Shindaiwa EB802 User Manual

EB802RT

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

EB802 BLOWER

EB802RT BLOWER

X750-015021

X750196-0201

1110Mrh 0820 ES

Printed in Japan

EB802

WARNING!

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with the contents. Always

wear eye and hearing protection when operating this unit.

Introduction

The shindaiwa EB802 has been

designed and built to deliver superior

performance and reliability without

compromise to quality, comfort, safety,

or durability.

The information contained in this manual

describes units available at the time of

production. While every attempt has been

made to give you the very latest information about your shindaiwa EB802 blower.

There may be some differences between

your EB802 blower and what is described

here.

WARNING!

The engine exhaust from

this unit contains chemicals known

to the State of California to cause

cancer, birth defects or other reproductive harm.

CAUTION!

This blower is equipped with a

spark-arresting muffl er! Never oper-

ate this unit without both the muffl er and spark arrester installed and

properly functioning!

ECHO, Inc. reserves the right to make

changes in production without prior notice,

and without obligation to make alterations

to units previously manufactured.

IMPORTANT!

Before using this unit, consult local regulations concerning noise restrictions

and hours of operation!

Contents

PAGE

Attention Statements ............................................. 2

General Safety Instructions ................................... 3

Unit Description ..................................................... 5

Specifi cations ........................................................ 6

Emission Control ................................................... 6

Assembly ............................................................... 7

Mixing Fuel ............................................................ 9

Filling the Fuel Tank ............................................. 10

Starting and Stopping ..........................................10

Using the Blower .................................................13

Maintenance ........................................................ 13

Storage ................................................................ 17

Troubleshooting Guide ........................................ 18

Warranty .............................................................. 21

PAGE

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit and also to protect you

and others from harm. These procedures are general guidelines only, and are not intended to replace any safety rules/laws that

may be in force in your area. If you have any questions regarding your EB802 blower, or if you do not understand something in

this manual, your shindaiwa dealer will be glad to assist you. For additional information, you may also contact shindaiwa at the

address printed on the back of this manual.

Attention Statements

Throughout this manual are special “Attention Statements”.

WARNING!

A statement preceded by the

triangular Attention Symbol and the

word “WARNING” indicates a potentially hazardous situation which, if not

avoided, COULD result in death or

serious injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to avoid

damaging the unit.

A statement preceded by the word

“IMPORTANT” is one that possesses

special signifi cance.

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

IMPORTANT!

NOTE:

Safety and operation labels

Read and follow this manual.

Failure to do so could result in

serious injury.

Wear eye and hearing protection at all times during the

operation of this unit.

2

Keep hair and loose clothing

clear of the air inlet.

This unit is intended for outdoor

use only and should be used

only in well ventilated areas.

WARNING: Surface can be

hot. Always wear gloves when

handling this unit.

HOT SURFACE

General Safety Instructions

Work Safely

Blowers operate at a very high speed and can do serious damage or injury if they are misused or abused. Never allow a person without training or instruction to operate your Blower!

Stay Alert

You must be physically and mentally fi t

to operate this unit safely.

WARNING!

Never make unauthorized

modifi cations or attachment instal-

lations. Never use attachments not

approved by shindaiwa for use on this

unit.

WARNING!

Never operate

power equipment of any kind if you

are tired or if you are under the infl u-

ence of alcohol, drugs, medication or

any other substance that could affect

your ability or judgement.

WARNING!

Use Good Judgment

ALWAYS wear eye protection that complies with ANSI Z 87.1 or your applicable national standard to shield against

thrown objects.

NEVER run the engine indoors! Make sure there is always good ventilation. Fumes from engine exhaust can cause serious injury or death.

ALWAYS stop the unit immediately if it suddenly begins to vibrate or shake. Inspect for broken, missing or improperly

installed parts.

ALWAYS keep the unit as clean as practical. Keep it free of loose vegetation, mud, etc.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug wire before performing any maintenance work.

ALWAYS turn off the engine before putting the unit down. When transporting the unit in a vehicle, properly secure it to

prevent the unit from over turning, fuel spillage and damage to the unit.

NEVER insert any foreign objects into the air intake or outlet opening of the blower while in operation.

NEVER smoke or light fi res near the

unit.

ALWAYS stop the engine and allow it

to cool before refuelling. Avoid overfi ll-

ing and wipe off any fuel that may have

spilled.

ALWAYS inspect the unit for fuel leaks

before each use. During each refi ll,

check that no fuel leaks from around

the fuel cap and/or fuel tank.

WARNING!

Minimize the Risk of Fire

If fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily fl ammable materials before

starting the engine.

NEVER place fl ammable material

close to the engine muffl er.

NEVER run the engine without the

spark arrester screen in place.

3

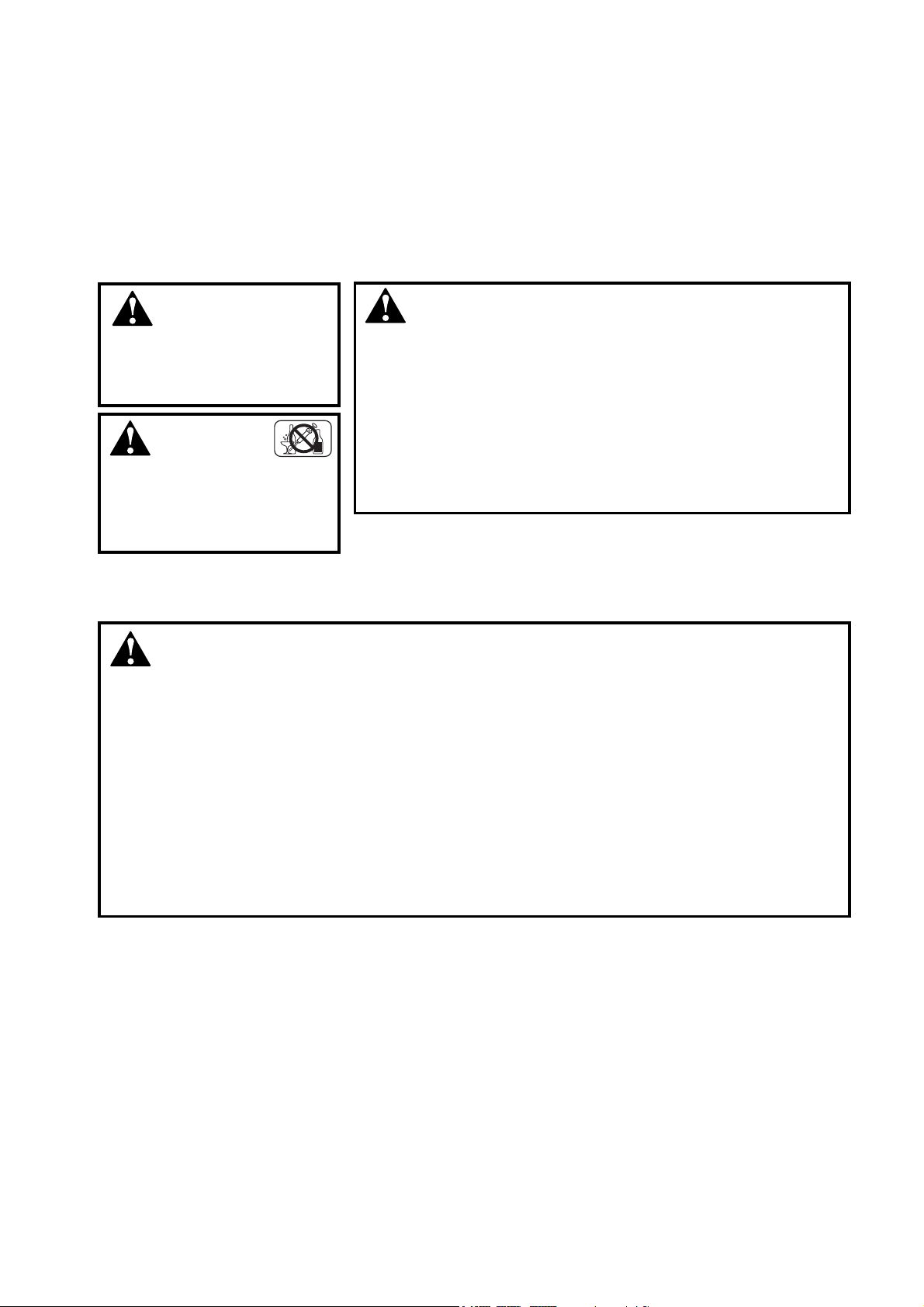

Safety Labels

WARNING!

Metal surfaces of crank-

case may be hot! Always wear

gloves when handling this unit.

IMPORTANT!

Safety and Operation Information

Labels: Make sure all information labels

are undamaged and readable. Immediately replace damaged or missing information labels. New labels are available

from your local authorized shindaiwa

dealer.

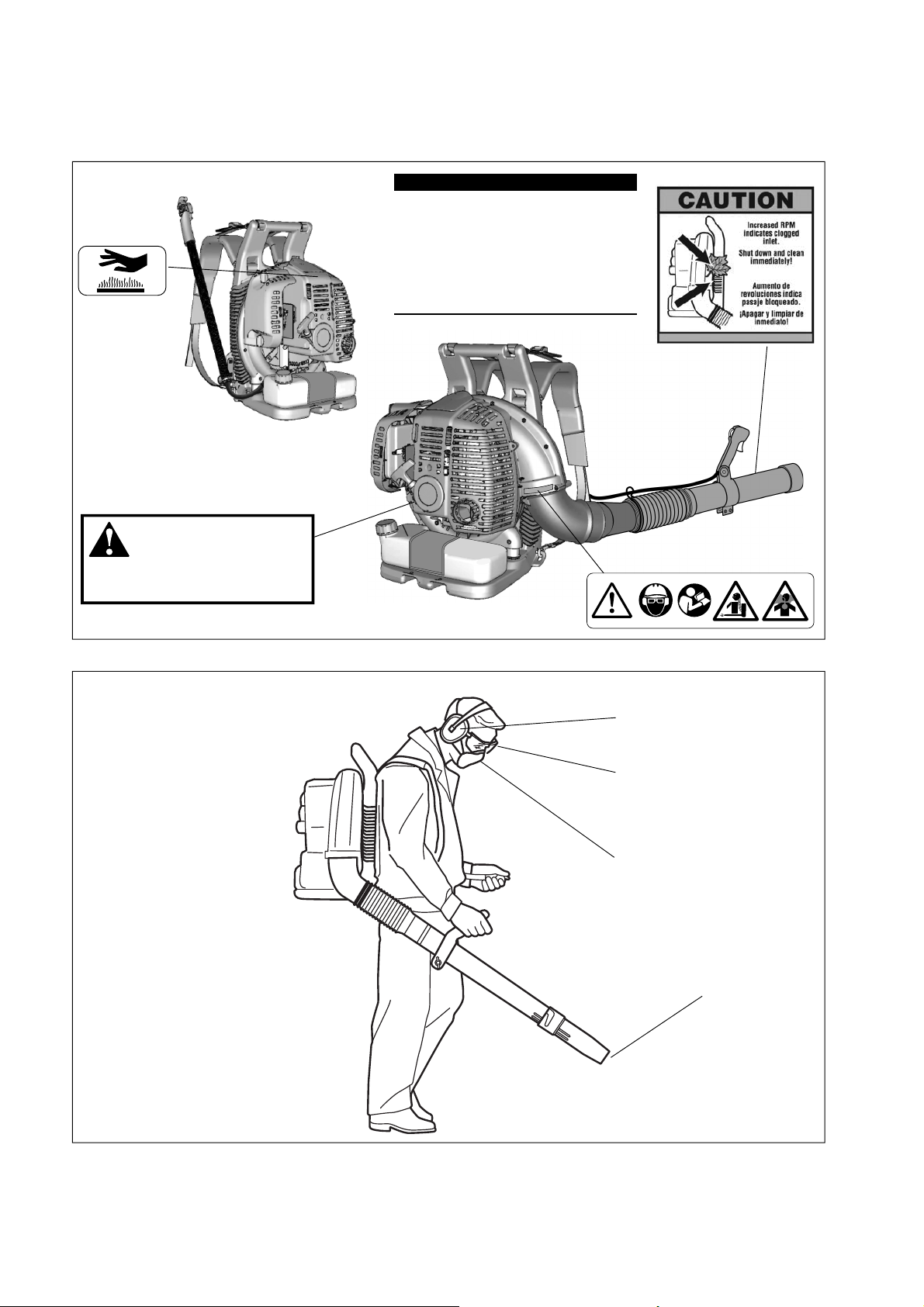

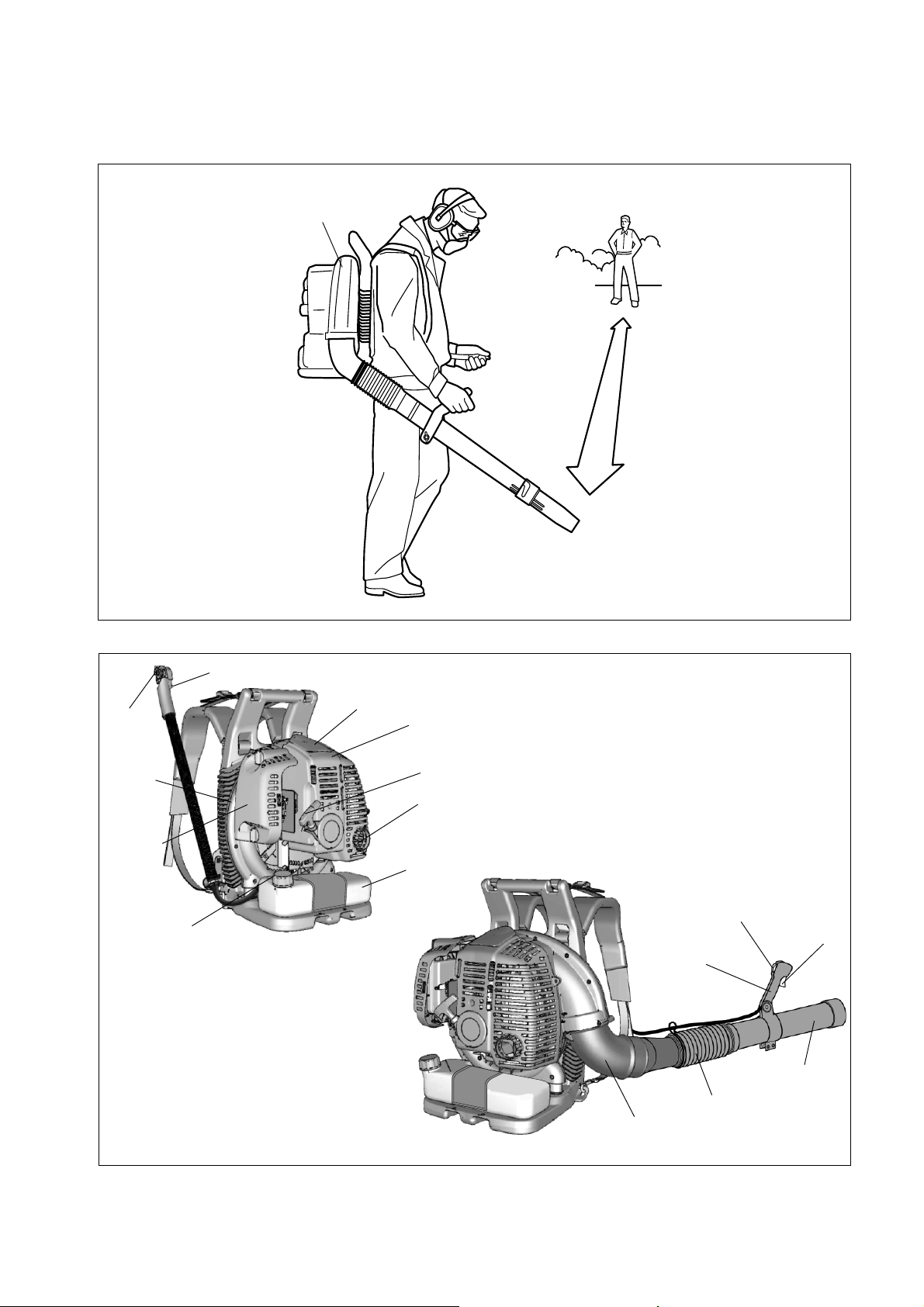

The Properly Equipped Operator

Wear close-fi tting clothing to protect legs and

arms. Gloves offer added protection and are

strongly recommended. Do not wear clothing

or jewelry that could get caught in machinery

or underbrush. Secure hair so it is above

shoulder level. NEVER wear shorts!

Keep a proper footing and

do not overreach. Maintain

your balance at all times

during operation.

Wear appropriate footwear (non-

skid boots or shoes): do not wear

open-toed shoes or sandals. Never

operate the unit while barefoot!

Wear hearing protection

when operating this unit.

Always wear eye protection

such as a face shield or

goggles while operating this

unit. Never operate the blower

when visibility is poor.

Wear a dust mask to reduce

the risk of inhalation injuries.

Always be aware of the strength

and direction of the blower

discharge stream. Never direct

the blower discharge stream

toward people or animals!

Figure 1

4

Be Aware of the Working Environment

Debris sometimes collects on the

blower intake. Never clean out debris

from the blower while the engine is

running!

Never operate the blower

if any component parts are

damaged, loose, or missing!

Be extremely careful of slippery

terrain, especially during rainy

weather. Never operate this

blower on a roof, ledge or ladder.

Figure 2

Be constantly alert

for objects and

debris that could be

thrown from the air

blast and bounced

from a hard surface.

15

Make sure bystanders or

observers outside the 15m

(50-foot) “danger zone” wear

eye protection.

15 METERS

Avoid long-term operation in

very hot or very cold weather.

Reduce the risk of

m

bystanders being struck

by fl ying debris. Make sure

no one is within 15 meters

(50 feet)—that’s about 16

paces—of an operating

blower.

Do not direct the air blast

towards bystanders. The

high air fl ow could blow

small objects at great

speed causing possible

eye injury.

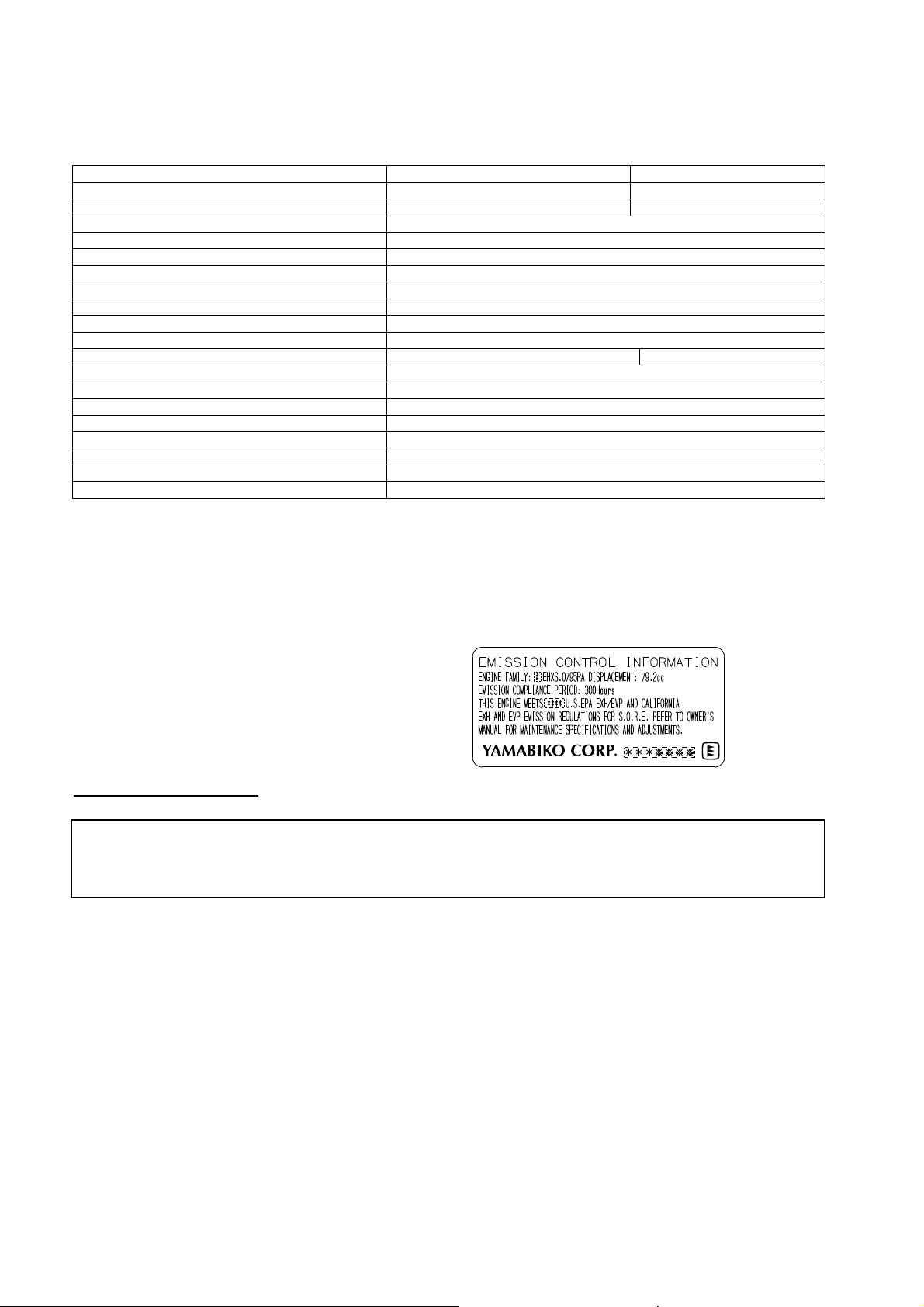

Unit Description

Stop Switch

Throttle

Lever

Volute

Case

Air Cleaner

Cover

Fuel Filler

Cap

EB802

Spark Plug

Engine

Cover

Starter

Handle

Exhaust Outlet

Fuel Tank

EB802RT

Throttle

Assembly

Stop Switch

Throttle

Lever

Swivel Tube

Figure 3

90° Discharge Tube

Flexible

Tube

5

Specifi cations

Model EB802 EB802RT

Dry Weight (without Blower Tubes) 10.5 kg 10.4 kg

Dimensions (LxWxH) 372 x 458 x 600 mm 372 x 457 x 545 mm

Engine Type 2 cycle air-cooled gasoline engine, vertical-cylinder

Bore & Stroke 49 x 42 mm (1.93 x 1.65 inches)

Displacement 79.2 cc (4.83 cu. inches)

Fuel/Oil Ratio 50:1 with *ISO-L-EGD or JASO FD class engine oil

Carburetor Diaphragm Type

Ignition CDI (Capacitor Discharge Ignition)

Spark Plug NGK BPMR8Y

Starting Recoil Starter

Stopping Push Button Switch (Grounding type) Slide Switch (Grounding type)

Fuel Tank Capacity 2.0 liters (67.6 oz)

Exhaust Spark Arrester Muffl er

Air Filtration Dry Element with pre-fi lter

Air Speed 191 mph / 85.4 m/sec

Air Volume 730 cfm / 18.7 m

Idle Speed 2,000 RPM

W.O.T.

Speed w/std. nozzle 7,500 RPM

Sound Level 76 dB(A) @ W.O.T and 50 feet per ANSI B175.2

Specifi cations are subject to change without notice.

3

/min

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modifi cation and 3-way Catalyst) and for the

fuel tank the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission

may be applicable to California models only.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by en-

gine FAMILY).

PRODUCT EMISSION DURABILITY

(EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

6

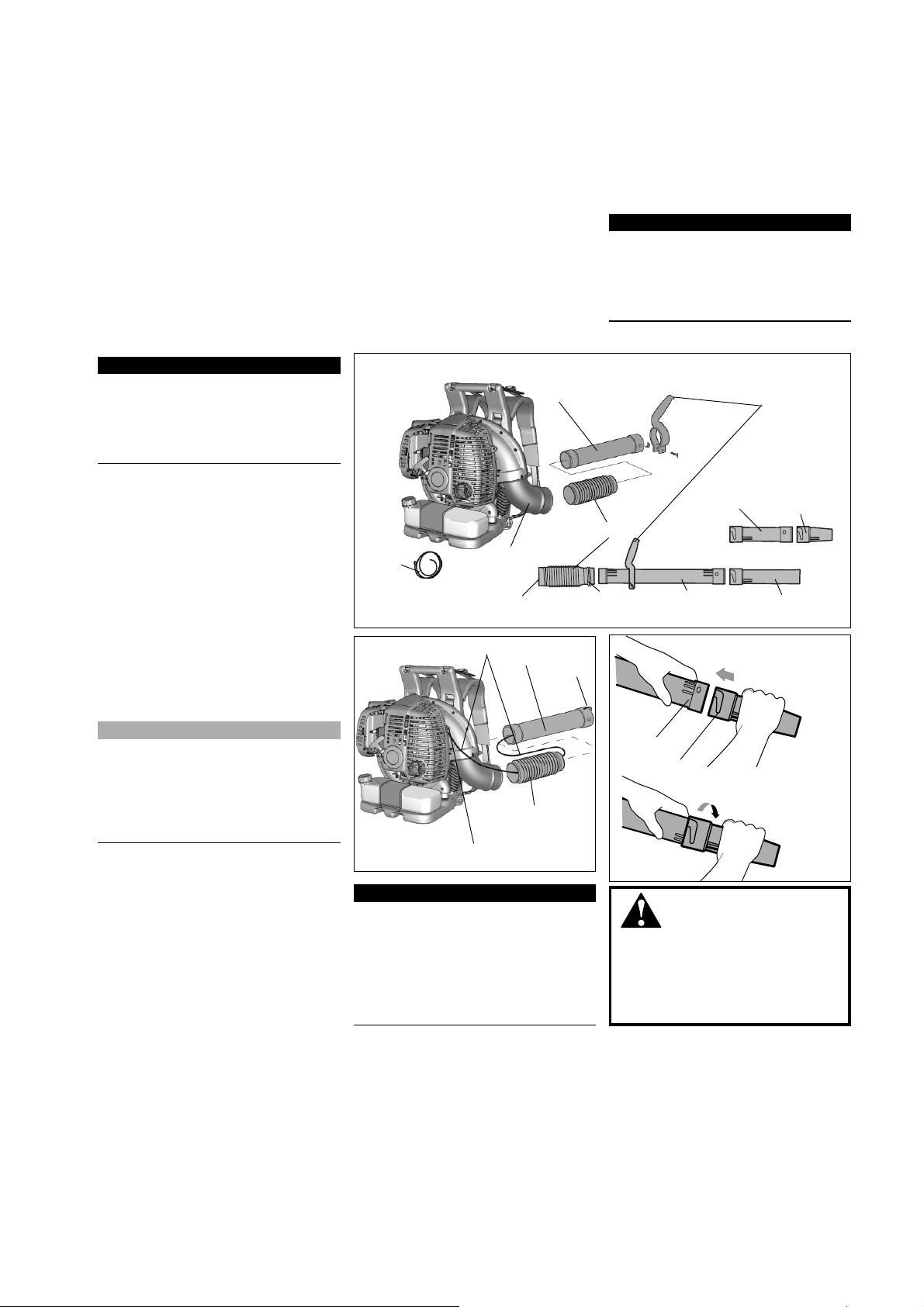

Assembly

Prior to Assembly

Before assembling the blower, make

sure you have all required components.

■ Power unit and blower assembly.

■ Flexible tube, swivel tube, two noz-

zles and straight tube.

■ Handgrip.

Assembling the EB802 Blower

IMPORTANT!

This unit is equipped with a static

discharge reduction wire. This wire

helps direct static buildup into the air

stream reducing the felt amount to the

operator.

1. Place the blower upright on the

ground or a sturdy work surface and

note parts orientation as shown in

Figure 4.

2. Remove static wire from package

and fi x eyelet to right hand engine

cover screw. See Figure 5.

3. Turn the discharge tube out to a

right angle and slip anti-static wire

through the 102 mm clamp and fl ex-

ible tube.

4. Slip the fl exible tube over the end of

the 90° discharge tube, and secure

with the 102 mm clamp.

■ Two tube clamps (102 and 89 mm).

■ This Owner’s/Operator’s Manual

and a tool kit containing a tool

bag, 4 mm hex wrench, 5 mm hex

wrench and a combination spark

plug wrench/screwdriver.

■ Lead wire assembly (anti-static).

Swivel

Tube

Anti-Static

Wire

Figure 4

90° Discharge Tube

102 mm Clamp

Static Wire

Swivel

Tube

Fold wire

Carefully inspect all components for

damage.

IMPORTANT!

The terms “left”, “left-hand”, “LH”;

“right”, “right-hand”, and “RH”; “front”

and “rear” refer to directions as

viewed by the operator during normal

operation.

StraightTube

Flexible Tube

89 mm Clamp

Swivel Tube

Standard Nozzle

Align the lock pins with the

lock slots and push the

Hand Grip

Optional Nozzle

(ø65 mm)

(ø74 mm)

tubes together

NOTE:

Check to make sure that the 90° discharge tube swivels freely. If any binding is present, loosen 102mm clamp

and pull wire towards engine to get

more slack and recheck for free

movement.

5. Insert the static wire through the

swivel tube, then install and tighten

the 89 mm clamp over the rotating

band on the swivel tube.

6. Slide the handgrip over the swivel

tube and secure with the bolt and

wingnut.

7. Fold the end of the static wire back

over the connection of the swivel

tube. See Figure 5.

8. Grasp the straight tube, and push

the straight tube over the swivel

tube locking pins securing the static

wire. See Figure 6.

9. Lock the straight tube to the swivel

tube by rotating the straight tube

noting the alignment marks. See

Figure 6.

Flexible Tube

Static Wire

Figure 5

Connector

IMPORTANT!

Blower tube installation affects blower

performance! Make sure the tubes and

straight tube are correctly assembled

per above, and that all connections are

tight. Blower tubes may come apart

during use unless tubes are aligned

and locked into place.

10. Grasp the nozzle, and push the

nozzle over the straight tube locking

pins. See Figure 6.

11. Lock the nozzle to the straight tube

by rotating the nozzle noting the

alignment marks. See Figure 6.

Lock Pin

Lock Slot

Rotate clockwise to lock making

sure the 3 lines are aligned on

both tubes.

Figure 6

WARNING!

Danger from rotating impel-

ler! Stop the engine before installing

of removing the blower tubes! Never

perform any maintenance or assembly procedures on this unit while the

engine is running!

12. Adjust handgrip for best operator

comfort, and tighten

securely.

7

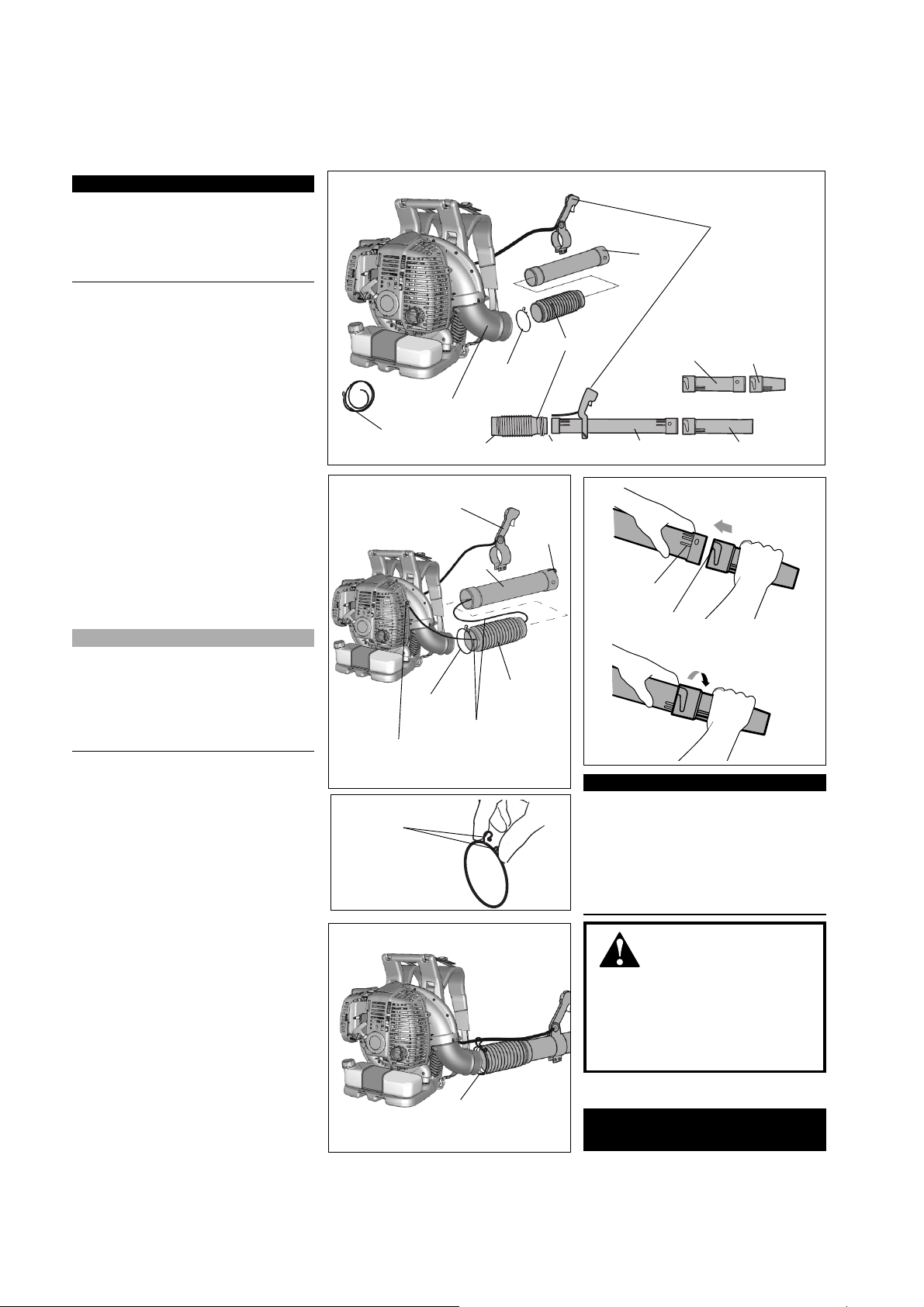

Assembly (continued)

Assembling the EB802RT Blower

IMPORTANT!

This unit is equipped with a static

discharge reduction wire. This wire

helps direct static buildup into the air

stream reducing the felt amount to the

operator.

1. Place the blower upright on the

ground or a sturdy work surface and

note parts orientation as shown in

Figure 7.

2. Remove static wire from package

and fi x eyelet to right hand engine

cover screw. See Figure 8.

3. Turn the discharge tube out to a

right angle and slip anti-static wire

through the 102mm clamp and fl ex-

ible tube.

4. Install throttle cable holder just forward of the 102 mm clamp, pinching

loops together to fi t over end of fl ex-

ible tube. See Figures 10A and 10B.

5. Slip the fl exible tube over the end of

the 90° discharge tube, and secure

with the 102 mm clamp.

6. Slide the throttle assembly over the

swivel tube. Do not tighten clamp at

this time.

NOTE:

Check to make sure that the 90° discharge tube swivels freely. If any

binding is present, loosen 102 mm

clamp and pull wire towards engine to

get more slack and recheck for free

movement.

7. Insert the static wire through the

swivel tube, then install and tighten

the 89mm clamp over the rotating

band on the swivel tube.

8. Fold the end of the static wire back

over the connection of the swivel

tube. See Figure 8.

9. Grasp the straight tube, and push

the straight tube over the swivel

tube locking pins securing the static

wire. See Figure 9.

10. Lock the straight tube to the swivel

tube by rotating the straight tube

noting the alignment marks. See

Figure 9.

11. Grasp the nozzle, and push the

nozzle over the straight tube locking

pins. See Figure 9.

12. Lock the nozzle to the straight tube

by rotating the nozzle noting the

alignment marks. See Figure 9.

13. Adjust throttle assembly for best

operator comfort, and tighten two

socket-head screws securely.

Figure 7

Static Wire

Connector

Figure 8

Loops

Figure 10A

Figure 10B

Anti-Static

Wire

Assembly

Throttle Cable

Throttle Cable

90° Discharge

Tube

102mm

Clamp

Throttle

Swivel

Tube

Holder

Static Wire

Throttle Cable Holder

Flexible Tube

Holder

89mm Clamp

Fold

Wire

Flexible Tube

Throttle

Assembly

Optional Nozzle

(ø65 mm)

Standard Nozzle

(ø74 mm)

Align the lock pins with the

lock slots, and push the

tubes together.

Rotate clockwise to lock

making sure the 3 lines are

aligned on both tubes.

Swivel Tube

Figure 9

Swivel

Tube

Straight Tube

Lock Pin

Lock Slot

IMPORTANT!

Blower tube installation affects blower

performance! Make sure the tubes and

nozzle are correctly assembled per

above, and that all connections are

tight. Blower tubes may come apart during use unless tubes are aligned and

locked into place.

WARNING!

Danger from rotating

impeller!

Stop the engine before installing or

removing the blower tubes! Never

perform any maintenance or assembly procedures on this unit while the

engine is running!

The blower should now be ready for

use.

8

Loading...

Loading...