Shindaiwa B530, BP530, BP530/EC1 Owner's Manual

SHINDAIWA OWNER’S/OPERTOR'S MANUAL

B530 BRUSHCUTTER

WARNING!

Part Number 62108-94310 Rev. 02/05

Read this manual and familiarize yourself with its contents.

This machine is designed for cutting grass, weed, and brush.

Do not use this machine for other purposes.

Minimize the risk of injury to yourself and others.

Do not operate or service this machine unless you clearly understand this

manual.

Keep this manual at a particular place so that you can reread it whenever

you have a question about its use.

2

Throughout this manual are special attention statements.

WARNING!

A statement preceded by the triangular

attention symbol and the word

“W

ARNING” contains information

that should be acted upon to prevent

serious bodily injury

.

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent

mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPOR

TANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Attention Statements

IMPORTANT!

The operational procedures described

in this manual are intended to help you

get the most from your unit as well as

to protect you and others from harm.

These procedures are guidelines for safe

operation under most conditions, and are

not intended to replace any safety rules

and/or laws that may be in force in your

area. If you have questions regarding your

Shindaiwa power tool, or if you do not

understand

something in this manual, your

Shindaiwa dealer will be glad to assist

you.

You may also contact Shindaiwa, Inc.

at the address printed on the back of this

manual.

Introduction

Shindaiwa B530 hand held power

equipment has been designed and built to

deliver superior per

formance and reliability

without compromise to quality, comfort,

safety or durability.

Shindaiwa’s high-performance engines

represent the leading edge of 2-cycle

engine technology, delivering exceptionally

high power with remarkably low

displacement and weight. As an owner/

operator

, you’ll soon discover for yourself

why Shindaiwa is simply in a class by itself!

IMPORTANT!

The information contained in this owner's/

operator's manual describes units

available at the time of publication. While

every attempt has been made to give

you the very latest information about your

Shindaiwa product, there may be some

dif

ferences between your machine and the

machine described in this manual.

Shindaiwa Inc. reserves the right

to make changes to products without

prior notice, and without obligation to

make alterations to units pr

eviously

manufactured.

Page

Attention Statements .................................. 2

General Safety Instructions ....................... 3

Safety Labels ................................................ 5

Checking Unit Condition ........................... 5

Unit Description .......................................... 6

Specifications ............................................... 6

Assembly Procedure ................................... 7

Mixing Fuel ............................................... 12

Starting the Engine ................................... 12

Stopping the Engine ................................. 14

Engine Idle Adjustment ............................ 14

Double Shoulder Harness ........................ 14

Operation .................................................. 15

Using a Brush Cutter

W

ith a Trimmer Head .................. 16

Maintenance .............................................. 16

Long T

erm Storage ................................... 18

Blade Sharpening ...................................... 18

Troubleshooting Guide ............................ 19

Declaration of Conformity ........................ 22

Contents

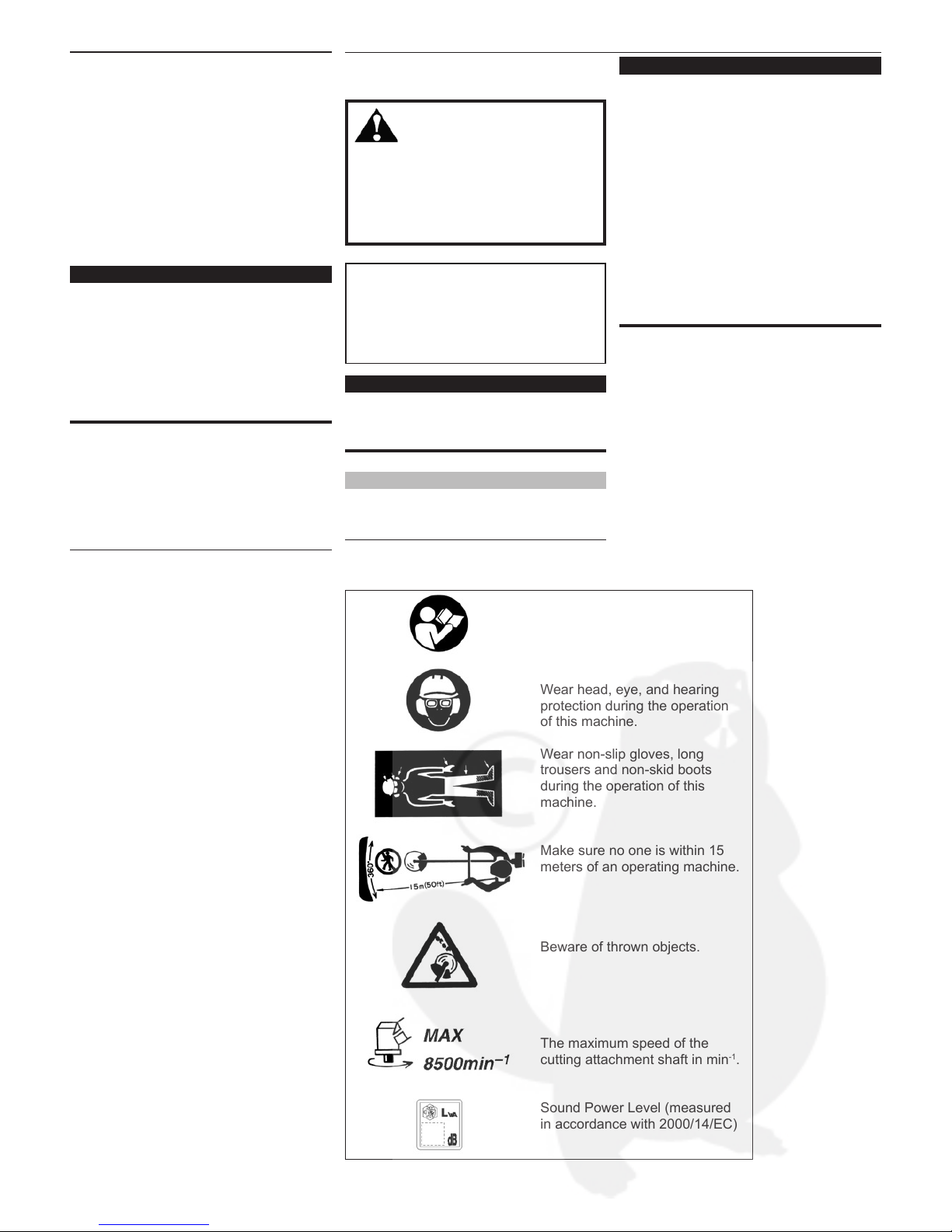

Read and follow this operators

manual. Failure to do so could

result in serious injury

.

Wear head, eye, and hearing

protection during the operation

of this machine.

W

ear non-slip gloves, long

trousers and non-skid boots

during the operation of this

machine.

Make sure no one is within 15

meters of an operating machine.

Beware of thrown objects.

The maximum speed of the

cutting attachment shaft in min

-1

.

Sound Power Level (measured

in accordance with 2000/14/EC)

Warning Labels

Warning labels placed on this unit mean the following:

3

Work Safely

Trimmers and brushcutters operate at very

high speeds and can do serious damage or

injur

y if they are misused or abused. Never

allow a person without training or instr

uc-

tion to operate this unit!

WARNING!

Use Good Judgment

NEVER run the engine when transporting the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation. Fumes from engine exhaust can

cause serious injury or death.

AL

WAYS use the proper cutting tool

for the job.

AL

WAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly installed parts or attachments.

NEVER extend trimming line beyond

the length specifi

ed for your unit.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation, mud, etc.

AL

WAYS hold the unit firmly with both

hands when cutting or trimming, and

maintain control at all times.

AL

WAYS keep the handles clean.

AL

WAYS disconnect the spark plug

wire before performing any

maintenance work.

AL

WAYS, if a saw blade should bind

fast in a cut, shut of

f the engine im-

mediately

. Push the branch or tree to

ease the bind and free the blade.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

General Safety Instructions

WARNING!

Never make unauthorized attachment

installations.

WARNING!

Never operate power equipment of any kind if you are

tired or if you are under the infl

uence of

alcohol, drugs, medication or any other

substance that could af

fect your ability

or judgement.

4

SAFETY

Be Aware of the Working Environment

Avoid long-term

operation in very hot or

very cold weather

.

Make sure bystand-

ers or observers

outside the 15 me-

ter “danger zone”

wear

eye protection.

Be extremely careful of

slippery terrain, especially

during rainy weather

.

Always make sure

the appropriate cutting

attachment shield is

correctly installed.

If contact is made with a hard object, stop the engine

and inspect the cutting attachment for damage.

Be constantly alert for objects and

debris that could be thrown either

from the rotating cutting attachment or

bounced from a hard surface.

Reduce the risk of bystanders being struck

by flying debris. Make sure no one is

within 15 meters — that’

s about 16 paces

— of an operating attachment.

Stop immediately if a child, pet, or person

comes within a 15 meter radius.

Beware of a coasting blade when brushcutting

or edging.

A coasting blade can injure while

it continues to spin after the throttle trigger is

released or after the engine is stopped.

15

METERS

ALWAYS clear your work area of trash or

hidden debris that could be thrown back at

you or toward a bystander

. When operating in

rocky terrain or near electric wires or fences,

use extreme caution to avoid contacting such

items with the cutting attachment.

The Properly Equipped Operator

Always wear a harness when operating

the unit . It adds comfort and helps ensure

safety by limiting movement fore and aft.

When the harness is adjusted properly

,

the unit should balance with the cutting

attachment parallel to the ground.

Always operate with both hands firmly

gripping the unit.

W

ear close-fitting clothing to protect legs and

arms. Gloves offer added protection and are

strongly recommended. Do not wear clothing

or jewelry that could get caught in machinery or

underbrush. Secure long hair so that it is above

shoulder level. NEVER wear shorts!

W

ear hearing protection devices and a broadbrimmed hat or helmet.

A helmet is required when using a blade-equipped

brushcutter to clear small trees.

Always wear eye protection such as

goggles or safety glasses to shield

against thrown objects.

When operating with a blade, make sure the

handle is positioned to provide you with maxi-

mum protection from contacting the blade.

Always make sure the handlebar is installed in

accordance with the manufacturers instructions.

Keep away from the rotating

trimmer line or blade at all

times, and never lift a moving

attachment above waist-high.

Wear appropriate footwear (non-skid boots

or shoes): do not wear open-toed shoes or

sandals. Never work barefooted!

Keep a proper footing and do not overreach.

Maintain your balance at all times during operation.

Always make sure the appropriate cutting attachment

shield is correctly installed and in good condition. Do

not operate the unit if the cutting attachment shield is

missing, loose, or broken.

Long-term exposure to vibration can damage

your hands.

Prolonged exposure to excessive noise is

fatiguing and could lead to impaired hearing.

Do not operate the unit if the

cutting attachment shield is

missing, loose, or broken.

5

Safety Labels

IMPORTANT!

Safety and Operation Information

Labels: Make sure all information labels are undamaged and

readable. Immediately replace

damaged or missing information

labels. New labels are available from your local authorized

Shindaiwa dealer

.

Checking Unit Condition

WARNING!

A cutting attachment shield or other protective device is no guarantee of protection against ricochet. YOU MUST ALWAYS

GUARD AGAINST FLYING DEBRIS!

Use only authorized Shindaiwa parts and accessories with your

Shindaiwa trimmer or brushcutter. Do not make modifications to

this unit without the written approval of Shindaiwa, Inc.

NEVER operate the unit with the cutting attachment shield or

other protective devices (harness, ignition switch, blade retention

clip, etc.) removed!

ALWAYS make sure the cutting attachment is properly installed

and fir

mly tightened before operation.

NEVER use a cracked or warped cutting attachment: If a properly

installed attachment vibrates, r

eplace the attachment with a new

one and re-check.

ALWAYS stop the engine immediately and check for damage if

you strike a for

eign object or if the unit becomes tangled. Do not

operate with broken or damaged equipment.

NEVER allow the engine to run at high RPM without a load. Do-

ing so could damage the engine.

NEVER operate a unit with worn or damaged fasteners or attach-

ment holders.

NEVER cut with a dull blade. Doing so will increase the risk of

blade thr

ust and may also cause equipment damage.

6

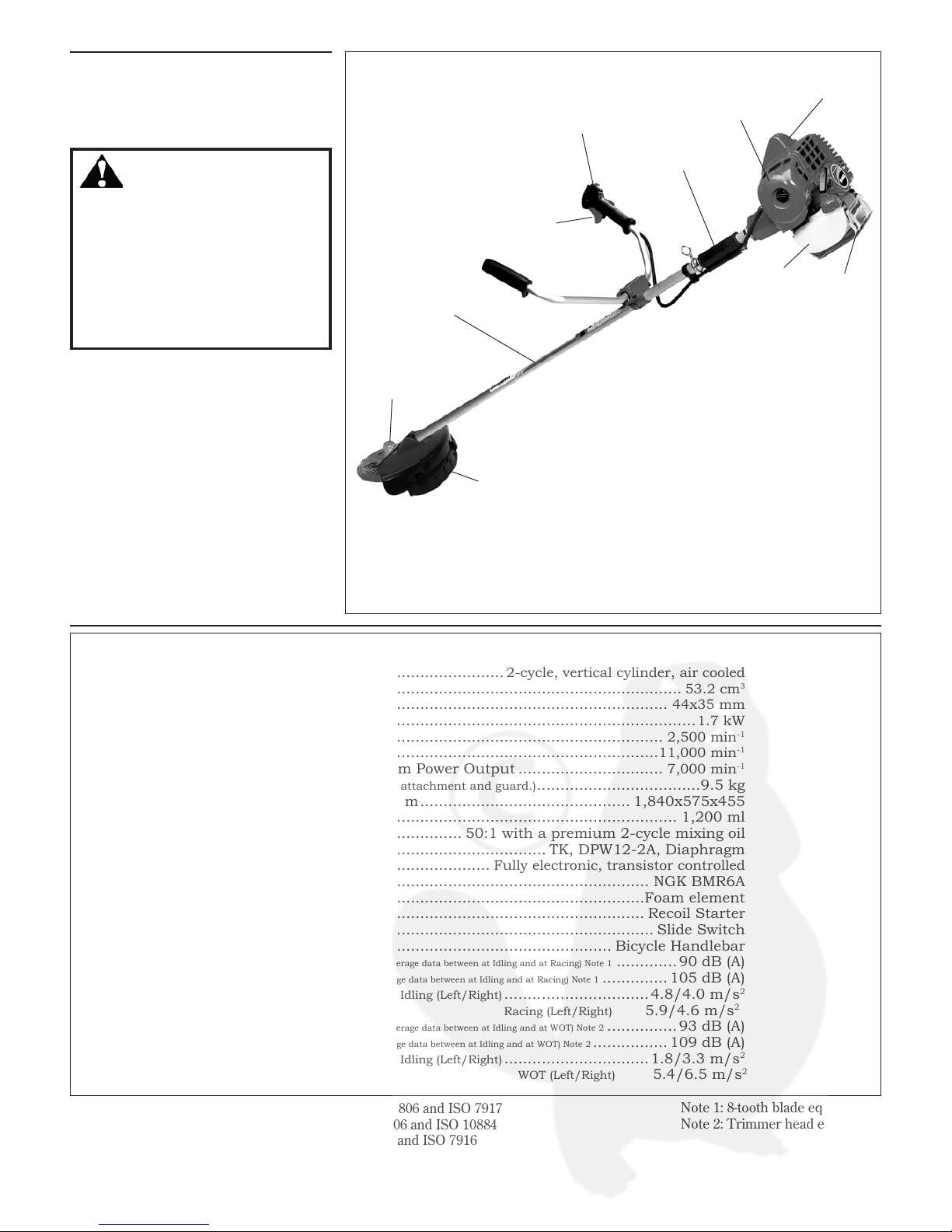

Specifications

Unit Description

Outer Tube

Grip

Cutting

Attachment

Shield

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. Understanding

the pr

oduct helps ensure top performance,

long service life, and safer operation.

WARNING!

Do not make unauthorized

modifications or alterations to this

machine or any of its components.

Shindaiwa must authorize alterations

and modifi

cations in writing.

Unauthorized modifications or

alterations may alter the machine

operation and could jeopardize

personal safety during operation.

Throttle

Trigger

Gearcase

Tank

Guard

Ignition

Switch

Fuel

T

ank

Spark

Plug

B530 BRUSH CUTTER

Air

Filter

Model Name .............................................................................B530/EC1

Engine Model ..........................................................................................S530EC1

Engine Type .......................................... 2-cycle, vertical cylinder, air cooled

Displacement ............................................................................. 53.2 cm

3

Bore and Stroke ....................................................................... 44x35 mm

Maximum Power Output ................................................................1.7 kW

Engine Speed at Idling ............................................................ 2,500 min

-1

Maximum Engine Speed ........................................................11,000 min

-1

Engine Speed at Maximum Power Output ............................... 7,000 min

-1

Dry Weight (Without cutting attachment and guard.) ...................................9.5 kg

Dimensions (L x H x W) mm ............................................. 1,840x575x455

Fuel Tank Capacity .................................................................... 1,200 ml

Fuel/Oil Ratio .............................. 50:1 with a premium 2-cycle mixing oil

Carburetor Type ............................................ TK, DPW12-2A, Diaphragm

Ignition .............................................. Fully electronic, transistor controlled

Spark Plug ........................................................................... NGK BMR6A

Air Cleaner Type .................................................................Foam element

Starting Method .................................................................. Recoil Starter

Stopping Method .................................................................. Slide Switch

Handle Type ................................................................ Bicycle Handlebar

Sound Pressure Level* (average data between at Idling and at Racing) Note 1 .............90 dB (A)

Sound Power Level** (average data between at Idling and at Racing) Note 1 .............. 105 dB (A)

Vibration Level*** Note 1 Idling (Left/Right) ...............................4.8/4.0 m/s

2

Racing (Left/Right) 5.9/4.6 m/s

2

Sound Pressure Level* (average data between at Idling and at WOT) Note 2 ............... 93 dB (A)

Sound Power Level** (average data between at Idling and at WOT) Note 2 ................ 109 dB (A)

Vibration Level*** Note 2 Idling (Left/Right) ...............................1.8/3.3 m/s

2

WOT (Left/Right) 5.4/6.5 m/s

2

* Sound Pressure Level: In accordance with EN ISO 11806 and ISO 7917

** Sound Power Level In accordance with EN ISO 11806 and ISO 10884

*** Vibration Level: In accordance with EN ISO 11806 and ISO 7916

Note 1: 8-tooth blade equipped.

Note 2: T

rimmer head equipped.

7

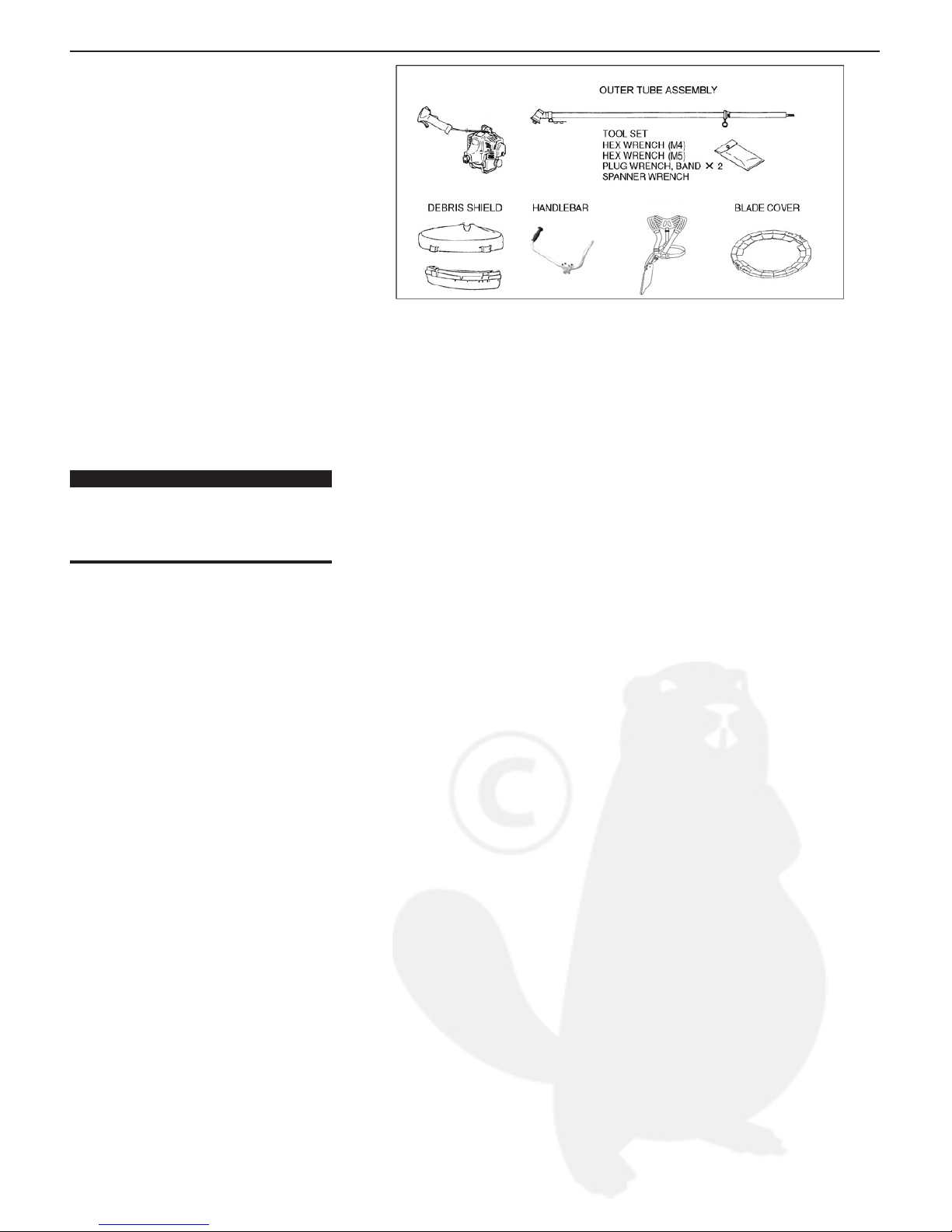

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit:

Engine assembly

Outer tube assembly

Debris shield

Double shoulder harness

Cutting attachment

Handlebar

Blade cover

Tool kit, which includes 3mm, 4mm,

and 5mm “L” type hexagonal wr

enches,

8mm/l0mm open-end wrench and

combination spark plug.

T

ool kits vary by model.

Components required for assembly

(cable ties, thr

ottle cable connector, and

throttle cable sleeve).

Carefully inspect all components for

damage.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

Assembly Procedure

HARNESS

8

Powerhead Assembly

4. Insert the shaft tube assembly into the

powerhead connector clamp. Make sure

the powerhead connector clamp aligns

with the outer tube “Insert up to here”

decal.

5. If necessar

y, rotate the outer tube

assembly until the gearcase output shaft

is pointing down, opposite to the spark

plug.

6. T

ighten the union clamp screw securely.

Install Mainshaft and Outer Tube

Installation Decal

Mainshaft

Outer Tube

B530ES_04

Hex

Wrench

Shim W

asher

Connector Clamp

CAUTION!

Do not remove the D-shaped shim

washer!

The shim washer prevents

damage from overtightening the tube

clamp screw

.

CAUTION!

Do not force the outer tube into the

powerhead! Forcing the outer tube

into the powerhead may damage

the splines on the mainshaft and/or

clutch drum shaft. If installation proves

difficult, rotate the powerhead or

mainshaft until you feel the mainshaft

splines slide into the clutch drum shaft.

1. Place the powerhead on a flat surface,

resting on its stand.

2. Lubricate the mainshaft splines with

molybdenum disulfide (moly) type

gr

ease.

3. Loosen the 6mm socket head cap screw

on the powerhead connector clamp.

Verify that the D-shaped shim washer is

positioned as shown below.

Fan Cover Housing

Powerhead

Tank Guard

1. Remove the 4mm retaining screws and

lower cap from the handlebar bracket.

2. Mount the handlebar on the outer tube

and align it with the “Attach Handle On

This Line” decal.

3. Reinstall the lower cap and r

etaining

bolts. Tighten the retaining screws

evenly.

Handlebar Installation

B530ES_11

Throttle Assembly

Handlebar

Cap

Lower Cap Retaining Screws

Outer T

ube

Installation

Decal

Handlebar Bracket

Throttle Cable

Throttle Cable Installation

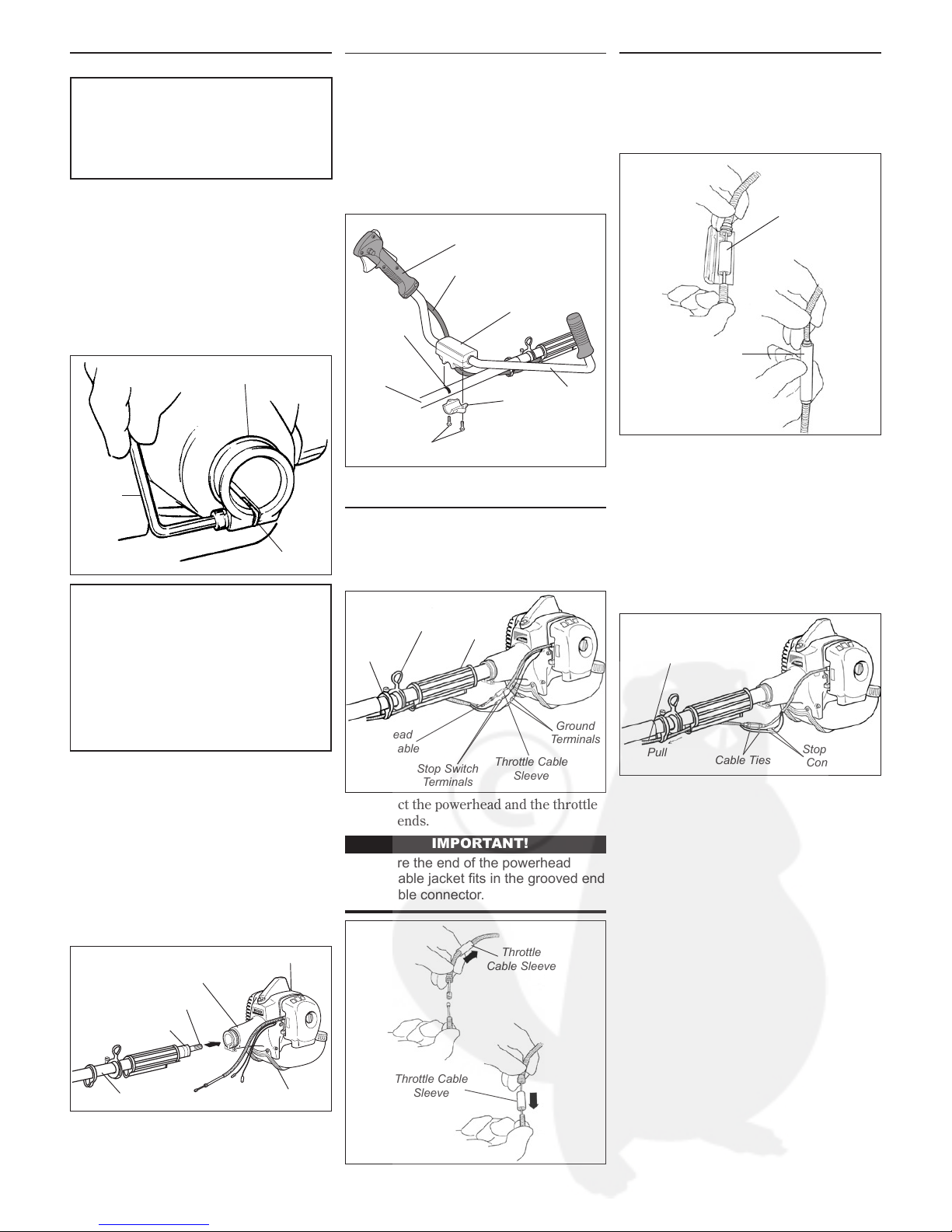

1. Slide throttle cable and terminal wires

through the cable clamp and grip.

2. Install the throttle cable sleeve on the

powerhead throttle cable.

Cable

Clamp

Hanger

Grip

Powerhead

Throttle Cable

Stop Switch

T

erminals

Throttle Cable

Sleeve

Ground

T

erminals

3. Connect the powerhead and the throttle

cable ends.

IMPORTANT!

Make sure the end of the powerhead

throttle cable jacket fits in the grooved end

of the cable connector

.

Throttle Cable

Sleeve

Throttle

Cable Sleeve

Throttle Cable Installation

(Continued)

(a) Center the throttle cable sleeve over

the connected cable ends and place the

assembly in the thr

ottle cable connector.

(b) Using hand pressure, close the throttle

cable connector.

Throttle Cable

Sleeve

Throttle Cable

Connector

(c) Secure each end of the throttle

connector with a cable tie.

4. Connect the power

head and stop switch

wire terminals.

5. Connect the stop switch ground wire and

the powerhead ground wire terminals.

6. Slide throttle cable and connect terminal

wires into grip by gently pulling on the

throttle cable housing.

Throttle Cable

Housing

Stop Switch

Connector

Cable T

ies

Pull

Loading...

Loading...