Shindaiwa EB3410-EVC, EB2510, 68907-94311, EB2510-EVC, EB3410 User Manual

English ..........................1

Español ................... SP_1

Francais .................. FR_1

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

EB2510/EVC BLOWER

EB3410/EVC BLOWER

EB2510

WARNING!

EB3410

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with the

contents. Always wear eye and hearing protection

when operating this unit.

Part Number EVC_68907-94311 Rev. 3/07

2

Introduction

WARNING!

The engine exhaust from this unit contains chemicals known to the state of

California to cause cancer, birth

defects or other reproductive harm.

CAUTION!

This blower is equipped with a spark-

arresting mufer! Never operate this

unit without both the mufer and

spark arrester installed and properly

functioning!

IMPORTANT!

Before using this unit, consult local

regulations concerning noise restrictions

and hours of operation!

The Shindaiwa EB2510/EB3410 has

been designed and built to deliver superior performance and reliability without

compromise to quality, comfort, safety, or

durability.

The information contained in this manual describes units available at the time of

production. While every attempt has been

made to give you the very latest information about your Shindaiwa EB2510/EB3410

blower, there may be some differences

between your EB2510/EB3410 blower

and what is described here. Shindaiwa

Inc. reserves the right to make changes in

production without prior notice, and without obligation to make alterations to units

previously manufactured.

Attention Statements

Throughout this manual are special

“Attention Statements”.

WARNING!

A statement preceded by the triangular

Attention Symbol and the word “WARN-

ING” indicates a potentially hazardous

situation which, if not avoided, COULD

result in death or serious injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to avoid

damaging the unit.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Read and follow this manual.

Failure to do so could result in

serious injury.

Wear eye and hearing

protection at all times during

the operation of this unit.

This unit is intended for

outdoor use only and should

be used only in well ventilated

areas.

WARNING! Surface can be

hot. Always wear gloves when

handling this unit.

IMPORTANT!

The operational procedures described in

this manual are intended to help you get

the most from this unit and also to protect

you and others from harm. These

procedures are general guidelines only,

and are not intended to replace any

safety rules/laws that may be in force in

your area.

If you have any questions regarding your

EB2510/EB3410 blower, or if you do not

understand something in this manual, your

Shindaiwa dealer will be glad to assist

you. For additional information, you may

also contact Shindaiwa Inc. at the address

printed on the back of this manual.

Contents

PAGE

Attention Statements .................................. 2

General Safety Instructions ....................... 3

Unit Description .......................................... 5

Specifications ............................................... 5

Assembling the Blower .............................. 6

Mixing Fuel ................................................. 7

Filling the Fuel Tank .................................. 7

Starting and Stopping the Blower ............. 7

Adjusting Engine Idle Speed ...................... 8

Throttle Control............................................9

Using the Blower ........................................ 9

Maintenance .............................................. 10

Spark Arrester Maintenance ................... 12

Long Term Storage ................................... 12

Troubleshooting Guide ............................ 13

Emission System Warranty ...................... 16

General Safety Instructions

Work Safely

Blowers operate at a very high speed and

can do serious damage or injury if they are

misused or abused. Never allow a person

without training or instruction to operate

your EB2510/EB3410 Blower!

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never make unauthorized modica-

tions or attachment installations. Never

use attachments not approved by

Shindaiwa for use on this unit.

WARNING!

Never operate power

equipment of any kind

if you are tired or if you are under the

inuence of alcohol, drugs, medication

or any other substance that could affect

your ability or judgement.

WARNING!

Use Good Judgment

ALWAYS wear eye protection that

complies with ANSI Z 87.1 or your

applicable national standard to shield

against thrown objects.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS stop the unit immediately

if it suddenly begins to vibrate or

shake. Inspect for broken, missing or

improperly installed parts.

ALWAYS keep the unit as clean as

practical. Keep it free of loose

vegetation, mud, etc.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any maintenance work.

ALWAYS turn off the engine before

putting the unit down. When transporting the unit in a vehicle, properly

secure it to prevent the unit from over

turning, fuel spillage and damage to

the unit.

NEVER insert any foreign objects into

the air intake or outlet opening of the

blower while in operation.

WARNING!

Minimize the Risk of Fire

NEVER smoke or light res near

the unit.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid overlling and wipe off any fuel that may have

spilled.

ALWAYS inspect the unit for fuel leaks

before each use. During each rell,

check that no fuel leaks from around

the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily ammable materials before

starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER run the engine without the

spark arrester screen in place.

3

4

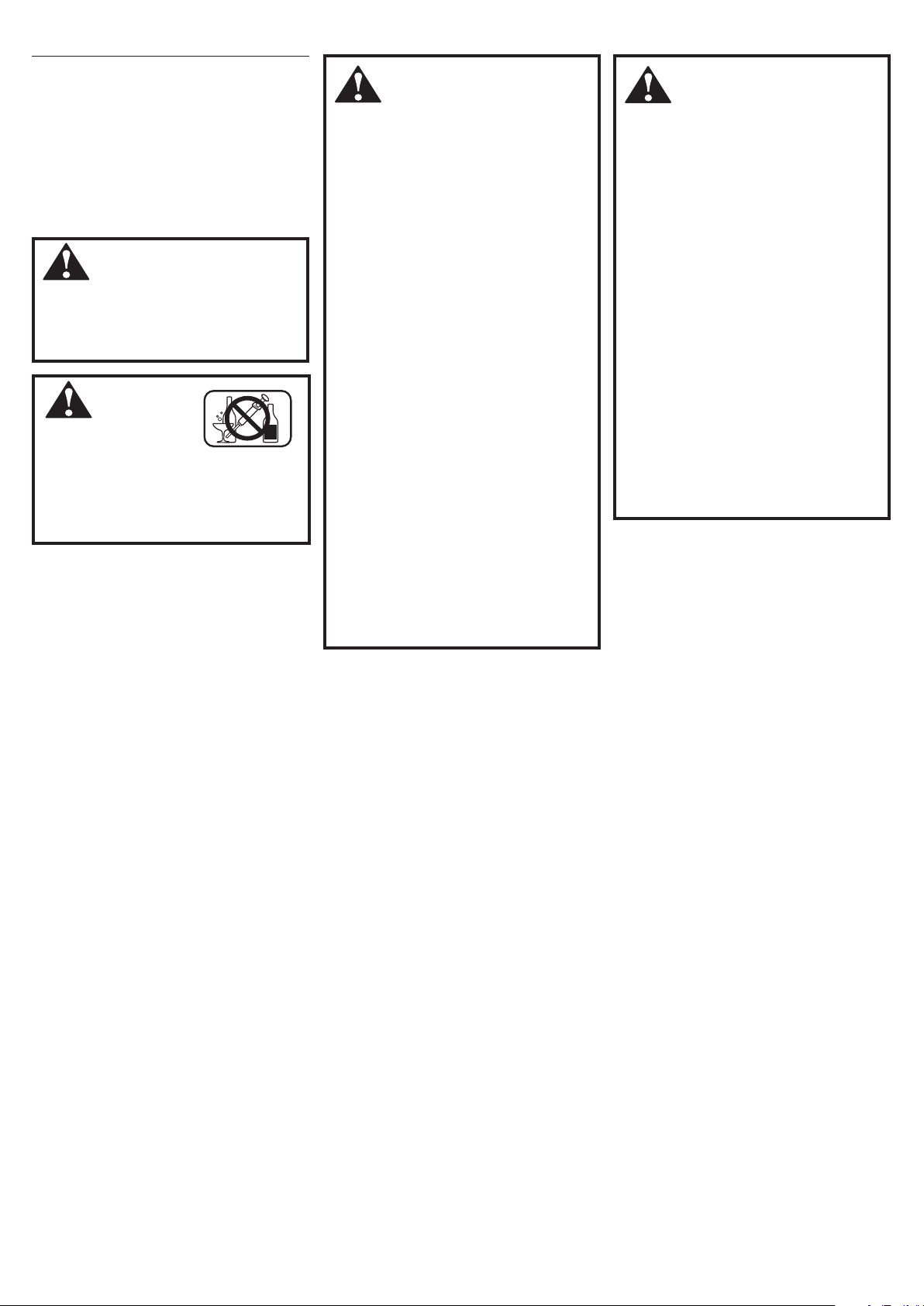

The Properly Equipped Operator

Always wear eye protection such as a face shield

or goggles while operating this unit. Never operate

the blower when visibility is poor.

Wear a dust mask to reduce

the risk of inhalation injuries.

Wear close-tting clothing to protect legs and arms.

Gloves offer added protection and are strongly recommended.

Do not wear clothing or jewelry that could get caught in machinery

or underbrush. Secure hair so it is above shoulder level.

NEVER wear shorts!

Always be aware of the strength

and direction of the blower

discharge stream. Never direct

the blower discharge stream

toward people or animals!

Wear hearing protection

when operating this unit.

Keep a proper footing and

do not overreach. Maintain

your balance at all times

during operation.

Wear appropriate footwear

such as non-skid boots or shoes.

Do not wear open-toed shoes

or sandals and never operate

the unit while barefoot!

Figure 1

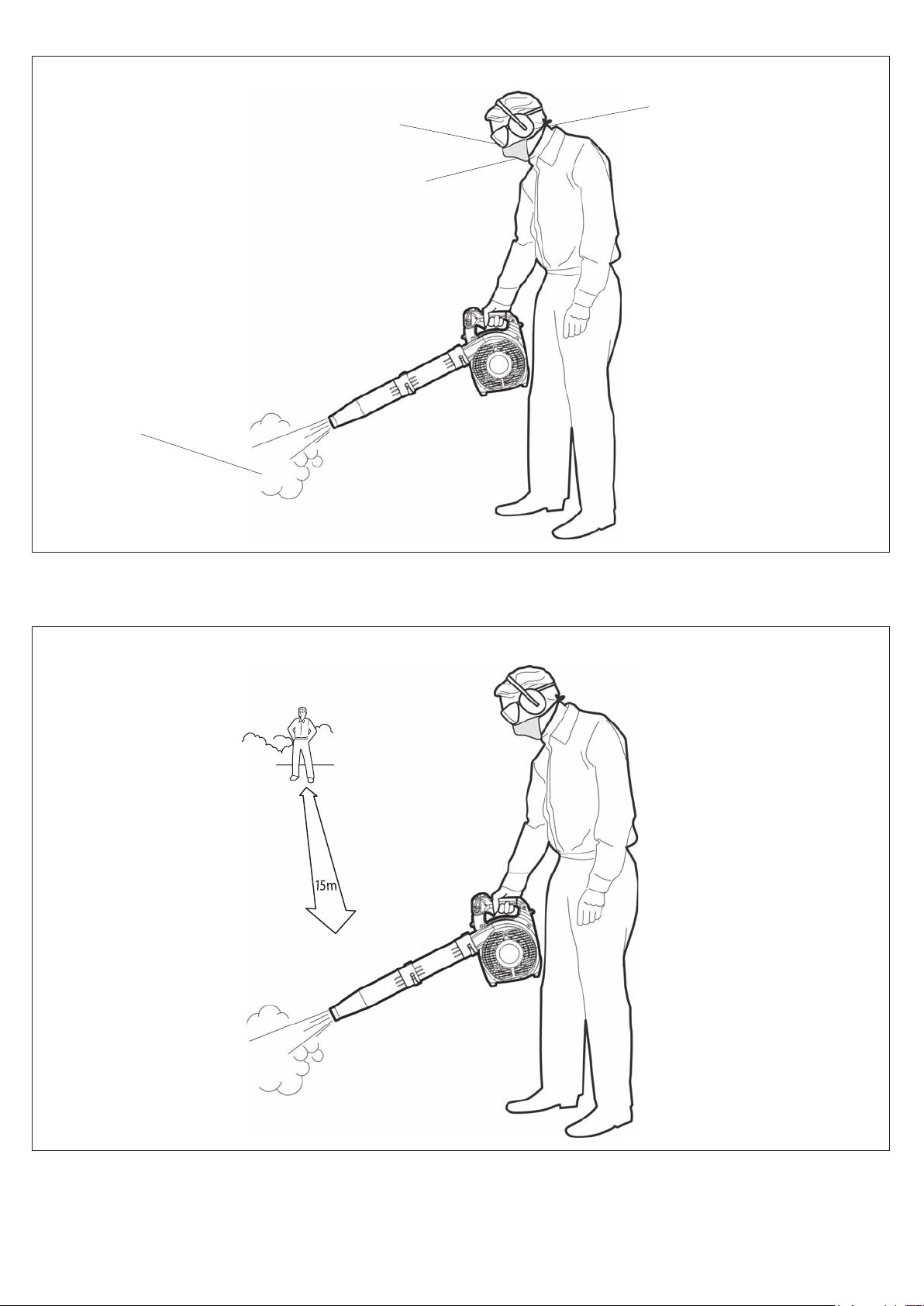

Be Aware of the Working Environment

Reduce the risk of bystanders

being struck by ying debris.

Make sure no one is within

15 m (50 feet)—that’s

about 16 paces—of an

operating blower.

Make sure bystanders

15

METERS

Do not direct the air blast

towards bystanders. The high

air ow could blow small

objects at great speed

causing possible eye injury.

or observers outside the

15 m (50 feet) “danger zone”

wear eye protection.

Avoid long-term

operation in very hot

or very cold weather.

Never operate the

blower if any

component parts

are damaged,

loose, or missing!

Be constantly alert

for objects and debris that

could be thrown from

the air blast and bounced

from a hard surface.

Figure 2

Be extremely careful of

slippery terrain, especially

during rainy weather.

Never operate this blower

on a roof, ledge or ladder.

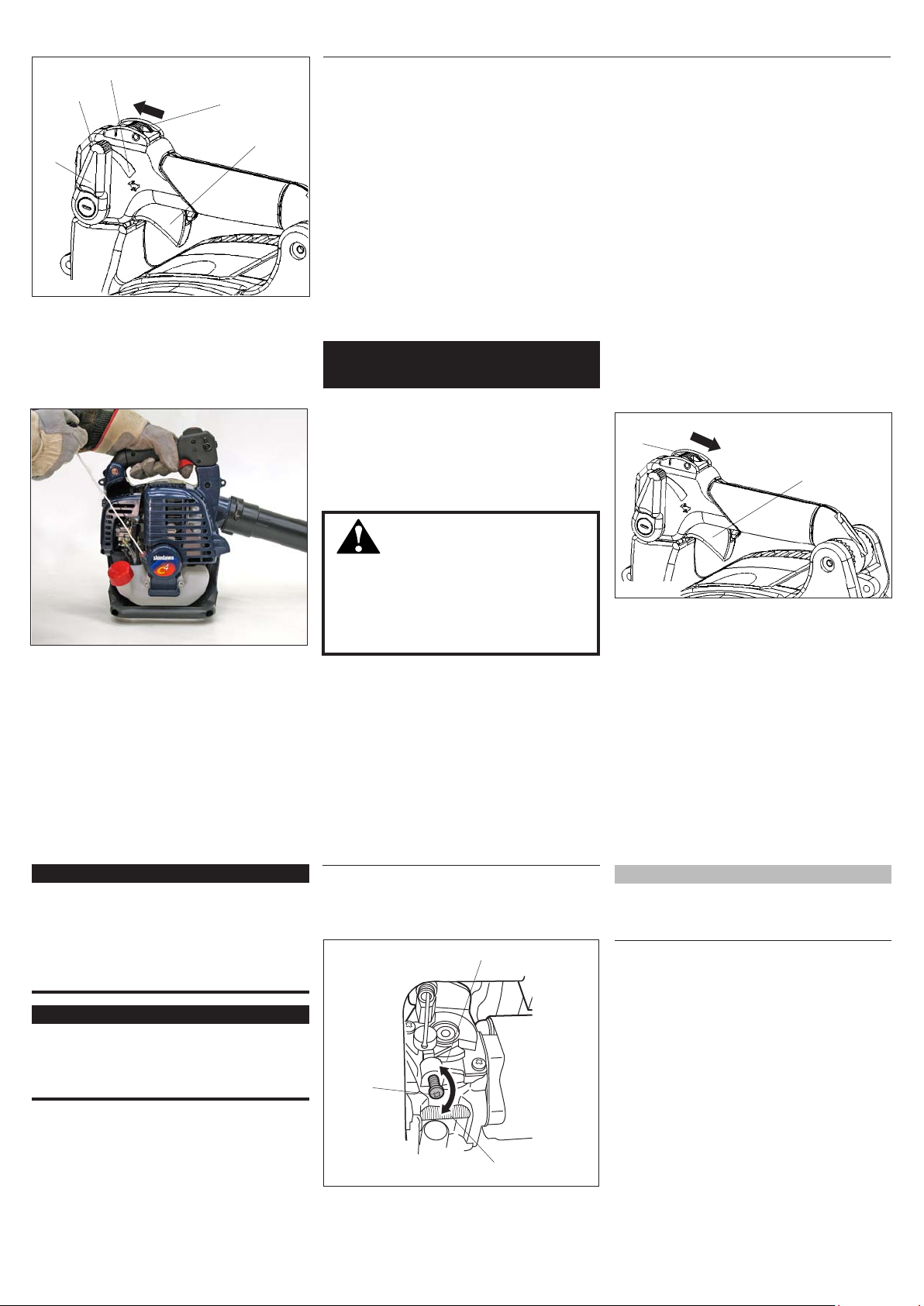

Unit Description

Air Cleaner

Cover

Fuel

Primer

Bulb

Recoil/

Starter

Handle

Fuel Filler

Cap

Throttle

Limiter Lever

Exhaust

Throttle

Lever

EB3410 and EB2510)

Blower Tube

IMPORTANT!

Safety and Operation Information Labels:

Make sure all information labels are

undamaged and readable. Immediately

replace damaged or missing information

labels. New labels are available from your

local authorized Shindaiwa dealer.

Ignition Switch

Nozzle

(Standard on

Blower

Tube

Blower Air

Carefully inspect all components for damage.

IMPORTANT!

The terms “left”, “left-hand”, “LH”; “right”,

“right-hand”, and “RH”; “front” and “rear”

refer to directions as viewed by the

operator during normal operation.

Figure 3

Prior to Assembly

Using Figure 3 as a guide, familiarize yourself with the blower and its components.

Understanding the unit helps ensure top

performance, longer service life, and safer

operation.

Fan Tip Nozzle

(Standard on EB3410

Optional on EB2510)

Before assembling the blower, make

sure you have all required components.

n Power unit and blower assembly.

n This Owner’s/Operator’s Manual

and a tool kit containing a tool bag

and a combination spark plug

wrench/screwdriver.

Specications

Model...................................................................................................................

Dry Weight (without Blower Tubes).........................................................

EB2510

4.9 kg (10.8 lb.)

Dimensions (LxWxH)......................................................................................................896 x 255 x 373 mm ( 35 x 10 x 15 in.)

Engine type........................................................................................................4 cycle air-cooled gasoline engine, vertical cylinder

Bore & Stroke.......................................................................................

34 x 27 mm (1.3 x 1.1 in.)

Displacement.............................................................................................

Max Output/min-1........................................................................

0.8 kW/1.1hp @ 7,500 min-1 (rpm)

24.5 cm3(1.5 cu. in.)

38 x 30 mm (1.50 x 1.18 in.)

1.0 kW/1.4 hp @ 8,000 min-1(rpm)

Fuel/oil ratio...........................................................................................................50:1 with Shindaiwa Premium 2-cycle mixing oil

Carburetor.........................................................................................................................Walbro rotary-type with primer bulb

Ignition...............................................................................................................................CDI (Capacitor Discharge Ignition)

Spark Plug.............................................................................................................................................NGK CMR5H

Starting..................................................................................................................................................Recoil Starter

Stopping....................................................................................................................................Slide Switch (Grounding type)

Fuel Tank Capacity................................................................................................................................0.6 L (20.0 oz)

Exhaust......................................................................................................................................... Spark Arrester Muffler

Air Filtration..........................................................................................................................................Dry Element

EB3410

5.1 kg (11.2 lb.)

34 cm3 (2.07 cu. in.)

Specifications are subject to change without notice.

5

6

Assembling the Blower

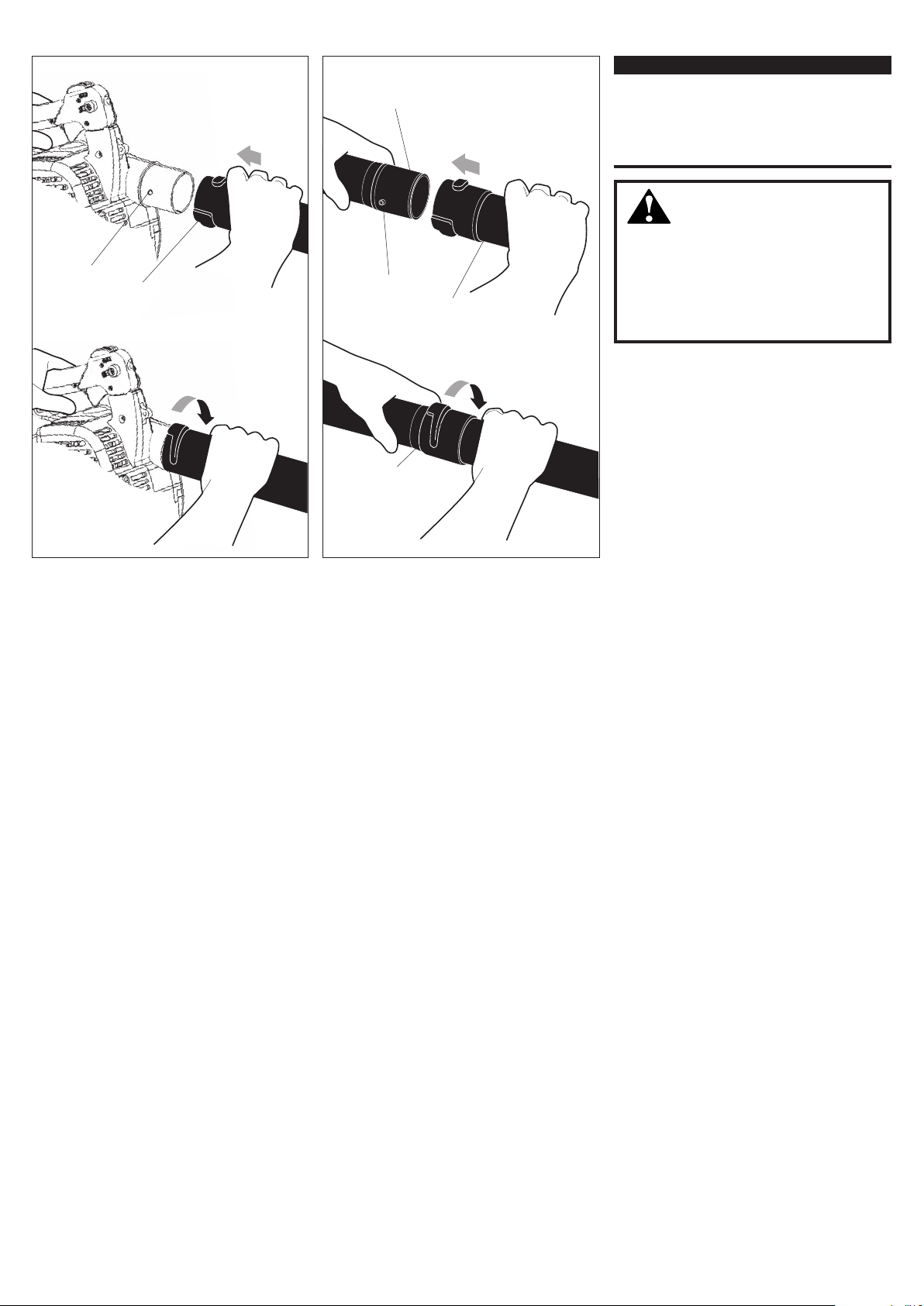

Push the blower tube

over the discharge port

and locking pin

Locking Pin

1 3

Blower

Tube

Blower Tube

Locking Pin

Push the nozzle

over the blower

tube and locking

Nozzle

pin

IMPORTANT!

Blower tube installation affects both blower balance and performance! The tube

and nozzle are correctly installed when

the mark “THIS SIDE UP” is visible to the

operator during normal operation.

WARNING!

Danger from rotating impeller!

Stop the engine before installing or

removing the blower tubes! Never

perform any maintenance or assembly

procedures on this unit while the

engine is running!

Rotate clockwise to lock

2 4

Place the blower upright on the ground or

on a sturdy work surface.

1. Grasp the blower tube as shown, and

push the tube over the blower discharge

port and locking pins.

2. Lock the blower tube to the blower

discharge port by rotating the tube as

shown.

Rotate clockwise to lock

Mark

“THIS SIDE UP”

must face up

3. Grasp the nozzle with the mark “THIS

SIDE UP” positioned as shown, and

then push the nozzle over the straight

tube and locking pins.

4. Lock the nozzle to the straight tube by

rotating the nozzle as shown.

Mixing Fuel

CAUTION!

Some gasolines contain alcohol as

an oxygenate! Oxygenated fuels may

cause increased operating temperatures. Under certain conditions,

alcohol-based fuels may also reduce

the lubricating qualities of some mixing

oils. Never use any fuel containing

more than 10% alcohol by volume!

Generic oils and some outboard motor

oils may not be intended for use in

high-performance air cooled 2-cycle

engines, and should never be used in

your Shindaiwa engine!

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and a premium 2-cycle mixing

oil only. Use of non-approved mixing

oils can lead to excessive maintenance

costs and/or engine damage.

n Use only fresh, clean unleaded gasoline

with a pump octane rating of 87 or higher.

n Mix gasoline with 50:1 Shindaiwa

Premium 2-cycle mixing oil or with an

equivalent high quality 2-cycle mixing oil.

Example of 50:1 mixing quantities:

n 5 liters of gasoline to 0.1 liter mixing oil.

n 1 gallon of gasoline to 2.6 oz. mixing oil.

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than

30 days and Shindaiwa One oil with

fuel stabilizer is not used, it should rst

be treated with a fuel stabilizer such as

STA-BIL™.

WARNING!

Minimize the risk of re!

n STOP the engine before refueling.

n ALWAYS allow the unit to cool

before refueling!

n ALWAYS store gasoline in a

container approved for ammable

liquids.

n Wipe all spilled fuel and move the

unit at least 3 m (10 feet) from the

fueling point before restarting!

n NEVER start or operate this unit if

there is a fuel leak.

n NEVER start or operate this unit if

the carburetor, fuel lines, fuel tank

and/or fuel tank cap are damaged.

n NEVER smoke or light any res

near the unit or fuels!

n NEVER place any ammable mate-

rial near the engine mufer!

n NEVER operate the engine without

the mufer and spark arrester in

place and properly functioning!

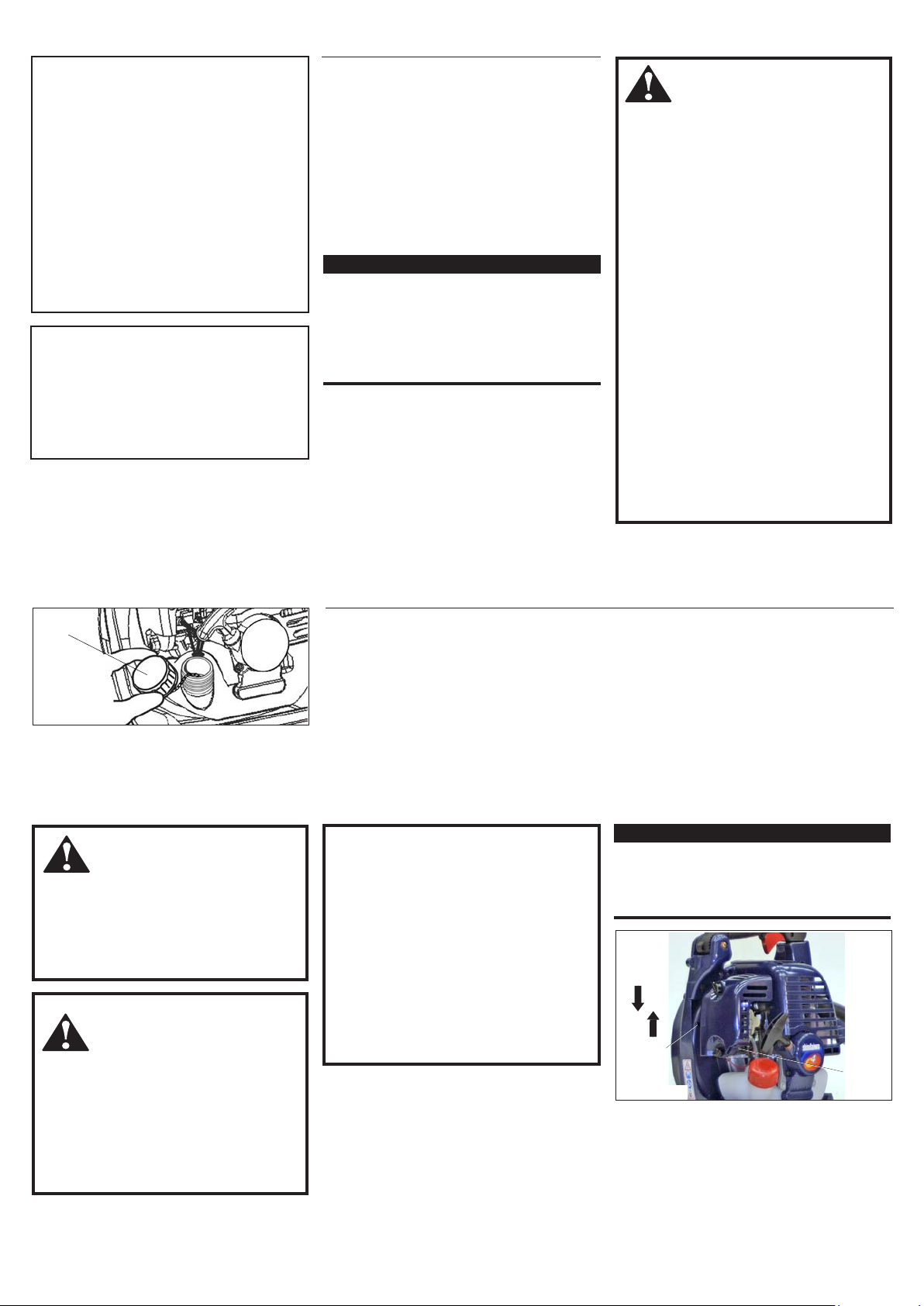

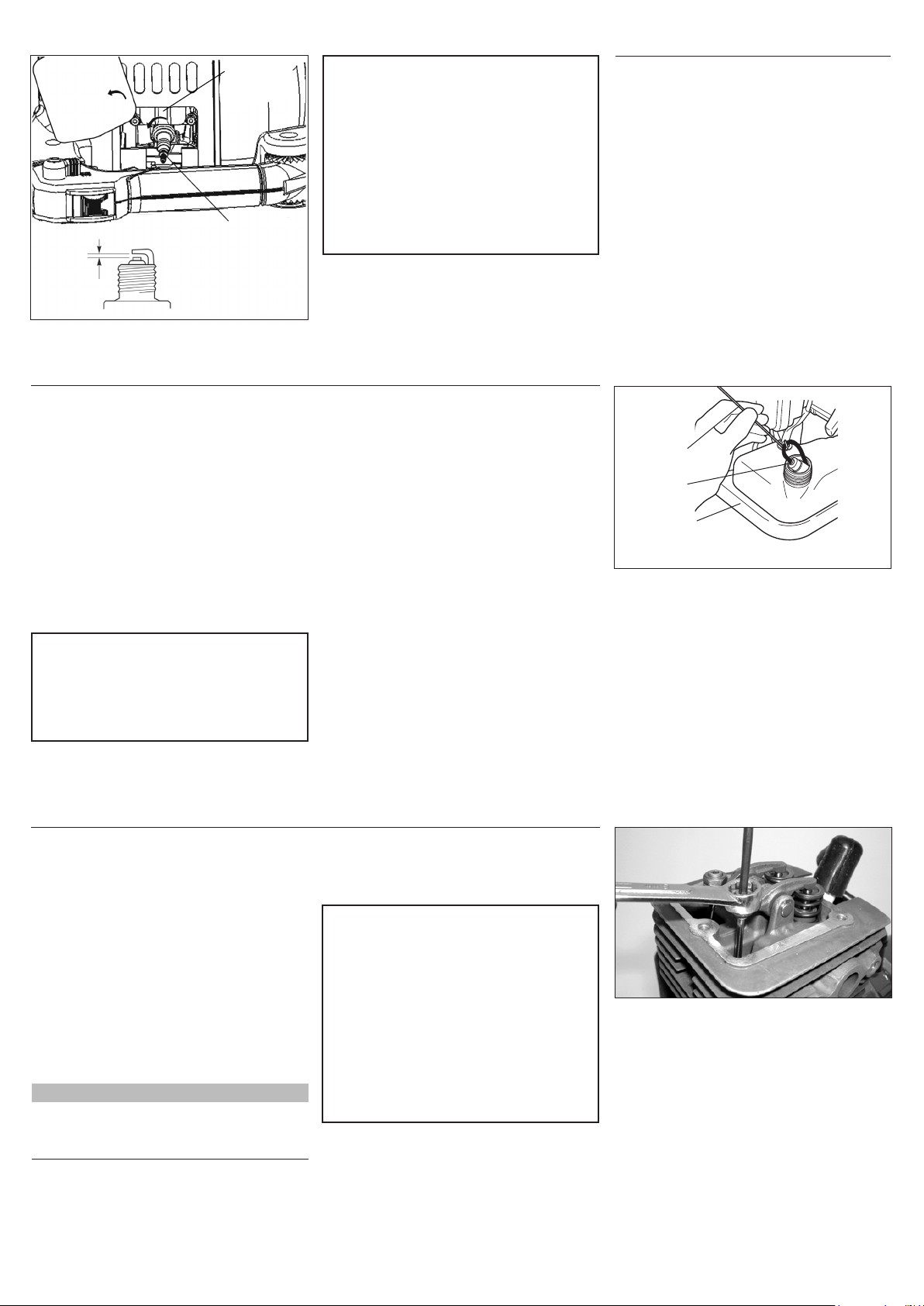

Filling the Fuel Tank

Remove

the

Fuel

Filler

Cap

Figure 4

Starting the Engine

The impeller will rotate whenever the

blower is operated! Never operate this

blower unless the intake cover and

blower tubes are properly installed and

in good working order!

WARNING!

Danger from thrown dust

or debris!

Always wear eye protection when

operating this machine! Never direct

the blower stream toward people or

animals!

Never operate this blower unless all

controls are properly installed and in

good working order.

WARNING!

Danger from rotating impeller!

1. Place the blower on a flat, level surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the tank

with clean, fresh fuel.

CAUTION!

The recoil starter can be damaged by

abuse!

n Never pull the starter cord to its full

length!

n Always engage the starter before

cranking the engine!

n Always rewind the starter cord

slowly!

Never operate the blower if blower

tubes are missing or damaged!

Starting Procedure

1. Place the blower on the ground.

2. Prime the fuel system by repeatedly

depressing the fuel primer bulb until

no air bubbles are visible in the fuel

discharge line.

4. Reinstall the fuel filler cap and tighten

firmly.

5. Wipe away any spilled fuel before starting the blower.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not ood

the engine with fuel.

Choke

Open

Choke

Closed

Figure 5

Fuel

Primer

Bulb

3. Cold Engine Only. Choke the engine

by moving the choke lever up (choke is

closed). See Figure 5.

7

8

Starting the Engine (continued)

Full Throttle

Idle

Throttle

Lock

Lever

Figure 6

ON

Ignition

Switch

Throttle

Lever

4. Slide the ignition switch to the “I” (ON)

position, then depress the throttle lever

half way and lock throttle by moving

throttle lock lever halfway down. See

Figure 6.

7. As the starter engages, pull the starter

handle upward rapidly.

8. If necessary, repeat Steps 6 and 7 until

the engine starts.

When The Engine Starts–

1. Open the choke (if it is not already

open) by moving the choke lever down.

2. If the engine does not continue to run,

repeat the appropriate starting procedures for a cold or warm engine.

3. Operate the throttle to reduce engine to

idle speed until operating temperature is

reached (2–3 minutes).

The blower should

now be ready for use.

Starting A Flooded Engine

1. Disconnect the spark plug lead, and

remove the spark plug (see page 11 for

procedures).

2. If the spark plug is fouled or is soaked

with fuel, clean or replace the plug as

required.

3. With the spark plug removed, open the

choke, put the throttle lever in the full

throttle position, then clear excess fuel

from the combustion chamber by cranking the engine several times.

4. Install and tighten the spark plug, and

reconnect the spark plug lead.

5. Repeat the starting procedures for a

warm engine.

6. If the engine still fails to start or fire,

refer to the troubleshooting flow chart

at the end of this manual.

Pull upward

rapidly

Repeat the appropriate starting procedures

for warm or cold engine. If the engine still

will not start, follow the “Starting a Flooded

Engine” procedure.

If The Engine Does Not Start–

Figure 7

5. Hold the blower firmly with your left

hand on the handle.

6. Using your right hand, pull the starter

handle slowly until you feel the starter

engage. See Figure 7.

Adjusting Engine Idle Speed

IMPORTANT!

A clean and unrestricted airow is essential to your blower’s engine performance

and durability! Before attempting any

carburetor adjustments, inspect and clean

the engine air lter as described on page

10 of this manual.

2. If a tachometer is available, the engine idle

WARNING!

Never operate the blower unless all

controls are properly installed and in

good working order. Never operate the

blower if the cylinder cover is missing

or damaged!

speed should be final adjusted to 3000

(±300)min-1 (rpm). See Figure 9.

Idle Decrease

Ignition

Switch

Figure 8

OFF

Throttle Lever

Stopping The Engine

1. Cool the engine by allowing it to run at

idle for 2–3 minutes.

2. Slide the ignition switch towards the

rear to “O” (OFF). See Figure 8.

NOTE:

Carburetor fuel mixture adjustments are preset at factory on units with emission control

systems and cannot be serviced in the field.

IMPORTANT!

Blower tubes and the air cleaner must be

in place while adjusting engine idle! Engine

idle speed will also be affected if the blower

tubes are blocked or incorrectly installed!

1. Place the unit on the ground and start

the engine, then allow it to idle 2-3

minutes until warm.

Idle

Adjustment

Screw

Figure 9

Idle Increase

Throttle Control

The EB2510/EB3410 is equipped with a

multi-function throttle control. The “Cruise”

function allows the operator to use a thumb

controlled lever for constant speed use

without using the throttle trigger. This is

useful for limiting the fatigue caused from

holding the throttle for extended periods of

time.

On the opposite side, a two position

“Limiter” control allows full engine speed

when set for “Turbo” or limits the throttle

to a pre-set engine speed when set to low

noise (dB) setting.

Cruise Function

Using the right thumb, push the throttle

lock lever down until the desired min-1

(rpm) setting is reached. See Figure 10.

Thumb

Control

Lever

Figure 10

To bring RPM down to idle, push lever

back up into original position.

Throttle Limiter

The EB2510/EB3410 has a throttle limiter

function that allows the operator to pre-set

the maximum engine speed. This is useful for reducing the noise emitted by the

blower in noise sensitive areas.

Setting Throttle Limiter:

For reduced noise setting, move the

throttle limiter located on the right side of

the throttle control to the dB setting.

See Figure 11.

Throttle Limiter

Turbo Setting

dB Setting

Figure 11

Lever

Throttle Limiter

Adjustment

Adjusting Throttle Limiter:

1. Remove the plug located at the top of

the throttle assembly. See Figure 12.

2. Move the throttle limiter lever to the

“dB” setting. See Figure 12.

3. With the engine running and while

depressing the throttle trigger, use a

small Phillips screw driver to turn the

adjustment screw clockwise to decrease

min-1 (rpm) and counter-clockwise to increase until desired limited min-1 (rpm)

is achieved.

4. Reinstall limiter adjustment plug.

Remove limiter

adjustment plug

Figure 12

Note:

With the throttle limiter adjusted to 7,000 min

(rpm), the EB2510 will have a sound level of

65 dB(A) measured at 15 m (50 feet).

Note:

With the throttle limiter adjusted to 6,500 min

(rpm), the EB3410 will have a sound level of

65 dB(A) measured at 15 m (50 feet).

-1

-1

Using The Blower

Operating Tips

In the hands of an experienced operator,

the EB2510/EB3410 can efficiently move

a wide variety of debris ranging from grass

clippings to gravel. As a general rule,

operate your blower at the lowest throttle

setting required to get the job done:

n Use low throttle settings when clearing

lightweight materials from around

lawns or shrubbery.

n Use medium to higher throttle settings

to move grass or leaves from parking

lots or walkways.

n Use full throttle when moving heavy

loads such as dirt or snow.

IMPORTANT!

Blower noise increases at higher throttle

settings! Always use the lowest throttle

setting required to get the job done!

9

10

Maintenance

IMPORTANT!

Maintenance, replacement or repair of

emission control devices and systems

may be performed by any repair estab-

lishment or individual, However, warranty

repairs must be performed by a dealer or

service center authorized by Shindaiwa

Corporation. The use of parts that are not

equiv-alent in performance and durability

to authorized parts may impair the effectiveness of the emission control system

and may have a bearing on the outcome

of a warranty claim.

Daily Maintenance

WARNING!

To reduce re hazard, keep the engine

and mufer free of dirt, debris, and

leaves.

WARNING!

Before performing any maintenance,

repair or cleaning work on the unit,

make sure the engine is completely

stopped. Disconnect the spark plug

wire before performing service or

maintenance work.

CAUTION!

The engine is cooled by air drawn into

the air intake cover on the blower

housing. The blower fan then pushes

the cooling air through an opening

in the fan housing, forcing it past the

cylinder cooling ns. Failure to keep

the cooling system and its passages

clear of debris will likely result in engine

overheating, a major cause of serious engine problems that can lead to

failure.

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

NOTE:

Using non-standard replacement parts could

invalidate your Shindaiwa warranty.

Prior to each workday, perform

the following:

n Remove all dirt and debris from blower

exterior and the engine. Check the cooling fins and air cleaner for clogging and

clean as necessary.

n Inspect the engine, tank, and hoses for

possible fuel leaks, and repair as necessary.

n Inspect the entire blower for loose, dam-

aged, or missing components, and repair

as necessary.

n Carefully remove any accumulations

of dirt or debris from the muffler and

fuel tank. Dirt build-up in these areas

can lead to engine overheating, fire or

premature wear.

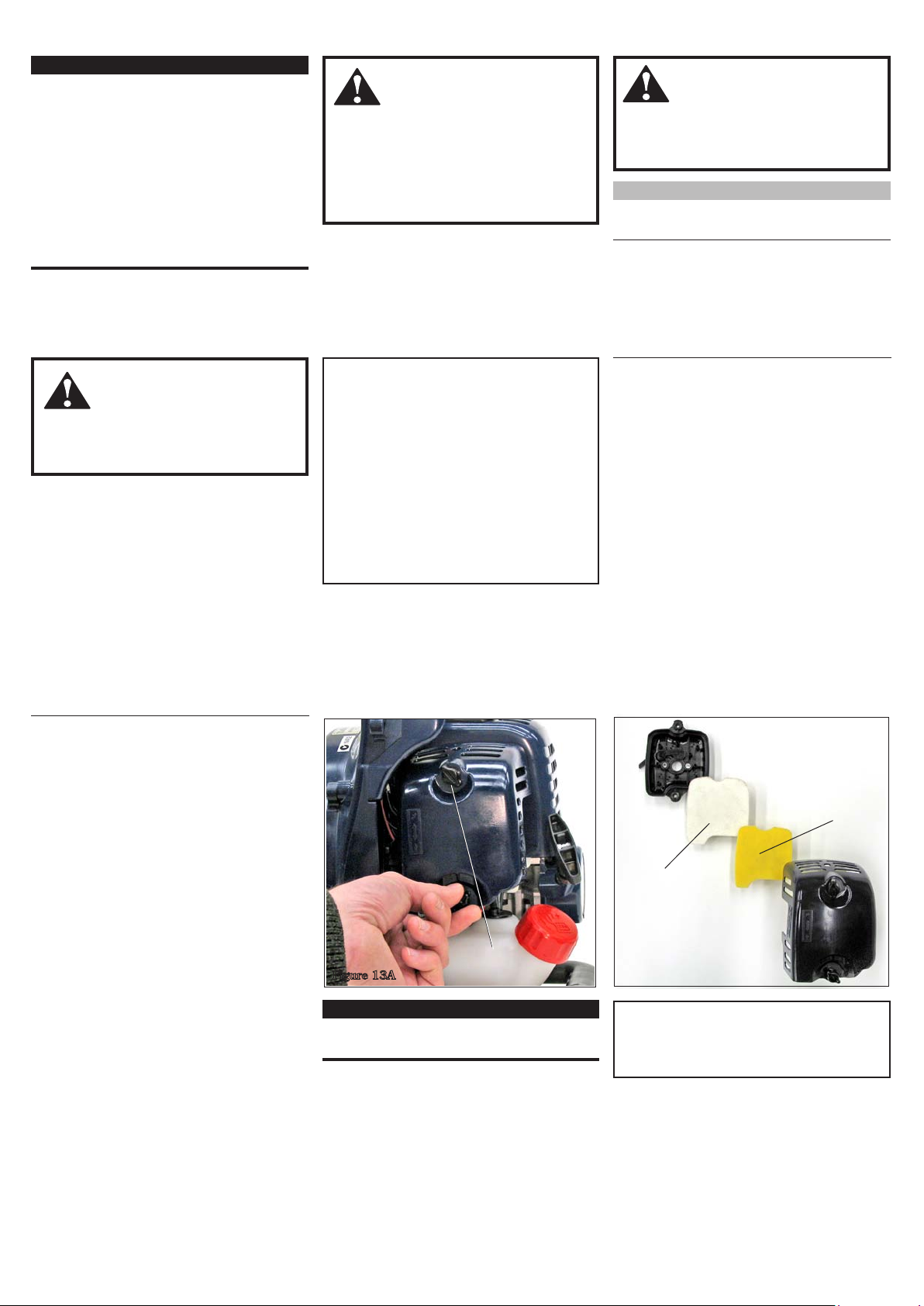

Every 10 Hours

(more frequently in dusty

conditions)

1. Remove the air cleaner cover by loosening the thumb screw and lifting up. See

Figure 13A.

2. Remove and inspect the pre-filter. If the

pre-filter is torn or otherwise damaged,

replace it with a new one. See Figure 13B.

3. Clean the pre-filter with soap and water.

Let dry before reinstalling.

4. Inspect the air cleaner element. If the

element is damaged or distorted, replace

it with a new one. See Figure 13B.

5. Tap filter gently on a hard surface to

dislodge debris from element or use

compressed air from the inside to blow

debris out and away from the air filter

element.

Unscrew

Figure 13A

Fasteners

IMPORTANT!

Direct the air stream at the inside face of

the lter only!

6. Install the filter element, pre-filter and

cover in the reverse order of removal.

Pre-Filter

Filter

Element

Figure 13B

CAUTION!

Never operate the blower if the air

cleaner assembly is damaged or missing!

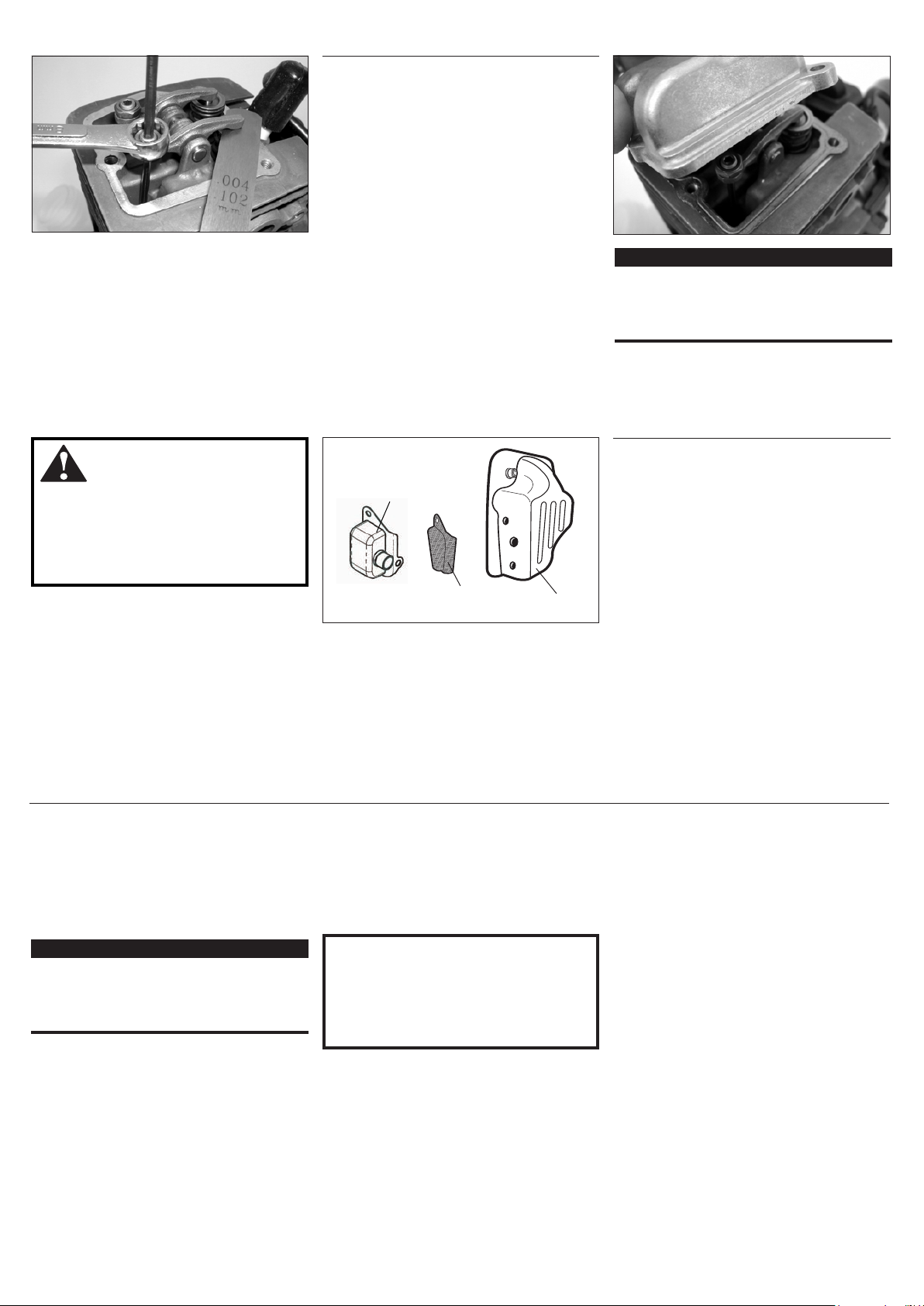

Every 10/15 Hours

Clean the spark plug

and check the gap

0.6mm

(0.024 in.)

Figure 14

at the electrode.

NGK CMR5H

Every 50 Hours

Counter-

clockwise

to remove.

CAUTION!

Never allow dirt or debris to enter the

cylinder bore! Before removing the

spark plug, thoroughly clean the spark

plug and cylinder head area!

Allow the engine to cool before servicing the spark plug! Cylinder threads

can be damaged by tightening or loosening the spark plug while the engine

is hot!

1. Use the spark plug wrench to remove

the spark plug. See Figure 14.

2. Clean and adjust the spark plug gap

to 0.6mm (0.024 in.). If the plug must be

replaced, use a NGK CMR5H or equivalent type plug of the correct

heat range.

3. Install the spark plug finger-tight in the

cylinder head, then tighten it firmly

with the spark plug wrench. If a torque

wrench is available, torque the spark

plug to 16.7-18.6 Nm (148-165 inchpounds)

(more frequently if reduced

performance is noted)

n INSPECTION Inspect the entire blower

and tubes for damage, including loose

or missing components, and repair as

necessary.

n SPARK PLUG Replace the spark plug

with a NGK CMR5H (or equivalent),

gapped to 0.6mm (0.024 in.).

n FUEL FILTER Use a hooked wire to

extract the fuel filter from inside the fuel

tank. See Figure 15.

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be damaged easily.

139/150-Hour Maintenance

Maintenance after rst

139-hours, then every 150-hours

thereafter.

n Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

n Replace the spark plug annually: Use

only NGK CMR5H or equivalent

resistor type spark plug of the correct

heat range. Set spark plug electrode gap

to 0.6mm (0.024 in.).

NOTE:

The NGK CMR5H also meets the

requirements for electro magnetic

compliance (EMC).

n Inspect the filter element for signs of

contamination from debris. A contaminated fuel filter should be replaced with

a new Shindaiwa replacement element.

Before reinstalling the filter, inspect the

condition of the fuel line. If you note

damage or deterioration, the blower

should be removed from service until it

can be inspected by a Shindaiwa-trained

service technician.

n COOLING SYSTEM Use a wood or

plastic scraper and a soft brush to

remove dirt and debris from the cylinder

fins and crankcase.

Valve Adjustment

1.

Remove cylinder cover, rocker arm cover,

and set piston at TDC-compression.

CAUTION!

n Performing a valve adjustment

incorrectly may cause hard starting

and/or can damage the unit. Refer

to the C-4 Service Manual for complete valve adjustment procedure

and torque specications.

n If you are unfamiliar with this engine

or uncomfortable with this procedure, consult with an authorized

Shindaiwa servicing dealer.

Hooked

Wire

Fuel

Filter

Fuel Tank

Figure 15

2. Loosen adjuster locknut so that the 2.5

mm Allen socket head adjustment screw

can turn freely.

11

12

139/150-Hour Maintenance (continued)

just enough to allow gauge to slip out

with limited resistance.

5. While holding adjustment screw in place

with Allen driver, tighten locknut with

wrench.

6. Turn engine over several times, and

return to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change as

a result of tightening locknut. Readjust

3. Insert 0.10 mm (0.004 in.) feeler gauge

between valve stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

as necessary.

7. Replace rocker arm cover gasket to assure proper sealing and install cover.

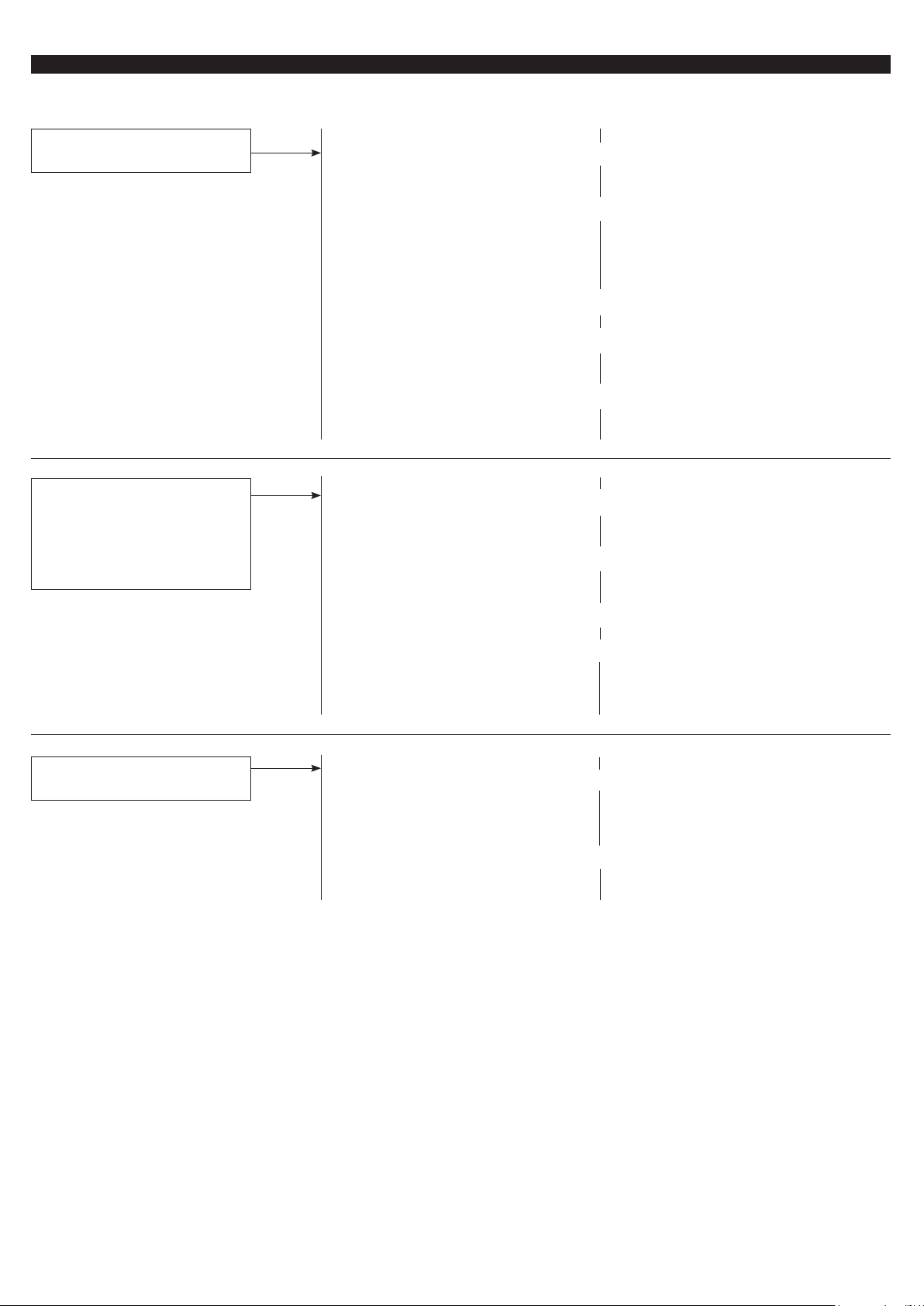

Spark Arrester Maintenance

WARNING!

Never operate this blower with a damaged or missing mufer or spark arrest-

er! Operating with missing or damaged

exhaust components is a re hazard,

and can also damage your hearing!

Hard starting or a gradual loss of performance can be caused by carbon deposits

lodged in the spark arrester screen. For

maximum performance, the spark arrester

screen should be periodically cleaned as

follows. See Figure 16.

Arrester Screen

Cover

Figure 16

1. Remove engine cover to expose muffler.

Remove the spark arrester from the

muffler. The arrester is press-fit in place;

there are three screws to remove.

Arrester

Screen

Mufer

IMPORTANT!

If new gasket is not available and/or old

gasket is not damaged, old gasket may be

reused. Never use cracked or damaged

gaskets!

2. Use a plastic scraper or wire brush to remove carbon deposits from the arrester

screen and wipe clean exhaust base.

3. Inspect the screen carefully, and replace

any screen that has been perforated,

distorted, or is otherwise unserviceable.

4. Press the spark arrester into the exhaust base.

If carbon accumulation in the muffler or

cylinder are severe, or if you do not notice

an improvement in performance after

servicing, have the unit inspected by an

authorized servicing Shindaiwa dealer.

Long Term Storage

Whenever the unit will not be

used for 30 days or longer, use

the following procedures to prepare it for

storage:

n Clean external parts thoroughly.

n Drain all the fuel from the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL™ if

Shindaiwa One oil with fuel stabilizer is

not used.

To remove the remaining fuel from the

fuel lines and carburetor and with the fuel

drained from the fuel tank.

1. Prime the primer bulb until no more fuel

is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine will

no longer start.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard starting, and could also lead to increased

service and maintenance costs.

n Remove the spark plug and pour

about 10 cm3 (1/4 oz.) of 2-cycle mixing

oil into the cylinder through the spark

plug hole. Slowly pull the recoil starter

2 or 3 times so oil will evenly coat the

interior of the engine. Reinstall the spark

plug.

n Before storing the unit, repair or replace

any worn or damaged parts.

n Remove the air cleaner element from

the unit and clean it as outlined on

page 10.

n Store the unit in a clean, dust-free area.

Troubleshooting Guide

What To Check Possible Cause Remedy

ENGINE DOES NOT START

Does the engine crank?

YES

Good compression?

YES

Does the tank contain fresh

fuel of the proper grade?

YES

Is fuel visible and moving in

the return line when priming?

YES

NO

NO

NO

NO

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Loose spark plug.

Excess wear on cylinder, piston, rings.

Fuel incorrect, stale, or contaminated;

mixture incorrect.

Check for clogged fuel lter and/or vent.

Priming pump not functioning properly.

Consult with an authorized

servicing dealer.

Tighten and re-test.

Consult with an authorized

servicing dealer.

Rell with clean, fresh unleaded

gasoline with a pump octane of 87 or

higher, mixed with a 2-cycle air cooled

mixing oil that meets or exceeds ISO-LEGD and/or JASO FC classied oils at

50:1 gasoline/oil ratio.

Replace fuel lter or vent as required.

Re-start.

Consult with an authorized

servicing dealer.

Is there spark at the spark

plug wire terminal?

YES

Check the spark plug.

NO

The ignition switch is in “O” (OFF) position.

Shorted ignition ground.

Faulty ignition unit.

If the plug is wet, excess fuel may

be in the cylinder.

The plug is fouled or improperly gapped.

The plug is damaged internally or

of the wrong size.

Move switch to “I” (ON) position

and re-start.

Consult with an authorized

servicing dealer.

Crank the engine with the plug removed,

re-install the plug and re-start.

Clean and re-gap the plug to

0.6 mm (0.024 in.). Re-start.

Replace the plug with a NGK CMR5H or

equivalent resistor type spark plug of the

correct heat range. Set spark plug electrode

gap to 0.6mm (0.024 in.).

13

14

Troubleshooting Guide (continued)

What To Check Possible Cause Remedy

LOW POWER OUTPUT

Is the engine overheating?

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fallen leaves or debris on intake cover.

Fan, fan cover, cylinder ns dirty

or damaged.

Carbon deposits on the piston or

in the mufer.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Use a lower throttle setting.

Consult with an authorized

servicing dealer.

Rell with clean, fresh unleaded gasoline

with a pump octane of 87 or higher, mixed

with a premium 2-cycle air cooled mixing oil

or equivalent at a 50:1 gasoline ratio.

Clean the intake cover.

Clean, repair or replace as necessary.

Consult with an authorized

servicing dealer.

Service the air cleaner element.

Tighten or replace the spark plug.

See page 11.

Repair or replace fuel lter and/or

fuel line.

Engine is knocking.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm.

Overheating condition.

Improper fuel.

Carbon deposits in the

combustion chamber.

Replace the fuel. See page 7.

Consult with an authorized

servicing dealer.

See above.

Check fuel octane rating; check for

presence of alcohol in the fuel. See

page 7. Refuel as necessary.

Consult with an authorized

servicing dealer.

Troubleshooting Guide (continued)

ADDITIONAL PROBLEMS

Symptom Possible Cause Remedy

Poor acceleration.

Engine stops abruptly.

Clogged air lter.

Clogged fuel lter.

Lean fuel/air mixture.

Idle speed set too low.

Ignition switch turned off.

Fuel tank empty.

Clogged fuel lter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Clean the air lter.

Replace the fuel lter.

Consult with an authorized

servicing dealer.

Adjust: 3000 (±300) min-1 (rpm).

Reset the switch and re-start.

Refuel. See page 7.

Replace fuel lter.

Drain; replace with clean fuel.

See page 7.

Clean or replace spark plug, tighten

the terminal.

Replace the ignition unit.

Consult with an authorized

servicing dealer.

Engine difcult to shut off.

Excessive vibration.

Engine overspeeding.

Ground (stop) wire is disconnected,

or switch is defective.

Overheating due to incorrect spark plug.

Overheated engine.

Debris build-up in impeller.

Loose or damaged impeller.

Loose or damaged engine mounts.

Blower intake or discharge ports or tubes

are clogged with debris.

Impeller blades are missing or damaged.

Test and replace as required.

Idle engine until cool. Clean and regap

the plug to 0.6 mm (0.024 in.). Correct plug:

NGK CMR5H or equivalent resistor type

spark plug of the correct range.

Idle engine until cool.

Clean debris from impeller as required.

Inspect and replace impeller as required.

Tighten or replace engine mounts as

required.

Inspect and remove debris.

Consult with an authorized

servicing dealer.

15

16

Emission System Warranty Statement

Your Warranty Rights and Obligations

The California Air Resources Board, the U.S. Environmental

Protection Agency and Shindaiwa Corporation are pleased to

explain the exhaust and evaporative emission control system

warranty on your new small off-road (non-road) engine.

In California, new small off-road engines must be designed,

built, and equipped to meet the State’s stringent anti-smog standards. In other states, new 1997 and later non-road engines must

meet the Federal EPA’s stringent anti-smog standards.

Shindaiwa Corporation must warrant the emission control system on your small off-road engine for the periods of time listed

below, provided there has been no abuse, neglect, or improper

maintenance of your small off-road engine.

Your engine exhaust and evaporative emission control system

includes parts such as the carburetor, fuel tank, the ignition system and, if equipped, the catalytic converter. These components

are specifically listed below.

Where a warrantable condition exists, Shindaiwa Corporation

will repair your small off-road engine at no cost to you including

diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

When sold within the U.S., this engine’s emission control

system is warranted for a period of two (2) years from the date

this product is first delivered to the original retail purchaser.

During the warranty period, Shindaiwa Corporation will, at

their option, repair or replace any defective emission-related

component on this engine. During the original Warranty Period,

these Warranty Rights are automatically transferable to subsequent owners of this product.

What is Covered by this Warranty

1. Carburetor Internal Components

nThrottle Valve, Needle, Jet, Metering Diaphragm

2. Fuel Tank

3. Ignition System Components

n Ignition Coil

n Flywheel Rotor

4. Catalytic Converter (if originally equipped)

The emission control system for your particular Shindaiwa

engine may also include certain related hoses and connectors.

Owners Warranty Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in this owners manual. Shindaiwa Corporation recommends that you retain

all receipts covering maintenance on your small off-road engine,

but Shindaiwa Corporation cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of

all scheduled maintenance.

As the small off-road engine owner, you should be aware,

however, that Shindaiwa Corporation may deny you warranty

coverage if your small off-road engine or a part has failed due to

abuse, neglect, improper maintenance, or unapproved modifications.

You are responsible for presenting your small off-road engine

to an authorized Shindaiwa Dealer as soon as a problem exists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights

and responsibilities, you should contact a Shindaiwa customer

service representative at (503) 692-3070 or your local Shindaiwa

Dealer.

Consequential Damages

In the event that other component parts of this product

are damaged by the failure of a warranted part, Shindaiwa

Corporation will repair or replace such component parts at no

charge to you.

What is Not Covered

n Failures caused by abuse, neglect, or improper

maintenance procedures.

n Failures caused by the use of modified or non-approved parts

or attachments.

This Warranty is Administered by:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, OR 97062

(503) 692-3070

NOTES

17

Loading...

Loading...