Shindaiwa EC7600, EC7500 User Manual

SHINDAIWA OWNER’S AND

OPERATOR’S MANUAL

EC7500/EC7600

ENGINE CUTOFF

SAW(EPA VERSION)

USE |

ONLY G |

SHINDAIWAENUINE |

|

NgoeNnpUoueu-srislenofeoearardebSmilnrheaefinonvpcrodecelarueiimgwdtiuBLADESoaeaantbbreraslraanpvsdteeieevelesoed.cw:bi4tiltya1hd8ooe0fus2tmw4ui8isntih-nf1tgm/(sreapcxm.im) um |

|

|

EC7500 AMMrabaxxoiirmmduuiammmbbelltaaeddr:ee1tdhiiniacmckhneetesrs::102.1in6.in. |

WARNING!

■Read this manual and familiarize yourself with its contents.

■This unit is designed primarily for cutting construction materials and metal according to the type of cutting wheel installed.

■To minimize the risk of injury to yourself and others, always wear hearing protection, a dustproof mask, goggles and a helmet when operating this unit.

■Keep this manual handy so you can refer to it when required.

Part Number 68002-94310 Rev. 12/02

Contents |

|

|

|

Page |

|

Attention Statements ............................ |

|

2 |

Labels and Symbols ............................. |

|

2 |

Safety Precautions ................................ |

|

3 |

Safety/Operation Information Labels |

... 7 |

|

Unit Description ................................... |

|

8 |

Technical Specifications ...................... |

|

9 |

Assembly ............................................. |

|

10 |

Filling the Fuel Tank ......................... |

|

11 |

Starting/Stopping the Engine ........... |

|

12 |

Operation ............................................. |

|

14 |

Inspection and Maintenance ............. |

|

16 |

Long Term Storage ............................ |

|

23 |

Troubleshooting ................................. |

|

24 |

Emission Warranty Statement .......... |

|

25 |

Shindaiwa Inc. reserves the right to make changes to products without prior notice, and without obligation to make alterations to units previously manufactured.

Attention Statements

Throughout this manual are special “attention statements”.

WARNING!

A statement preceded by the word “WARNING” contains information that should be acted upon to prevent serious injury.

CAUTION!

A statement preceded by the word “CAUTION” contains information that should be acted upon to prevent unit damage.

IMPORTANT!

A statement preceded by the word “IMPORTANT” is one that possesses special significance.

NOTE:

A statement preceded by the word “NOTE” contains information that is handy to know and may make your job easier.

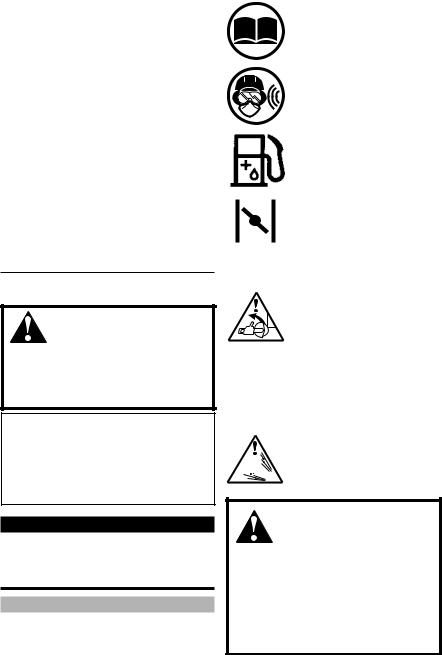

Labels and Symbols

The following are symbols that appear on the unit.

Read and follow the operator’s manual. Failure to do so could result in serious injury.

Always wear hearing protection, a dustproof mask, goggles and a helmet when operating this unit.

Fuel Filler

Choke

The following symbols are meant to provide important reminders.

Be aware of kickback!

Kickback may force the cutting-off wheel up and back toward the operator with a lightning-fast reaction. Kickback can occur whenever the upperhalf of the cutting-off wheel touches an object while operating the unit.

Be aware of thrown  objects!

objects!

WARNING!

Using this cut-off saw, or any other high-speed power tool, can be hazardous. As a result, you must employ special safety precautions to reduce the risk of injury or fire.

2

Safety Precautions

WARNING!

Before Operation

■Children and people who do not understand this manual must not use this unit.

■Never allow other people or animals to be near the unit when starting or operating.

■Never touch a rotating cut-off wheel.

■Operate the unit only in a well ventilated area.

■Never operate the unit in a closed area such as a room, warehouse or tunnel. Running the unit in a closed area may cause serious illness or even death due to exhaust gas.

■Never allow any people or animals near exhaust gas.

■Never inhale exhaust gas.

■Never make unauthorized modifications or alterations to any of the components of the unit, and never operate the unit without the wheel guard or muffler.

■This unit is designed for oneman operation and must be operated by only one person.

■Never operate the unit when you are tired or under influence of any substance that could impair vision, dexterity or judgement.

■When operating the unit, always wear snug-fitting clothing, safety gloves, safety non-skid footwear, hearing protection, a dust-proof mask, a helmet and goggles. Never wear floppy clothing, shorts, sandals or accessories that could become entangled.

■To minimize the risk of sparks igniting clothing while operating the unit, wear clothing made of leather, wool, tightly-woven cotton, or cotton treated with flame-retardant.

■Never use any cut-off wheel that is not recommended in this manual.

■Do not start or operate the unit unless you have a clear work area and secure footing.

■Never smoke or use fire near the unit or its fuel.

■Since the muffler and exhaust gas become very hot, make sure there are no flammable substances near the unit.

■Never run the unit if you discover a fuel leak.

■A first-time operator should obtain practical instruction from a dealer or an experienced user before using the unit.

■Make sure all the components are in place and the bolts are securely fastened.

■Make sure the cut-off wheel is securely fastened and is not damaged. Never use a cut-off wheel with cracks, distortion, or one that is unbalanced.

■Make sure the belt tension is properly adjusted and the wheel guard, belt guard and clutch cover are securely assembled.

■Always inspect the front handle, rear handle and wheel guard before use, and never use the unit if the parts are damaged.

3

Safety Precautions (continued)

Before Operation (continued)

■Before cutting into a material, familiarize yourself with the risks associated with dust, fumes, or mists that may be generated during operation.

Make sure you provide adequate protection against harmful emissions. A highperformance respirator and/or water attachment may be required.

WARNING!

■Do not use the cut-off saw to cut or disturb asbestos or products containing or wrapped in asbestos. If you believe you might be cutting asbestos, contact your supervisor.

Fueling the Unit

■Mixing fuel and engine fueling must be done outside, and where no other combustibles are nearby.

■Open the fuel cap slowly to release any possible build-up of pressure.

■Never refuel when the unit is hot. Allow to cool before refueling.

■Never fuel when the engine is running.

■After fueling, wipe all spilled fuel. Cutting metal may cause sparks from the cut-off wheel and may ignite spilled fuel which could result in serious injury.

Figure 1. Start the engine at least 10 feet (3 meters) from a fueling location.

Starting The Engine

■Start the engine at least 10 feet (3m) away from a fueling location.

■When starting the engine, make sure the cut-off wheel does not touch any object or ground. As soon as the engine starts, the cut-off wheel may begin to rotate.

■Start the engine according to the instructions in this manual. Start the engine on a firm, stable surface. Make sure the area is clear of bystanders. Starting the engine must be done by only one person without any assistance.

■The cut-off wheel should not rotate at engine idle. If it does, reduce idle speed.

■Never leave the unit running unattended.

4

Safety Precautions (continued)

WARNING!

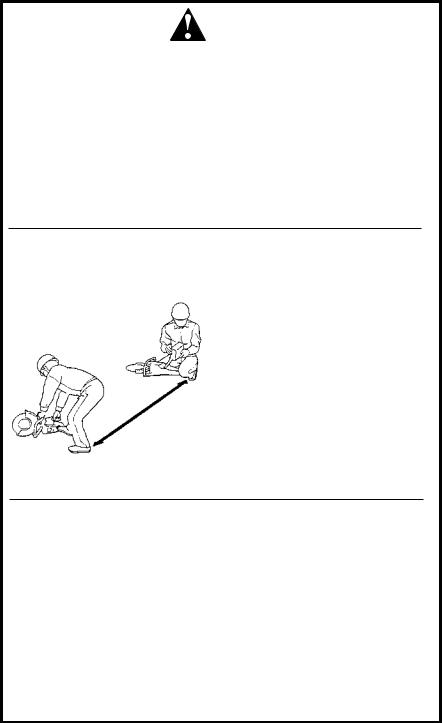

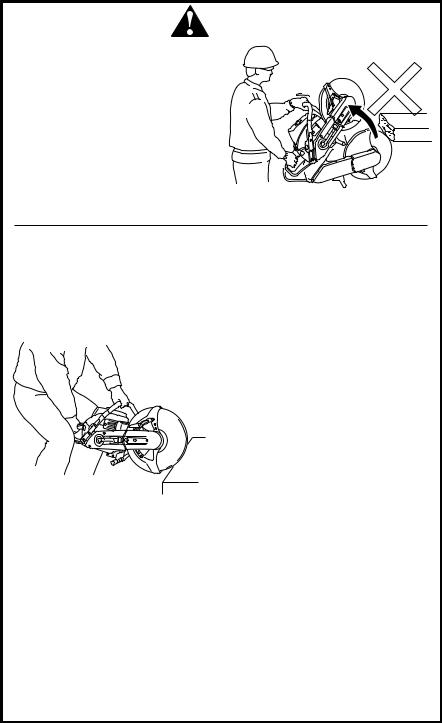

Kickback

■Kickback may force the cut-off wheel up and back toward the

operator lightning-fast.

■ Kickback can occur whenever |

|

the upper half of the cut-off |

|

wheel touches an object. Never |

EC7500.14 |

cut an object using the upper |

|

half of the cut-off wheel. |

|

|

Figure 2. Always be aware of, and |

|

prepared for, kickback. |

Operation

■The unit must be held firmly with both hands, one hand on the rear handle, the other on the front handle. Never hold onto any other part of the unit.

Figure 3. Always operate |

EC7500.17 |

|

|

below chest level. |

|

■This unit must be operated below chest level. Operating above chest level may result in serious injury.

■When cutting vertically, the unit should be positioned horizontally or with the wheel side tilted slightly down. When cutting horizontally, the recoil starterside should face up.

■Never impact or apply pressure to the sides of the cut-off wheel for any reason.

■Maintain firm and stable footing during operation. Do not overreach.

■When working in a group, make sure operators are least 30 feet (10 meters) away from each other.

■If you drop the unit or strike it against a hard surface, stop the engine immediately and inspect for damage. If you discover damage, have it repaired before you return the unit to service.

■Check the fuel filler cap regularly during operation to make sure it remains securely tightened.

5

Safety Precautions (continued)

WARNING!

Operation (continued)

■If you discover fuel leakage, immediately stop the engine.

■Cutting may cause sparks from the cut-off wheel. Make sure there is no flammable substances nearby.

■Never cut live electrical wires. The shock you might receive could be very serious.

■Do not touch hot parts such as the muffler or cylinder. You could burn yourself severely.

■The cut-off wheel gets hot while cutting. Never touch the wheel immediately after cutting. You could burn yourself severely.

■While the engine is running, never touch high voltage parts such as the spark plug cap and plug cord.

Stopping The Engine

■The cut-off wheel coasts for a while after the engine is stopped. Keep hold of the unit firmly until the wheel stops completely and then place it on the ground.

Inspection and Maintenance

■Before performing any inspection, maintenance, repair or cleaning of the unit, make sure engine and cut-off wheel are completely stopped and cooled down.

■Inspection and maintenance operations should be done in a well ventilated location and where there are no combustibles nearby.

■When replacing parts, always use Shindaiwa genuine parts. Using non-Shindaiwa genuine parts may result in serious injury.

■Inspection and maintenance operations not mentioned in this manual should be performed by an authorized Shindaiwa dealer.

Transport and Storage

■When carrying the unit, make sure engine and cut-off wheel are completely stopped.

■Carry the unit with the front handle and with cut-off wheel facing rearward.

■When storing the unit, make sure the cut-off wheel is removed and the unit is placed on a secure, dry place.

■Keep the unit away from children.

■When storing the unit for more than a few days, empty the fuel tank completely.

■Store gasoline and mixed fuel in a closed, dry place and where combustibles are not nearby.

6

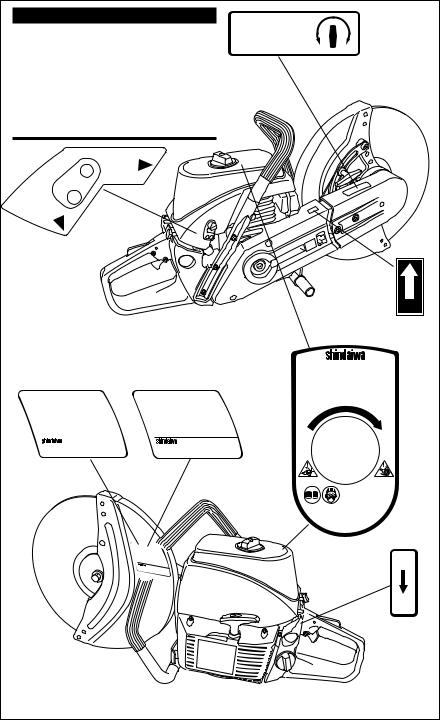

Safety and Operation Information Labels

IMPORTANT!

Make sure all safety and operation information labels are undamaged and readable. Immediately replace damaged or missing safety and operation information labels, which are available from your authorized Shindaiwa dealer.

DECOMPRESSION

VALVE

T

PRIMER

USE ONLY GENUINE |

USE ONLY GENUINE |

|

SHINDAIWA BLADES |

SHINDAIWA BLADES |

|

No performance guarantee without |

No performance guarantee without |

|

using genuine Shindaiwa blades |

using genuine Shindaiwa blades |

|

No-load revolution speed: 4220 min-1 (rpm) |

No-load revolution speed: 3680 min-1 (rpm) |

|

Use reinforced abrasive blades with |

Use reinforced abrasive blades with |

|

maximum useable perimeter velocity of: |

maximum useable perimeter velocity of: |

|

15,749 ft/min.(4800 m/min.) |

15,749 ft/min.(4800 m/min.) |

|

|

|

|

TURN THE KNOB ALL

THE WAY TO FREE

OR LOCK THE GUARD FREE LOCK

EC7500.18

BELT

DIRECTION

ENGINE START PROCEDURES

1. Press PRIMER bulb 4–5 times, |

6. Make sure the CHOKE knob is |

||||

or until fuel is in the bulb. |

|

pressed IN. |

|||

2. COLD ENGINE: Pull the CHOKE |

7. Make sure the DECOMPRESSION |

||||

knob OUT. |

|

|

valve is pressed IN. |

||

WARM ENGINE: Pull the CHOKE |

8. Pull the recoil starter. |

||||

knob once, then press it back IN. |

|||||

3. Press the DECOMPRESSION |

9. Once the engine starts, pull back |

||||

valve IN. |

|

|

the throttle lever slightly to idle |

||

|

|

(the CHOKE knob will |

|||

4. Place OFF/ON switch to “ON”. |

|

||||

|

automatically go back IN). |

||||

5. Pull the recoil starter until you |

|

||||

|

|

|

|

||

hear first firing. |

E KN |

O |

|

|

|

|

|

|

|

||

|

B S |

EC |

|

||

|

TH |

|

|

U |

|

|

N |

|

|

|

|

E |

|

|

|

RE |

|

T |

|

|

|

|

L |

|

|

|

|

Y |

|

H |

|

|

|

|

! |

IG |

|

|

|

|

|

T |

|

|

|

|

|

|

Max. blade diameter: 12" (305mm) |

|

Max. blade diameter: 14" (355mm) |

EC7500 |

Max. blade thickness: 0.157" (4.0mm) |

EC7600 |

Max. blade thickness: 0.177" (4.5mm) |

Standard arbor: 0.86" (22mm), |

Standard arbor: 0.86" (22mm), |

||

|

others available; see owner’s manual |

|

others available; see owner’s manual |

Be aware of |

Be aware of |

kickback! |

thrown objects! |

USE |

ONLY G |

ENUINE |

SHINDAI |

||

NuoNsUiponms1e-glear5ofxg,rao7ieedmr4nimnr9uufeamioWfvnntro/eccmuleeuSAsditgehnioauai.nBLADES(bnba4dlrres8aaap0inspwe0iteveearemedibm:bw/lm4aleaid1ttidhene8eros.0s)uvmetwloiitnch-i1ty(ropf:m) |

||

|

EC7500 SMMotaaathnxxe.d.rbabsrllaadaddvaeearibtdlhaoiaibcrml:ke0n;e.est8ese6rse:":1o0(2w2."12n5m(e37rm0’"s5()mm4, .a0mnm)umal) |

|

|

|

IMPORTANT! |

|

|

● Clean and inspect the filter |

|

|

at least once a day. |

Read the |

Wear eye, |

● Make sure the filter |

screw is tight. |

||

operator’s |

hearing, and |

● Use only 2-cycle |

manual |

breathing |

|

|

protection |

mixed fuel. |

|

|

GASOLINE TO FUEL |

|

|

OIL RATIO—50:1 |

ON

OFF

EC7500.1

Figure 4

7

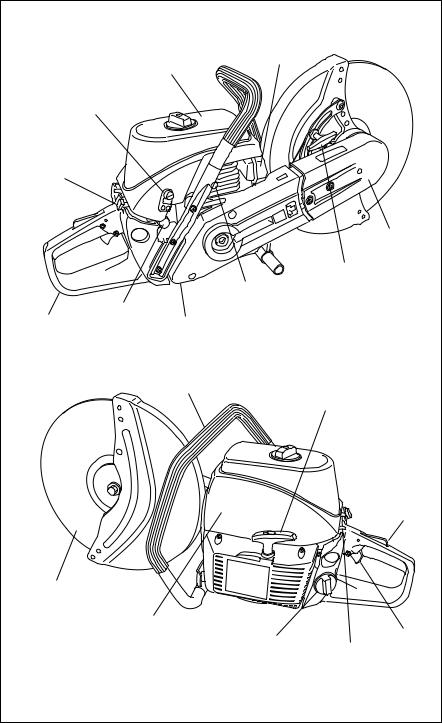

Unit Description

|

|

Air Cleaner |

Muffler |

|

|

|

|

|

Cover |

|

|

|

|

Carburetor Idle |

|

|

|

|

|

|

Adjustment Screw |

|

|

|

|

|

|

Choke |

|

|

|

|

|

|

|

|

|

EC7500.18 |

Belt Guard |

||

|

|

|

|

|

||

|

|

|

|

Wheel Guard |

|

|

|

|

|

Decompression |

|

Lock Knob |

|

|

|

|

|

|

|

|

|

Primer |

|

Valve |

|

|

|

|

|

|

|

|

|

|

Rear |

Pump |

Clutch Cover |

|

|

|

|

Handle |

|

|

|

|

|

|

|

|

Front |

|

Recoil |

|

|

|

|

Handle |

|

|

||

|

|

|

|

Starter |

|

|

|

|

|

|

|

|

Throttle |

|

|

|

|

|

|

Trigger |

|

|

|

|

|

|

Lockout |

Cut-off Wheel |

|

|

|

|

|

|

|

|

|

EC7500.1A |

|

|

|

|

Cylinder |

|

|

|

|

|

|

|

Cover |

Fuel Filler |

|

|

Throttle |

|

|

|

|

ON/OFF |

Trigger |

|

|

|

|

Cap |

|

Switch |

|

|

|

|

|

|

|

|

Figure 5 |

|

|

|

|

|

|

8 |

|

|

|

|

|

|

Technical Specifications

Engine Type ........................... |

2-Cycle, |

vertical-cylinder, air-cooled |

|

Displacement ....... |

4.5 cu. in. (73.5cc)* |

Bore x Stroke .. 2 x 1.4 in. (51 x 36mm)

Max. Power Output** .. 4.5 hp (3.3kW)

Recommended Engine Idling

Speed ................ |

|

2,500 min-1 (rpm)** |

Recommended Maximum Engine |

||

Speed ............. |

10,550 min-1 (rpm)** |

|

Maximum Cutting Depth, EC7500 |

||

Abrasive Wheel |

|

|

12 in. (305mm) ........... |

4 in. (102mm) |

|

Diamond Wheel |

|

|

12.5 in. (320mm) .... |

4.4 in. (109mm) |

|

Maximum Cutting Depth, EC7600 |

||

Abrasive Wheel |

|

|

13.9 in. (355mm) ........ |

5 in. (127mm) |

|

Diamond Wheel |

|

|

14.1 in. (360mm) .... |

5.1 in. (129mm) |

|

Rated Spindle Speed† |

||

EC7500 ............... |

|

3,800 min-1 (rpm) |

EC7600 ................ |

|

3,320 min-1 (rpm) |

Maximum Spindle Speed† |

||

EC7500 ................ |

|

4,220 min-1 (rpm) |

EC7600 ............... |

|

3,680 min-1 (rpm) |

Maximum Peripheral Wheel Speed† |

||

EC7500 .... |

13,300 ft/min. (67.5m/sec) |

|

EC7600 .... |

13,500 ft/min. (68.0m/sec) |

|

Speed Reduction Ratio |

||

EC7500 .................................. |

|

2.50:1 |

EC7600 .................................. |

|

2.87:1 |

Type of Fuel ........... |

|

Unleaded gasoline |

plus 2-cycle engine oil (50:1) |

||

Fuel Tank Capacity |

................... 800ml |

|

Carburetor Type ................ |

Diaphragm |

|

Ignition System ................... |

Electronic |

|

Spark Plug ................ |

|

Champion, CJ6Y |

Engine Starting/Stopping ..................

Toggle switch, recoil starter

Power Transmission .......... |

Automatic |

|

centrifugal clutch, V-ribbed belt |

||

Anti-Vibration System ............. |

Unified |

|

handles with 7-point support |

||

Safety Devices |

......... Throttle lock-out, |

|

wheel guard |

|

|

Dry Weight (without wheel) |

||

EC7500 .................... |

22 lbs (10.0kg) |

|

EC7600 .................... |

23 lbs (10.5kg) |

|

Dimensions (L x W x H) |

|

|

EC7500 ............ |

29.1 x 8.6 x 14.7 in. |

|

(740 x 220 x 375mm) |

|

|

EC7600 ............ |

30.1 x 8.6 x 15.3 in. |

|

(765 x 220 x 390mm) |

|

|

Sound Pressure Level† |

|

|

EC7500 ........................... |

|

101 dB (A) |

EC7600 ........................... |

|

101 dB (A) |

Sound Power Level†† |

|

|

EC7500 ........................... |

|

108 dB (A) |

EC7600 ........................... |

|

111 dB (A) |

Vibration Level§

Front handle (idle/rated spindle)

EC7500 .................. |

6.96/5.48m/sec2 |

EC7600 .............. |

10.09/10.49m/sec2 |

Rear handle (idle/rated spindle) |

|

EC7500 ................ |

8.61/14.60m/sec2 |

EC7600 ................ |

8.93/13.70m/sec2 |

Recommended Cut-off Wheels |

|

EC7500, abrasive ..... |

12 in. (305mm) dia |

EC7500, diamond .. |

12.5 in. (320mm) dia |

EC7600, abrasive .. |

13.9 in. (355mm) dia |

EC7600, diamond .. |

14.2 in. (360mm) dia |

Arbor Sizes ..................... |

0.78" (20mm), |

0.86" (22mm), and 1.0" (25.4mm)

*Measured in accordance with EN ISO 11201: 1995.

**Measured in accordance with ISO 7293: 1983.

†Measured with 305mm wheel (EC7500) and 355mm wheel (EC7600).

††Measured in accordance with EN ISO 3744: 1995.

§Measured in accordance with EN 28662-1: 1992.

9

Loading...

Loading...