Page 1

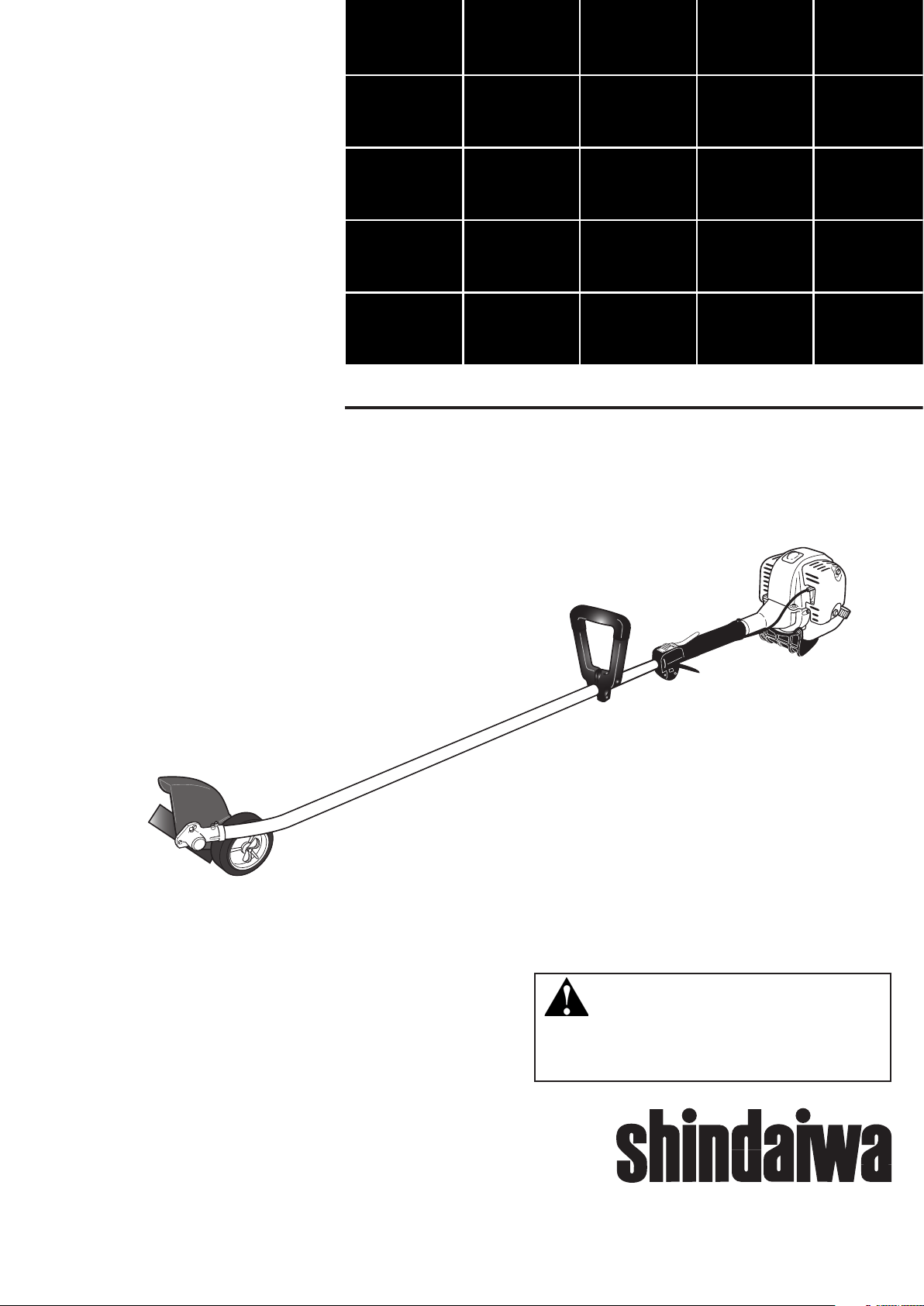

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

LE2510 LAWN EDGER

LE2510

WARNING!

Minimize the risk of injury to yourself and

others! Read this manual and familiarize yourself with

the contents. Always wear eye and hearing protection

when operating this unit.

Part Number 81719 Rev. 2/07

Page 2

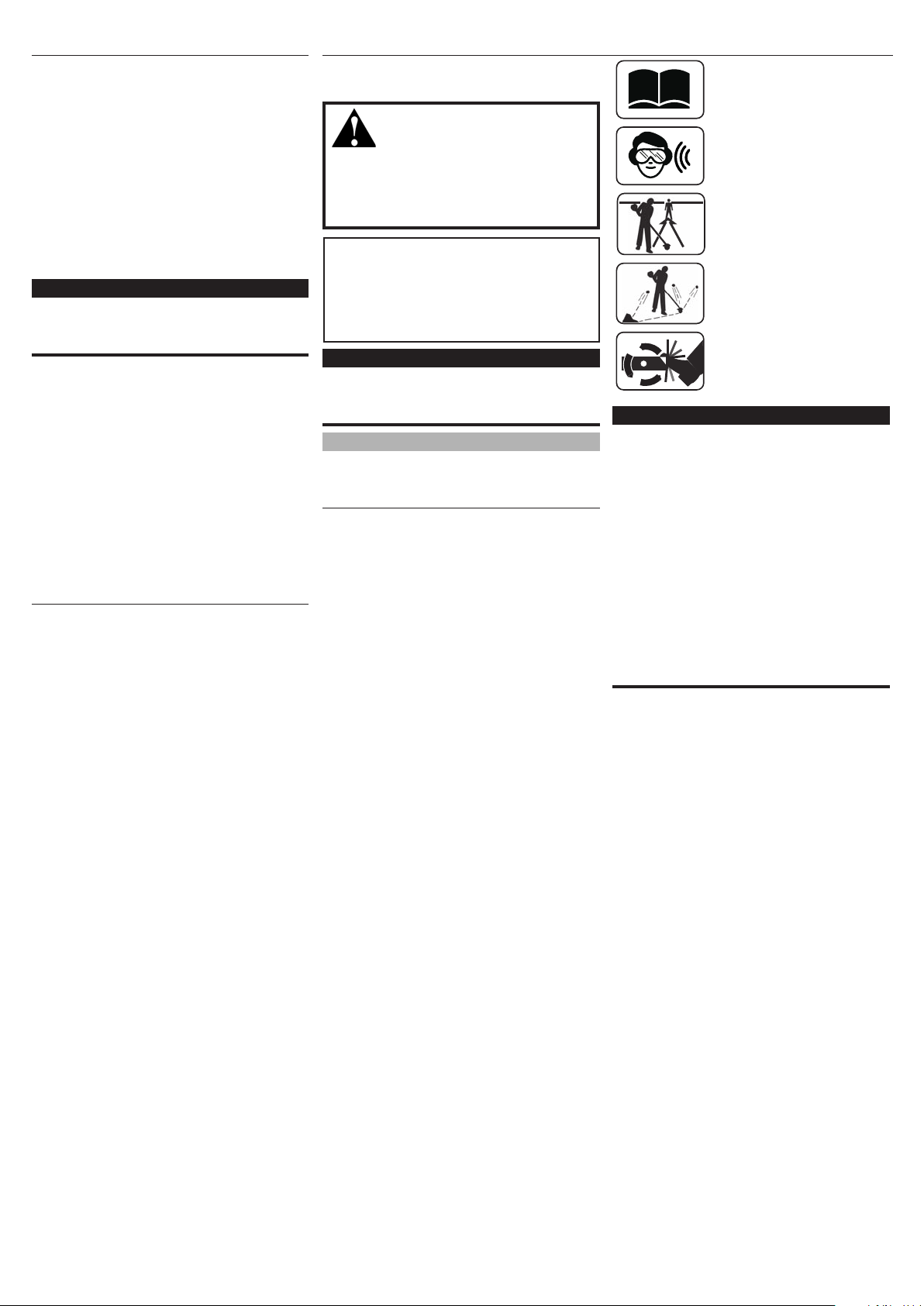

Introduction

50 FEET

(15m)

Read and follow this operators

manual. Failure to do so could

result in serious injury.

Wear eye and hearing protection

at all times during the operation

of this unit.

Keep bystanders at least 50 feet

(15 m) away during operation.

Beware of thrown or ricocheted

objects.

Keep feet away from blade.

Rotating blade may cause

injury. Blade may continue

to rotate after unit is shut off.

The Shindaiwa 2510 Series hand held

power equipment has been designed and

built to deliver superior performance and

reliability without compromise to quality,

comfort, safety or durability.

Shindaiwa engines represent the leading

edge of high-performance engine technology, delivering exceptionally high power

with remarkably low displacement and

weight. As an owner/operator, you’ll soon

discover for yourself why Shindaiwa is

simply in a class by itself!

IMPORTANT!

The information contained in this owner’s/

operator’s manual describes units available at the time of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

Contents

Attention Statements ...................................2

Safety Instructions .......................................2

Safety Labels .................................................4

PAGE

Attention Statements

Throughout this manual are special

“Attention Statements”.

WARNING!

A statement preceded by the

triangular attention symbol and

the word “WARNING” contains information that should be acted upon to

prevent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to prevent mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

NOTE:

A statement preceded by the word ”NOTE”

contains information that is handy to know

and may make your job easier.

IMPORTANT!

The operational procedures described

in this manual are intended to help you

get the most from this unit as well as

to protect you and others from harm.

These procedures are guidelines for safe

operation under most conditions, and are

not intended to replace any safety rules

and/or laws that may be in force in your

area. If you have questions regarding your

2510 series hand held power equipment,

or if you do not understand something in

this manual, your Shindaiwa dealer will be

glad to assist you. You may also contact

Shindaiwa, Inc. at the address printed on

the back of this Manual.

Product Description .....................................5

Specifications ................................................5

Assembly and Adjustments .........................6

Mixing Fuel ..................................................7

Starting the Engine ......................................8

Stopping the Engine ....................................9

Adjusting Engine Idle ..................................9

Checking Unit Condition.............................9

Using a Hand Held Edger .........................10

Adjusting the Blade ....................................10

General Maintenance ................................11

Replacing the Edger Blade........................14

Long Term Storage ....................................14

Troubleshooting Guide .............................15

Emission System Warranty .......................17

2

Page 3

Safety Instructions

DO NOT OPERATE THIS UNIT�

IF YOU ARE TIRED, ILL OR�

UNDER THE INFLUENCE OF�

ALCOHOL, DRUGS, OR�

MEDICATION.�

�

Work Safely

Shindaiwa Edgers operate at very high speeds

and can do serious damage or injury if they

are misused or abused. Never allow a person

without training or instruction to operate this unit!

WARNING!

Never make unauthorized attachment installations. Do not use attachments not

approved by Shindaiwa for use on this unit.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never operate

power equipment of any

kind if you are tired or if you

are under the inuence of alcohol, drugs,

medication or any other substance that

could affect your ability or judgement.

WARNING!

The engine exhaust from this

product contains chemicals known to

the State of California to cause cancer,

birth defects or other reproductive harm.

WARNING!

Use Good Judgment

WARNING!

Minimize the Risk of Fire

NEVER smoke or light res near the engine.

ALWAYS stop the engine and allow it to

cool before refueling. Avoid overlling and

wipe off any fuel that may have spilled.

ALWAYS inspect the unit for fuel leaks

before each use. During each rell, check

that no fuel leaks from around the fuel cap

and/or fuel tank. If fuel leaks are evident,

stop using the unit immediately. Fuel leaks

must be repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily ammable materials before starting

the engine.

NEVER place ammable material close to

the engine mufer.

NEVER operate the engine without the

spark arrester screen in place.

ALWAYS wear eye protection to shield

against thrown objects.

NEVER run the engine when transporting

the unit.

NEVER run the engine indoors! Make sure

there is always good ventilation. Fumes

from engine exhaust can cause serious

injury or death.

ALWAYS clear your work area of trash or

hidden debris that could be thrown back at

you or toward a bystander.

ALWAYS use the proper cutting

attachment.

ALWAYS stop the engine immediately

if it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly

installed parts or attachments.

NEVER use a non-Shindaiwa approved

cutting attachment.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation,

mud, etc.

The Properly Equipped Operator

Wear close-tting clothing to protect legs and arms.

Gloves offer added protection and are strongly recommended. Do not wear clothing or jewelry that could get

caught in machinery or underbrush. Secure hair so it

is above shoulder level. NEVER wear shorts!

ALWAYS hold the unit rmly with both

hands when edging, and maintain control

at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug wire

before performing any maintenance work.

Wear hearing protection devices and a

broad-brimmed hat or helmet.

Always wear eye protection such as

goggles or safety glasses.

Always operate with both

hands rmly gripping the unit.

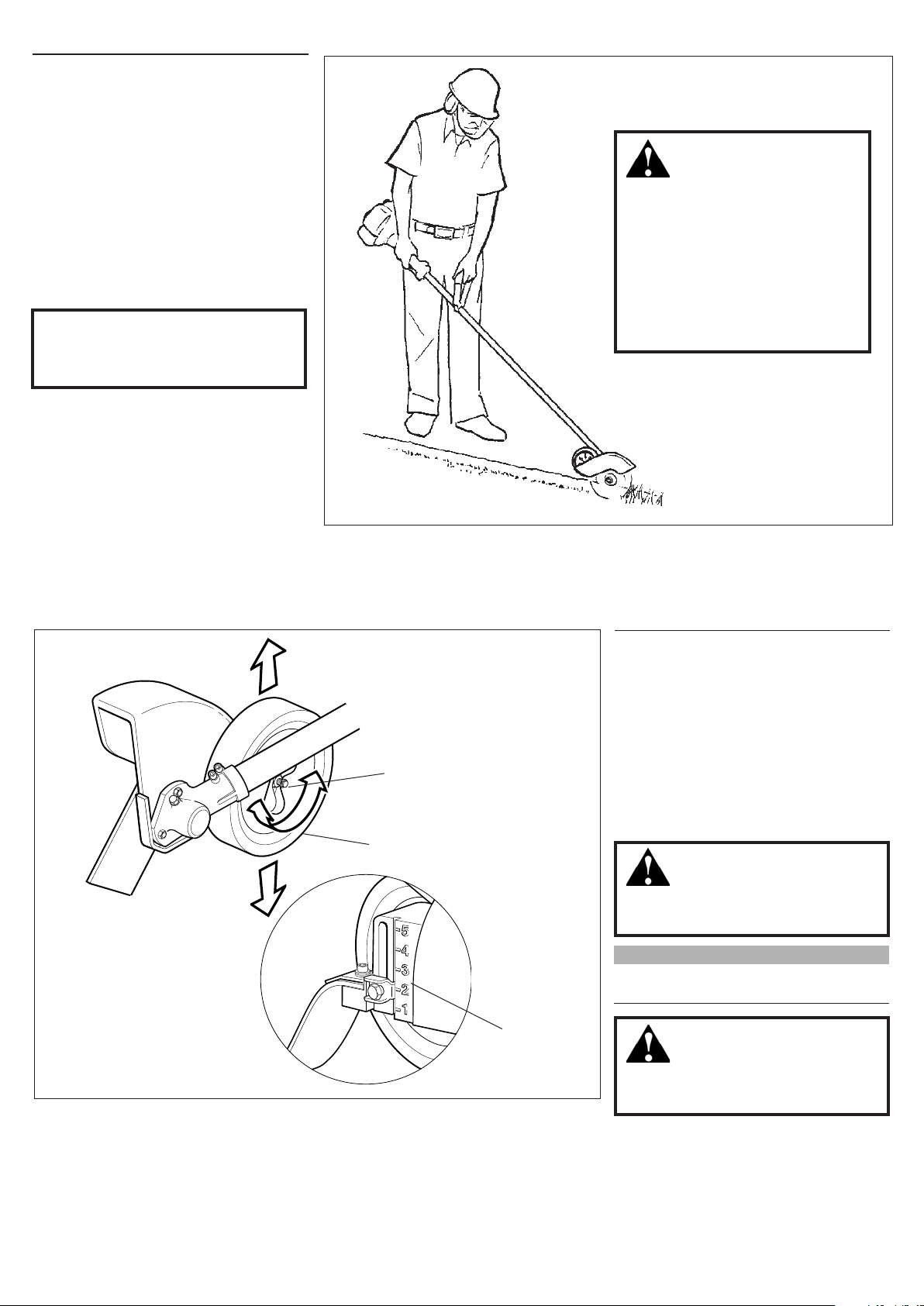

Figure 1

Keep a proper footing and

do not overreach—maintain your balance at all

times during operation.

Wear appropriate footwear (non-skid boots or shoes): do

not wear open-toed shoes or sandals. Never operate the

unit while barefoot!

Always make sure the appropriate cutting

attachment shield is correctly installed and

in good condition.

Keep away from the rotating blade at all

times, and never lift a moving attachment

above waist-high.

3

Page 4

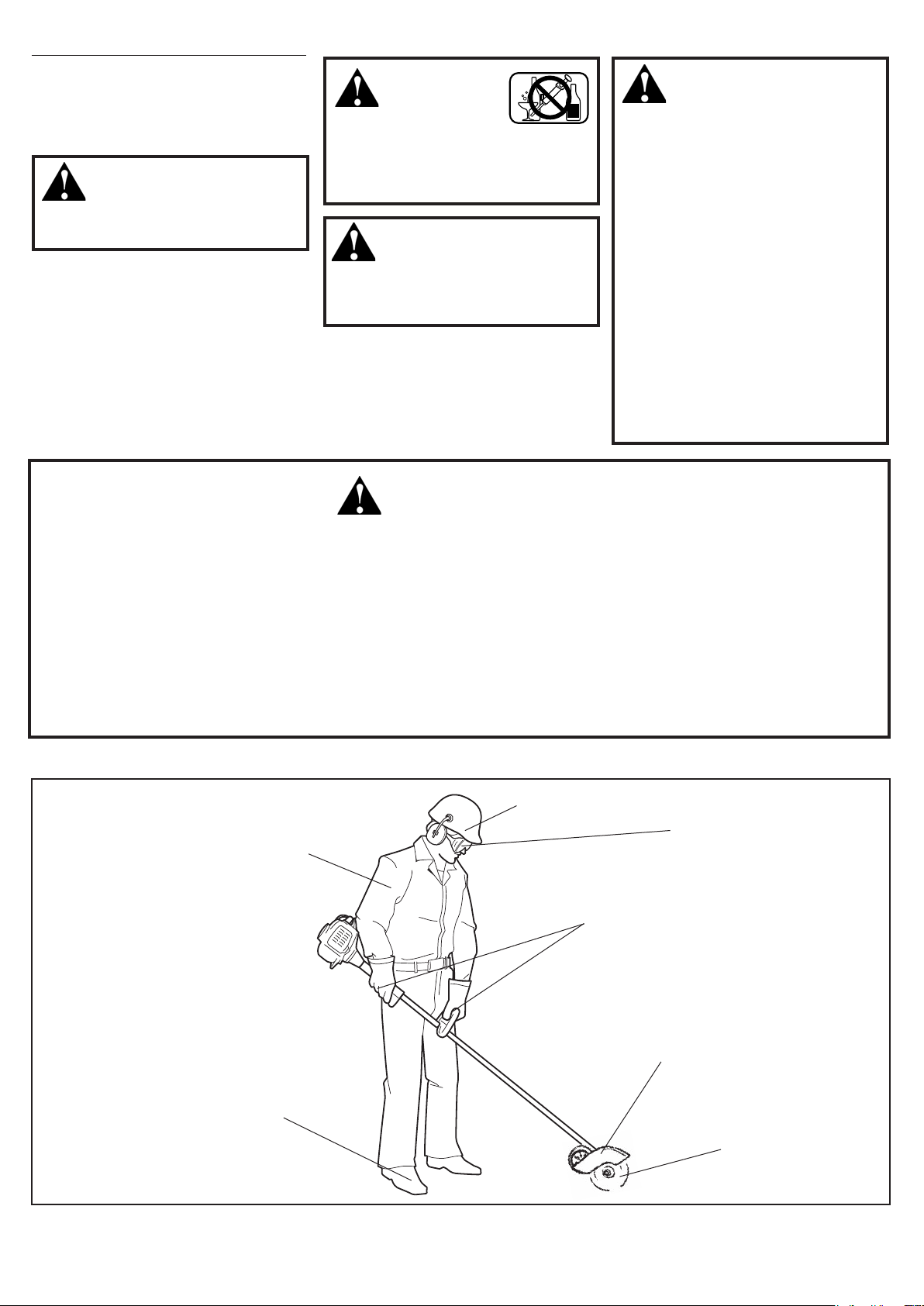

Be Aware of the Working Environment

50 FEET

(15m)

KEEP BYSTANDERS AWAY

AT LEAST 50 FEET (15m)

BEWARE OF THROWN OR

RICHOCHETED OBJECTS

KEEP AWAY FROM

ROTATING BLADE

Shindaiwa

READ THE

OPERATOR’S MANUAL

WEAR HEARING AND

ANSI Z87.1 APPROVED

EYE PROTECTION

P/N 19422-00046

Avoid long-term operation

in very hot or very cold

weather.

Always make sure the appropriate cutting attachment shield

is correctly installed.

Be extremely careful of

slippery terrain, especially

during rainy weather.

Be constantly alert for objects and

debris that could be thrown either

from the rotating cutting attachment

or bounced from a hard surface.

50 FEET

Make sure bystanders or observers

outside the 50-foot “danger zone”

wear eye protection.

Reduce the risk of by-

standers being struck by

ying debris. Make sure

no one is within 50 feet

(15 meters)—that’s about

16 paces—of an operating

attachment.

When operating in rocky terrain or

near electric wires or fences, use ex-

treme caution to avoid contacting such

items with the cutting attachment.

If contact is made with a hard

object, stop the engine and inspect

the cutting attachment for damage.

Figure 2

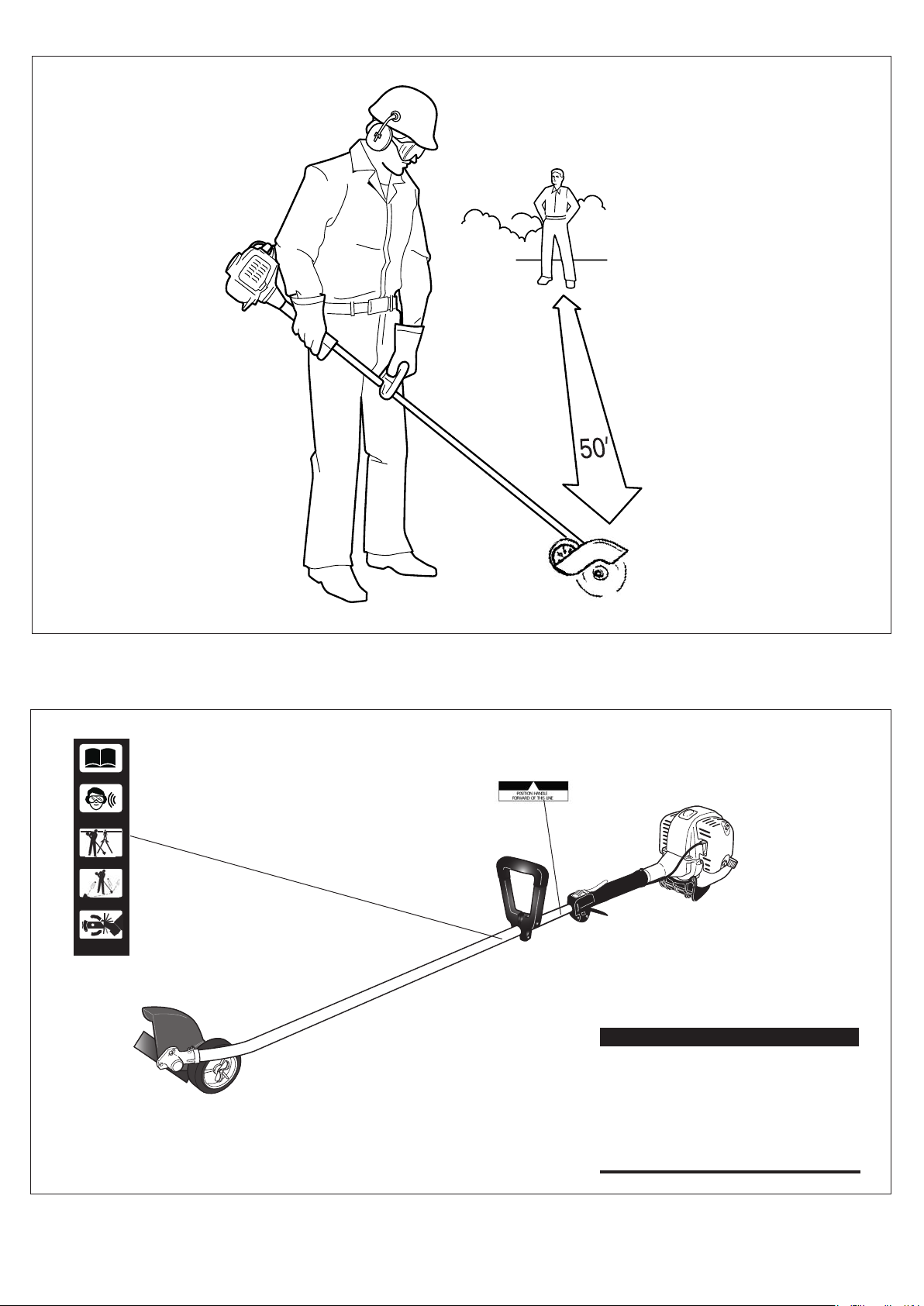

Safety Labels

Figure 3

This label indicates the minimum

distance between front handle and

rear grip.

LE2510

IMPORTANT

Safety and Operation Information

Labels: Make sure all information

labels are undamaged and readable.

Immediately replace damaged or missing information labels. New labels are

available from your local authorized

Shindaiwa dealer.

4

Page 5

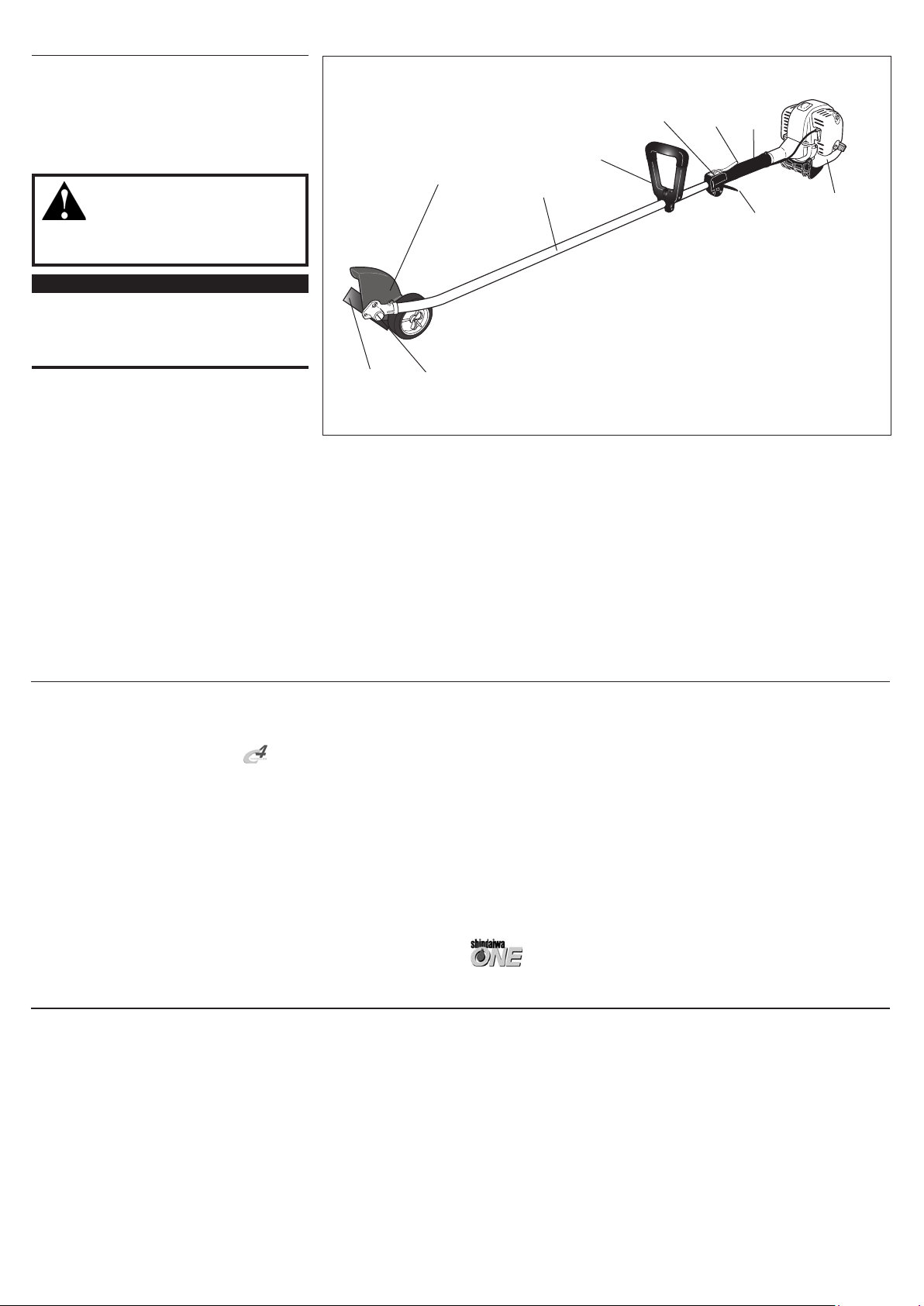

Product Description

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. See Figure 4.

Understanding your unit helps ensure top

performance, long service life, and safer

operation.

WARNING!

Do not make unauthorized

modications or alterations to any of

these units or their components.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete unit:

Engine and outer tube assembly with

handle

Gearcase assembly

Kit containing this manual and tool kit

for routine maintenance. Tool kits vary

by model and may include a hex wrench,

spark plug/screwdriver combination

wrench, and spanner wrench.

Carefully inspect all components for damage.

Cutting

Attachment

Figure 4

Cutting

Attachment Shield

Gear case

Outer Tube

Handle

Ignition

Switch

LE2510 LAWN EDGER

Throttle

Interlock

Grip

Throttle

Trigger

Fuel

Tank

Specications

LE2510 dry weight

(Including attachments) .............................................13.4 lb./6.1 kg

Engine model .SF2510E

Engine type ................................... with Power Boost Chamber

Bore x stroke .............................................. 1.3 x 1.1 in./34 x27 mm

Displacement ....................................................... 1.5 cu. in./ 24.5 cc

Maximum power .......................................................1.1 HP/0.8 kW

@ 7500 rpm (min-1)

Fuel/oil ratio .............................. 50:1 with ISO-L-EGD or JASO FC

class 2-cycle mixing oil*

Carburetor type ................................Walbro WYL, diaphragm-type

Fuel tank capacity ....................................................20.0 oz./590 ml

Ignition ............................................................One-piece electronic,

program contolled

Specifications are subject to change without notice.

Spark plug ....................................................................NGK CMR5H

Air cleaner type .....................................Non-reversible heavy-duty

filter element

Starting method .......................................................................Recoil

Stopping method ............................................................ Slide switch

Transmission type .............................Automatic, centrifugal clutch

w/bevel gear

EPA Emission Compliance Period** ............................Category A

** The EPA emission compliance referred to on the emission compliance label

located on the engine, indicates the number of operating hours for which the

engine has been shown to meet Federal emission requirements. Category

C = 50 hours (Moderate), B = 125 hours (Intermediate) and A = 300 hours

(Extended).

* meets or exceeds these specifications and is recommended for

all Shindaiwa products.

5

Page 6

Assembly and Adjustments

Install Gearcase Assembly

Figure 5

Assembly and Adjustments

Adjust Throttle Lever Free Play

1. Loosen gearcase clamp screw.

2. Remove the gearcase index screw.

3. Slide the gearcase oriented as shown in

Figure 5 onto the shaft tube insuring that

the flex drive is engaged in the gearcase.

NOTE:

It may be necessary to pull the flex cable out

from the shaft tube, engage into the gearcase

and then slide the assembly onto the shaft tube.

4. Reinstall the index screw and tighten

securely.

5. Tighten the clamp screw and torque to 52

– 69 inch pounds.

The throttle lever free play should be approximately 3/16-1/4 inch (4-6 mm). See Figure

6. Make sure that the throttle lever operates

smoothly without binding. If it becomes

necessary to adjust the lever free play, follow

the procedures and illustrations that follow.

3/16-1/4 inch (4-6 mm)

Figure 6

Throttle Free Play

Figure 7

1. Loosen the air cleaner cover knob and

remove the air cleaner cover. See Figure 7.

2. Loosen the lock nut on the cable adjuster. See Figure 8.

3. Turn the cable adjuster in or out as

required to obtain proper free play

3/16-1/4 inch (4-6 mm). See Figure 8.

4. Tighten the locknut.

Cable

Adjuster

Figure 8

Lock Nut

5. Reinstall the air cleaner cover.

6

Page 7

Mixing Fuel

CAUTION!

Some types of gasoline contain

alcohol as an oxygenate. Oxygenated

gasoline may cause increased operating temperatures. Under certain conditions, alcohol-based gasoline may

also reduce the lubricating qualities of

some 2-cycle mixing oils. Never use

any type of gasoline containing more

than 10% alcohol by volume! Generic

oils and some outboard oils may not

be intended for use in high-performance C4 engines, and should never

be used in your Shindaiwa engine.

Filling the Fuel Tank

WARNING!

Minimize the risk of re!

STOP engine before refueling.

ALWAYS allow the engine to cool

before refueling!

Wipe all spilled fuel and move the

engine at least 10 feet (3 meters)

from the fueling point and source

before restarting!

NEVER start or operate this unit if

there is a fuel leak.

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FC

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

Use only fresh, clean unleaded gasoline

with a pump octane of 87 or higher.

Mix all fuel with a 2-cycle air-cooled

mixing oil that meets or exceeds ISO-LEGD and/or JASO FC classified oils at

50:1 gasoline/oil ratio.

NEVER start or operate this unit if

the carburetor, fuel lines, fuel tank

and/or fuel tank cap are damaged.

NEVER smoke or light any res

near the engine or fuel source!

NEVER place any ammable ma-

terial near the engine mufer!

NEVER operate the engine with-

out the mufer and spark arrester

in good working condition.

Examples of 50:1 mixing quantities

1 gallon of gasoline to 2.6 oz. mixing oil

5 liters of gasoline to 100 ml. mixing oil

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than

30 days and oil with fuel stabilizer

is not used, it should rst be treated with a

fuel stabilizer such as STA-BIL™.

sified oil and also meets or exceeds ISO-LEGD performance requirements. Shindaiwa

One is recommended for use in all Shindaiwa

low emissions engines.Shindaiwa One also

includes a fuel stabilizer.

1. Place the edger on a flat, level surface.

2. Clear any dirt or other debris from

3. Remove the fuel cap, and fill the tank

4. Reinstall the fuel filler cap and tighten

Oil is a registered JASO FC clas-

around the fuel filler cap.

with clean, fresh fuel.

firmly.

7

Page 8

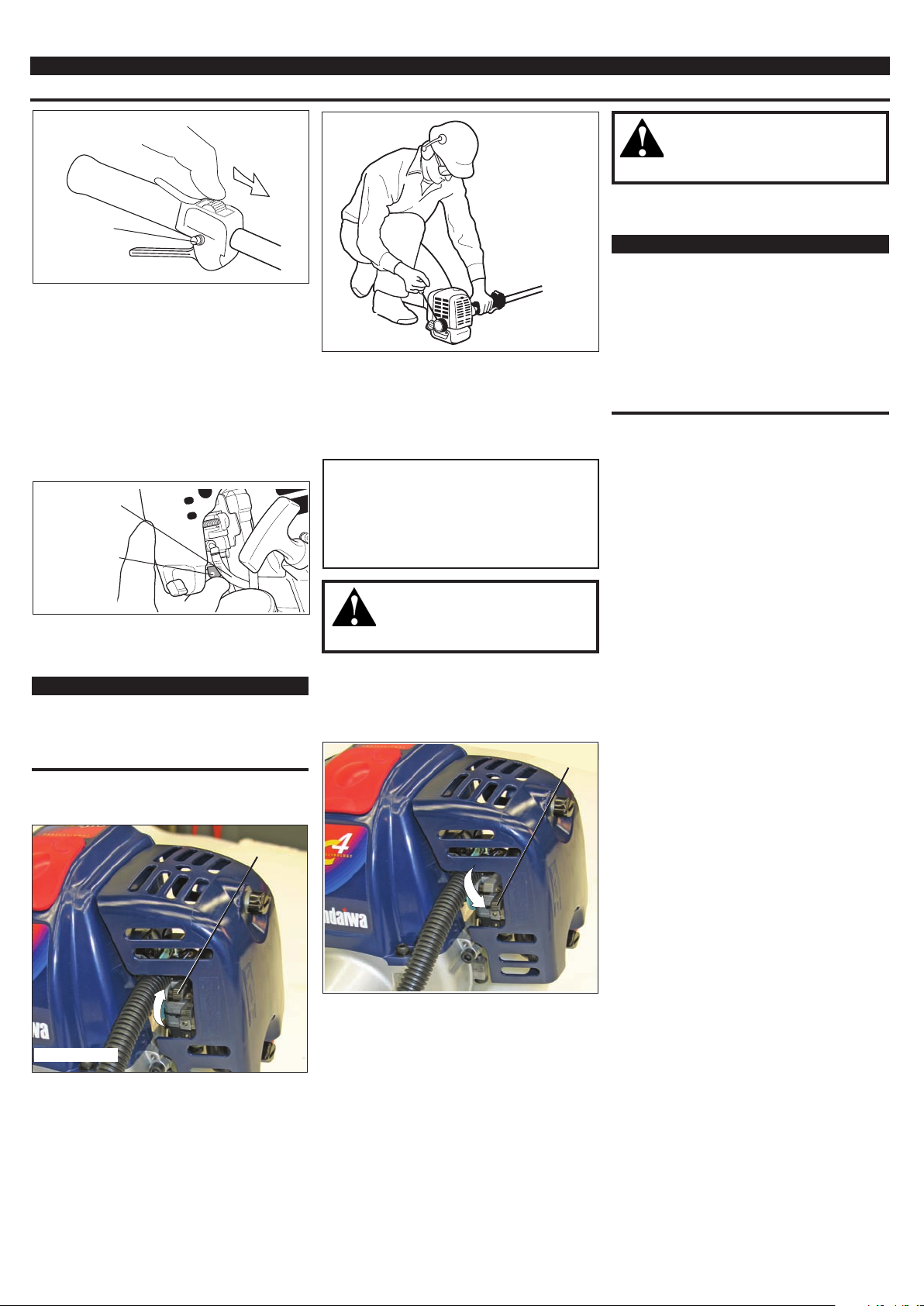

Starting the Engine

IMPORTANT!!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, “I” for ON or START and “O” for OFF or STOP.

ON

Throttle Lock

Button

Figure 9

1. Slide the ignition switch to the “ON”

position. See Figure 9.

2. Set the throttle lever to the “fast idle”;

a. Squeeze the throttle lever toward the

handgrip on the shaft tube.

b. Depress and hold the throttle lock button.

c. While depressing the throttle lock

button, release the throttle lever. See

Figure 9.

Return Tube

Primer Bulb

Figure 10

3. Press the primer bulb until fuel can be seen

flowing in the transparent return tube.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not ood the

engine with fuel.

Make sure the

cutting attatchment

is clear of

obstructions!

Figure 12

5. While holding the outer tube firmly

with left hand. Use your other hand to

slowly pull the recoil starter handle until

resistance is felt, then pull quickly to

start the engine.

CAUTION!

Do not pull the recoil starter to the end

of the rope travel. Pulling the recoil

starter to the end of the rope travel

can damage the starter.

WARNING!

The cutting attachment may

rotate when the engine is started!

6. When the engine starts, slowly move the

choke lever to the “OPEN” position. See

Figure 13. (If the engine stops after the

initial start, close the choke and restart.)

Open

WARNING! Never start the engine from the operating position.

7. Operating the throttle will automatically

disengage the fast idle setting.

IMPORTANT!

If the engine fails to start after several attempts with the choke in the closed posi-

tion, the engine may be ooded with fuel.

If ooding is suspected, move the choke

lever to the open position and repeatedly

pull the recoil starter to remove excess

fuel and start the engine. If the engine still

fails to start, refer to the troubleshooting

section of this manual.

When the Engine Starts...

After the engine starts, allow the engine

to warm up at idle 2 or 3 minutes before

operating the unit.

Advancing the throttle makes the cut-

ting attachment turn faster; releasing

the throttle permits the attachment to

stop turning. If the cutting attachment

continues to rotate when the engine

returns to idle, carburetor idle speed

should be adjusted (see “Adjusting

Engine Idle” below).

4. Set the choke lever to the CLOSED

position if engine is cold.

Closed

Figure 11

8

Figure 13

Page 9

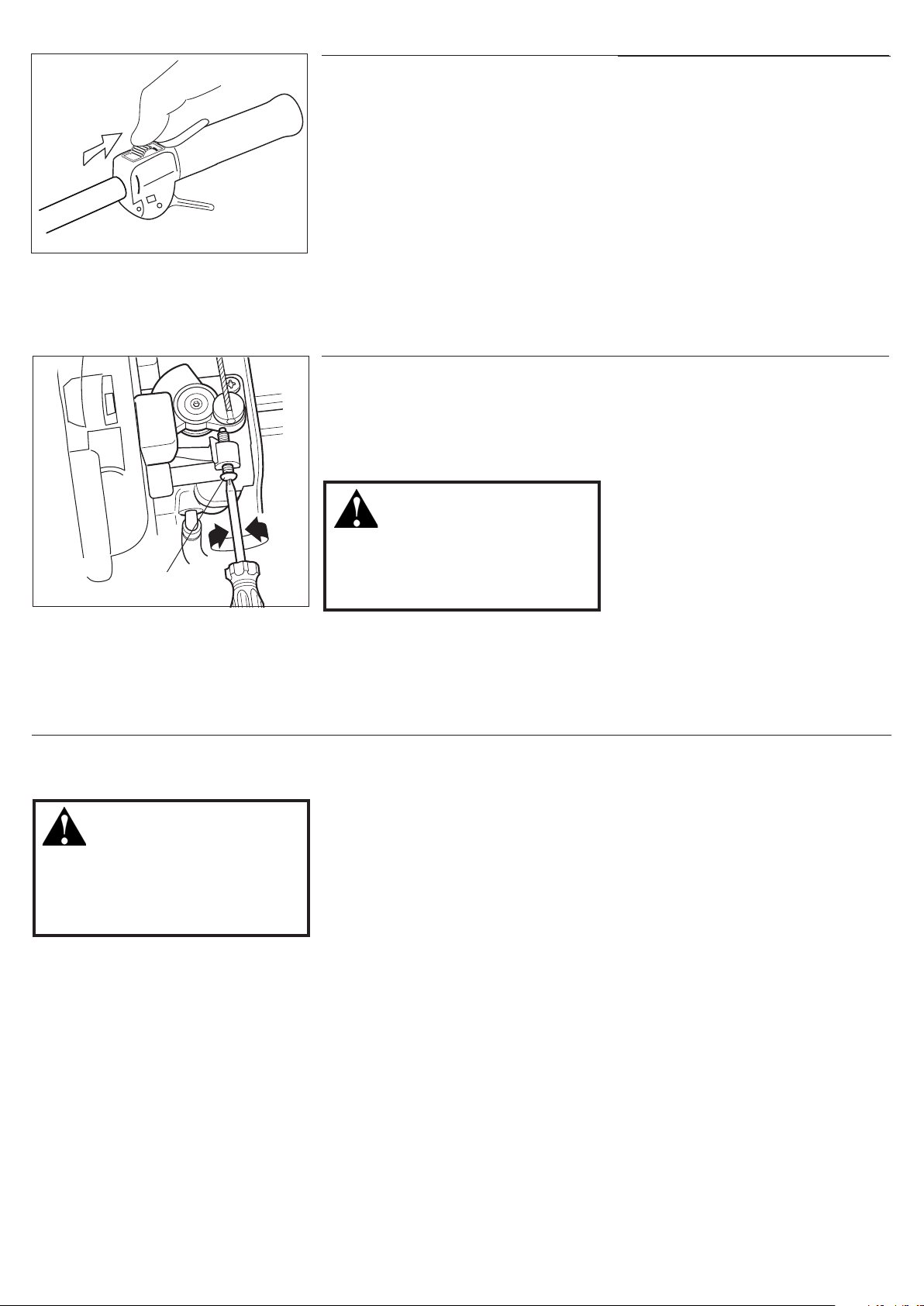

Stopping the Engine

OFF

Figure 14

Adjusting Engine Idle

Idle the engine briefly before stopping

(about 2 minutes), then slide the ignition

switch to the “O” (Engine OFF) position.

Idle Adjusting

Figure 15

Screw

Checking Unit Condition

NEVER operate the unit with the cutting

attachment shield or other protective

devices removed!

WARNING!

A cutting attachment shield or

other protective device is no guarantee

of protection against ricochet. YOU

MUST ALWAYS GUARD AGAINST

FLYING DEBRIS!

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment.

Idle Speed Adjustment

WARNING!

The cutting attachment must

NEVER rotate at engine idle! If the idle

speed cannot be adjusted by the procedure described here, return the trimmer

to your Shindaiwa dealer for inspection.

Use only authorized Shindaiwa parts and

accessories with your Shindaiwa trimmer. Do

not make modifications to this unit without

written approval from Shindaiwa, Inc.

ALWAYS make sure the cutting attachment

is properly installed and firmly tightened

before operation.

NEVER use a cracked or warped cutting

attachment: replace it with a serviceable one.

ALWAYS make sure the cutting attachment

fits properly into the appropriate attachment

holder. If a properly installed attachment

vibrates, replace the attachment with new

one and re-check.

1. Place the trimmer on the ground, then

start the engine, and then allow it to idle

2-3 minutes until warm.

2. If the attachment rotates when the

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise. See Figure 15.

3. If a tachometer is available, the engine idle

speed should be final adjusted to 3,000

(±300) rpm (min-1).

4. Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

in the field.

ALWAYS stop the engine immediately and

check for damage if you strike a foreign

object or if the unit becomes tangled. Do not

operate with broken or damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could

damage the engine.

NEVER operate a unit with worn or

damaged fasteners or attachment holders.

9

Page 10

Using a Hand-held Edger

26021

Guidelines for Operating the Edger

Before edging, make sure the area is soft

enough so the blade does not bog down. If

necessary, water the area before edging.

Remove debris and other obstacles that

could be thrown by the rotating blade.

Plan your work so the edger blade is

always on your right-hand side.

Begin each pass by positioning the unit

over the work, and with the engine running at about half-throttle. Slowly lower

the blade to the ground while applying

full throttle. See Figure 16.

CAUTION!

Low-speed edging can lead to premature

clutch failure.

Do not move the edger into the work so

fast that the engine or blade bogs down.

Do not pull the unit backward over the

ground with the engine running. Doing

so will tend to bury the blade.

Regular and frequent use of the edger

will make a neater lawn, and a frequently

trimmed edge will be easier to maintain.

Figure 16

WARNING!

Wear eye protection, long pants, and

boots when operating this machine

Whenever you strike a hard

object with the blade, always stop

the edger and carefully inspect

the blade for damage. NEVER

OPERATE THE EDGER WITH A

DAMAGED BLADE!

!

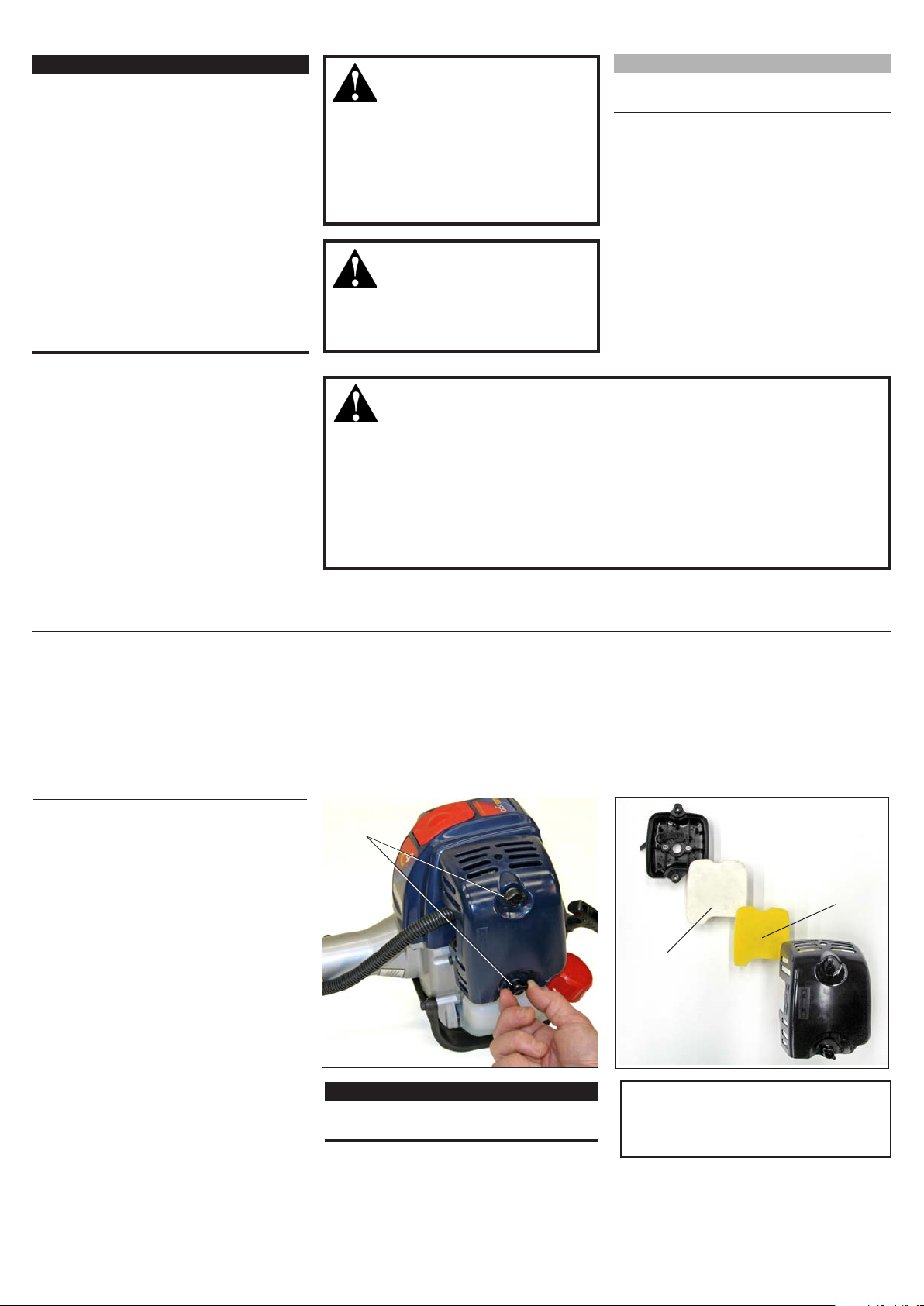

Figure17

Figure 17a

Guide Wheel

Adjusting knob

Guide Wheel

The numbers are for

reference only; they do

NOT refer to depth in

inches

Adjusting the Blade

The edger’s depth of cut is controlled by a

combination of operator height, blade wear,

and the positioning of the edger’s guide wheel.

To adjust blade height:

1. Loosen the guide wheel adjusting knob.

See Figure 17.

2. Raise or lower the guide wheel to the

desired setting. See Figure 17a.

3. Tighten the guide wheel adjusting knob

firmly. See Figure 17.

WARNING!

Never adjust the guide wheel while the

engine is running.

NOTE

Guide wheel adjustment is also required to

compensate for blade wear.

WARNING!

Use only Shindaiwa replacement

edger blades.

10

Page 11

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR

REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE

PERFORMED BY ANY REPAIR

ESTABLISHMENT OR INDIVIDUAL;

HOWEVER, WARRANTY REPAIRS

MUST BE PERFORMED BY A DEALER

OR SERVICE CENTER AUTHORIZED

BY SHINDAIWA CORPORATION

THE USE OF PARTS THAT ARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF

THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

WARNING!

Before performing any maintenance, repair or cleaning work on the unit, make

sure the engine and cutting attachment

are completely stopped. Disconnect

the spark plug wire before performing

service or maintenance work..

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury

WARNING!

Never repair a damaged blade by

welding, straightening, or by modifying its shape. An altered blade may

break during operation, resulting in

serious personal injury.

NOTE:

Using non-standard replacement parts could

invalidate your Shindaiwa warranty.

Mufer

This unit must never be operated with a

faulty or missing spark arrester or muffler. Make sure the muffler is well secured

and in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

Blades are not interchangeable

between Shindaiwa edgers and

trimmer/brushcutter models.

Operating any unit with a blade or

attachment not approved for that

unit can be hazardous and may

cause serious injury.

Daily Maintenance

Prior to each work day, perform the following:

Remove dirt or debris from the engine,

check the cooling fins and air cleaner for

clogging and clean them as necessary.

10-Hour Maintenance

(more frequently in dusty

conditions)

1. Remove the air cleaner cover by loosening the two thumbscrews. See Figure 18A.

2. Remove and inspect the pre-filter. If the

pre-filter is torn or otherwise damaged,

replace it with a new one. See Figure 18B.

3. Clean the pre-filter with soap and water.

Let dry before reinstalling.

4. Inspect the air cleaner element. If the

element is damaged or distorted, replace it with a new one.

5. Tap filter gently on a hard surface to

dislodge debris from element or use compressed air from the inside to blow debris

out and away from the air filter element.

Carefully remove any accumulation of

dirt or debris from the muffler or the

fuel tank. Dirt build-up in these areas

could cause engine overheating, induce

premature wear, or create a fire hazard.

Unscrew

Fasteners

Figure 18A

IMPORTANT!

Direct the air stream at the inside face of

the lter only!

6. Install the filter element, pre-filter and

cover in the reverse order of removal.

Check for loose or missing screws or

components. Make sure the cutting

attachment is securely fastened.

Check the entire unit for leaking fuel

or grease.

Pre-Filter

Filter

Element

Figure 18B

CAUTION!

Never operate the unit if the air cleaner

assembly is damaged or missing!

11

Page 12

XST021

10/15-Hour Maintenance

Clean the spark plug

0.024–0.028 inch

(0.6–0.7 mm)

Figure 19

and check the gap at

the electrode.

50-Hour Maintenance

Every 50 hours of operation (more frequently in dusty or dirty conditions):

Remove the cylinder cover and clean

grass and dirt from the cover and

cylinder fins.

Remove the cutting attachment, cutting

attachment holder and gear shaft collar.

Remove the filler plug from the side

of the gearcase and press new grease

into the gearcase until grease is pushed

out. Use only lithium-base grease such

as Shindaiwa Gear Case Lubricant or

equivalent. See Figure 20.

Old

Grease

Shaft

Bolt

Figure 20

Bolt

Guard

Blade

Holder

A

Shaft Collar

Holder

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be damaged easily.

New

Grease

Output

B

Use a hooked wire to extract the fuel filter

from inside the fuel tank. See Figure 22.

Remove and replace the filter element.

Before reinstalling the new filter element, inspect the condition of all the

fuel system components (fuel pick-up

line, fuel return line, tank vent line, tank

vent, fuel cap and fuel tank). If damage,

splitting or deterioration is noted, the

unit should be removed from service

until it can be inspected or repaired by a

Shindaiwa-trained service technician.

Hooked

Wire

Filter Element

Figure21

Lubricate the Flexible Shaft.

Lack of lubrication will cause rapid wear to

the flexible shaft and also to the shaft tube

liner, resulting in increased vibration and

greatly decreased service life. Remove and

lubricate the flexible shaft as follows:

1. Loosen the gearcase clamp screw.

2. Remove the gearcase index screw.

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024

0.028 inch (0.6-0.7 mm). If the spark

plug must be replaced, use only an

NGK CMR5H or equivalent resistor

type spark plug of the correct heat

range. See Figure 19.

NOTE:

The NGK CMR5H also meets the requirements for electro magnetic compliance (EMC).

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine’s internal parts.

Gearcase Index

Screw

Flexible Shaft

Shaft Tube

Figure 22

3. Slide the gearcase and shield assembly

from the shaft tube.

4. Pull the flexible shaft from the shaft tube

assembly, and clean the shaft thoroughly

in solvent.

5. Inspect the shaft carefully, and replace

if worn or damaged. If flexible shaft

is worn and needs replacement, liner

should also be replaced.

6. Coat the entire length of the shaft with

Shindaiwa Premium Gearcase Lube (or

equivalent), and reinstall the shaft in the

shaft tube assembly.

NOTE:

For extended shaft life, the flexible cable

should be reversed end-for-end during the

reinstallation process.

7. Insert the flexible shaft into the female

end of the gearcase pinion.

8. Install the gearcase on the shaft tube in

the reverse order of removal.

12

Page 13

26024

50-Hour Maintenance (continued)

CAUTION!

The D-shaped shim washer must be

positioned with its at edge toward the

shaft tube.

Gearcase

Shaft

Tube

D-shaped Shim

Washer

Figure 23

Flat (toward

tube)

Inspect the Gearcase Protector

The metal gearcase protector (p/n 72958-

16210) is installed to protect the gearcase

flange from damage when working close to

sidewalks or other abrasive surfaces, and

should be routinely inspected for damage

or excessive wear.

When replacing the protector, inspect to be

sure that both of the protector mounting

screws are firmly tightened and each screw

is locked in place with a nut as shown.

139/150-Hour Maintenance

Figure 24

Nut

Gearcase Protector (P/N

72958-16210)

Maintenance after rst 139-hours,

then every 150-hours thereafter.

Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

Replace the spark plug annually: Use

only NGK CMR5H or equivalent resistor type spark plug of the correct heat

range. Set spark plug electrode gap to

0.024-0.028 inch (0.6 -0.7 mm).

NOTE:

The NGK CMR5H also meets the requirements

for electro magnetic compliance (EMC).

Valve Adjustment

1. Remove cylinder cover, rocker arm cover,

and set piston at TDC-compression.

CAUTION!

Performing a valve adjustment incor-

rectly may cause hard starting and/or

can damage the engine.

If you are unfamiliar with this engine

or uncomfortable with this procedure,

consult with an authorized Shindaiwa

servicing dealer.

2. Loosen adjuster locknut so that the 2.5

mm Allen socket head adjustment screw

can turn freely.

3. Insert feeler gauge .004” (0.10 mm) for

both intake and exhaust between valve

stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

just enough to allow gauge to slip out

with limited resistance.

5. While holding adjustment screw in place with

Allen driver, tighten locknut with wrench.

6. Turn engine over several times, and

return to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change as

a result of tightening locknut. Readjust

as necessary.

7. Replace rocker arm cover gasket to assure proper sealing and install cover.

IMPORTANT!

If new gasket is not available and/or old

gasket is not damaged, old gasket may be re-

used. Never use cracked or damaged gaskets!

13

Page 14

Spark Arrester Screen Maintenance

26118

If the engine becomes sluggish and low on

power, check and clean the spark arrester

screen.

WARNING!

Never operate this unit with a

damaged or missing mufer or spark

arrester! Operating with missing or

damaged exhaust components is a

re hazard, and can also damage

your hearing!

Engine Cover

Screws

Cover

Mufer

Mufer Gasket

1. With a 3 mm hex wrench remove the

4 engine cover screws and the engine

cover. See Figure 25.

2. With a small flat bladed screwdriver

remove the 2 screws holding the spark

arrester screen and cover to the muffler. See Figure 25.

3. Remove the screen and clean it with a

stiff bristle brush.

Exhaust Port Inspection

4. With a 4 mm hex wrench remove the

3 muffler bolts and the muffler. See

Figure 25.

5. Inspect the cylinder exhaust port for

any carbon buildup.

Replacing the Edger Blade

WARNING!

Always wear gloves when handling the

edger blade.

1. Align the hole in holder A with the

matching hole in the gearcase and then

use the hex wrench to temporarily lock

the output shaft.

2. Use the combination wrench to loosen

the shaft bolt then remove the output

shaft bolt, Holder B and the edger blade

from the gearcase.

Figure 25

IMPORTANT!

If you note excessive carbon buildup,

consult with an authorized Shindaiwa

servicing dealer.

3. Mount the edger blade and holder B

onto the shaft, and then install the bolt

guard and shaft bolt (turn bolt counterclockwise to install). See Figure 26.

4. Align the hole in holder A with the

matching hole in the gearcase, and then

use the hex wrench to temporarily lock

the output shaft. See Figure 26.

5. Use the combination wrench to firmly

tighten the shaft bolt. Remove the hex

wrench. See Figure 26.

Spark Arrester

Cover

Mufer Bolts

Spark Arrester

Screen

Cover Screws

6. Reassemble the spark arrester, muffler

and engine cover in the reverse order of

disassembly.

Holder A

Output Shaft

Bolt

Lock the

shaft

Bolt

Guard

Holder B

Edger

Blade

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following procedures to prepare it for storage:

Clean external parts thoroughly.

Drain all the fuel from the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with a

fuel stabilizer such as STA-BIL™, if

oil with fuel stabilizer is not used.

Remove the remaining fuel from the fuel

lines and carburetor.

14

CAUTION!

Gasoline stored in the carburetor for extended periods can cause hard starting

and could also lead to increased service

and maintenance cost.

1. Prime the primer bulb until no more

fuel is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine

will no longer start.

Figure 26

Remove the spark plug and pour about

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3 times

so oil will evenly coat the interior of the

engine. Reinstall the spark plug.

Before storing the unit, repair or replace

any worn or damaged parts.

Remove the air cleaner element from the

carburetor and clean it thoroughly with

soap and water. Let dry and reassemble

the element.

Store the unit in a clean, dust-free area.

Page 15

Troubleshooting Guide

iÃÊÌiÊi}iÊVÀ>¶

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

NO

`ÊV«ÀiÃö

Loose spark plug.

Excess wear on cylinder, piston, rings.

Valves not seating.

Tighten and re-test.

NO

YES

iÃÊÌiÊÌ>ÊVÌ>Ê

vÀiÃÊvÕiÊvÊÌiÊ«À«iÀÊ

}À>`i¶

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Fuel incorrect, stale or contaminated;

mixture incorrect.

NO

YES

ÃÊvÕiÊÛÃLiÊ>`ÊÛ}Ê

ÊÌiÊÀiÌÕÀÊiÊÜiÊ

«À}¶

Check for clogged fuel filter and/or vent.

Priming pump not functioning properly.

Replace fuel filter or vent as required; restart.

Consult with an authorized servicing dealer.

NO

ÃÊÌiÀiÊë>ÀÊ>ÌÊÌiÊë>ÀÊ

«Õ}ÊÜÀiÊÌiÀ>¶

The ignition switch is in “O” (OFF)

position.

Shorted ignition ground.

Faulty ignition unit.

Move switch to “I” (ON) position and restart.

NO

YES

YES

iVÊÌiÊë>ÀÊ«Õ}°

If the plug is wet, excess fuel may be in

the cylinder.

The plug is fouled or improperly gapped.

The plug is damaged internally or of the

wrong size.

Crank the engine with the plug removed,

reinstall the plug, and restart.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Restart.

Replace the plug with an NGK CMR5H or

equivalent resistor type spark plug of the

correct heat range. Set spark plug electrode

gap to 0.024-0.028 inch (0.6-0.7 mm).

YES

What To Check Possible Cause Remedy

Is the engine overheating?

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty

or damaged.

Carbon deposits on the piston or in

the muffler.

Cut at a slower rate.

Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing dealer.

What To Check Possible Cause Remedy

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm.

Valve clearance set incorrectly.

Service the air cleaner element.

Tighten or replace.

Repair or replace filter and/or fuel line.

Replace the fuel. See page 7.

Consult with an authorized servicing dealer.

Engine is knocking.

Overheating condition.

Improper fuel.

Carbon deposits in the combustion

chamber.

Valve clearance set incorrectly.

See above.

Check fuel octane rating; check for presence of

alcohol in the fuel (pg. 7). Refuel as necessary.

Consult with an authorized servicing dealer.

Adjust valves (see page 13).

ENGINE DOES NOT START

LOW POWER OUTPUT

15

Page 16

Poor acceleration.

Clogged air filter.

Clogged fuel filter.

Lean fuel/air mixture.

Idle speed set too low.

Clean the air filter.

Replace the fuel filter.

Consult with an authorized servicing dealer.

Adjust: 3,000 (±300) RPM (min-1).

Symptom Possible Cause Remedy

Engine stops abruptly.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Reset the switch and restart.

Refuel. See page 7.

Replace fuel filter.

Drain; replace with clean fuel. See page 7.

Clean and replace spark plug, tighten

the terminal.

Replace the ignition unit.

Consult with an authorized servicing dealer.

Engine difficult to shut off.

Ground (stop) wire is disconnected or

switch is defective.

Overheating due to incorrect spark plug.

Overheated engine.

Test and replace as required.

Idle engine until cool.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Correct plug: NGK CMR5H

or equivalent resistor type spark plug of the

correct range.

Idle engine until cool.

Cutting attachment

rotates at engine idle.

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Set idle: 3,000 (±300) RPM (min-1).

Replace spring/shoes as required, check

idle speed.

Inspect and re-tighten holders securely.

Engine will not idle down.

Engine idle set too high.

Engine has an air leak.

Set idle: 3,000 (±300) RPM (min-1).

Consult with an authorized servicing dealer.

Top of engine is getting

dirty and oily.

Valve cover is leaking. Consult with an authorized servicing dealer.

Troubleshooting Guide (continued)

Symptom Possible Cause Remedy

Excessive vibration.

Warped or damaged cutting attachment.

Loose gearcase.

Bent main shaft/worn or damaged

liner.

Inspect and replace attachment as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Cutting attachment will

not rotate.

Shaft not installed in powerhead or

gearcase.

Broken shaft.

Damaged gearcase.

Inspect and reinstall as required.

Consult with an authorized servicing dealer.

ADDITIONAL PROBLEMS

ADDITIONAL PROBLEMS

16

Page 17

The following statement only applies to United States and its territories

Shindaiwa Corporation

Federal Emission Design And Defect Limited Warranty

Utility And Lawn And Garden Engines

Shindaiwa Corporation warrants to the initial purchaser and each

subsequent owner, that this utility equipment engine (herein

engine) is designed, built and equipped to conform at the time of

initial sale, to all applicable regulations of the U.S. Environmental

Protection Agency (EPA), and that the engine is free of defects in

materials and workmanship that would cause this engine to fail

to conform with EPA regulations during its warranty period. This

emission warranty is applicable in all States, except the State of

California.

For parts listed under PAR TS COVERED, the dealer authorized

by Shindaiwa Corporation will, at no cost to you, make the necessary diagnosis, repair, or replacement of any defective emission-related component to ensure that the engine complies with

applicable U.S. EPA regulations.

MANUFACTURERS WARRANTY COVERAGE

When sold within the U.S., this engine’s emission control system is

warranted for a period of two (2) years from the date this product is first

delivered to the original retail purchaser.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of

the required maintenance listed in your owner’s manual. Shindaiwa

Corporation recommends that you retain all receipts covering maintenance on your engine, but Shindaiwa Corporation cannot deny a warranty claim solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

As the engine owner, you should however be aware that Shindaiwa

Corporation may deny your warranty coverage if your engine or a part

has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your engine to the nearest dealer

authorized by Shindaiwa Corporation when a problem exists.

If your Shindaiwa Dealer is unable to answer questions regarding your

warranty rights and responsibilities, you should then contact your

Shindaiwa Distributor.

For the name and telephone number of the Shindaiwa Distributor in your

area, please call Shindaiwa Inc. at (503) 692-3070 between the hours of

8:00 AM and 5:00 PM Pacific Standard Time.

PARTS COVERED

Listed below are the parts covered by the Federal Emission Design and

Defect Warranty. Some parts listed below may require scheduled maintenance and are warranted up to the first scheduled replacement of that

part. The warranted parts include:

1. Carburetor Internal Components

• Valve Assembly-throttle, Jet, Metering Diaphragm

2. Ignition System Components

• Ignition Coil

• Flywheel Rotor

The emission control system for your particular Shindaiwa engine may

also include certain related hoses and connectors.

LIMITATIONS

The Federal Emission Design and Defect Warranty shall not cover any of

the following:

(a) conditions resulting from tampering, misuse, improper adjust-

ment (unless they were made by the dealer or service center

authorized by Shindaiwa Corporation during a warranty repair),

alteration, accident, failure to use the recommended fuel and oil,

or not performing required maintenance services,

(b) the replacement parts used for required maintenance services,

(c) consequential parts used for required maintenance services,

(d) diagnosis and inspection fees that do not result in eligible war-

ranty service being performed, and

(e) any non-authorized replacement part, or malfunction of autho-

rized parts due to use of non-authorized parts.

MAINTENANCE AND REPAIR REQUIREMENTS

You are responsible for the proper use and maintenance of the engine.

You should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise. These

receipts and maintenance records should be transferred to each subsequent owner of the engine. Shindaiwa Corporation reserves the right to

deny warranty coverage if the owner has not properly maintained the

engine. Shindaiwa Corporation will not deny warranty repairs, however,

solely because of the lack of repair, maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY

REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY

REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA CORPORATION THE USE OF PARTS

THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY

TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE

EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by Shindaiwa Corporation are used

for maintenance replacements or for the repair of components affecting

emission control, you should assure yourself that such parts are warranted by their manufacturer to be equivalent to the parts authorized by

Shindaiwa Corporation in their performance and durability.

OBTAINING WARRANTY SERVICE

All repairs qualifying under this limited warranty must be performed by a

dealer authorized by Shindaiwa Corporation

If any emission-related part is found defective during the warranty

period, it is your responsibility to present the product to an authorized

Shindaiwa dealer. Bring your sales receipts showing the date of purchase for this engine. The dealer authorized by Shindaiwa Corporation

will perform the necessary repairs or adjustments within a reasonable

amount of time and furnish you with a copy of the repair order. All parts

and accessories replaced under this warranty become the property of

Shindaiwa Corporation

To locate an authorized Shindaiwa dealer near you, contact your

Shindaiwa Distributor. For the name and telephone number of the

Shindaiwa Distributor in your area, please call Shindaiwa Inc. at (503)

692-3070 between the hours of 8:00 AM and 5:00 PM Pacific Standard

Time.

THIS WARRANTY IS ADMINISTERED BY

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin OR. 97062

(503) 692-3070

17

Page 18

NOTES

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, Oregon 97062 USA

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

18

Shindaiwa Corporation

Head Ofce:

6-2-11, Ozuka-Nishi Asaminami-Ku, Hiroshima

731-3167, Japan

Telephone: 81-82-849-2220

Fax: 81-82-849-2481

©2007 Shindaiwa, Inc.

Part Number 81719

Revision 2/07

Shindaiwa is a registered trademark of Shindaiwa, Inc.

Specications subject to change without notice.

Page 19

18

Especificaciones sujetas a cambio sin previo aviso.

Shindaiwa es una marca registrada de Shindaiwa, Inc.

Revisión 2/07

Despida el Número 81719

©2007 Shindaiwa, Inc.

Fax: 81-82-849-2481

Teléfono: 81-82-849-2220

731-3167, Japan

6-2-11,

Ozuka-Nishi Asaminami-Ku, Hiroshima

Head Office:

Shindaiwa Corporation

www.shindaiwa.com

Fax: 503 692-6696

Teléfono: 503 692-3070

Tualatin, Oregon 97062 USA

11975 S.W. Herman Rd.

Shindaiwa Inc.

NOTAS

Page 20

17

(503) 692-3070

Tualatin OR 97062

11975 S.W. Herman Rd.

Shindaiwa Inc.

ESTA GARANTÍA ES ADMINISTRADA POR:

8:00 a.m. a 5:00 p.m., hora del Pacífico.

localidad, comuníquese con Shindaiwa Inc., al (503) 692-3070 de

el nombre y el número telefónico del distribuidor de Shindaiwa en su

favor de ponerse en contacto con su distribuidor Shindaiwa. Para obtener

Para localizar a un agente de servicio Shindaiwa más cercano a usted,

ser propiedad de Shindaiwa Corporation.

Todas las piezas y accesorios reemplazados bajo esta garantía pasarán a

razonable, suministrándole una copia de dicha orden de reparación.

llevará a cabo las reparaciones o ajustes necesarios en un lapso

compra del motor. El distribuidor autorizado de Shindaiwa Corporation

Presente sus comprobantes de venta en los que aparezca la fecha de

presentar el producto a un distribuidor autorizado de Shindaiwa.

defectuosa durante el período de garantía, es su responsabilidad

Si cualquier pieza vinculada con las emisiones es encontrada

Shindaiwa Corporation.

limitada deberá ser llevada a cabo por un distribuidor autorizado por

Toda reparación realizada conforme a los términos de esta garantía

SOLICITUDES DE SERVICIO DE GARANTÍA

y durabilidad.

por Shindaiwa Corporation en lo relativo al rendimiento

garantizadas por el fabricante como equivalentes a las piezas autorizadas

el control de emisiones, se deberá asegurar que dichas piezas estén

reemplazos por mantenimiento o reparación de componentes que afecte

Si se utilizaran piezas no autorizadas por Shindaiwa Corporation para

DE UNA RECLAMACIÓN DE GARANTÍA.

DE CONTROL DE EMISIONES Y PUEDE AFECTAR EL RESULTADO

AUTORIZADAS PUEDE REDUCIR LA EFECTIVIDAD DEL SISTEMA

EQUIVALENTES EN RENDIMIENTO Y DURABILIDAD A LAS PIEZAS

SHINDAIWA CORPORATION EL EMPLEO DE PIEZAS QUE NO SON

POR UN DISTRIBUIDOR O CENTRO DE SERVICIO AUTORIZADO POR

CUBIERTAS POR LA GARANTÍA DEBEN SER LLEVADAS A CABO

DEDICADOS A ELLO; SIN EMBARGO, LAS REPARACIONES

SER REALIZADO POR CUALQUIER ESTABLECIMIENTO O PERSONA

DISPOSITIVOS Y SISTEMAS DE CONTROL DE EMISIONES PUEDE

EL MANTENIM I E NTO, R EEMPLAZO O R E PARACIÓN DE

mantenimiento.

reparaciones o mantenimiento o por la omisión de mantener registros de

reparaciones bajo garantía por el solo hecho de no haberse efectuado

correctamente el motor. Shindaiwa Corporation, sin embargo, no negará

a negar la cobertura de garantía si el propietario no ha mantenido

subsiguiente del motor. Shindaiwa Corporation se reserva el derecho

de mantenimiento deberán ser transferidos a cada propietario

en caso de que surjan preguntas. Estos comprobantes y los registros

mantenimiento que cubran la realización de mantenimiento regular

Usted deberá conservar todos los comprobantes y registros de

Usted es responsable del uso y mantenimiento correctos del motor.

REQUISITOS DE MANTENIMIENTO Y REPARACIÓN

pudieran deberse al uso de partes no autorizadas.

(e) Todo repuesto no autorizado o la falla de partes autorizadas que

cubiertos por la garantía,

(d) Cuotas de diagnóstico e inspección que no resulten en servicios

mantenimiento requeridos,

(c) Partes consecuenciales utilizadas para efectuar los servicios de

requeridos,

(b) Los repuestos usados para los servicios de mantenimiento

cumplimiento de los servicios de mantenimiento requeridos,

combustible y aceite recomendados o de una omisión en el

garantía), una alteración, accidente, omisión en el uso del

de Shindaiwa Corporation, en el curso de una reparación de

efectuado un distribuidor o un centro de servicio autorizado

un mal uso, un ajuste inapropiado (a menos de que los hubieran

(a) Condiciones que resulten de una intervención no autorizada,

de lo siguiente:

La garantía por diseño federal de emisiones y defectos no cubrirá nada

LIMITACIONES

incluir ciertas mangueras y conexiones afines.

El sistema de control de emisiones del motor Shindaiwa puede también

• Rotor del volante

• Bobina de encendido

2. Componentes del sistema de encendido

• Armado y medición del chorro y el diafragma

1. Componentes internos del carburador

partes garantizadas incluyen:

garantizadas hasta el primer reemplazo programado de las mismas. Las

a continuación pueden requerir mantenimiento periódico y están

diseño federal de emisiones y defectos. Algunas partes mencionadas

A continuación se listan las piezas cubiertas por la garantía de

PIEZAS CUBIERTAS

(503) 692-3070 de 8:00 a.m. a 5:00 p.m., hora del Pacífico.

de Shindaiwa en su localidad, comuníquese con Shindaiwa Inc., al

Para obtener el nombre y el número telefónico del distribuidor

entonces comunicarse con su distribuidor regional de Shindaiwa.

respecto a sus derechos y responsabilidades de garantía, deberá

Si el distribuidor Shindaiwa no puede responder su pregunta con

problema.

autorizado de Shindaiwa Corporation más cercano cuando exista algún

Usted es responsable de la presentación del motor al distribuidor

mantenimiento inadecuado o modificaciones no autorizadas.

el motor o alguna pieza ha fallado debido a uso abusivo, negligencia,

de que Shindaiwa Corporation podrá negarle cobertura de garantía si

Como propietario del motor, usted deberá sin embargo estar enterado

de todos los mantenimientos programados.

falta de comprobantes o porque usted no pueda asegurar la realización

puede negar una reclamación de garantía exclusivamente debido a la

cubran el mantenimiento de su motor, pero Shindaiwa Corporation no

Corporation le recomienda conservar todos los comprobantes que

mantenimiento requerido listado en su manual del propietario. Shindaiwa

Como propietario del motor, usted es responsable de la realización del

GARANTÍA

RESPONSABILIDADES DEL PROPIETARIO RESPECTO DE LA

al comprador minorista original.

partir de la fecha en que el producto haya sido entregado por primera vez

emisiones del mismo está garantizado por un período de 2 (dos) años a

Cuando este equipo se vende en EE.UU., el sistema de control de

COBERTURA DE LA GARANTÍA DEL FABRICANTE

EE.UU. aplicables.

asegurar que el motor cumpla con las reglamentaciones de la EPA de

cualquier componente defectuoso en relación con las emisiones para

propietario, los diagnósticos, reparaciones o reemplazos necesarios de

autorizado por Shindaiwa Corporation efectuará, sin costo para el

Para las piezas listadas en PIEZAS CUBIERTAS, el Distribuidor

California.

normas de emisión rige para todos los estados, excepto para el Estado de

EPA durante el período de vigencia de la garantía. Esta garantía sobre

pudieran hacer que el motor no cumpla con las reglamentaciones de la

(EPA) y que no tiene defectos materiales ni de mano de obra que

vigentes de la Administración de Protección Ambiental de EE.UU.

cumplir, en el momento de la venta inicial, con todas los reglamentos

(de aquí en adelante motor) está diseñado, fabricado y equipado para

propietario siguiente, que este motor para equipos de uso general

Shindaiwa Corporation garantiza al comprador inicial y a cada

Motores de uso general y para parques y jardines

Garantía limitada de defectos y diseño de emisiones federales

Shindaiwa Corporation

Page 21

16

Aceleración deficiente.

Filtro de aire obstruído.

Filtro de combustible obstruído.

La mezcla de combustible/aire es

muy pobre.

Marcha mínima ajustada muy baja.

Limpie el elemento del filtro de aire.

Cambie el filtro de combustible.

Consulte con su agente de servicio autorizado.

Ajuste: a 3,000 RPM (±300) rpm (min

-1

).

Sintoma Posible Causa Remedio

El motor se apaga

abruptamente.

El interruptor está en la posición

de apagado.

El tanque de combustible está vacío.

Filtro de combustible obstruído.

Agua en el combustible.

Bujía defectuosa o terminal flojo.

Falla en el sistema de encendido.

Pistón trabado.

Fije el interruptor y vuelva arrancar.

Vuelva a llenar. Consulte página 7.

Cambie el filtro de combustible.

Drene; cambie con combustible limpio.

Consulte página 7.

Limpie y cambie la bujía; Apriete el terminal

Reemplace el sistema de encendido.

Consulte con su agente de servicio autorizado.

Se hace difícil apagar

el motor.

La conexión a tierra está desconectada,

o el interruptor está defectuoso.

Sobrecalentamiento debido a bujía

incorrecta.

Motor sobrecalentado.

Pruebe y reemplace como sea requerido.

Ponga el motor en marcha mínima hasta que

enfríe. Limpie y fije la holgura de la bujía a

0.024 – 0.028 pulgadas (0.6 – 0.7 mm).

Bujía correcta: NGK CMR5H o su equivalente

con resistencia al calor correcta.

Marcha mínima hasta que enfríe.

El accesorio de corte gira

con el motor en

marcha mínima.

Marcha mínima ajustada muy alta.

Resorte del embrague está quebrado o el

resorte patrón del embrague está gastado.

El soporte del accesorio está flojo.

Fije la marcha mínima: 3,000 rpm (±300) rpm (min

-1

).

Cambie los resortes/zapatas como sea necesario,

revise la marcha mínima.

Inspeccione y apriete seguramente los soportes

El motor no baja a

marcha mínima.

Marcha mínima ajustada muy alta.

El motor tiene una fuga de aire.

Fije la marcha mínima: 3,000 rpm (±300) rpm (min

-1

).

Consulte con su agente de servicio autorizado.

La parte superior del

motor se está ensuciando

y engrasando.

La tapa de la válvula está goteando. Consulte con su agente de servicio autorizado.

Sintoma Posible Causa Remedio

Vibración excesiva.

El accesorio está dañado o doblado.

La caja de cambios está floja.

El eje principal está doblado/

forros están dañados o gastados.

Inspeccione y cambie el accesorio como sea necesario.

Apriete la caja de cambios firmemente.

Inspeccione y cambie como sea necesario.

El cortador no gira.

El eje no está instalado en el tren

motríz o en la caja de cambios.

Eje quebrado.

Caja de cambios dañada.

Inspeccione y vuelva a instalar como sea necesario.

Consulte con su agente de servicio autorizado.

PROBLEMAS ADICIONALES

PROBLEMAS ADICIONALES

Guia Diagnostico (continuación)

Page 22

15

¿Arranca el motor?

Arrancador defectuoso.

Liquido en el cárter.

Daños internos.

Consulte con su agente de servicio autorizado.

Consulte con su agente de servicio autorizado.

Consulte con su agente de servicio autorizado.

NO

¿Buena compresión?

Bujía floja.

Desgaste en el cilindro, pistón, anillos.

Las válvulas no están asentadas.

Ajuste y pruebe otra vez.

NO

SI

¿Contiene el tanque

combustible fresco y del

octanaje correcto?

Vuelva a llenar con combustible fresco, limpio y

sin plomo con un octanaje de 87 o superior mezclado

con aceite de mezcla para motores de 2 tiempos

Shindaiwa enfriado por aire que cumple o excede

los aceites clasificados ISO-L-EGD y/o JASO FC

a una proporción de 50:1 de gasolina/aceite.

Combustible incorrecto, viejo, o

contaminado; mezcla incorrecta.

NO

SI

¿Se ve el combustible

circular por la línea de

retorno al realizar el cebado?

Revise el filtro y/o el ventilador en busca

de obstrucción.

Bomba de Cebado no funciona

propiamente.

Reemplace el filtro de combustible o la valvula de

presion cuando sea necesario; vuelva a encender.

Consulte con su agente de servicio autorizado.

NO

¿Hay chispa en el terminal

del cable de bujía?

El interruptor de encendido está en

posición “O” (OFF) (apagado).

Corta conexión a tierra.

Sistema de encendido o ignición defectuoso.

Mueva el interruptor a la posición de encendido

(I) y vuelva arrancar.

NO

SI

SI

Revise la bujía.

Si la bujía está húmeda, puede haber

exceso de combustible en el cilindro.

La bujía está obstruída o tiene la holgura

incorrecta.

La bujía está dañada internamente o es el

tamaño equivocado.

Retire la bujía y arranque el motor;

reinstale la bujía y vuelva arrancar.

Limpie y calibre la bujía a 0.024 – 0.028 pulgadas

(0.6 – 0.7mm). Vuelva arrancar.

Cambie la bujía por una NGK CMR5H o una

equivalente con resistencia al calor correcta.

Fije la holgura del electrodo de la bujía a

0.024 – 0.028 pulgadas (0.6 – 0.7 mm).

SI

Que Revisar Posible Causa Remedio

¿Se está sobrecalentando

el motor?

El operador esta sobre trabajando

la máquina.

La mezcla del carburador es muy pobre.

Proporción de combustible inapropiada.

Ventilador, tapa del ventilador, aletas

del cilindro están sucios o dañados.

Depósitos de carbón en el pistón o en el

silenciador.

Corte más despacio.

Consulte con su agente de servicio autorizado.

Vuelva a llenar con combustible fresco, limpio y

sin plomo con un octanaje de 87 o superior mezclado

con aceite de mezcla para motores de 2 tiempos

Shindaiwa enfriado por aire que cumple o excede los

aceites clasificados ISO-L-EGD y/o JASO FC a una

proporción de 50:1 de gasolina/aceite.

Limpie, repare o cambie si es necesario.

Consulte con su agente de servicio autorizado.

Que Revisar Posible Causa Remedio

El motor funciona

bruscamente en cualquier

velocidad. Puede tener

humo negro y/o

combustible sin usar en

el escape.

Filtro de aire obstruído.

Bujía floja o dañada.

Fuga de aire o línea de combustible

obstruída.

Agua en el combustible.

Pistón trabado.

Carburador defectuoso y/o diafragma.

Espacio de la válvula ajustada.

Limpie el elemento del filtro de aire.

Apriete o cámbiela. Cambie la bujía por NGK BMR5A.

Repare o cambie el filtro y/o la manguera de combustible.

Cambie el combustible. Consulte la pagina 7.

Consulte con su agente de servicio autorizado.

El motor está pateando.

Sobrecalentamiento.

Combustible inadecuado.

Depósitos de carbón en la cámara

de combustión.

Espacio de la válvula ajustada.

Consulte arriba.

Revise el índice de octanaje del combustible.

Revise si hay alcohol en el combustible. (página 7).

Vuelva a llenar si es necesario.

Consulte con su agente de servicio autorizado.

Ajuste válvulas (ve página 13).

BAJA POTENCIA

EL MOTOR NO ARRANCA

Guia Diagnostico

Page 23

26118

de la orilladora

Cuchilla

Sujetador B

perno

14

libre de polvo.

n Almacene la máquina en un sitio limpio y

seque y vuelva a ensamblar el elemento.

minuciosamente con agua y jabón. Deje que

n Retire el elemento del filtro de aire y limpielo

cambie cualquier pieza dañada o gastada.

n Antes de almacenar la máquina, repare o

Reínstale la bujía.

uniformemente en el interior del motor.

2 ó 3 veces para que el aceite se aplique

de la bujía. Lentamente jale el arrancador

2 tiempos en el cilindro a través del agujero

de onza de aceite de mezcla para motores de

n Retire la bujía y vierta aproximadamente 1/4

ya no arranque.

3. Repita los pasos 1 y 2 hasta que el motor

hasta que pare de funcionar.

2. Arranque y mantenga prendido el motor

combustible deje de pasar.

1.

Empuje la bombilla de cebado hasta que el

tuberias de combustible y carburador.

IMPORTANTE!

n Retire el resto del combustible en las

DE SERVICIO Y MANTENIMIENTO.

CONDUCIR A UN AUMENTO EN COSTO

CAUSAR UN ARRANQUE DURO Y PUEDE

RADOR POR PERIÓDOS LARGOS PUEDE

GASOLINA ALMACENADA EN EL CARBU-

PRECAUCIÓN!

de combustible.

que use aceite con estabilizador

combustible tal como STA-BIL™, l menos

estar estabilizado con un estabilizador de

Todo combustible almacenado debe

n Drene todo combustible en el tanque.

ligera de aceite a todas las superficies metálicas.

n Limpie las partes externas y aplique una capa

almacenamiento:

siguientes procedimientos para preparar su

ser usada por 30 días o más, siga los

Cada vez que la máquina no va a

Almacenamiento de Largo Plazo

Figura 26

caja de engranaje.

llave inglesa.. Vea la Figura 26.

túnel

Cierre el

salida del eje.

Collar de

apretar firmemente el perno del eje. Quite la

5. Utilice la llave inglesa de la combinación para

salida del eje. Vea la Figura 26.

inglesa asegurar temporalmente la

engranajes y en- tonces utilice la llave

hoyo cor- respondiente en la caja de

4. Alinee el hoyo del sujetador A con el

la izquierda para instalar). Vea la Figura 26.

del perno y perno del eje (gire el perno hacia

Protector del

Sujetador A

dor B en el eje, y entonces instale al seguro

3. Monte la cuchilla de la orilladora y el sujeta-

dor B y la cuchilla de la orilladora de la

quite el perno de salida de eje, el sujetapara aflojar el perno del eje entonces

2.

Utilice la llave inglesa de la combinación

temporalmente la salida del eje.

y entonces utilice la llave inglesa asegurar

correspondiente en la caja de engranajes

1. Alinee el hoyo del sujetador A con el hoyo

toque la cuchilla de la orilladora.

Siempre use guantes cuando

¡ADVERTENCIA!

silenciador

Pernos del

chispas

Maya del guarda-

Silenciador

Tapa

reversa al order de desemblaje.

silenciador y la tapa del motor en forma

6. Vuelva a ensamblar el guardachispas, el

Tornillos de la tapa

chispas

Tapa del guarda-

silenciador

Empaquetadura del

IMPORTANTE!

buidor autorizado Shindaiwa.

consulte con su centro de servicio o distriSi nota acumulación excesiva de carbón,

Figura 25

tapa del motor

Tornillos de la

Reemplazar la Cuchilla de la Orilladora

busca de acumulación de carbón.

5. Inspeccione el escape del cilindro en

dor. Consulte la figura 25.

los pernos del silenciador y el silencia-

4. Con una llave hexagonal de 3 mm retire

Inspección de Escape del Cilindro

cerdas gruesas.

3. Retire la maya y limpie con un cepillo de

ciador. Consulte la figura 25.

maya guardachispas y la tapa del silenretire los dos tornillos sosteniendo la

2. Con un destornillador de cuchila plana

la tapa del motor. Consulte la figura 25.

los cuatro tornillos de la tapa del motor y

1. Con una llave hexagonal de 3 mm retire

podría también lesionar sus oídos.

puede constituir un riesgo de incendio y

o faltante. De lo contrario, la operación

silenciador o un guardachispas dañado

Nunca opere esta unidad con un

¡ADVERTENCIA!

cia, revise y limpie la maya del guardachispas.

Si el motor se pone peresoso o tiene baja poten-

Mantenimiento de la Maya Guardachispas

Page 24

13

26024

quetaduras rotas o ¡dañadas!

puede volverse a usar. Nunca use empay/o la usada no esta dañada, la usada

Si la empaquetadura no está disponible

IMPORTANTE!

damente e instale la tapa.

asegurarse de que esté sellado apropia-

7. Reemplace la cubierta del balancín para

brazo del balancín.

medio de la punta de la válvula y del

por los dos lados, entrada y escape en

3. Introduzca el calibrador .004” (0.10 mm)

autorizado Shindaiwa.

proceso, consulte con un agente

motor o no se siente seguro del

n Si no esta familiarizado con este

correctas de torsión.

las válvulas y las especicaciones

ciones completas de cómo ajustar

de servicio del C-4 para instrucy/o dañar la máquina. Vea el manual

puede causar dicultad al arrancar

n El ajustar la válvula incorrectamente

¡PRECAUCIÓN!

ajustarlo si es necesario.

apretado la contratuerca. Vuelva a

no cambió como resultado de haber

para asegurarse que el espacio de ajuste

a chequear con el calibrador apropiado

a ajustar la compresión a TDC. Vuelva

6. Vuelque el motor varias veces y vuelva

apriete la contratuerca con la llave.

en su lugar con un destornillador Allen,

5. Mientras sostiene el tornillo ajustador

salga sin mucha resistencia.

un poco para permitir que el calibrador

el calibrador este bien ajustado. Quítelo

= aprieta, izquierda = afloja) hasta que

4. De vuelta al tornillo ajustador (derecha

sin problemas.

dela Allen de 2.5mm pueda dar vueltas

para que el tornillo ajustador de la aran-

2. Vaya soltando la contratuerca ajustadora

compresión de TDC.

del balancín, y ajuste el pistón a

1. Remueva la tapa del cilindro, la cubierta

Ajuste de la válvula

néticos (EMC).

requisitos de la regulación de electro mangLa NGK CMR6H tambíen cumple con los

NOTA

0.6 – 0.7 mm (0.024 – 0.028 pulgadas)

Fije la holgura del electrodo de la bujía a

lente con resistencia al calor correcta.

mente NGK CMR5H o una bujía equiva-

n Reemplace la bujía anualmente: Use sola-

por Shindaiwa.

sea efectuado por un técnico entrenado

Es sumamente recomendado que esto

ajustado anualmente o cada 135 horas.

n El espacio libre de la válvula debe ser

horas después.

de 139 horas, entonces cada de 150

La conservación después de primero

Mantenimiento Cada 139/150 Horas

16210)

Tuerca

Engranajes (N/P 72958-

El Protector de Caja de

Figura 2

con una tuerca como se muestra.

y cada tornillo este asegurado en el lugar

los protectores estén apretados firmemente

para estar seguro que los dos soportes del

el tubo)

Plano (hacia

Al reemplazar el protector inspecciónelo

que haya daño o el uso excesivo.

debe inspeccionar rutinariamente en caso

aceras u otras superficies abrasivas y se

engranajes del daño al trabajar cerca de

engranajes

Caja de

para proteger el reborde de la caja de

granajes (N/P 72958-16210) es instalado

El protector de metal de la caja de en-

de Engranajes

Inspeccione el Protector de la Caja

Figura 23

de D

en forma

de Calce

Arandela

eje

Tubo del

hacia el tubo del eje.

se debe posicionar con su orilla plana

La arandela de calce de en forma de D

PRECAUCIÓN!

Mantenimiento Cada 50 Horas (continuación)

Page 25

12

XST021

Tubo del eje

Eje exible

NOTA

caja de engranajes

Índice de tornillos de la

reverso a la extracción de la misma.

8. Instale la caja de engranajes en orden

hembra.

7. Inserte el eje flexible al final del piñón

volver a instalar.

se debe de revertir las puntas a la hora de

Para extender la vida del eje y el cable flexible

y vuelva a instalar el eje en el tubo .

el equivalente) para la caja de engranaje

Lubricante de Primera de Shindaiwa (o

6. Revista la longitud entera del eje con

también.

reemplazado el forro debe remplazarse

eje flexible esta gastado o necesita ser

remplace si esta gastado o dañado. Si el

Elemento del ltro

Alambre

Gancho de

5. Inspeccione el eje cuidadosamente, y

limpie el eje detalladamente con solvente.

4. Tire el eje flexible del tubo del eje, y

tor del tubo del eje.

3. Deslice la caja de engranajes y el protec-

engranajes.

2. Quite el tornillo del índice de caja de

de engranajes.