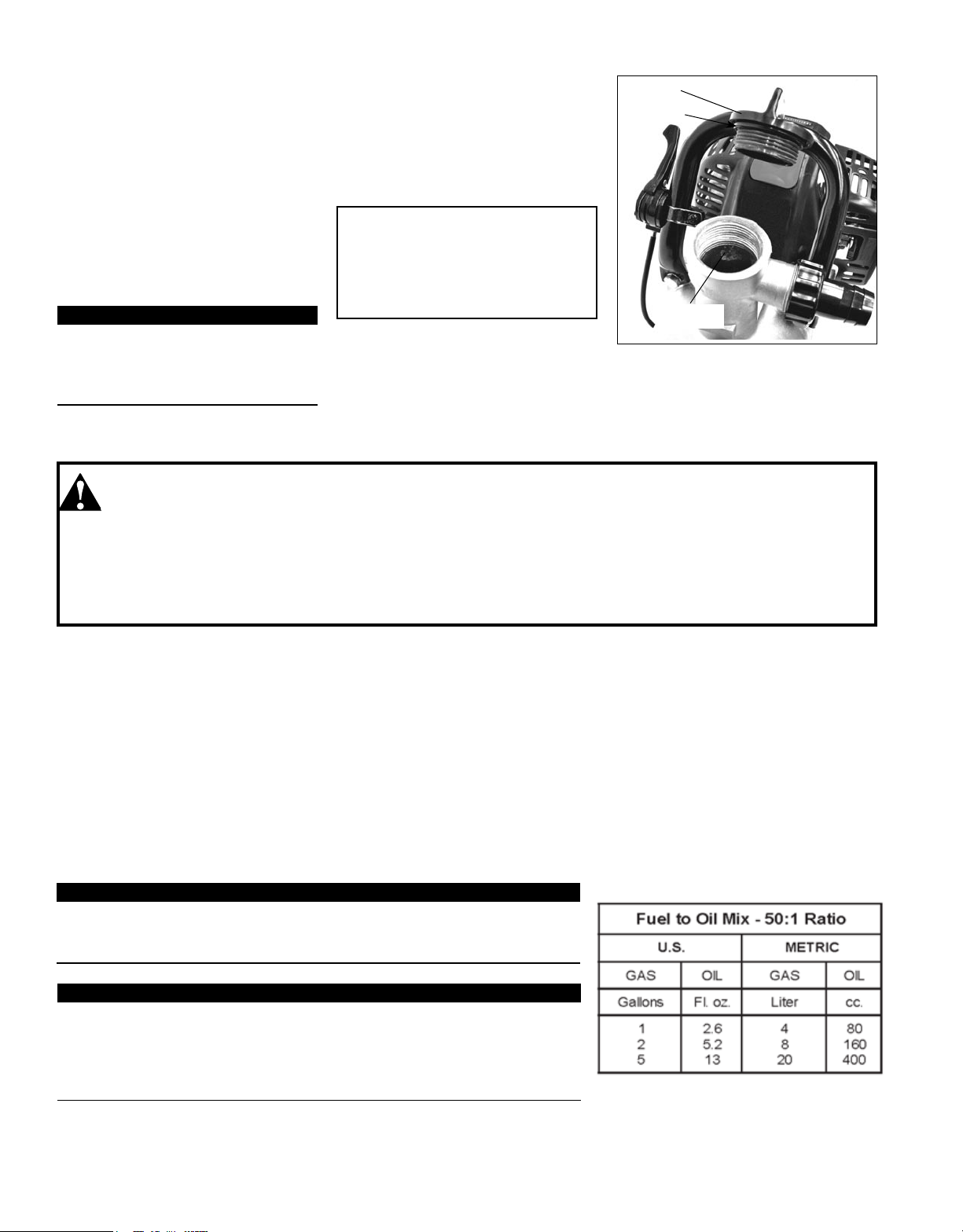

Unit Description

Filler Plug

Spark Plug

Discharge

Connection

Priming

Port

Choke

Stop Switch

Using the illustrations above as a guide,

familiarize yourself with this unit and its

various components. Understanding the

unit helps ensure top performance, long

service life, and safer operation.

Air Cleaner

Fuel Tank

Recoil Starter

Handle

Fuel Filler

Cap

Mufer

Fuel Tank

Throttle

Lever

Handle

Filler Plug

Priming Port

Discharge

Connection

Suction

Connection

Drain

Plug

Specications

Model GP344

Engine Type 4 cycle air-cooled gasoline engine, vertical cylinder

Displacement 34 cc (38mm x 30mm); 2.07 cu. in. (1.50 x1.18 in.)

Fuel/Oil Ratio 50:1 with *ISO-L-EGD or JASO FD class engine oil

Carburetor Walbro rotary type with primer bulb

Ignition PCI

Spark Plug NGK CMR5H

Plug Gap 0.6 mm / 0.024 inch

Torque 16.7 - 18.6 N∙m / 148 -165 in • lbs

Starting Recoil starter

Stopping Push button

Fuel tank capacity 22.4 oz. (0.6661 liter)

Weight 15.6 pounds (7.1 kg)

Engine Idle Speed 3,000 RPM

Clutch Engagement Speed N/A

Wide Open Throttle Speed (W.O.T.) 7,500 RPM

PUMP

Type General purpose, centrifugal, self-priming

Suction Diameter 1.0 inches (25mm)

Discharge Diameter 1.0 inches (25mm)

Maximum Suction Head (vertical lift) 26.25 feet (8 meters)

Maximum Total Pump Head 157 feet (48 m)

Maximum Pump Discharge 34.8 gal/min (132 liters/min)

Specications are subject to change without notice.

IMPORTANT

This spark ignition system complies with the Canadian standard ICES-002.

4

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modication and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by engine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

Assembly

Prior to Assembly

Before assembling this unit, make sure

you have all the components required

for a complete unit:

■

GP344 engine-driven pump

Spark plug wrench ■

Install the Suction and Discharge Hoses

Spanner ■

3mm Hex Wrench ■

4mm Hex Wrench ■

Parts bag including: ■

1.0" hose clamps (3 each) ■

hose ttings and gaskets ■

(2 each)

■

strainer

garden hose adapter (use gar- ■

den hose only to discharge

water!)

CAUTION!

This pump is intended for pump-

■

ing fresh water only.

■

Ingested debris can damage the

pump impeller and seals.

■

Never operate the pump if the

strainer is missing or damaged.

Assemble a barbed hose tting, 1.

ring nut, and gasket as shown, and

thread the completed hose tting

assembly onto the pump suction

port.

Push a 1.0" suction hose (not pro-2.

vided) over the suction hose tting on

the pump body, and secure with a 1.0"

hose clamp as shown. Working at the

opposite end of the suction hose, use

a second 1.0" hose clamp to install and

secure the suction strainer.

Submerge the suction hose strainer 3.

in the water source. For maximum

performance, avoid placing the

strainer directly in heavy accumulations of leaves, silt, or other debris.

Ring Nut

Hose Clamp

Barbed Hose

Suction

Hose

Assembling the hoses

Install the discharge hose (not 4.

provided) using the garden hose

adapter.

Recheck that both the suction and 5.

discharge hoses are free from

obstructions, and that all connections are tightly secured.

Priming Port

Gasket

Suction Port

Fitting

Hose Clamp

Discharge Port

Suction

Strainer

IMPORTANT!

Place the pump as close to the water

source as possible. Increases in suction lift will lower pump performance.

Do not exceed maximum suction head

of 26 feet.

5

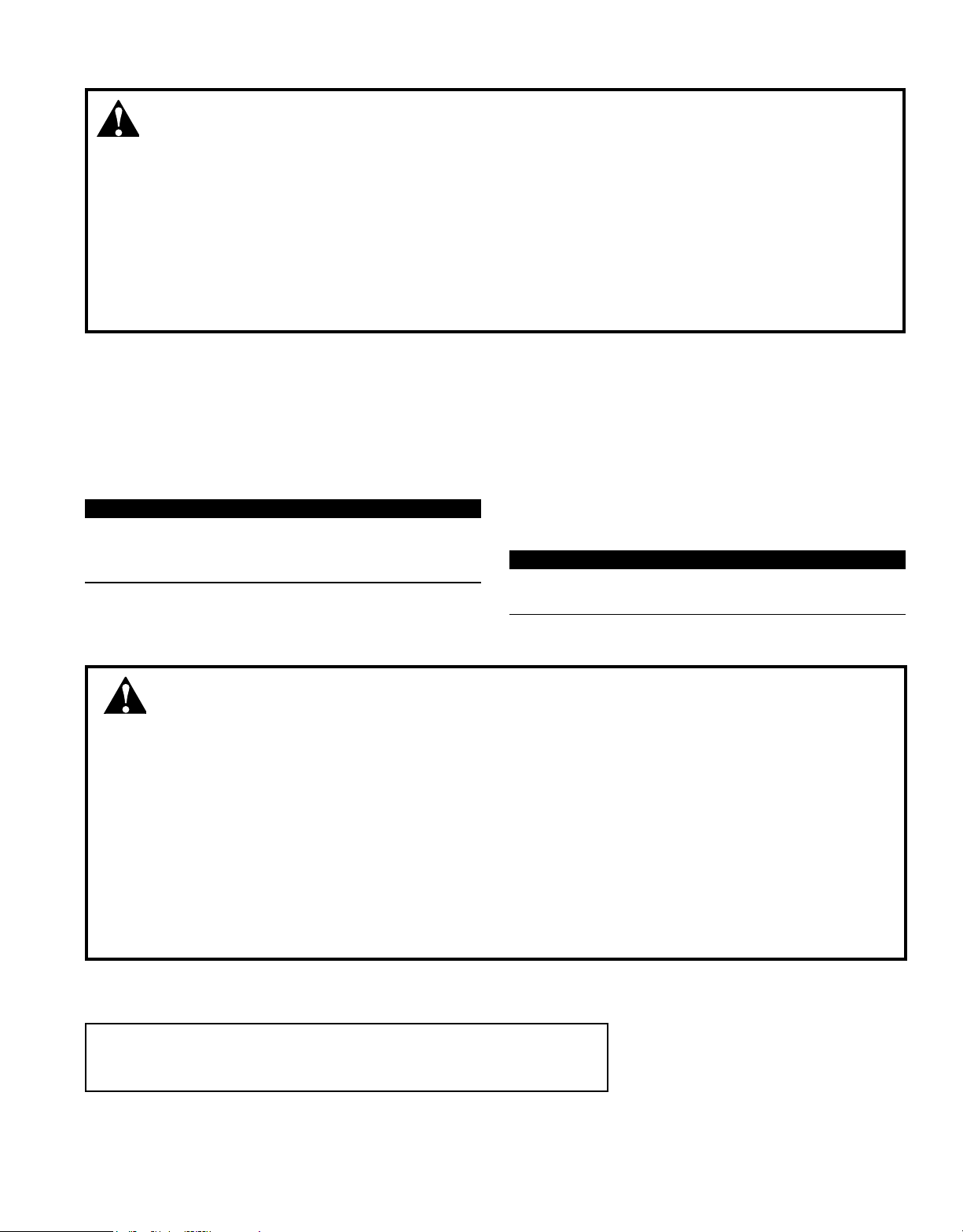

Priming

Before the pump can develop suction

or “lift” at the water source, the pump

impeller must rst be primed by lling

the pump housing with water. Once the

water pump has been primed, additional priming should be required only

if the pump has been drained or otherwise emptied.

Remove the ller plug at the top of 1.

the pump housing. Use care not to

lose the sealing ring beneath the

ller plug.

IMPORTANT!

A damaged or missing ller plug

seal may allow air to leak into the

pump housing. Air leakage can lower

performance!

Fill the pump housing through the 2.

priming port with clean water until

water overows from the ller plug

hole on the pump body.

Replace and securely tighten the 3.

ller plug.

CAUTION!

Never allow the pump to run dry!

Operation without water can permanently damage the pump seals.

Filler plug

Sealing ring

Priming

port

Mixing Fuel

WARNING!

Alternative fuels, such as E15 (15% ethanol), E-85 (85% ethanol) or any fuels not meeting Shindaiwa

requirements are NOT approved for use in Shindaiwa gasoline engines. Use of alternative fuels may cause

performance problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including,

but not limited to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel

lines, gaskets, carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain

up to 10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood

alcohol) is NOT approved.

Hybrid 4TM Mixture Oil - Engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD standards must be

used. Shindaiwa highly recommends using Shindaiwa Red ArmorTM engine oil in all Shindaiwa Hybrid 4TM engines to

protect the engine from harmful carbon build up, maintain engine performance, and increase engine life. Shindaiwa

Red ArmorTM engine oil exceeds ISO-L-EGD and J.A.S.O. M345/FD performance requirements. Engine problems

due to inadequate lubrication caused by failure to use an ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD certied

oil will void the engine warranty.

IMPORTANT!

Shindaiwa Red Armor

in all Shindaiwa engines sold in the past, regardless of ratio specied in those

manuals.

Stored fuel ages. Do not mix more fuel than you expect to use in thirty (30)

days, ninety (90) days when a fuel stabilizer is added. Use of unmixed, improperly mixed, or stale fuel, may cause hard starting, poor performance, or severe

engine damage and void the product warranty. Read and follow instructions in

the Long Term Storage section of this manual.

6

TM

engine oil may be mixed at 50:1 ratio for application

IMPORTANT!

Examples of 50:1 mixing quantities

Handling Fuel

DANGER

Fuel is VERY ammable. Use extreme care when mixing, storing or handling or serious personal injury may result.

• Use an approved fuel container.

• DO NOT smoke near fuel.

• DO NOT allow ames or sparks near fuel.

• Fuel tanks/cans may be under pressure. Always loosen fuel caps slowly allowing pressure to equalize.

• NEVER refuel a unit when the engine is HOT or RUNNING!

• DO NOT ll fuel tanks indoors. ALWAYS ll fuel tanks outdoors over bare ground.

• DO NOT overll fuel tank. Wipe up spills immediately.

• Securely tighten fuel tank cap and close fuel container after refueling.

• Inspect for fuel leakage. If fuel leakage is found, do not start or operate unit until leakage is repaired.

• Move at least 3m (10 ft.) from refueling location before starting the engine.

Mixing Instructions

1. Fill an approved fuel container with half of the required amount of gasoline.

2. Add the proper amount of engine oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and

remix.

IMPORTANT!

Spilled fuel is a leading cause of hydrocarbon emissions.

Some states may require the use of automatic fuel shutoff containers to reduce fuel spillage.

Filling the fuel tank

WARNING!

Minimize the Risk of Fire

NEVER ■ smoke or light res near the engine.

■ stop the engine and allow it to cool before

ALWAYS

refueling.

■ Wipe all spilled fuel and move at least 3

ALWAYS

meters (10 feet) from the fueling point and source before

starting.

■ place ammable material close to the engine

NEVER

mufer.

NEVER ■ operate the engine without the mufer and spark

arrester screen in place and in good working condition.

FUEL IS HIGHLY FLAMMABLE. ■

After use

• DO NOT store a unit with fuel in its tank. Leaks can

occur. Return unused fuel to an approved fuel storage

container.

Storage - Fuel storage laws vary by locality. Contact

your local government for the laws affecting your area.

As a precaution, store fuel in an approved, airtight container. Store in a well-ventilated, unoccupied building,

away from sparks and ames.

IMPORTANT!

Stored fuel may separate. ALWAYS shake fuel container

thoroughly before each use.

ALWAYS ■ store gasoline in a container approved for

ammable liquids.

■ inspect the unit for fuel leaks before each

ALWAYS

use. During each rell, check that no fuel leaks from

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using the unit immediately. Fuel leaks must be repaired before using the unit.

ALWAYS ■ move the unit at least 3 meters (10 feet)

away from a fuel storage area or other readily am-

mable materials before starting

the engine.

Place the unit on a at, level surface.1.

Clear any dirt or other debris from around the fuel ller cap.2.

CAUTION!

Slowly remove the fuel cap only after stopping the engine

Remove the fuel cap, and ll the tank with clean, fresh fuel.3.

Reinstall the fuel ller cap and tighten rmly.4.

Wipe away any spilled fuel before starting engine.5.

7

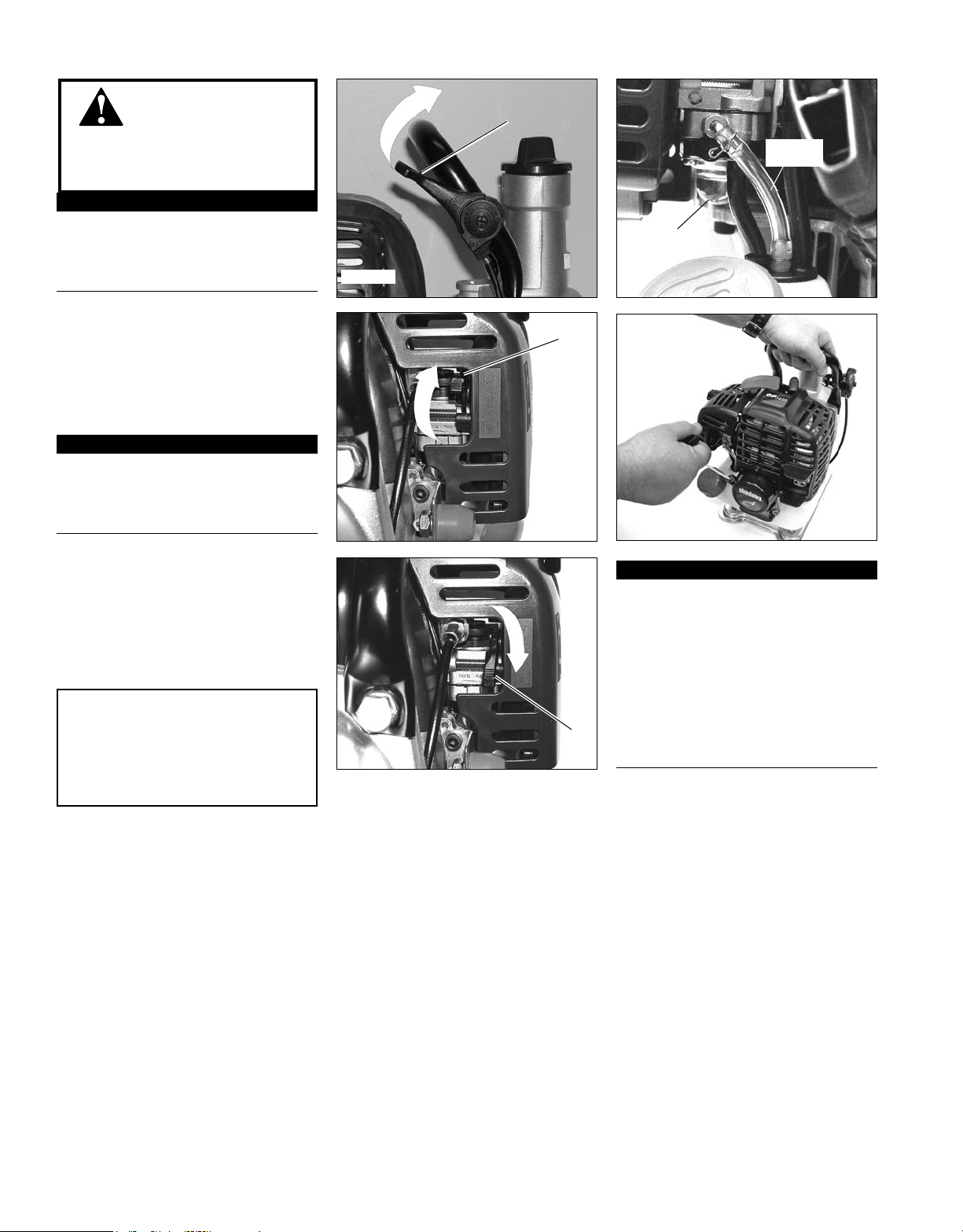

Starting the Engine

WARNING!

Do not run engine in an

enclosed area. Exhaust gas contains carbon monoxide, an odorless

and deadly poison.

IMPORTANT!.

Do not start or run the pump without

priming the pump with water. Serious

damage to the pump seals will occur

when the pump is run dry.

Place suction intake and strainer 1.

in the water to be pumped prior to

starting engine.

Set throttle control lever to the half 2.

open position. See Figure 3.

Press the primer bulb until fuel can 3.

be seen owing in the transparent

return tube. See Figure 4.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not ood

the engine with fuel.

Set the choke lever to the CLOSED 4.

position if the engine is cold.

While holding the pump handle 5.

rmly with your left hand, use your

other hand to slowly pull the recoil

starter handle until resistance is

felt, then pull quickly to start the

engine. See Figure 6

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

When the engine starts, slowly 6.

move the choke lever to the

"OPEN" position. See Figure 7. (If

the engine stops after the initial

start, close the choke and restart.)

Figure 3

Figure 5

Figure 7

When the engine starts, gradu-7.

ally move the throttle control

lever back to the idle position

(counterclockwise).

D

Return tube

Primer bulb

Figure 4

Close

L

Figure 6

IMPORTANT!

If the engine fails to start after several

attempts with the choke in the closed

position, the engine may be ooded

with fuel. If ooding is suspected, move

the choke lever to the open position

and repeatedly pull the recoil starter

to remove excess fuel and start the

engine. If the engine still fails to start,

Open

refer to the troubleshooting section of

this manual.

After the engine starts, allow the 8.

engine to warm up at idle 2 or 3

minutes before operating the unit.

Place throttle lever (D) in half throt-9.

tle position until pump begins to

pump water. Then move lever to full

throttle.

If the engine does not start

Repeat the appropriate procedures for starting a warm or cold engine.1.

If the engine fails to start, follow the procedures in “Starting a Flooded 2.

Engine”.

Starting A Flooded Engine

Open the choke, put the throttle trigger in the full throttle position, then clear excess fuel from the combustion chamber by 1.

cranking the engine several times.

If the engine still fails to start or re, refer to the troubleshooting ow chart at the end of this manual.2.

8

Loading...

Loading...