Shindaiwa F220, T220, C220 Owner's/operator's Manual

F220

Part Number 62090-94310 Rev. 10/04

WARNING!

Read this manual and familiarize yourself with its contents.

This machine is designed for cutting grass, weed, and bushes. Do

not use this machine for other purposes.

Minimize the risk of injury to yourself and others.

Do not operate or service this machine unless you clearly

understand this manual.

Keep this manual at a particular place so that you can reread it

whenever you have a question about its use.

SHINDAIWA OWNER’S/OPERATOR'S MANUAL

F220 GRASS TRIMMER

T220 GRASS TRIMMER

C220 BRUSHCUTTER

T220

C220

2

1 Attention Statements ...................... 2

2 Warning Labels .............................. 2

2-1 The Properly Equipped Operator ..... 3

2-2 General Safety Instructions ............. 4

2-3 Working Environment Warning ........ 4

3 Product Description ........................ 5

4 Technical Specifications ................. 6

5 Assembly Procedure ...................... 6

5-1 Prior to Assembly ........................ 6

5-2 Before assembling Outer Tube ...7

5-3 Assembly of the Outer Tube.......... 7

5-4 Assembly of the Handle................. 7

5-5 Adjustment of the Throttle Cable... 8

5-6 Cutting Attachment Shield Assembly .. 9

5-7 Trimmer Head Installation ............. 9

5-8 Mounting a Blade ........................ 10

6 Starting - Stopping -

Adjusting the Engine .................... 11

6-1 Filling the Fuel Tank .................... 11

6-2 Starting the Engine ...................... 11

6-3 Stopping the Engine .................... 12

6-4 Engine Idle Adjustment ................ 12

7 Unit Condition Check ...................... 13

8 Operation ........................................ 13

8-1 Engine Operating Speeds ........... 13

8-2 Standard Shoulder Strap ............. 13

8-3 Units equipped with trimmer heads

....................................................... 14

9 Blades ............................................. 14

9-1 Using a Blade .............................. 14

10 Recommended Cutting

Attachments .............................. 15

11 Maintenance ................................. 16

11-1 Daily Maintenance ..................... 16

11-2 10-Hour Maintenance ................ 16

11-3 10/15-Hour Maintenance ........... 16

11-4 50-Hour Maintenance ................ 16

11-5 Gearcase Lubrication ................ 17

11-6 Fuel Filter Maintenance ............. 18

11-7 Muffler Maintenance .................. 18

11-8 Long Term Storage .................... 18

12 Blade Sharpening ......................... 19

13 Troubleshooting Guide ................. 19

14

Declaration of Conformity ..................... 22

Contents

Throughout this manual are special

“attention statements” surrounded

by boxes and preceded by the triangular Attention Symbol.

1 Attention Statements

WARNING!

A statement preceded by the

triangular attention symbol and

the word “WARNING” contains information that should be acted

upon to prevent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to prevent mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

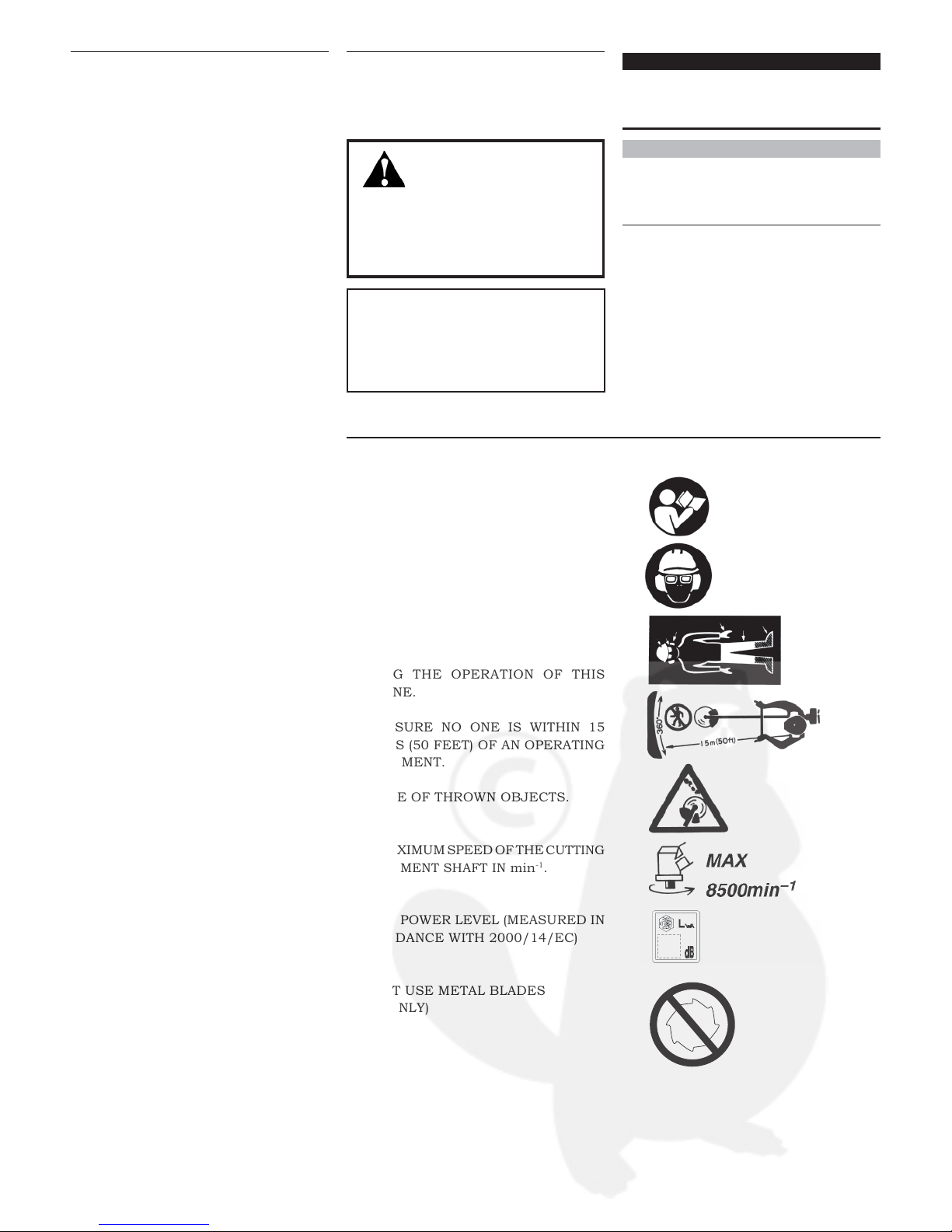

2 Warning Labels

Warning labels affixed to the

machine are as follows:

READ AND FOLLOW THE OPERATOR’S

MANUAL. FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY.

WEAR HEAD, EYE AND HEARING

PROTECTION DURING THE OPERATION

OF THIS MACHINE.

WEAR NONSLIP GLOVES, LONG

TROUSERS AND NONSKID BOOTS

DURING THE OPERATION OF THIS

MACHINE.

MAKE SURE NO ONE IS WITHIN 15

METERS (50 FEET) OF AN OPERATING

ATTACHMENT.

BEWARE OF THROWN OBJECTS.

THE MAXIMUM SPEED OF THE

CUTTING

ATTACHMENT SHAFT IN

min-1.

SOUND POWER LEVEL (MEASURED IN

ACCORDANCE WITH 2000/14/EC)

DO NOT USE METAL BLADES

(F220 ONLY)

PAGE

3

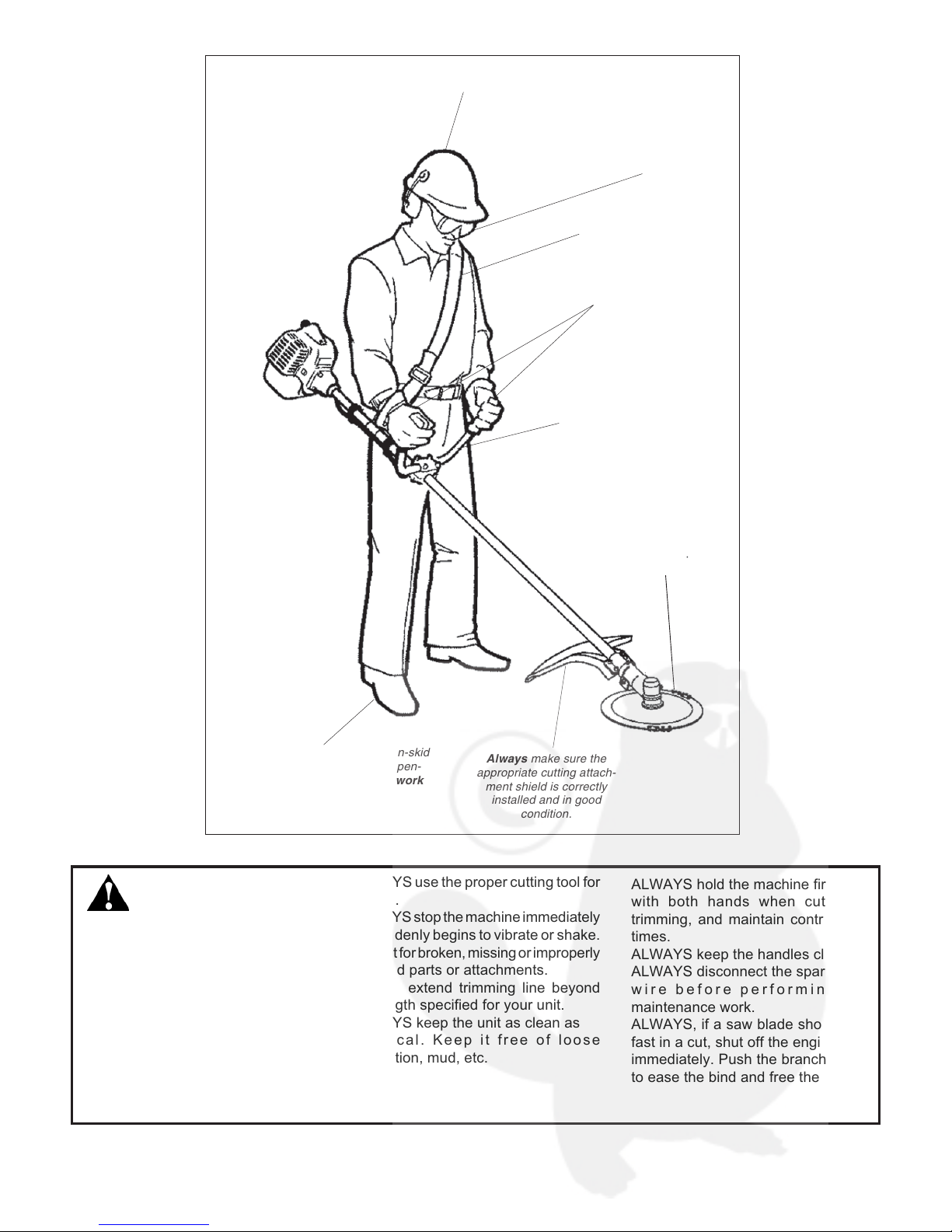

2-1 The Properly Equipped Operator

Always wear a harness

when operating a unit

equipped with a blade.

Always operate with

both hands firmly

gripping the unit.

Wear close-fitting clothing to

protect legs and arms. Gloves

offer added protection and are

strongly recommended. Do not

wear clothing or jewelry that

could get caught in machinery

or underbrush. Secure long

hair so that it is above

shoulder level.

NEVER wear shorts!

Wear hearing protection devices and a

broad-brimmed hat or helmet.

When operating with a blade,

make sure the handle is posi-

tioned to provide you with

maximum protection from

contacting the blade.

Keep away from the rotating

trimmer line or blade at all

times, and never lift a moving

attachment above waist-high.

Wear appropriate footwear (non-skid

boots or shoes): do not wear open-

toed shoes or sandals. Never work

barefooted!

Keep a proper

footing and do not

overreach.

Maintain your

balance at all times

during operation.

Always make sure the

appropriate cutting attach-

ment shield is correctly

installed and in good

condition.

WARNING!

Use Good Judgment

ALWAYS wear eye

protection to shield against thrown

objects.

NEVER run the engine when

transporting the machine.

NEVER run the engine indoors - make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

ALWAYS use the proper cutting tool for

the job.

ALWAYS stop the machine immediately

if it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly

installed parts or attachments.

NEVER extend trimming line beyond

the length specified for your unit.

ALWAYS keep the unit as clean as

practical. Keep it free of loose

vegetation, mud, etc.

ALWAYS hold the machine firmly

with both hands when cutting or

trimming, and maintain control at all

times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any

maintenance work.

ALWAYS, if a saw blade should bind

fast in a cut, shut off the engine

immediately. Push the branch or tree

to ease the bind and free the blade.

4

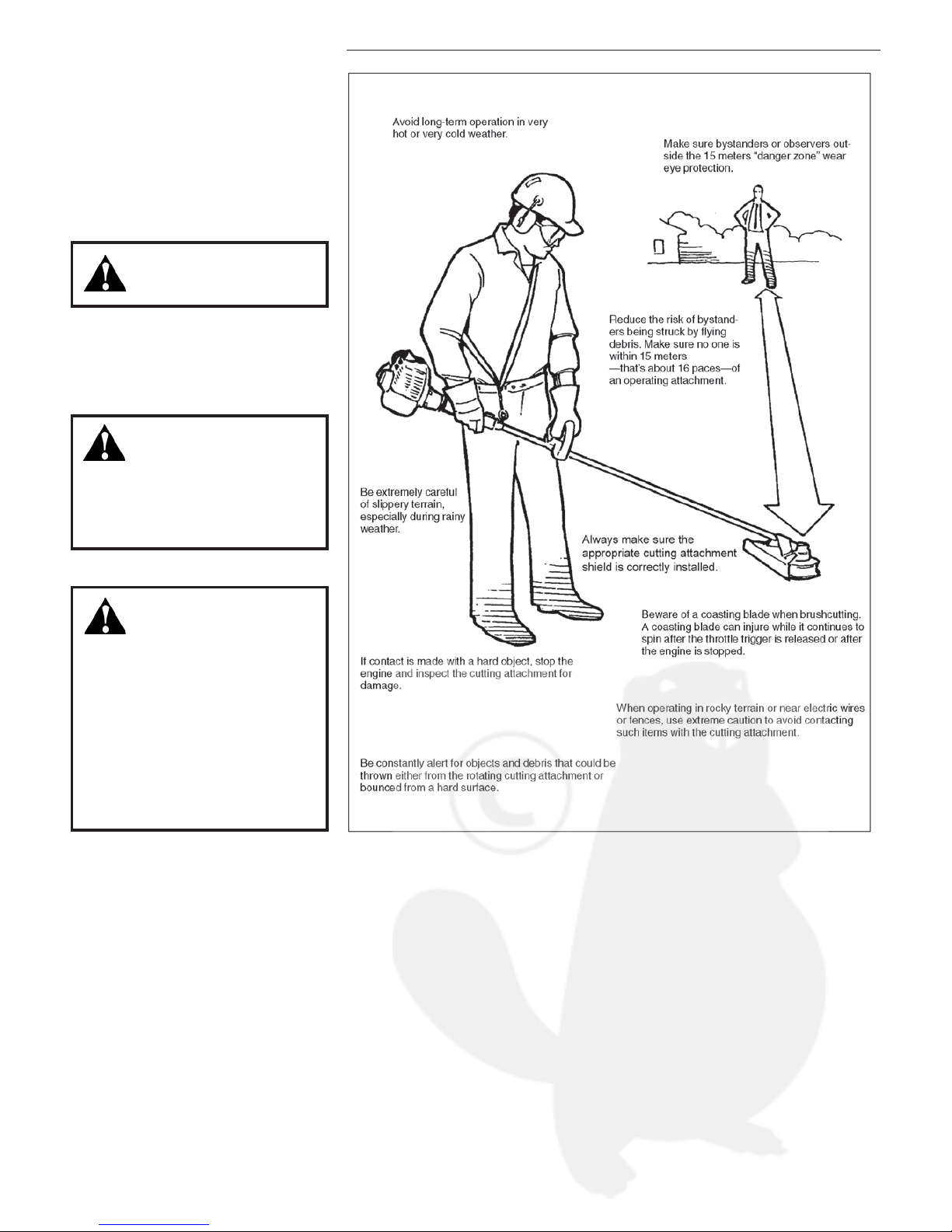

WARNING!

Never make unauthorized

attachment installations.

WARNING!

Never operate power

equipment of any kind if

you are tired or if you are under the

influence of alcohol, drugs, or any

other substance that could affect your

ability or judgement.

WARNING!

Minimize the Risk of Fire

NEVER smoke or light fires

near the trimmer or brushcutter.

ALWAYS stop the engine and let it

cool before refueling. Avoid overfilling

and wipe off any fuel that may have

spilled. ALWAYS move the unit to a

place well away from a fuel storage

area or other readily flammable

materials before starting the engine.

NEVER place flammable material

close to the engine muffler.

2-2 General Safety

Instructions

Work Safely

Trimmers and brushcutters run at

very high speeds and can do serious

damage or injury if they are misused

or abused. Never allow a person

without training or instruction to

operate your machine.

Stay Alert

You must be physically and mentally

fit to operate this machine safely.

2-3 Working Environment Warning

5

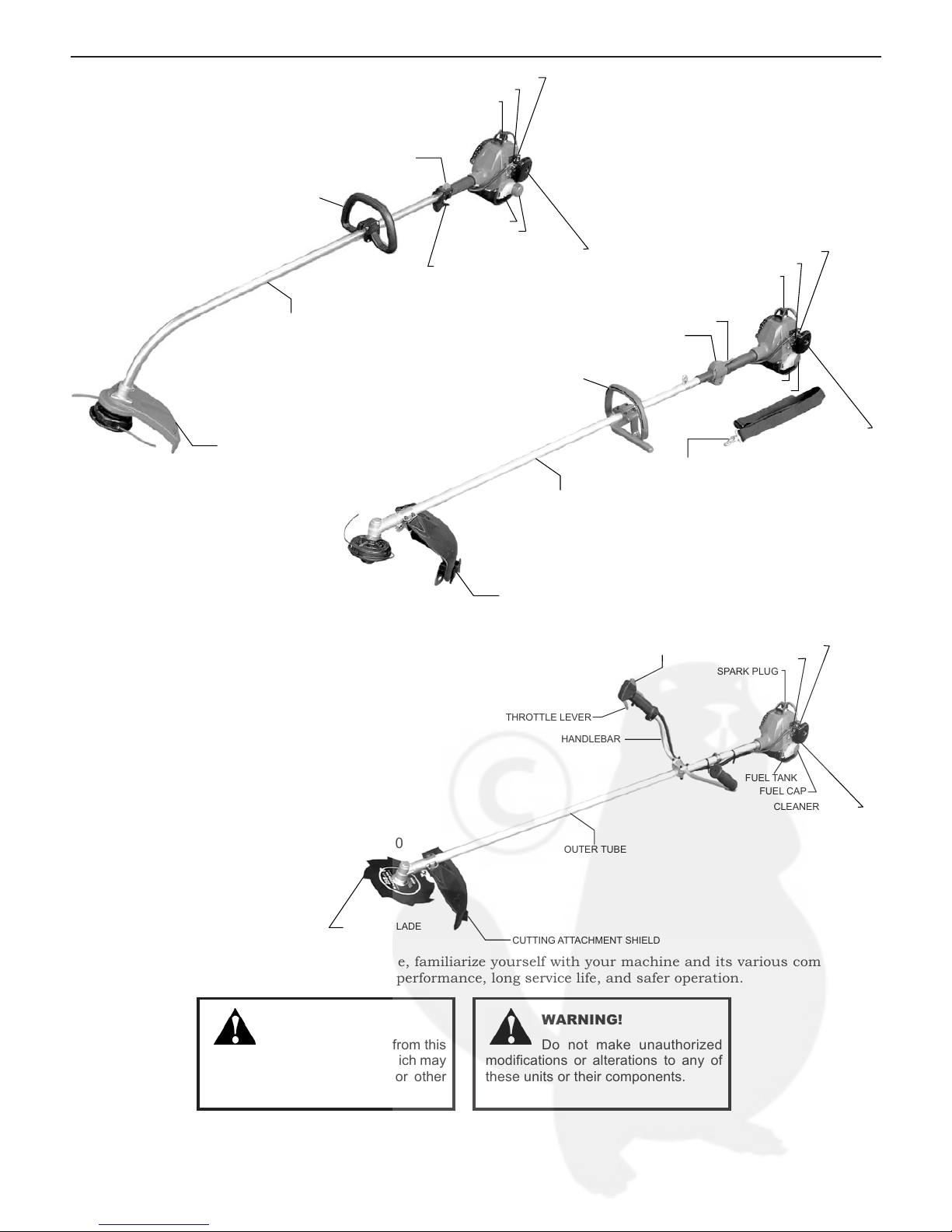

FRONT HANDLE

THROTTLE LEVER

ON-OFF SWITCH

SPARK PLUG

CHOKE LEVER

RECOIL STARTER

FUEL TANK

FUEL CAP

CLEANER COVER

OUTER TUBE

FRONT HANDLE

THROTTLE LEVER

ON-OFF SWITCH

SPARK PLUG

CHOKE LEVER

RECOIL STARTER

FUEL TANK

FUEL CAP

CLEANER COVER

CUTTING ATTACHMENT SHIELD

STRAP

OUTER TUBE

THROTTLE LEVER

ON-OFF SWITCH

SPARK PLUG

CHOKE LEVER

RECOIL STARTER

FUEL TANK

FUEL CAP

CLEANER COVER

CUTTING ATTACHMENT SHIELD

OUTER TUBE

HANDLEBAR

8-TOOTH BLADE

3 Product Description

WARNING!

The engine exhaust from this

product contains chemicals which may

cause cancer, birth defects, or other

reproductive harm.

WARNING!

Do not make unauthorized

modifications or alterations to any of

these units or their components.

Using the accompanying illustrations as a guide, familiarize yourself with your machine and its various components.

Understanding your machine helps ensure top performance, long service life, and safer operation.

F220

T 220

C 220

CUTTING ATTACHMENT SHIELD

6

F220/EC1 T220/EC1 C220/EC1

S220EC

2-cycle, vertical cylinder, air cooled

4.3kg 4.4kg 4.7kg

31mm x 28mm

21.1 cm

3

7,500 rpm (min-1)

0.65 kW

2,900 rpm (min

-1

)

9,750 (min

-1

) 10,000 (min-1) 10,000 (min-1)

50:1

430 cm

3

Walbro WYL, Diaphragm

Fully Electronic, transistor controlled

NGK BMR6A

Foam Element

Recoil Starter

Slide Switch

Loop Type Loop Type Bicycle Type

1,555x255x435 1,690x365x335 1,715x605x450

N/A 91 dB (A) 90dB (A)

N/A 102 dB (A) 102 dB (A)

N/A 2.8/2.0m/s2 1.6/2.0m/s

2

N/A 6.1/7.3m/s2 2.4/1.8m/s

2

95dB (A) 95dB (A) 95dB (A)

105dB (A) 106dB (A) 106dB (A)

2.6/2.1m/s2 3.2/1.7m/s2 1.4/2.2m/s

2

11.9/10.6/m/s2 6.7/5.1m/s2 4.2/4.6m/s

2

* Sound Pressure Level: in accordance with EN ISO 11806 and ISO 7917

* Sound Power Level: in accordance with EN ISO 11806 and ISO 10884

* Vibration Level: in accordance with EN ISO 11806 and ISO 7916

Note 1: 8-tooth blade equipped

Note 2: Trimmer head equipped

4 Technical Specifications

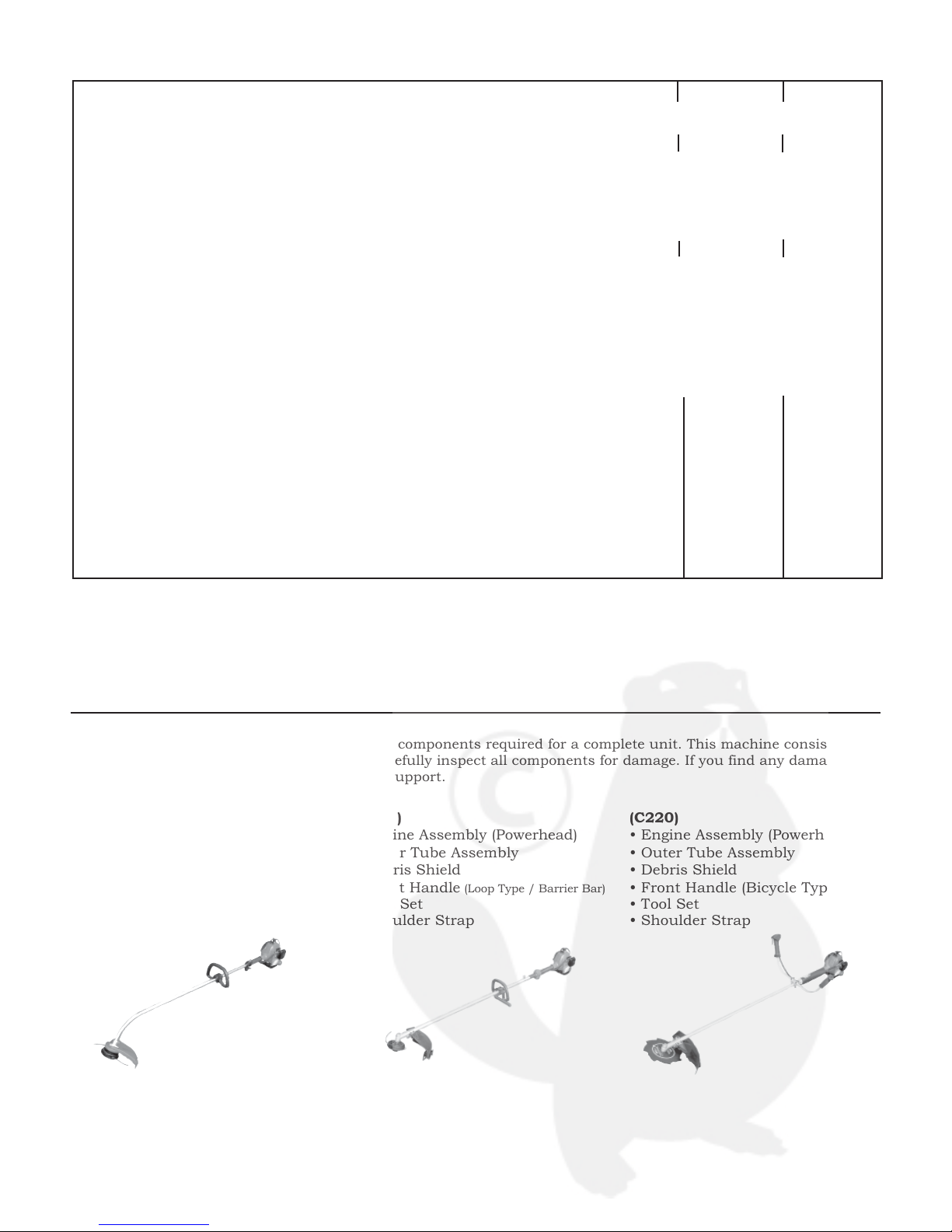

Before assembling, make sure you have all the components required for a complete unit. This machine consists of

the following components and accessories. Carefully inspect all components for damage. If you find any damaged or

missing items, ask your Shindaiwa dealer for support.

5 Assembly Procedure

5-1 Prior to Assembly

Model Name ......................................................................................

Engine Model ....................................................................................

Engine Type ......................................................................................

Dry Weight .......................................... Excluding cutting attachment

Bore x Stroke ....................................................................................

Displacement ....................................................................................

Engine Speed at Maximum Power Output ..........................................

Maximum Power Output ....................................................................

Engine Speed at Idling .......................................................................

Maximum Engine Speed ....................................................................

Fuel/Oil Ratio ...................................................................................

Fuel Tank Capacity ...........................................................................

Carburetor ........................................................................................

Ignition System .................................................................................

Spark Plug ........................................................................................

Air Cleaner ........................................................................................

Starting Method ................................................................................

Stopping Method ...............................................................................

Handle ..............................................................................................

Dimensions (LxWxH=mm) ..................................................................

Sound Pressure Level * (average data between at Idling and at Racing) note.1 .

Sound Power Level * (average data between at Idling and at Racing) note.1 .....

Vibration Level *, note.1 ............................................. Idling left/right

Vibration Level *, note.1 ........................................... Racing left/right

Sound Pressure Level * (average data between at Idling and at WOT) note.2 ...

Sound Power Level * (average data between at Idling and at WOT) note.2 .......

Vibration Level *, note.2 ............................................. Idling left/right

Vibration Level *, note 2 .............................................. WOT left/right

(F220) (T220) (C220)

• Engine Assembly (Powerhead) • Engine Assembly (Powerhead) • Engine Assembly (Powerhead)

• Outer Tube Assembly • Outer Tube Assembly • Outer Tube Assembly

• Debris Shield • Debris Shield • Debris Shield

• Front Handle (Loop Type) • Front Handle (Loop Type / Barrier Bar) • Front Handle (Bicycle Type)

• Tool Set • Tool Set • Tool Set

• Shoulder Strap • Shoulder Strap

7

(A) F220

(1) Position the front handle on the

outer pipe where the "Handle

Label" is placed.

(2) Press the handle on the outer

pipe gently so that the handle stays

as shown.

(3) Tighten two 30mm screws on

upper and two 45mm screws on

lower on the handle with nuts.

IMPORTANT!

The terms “left,” “left-hand,” and “LH”,

“right,” “right-hand,” and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation of this

product.

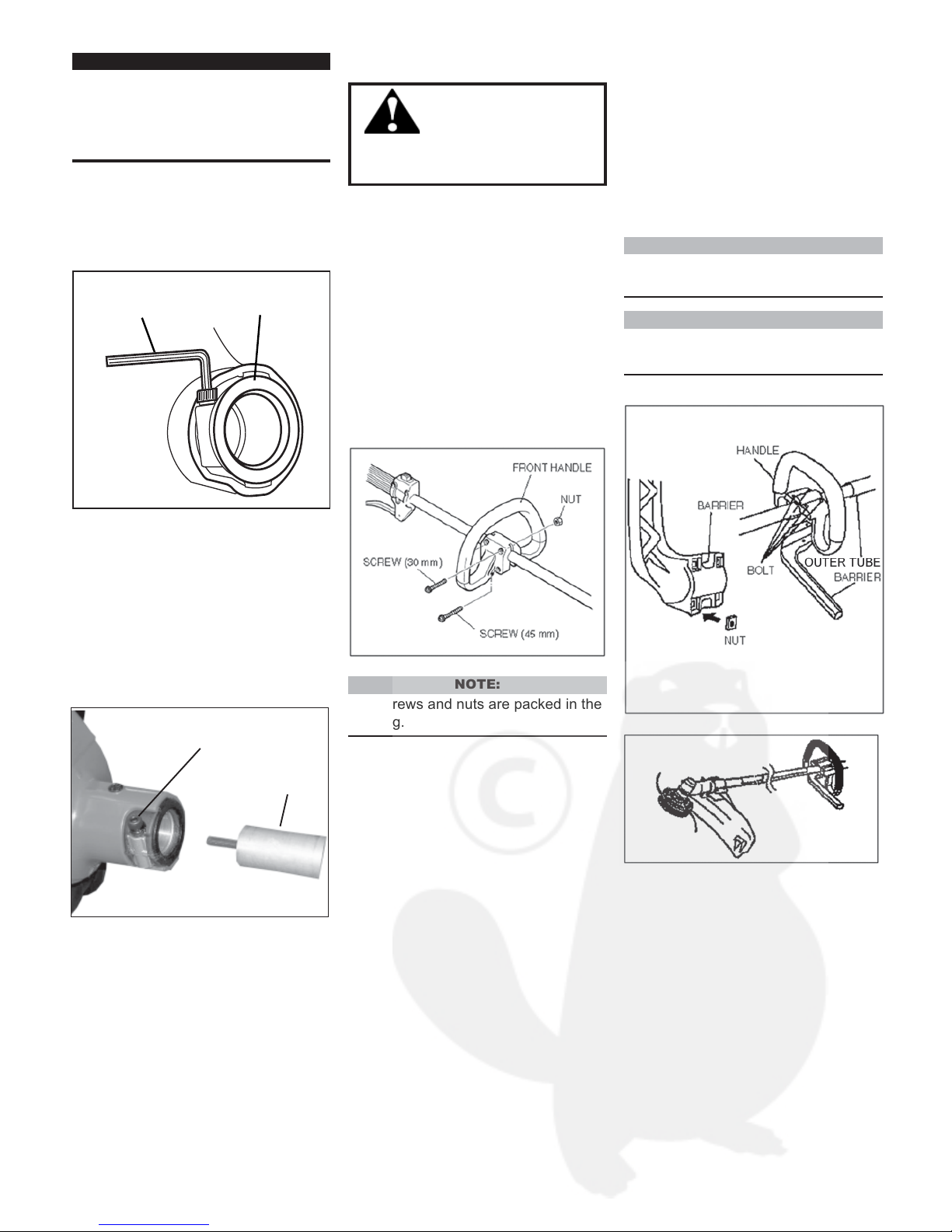

5-2 Before Assembling

the Outer Tube

(1) Using the hex wrench, Loosen the

joint bolt.

5-3 Assembly of the

Outer Tube

(1). Slip the outer tube into the

joint until the tube bottoms. The

outer tube or gear case shaft may

have to be rotated slightly for the

splines on the main shaft to fully

engage to the engine.

(2). Tighten the joint bolt securely

using the hex wrench.

WARNING!

NEVER operate this

machine without the front

handle. Operating without the front

handle may result in serious injury.

5-4 Assembly of the Handle

NOTE:

The screws and nuts are packed in the

tool bag.

(B) T220

(1) Put 4 square nuts in the frame

of barrier.

(2) Fit the handle and barrier over

the outer tube and tighten four

bolts.

NOTE:

Tighten four bolts in diagonal fashion

for protection of the handle.

NOTE:

Adjust the handle to the best position

for operator comfort.

OUTER

TUBE

JOINT BOLT

HEX

WRENCH

TUBE

CLAMP

8

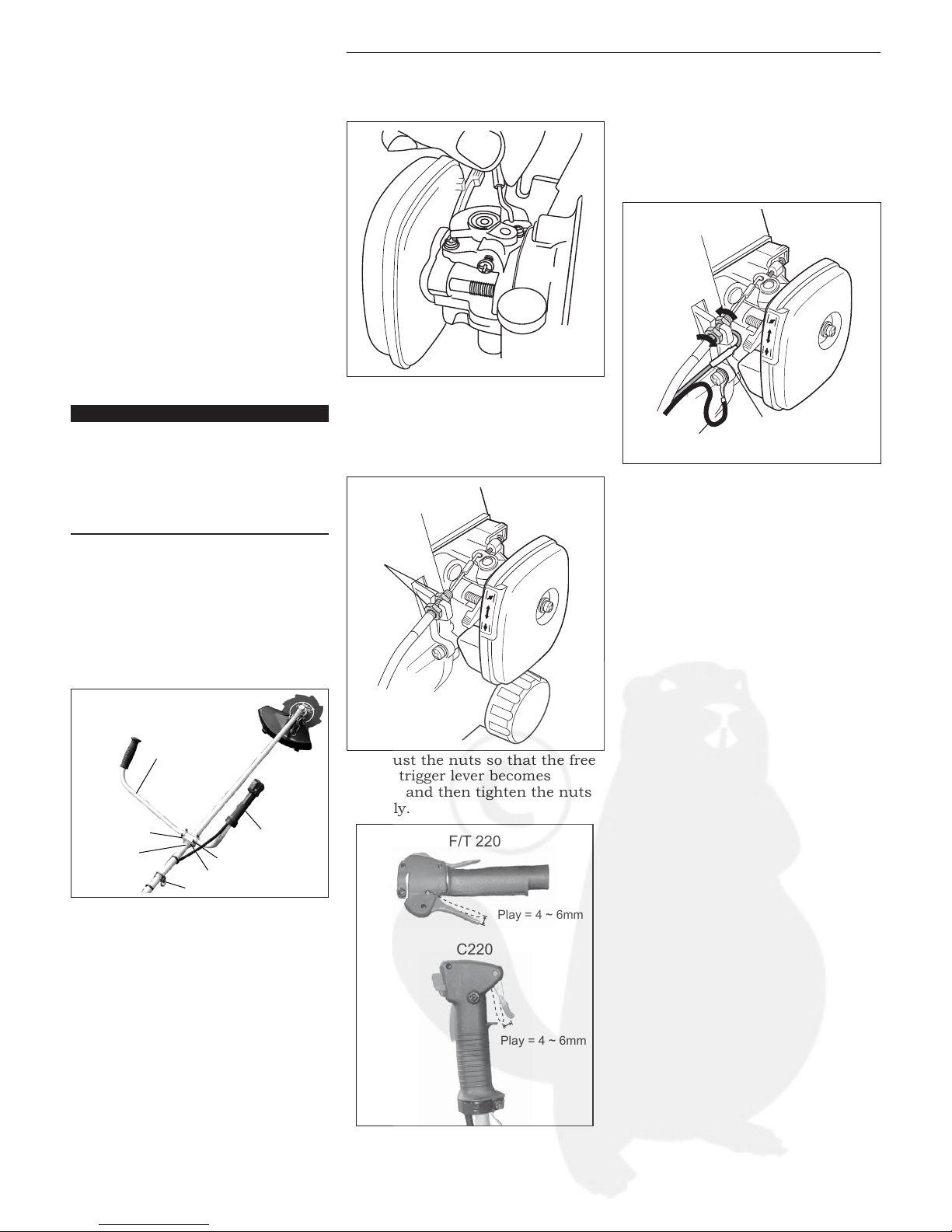

5-5 Throttle Cable Adjustment

(C) C220

(1) Position the handle over the

handle lable on the outer tube.

Make sure the throttle lever is on

the right-hand side of the outer

tube.

(2) Attach the handle mounting

bracket using the two socket-head

cap screws, washers, and lock

washers. At this time, ONLY finger

tighten the screws.

(3) Locate the handle about 5

inches ahead of the shoulder strap

hanger or at the best position for

operator comfort.

IMPORTANT!

Regardless of handlebar location, the aluminum collar must remain in position between the handlebar and the outer tube.

If the collar is omitted or is improperly installed, the handlebar bracket can not be

properly secured.

(4) Using the hex wrench, securely

tighten the two handlebar cap

screws.

(5) Route the ribbed throttle cable

tube along the handlebar and outer

tube. Install the protector sleeve on

the outer tube.

HANDLEBAR

HANDLE BRACKET

HANDLE LABEL

LOWER CAP

BOLT

THROTTLE GRIP

STRAP HANGER

C220

F/T 220

Play = 4 ~ 6mm

Play = 4 ~ 6mm

(1) Hook the end of the throttle

cable to the carburetor.

(2) Place the throttle cable in the

fan cover slot and tighten (finger

tight only) the nuts so that the

nuts are on either side of the slot.

(3) Adjust the nuts so that the free

play of trigger lever becomes

4~6mm and then tighten the nuts

securely.

(4) Fix the earth wire (black) to the

fan cover using the bolt below the fan

cover platform which holds the

throttle cable.

(5) Connect the switch and wire to

the red wire from the engine.

JAM NUTS

(BLACK)

GROUND WIRE

(RED)

IGNITION WIRE

Loading...

Loading...