Page 1

English ........... 1

Español ....SP_1

Français ... FR_1

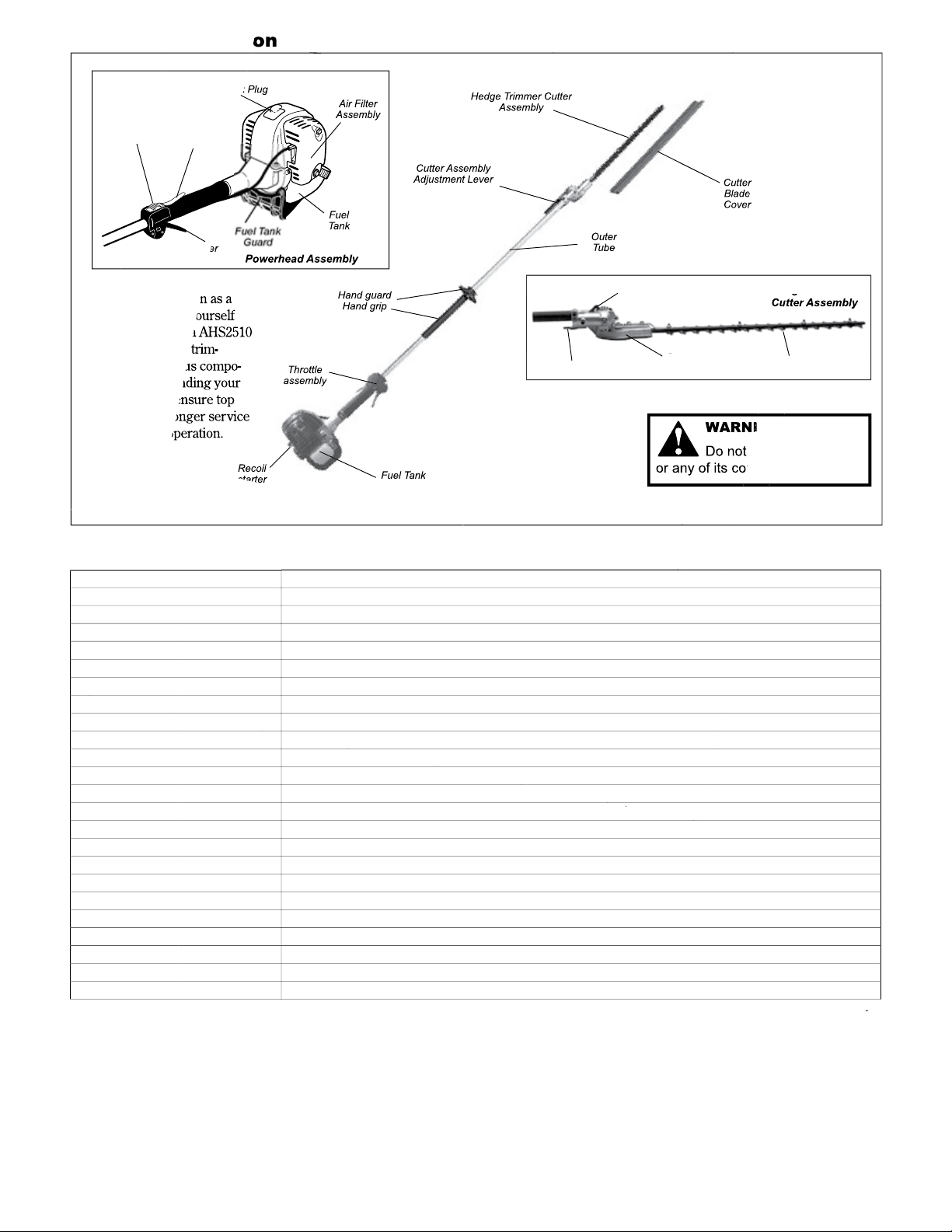

SHINDAIWA OWNER’S/OPERATOR'S MANUAL

AH2510/EVC

ARTICULATED HEDGE TRIMMER

WARNING!

Always wear eye and ear protection

when operating this machine! To minimize the

risk of injury to yourself and others, read this

manual and familiarize yourself with its contents.

Part Number 89310 Rev. 6/09

Page 2

Introduction

The Shindaiwa C4 series of hand-held

power equipment is designed and built to

deliver superior performance and reliability without compromise to quality, comfort,

safety or durability. Shindaiwa engines

represent the leading edge of high-performance engine technology, delivering

exceptionally high power with remarkably

low displacement and weight. As an owner/

operator, you’ll soon discover for yourself

why Shindaiwa is simply in a class by itself!

IMPORTANT!

The information contained in these instructions describes units available at the time

of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

WARNING!

The engine exhaust from this

product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

Contents

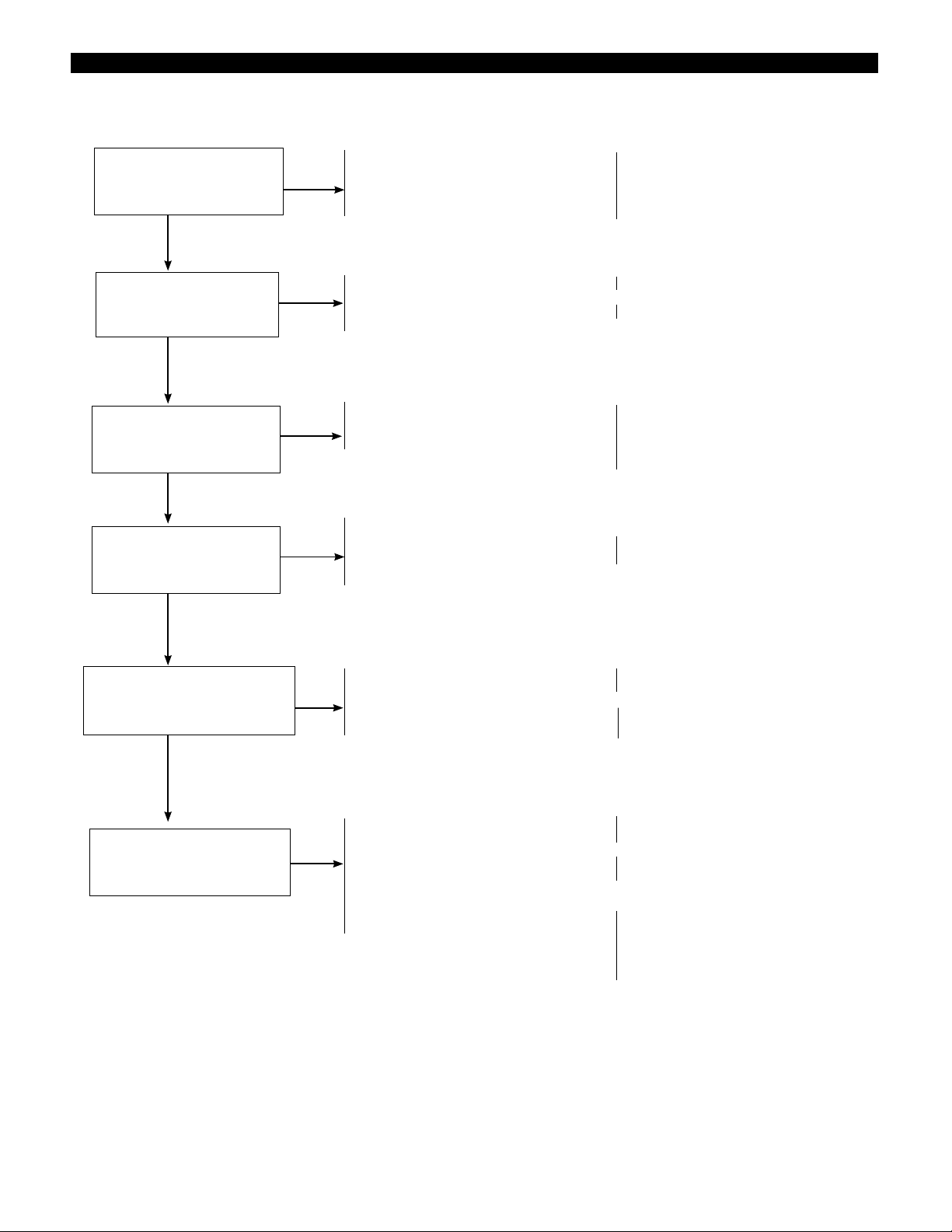

Safety...........................................................3

Product Description................................... 5

Specifications.............................................. 5

Assembly.....................................................6

Mixing fuel..................................................9

PAGE PAGE

Filling the fuel tank....................................9

Starting the Engine .................................10

Stopping the Engine ................................11

Adjusting Engine Idle..............................11

Operation ..................................................12

PAGE

Maintenance............................................. 12

Long Term Storage..................................16

Troubleshooting Guide ...........................17

Emission System Warranty.....................20

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit as well as to protect you and others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to replace any safety rules

and/or laws that may be in force in your area. If you have questions regarding your Shindaiwa hand-held power equipment, or if you do not

understand something in this manual, contact Shindaiwa Inc. at the address printed on the back of this Manual.

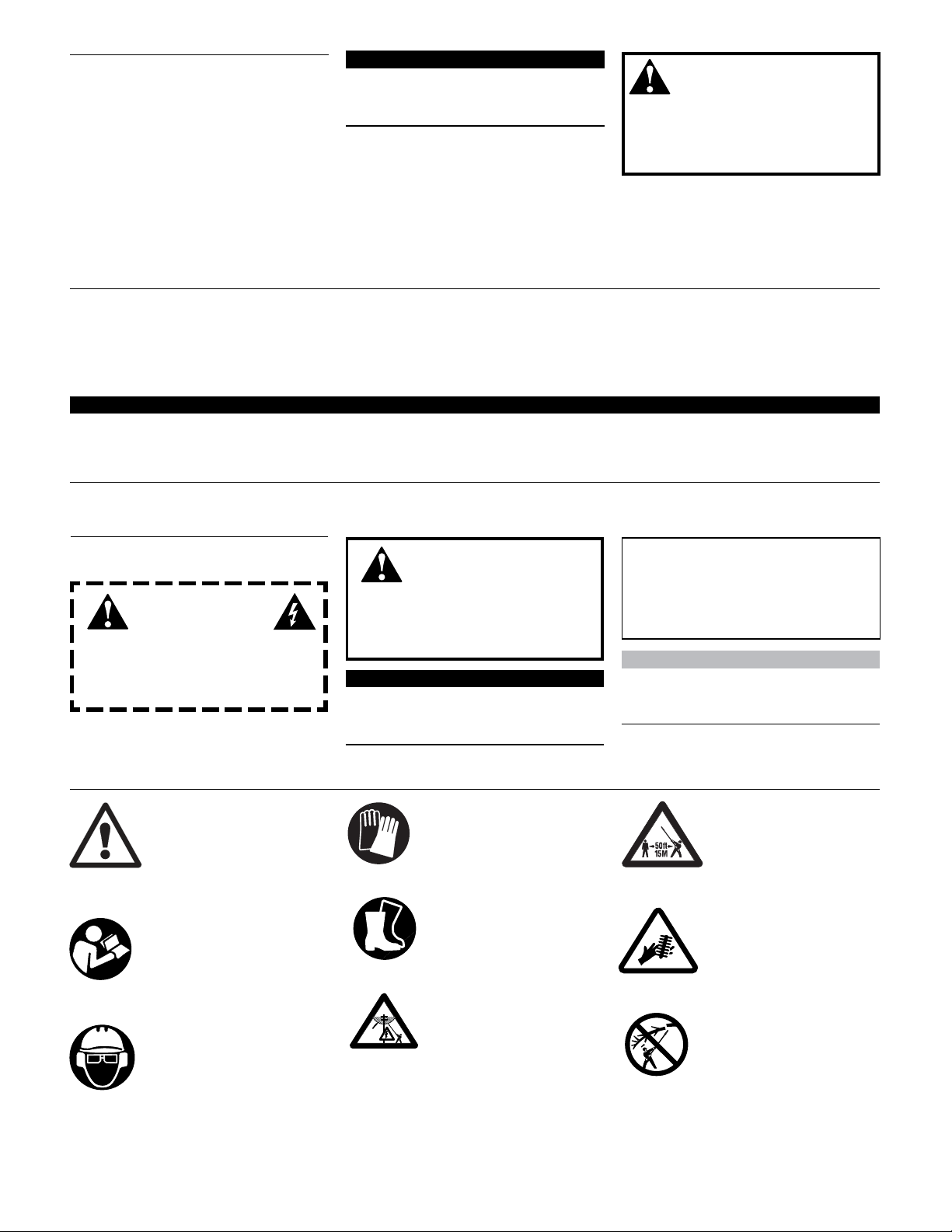

Attention Statements

Throughout this manual are special “attention statements”.

DANGER!

A statement preceded by the triangular attention symbol and the word “DANGER” contains

information that should be acted upon

to prevent serious injury or death.

triangular attention symbol and the

word “WARNING” contains information

that should be acted upon to prevent

serious bodily injury.

A statement preceded by the word

“IMPORTANT” is one that possesses special significance.

WARNING!

A statement preceded by the

IMPORTANT!

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent

mechanical damage.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Safety and operation labels

An articulated hedge trimmer has

the potential to cause serious

personal injury to the operator or

bystanders if misused, abused or

mishandled. You must observe

all special safety iinstructions to

reduce the risk of personal injury.

Read and follow this manual,

make sure anyone using the trimmer does likewise. Failure to do

so could result in serious personal

injury or machine failure. Keep

this manual for future reference.

Always wear a hard hat to reduce

the risk of head injuries during

operation of this machine. In addition, always wear eye and hearing

protection. Shindaiwa recommends wearing a face shield as

additional face and eye protection.

2

33 ft

10 M

Wear non-slip heavy-duty

gloves.

Safety tip shoes or boots with

non-slip sole should be worn.

This product conducts electricity.

Keep the product and/or operator a minimum distance of 33

feet (10 meters) away from electrical sources and power lines.

Keep bystanders at least 50

feet (15 meters) away from the

operating trimmer to reduce

the risk of being cut by the cutting blades or struck by falling

objects or thrown debris.

The blades / cutting attachments are SHARP! Handle

with care.

Be aware of the danger of falling debris.

Page 3

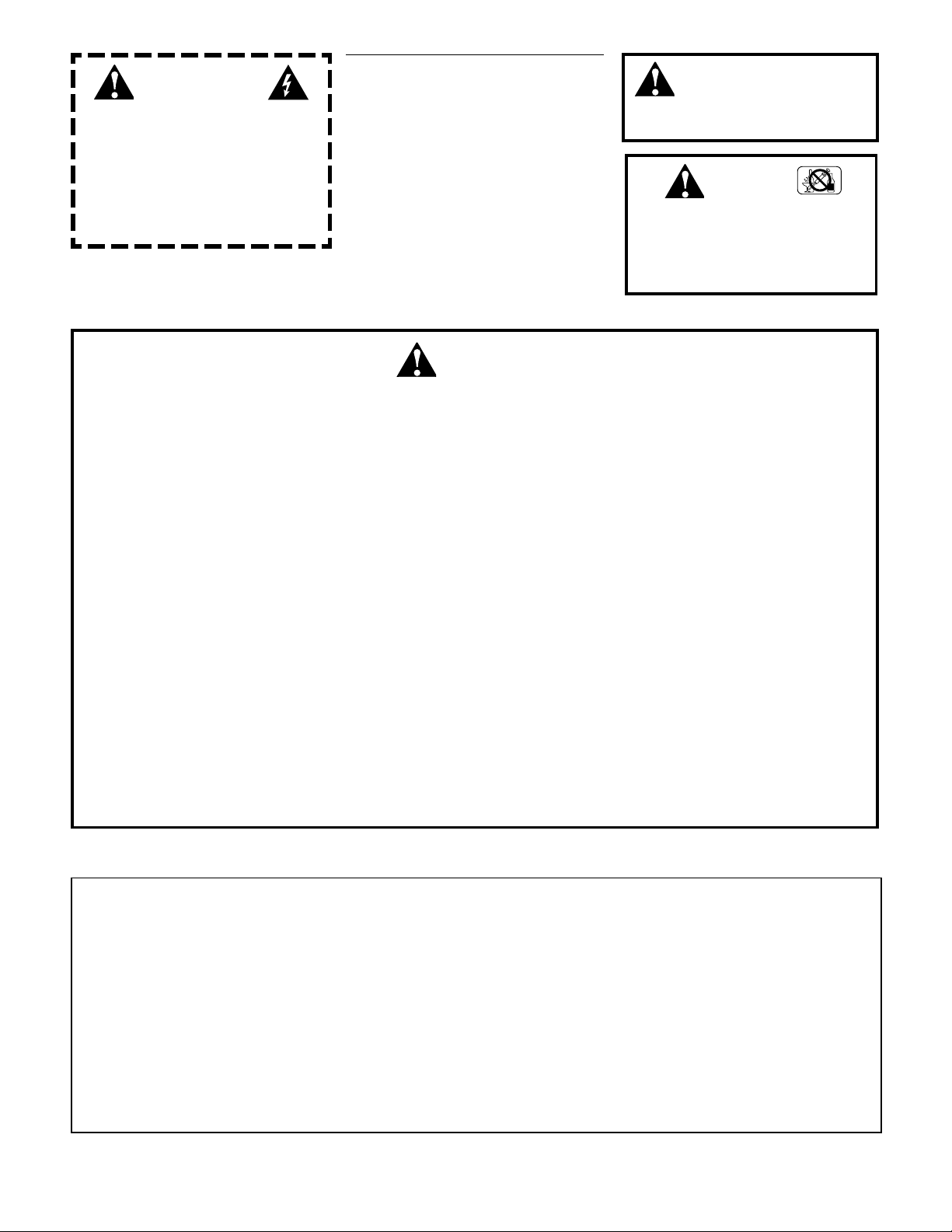

Safety

DANGER!

THE ARTICULATED

HEDGE TRIMMER IS NOT INSULATED

AGAINST ELECTRICAL SHOCK!

Approaching or contacting electrical

lines with the trimmer could cause

death or serious injury. Keep the trimmer at least 10 meters away from

electrical lines or branches that contact electrical lines.

Operating Precautions

An articulated hedge trimmer has the

potential to cause serious personal injury

to the operator or bystanders if misused,

abused or mishandled. To reduce the risk

of injury, you must maintain control at all

times, and observe all safety precautions

during operation. Never permit a person

without training or instruction to operate

this trimmer!

WARNING!

WARNING!

Do not make unauthorized

PRGL¿FDWLRQVRUDOWHUDWLRQVWR\RXUDUWLFulated hedge trimmer or its components.

WARNING!

Never operate this tool or any other

power equipment if you are tired, ill, or

XQGHUWKHLQÀXHQFHRIDOFRKROGUXJV

or any substance that could affect

your ability or judgement.

Never transport the articulated hedge Ŷ

trimmer or leave it unattended with the

engine running. An engine that’s running could be accidently accelerated

causing the blades to oscillate.

Ŷ

Make sure that the blade cover is in

place when transporting or storing the

articulated hedge trimmer.

Ŷ

Always make sure that the cutter

attachment and all handles and guards

DUHSURSHUO\LQVWDOOHGDQG¿UPO\WLJKWened before operation.

Ŷ

Inspect for broken, missing or improperly installed parts or attachments.

Never use a cracked or warped cutter

Ŷ

or cutter bar: replace it with a service-

DEOHRQHDQGPDNHVXUHLW¿WVSURSHUO\

Make sure there are no missing or loose

Ŷ

fasteners, and that the stop switch and

throttle controls are working properly.

Ŷ Make sure there is always good ven-

tilation when operating the articulated

hedge trimmer. Fumes from engine

exhaust can cause serious injury or

death. Never run the engine indoors!

Ŷ

1HYHUVPRNHRUOLJKW¿UHVQHDUWKH

hedge trimmer. Keep the unit away

from excessive heat. Engine fuel is very

ÀDPPDEOHDQG¿UHFRXOGOHDGWRVHULRXV

personal injury or property damage.

Ŷ

When carrying the articulated hedge

trimmer by hand, the cutter attachment

should be pointing backward with the

cutter blade in the retracted or transporting position. (Refer to the section,

”Transporting the Articulated Hedge

Trimmer”.)

Ŷ

Do not operate this machine with the

PXIÀHUUHPRYHG

Make sure the cutters are correctly

Ŷ

adjusted before operating the articulated hedge trimmer (see the section

”Cutter Adjustment” for cutter adjustment procedures). Never attempt cutter adjustment with the engine running!

Ŷ

Before starting the engine, make sure

the cutter is not contacting anything.

Ŷ

$OZD\VFRQ¿UPVDIHRSHUDWLRQZKHQ

using the machine, especially when

operating on steps or a ladder.

Immediately stop the engine with the

Ŷ

stop switch if the machine suddenly

begins to vibrate or shake.

Ŷ

Always stop the engine immediately

and check for damage if you strike

a foreign object or if the machine

becomes tangled. Do not operate with

broken or damaged equipment.

Ŷ

When cutting a branch that is under

tension, be alert for spring-back so that

you will not be struck by the moving

branch.

Ŷ

If a cutter should bind fast in a cut,

shut off the engine immediately. Push

the branch or tree to ease the bind and

free the cutter.

Ŷ

Always stop the engine and allow it to

FRROEHIRUHUHIXHOLQJ$YRLGRYHU¿OOLQJ

and wipe off any fuel that may have

spilled.

Ŷ

7RUHGXFH¿UHKD]DUGNHHSWKHHQJLQH

DQGPXIÀHUIUHHRIGHEULVOHDYHVRU

excessive grease.

CAUTION!

Always maintain the articulated

Ŷ

hedge trimmer according to this owner’s manual and follow the recommended scheduled maintenance.

Ŷ

Never modify or disable any of the

hedge trimmer’s safety devices.

Doing so may cause damage and

lead to personal injury

Ŷ

Always use genuine Shindaiwa parts

and accessories when repairing or

maintaining this machine.

Ŷ

'RQRWPDNHXQDXWKRUL]HGPRGL¿FD-

tions to the articulated hedge trimmer

or its components.

Ŷ

Keep the cutters sharp and properly

adjusted.

Never allow the engine to run at high

Ŷ

without a load. Doing so could damage the engine.

Ŷ

When transporting the hedge trimmer in a vehicle, tie it down securely

to prevent fuel spillage or damage to

the machine.

Ŷ

Always stop the engine and allow it

to cool before refueling. Avoid over-

¿OOLQJDQGZLSHRIIDQ\IXHOWKDWPD\

have spilled.

Ŷ

1HYHUSODFHÀDPPDEOHPDWHULDOFORVH

WRWKHHQJLQHPXIÀHUDQGQHYHUUXQ

the engine without the spark arrestor

screen in place.

Ŷ

Always clear your work area of trash

or hidden debris to help ensure

good footing.

Ŷ

Keep the articulated hedge trimmer

as clean as possible. Keep it free of

loose vegetation, mud, etc.

3

Page 4

Safety (continued)

Safety Equipment and Labels

Hand guard

Ignition

(STOP)

switch

Throttle

interlock

Blade cover

IMPORTANT!

Caution, Danger, Warning, and Operation

Information Labels: Make sure all information labels are undamaged and readable.

Immediately replace damaged or missing

information labels. New labels are available

from your local authorized Shindaiwa dealer.

Operator Safety

Always wear a hard hat

to reduce the risk of head

injuries during operation of

this machine.

ALWAYS protect

yourself from hazards

such as thorny brush

DQGÀ\LQJGHEULVE\

wearing gloves and

FORVH¿WWLQJFORWKLQJ

that covers arms and

legs. Never wear

shorts. Don't wear loose

clothing or items such

as jewelry that could

get caught in machinery

or underbrush. Secure

long hair so it is above

shoulder level.

This machine is designed

for trimming hedges. Do

not use this machine for

other purposes.

Always wear eye and hearing protection.

Shindaiwa recommends wearing a

face shield as additional face and eye

Always operate with both hands

¿UPO\JULSSLQJWKHPDFKLQH

Keep a proper footing

and do not overreach—

maintain your balance

at all times during

operation.

ALWAYS be aware of

your surroundings and

alert to any danger that

you may not hear due to

machine noise.

Wear sturdy footwear with nonslip

soles to provide good footing.

Steel-toed safety boots are

recommended. Never operate

machine bare-footed.

ALWAYS clear your work area

of trash or hidden debris that

could be thrown back at you or

toward a bystander.

protection.

NEVER allow children to

use the unit. Avoid operating

near bystanders or when

children are nearby.

Keep bystanders at least

15 meters away from the

operating trimmer to reduce

the risk of being struck by

falling objects or thrown

debris.

$/:$<6ZHDUFORVH¿WWLQJ

clothing. Gloves offer added

proctection and are strongly

recommended. Do not wear

clothing or jewelry that could

get caught in machinery.

4

Page 5

!

G!

alter

5

Using

guid

with

arti

me

ne

m

p

performance, lo

life, and safer o

starte

Hedg

Latch

Release

Latc

I

gnition

e

i

k

6S

* The EPA emission compliance referred to on the emission compliance label located on the engine, indicates the number of operat

i

h

*

b

.

AH2510

E

e

d

E

e

Engi

t

2

U

kg/

.

U

)

.

0

-1

(rpm)

Recommended

3

1

F

y

.

F

o

Oil

50:1 with *ISO-L-EGD or JASO FC class 2-cycle Mixing O

C

r

Walb

I

n

Fu

Fully electronic, program controlled

S

NGK C

NGK CMR5H

p

0.6 - 0.7 mm/ .024 -.028 in.

e

A

F

S

S

Slid

/

C

e

G

e

Sp

s

G

e

S

EPA

Throttl

nterloc

HFLÀFDWLRQV

Model

ngine Typ

ngine Bore x Strok

ne Displacemen

nit Weight, Less Fuel 6.3

nit Dimensions (LxWxH

Max. Power

uel Tank Capacit

uel/oil rati

arbureto

gnitio

park Plug**

Electrode Ga

Torqu

ir Cleaner

tarting Method Recoil type

topping Method

Blade Length 567 mm

lutch Typ

ear Typ

ear Lubrication Lithium-based greas

tandard Equipment

Tool kit w/ spark plug wrench, 4mm hex wrench, 8 x 10 mm spanner, blade scabbard.

Emission Compliance Period* Category A

Specifications are su

ject to change without notice

ng hours for which the engine has been shown to meet Federal emission requirements. Category C = 50 hours (Moderate), B = 125

ours (Intermediate) and A = 300 hours (Extended).

* The NGK CMR5H also meets the requirements for electro magnetic compliance (EMC).

4-cycle, vertical cylinder, air coole

34 x 27 mm/1.34 x 1.06 in.

4.5cc/1.5 cu. in.

14 lbs

2360 x 225 x 235 mm / 92.9 x 8.9 x 9.3 in

.8 KW / 1.1 hp @ 7,500 min

,000 (±250) min

590 ml/20.3 oz.

ro WYL, Diaphragm type

100-150 kg cm / 9.8 - 14.7 N∙m

oam pre-filter; sealed felt main filter

e switch, grounding type

22.3 in

Automatic, centrifugal clutch with bevel gear

ur gear

h Lock

-

e Trimmer

earcase

utter Blades

Page 6

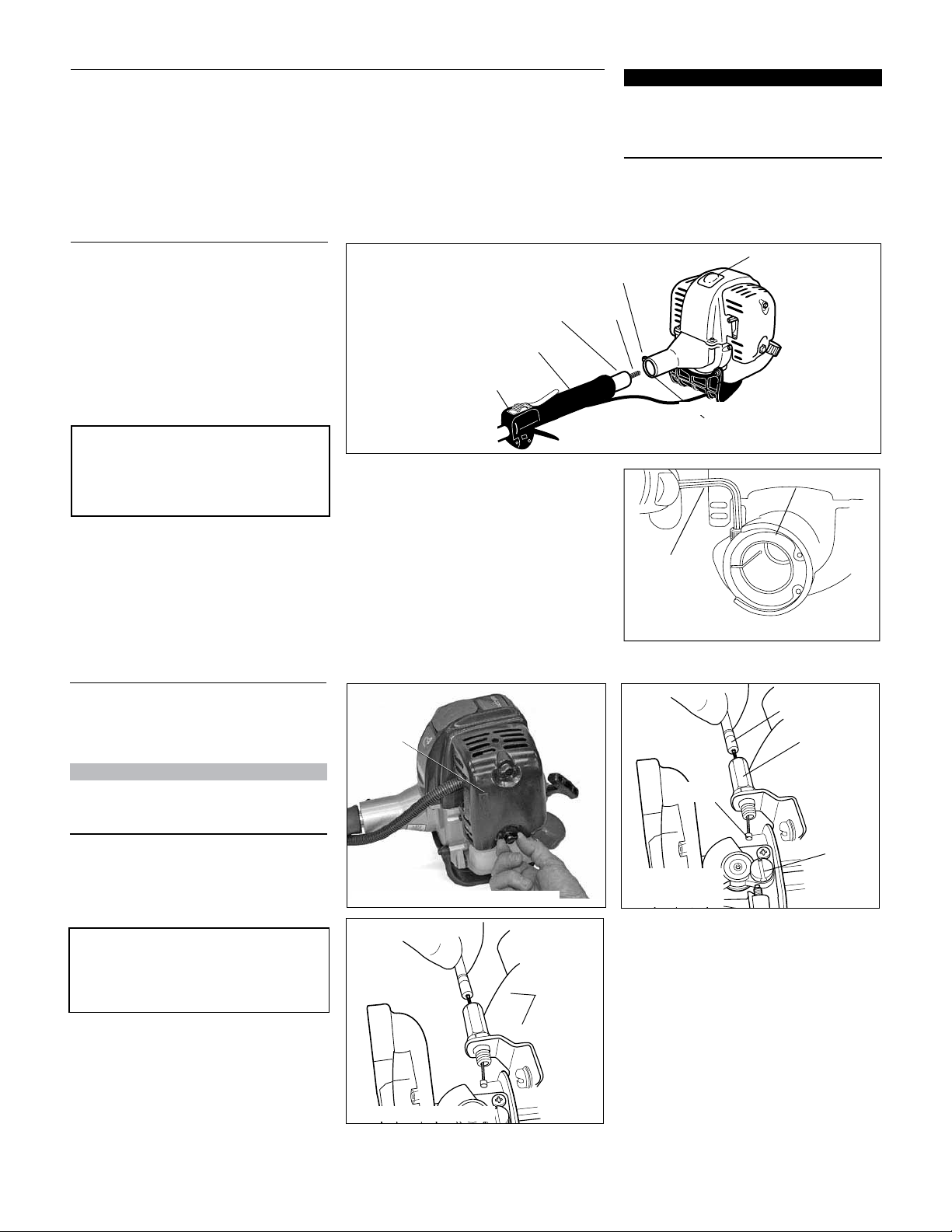

Assembly

Prior To Assembly

Before assembling, make sure you have

all the components required for a complete unit:

Engine assembly

Ŷ

Outer tube/cutter assemblyŶ

StrapŶ

Connect the Outer Tube to the Powerhead

Place the powerhead on a clean, flat 1.

surface, spark plug facing up.

Use the 4 mm hex wrench to loosen the 2.

tube clamp screw.

Slide the outer tube into the tube 3.

clamp until the tube bottoms. If installation is difficult, rotate the outer tube

or main shaft slightly until you feel

the mainshaft splines engage with the

powerhead.

CAUTION!

Do not force the shaft tube into the

powerhead! Excessive force can damage the shaft tube and mainshaft.

Position the outer tube so that the 4.

gearcase output shaft is facing left on

muffler cover.

Kit with this manual and tool kit for rou-Ŷ

tine maintenance.

Cutter blade cover

Ŷ

Carefully inspect all components for

damage.

Connect outer tube to

powerhead

Slide the outer tube into the powerhead 5.

until the throttle grip just contacts the

tube clamp.

Tighten the clamp screw firmly.6.

Trigger

Housing

Outer Tube

Grip

Clamp Screw

Mainshaft

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

Spark Plug

Tube Clamp

Tube Clamp

Hex

Wrench

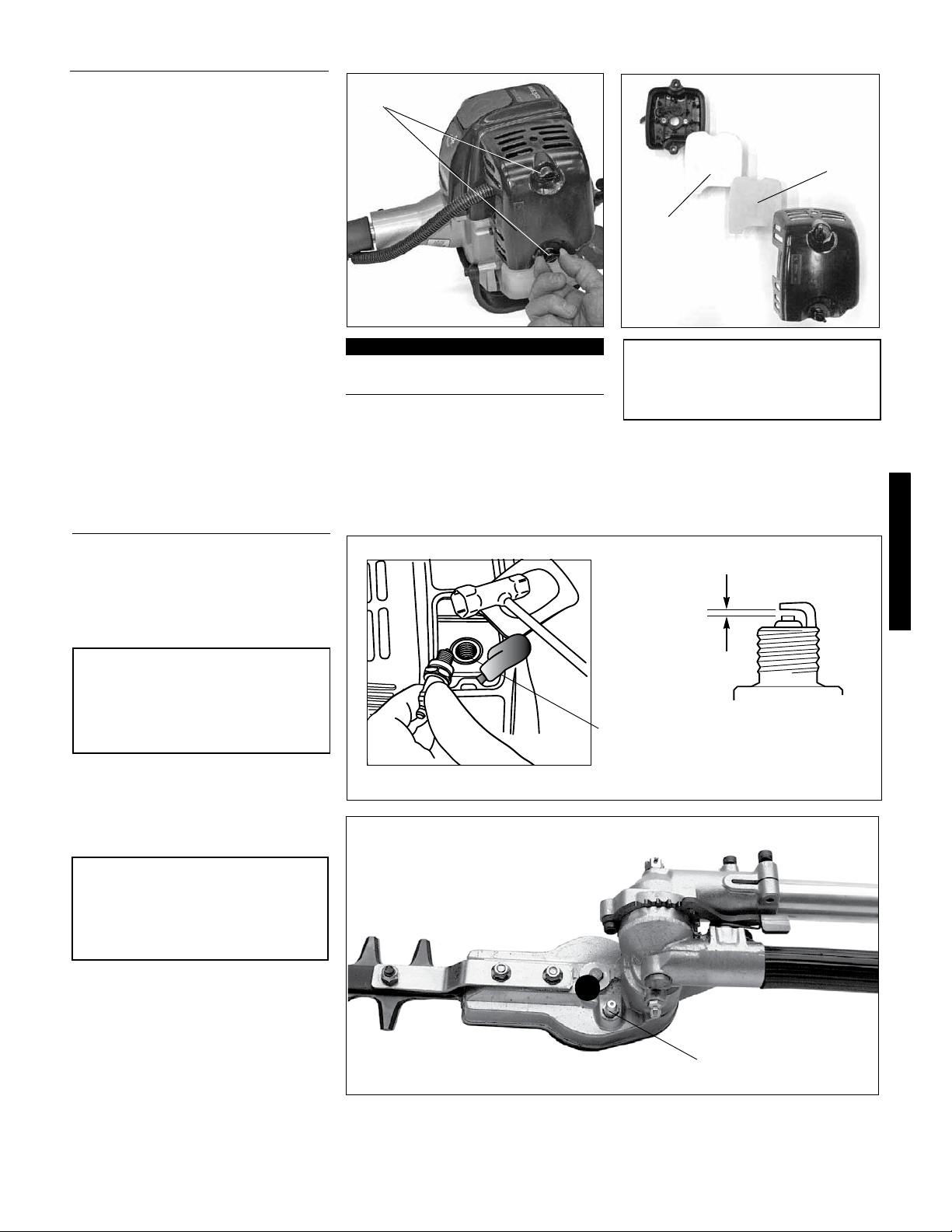

Connect the Throttle Cable

Loosen the air cleaner cover knob and 1.

remove the air cleaner cover.

Push the throttle cable through the 2.

cable adjustor.

NOTE

Make sure the ribbed cable tube is on

the left side of the engine before connecting the throttle cable.

Connect the bullet-shaped end of the throt-3.

tle cable to the throttle lever on top of

the carburetor.

Connect ignition leads.4.

CAUTION!

Wiring runs must not interfere with

throttle operation.

Filter

Cover

Loosen air cleaner cover knobs

Ignition Lead

7LJKWHQFODPSVFUHZ¿UPO\

End of

throttle cable

Push the throttle

cable through the

cable adjustor

Throttle cable

Cable

Adjuster

Connect

end of

throttle

cable here

Connect ignirtion leads

6

Page 7

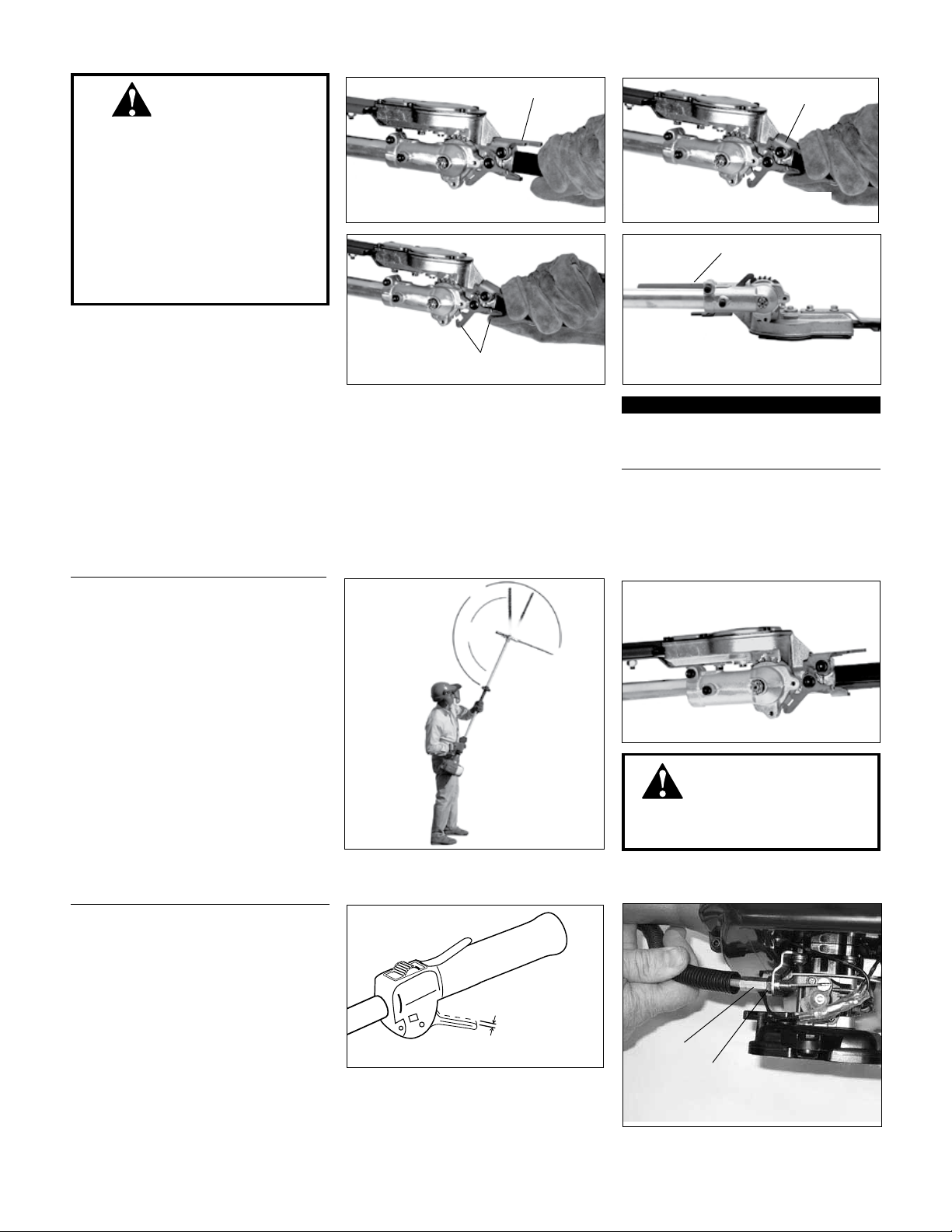

Assembly (continued)

Adjusting the Hedge Trimmer Cutter Assembly

WARNING!

The cutter blades are very sharp. Ŷ

Do not grasp the blades with your

hands. Always use gloves when

working near the cutter assembly.

Ŷ

Do not allow the blades to contact

your body.

Ŷ

Do not touch the cutter blades

when the engine is running. The

blades can oscillate even if the

engine is idling.

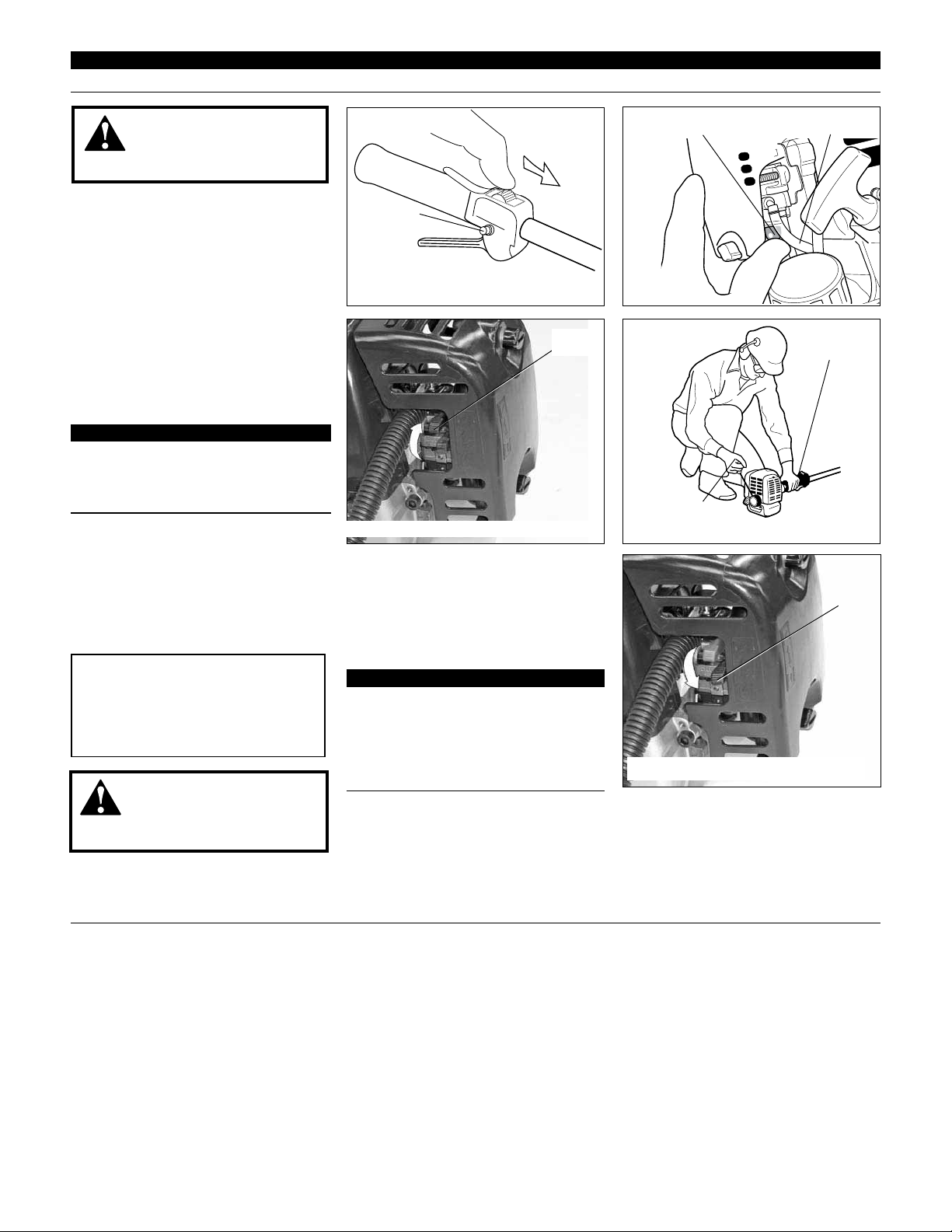

Position the hedge trimmer on a flat,1.

level surface with the engine resting

on the fuel tank guard. Make sure the

scabbard is in place on the blade.

With your right hand, grasp the outer 2.

tube near the handle. With your left

hand, grip the adjustment lever on the

cutter assembly. With the index finger of your left hand, press the latch

release. With your left thumb, press the

latch lock.

Grasp the outer tube near the handle

Press the latch lock

While holding the latch release down, 3.

pivot the cutter assembly using the

adjustment lever until it is at the

desired cutting angle.

Release the latch lock and the latch 4.

release. Make sure the latch lock and

the latch release return securely to the

straight ahead position.

Latch Lock

Adjustment Lever

Latch Release

Pivot the cutter assembly using the

adjustment lever...

Adjustment Lever

Make sure the latch lock and the latch release

return securely to the straight ahead position

IMPORTANT!

The latch lock provides an interlock to

help prevent inadvertent depression of

the latch release.

Remove the cover from the cutter blade. 5.

The engine now may be started (refer to

the section ”Starting the Engine”).

Cutter Assembly Positions

The cutter assembly can be adjusted to

eleven different positions ranging from

120° to 270° from the outer tube as shown.

Always make sure the lock latch is securely

locked after each adjustment.

Adjusting for Storage or Transportation

With the engine off, install the scab-1.

bard onto the blade.

Using the procedures described on the 2.

previous page, rotate the cutter assembly so it is parallel to the tube. Make

sure the latch lock and the latch release

return securely to a locking position.

Make sure the scabbard is in place on the 3.

cutters before storing or transporting.

Throttle lever free play

The throttle lever free play should be approximately 4 - 6 mm. Make sure that the throttle

lever operates smoothly without binding. If

it becomes necessary to adjust the lever free

play, follow the procedures and illustrations

that follow.

Loosen the air cleaner cover knob(s) and 1.

remove the air cleaner cover.

Loosen the lock nut on the cable 2.

adjuster. Turn the cable adjuster in or

out as required to obtain proper free play

4 - 6 mm.

Cutter

Assembly

Positions

Throttle lever free play

Tighten the locknut.3.

Reinstall the air cleaner cover.4.

120°

270°

Various blade

positions

possible

4 - 6 mm

Gearcase rotated to the storage/

transportation position

Adjusting for Storage or Transportation

WARNING!

Never run the engine when

adjusting the cutter assembly to the

storage position.

Cable

Adjuster

Lock Nut

Rotate cable

adjuster in or

out to obtain proper free play

7

Page 8

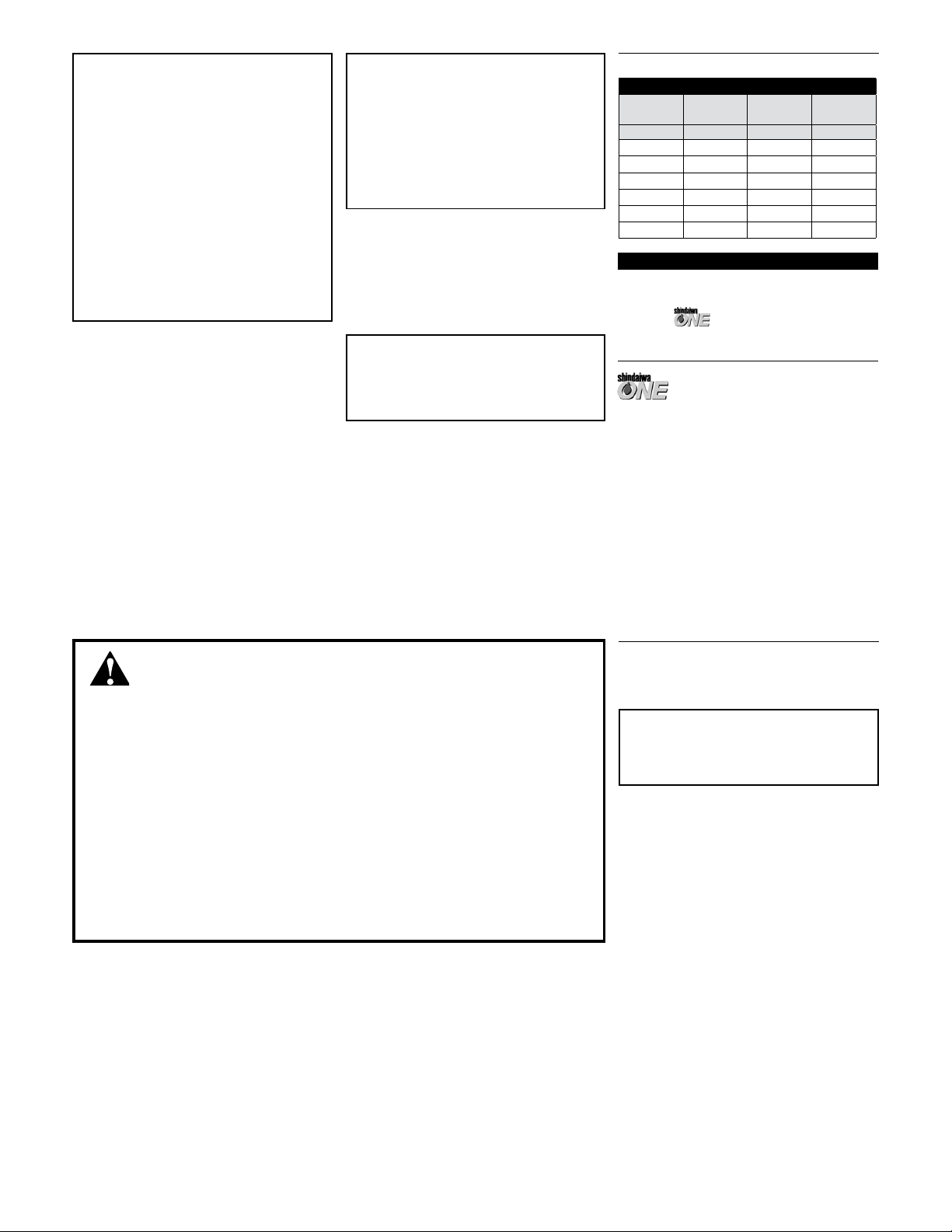

Mixing fuel

Mixing fuel

CAUTION!

Never use any type of gasoline containing more than 10% alcohol by volume! Some types of gasoline contain

alcohol as an oxygenate. Oxygenated

gasoline may cause increased operating temperatures. Under certain conditions, alcohol-based gasoline may

also reduce the lubricating qualities of

some 2-cycle mixing oils.

Generic oils and some outboard

oils should never be used in your

Shindaiwa engine.

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FD

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

Use only fresh, clean unleaded gasoline Ŷ

with a pump octane of 87 or higher.

Ŷ

Mix all fuel with a 2-cycle air-cooled

mixing oil that meets or exceeds ISO-LEGD and/or JASO FD classified oils at

50:1 gasoline/oil ratio.

CAUTION!

Mix and pour fuel outdoors where

WKHUHDUHQRVSDUNVDQGÀDPHV

Examples of 50:1 mixing quantities

U.S. METRIC

Gasoline

US Gallons Fl.oz. Liter cc.

1 2.6 4 80

2 5.2 8 160

5 13 20 400

10 25.6 30 600

20 51.2 50 1000

50 128 100 2000

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than 30

days and

used, it should first be treated with a fuel

stabilizer such as STA-BIL™.

fied oil and also meets or exceeds ISO-L-EGD

performance requirements. Shindaiwa One is

recommended for use in all Shindaiwa low emissions engines. Shindaiwa One also includes a

fuel stabilizer.

2-cycle

mixing oil

IMPORTANT!

Oil is a registered JASO FD classi-

Gasoline

oil with fuel stabilizer is not

2-cycle

mixing oil

Filling the fuel tank

WARNING!

Minimize the Risk of Fire

NEVER

Ŷ VPRNHRUOLJKW¿UHVQHDUWKH

engine.

Ŷ stop the engine and allow

ALWAYS

it to cool before refueling.

Ŷ Wipe all spilled fuel and

ALWAYS

move at least 3 meters (10 feet) from

the fueling point and source before

starting.

Ŷ SODFHÀDPPDEOHPDWHULDO

NEVER

FORVHWRWKHHQJLQHPXIÀHU

NEVERŶ operate the engine without the

PXIÀHUDQGVSDUNDUUHVWHUVFUHHQLQ

place and in good working condition.

FUEL IS HIGHLY FLAMMABLE.

Ŷ

ALWAYS Ŷstore gasoline in a con-

WDLQHUDSSURYHGIRUÀDPPDEOHOLTXLGV

Ŷ

ALWAYS

leaks before each use. During each

UH¿OOFKHFNWKDWQRIXHOOHDNVIURP

around the fuel cap and/or fuel tank. If

fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYSŶ move the unit at least 3

meters (10 feet) away from a fuel

VWRUDJHDUHDRURWKHUUHDGLO\ÀDPmable materials before starting the

engine.

inspect the unit for fuel

Place the unit on a flat, level surface.1.

Clear any dirt or other debris from 2.

around the fuel filler cap.

CAUTION!

Slowly remove the fuel cap only after

stopping the engine

Remove the fuel cap, and fill the tank 3.

with clean, fresh fuel.

Reinstall the fuel filler cap and tighten 4.

firmly.

Wipe away any spilled fuel before start-5.

ing engine.

8

Page 9

Starting the Engine

IMPORTANT!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, “I” for ON or START and “O” for OFF or STOP.

WARNING!

Never start the engine from

the operating position.

Slide the ignition switch to the “ON” 1.

position.

Set the throttle lever to the “fast idle”:2.

Squeeze the throttle lever toward a.

the handgrip on the shaft tube.

Depress and hold the throttle lock b.

button.

While depressing the throttle lock c.

button, release the throttle lever.

Press the primer bulb until fuel can 3.

be seen flowing in the transparent

return tube.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly pressing the primer bulb will not flood the

engine with fuel.

Set the choke lever to the CLOSED 4.

position if engine is cold.

While holding the outer tube firmly 5.

with left hand. Use your other hand

to slowly pull the recoil starter handle

until resistance is felt, then pull quickly

to start the engine.

CAUTION!

Do not pull the recoil starter to the end

of the rope travel. Pulling the recoil

starter to the end of the rope travel

can damage the starter.

WARNING!

The cutting attachment may

move when the engine is started!

ON

Throttle Lock

Button

Slide ignition to ON

Close

choke

Set the choke lever to the CLOSED position

When the engine starts, slowly move 6.

the choke lever to the “OPEN” position. (If the engine stops after the initial

start, close the choke and restart.)

Operating the throttle will automatically 7.

disengage the fast idle setting.

IMPORTANT!

If the engine fails to start after several

attempts with the choke in the closed

position, the engine may be flooded with

fuel. If flooding is suspected, refer to the

”Starting a Flooded Engine” section of

this manual.

Primer Bulb

Press primer

bulb...

...and pull recoil

starter handle

upward

After engine starts, move choke to OPEN

position

Return Tube

Hold

the unit

¿UPO\

Make sure the

attachment is clear

of obstructions!

Open

When the Engine Starts...

Ŷ

After the engine starts, allow the

engine to warm up at idle 2 or 3 minutes before operating the unit.

Ŷ

After the engine is warm, pick up the

unit and clip on the shoulder strap, if

so equipped.

Advancing the throttle makes the cutting

Ŷ

attachment move faster; releasing the

throttle permits the attachment to stop

moving. If the cutting attachment con-

tinues to move when the engine returns

to idle, carburetor idle speed should be

adjusted (see “Adjusting Engine Idle”.).

9

Page 10

Starting the Engine (continued)

Starting A Flooded Engine

Disconnect the spark plug lead and use 1.

the spark plug wrench to remove the

spark plug (turn counter clockwise to

remove).

Slide the ignition switch to the “O” 2.

(STOP) position.

Ŷ

If the spark plug is fouled or

soaked with fuel, clean the plug as

necessary.

Stopping the Engine

Idle the engine briefly before stopping

(about 2 minutes), then slide the ignition

switch to the “O” (Engine OFF) position.

Adjusting Engine Idle

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment.

WARNING!

The cutting attachment must

NEVER rotate at engine idle! If the

idle speed cannot be adjusted by

the procedure described here, return

the unit to your Shindaiwa dealer for

inspection.

Open the choke and fully depress the 3.

throttle lever with your left hand, then

pull the starter handle rapidly with your

right hand to clear excess fuel from the

combustion chamber.

Replace the spark plug and tighten it 4.

firmly with the spark plug wrench. If a

torque wrench is available, torque the

spark plug to the values recommended

in the “Specifications” section.

OFF

Slide ignition to OFF

Idle Speed Adjustment

Place the unit on the ground, then start 1.

the engine, and then allow it to idle 2-3

minutes until warm.

If the attachment rotates when the 2.

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise.

If a tachometer is available, adjust idle. 3.

Check Specifications page for correct

idle speed

NOTE

Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

LQWKH¿HOG

Repeat the starting procedure for a 5.

warm engine.

If the engine still fails to start, refer to 6.

the troubleshooting section near the

end of this manual.

Idle Adjusting

Screw

Checking Unit Condition

NEVER operate the unit with the cutting attachment shield or other protective devices removed!

Use only authorized Shindaiwa parts and

accessories with your Shindaiwa trimmer.

Do not make modifications to this unit without written approval from Shindaiwa, Inc.

ALWAYS make sure the cutting attachment is properly installed and firmly

tightened before operation.

NEVER use a cracked or warped

cutting attachment: replace it with a

serviceable one.

10

ALWAYS make sure the cutting attachment fits properly into the appropriate

attachment holder. If a properly installed

attachment vibrates, replace the attachment with new one and re-check.

ALWAYS stop the engine immediately

and check for damage if you strike a

foreign object or if the unit becomes

tangled. Do not operate with broken or

damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could damage the engine.

NEVER operate a unit with worn or damaged fasteners or attachment holders.

WARNING!

A cutting attachment shield or

other protective device is no guarantee

of protection against ricochet. YOU

MUST ALWAYS GUARD AGAINST

FLYING DEBRIS!

Page 11

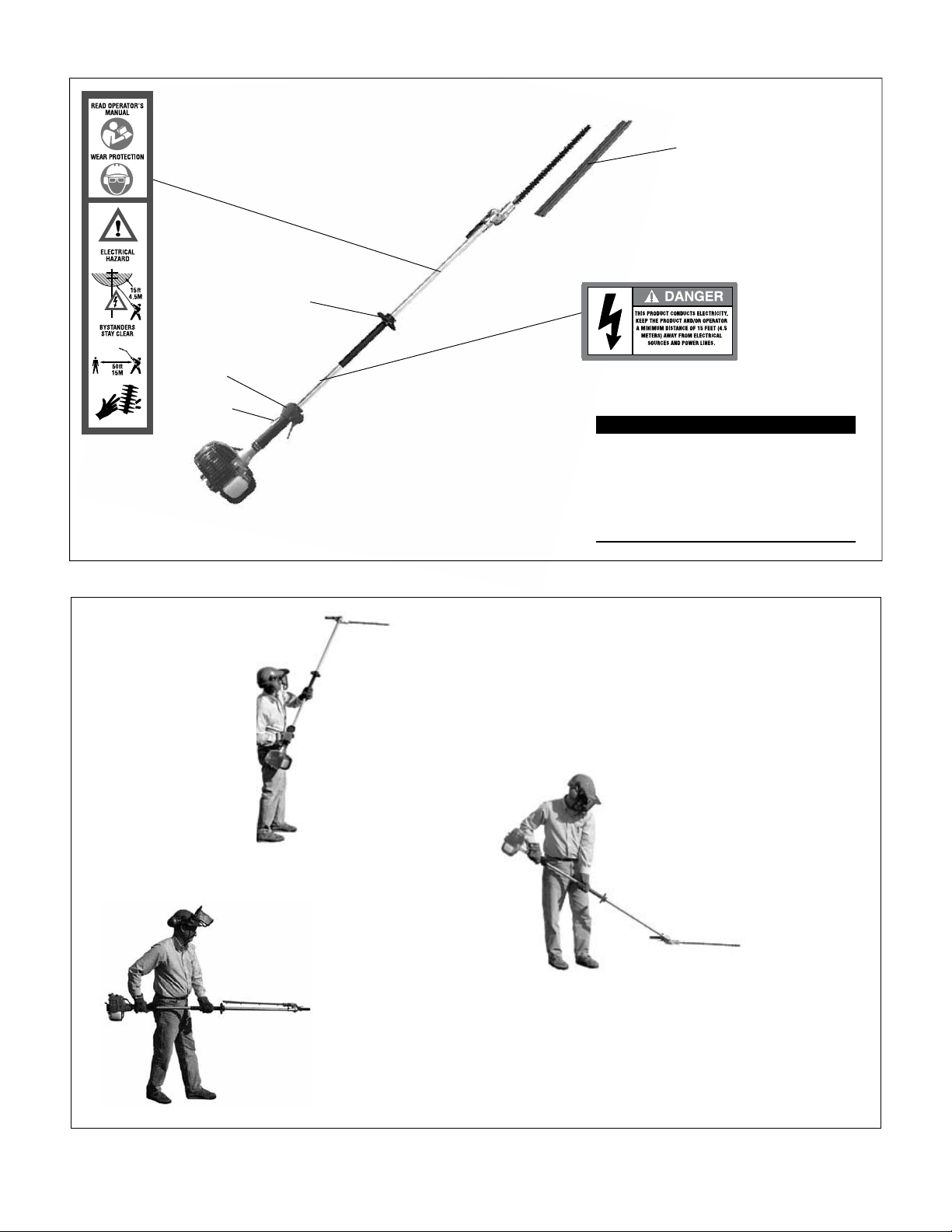

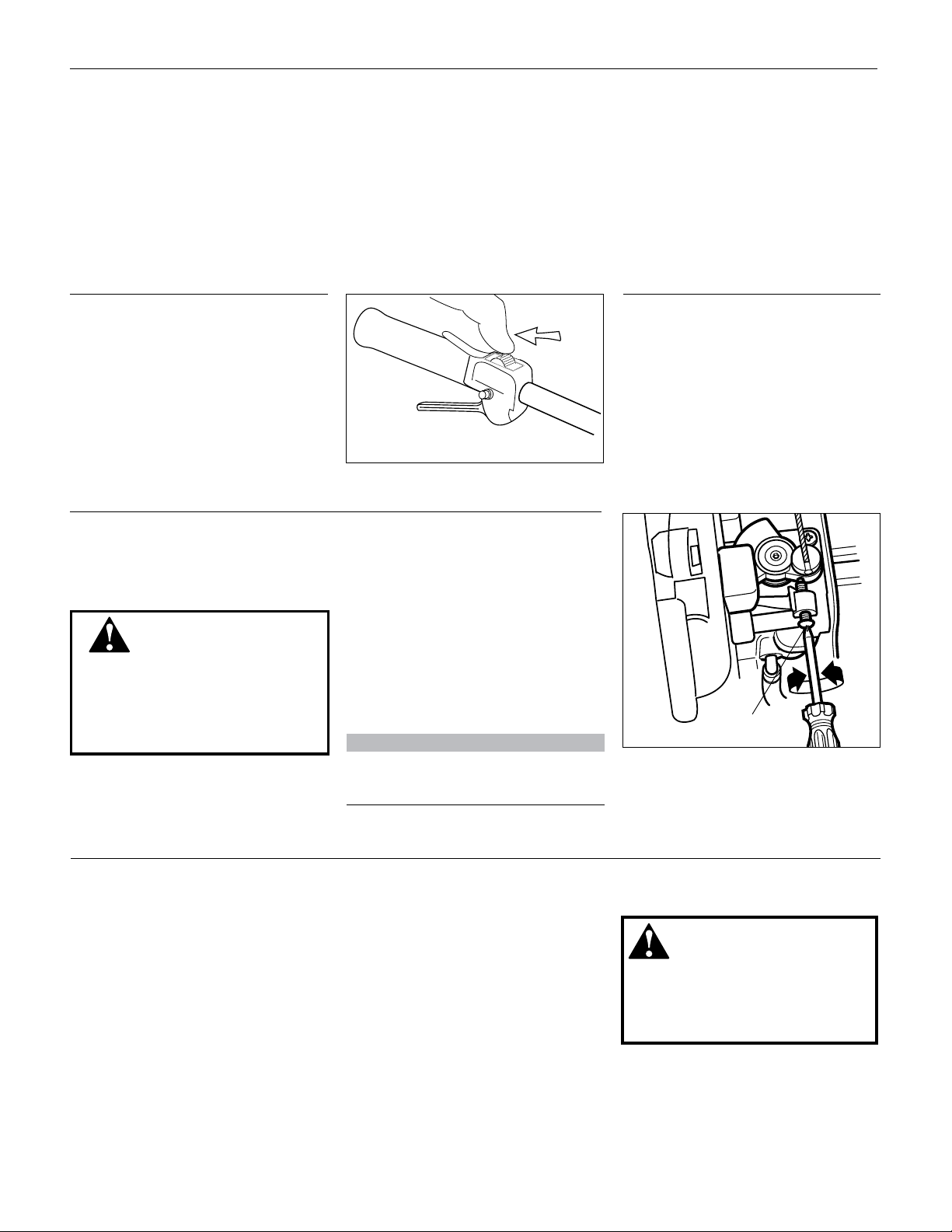

Operation

Using the Hedge Trimmer

Preparations

Use lopping shears to cut out thick

branches first.

Cutting Sequence

If a radial cut is necessary, cut a little at a

time in several passes.

Cutting Techniques

Vertical Cut:

Swing the blade up and down in an arc as

you move along the hedge. Use both sides

of the cutting blade.

Cut without standing directly next to the

hedge, e.g. with a flower bed between

operator and hedge.

Overhead Cut:

Hold the shaft upright with a 90° blade

angle to cut an upper surface of a hedge.

Horizontal Cut:

Hold the cutting blade at an angle of 0°

to 10° as you swing the hedge trimmer

horizontally.

Swing the blade in an arc towards the

outside of the hedge so that the cuttings

are swept on to the ground.

Cut without standing directly in front of the

hedge, e.g. reach over a flower bed.

Cut close to the ground from a standing position, e.g., for low shrubs.

Vertical Cut

Overhead Cut

Horizontal Cut

Horizontal Cut at ground level

11

Page 12

Maintenance

General maintenancel

IMPORTANT!

MAINTENANCE, REPLACEMENT

OR REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED

BY A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA INC. THE

USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY

IMPAIR THE EFFECTIVENESS OF THE

EMISSION CONTROL SYSTEM AND MAY

HAVE A BEARING ON THE OUTCOME

OF A WARRANTY CLAIM.

NOTE:

Using non-standard replacement parts

could invalidate your Shindaiwa warranty.

WARNING!

Before performing any maintenance, repair, or cleaning work on the

unit, make sure the engine and cutting

attachment are completely stopped.

Disconnect the spark plug wire before

performing service or maintenance.

0XIÁHU

This unit must never be operated with a

faulty or missing spark arrester or muffler. Make sure the muffler is well secured

and in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

WARNING!

Non-standard accessories, cutting attachment, or replacement parts

may not operate properly with your unit

and may cause damage and lead to

personal injury.

Air Filter

The C4 engine that powers your Shindaiwa

model is a hybrid 4-stroke engine. As a

hybrid, the engine is lubricated by oil mixed

with the gasoline and air from the carburetor

that moves through and around the internal

parts of the engine in a similar way that a

2-stroke engine is lubricated. Without the

heavy duty 2-stage air filter equipped on all

C4 engines, dust and dirt could also move

through the engine, decreasing engine life,

increasing valve wear and the need for more

frequent valve adjustments. To keep your

C4 engine strong and reliable, Shindaiwa

recommends that you check and service the

air filter as instructed in the 10-Hour Maintenance section that follows.

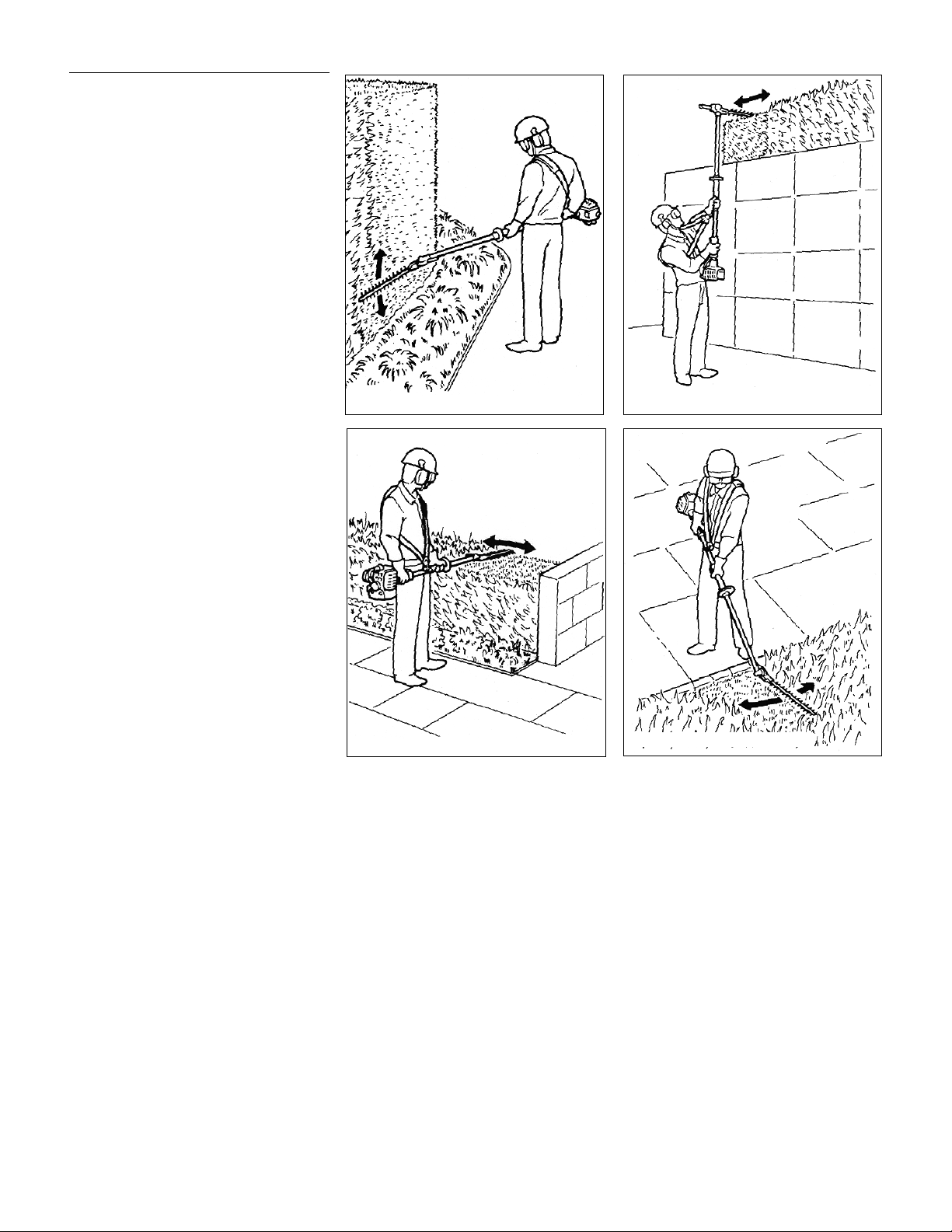

Daily maintenance

Prior to each work day, perform the

following:

Ŷ

Remove all dirt and debris from the

engine, check the cooling fins and

air cleaner for clogging, and clean as

necessary.

Ŷ

Carefully remove any accumulations

of dirt or debris from the muffler and

fuel tank. Check cooling air intake

area at base of crankcase. Remove

all debris. Dirt build-up in these areas

can lead to engine overheating, fire,

or premature wear.

WARNING!

Always wear gloves when

working around the cutter assembly.

Lubricate the blades before use and Ŷ

after refueling. Check the cutters for

damage or incorrect adjustment.

Ŷ

Clean any debris or dirt from the cutting attachment.

Cooling

¿QV

Cooling

¿QV

5HPRYHDOOGLUWDQGGHEULVIURPWKHHQJLQHDQGFKHFNWKHFRROLQJ¿QV

Check for loose or missing screws or Ŷ

components. Make sure the cutter

attachment is securely fastened.

Ŷ

Check the entire unit for leaking fuel

or grease.

Make sure nuts, bolts, and screws

Ŷ

(except carburetor idle speed adjusting

screws) are tight.

Air

intake

12

Page 13

Maintenance (continued)

10-Hour maintenance

(more frequently in dusty conditions)

Remove the air filter cover by loosen-1.

ing the cover screw(s) and lifting.

Remove and inspect the pre-filter. If 2.

the pre-filter is torn or otherwise damaged, replace it with a new one.

Clean the pre-filter with soap and water. 3.

Let dry before reinstalling.

Inspect the air filter element. If the ele-4.

ment is damaged or distorted, replace it

with a new one.

Tap filter gently on a hard surface to dis-5.

lodge debris from element or use compressed air from the inside to blow debris

out and away from the air filter element.

Install the air filter element, pre-fil-6.

ter and cover in the reverse order of

removal.

10/15-Hour maintenance

Remove and clean or replace the spark

plug.

Clean the spark plug. Adjust electrode

Ŷ

gap according to the values listed in the

”Specifications” section. If the spark plug

must be replaced, use only the type recommended in ”Specifications” or equivalent resistor type spark plug of the correct

heat range.

Loosen

fasteners

5HPRYHWKHFRYHURIWKHDLU¿OWHU

IMPORTANT!

Direct the air stream at the inside face of

the filter only!

3UH¿OWHU

Filter element

&RPSRQHQWVRIDLU¿OWHU

CAUTION!

Never operate the unit if the air cleaner

assembly is damaged or missing!

Clean the spark

plug and check

the gap at the

electrode.

0,6 - 0.7 mm

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine’s internal parts.

Gearcase lubrication

Lubricate the cutter assembly Ŷ

gearcase by pumping one or two

strokes of lithium-base grease into the

grease fitting (A) using a lever-type

grease gun.

CAUTION!

Over lubricating can cause the gearcase to operate sluggishly and can

cause grease to leak out.

Remove and inspect spark plug

A

Lubricate cutter assembly and gearcase

Gearcase

JUHDVH¿WWLQJV

13

Page 14

Maintenance (continued)

50-hour maintenance

Every 50 hours of operation; more frequently in dusty conditions:Remove and

clean the cylinder cover and clean dirt and

debris from the cylinder cooling fins.

Remove and replace the fuel filter

element.

Use a hooked wire to extract the fuel filter

Ŷ

from inside the fuel tank. Inspect the fuel

filter element. If it shows signs of contamination, replace with a genuine Shindaiwa

replacement fuel filter element.

CAUTION!

Make sure you do not pierce the fuel line

with the end of the hooked wire. The line

is delicate and can be damaged easily.

Before reinstalling the new filter element,

inspect the condition of all the fuel

system components (fuel pick-up line,

fuel return line, tank vent line, tank

vent, fuel cap and fuel tank). If damage,

splitting or deterioration is noted, the

unit should be removed from service

until it can be inspected or repaired by a

Shindaiwa-trained service technician.

Gearcase lubrication

To perform this operation, first remove the

gearcase from the outer tube as follows:

Loosen the gearcase clamp bolt.1.

Remove the index bolt from the 2.

gearcase.

CAUTION!

Do not remove the D-shaped shim

washer from the gearcase clamp! The

shim washer prevents damage from

overtightening the tube clamp bolt.

Hooked wire

)XHO¿OWHUPDLQWHQDQFH

Gearcase lubrication

Outer tube

Remove the outer tube from the gearcase

Gearcase

)XHO¿OWHUHOHPHQW

Gearcase Clamp bolt

Index bolt

Slide the gearcase out of the tube. 3.

Using a grease gun, pump lithium-

base grease (about 10 grams) into the

grease fitting (B) on the gearcase until

you see old grease being purged from

the gearcase. Purged grease will be

visible in the outer tube cavity.

Clean up excess grease, then reas-4.

semble the gearcase onto the outer

tube. Make sure the index bolt fits into

the hole on the outer tube. Securely

tighten both bolts.

14

Pump lithium-based grease into gearcase

JUHDVH¿WWLQJ

B

Gearcase

JUHDVH¿WWLQJV

Page 15

Maintenance (continued)

139/150-Hour Maintenance

Maintenance after first 139-hours,

then every 150-hours thereafter.

Ŷ

Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

Valve Adjustment

Remove cylinder cover, rocker arm cover, 1.

and spark plug.

while observing the piston through the

spark plug opening. When the piston

is at the top of the compression stroke

(TDC), the valves can be adjusted.

CAUTION!

Ŷ

Performing a valve adjustment

incorrectly may cause hard starting

and/or can damage the engine.

Ŷ

If you are unfamiliar with this

engine or uncomfortable with this

procedure, consult with an authorized Shindaiwa servicing dealer.

Rotate the crankshaft

Replace the spark plug annually: Use

Ŷ

only the type recommended in the

”Specifications” section or an equivalent

resistor type spark plug of the correct

heat range. Set spark plug electrode

gap to 0.6 -0.7 mm.

Loosen adjuster locknut so that the 2.

2.5 mm Allen socket head adjustment

screw can turn freely.

Insert 0.10 mm feeler gauge between 3.

valve stem tip and rocker arm.

Turn adjustment screw (clockwise = 4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug. Back

off just enough to allow gauge to slip

out with limited resistance.

While holding the adjustment screw in 5.

place with the Allen driver, tighten the

locknut with a wrench.

The valve clearance should be adjusted Ŷ

annually or every 135 hours. It is

highly recommended that this is

done by a Shindaiwa-trained service

technician.

Turn engine over several times, and 6.

returnthe to TDC-compression.

Recheck with proper feeler gauge to

make sure clearance adjustment did

not change as a result of tightening the

locknut. Readjust as necessary.

Replace rocker arm cover gasket to 7.

assure proper sealing and install cover.

IMPORTANT!

If a new gasket is not available and/or the

old gasket is not damaged, the old gasket

may be reused. Never use cracked or damaged gaskets!

Cutter blade adjustment

WARNING!

The cutter blades are very

sharp! Always wear gloves when working around the cutter assembly.

Cutting performance of your machine

depends a great deal on proper cutter blade

adjustment. Properly adjusted blades will

oscillate freely yet help prevent binding of

cut material between blades. Adjust blades

as follows:

Loosen all blade locknuts at least one 1.

full turn.

Tighten each blade shoulder bolt 2.

firmly, and then loosen the shoulder

bolts 1/4 to 1/2 turn.

Working from the gearcase end, lock 3.

each bolt in place by firmly tightening

its locknut while preventing the shoulder bolt from turning.

When shoulder bolt adjustment is correct, there should be a gap of 0.25–0.50

mm between the cutter blades and the flat

washers, and the flat washer beneath each

bolt head should turn freely.

CAUTION!

Operating the trimmer with worn or

improperly adjusted cutters will reduce

cutter performance and may also damage your machine. Never operate the

machine with damaged or worn cutters.

Guide Bar

Cutter

Blades

Adjusting cutter blades

Shoulder Bolt

Locknut

Washer (should

turn freely)

15

Page 16

Maintenance (continued)

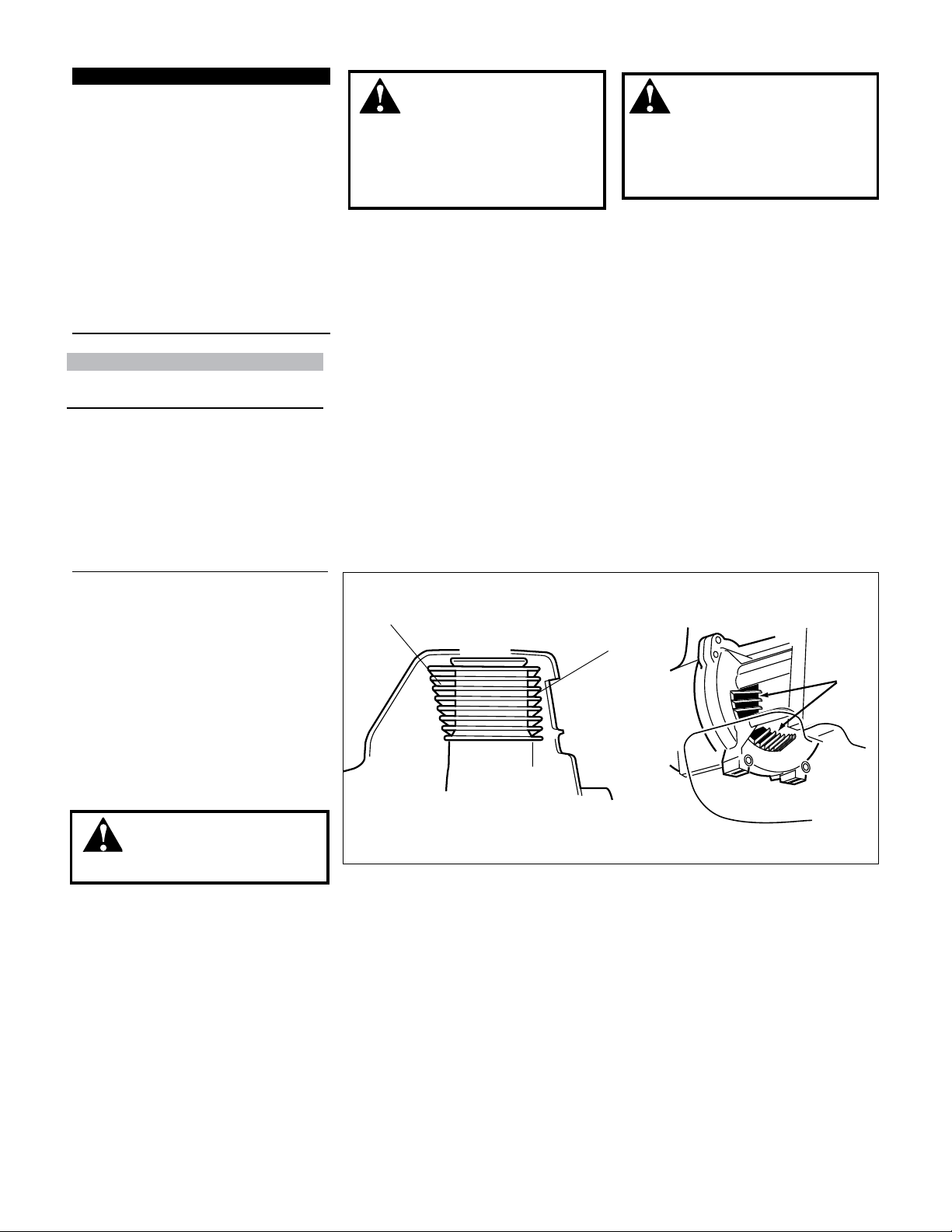

0XIÁHUDQGVSDUNDUUHVWHUPDLQWHQDQFH

If the engine becomes sluggish and low

on power, check and clean the spark

arrester screen.

WARNING!

Never operate the unit with a

GDPDJHRUPLVVLQJPXIÀHURUVSDUN

arrester! Operating with a missing or

GDPDJHGVSDUNDUUHVWHULVD¿UHKD]DUG

and could also damage your hearing.

With a 3 mm hex wrench remove the 1.

4 engine cover screws and the engine

cover.

With a 4 mm hex wrench, remove the 3 2.

muffler bolts and the muffler.

With a small flat bladed screwdriver 3.

remove the 2 screws holding the

spark arrester screen and cover to the

muffler.

Remove the screen and clean it with a 4.

stiff bristle brush.

Inspect the cylinder exhaust port for 5.

any carbon buildup.

Reassemble the spark arrester, muffler 6.

and engine cover in the reverse order

of disassembly.

IMPORTANT!

If you note excessive carbon buildup, consult with an authorized servicing dealer.

Engine Cover

Engine Cover

Screws

0XIÀHU

0XIÀHU*DVNHW

0XIÀHU%ROWV

Spark Arrester Screen

Spark Arrester Cover

Cover Screws

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following procedures to prepare it for storage:

Ŷ

Clean external parts thoroughly.

Drain all the fuel from the carburetor Ŷ

and the fuel tank.

To do so:

Prime the primer bulb until no more 1.

fuel is passing through.

Start and run the engine until it 2.

stops running.

Repeat steps 1 and 2 until the engine 3.

will no longer start.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard starting, and could also lead to increased

service and maintenance costs.

IMPORTANT!

All stored fuels should be stabilized with a

fuel stabilizer such as STA-BIL.

NOTE

Damage caused by stale or contaminated

fuel is not covered by the Shindaiwa warranty policy.

Remove the spark plug and pour about Ŷ

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the interior

of the engine. Reinstall the spark plug.

Ŷ

Before storing the unit, repair or

replace any worn or damaged parts.

Ŷ

Remove the air cleaner element from

the carburetor and clean it thoroughly

with soap and water, let dry and reassemble the element.

Ŷ

Store the unit in a clean, dust-free area.

16

Page 17

Troubleshooting Guide

What To Check Possible Cause Remedy

ENGINE DOES NOT START

Does the engine crank?

YES

Good compression?

YES

Does the tank contain

fresh fuel of the proper

grade?

YES

Is fuel visible and moving

in the return line when

priming?

NO

NO

NO

NO

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Loose spark plug.

Excess wear on cylinder, piston,

rings.

Fuel incorrect, stale, or contaminated;

mixture incorrect.

Check for clogged fuel filter and/

or vent.

Consult with an authorized servicing

dealer.

Tighten and re-test.

Consult with an authorized servicing

dealer.

Refill with fresh, clean unleaded gasoline

with a pump octane of 87 or higher

mixed with a premium 2-cycle mixing oil

or with an equivalent high quality 2-cycle

mixing oil.

Replace fuel filter or vent as required.

Restart.

YES

Is there spark at the spark

plug wire terminal?

YES

Check the spark plug.

NO

The ignition switch is in “O” (OFF)

position.

Shorted ignition ground.

Faulty ignition unit.

If the plug is wet, excess fuel may be in

the cylinder.

The plug is fouled or improperly gapped.

The plug is damaged internally or of the

wrong size.

Move switch to “I” (ON) position and

restart.

Consult with an authorized servicing

dealer.

Crank the engine with the plug removed,

reinstall the plug, and restart.

Clean the spark plug. Check the

Specifications section for the correct plug

and gap for your unit. Restart.

Replace the spark plug. Check the

Specifications section for the correct plug

and gap for your unit. Restart.

17

Page 18

Troubleshooting Guide (continued)

What To Check Possible Cause Remedy

LOW POWER

Is the engine overheating?

Engine is rough at all

speeds. May also have black

smoke and/or unburned

fuel at the exhaust.

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty or

damaged

Carbon deposits on the piston or in the

muffler.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Operate at slower rate.

Consult with an authorized servicing

dealer.

Refill with clean fresh unleaded gasoline

with a pump octane of 87 or higher, mixed

with a premium 2-cycle mixing oil at a 50:1

gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing

dealer

Clean or replace the air filter

Tighten or replace the spark plug.

Restart. Check the Specifications section

in this manual for the correct spark plug

for this unit.

Repair or replace fuel filter and/or fuel

line.

Engine is knocking.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm

Overheating condition.

Improper fuel.

Carbon deposits in the

combustion chamber.

Valve clearance set incorrectly.

Refill with fresh fuel/oil mixture.

Consult with an authorized servicing

dealer.

Consult with an authorized servicing

dealer.

Check fuel octane rating; check for

presence of alcohol in the fuel. Refuel as

necessary.

Consult with an authorized servicing

dealer.

18

Page 19

Troubleshooting Guide (continued)

ADDITIONAL PROBLEMS

What To Check Possible Cause Remedy

Clogged air filter.

Poor acceleration.

Clogged fuel filter.

Lean fuel/air mixture.

Idle speed set too low.

Clean or replace the air filter.

Replace the fuel filter.

Consult with an authorized

servicing dealer.

Adjust idle. Check Specifications page for

correct idle speed.

Engine stops abruptly.

Engine difficult to

shut off.

Top of engine is getting

dirty and oily.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected or

switch is defective

Overheating due to incorrect spark plug

Overheated engine.

Valve cover is leaking. Consult with an authorized

Reset the switch and re-start.

Refuel. See Fuel section of manual.

Replace fuel filter.

Drain; replace with clean fuel. See Fuel

section of manual..

Clean or replace spark plug. Check the

Specifications page in this manual for the

proper spark plug for your unit. Tighten

the terminal.

Replace the ignition unit.

Consult with an authorized

servicing dealer

Test and replace as required.

Replace the spark plug. Check the

Specifications page in this manual for the

proper spark plug for your unit.

Idle engine until cool.

servicing dealer.

Engine will not

idle down.

Cutting attachment

moves at engine idle.

Excessive vibration.

Cutting attachment will

not move.

Idle set too high. Adjust idle. Check Specifications page for

Engine has an air leak. Consult with an authorized servicing dealer.

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Warped or damaged attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Shaft not installed in powerhead or

gearcase.

Broken shaft.

Damaged gearcase.

correct idle speed.

Adjust idle. Check Specifications page for

correct idle speed.

Replace spring/shoes as required,

check idle speed.

Inspect and re-tighten holders securely.

Inspect and replace attachment

as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Inspect and reinstall as required.

Consult with a authorized

servicing dealer.

19

Page 20

Emission System Warranty Statement

Your Warranty Rights and Obligations

The California Air Resources Board, the U.S. Environmental Protection Agency and Shindaiwa Inc. are pleased

to explain the exhaust and evaporative emission control

system warranty on your new small off-road (non-road)

engine.

In California, new small off-road engines must be

designed, built, and equipped to meet the State’s stringent

anti-smog standards. In other states, new 1997 and later

non-road engines must meet the Federal EPA’s stringent

anti-smog standards.

Shindaiwa Inc. must warrant the emission control system on your small off-road engine for the periods of time

listed below, provided there has been no abuse, neglect,

or improper maintenance of your small off-road engine.

Your engine exhaust and evaporative emission control

system includes parts such as the carburetor, fuel tank,

the ignition system and, if equipped, the catalytic converter. These components are specifically listed below.

Where a warrantable condition exists, Shindaiwa Inc.

will repair your small off-road engine at no cost to you

including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

When sold within the U.S., this engine’s emission control

system is warranted for a period of two (2) years from the

date this product is first delivered to the original retail

purchaser.

During the warranty period, Shindaiwa Inc. will, at their

option, repair or replace any defective emission-related

component on this engine. During the original Warranty

Period, these Warranty Rights are automatically transferable to subsequent owners of this product.

What is Covered by this Warranty

Carburetor Internal Components1.

Ŷ

Throttle Valve, Needle, Jet, Metering Diaphragm

Fuel Tank2.

Ignition System Components3.

Ŷ

Ignition Coil

Flywheel RotorŶ

Catalytic Converter (if originally equipped)4.

The emission control system for your particular

Shindaiwa engine may also include certain related hoses

and connectors.

Owners Warranty Responsibilities

As the small off-road engine owner, you are responsible

for the performance of the required maintenance listed in

this owners manual. Shindaiwa Inc. recommends that you

retain all receipts covering maintenance on your small

off-road engine, but Shindaiwa Inc. cannot deny warranty

solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the small off-road engine owner, you should be

aware, however, that Shindaiwa Inc. may deny you warranty coverage if your small off-road engine or a part has

failed due to abuse, neglect, improper maintenance, or

unapproved modifications.

You are responsible for presenting your small off-road

engine to an authorized Shindaiwa Dealer as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights

and responsibilities, you should contact a Shindaiwa customer service representative at (503) 692-3070 or your local

Shindaiwa Dealer.

Consequential Damages

In the event that other component parts of this product

are damaged by the failure of a warranted part, Shindaiwa

Inc. will repair or replace such component parts at no

charge to you.

What is Not Covered

Failures caused by abuse, neglect, or improper main-

Ŷ

tenance procedures.

Ŷ

Failures caused by the use of modified or nonapproved parts or attachments.

This Warranty is Administered by:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, OR 97062

(503) 692-3070

20

Page 21

NOTES

NOTAs

REMARQUES

21

Page 22

NOTES

NOTAs

REMARQUES

22

Page 23

NOTES

NOTAs

REMARQUES

23

Page 24

NOTES

NOTAs

REMARQUES

Shindaiwa Inc.

11975 SW Herman Rd.

Tualatin, Oregon 97062

U.S.A.

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

Shindaiwa Corporation.

6-2-11, Ozuka-Nishi,

Asaminami-Ku, Hiroshima

731-3167, Japan

Telephone: 81-82-849-2220

Fax: 81-82-849-2481

© 2009 Shindaiwa Inc.

Shindaiwa is a registered trademark of Shindaiwa Inc.

Specifications subject to change without notice.

Page 25

SHINDAIWA MANUAL DEL PROPIETARIO/OPERADOR

CORTASETOS ARTICULADO

AH2510/EVC

¡ADVERTENCIA!

Minimize el riesgo de accidentes contra usted u

otras personas. Lea este manual y familiaricese con sus

contenidos. Siempre utilice protección para los ojos y

oídos cuando la unidad sea usada.

Número de pieza 89310 Rev. 6/09

Page 26

Introducción

Los cortasetos articulado Shindaiwa serie

C4 ha sido diseñada y construida para suministrar rendimiento superior y seguridad sin

comprometer calidad, comodidad o durabilidad. Los motores de alto rendimiento

Shindaiwa representan la tecnología líder en

motores de enfriados por aire, de cilindrada

y peso notablemente bajos que desarrollan

suma potencia. ¡Como dueño/operario, usted

muy pronto descubrirá por que Shindaiwa,

Español

simplemente, es la única en su clase!

¡IMPORTANTE!

Estas instrucciones contienen información que

describe los modelos disponibles en el momento

de su publicación. .

Shindaiwa Inc. se reserva el derecho de

realizar cambios a sus productos sin previo

aviso, y sin la obligación de hacer modificaciones a máquinas fabricadas previamente.

¡ADVERTENCIA!

Las emisiones liberadas por

el escape del motor de este producto

contienen sustancias químicas que, en

el estado de California, son consideradas como causantes de cáncer, defectos congénitos u otros efectos nocivos

para la reproducción.

Contenido

Seguridad....................................................3

Descripción del Producto.......................... 5

Especificaciones.........................................5

Ensamblar...................................................6

Mezcla de Combustible.............................9

PAGE PAGE PAGE

Llenando el Tanque de Combustible .......9

Arranque del motor .................................10

Detención del motor................................11

Ajuste del ralenti del motor..................... 11

Mantenimiento ......................................... 12

Almacenamiento de Largo Plazo............16

Guia Diagnostico...................................... 17

Declaración de Garantía..........................20

Aplicaciones..............................................12

¡IMPORTANTE!

Los procedimientos descritos en este manual están pensados para ayudarle a sacar el máximo provecho de esta máquina, así como evitar

posibles daños y lesiones. Estos procedimientos deben contemplarse como directrices para un manejo seguro en la mayoría de las condiciones y no pretenden reemplazar ninguna norma ni legislación sobre seguridad que pueda estar vigente en su jurisdicción. Si tiene alguna

duda acerca de su herramienta mecánica o si no comprende alguna explicación de este manual, su distribuidor de Shindaiwa estará encantado de atenderle. También puede ponerse en contacto con Shindaiwa Inc. en la dirección impresa en el dorso de este manual.

Declaraciones De Seguridad

A travéz de este manual se encuentran

“declaraciones de seguridad” especiales.

¡PELIGRO!

Toda explicación precedida por el símbolo de atención triangular y la palabra “PELIGRO” indica

una situación potencialmente peligrosa

que, en caso de no evitarse, se causarán

lesiones graves o incluso la muerte.

símbolo de atención triangular y la palabra “ADVERTENCIA” indica una situación

potencialmente peligrosa que, en caso de

no evitarse, PODRÁ provocar la muerte o

lesiones graves.

Toda explicación precedida por la

palabra “IMPORTANTE” tiene especial

trascendencia.

¡ADVERTENCIA!

Toda explicación precedida por el

¡IMPORTANTE!

¡PRECAUCIÓN!

Toda explicación precedida por la

palabra “PRECAUCIÓN” contiene

información de obligado cumplimiento

para evitar que se produzcan daños

en la máquina.

NOTA:

Toda explicación precedida por la palabra

“NOTA” contiene información que conviene

conocer y que puede facilitarle su trabajo.

Etiquetas de seguridad

Un cortasetos articulado puede causar

graves conjunto de la cuchilla al operario o transeúntes, si se utiliza mal o de

forma incorrecta. Para reducir el riesgo de

lesiones, debe mantener el control en todo

momento y respetar todas las precauciones

de seguridad durante la utilización

Lea y siga las instrucciones de este manual, y asegúrese de que todas las personas que utilicen el cortasetos también lo

hagan. De lo contrario, se podrían producir lesiones físicas graves y daños en

la máquina. Conserve este manual para

futuras consultas.

Lleve siempre un casco rígido para

reducir el riesgo de lesiones en la cabeza

durante el manejo de esta máquina.

Además, protéjase siempre los ojos y los

oídos. Shindaiwa recomienda llevar un

protector facial como protección adicional

para la cara y los ojos.

SP_2

33 ft

10 M

Utilice guantes resistentes y

antideslizantes

Utilice zapatos o botas con

punta de seguridad y suelas

antideslizantes.

Este producto es un conductor de electricidad. Mantenga

el producto y el usuario alejado

a una distancia mínima de 10

metros de las fuentes eléctricas

y líneas eléctricas.

Mantenga a los transeúntes a

una distancia mínima de 15 metros del cortasetos en funcionamiento para reducir el riesgo de

golpearlos con los objetos que

puedan caer o los residuos que

salgan despedidos.

Manipule con mucho cuidado.

/DVFXFKLOORVHVWDQELHQD¿ODGDV

Sea consciente del peligro de

los residuos que puedan caer.

Page 27

Seguridad

¡PELIGRO!

ESTE CORTASETOS ARTICULADO

NO POSEE AISLAMIENTO CONTRA

DESCARGAS ELÉCTRICAS.

Acercarse o tocar una línea eléctrica

con el cortasetos puede provocar

lesiones graves o incluso la muerte.

Mantenga el cortasetos al menos

a 10 metros de distancia de líneas

eléctricas o de ramas que estén en

contacto con dichas líneas eléctricas.

Precauciones de utilización

Nunca transporte o pierda de vista el Ŷ

cortasetos articulado con el motor en

marcha. Un motor en funcionamiento

se puede acelerar accidentalmente

haciendo que las cuchillas oscilen.

Ŷ

Al transportar el cortasetos articulado,

asegúrese de que la cubierta de la

cuchilla de corte esté bien colocada.

Ŷ

Asegúrese siempre de que el accesorio de corte esté instalado correcta-

PHQWH\DMXVWDGR¿UPHPHQWHDQWHV

de utilizarlo.

Ŷ

Compruebe que no faltan piezas ni

componentes, ni que estén dañados o

instalados incorrectamente.

Ŷ

Nunca utilice una cuchilla o barra de

cuchilla que esté rota o torcida: reemplácela por una en buenas condiciones y asegúrese de que queda

correctamente ajustada.

Ŷ

Nunca intente ajustar una cuchilla con

el motor en funcionamiento.

Un cortasetos articulado puede causar

graves conjunto de la cuchilla al operario o transeúntes, si se utiliza mal o de

forma incorrecta. Para reducir el riesgo de

lesiones, debe mantener el control en todo

momento y respetar todas las precauciones

de seguridad durante la utilización. No

permita bajo ningún concepto que una persona sin la formación o las instrucciones

adecuadas utilice este cortasetos.

¡ADVERTENCIA!

Asegúrese de que no falta ninguna

Ŷ

VXMHFLyQ\GHTXHQLQJXQDHVWiÀRMD

Asimismo, compruebe que el interruptor de parada y los controles de aceleración funcionan correctamente.

Asegúrese de que siempre dispone

Ŷ

de una buena ventilación al utilizar el

cortasetos articulado. El humo o los

gases de escape del motor pueden

causar lesiones graves o la muerte.

Nunca haga funcionar el motor en espacios cerrados.

Nunca fume o encienda fuego cerca Ŷ

del cortasetos. Mantenga el cortasetos protegido de temperaturas extremas. El combustible del motor es

PX\LQÀDPDEOH\XQLQFHQGLRSRGUtD

causar graves conjunto de la cuchilla

o daños materiales.

Ŷ

Asegúrese de que las cuchillas están

correctamente ajustadas antes de

poner en funcionamiento el cortasetos

articulado (para obtener información

acerca de los procedimientos de

ajuste de cuchillas, consulte “Ajuste

¡ADVERTENCIA!

1RHIHFW~HPRGL¿FDFLRQHVQL

cambios no autorizados en el cortasetos

articulados o en sus componentes.

¡ADVERTENCIA!

Nunca opere nin-

guna máquinaria motorizada si está

FDQVDGRRVLHVWiEDMRODLQÀXHQFLD

de alcohol, drogas o medicamentos o

cualquier otra substancia que pueda

afectar su abilidad y juicio.

de la cuchilla de corte” en la sezione

“Mantenimiento”.

Ŷ

Antes de arrancar el motor, asegúrese

de que la cuchilla no esté en contacto con nada.Si de repente empieza

a vibrar o dar sacudidas, detenga la

máquina inmediatamente.

Ŷ

Si golpea algún objeto extraño o

si la máquina se enreda con algo,

detenga siempre la máquina de inmediato y compruebe si se ha producido

algún daño. No trabaje con el equipo

dañado o roto.

Ŷ

Al cortar una rama sometida a tensión, esté atento al rebote de la rama

para no resultar golpeado.

Ŷ

Si una cuchilla se atasca en el

corte, detenga el motor de inmediato. Empuje la rama o arbusto para

desatascar la cuchilla.

Ŷ

Detenga siempre el motor y deje que

se enfríe antes de repostar. Evite llenar en exceso el depósito y limpie el

combustible que se haya derramado.

Español

Realice siempre el mantenimiento Ŷ

del cortasetos articulado de acuerdo

con las instrucciones del manual y

siga el programa de mantenimiento

recomendado.

Ŷ

1XQFDPRGL¿TXHRGHVDFWLYHQLQJXQR

de los dispositivos de seguridad del

cortasetos articulado.

Utilice siempre piezas y accesorios de

Ŷ

Shindaiwa al realizar reparaciones o tareas de mantenimiento en esta máquina.

Nunca permita que el motor funcione Ŷ

a revoluciones altas sin carga. Si lo

hace, podría dañar el motor.

¡PRECAUCIÓN!

Al transportar el cortasetos en un

Ŷ

vehículo, sujételo de un modo seguro

para que no se produzcan derrames de

combustible ni daños en la máquina.

Detenga siempre el motor y deje que Ŷ

se enfríe antes de repostar. Evite llenar

en exceso el depósito y limpie el combustible que se haya derramado.

1XQFDFRORTXHPDWHULDOLQÀDPDEOH

Ŷ

cerca del silenciador del motor ni ponga

en funcionamiento el motor sin comprobar que la pantalla del guardachispas

del silenciador esté en su sitio.

Limpie siempre su área de trabajo de Ŷ

basura o residuos ocultos para lograr

un buen apoyo de los pies.

Ŷ

0DQWHQJDODVFXFKLOODVD¿ODGDV\

bien ajustadas.

Ŷ

Mantenga el cortasetos articulado lo

más limpio posible. Limpie los restos

de hierba, barro, etc.

Ŷ

1RUHDOLFHPRGL¿FDFLRQHVQRDXWRU-

izadas en este cortasetos articulado.

SP_3

Page 28

SP_4

qg

habitual de S

e

.

S

eguridad

)

to

Ll

ígid

esiones e

cabeza durante

.

suj

qued

.

i

a

ag

Ll

r

p

lib

m

s

P

i

ilibri

.

a

5

m

f

los objetos que puedan caer

j

p

.

iend

pued

bid

máqui

p

Español

continuación

lla

¡IMPORTANTE!

s de precaución, peligro,

amiento, asegúrese de

nformativas sean legibles

mplace inmediatamente

sté dañada o que falte. Su

hindaiwa l

nuevas

uncionamien

eve siempre un casco r

para reducir el riesgo de

l

el manejo de esta máquina

ntideslizantes para

cortasetos.

opa ajustada que

ermita

ovimiento. NUNCA

lleve pantalone

n la

i tiene el pelo largo,

éteselo para que

e por encima de

los hombros

Utilice guantes

stentes y

res

arrar mejor el

eve

ertad de

o

empre la

s

con ambas

ujetando el

UPHPHQWH

IEMPRE sea consciente

e tus alrededores y siga

o cauteloso para los

s

peligros posibles que no

es oír de

na.

oye bien los pies y no se

tire demasiado: mantenga

u

o en todo momento

ntras utiliza esta máquina

rotéjase siempre los ojos y los oídos.

hindaiwa recomienda llevar un protector

facial como protección adicional para la cara

o a la

y los ojos.

Mantenga a los transeúntes

una distancia mínima de

etros del cortasetos en

1

uncionamiento para reducir

el riesgo de golpearlos con

se botas o zapatos

antideslizantes de traba

hindaiwa recomienda botas

ara los pies de acero

que salgan

dos.

mitir que los

n la máquina.

nar cerca de

resentes.

o.

Page 29

autor

B

hill

cuchillas de corte

Desbl

o

Interruptor d

p

ara

da

Monta

Palan

acele

Palanca del

seguridad

S

Use l

guía,

unid

nen

dad

re

pr

s

V

r

A

0

Ti

4

34m

7

mm

o

24.5

cc

P

kg/

)

2

P

0

)

Régimen de giro al ralentí (recomendado)

1

)

Capacidad del t

Proporción de combustible/

50:1 con aceite de mezcla de 2 tiempos de clase ISO-L-E

Walb

E

did

Totalmente electrónico, controlado por tran

Hueco del electrode

”

T

Pre-filtro: espuma ; filtro principal: elemento seco

principal: elemen

e

Arrancador autorretráctil

I

e

5

p

Emb

o

Imp

j

L

e

Grasa de litio

P

r

.

P

C

ind

C

.

.

.

Español

VSHFLÀFDFLRQH

Modelo del moto

po de motor

Diámetro x carrera

Desplazamient

eso secco

Dimensiones (longitud x anchura x altura

otencia máxima

Tipo de carburador

ncen

Bujía**

Tipo de filtro de aire

Método de arranqu

Método de detención

Tamaño de barra

Ti

Las especificaciones están sujetas a cambios sin previo aviso

o

orsión

o de transmisión

ulsión el cortador

ubricante de Caja de Engranaj

iezas estánda

eríodo de conformidad de emisiones de la EPA*

Bloque

oqueo

onjunto de la cuchilla del cortasetos

aja de engranajes

arra de cuc

as y

H-251

-temps, cylindre vertical, refroidissement à air

m x 2

6,3

360 x 225 x 235 mm / 92.9 x 8.9 x 9.3 in.

.8 KW / 1.1 hp @ 7,500 min

3,000 min

14 lbs

-

(rpm

-

(rpm

590 ml/20.3 oz.

ro WYL, Tipo Diapragma

NGK CMR5H

0.6 - 0.7 mm/ .024 -.028

nterruptor deslizant

67 mm/22.3 in

rague centrifugo, Tipo sec

e cilíndrico

Engrana

Bolsa de herramientas: llave de bujia/destornillador, llave de iglesia, llave hexagonal de 4 mm, llave de

iglesia 8 x 10 mm, mango, funda de la cuchilla de corte

ategoría A

* El período de conformidad de emisiones de la EPA relativo a la etiqueta de conformidad de emisiones colocada en el motor

ica el número de horas de funcionamiento en las que el motor ha demostrado cumplir los requisitos de emisiones federales.

ategoría C = 50 horas (moderado), B = 125 horas (intermedio) y A = 300 horas (ampliado)

** La NGK BPMR5A tambíen cumple con los requisitos de la regulación de electro mangnéticos (EMC)

P_5

Page 30

Ensamblar

Antes de Ensamblar

Antes de ensamblar, asegúrese de contar

con todos los componentes que requiere

la unidad completa:

Ŷ

Conjunto del motor/tubo externo.

Conjunto de la caja de engranajes/Ŷ

cuchilla.

Español

Conecte el tubo exterior de bloque de motor

Coloque el bloque motor en una super-1.

ficie plana y limpia, con la bujía hacia

arriba.

Utilice una llave hexagonal de 4 mm para 2.

aflojar el tornillo de fijación del tubo.

Deslice el tubo externo por dentro de la 3.

abrazadera del tubo hasta que éste toque

fondo. Si le resulta difícil el montaje, gire

ligeramente el tubo externo o el eje central hasta que sienta cómo las ranuras del

eje central se acoplan al bloque motor. El

tubo externo tiene que insertarse de tal

forma que el extremo del agarre toque la

tapa de la junta.

¡PRECAUCIÓN!

No fuerce el tubo del eje en el bloque

motor. La fuerza excesiva puede dañar

el tubo del eje y el eje central.

Kit con este manual y caja de her-Ŷ

ramientas para el mantenimiento

rutinario.

Ŷ

Cubierta de las cuchillas de corte.

Inspeccione detenidamente todos los componentes para detectar posibles daños

Tubo exterior

Conecte el tubo exterior de bloque de motor

7RUQLOORGHO¿[DFLRQ

Eje central

Empuñadura

Ensamblaje del

acelerador

Coloque el tubo exterior a fin de que el 4.

eje central de la caja de engranajes se

enfrenta a la izquierda de la cubierta

del silenciador.

Deslice el tubo externo por bloque 5.

motor hasta que éste toque la empuñadura del acelerador en contacto con la

abrazadera del tubo.

Apriete el tornillo de fijación firmemente.6.

¡IMPORTANTE!

Los términos “izquierda”, “mano izquierda”, y “LH”; “derecha”, “mano derecha”,

y “RH”, “delantera” y “trasera”, indican

direcciones desde el punto de vista del

operador durante la operación normal de

este producto.

Bujía

Abrazadera del tubo

Abrazadera

del tubo

Llave

hexagonal

$SULHWHHOWRUQLOORGH¿MDFLyQ¿UPHPHQWH

Conexión del cable del acelerador

Quite la cubierta de filtro de aire por 1.

aflojando el tornillo(s) de cubierta y el

levantamiento.

Empuje el cable del acelerador a través 2.

del cable ajustador.

Conecte el final del cable de acelerador 3.

(formado como una bala) a la palanca