Page 1

English ...............1

Spanish ....... SP_1

French ........FR_1

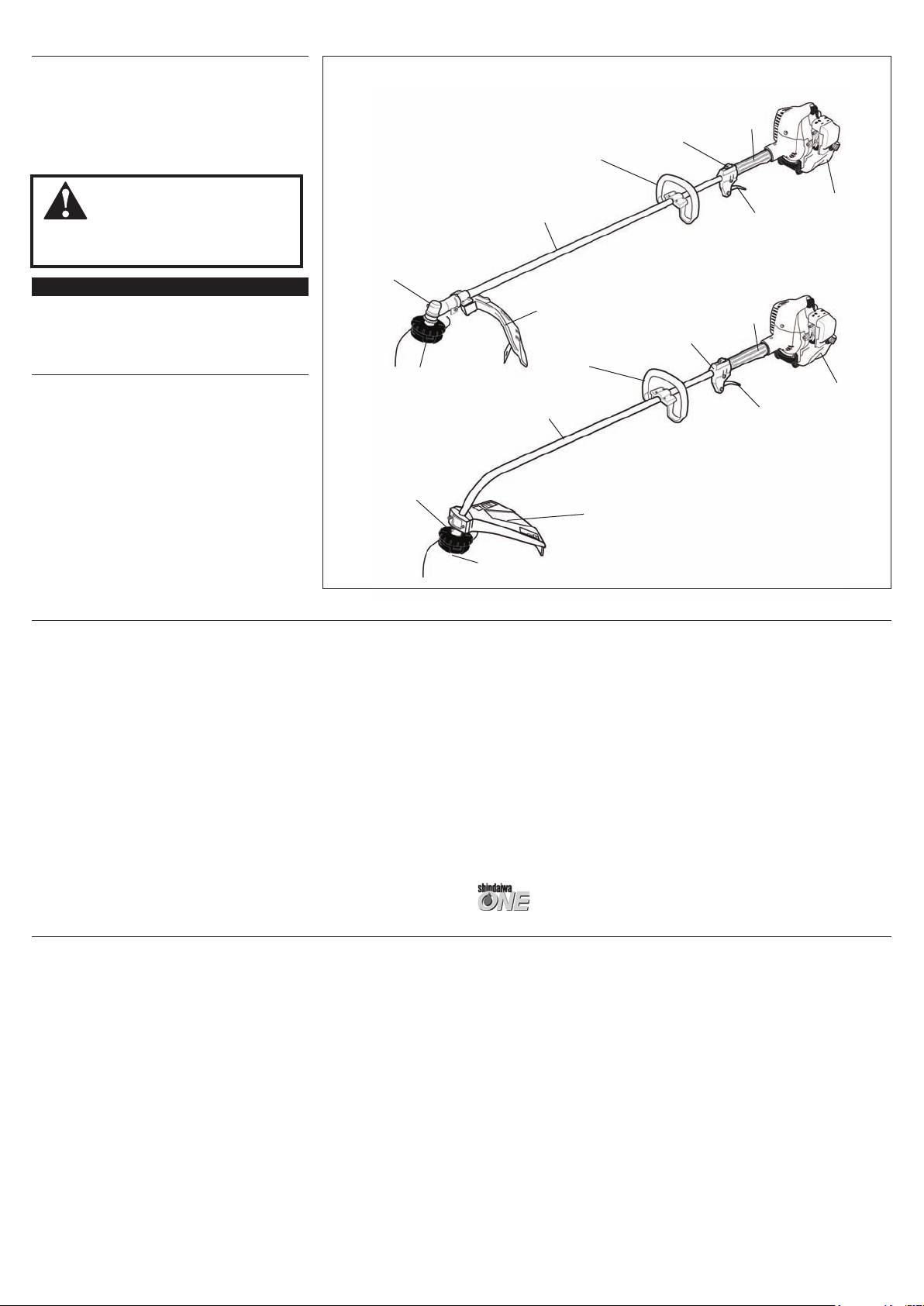

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

T222 TRIMMER

F222 TRIMMER

T222

F222

WARNING!

Minimize the risk of injury to yourself and

others! Read this manual and familiarize yourself with

the contents. Always wear eye and hearing protection

when operating this unit.

Part Number 81372 Rev. 3/07

Page 2

50FEET

(15m)

Introduction

The Shindaiwa 222 Series hand held

power equipment has been designed and

built to deliver superior performance and

reliability without compromise to quality,

comfort, safety or durability.

Shindaiwa engines represent the

leading edge of high-performance engine

technology, delivering exceptionally high

power with remarkably low displacement

and weight. As an owner/operator, you’ll

soon discover for yourself why Shindaiwa is

simply in a class by itself!

IMPORTANT!

The information contained in this owner’s/

operator’s manual describes units available

at the time of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

WARNING!

The engine exhaust from

this product contains chemicals

known to the State of California

to cause cancer, birth defects

or other reproductive harm.

Contents

Attention Statements .................................2

Safety Instructions .....................................3

Safety Labels ...............................................4

Product Description ...................................5

Specifications ..............................................5

Assembly and Adjustments ....................... 6

Mixing Fuel ................................................8

Starting the Engine ................................... 8

Stopping the Engine ..................................9

Adjusting Engine Idle ................................ 9

Checking Unit Condition.........................10

Cutting Grass ............................................10

Maintenance .............................................11

Long Term Storage ..................................13

Troubleshooting Guide ...........................14

Emission System Warranty ..................... 16

PAGE

Attention Statements

Throughout this manual are special

“Attention Statements”.

WARNING!

A statement preceded by

the triangular attention symbol and

the word “WARNING” contains

information that should be acted upon

to prevent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent

mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word

”NOTE” contains information that is

handy to know and may make your job

easier.

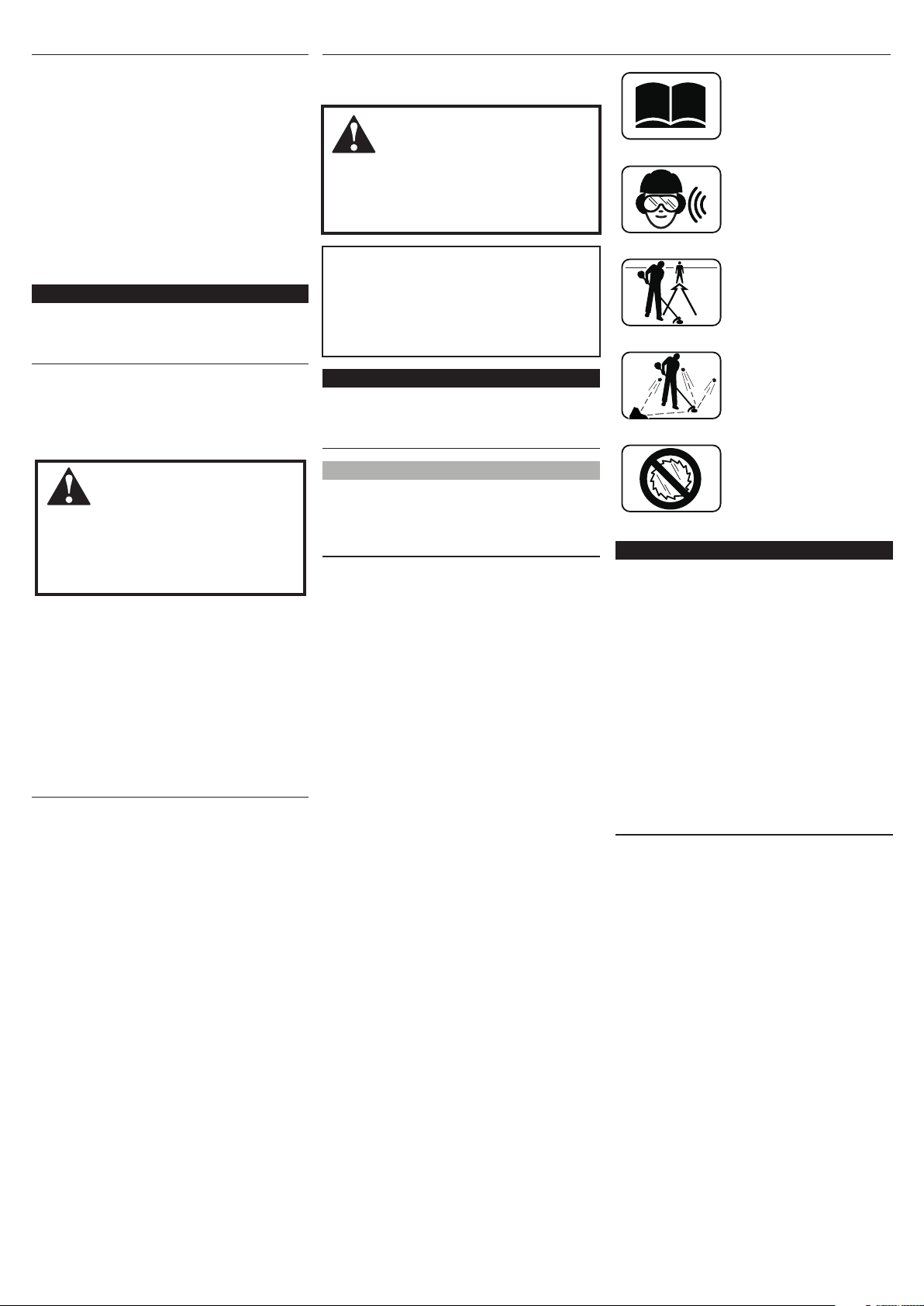

Read and follow this

operator’s manual.

Faulure todo so could

result in serious injury.

Wear eye and hearing

protection at all tims

during the operation of

the unit.

Keep bystanders at least

50 feet (15 m) away

during operation.

Beware of thrown or

ricocheted objects.

Do not operate this

machine with a blade.

IMPORTANT!

The operational procedures described

in this manual are intended to help you

get the most from this unit as well as

to protect you and others from harm.

These procedures are guidelines for safe

operation under most conditions, and are

not intended to replace any safety rules

and/or laws that may be in force in your

area. If you have questions regarding your

222 series hand held power equipment,

or if you do not understand something in

this manual, your Shindaiwa dealer will be

glad to assist you. You may also contact

Shindaiwa, Inc. at the address printed on

the back of this Manual.

2

Page 3

Safety Instructions

Work Safely

Shindaiwa trimmers operate at very high

speeds and can do serious damage or

injury if they are misused or abused.

Never allow a person without training or

instruction to operate this unit!

WARNING!

Never make unauthorized

attachment installations. Do

not use attachments not approved

by Shindaiwa for use on this unit.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never operate power

equipment of any kind if

you are tired or if you are under the

inuence of alcohol, drugs, medication

or any other substance that could

affect your ability or judgement.

WARNING!

Minimize the Risk of Fire

NEVER smoke or light fires near the

engine.

ALWAYS stop the engine and

allow it to cool before refueling.

Avoid overlling and wipe off any

fuel that may have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

rell, check that no fuel leaks from

around the fuel cap and/or fuel tank.

WARNING!

Use Good Judgment

ALWAYS wear eye protection to

shield against thrown objects.

NEVER run the engine when

transporting the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

ALWAYS use the proper cutting tool

for the job.

If fuel leaks are evident, stop using

the unit immediately. Fuel leaks must

be repaired before using the unit.

ALWAYS move the unit to a place

well away from a fuel storage area

or other readily ammable materials

before starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER operate the engine without

the spark arrester screen in place.

ALWAYS stop the engine immediately

if it suddenly begins to vibrate or

shake. Inspect for broken, missing

or improperly installed parts or

attachments.

NEVER extend trimming line beyond

the length specied for your unit.

ALWAYS keep the unit as clean

as practical. Keep it free of loose

vegetation, mud, etc.

ALWAYS hold the unit rmly with both

hands when cutting or trimming, and

maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug wire

before performing any maintenance work.

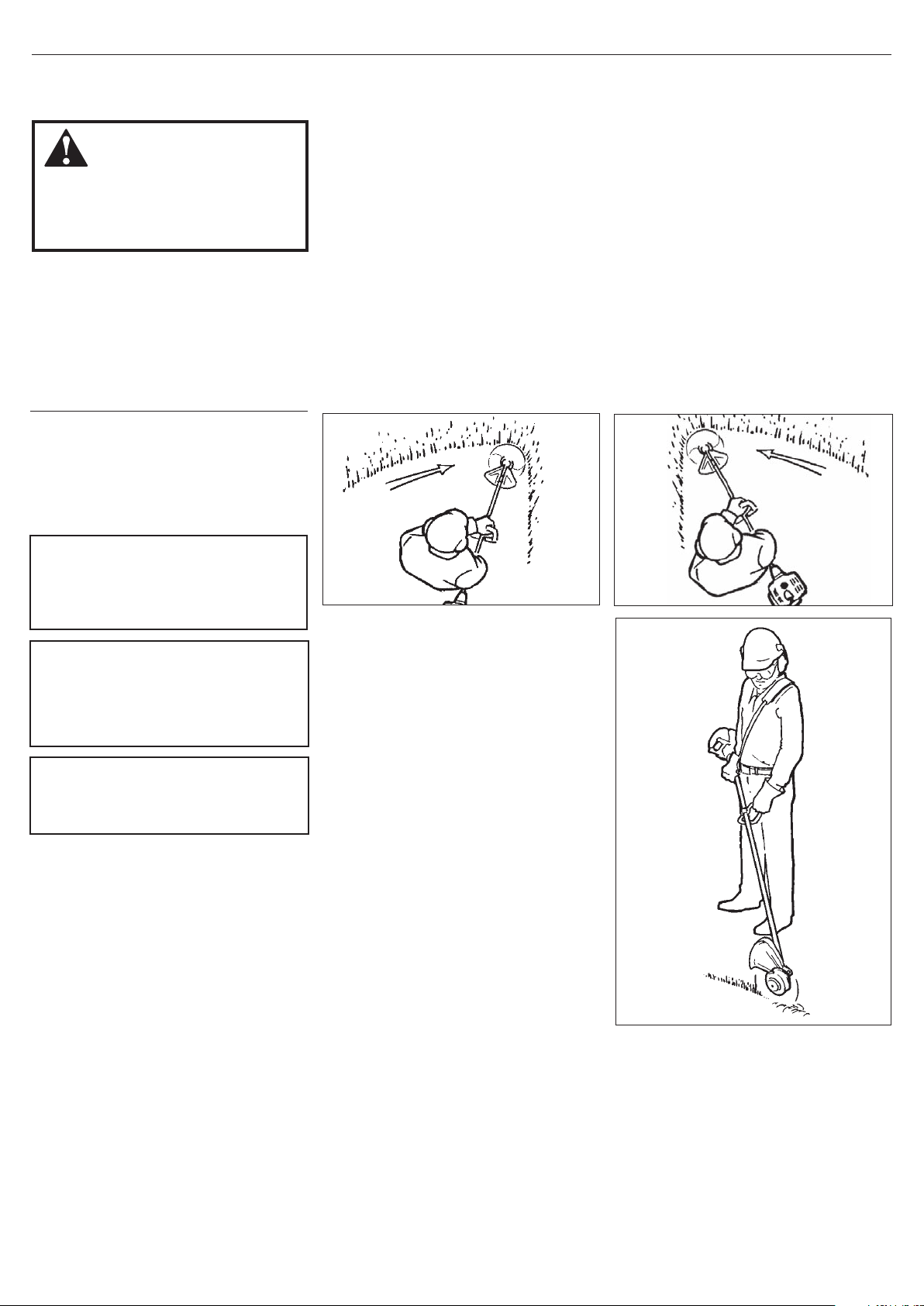

The Properly Equipped Operator

Wear close-tting clothing to protect legs and arms.

Gloves offer added protection and are strongly

recommended. Do not wear clothing or jewelry that

could get caught in machinery or underbrush. Secure

hair so it is above shoulder level. NEVER wear shorts!

Keep a proper footing

and do not overreach—

maintain your balance at all

times during operation.

Wear appropriate footwear (non-skid boots or

shoes): do not wear open-toed shoes or sandals.

Never operate the unit while barefoot!

Wear hearing protection devices and a

broad-brimmed hat or helmet.

Always wear eye protection such as

goggles or safety glasses.

Always operate with both hands

rmly gripping the unit.

Keep away from the rotating trimmer

line at all times, and never lift a moving

attachment above waist-high.

Always make sure the appropriate

cutting attachment shield is correctly

installed and in good condition.

3

Page 4

READTHE

OPERATOR’SMANUAL

WEARHEARINGANDANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST50 FEET(15m)

BEWAREOFTHROWNOR

RICOCHETEDOBJECTS

DONOTOPERATETHIS

MACHINEWITHA BLADE

50FEET

(15m

)

19422-00028ShindaiwaInc.

READTHE

OPERATOR’SMANUAL

WEARHEARINGANDANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST50 FEET(15m)

BEWAREOFTHROWNOR

RICOCHETEDOBJECTS

DONOTOPERATETHIS

MACHINEWITHA BLADE

50FEET

(15m)

19422-00028ShindaiwaInc.

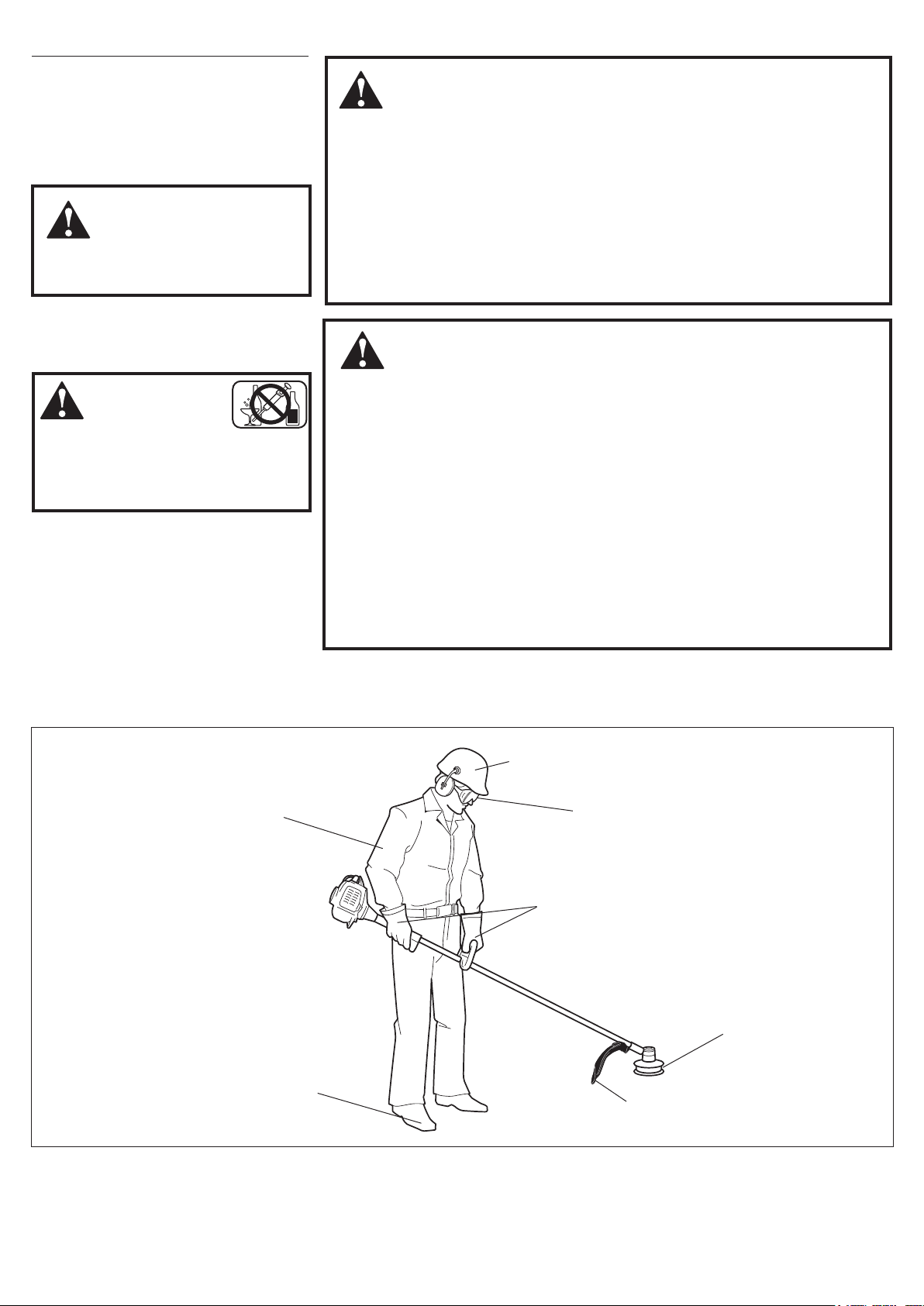

Be Aware of the Working Environment

Avoid long-term operation

in very hot or very cold

weather.

Be extremely careful of

slippery terrain, especially

during rainy weather.

Reduce the risk of

bystanders being struck

by ying debris. Make

sure no one is within 50

feet (15 meters)—that’s

about 16 paces—of an

operating attachment.

Make sure bystanders or

observers outside the 50-

foot “danger zone” wear eye

protection.

50

FEET

When operating in rocky terrain

or near electric wires or fences,

use extreme caution to avoid

contacting such items with the

cutting attachment.

Always make sure

the appropriate cutting

attachment shield is correctly

installed.

Figure 2

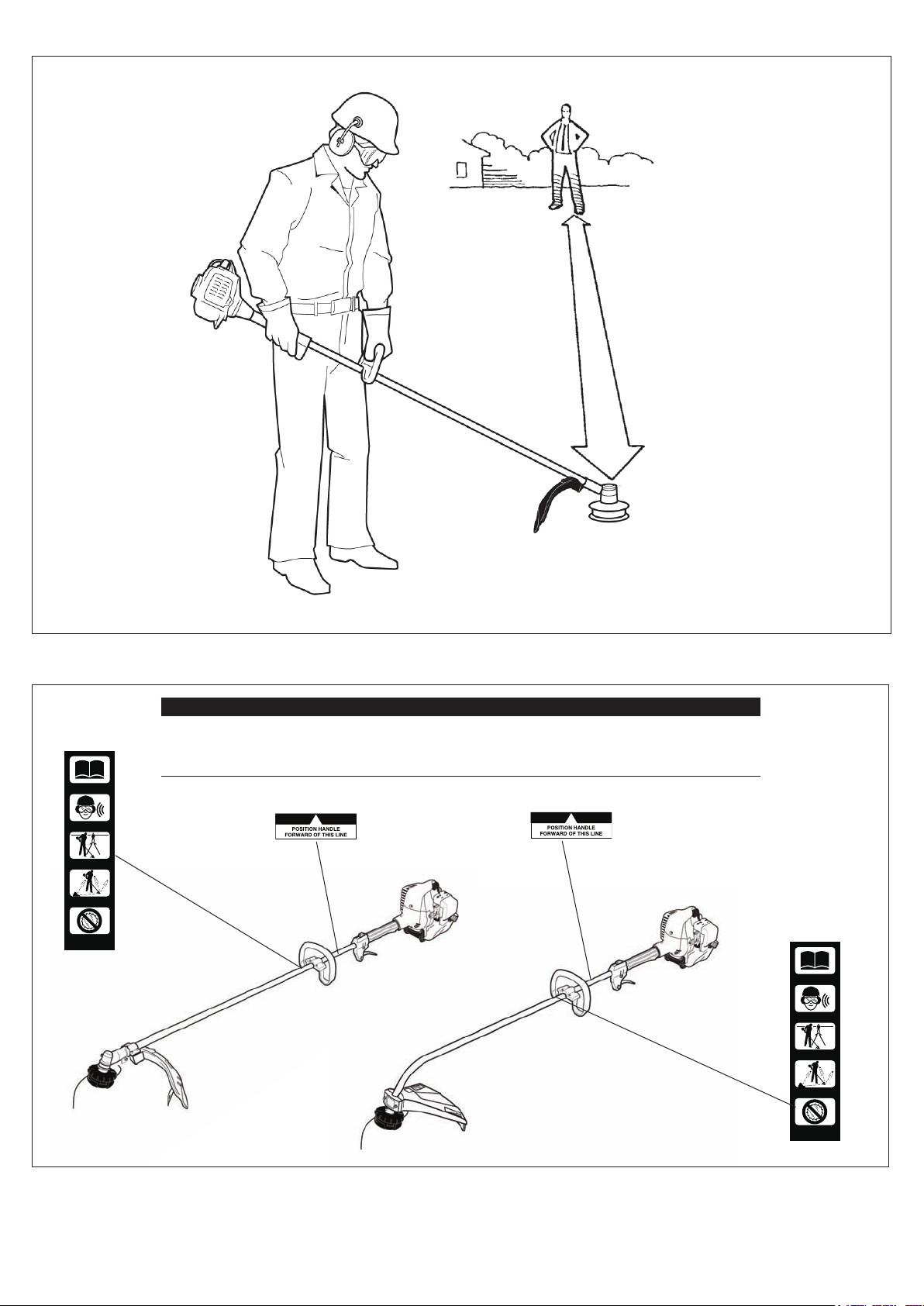

Safety Labels

Safety and Operation Information Labels: Make sure all information labels are undamaged

and readable. Immediately replace damaged or missing information labels. New labels are

available from your local authorized Shindaiwa dealer.

Be constantly alert for objects and

debris that could be thrown either

from the rotating cutting attachment or

bounced from a hard surface.

IMPORTANT

This label indicates the minimum distance

between front handle and rear grip per ANSI

B175.3.

T222

If contact is made with a hard

object, stop the engine and

inspect the cutting attachment

for damage.

F222

4

Figure 3

Page 5

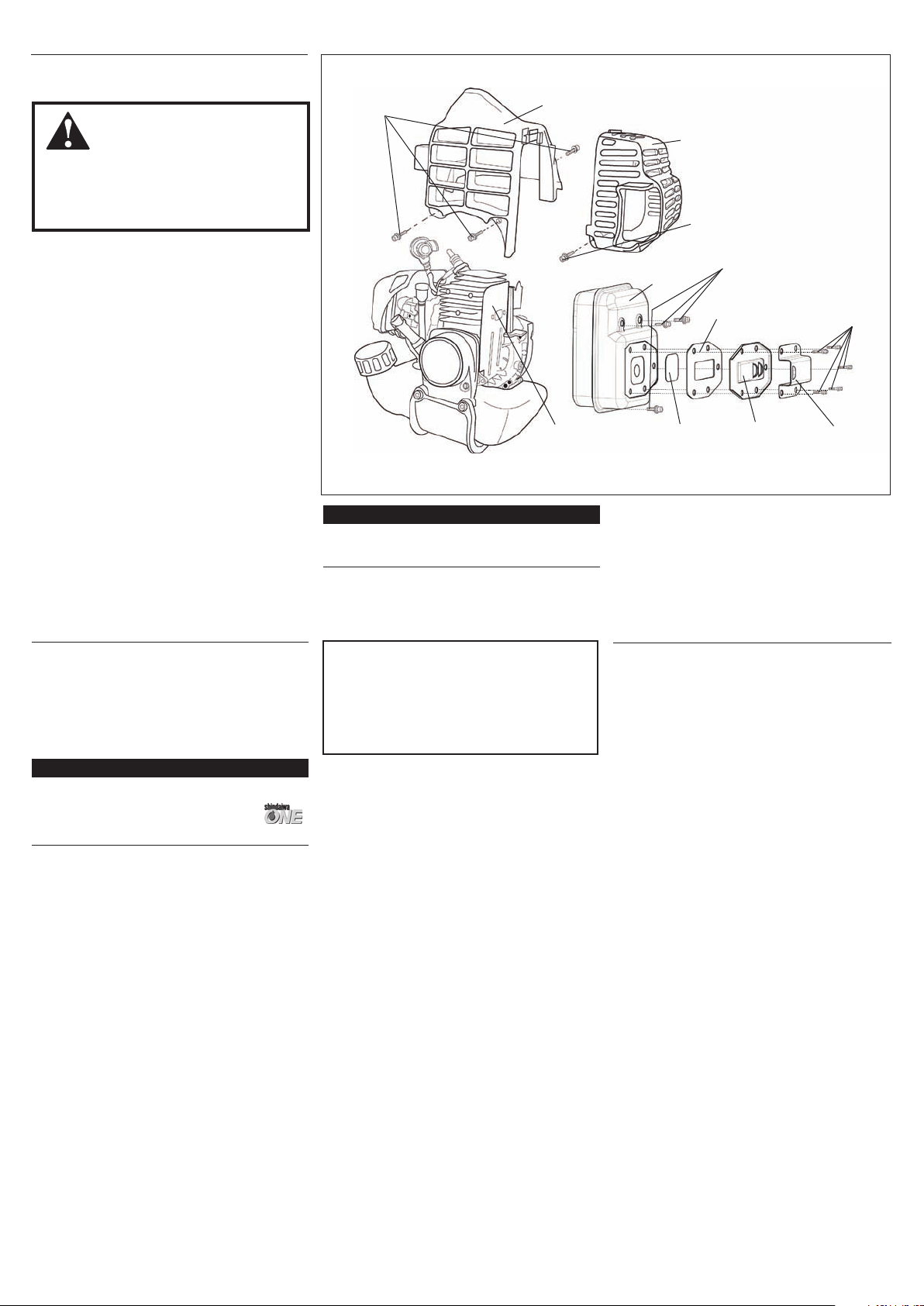

Product Description

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. See Figure 4.

Understanding your unit helps ensure top

performance, long service life, and safer

operation.

Handle

Ignition

Switch

T222

Grip

WARNING!

Do not make unauthorized

modications or alterations to any of

these units or their components.

IMPORTANT!

Gear case

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

Figure 4

Trimmer

Head

Shaft case

Specications

T222 dry weight

(less cutting attachment) ...........................................10.8 lb./4.9 kg

F222 dry weight

(less cutting attachment) ...........................................10.8 lb./4.9 kg

Engine model ........................................................................... S222E

Engine type ................................................................2-cycle catalyst

Bore x stroke ............................................. 1.3 x 1.1 in./33 x 28 mm

Displacement ........................................................ 1.5 cu. in./23.9 cc

Maximum power .......................................................... 1 HP/0.8 kW

@ 8000 rpm (min

Fuel/oil ratio .............................. 50:1 with ISO-L-EGD or JASO FC

class 2-cycle mixing oil*

Carburetor type ...........................................TK TZ, diaphragm-type

Fuel tank capacity ....................................................21.0 oz./620 ml

-1

Outer Tube

Cutting

Attachment Shield

Ignition

Switch

Handle

Outer Tube

Cutting

Attachment Shield

Trimmer Head

Throttle

Trigger

F222

Grip

Throttle

Trigger

Ignition ........................ One-piece electronic, transistor-controlled

Spark plug ............................................................................BPMR6A

Air cleaner type ........................ Non-reversible foam filter element

Starting method ....................................................................... Recoil

Stopping method ............................................................ Slide switch

Transmission type ............................. Automatic, centrifugal clutch

w/bevel gear

EPA Emission Compliance Period** ........................... Category B

** The EPA emission compliance referred to on the emission compliance label

)

located on the engine, indicates the number of operating hours for which the

engine has been shown to meet Federal emission requirements. Category

C = 50 hours (Moderate), B = 125 hours (Intermediate) and A = 300 hours

(Extended).

*meets or exceeds these specifications and is

recommended for all Shindaiwa products.

Fuel

Tank

Fuel

Tank

Specifications are subject to change without notice.

This unit comes fully assembled with the

exception of the cutting attachment shield

and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit and inspect unit and components for

any damage.

Engine and shaft assembly

■

Cutting attachment shield

■

Cutting attachment

■

Kit containing cutting attachment shield,

■

mounting bracket and hardware, this

owner’s/operator’s manual and tool

kit for routine maintenance. Tool kits

vary by model and may include a spark

plug/screwdriver combination wrench,

and a scraper.

5

Page 6

22010A

Assembly and Adjustments

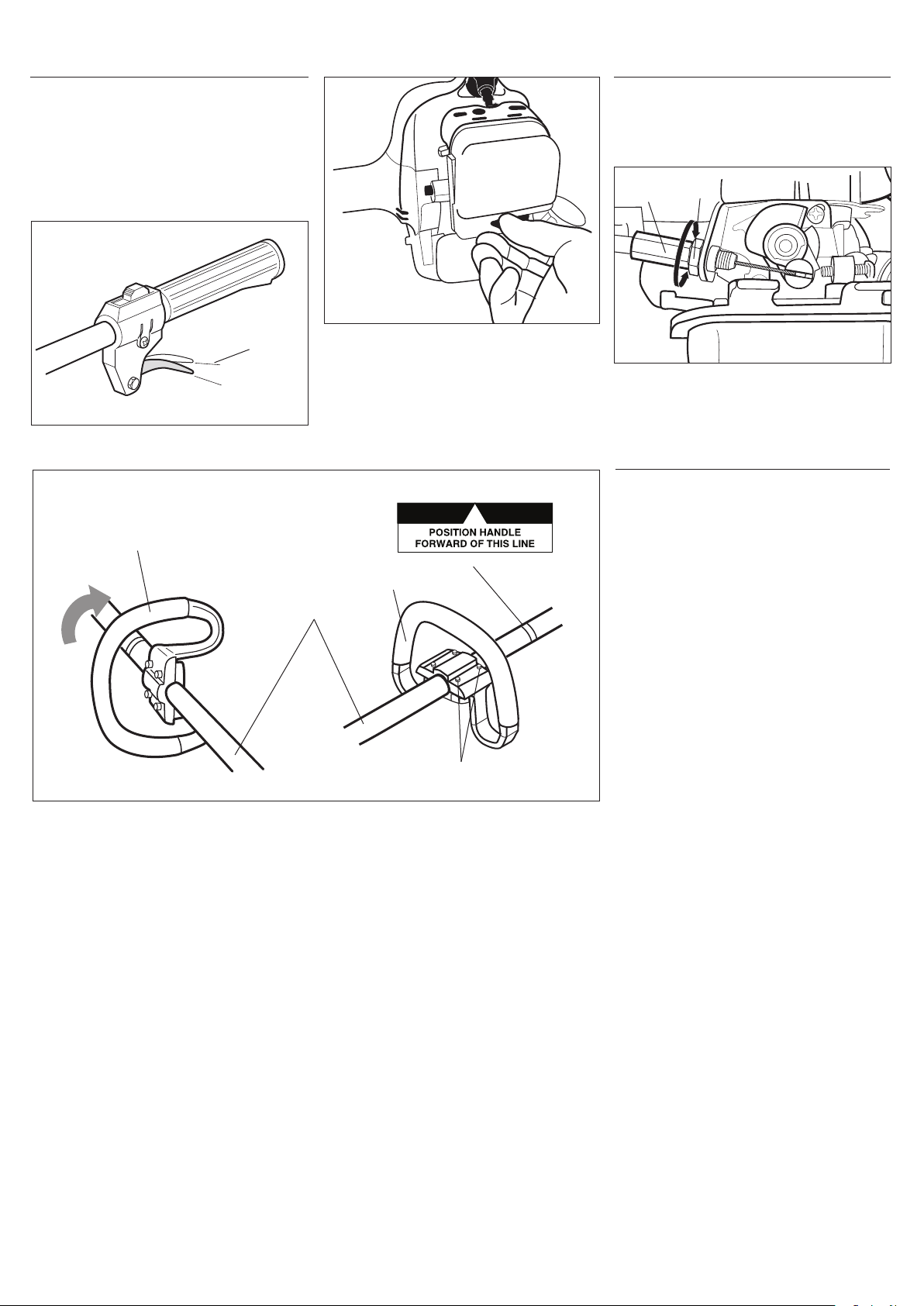

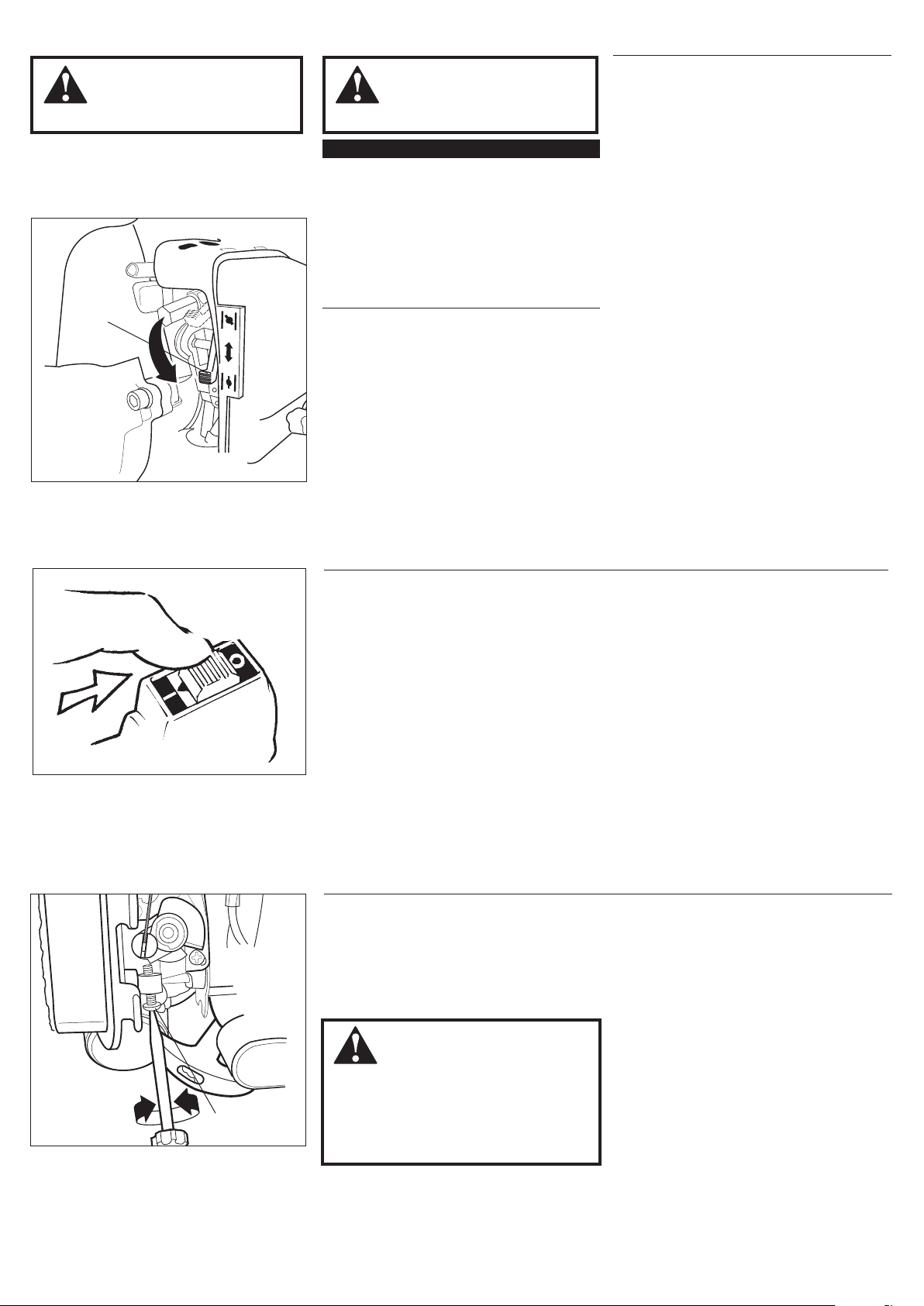

Adjust Throttle Lever Free Play

The throttle lever free play should be

approximately 3/16-1/4 inch (4-6 mm). See

Figure 5. Make sure that the throttle lever

operates smoothly without binding. If it

becomes necessary to adjust the lever free

play, follow the procedures and illustrations

that follow.

3/16-1/4 inch (4-6 mm)

Throttle Free Play

Figure 5

Handle

Handle

Outer Tube

Figure 6

Loosen the air cleaner cover knob and re-

1.

move the air cleaner cover. See Figure 6.

Loosen the lock nut on the cable ad-

2.

juster. See Figure 6.

Handle Positioning Label

Handle

Turn the cable adjuster in or out as re-

3.

quired to obtain proper free play 3/161/4 inch (4-6 mm). See Figure 7.

Tighten the locknut.

4.

Cable

Adjuster

Figure 7

Lock

Nut

Reinstall the air cleaner cover.5.

The handle is attached to the outer

1.

tube at the factory and positioned

vertically. See Figure 8A.

Loosen the 4 socket-head cap screws

2.

on the handle and rotate the handle 90

degrees. See Figure 8B.

Position the handle forward of the

3.

Handle Positioning Label at the best

position for operator comfort (usually

about 10 inches ahead of the throttle

housing).

Secure the handle by alternately tight-

4.

ening the four socket-head cap screws

in a diagonal or “crisscross” fashion.

Figure 8A

Screws

Figure 8B

6

Page 7

26013

Assembly and Adjustments

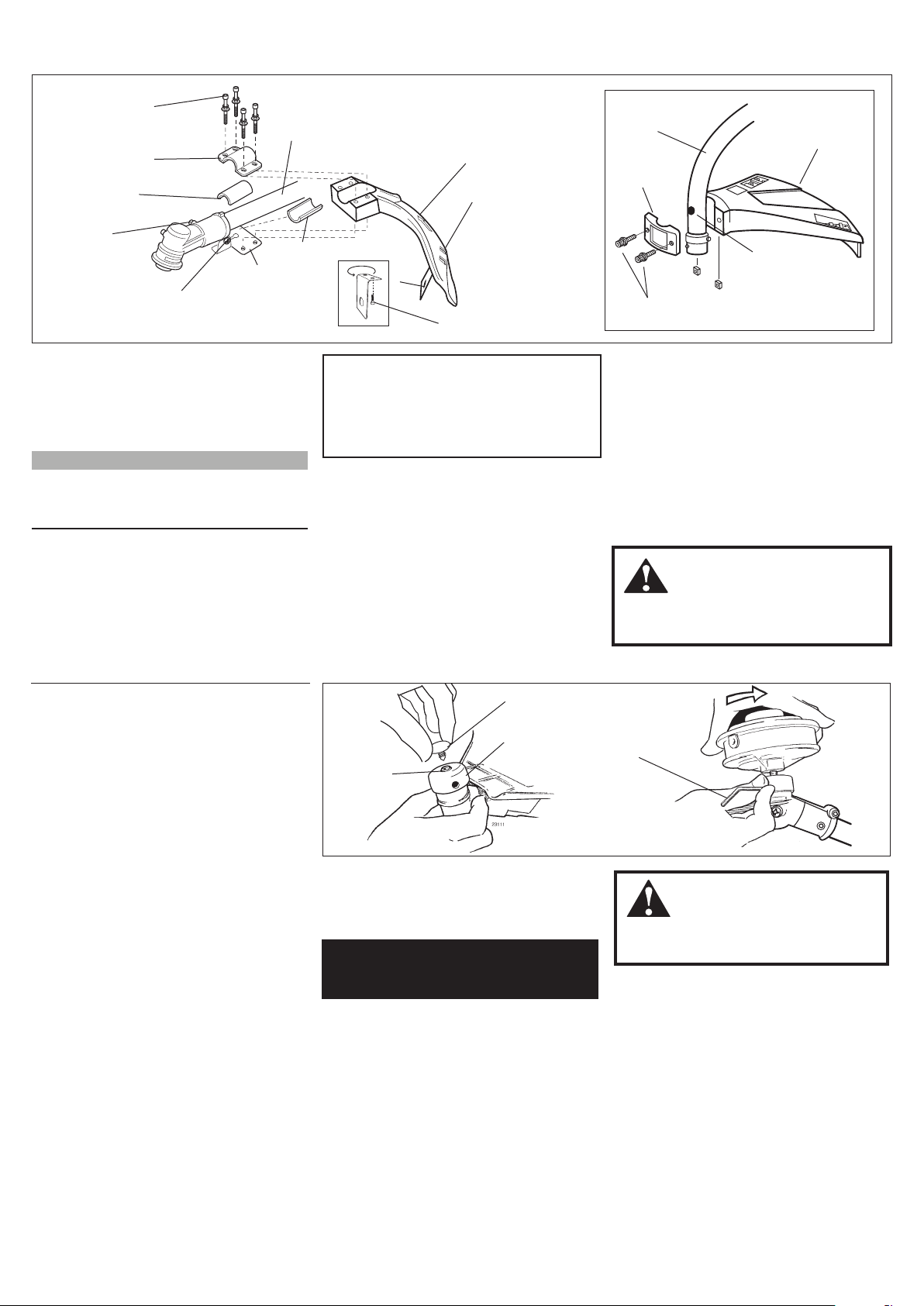

Cutting Attachment Shield

Socket-

Clamp

Screw

Figure 9A

Head Cap

Screw

Bracket

Shim

Retaining

Cutting Attachment

Mounting Plate

Nut

Outer

Tube

Install the Cutting Attachment

Shield T222.

Insert the cutting attachment shield

1.

between the outer tube and the cutting attachment mounting plate. See Figure 9A.

NOTE:

It may be necessary to loosen the

retaining nut and clamp screw to adjust

cutting attachment shield mounting plate.

T222

Cutting

Attachment

Shield

Nuts

Shim

Line Cutter

Figure 9B

Hex

Screws

CAUTION!

Make sure the clamp screw and

retaining nut are securely tightened

before tightening the four socket-head

cap screws.

Tighten the four socket-head cap screws

3.

to secure the cutting attachment shield.

Re-tighten clamp screw and retaining nut.

4.

F222

Outer Tube

Cap

Locating Hole

Screws

Figure 9C

Cutting

Attachment

Shield

Install the Cutting Attachment

Shield F222.

Install the shield and clamp as shown in

1.

figure 9B.

Align the hole in the outer tube with the

2.

locator on the cap; install the two (2)

screws finger tight.

Tighten the screws alternately to secure

3.

the cutting attachment shield in place.

Fit the two shims and the bracket over

2.

the outer tube and loosely install the

four socket-head screws. See Figure 9A.

Assembly

Trimmer Head

Install the Trimmer Head.

1.

Turn the trimmer over so that the gear

2.

case output shaft faces UP.

Remove and discard the black plastic

3.

protective cap from the output shaft. See

Figure 10.

Rotate the holder until the hole in the

4.

holder aligns with the notch on the

gear case. Use the long end of the hex

wrench to lock the holder and output

shaft. See Figure 10.

Remove the hex wrench.

5.

Retaining

Plug

Holder

Output

shaft

Figure 10

Adjust the trimmer line length to reach

6.

no further than the line cutter on the

cutting attachment shield. Trim to the

correct length if necessary.

The unit should now be

completely assembled and ready

for use with a trimmer head.

WARNING!

NEVER operate this unit without

the cutting attachment shield installed

and tightly secured!

Hex Wrench

WARNING!

A standard grass trimmer

with a loop handle should NEVER be

operated with blade-type attachments.

7

Page 8

XST013

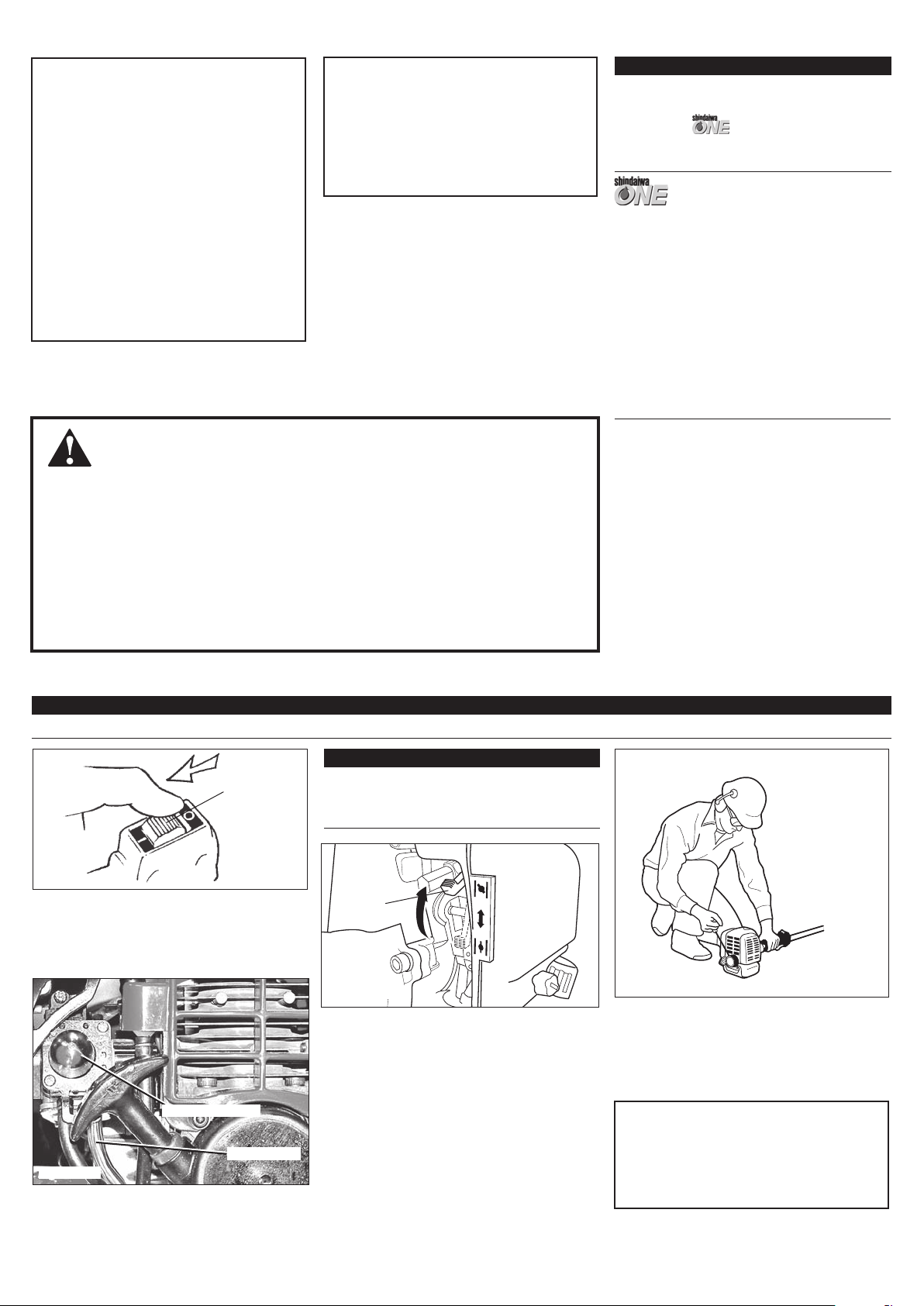

Mixing Fuel

CAUTION!

Some types of gasoline contain alcohol

as an oxygenate. Oxygenated gasoline may cause increased operating

temperatures. Under certain conditions, alcohol-based gasoline may also

reduce the lubricating qualities of some

2-cycle mixing oils. Never use any type

of gasoline containing more than 10%

alcohol by volume! Generic oils and

some outboard oils may not be intended

for use in high-performance air cooled

2-cycle engines, and should never

be used in your Shindaiwa engine.

Filling the Fuel Tank

WARNING!

Minimize the risk of re!

■

STOP engine before refueling.

■

ALWAYS allow the engine to cool

■

before refueling!

Wipe all spilled fuel and move the engine

■

at least 10 feet (3 meters) from the fueling

point and source before restarting!

NEVER start or operate this unit if

■

there is a fuel leak.

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FC

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

Use only fresh, clean unleaded gasoline

■

with a pump octane of 87 or higher.

■

Mix all fuel with a 2-cycle air-cooled

mixing oil that meets or exceeds ISO-LEGD and/or JASO FC classified oils at

50:1 gasoline/oil ratio.

Examples of 50:1 mixing quantities

1 gallon of gasoline to 2.6 oz. mixing oil

■

5 liters of gasoline to 100 ml. mixing oil

■

NEVER start or operate this unit if the

■

carburetor, fuel lines, fuel tank and/or

fuel tank cap are damaged.

NEVER smoke or light any res near

■

the engine or fuel source!

NEVER place any ammable material

■

near the engine mufer!

NEVER operate the engine without

■

the mufer and spark arrester in good

working condition.

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than

30 days and oil with fuel stabilizer is

not used, it should first be treated with a

fuel stabilizer such as STA-BIL™.

Oil is a registered JASO FC

classified oil and also meets or exceeds

ISO-L-EGD performance requirements.

Shindaiwa One is recommended for use

in all Shindaiwa low emissions engines.

Shindaiwa One also includes a fuel

stabilizer.

Place the trimmer on a flat, level surface.

1.

Clear any dirt or other debris from

2.

around the fuel filler cap.

Remove the fuel cap, and fill the tank

3.

with clean, fresh fuel.

Reinstall the fuel filler cap and tighten

4.

firmly.

Starting the Engine

IMPORTANT!!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, “I” for ON or START and “O” for OFF or STOP.

IMPORTANT!

Ignition Switch

Figure 11

Slide the ignition switch to the “I” posi-

1.

tion. See Figure 11.

Press the primer bulb until fuel can be seen

2.

flowing in the transparent return tube.

Primer Bulb

Return tube

Figure 12

The primer system only pushes fuel through

the carburetor. Repeatedly pressing the

primer bulb will not flood the engine with fuel.

Closed

Figure 13

Set the choke lever to the CLOSED

3.

position if engine is cold.

Make sure

the cutting

attachment

is clear of

obstructions!

Figure 14

While holding the outer tube firmly

4.

with left hand, use your other hand to

slowly pull the recoil starter handle until

resistance is felt, then pull quickly to

start the engine.

CAUTION!

Do not pull the recoil starter to the end

of the rope travel. Pulling the recoil

starter to the end of the rope travel

can damage the starter.

8

Page 9

Starting the Engine (continued)

WARNING!

The cutting attachment may

rotate when the engine is started!

When the engine starts, slowly move the

5.

choke lever to the “OPEN” position. See

Figure 15.

initial start, close the choke and restart.)

Figure 15

(If the engine stops after the

Open

WARNING!

Never start the engine from the

operating position.

IMPORTANT!

If the engine fails to start after several attempts

with the choke in the closed position, the

engine may be flooded with fuel. If flooding is

suspected, move the choke lever to the open

position and repeatedly pull the recoil starter

to remove excess fuel and start the engine.

If the engine still fails to start, refer to the

troubleshooting section of this manual.

When the Engine Starts...

After the engine starts, allow the engine

■

to warm up at idle 2 or 3 minutes before

operating the unit.

Advancing the throttle makes the

■

cutting attachment turn faster; releasing

the throttle permits the attachment to

stop turning. If the cutting attachment

continues to rotate when the engine

returns to idle, carburetor idle speed

should be adjusted (see “Adjusting

Engine Idle” below).

Stopping the Engine

Figure 16

Adjusting Engine Idle

Idle Adjusting

Figure 17

Screw

Idle the engine briefly before stopping

(about 2 minutes), then slide the ignition

switch to the “O” (Engine OFF) position.

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment.

Idle Speed Adjustment

WARNING!

The cutting attachment

must NEVER rotate at engine

idle! If the idle speed cannot be

adjusted by the procedure described

here, return the trimmer to your

Shindaiwa dealer for inspection.

Place the trimmer on the ground, then

1.

start the engine, and then allow it to idle

2-3 minutes until warm.

If the attachment rotates when the

2.

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise. See Figure 17.

If a tachometer is available, the engine idle

3.

speed should be final adjusted to 3,000

(±250) rpm (min

Carburetor fuel mixture adjustments are

4.

preset at factory and cannot be serviced

in the field.

-1

).

9

Page 10

Checking Unit Condition

NEVER operate the unit with the cutting

attachment shield or other protective

devices removed!

WARNING!

A cutting attachment shield

or other protective device is no

guarantee of protection against

ricochet. YOU MUST ALWAYS

GUARD AGAINST FLYING DEBRIS!

Use only authorized Shindaiwa parts and

accessories with your Shindaiwa trimmer. Do

not make modifications to this unit without

written approval from Shindaiwa, Inc.

Cutting Grass

Your Shindaiwa T222/F222 grass trimmer

is equipped with a semi-automatic nylon

trimmer head.

Engine Operating Speeds

Operate the unit at full throttle while

cutting grass.

ALWAYS make sure the cutting

attachment is properly installed and firmly

tightened before operation.

NEVER use a cracked or warped cutting

attachment: replace it with a serviceable one.

ALWAYS make sure the cutting

attachment fits properly into the

appropriate attachment holder. If a properly

installed attachment vibrates, replace the

attachment with new one and re-check.

ALWAYS stop the engine immediately and

check for damage if you strike a foreign

object or if the unit becomes tangled.

Do not operate with broken or damaged

equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could

damage the engine.

NEVER operate a unit with worn or

damaged fasteners or attachment holders.

CAUTION!

Do not push the rotating line into trees,

wire fences or any material that could

tangle or break the nylon lines.

CAUTION!

Operation of trimmer without a cutting

attachment shield and using excessive

line length can lead to premature clutch

failure.

CAUTION!

Operation at low rpm can lead to

premature clutch failure.

Figure 18

T222

Trimming and Mowing Grass

Hold the grass trimmer as shown in Figure

18. The trimmer head should

slightly into the area to be cut.

be angled

To ensure

maximum trimmer-line service life, cut only

with the tip of the trimmer line. Sweep the

trimmer head left to right (T222),

and right

to left (F222) to trim the grass. During

cutting operations, the trimmer head

should be kept horizontal to the ground at

all times.

Edging

Tilt the handle approximately 100 degrees

to the right (from horizontal) and move

forward while holding the trimmer

vertical. See Figure 20.

Figure 19

F222

10

Figure 20

Page 11

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT

OR REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY

BE PERFORMED BY ANY REPAIR

ESTABLISHMENT OR INDIVIDUAL;

HOWEVER, WARRANTY REPAIRS

MUST BE PERFORMED BY A DEALER

OR SERVICE CENTER AUTHORIZED

BY SHINDAIWA CORPORATION.

THE USE OF PARTS THAT ARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF

THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

maintenance, repair or cleaning work on

the unit, make sure the engine and cutting

attachment are completely stopped.

Disconnect the spark plug wire before

performing service or maintenance work.

operate properly with your unit and may

cause damage and lead to personal injury.

Daily Maintenance

Prior to each work day, perform the following:

Remove dirt or debris from the engine,

■

check the cooling fins and air cleaner for

clogging and clean them as necessary.

Carefully remove any accumulation of

■ Check for loose or missing screws or

dirt or debris from the muffler or the

fuel tank. Dirt build-up in these areas

could cause engine overheating, induce

premature wear, or create a fire hazard.

WARNING!

Before performing any

WARNING

Non-standard parts may not

NOTE:

Using non-standard replacement parts

could invalidate your Shindaiwa warranty.

Mufer

This unit must never be operated with a

faulty or missing spark arrester or muffler.

Make sure the muffler is well secured and

in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

■

components. Make sure the cutting

attachment is securely fastened.

Check the entire unit for leaking fuel or

■

grease.

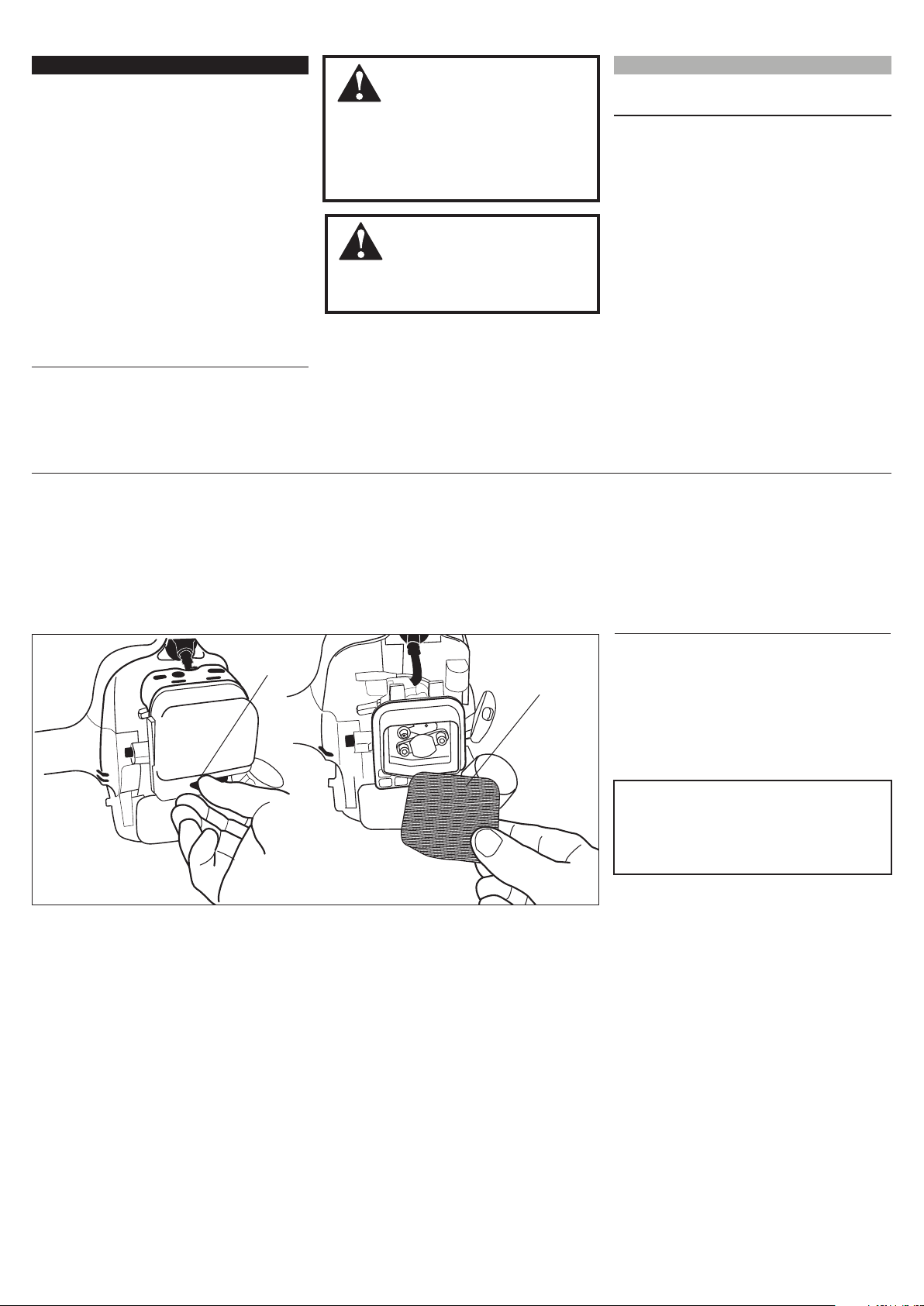

10-Hour Maintenance

Unscrew

Fastener

Figure 21

Remove and

clean or replace

the element

Every 10 hours of operation (more

frequently in dusty or dirty conditions):

Remove the air cleaner element. See

■

Figure 21. Clean or replace as necessary.

To clean element: wash it thoroughly

in soap and water. Let it dry before

reinstalling the element.

CAUTION!

Do not operate the unit if the air cleaner

or element is damaged, or if the

element is wet.

11

Page 12

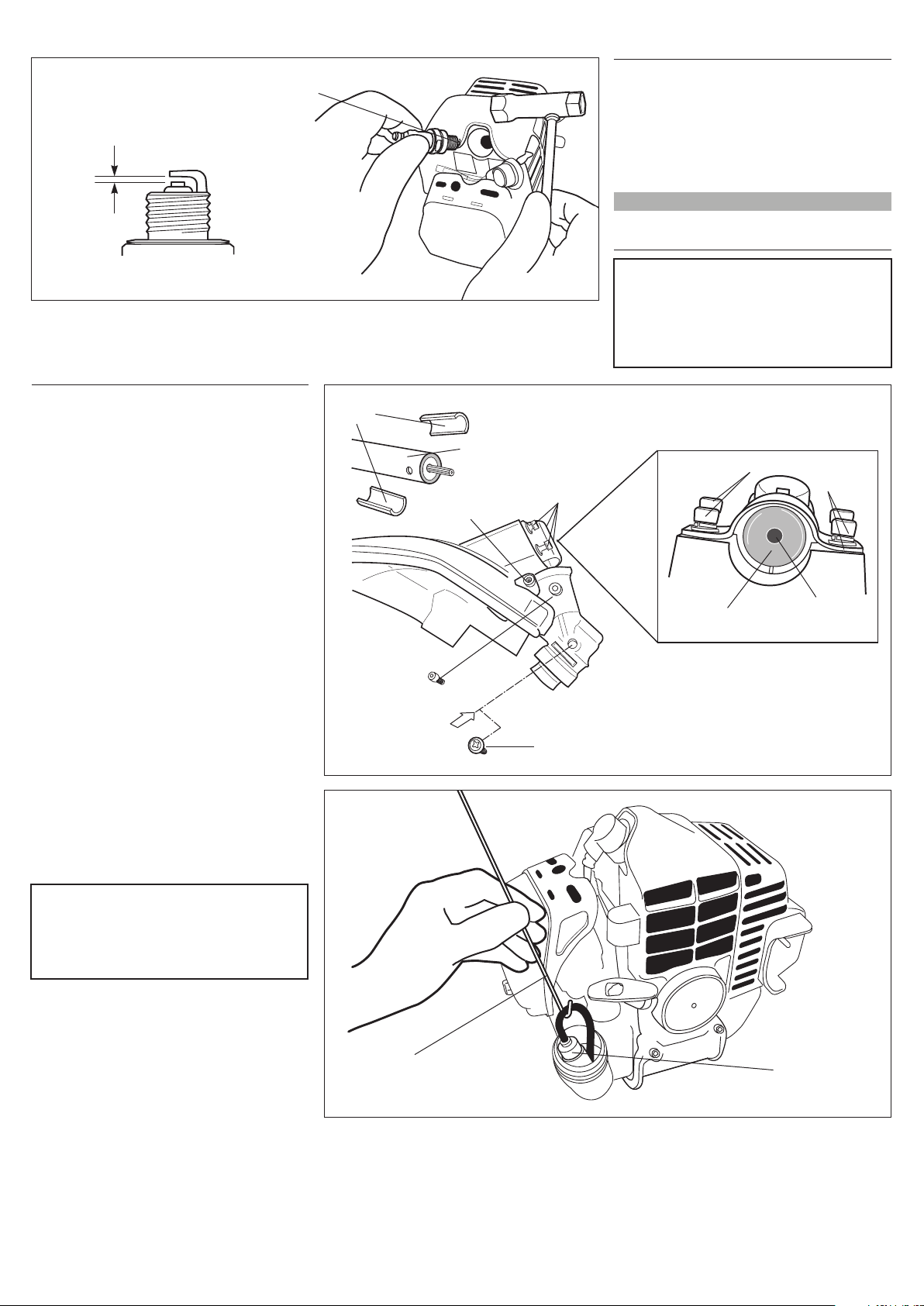

10/15-Hour Maintenance

Clean the spark

plug and check

the gap at the

0.024–0.028 inch

(0.6–0.7 mm)

electrode.

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

■

the spark plug electrode gap to 0.024-

0.028 inch (0.6-0.7 mm). If the spark plug

must be replaced, use only an BPMR6A

or equivalent resistor type spark plug of

the correct heat range. See Figure 22.

NOTE:

The BPMR6A also meets the requirements

for electro-magnetic compliance (EMC).

Figure 22

50-Hour Maintenance

Every 50 hours of operation (more

frequently in dusty or dirty conditions):

Gearcase Lubrication (T222 Only)

To perform this operation, first remove

1.

the gearcase and debris shield from the

outer tube as follows. See Figure 23.

Remove the index bolt from the

■

gearcase.

Loosen the gearcase clamp screw.

■

Loosen the four socket head cap screws

■

that secure the cutting attachment

shield.

Slide the gearcase and cutting

■

attachment shield off the tube. (Do not

lose the two shims).

Remove the filler plug and press new

2.

grease into the gearcase until old grease

is purged from the gearcase, which can

be seen in the outer tube cavity.

Clean up the excess grease and rein-

3.

stall the cutting attachment shield, two

shims and the gearcase.

Remove and replace the lter

element.

Shims

Figure 23

Clamp Screw

Index Bolt

New Grease

Outer Tube

4 Socket Head

Screws

Grease Plug

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine’s internal parts.

4 Socket Head Screws

Outer Tube

Cavity

Old Grease

CAUTION!

Make sure you do not pierce the fuel line

with the end of the hooked wire. The line

is delicate and can be damaged easily.

Use a hooked wire to extract the fuel

1.

filter from inside the fuel tank. See

Figure 24.

Before reinstalling the new filter element,

inspect the condition of all the fuel system

components (fuel pick-up line, fuel return line,

tank vent line, tank vent, fuel cap and fuel

tank). If damage, splitting or deterioration is

noted, the unit should be removed from service

until it can be inspected or repaired by a

Shindaiwa-trained service technician.

12

Figure 24

Hooked

Wire

Filter Element

Page 13

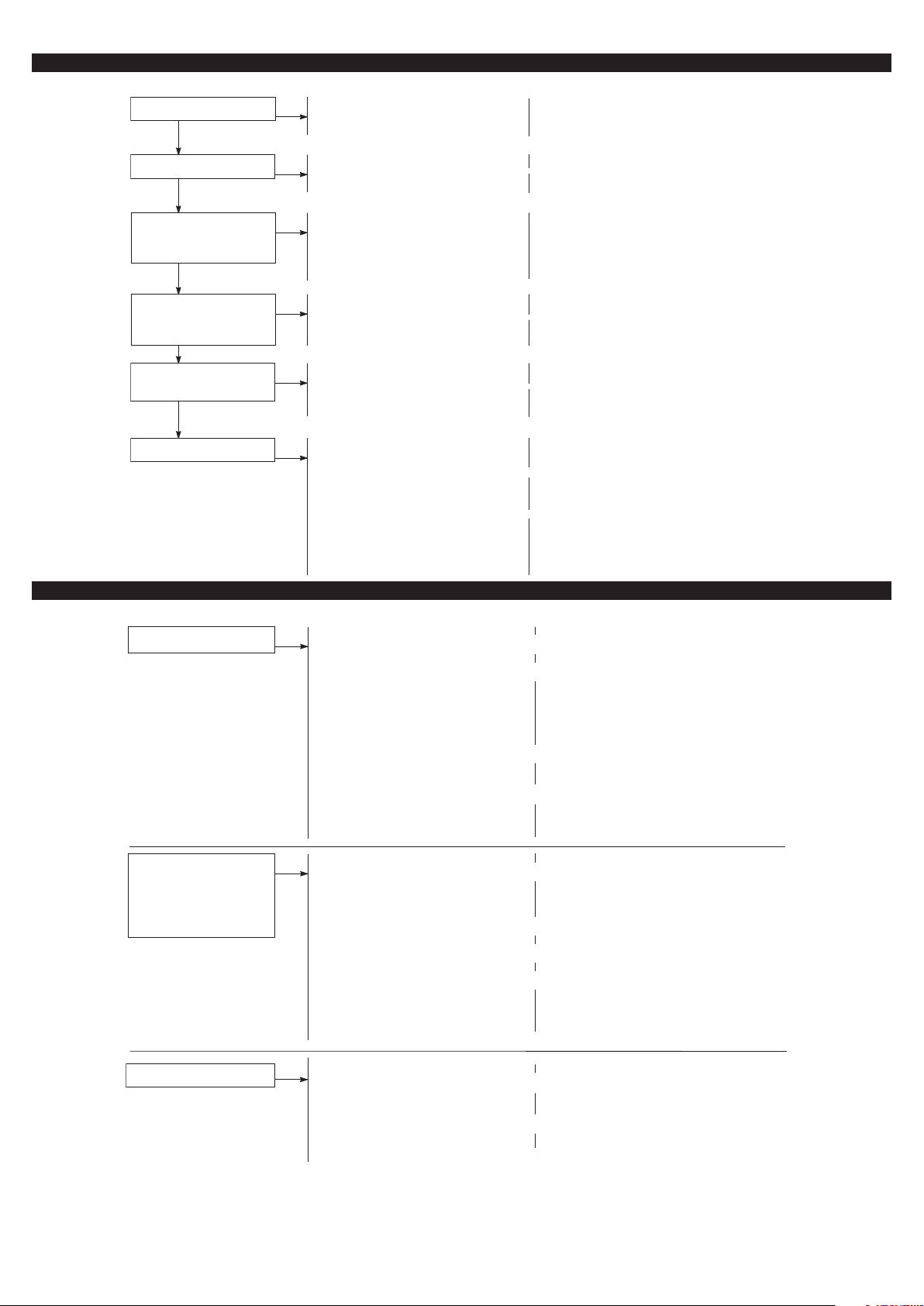

100-hour Maintenance

Every 100 hours of operation, remove

and clean the muffler.

WARNING!

Never operate this trimmer with

a damaged or missing muffler or spark

arrester! Operating with missing or damaged

exhaust components is a re hazard, and

can also damage your hearing!

Remove the spark plug boot.

1.

With a 3 mm hex wrench remove the 1

2.

muffler cover and 3 engine cover screws

and the engine cover. See Figure 25.

With a Phillips type screwdriver remove

3.

the 5 screws holding the spark arrester

screen and cover to the muffler. See

Figure 25.

Remove the screen and clean it with a

4.

stiff bristle brush.

With a 4 mm hex wrench remove the

5.

3 muffler bolts and the muffler. See

Figure 25.

Inspect the cylinder exhaust port for any

6.

carbon buildup.

Gently tap the muffler on a wood sur-

7.

face to dislodge any loose carbon.

Engine Cover

Screws

Figure 25

Engine

Cover

Mufer

Gasket

IMPORTANT!

If you note excessive carbon buildup, consult

with an authorized Shindaiwa servicing dealer.

Mufer

Cover

Mufer

Cover Screw

Mufer

Mufer

Spark Arrester

Screen

Reassemble the spark arrester, muffler

8.

Screws

Gasket

Spark Arrester

Cover

Screws

Outlet

and engine cover in the reverse order of

disassembly.

Long Term Storage

Whenever the unit will not be used for

30 days or longer, use the following

procedures to prepare it for storage:

Clean external parts thoroughly.

■

Drain all the fuel from the fuel tank.

■

IMPORTANT!

All stored fuels should be stabilized with a

fuel stabilizer such as STA-BIL™, if oil

with fuel stabilizer is not used.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard

starting and could also lead to increased

service and maintenance cost.

Remove the remaining fuel from the fuel

■

lines and carburetor.

Prime the primer bulb until no more

1.

fuel is passing through.

Start and run the engine until it stops

2.

running.

3.

Repeat steps 1 and 2 until the engine

will no longer start.

Remove the spark plug and pour about

■

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3 times

so oil will evenly coat the interior of the

engine. Reinstall the spark plug.

Before storing the unit, repair or replace

■

any worn or damaged parts.

Remove the air cleaner element from the

■

carburetor and clean it thoroughly with

soap and water. Let dry and reassemble

the element.

Store the unit in a clean, dust-free area.

1.

13

Page 14

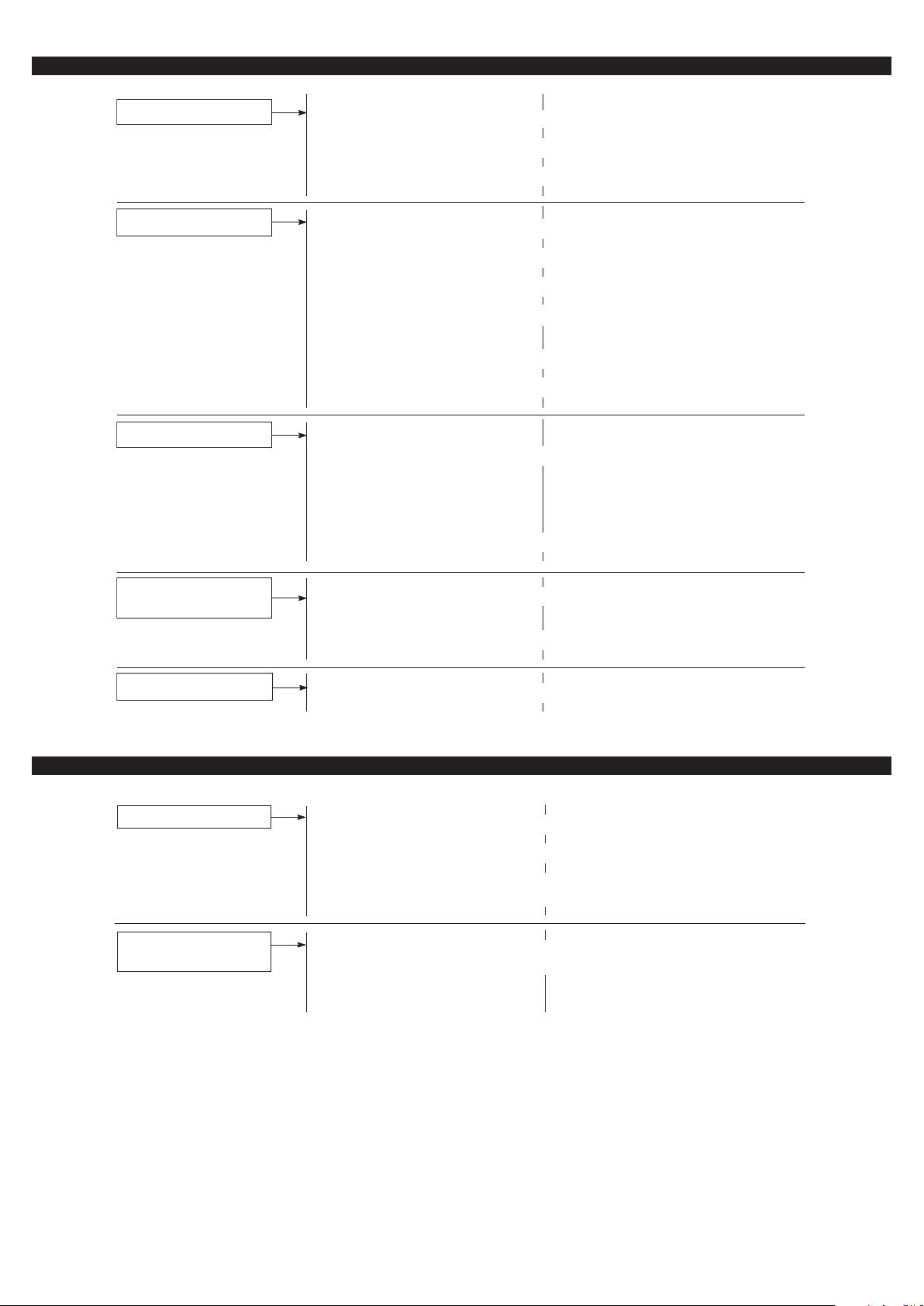

Troubleshooting Guide

Does the engine crank?

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

NO

Good compression?

Loose spark plug.

Excess wear on cylinder, piston, rings.

Tighten and re-test.

NO

YES

Does the tank contain

fresh fuel of the proper

grade?

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Fuel incorrect, stale or contaminated;

mixture incorrect.

NO

YES

Is fuel visible and moving

in the return line when

priming?

Check for clogged fuel filter and/or vent.

Priming pump not functioning properly.

Replace fuel filter or vent as required; restart.

Consult with an authorized servicing dealer.

NO

Is there spark at the spark

plug wire terminal?

The ignition switch is in “O” (OFF)

position.

Shorted ignition ground.

Faulty ignition unit.

Move switch to “I” (ON) position and restart.

NO

YES

YES

Check the spark plug.

If the plug is wet, excess fuel may be in

the cylinder.

The plug is fouled or improperly gapped.

The plug is damaged internally or of the

wrong size.

Crank the engine with the plug removed,

reinstall the plug, and restart.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Restart.

Replace the plug with an BPMR6A or

equivalent resistor type spark plug of the

correct heat range. Set spark plug electrode

gap to 0.024-0.028 inch (0.6-0.7 mm).

YES

What To Check Possible Cause Remedy

Is the engine overheating?

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty

or damaged.

Carbon deposits on the piston or in

the muffler.

Shorten trimmer line. Cut at a slower rate.

Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing dealer.

What To Check Possible Cause Remedy

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm.

Service the air cleaner element.

Tighten or replace. Replace the plug with an

BPMR6A or equivalent resistor type spark plug

of the correct heat range.

Repair or replace filter and/or fuel line.

Replace the fuel. See page 8.

Consult with an authorized servicing dealer.

Engine is knocking.

Overheating condition.

Improper fuel.

Carbon deposits in the combustion

chamber.

See above.

Check fuel octane rating; check for presence of

alcohol in the fuel (pg. 8). Refuel as necessary.

Consult with an authorized servicing dealer.

ENGINE DOES NOT START

LOW POWER OUTPUT

14

Page 15

Troubleshooting Guide (continued)

Poor acceleration.

Clogged air filter.

Clogged fuel filter.

Lean fuel/air mixture.

Idle speed set too low.

Clean the air filter.

Replace the fuel filter.

Consult with an authorized servicing dealer.

Adjust: 3,000 (±250) RPM (min-1).

Symptom Possible Cause Remedy

Engine stops abruptly.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Reset the switch and restart.

Refuel. See page 8.

Replace fuel filter.

Drain; replace with clean fuel. See page 8.

Clean and replace spark plug, tighten

the terminal.

Replace the ignition unit.

Consult with an authorized servicing dealer.

Engine difficult to shut of f.

Ground (stop) wire is disconnected or

switch is defective.

Overheating due to incorrect spark plug.

Overheated engine.

Test and replace as required.

Idle engine until cool.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Correct plug: BPMR6A

or equivalent resistor type spark plug of the

correct range.

Idle engine until cool.

Cutting attachment

rotates at engine idle.

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Set idle: 3,000 (±250) RPM (min-1).

Replace spring/shoes as required, check

idle speed.

Inspect and re-tighten holders securely.

Engine will not idle down.

Engine idle set too high.

Engine has an air leak.

Set idle: 3,000 (±250) RPM (min-1).

Consult with an authorized servicing dealer.

Symptom Possible Cause Remedy

Excessive vibration.

Warped or damaged cutting attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Trimmer line not wound properly on spool.

Inspect and replace attachment as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Rewind trimmer line.

Cutting attachment will

not rotate.

Shaft not installed in powerhead or

gearcase.

Broken shaft.

Damaged gearcase.

Inspect and reinstall as required.

Consult with an authorized servicing dealer.

ADDITIONAL PROBLEMS

ADDITIONAL PROBLEMS

15

Page 16

The following statement only applies to United States and its territories

Shindaiwa Corporation

Federal Emission Design And Defect Limited Warranty

Utility And Lawn And Garden Engines

Shindaiwa Corporation warrants to the initial purchaser and each

subsequent owner, that this utility equipment engine (herein

engine) is designed, built and equipped to conform at the time of

initial sale, to all applicable regulations of the U.S. Environmental

Protection Agency (EPA), and that the engine is free of defects in

materials and workmanship that would cause this engine to fail

to conform with EPA regulations during its warranty period. This

emission warranty is applicable in all States, except the State of

California.

For parts listed under PAR TS COVERED, the dealer authorized by

Shindaiwa Corporation will, at no cost to you, make the necessary

diagnosis, repair, or replacement of any defective emission-related

component to ensure that the engine complies with applicable U.S.

EPA regulations.

MANUFACTURERS WARRANTY COVERAGE

When sold within the U.S., this engine’s emission control system is

warranted for a period of two (2) years from the date this product is first

delivered to the original retail purchaser.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of

the required maintenance listed in your owner’s manual. Shindaiwa

Corporation recommends that you retain all receipts covering

maintenance on your engine, but Shindaiwa Corporation cannot deny a

warranty claim solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the engine owner, you should however be aware that Shindaiwa

Corporation may deny your warranty coverage if your engine or a part

has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your engine to the nearest dealer

authorized by Shindaiwa Corporation when a problem exists.

If your Shindaiwa Dealer is unable to answer questions regarding your

warranty rights and responsibilities, you should then contact your

Shindaiwa Distributor.

For the name and telephone number of the Shindaiwa Distributor in your

area, please call Shindaiwa Inc. at (503) 692-3070 between the hours of

8:00 AM and 5:00 PM Pacific Standard Time.

PARTS COVERED

Listed below are the parts covered by the Federal Emission Design

and Defect Warranty. Some parts listed below may require scheduled

maintenance and are warranted up to the first scheduled replacement of

that part. The warranted parts include:

Carburetor Internal Components

1.

Valve Assembly-throttle, Jet, Metering Diaphragm

■

Ignition System Components

2.

Ignition Coil

■

Flywheel Rotor

■

The emission control system for your particular Shindaiwa engine may

also include certain related hoses and connectors.

LIMITATIONS

The Federal Emission Design and Defect Warranty shall not cover any of

the following:

(a) conditions resulting from tampering, misuse, improper adjustment

(unless they were made by the dealer or service center authorized

by Shindaiwa Corporation during a warranty repair), alteration,

accident, failure to use the recommended fuel and oil, or not

performing required maintenance services,

(b) the replacement parts used for required maintenance services,

(c) consequential parts used for required maintenance services,

(d) diagnosis and inspection fees that do not result in eligible warranty

service being performed, and

(e) any non-authorized replacement part, or malfunction of authorized

parts due to use of non-authorized parts.

MAINTENANCE AND REPAIR REQUIREMENTS

You are responsible for the proper use and maintenance of the engine.

You should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise.

These receipts and maintenance records should be transferred to each

subsequent owner of the engine. Shindaiwa Corporation reserves the

right to deny warranty coverage if the owner has not properly maintained

the engine. Shindaiwa Corporation will not deny warranty repairs,

however, solely because of the lack of repair, maintenance or failure to

keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY

REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY

REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA CORPORATION THE USE OF PARTS

THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY

TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE

EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by Shindaiwa Corporation are used

for maintenance replacements or for the repair of components affecting

emission control, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to the parts authorized

by Shindaiwa Corporation in their performance and durability.

OBTAINING WARRANTY SERVICE

All repairs qualifying under this limited warranty must be performed by a

dealer authorized by Shindaiwa Corporation

If any emission-related part is found defective during the warranty period,

it is your responsibility to present the product to an authorized Shindaiwa

dealer. Bring your sales receipts showing the date of purchase for this

engine. The dealer authorized by Shindaiwa Corporation will perform

the necessary repairs or adjustments within a reasonable amount of time

and furnish you with a copy of the repair order. All parts and accessories

replaced under this warranty become the property of Shindaiwa

Corporation

To locate an authorized Shindaiwa dealer near you, contact your

Shindaiwa Distributor. For the name and telephone number of the

Shindaiwa Distributor in your area, please call Shindaiwa Inc. at (503) 692-

3070 between the hours of 8:00 AM and 5:00 PM Pacific Standard Time.

THIS WARRANTY IS ADMINISTERED BY

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin OR. 97062

(503) 692-3070

Shindaiwa Inc.

11975 SW Herman Rd.

Tualatin, Oregon 97062 U.S.A.

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

Shindaiwa Corporation

6-2-11, Ozuka-Nishi,

Asaminami-Ku, Hiroshima

731-3167, Japan

Telephone: 81-82-849-2220

Fax: 81-82-849-2481

© 2007 Shindaiwa Inc.

Part Number 81372

Revision 3/07

Shindaiwa is a registered trademark of Shindaiwa, Inc.

Specifications subject to change without notice.

Page 17

MANUAL DEL PROPIETARIO/OPERADOR SHINDAIWA

PODADORA T222

PODADORA F222

T222

F222

¡ADVERTENCIA!

Disminuya el riesgo de sufrir lesiones

o causar lesiones a otros! Lea este manual

y familiarícese con su contenido. Siempre

use protección para los ojos y oídos cuando

opere esta máquina.

Número de producto 81372 Rev. 3/07

Page 18

50FEET

(15m)

Introducción

La podadora Shindaiwa Serie 222 ha

sido diseñada y construida para suministrar

un rendimiento superior sin comprometer

calidad, comodidad, seguridad ni

durabilidad.

Los motores Shindaiwa representan

la tecnología líder en motores de alto

rendimiento, de poco peso y pequeña

Español

cilindrada con excepcional alta potencia.

Como propietario/operario, usted no

tardará en comprobar que ¡Shindaiwa es la

única máquina en esta clase!

¡IMPORTANTE!

La información contenida en este manual

describe unidades disponibles a la fecha de

su publicación.

Shindaiwa Inc. se reserva el derecho

de realizar cambios a sus productos sin

previo aviso, y sin la obligación de hacer

modificaciones a máquinas fabricadas

previamente.

CONTENIDO

Instrucciones de Seguridad ......................3

El Operario Debidamente Equipado ........3

PÁGINA

Declaraciones de Seguridad

A través de este manual se encuentran

“declaraciones de seguridad” especiales.

¡ADVERTENCIA!

Toda información precedida por

un símbolo triangular de advertencia y

la palabra ¡ADVERTENCIA! contiene

información o procedimientos que se

deben cumplir para evitar serias lesiones

corporal.

¡PRECAUCiÓN!

Toda información precedida por la

palabra ¡PRECAUCIÓN! contiene

información que se debe cumplir para

evitar daños mecánicos.

¡IMPORTANTE!

Toda información precedida por la palabra

“IMPORTANTE!” contiene información

especial y significante.

NOTA:

Toda información precedida por la palabra

“NOTA” contiene información útil que

puede hacer su trabajo más fácil.

El propósito de los procedimientos

operacionales descritos en este manual es

ayudarle a obtener el más alto rendimiento

de su máquina y proteger a usted y a

otras personas de sufrir lesiones. Estos

procedimientos son pautas operativas para

una operación segura bajo la mayoría de

condiciones y no tienen el propósito de

substituir las normas y/o leyes vigentes

en su área. Si tiene alguna pregunta

relacionada con su Serie 222 o si no

entiende alguna información contenida

en este manual, consulte a su distribuidor

Shindaiwa, quien le atenderá con

gusto. También puede comunicarse con

Shindaiwa Inc. a la dirección que aparece

en la contra portada de este manual.

Lea y siga las recomendaciones

de este manual del operario.

De no hacerlo podría resultar

en lesiones graves.

Use protección para los ojos

y protección para los oídos

en todo momento que este

operando esta máquina.

Mantenga a los transeúntes

50 pies

a una distancia mínima de 15

metros (50 pies) mientras la

máquina esté en operación

Manténgase alerta por

objetos lanzados o rebotes.

No opere esta unidad con

una cuchilla.

¡IMPORTANTE!

Esté Alerta del Area de Trabajo ...............4

Etiquetas de Seguridad .............................4

Ensamblaje y Ajustes .................................6

Ensamblaje..................................................7

Cabezal de Corte ........................................ 7

Mezcla de Combustible .............................8

Llenando el Tanque de Combustible .......8

Arranque del Motor ...................................8

Parada del Motor ........................................9

Ajuste de Marcha Mínima del Motor ....... 9

Mantenimiento .........................................11

Almacenamiento de Largo Plazo ............13

Guía Diagnostico ......................................14

Garantía del sistema de emisiones .........16

SP_2

Page 19

Instrucciones de Seguridad

Trabaje con cuidado

Podadoras Shindaiwa operan a velocidades

altas y pueden causar daños o lesiones

serias si son mal usadas o abusadas. Nunca

permita que una persona sin entrenamiento

o instrucción opere esta unidad!

¡ADVERTENCIA!

Nunca instale accesorios no

autorizados. No use accesorios no

aprobados por Shindaiwa en esta

unidad.

Mantengase alerta

Usted debe estar en optimas condiciones

física y mental para operar esta maquina en

forma segura.

¡ADVERTENCIA!

Nunca opere ninguna

máquinaria motorizada si

está cansado o si está bajo

la inuencia de alcohol, drogas o

medicamentos o cualquier otra substancia

que pueda afectar su abilidad y juicio.

¡ADVERTENCIA!

Las emisiones emitidas por el

tubo de escape de este producto contienen

substancias químicas que en el estado de

California son consideradas como causantes

de cáncer, defectos congénitos u otros

efectos nocivos a la reproducción humana.

¡ADVERTENCIA!

Disminuya El Riesgo de Incendios

NUNCA fume ni encienda fuegos cerca

del motor.

SIEMPRE pare el motor y permita que se

enfrie antes de volver a llenar el tanque.

Evite sobre llenar el tanque y limpie

cualquier derrame de combustible.

SIEMPRE: Inspeccione la máquina por

pérdidas de combustible, antes de cada

uso. Durante cada llenado, verique

posibles pérdidas alrededor de la tapa

o tanque de combustible. Si existen

¡ADVERTENCIA!

Use Buen Juicio

SIEMPRE use protección para los ojos

como escudo contra objetos lanzados.

NUNCA opere el motor cuando

transporte la unidad.

NUNCA opere la unidad en el interior!

Cerciorese que siempre haya buena

ventilación. El humo o gases del

escape del motor pueden causar

serias lesiones o la muerte.

SIEMPRE mantenga su area de trabajo

libre de basura u objetos que pueden

rebotar contra usted o contra transeúntes.

SIEMPRE use el accesorio de corte

apropiado.

SIEMPRE pare el motor inmediatamente

si repentinamente empieza a vibrar.

Inspeccione el accesorio de corte por

pérdidas de combustible evidentes, pare

inmediatamente el motor. Pérdidas de

combustible deben de ser reparadas

antes de cada uso.

SIEMPRE aleje la máquina del área

de combustible o de otros materiales

inamables antes de arrancar el motor.

NUNCA coloque materiales inamables

cerca del silenciador de la máquina.

NUNCA opere el motor sin la malla del

guardachispas en su lugar.

partes quebradas, faltantes o instaladas

incorrectamente.

NUNCA extienda el cable de nylon más

allá de lo especicado para su máquina.

SIEMPRE mantenga la máquina lo

más limpia posible. Mantengala libre

de vegetación, barro, etc.

SIEMPRE sujete la máquina rmemente

con ambas manos cuando corte o recorte,

y mantenga el control en todo momento.

SIEMPRE mantenga los mangos

limpios.

SIEMPRE desconente el cable de bujía

antes de hacer mantenimiento a la

máquina.

SIEMPRE si el disco/cuchilla se

enreda en un corte, apague el motor

inmediatamente. Saque la rama o

árbol para liberar el disco/cuchilla.

Español

El Operario Debidamente Equipado

Use ropa de su talla para protejer su piernas y brazos. Los

guantes siempre proveen protección adicional y son altamente

recomendados. No use ropa holgada o joyas que puedan

atascarse en la máquina o en la vegetación. Amárrese el

cabello largo de tal forma que esté sobre el nivel de los

hombros. NUNCA use

pantalones cortos.

Mantenga una posición

segura y nunca extienda el

cuerpo- mantenga su balance

en todo momento durante el

uso de la máquina.

Use calzado apropiado (botas o zapatos

antideslizantes): no use zapatos con los

dedos descubiertos o sandalias. NUNCA

opere la máquina descalzo!

Figura 1

Use un protector auditivo y un

casco o sombrero.

Siempre use protección para los ojos tal como lentes

de seguridad para protegerse de objetos lanzados.

Siempre opere con ambas manos

sujetando el mango rmemente.

Mantengase alejado de la línea de corte o

disco en rotación en todo momento, y nunca

levante un accesorio en rotación más arriba

de su cintura.

Siempre cerciórese de que el protector del

accesorio de corte esté instalado correctamente

y que esté en buena condición.

SP_3

Page 20

READTHE

OPERATOR’SMANUAL

WEARHEARINGANDANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST50 FEET(15m)

BEWAREOFTHROWNOR

RICOCHETEDOBJECTS

DONOTOPERATETHIS

MACHINEWITHA BLADE

50FEET

(15m)

19422-00028ShindaiwaInc.

READTHE

OPERATOR’SMANUAL

WEARHEARINGANDANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST 50 FEET(15m)

BEWAREOFTHROWNOR

RICOCHETEDOBJECTS

DONOTOPERATETHIS

MACHINEWITHABLADE

50FEET

(15m

)

19422-00028ShindaiwaInc.

READTHE

OPERATOR’SMANUAL

WEARHEARINGANDANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST 50 FEET(15m)

BEWAREOFTHROWNOR

RICOCHETEDOBJECTS

DONOTOPERATETHIS

MACHINEWITHABLADE

50FEET

(15m

)

19422-00028ShindaiwaInc.

Esté Alerta En Su Área De Trabajo

Evite trabajar durante

largo tiempo bajo

temperaturas muy

calientes o muy frías.

Español

Tenga mucho

cuidado al

trabajar sobre

terrenos

resbalosos,

especialmente

en tiempo de

lluvia.

Si hace contacto con un objeto sólido,

detenga el motor e inspeccione el

accesorio de corte en busca de daños.

Mantengase en constante alereta sobre

los objetos o despojos que puedan ser

lanzados o rebotados por el accesorio de

corte.

Cerciórese de que los transeúntes

u observadores estén fuera de

la “zona de peligro” de 50 pies y

usen protección de ojos.

50

pies

Reduzca el riesgo de que

algún transeúnte sea golpeado

por un objeto volante.

Asegurese de que nadie esté

dentro de 50 pies (15 metros)

de distancia de un accesorio

en operación. Esto es

aproximadamente 16 pasos.

Siempre cerciórese

de que el protector

del accesorio de corte

esté correctamente

instalado.

Cuando trabaje en un terreno rocoso o cerca de cables

o cercas eléctricas, use extremo cuidado y evite tocarlos

con el accesorio de corte.

Figura 2

Etiquetas de Seguridad

Información de Operación: Asegurese que toda las etiquetas estén libres de daños y legibles.

Reemplace inmediatamente etiquetas dañadas o faltantes. Etiquetas nuevas están disponibles

en su centro de servicio local autorizado de Shindaiwa.

¡IMPORTANTE!

Esta etiqueta indica la distancia

mínima entre el mango delantero y

el mango trasero de acuerdo a la

norma ANSI B175.3

T222

F222

Figura 3

SP_4

Page 21

Descripción del Producto

Use las ilustraciones como guía,

familiarícese con esta unidad y sus varios

componentes. Consulte la figura 4.

Conociendo la unidad le ayudará a obtener

alto rendimiento, vida útil más prolongada

y operación con seguridad.

¡ADVERTENCIA!

No haga modicaciones o

alteraciones no autorizadas a

ninguna de éstas máquinas ni a sus

componentes.

Caja de

Engranajes

Tubo Exterior

Protector del

Accesorio de Corte

Interruptor de

Encendido

Mango

Agarrador

Gatillo del

Acelerador

T222

Tanque de

Combustible

Español

F222

¡IMPORTANTE!

Los términos “izquierda”, “mano izquierda”,

y “LH”; “derecha”, “mano derecha”, y “RH”,

“delantera” y “trasera”, indican direcciones

Cabezal

desde el punto de vista del operador

durante la operación normal de este

producto.

Caja del

exible

Figura 4

Especicaciones

T222 Peso sin Combustible

(sin accesorios para cortar) ................................10.8 libras/4.9 kg

F222 Peso sin Combustible

(sin accesorios para cortar) ................................10.8 libras/4.9 kg

Modelo de Motor .................................................................... S222E

Tipo de Motor ...............................................Catalizador de 2 ciclos

Diámetro x Carrera ...........................1.3 x 1.1 in./33 mm x 28 mm

Cilindrada .................................................1.5 pulg. Cúbicas/23.9 cc

Potencia Máxima ..........................................................1 HP/0.8 kW

@8000 rpm (min

Combustible/Aceite ...........................50:1 con ISO-L-EGD o JASO

FC aceite de mezcla de motor 2 tiempos

Tipo de Carburador .....................................TK TZ, tipo diafragma

Capacidad del Tanque de Combustible ...............21 onzas/620 ml

Especificaciones sujetas a cambios sin previo aviso.

Interruptor de

Encendido

Mango

Tubo Exterior

Protector del

Accesorio de Corte

Cabezal

Agarrador

Combustible

Gatillo del

Acelerador

Sistema de Encendido ................................ El un-pieza electrónica

el programa controlada

Bujía ..................................................................................... BPMR6A

Filtro de Aire ...................................Filtro de esponja no reversible

Metodo de Arranque ............................................................Recular

Metodo de Parada ........................................................... Interruptor

Tipo de Transmisión ................ Automática, embrague centrífugo

con engranajes helicoidales

Periodo de Cumplimiento con Regulaciones

-1

de Emisiones EPA* ........................................................Categoria B

)

** El cumplimiento de emisiones EPA referido en la etiqueta en el

motor, indica el número de horas de operación por la cual el motor

ha demostrado cumplir con los requisitos federales de emisiones.

Categoria C = 50 horas

(Moderado), B= 125 horas (Intermedio) y

A = 300 horas (Extendido).

* Cumple o excede estas especificaciones y es

recomendada para todo los productos de Shindaiwa.

Tanque de

Esta unidad viene completamente

ensamblada con la excepcion del accesorio

de corte y el protector del accesorio de corte.

Antes de Ensamblar

Antes de ensamblar, cerciórese de que

tenga todos los componentes necesarios

para armar una máquina completa e

inspeccione la unidad y componentes en

busca de danos.

Ensamblaje del motor y eje.

■

Protector del accesorio de corte.

■

Accesorio de corte.

■

Este paquete contiene el soporte y

■

utensilios de metal para montar el

protector del accesorio de corte, este

manual del propietario/operador

y juego de herramientas para

mantenimiento rutinario. Los paquetes

de herramientas varían por modelo

y pueden incluir una llave bujía y

destornillador, y un raspador.

SP_5

Page 22

22010A

Ensamblaje y Ajustes

Ajuste la holgura del acelerador

La holgura del gatillo debe ser aproximadamente de 3/16-1/4 pulgadas (4.6 mm).

Consulte la figura 6. Cerciórese que el

gatillo de aceleración opere suavemente sin

trabarse. Si es necesario ajustar la holgura,

siga los procedimientos e ilustraciones a

continuación.

Español

3/16-1/4

pulgadas (4.6

mm) Holgura

del acelerador

Figura 5

Mango

“POSICIONE EL MANGO HACIA ADELANTE”

Mango

T222

Figura 8A

Tornillos de

cabeza allen

Etiqueta de posicion del mango

Tubo

Exterior

Figura 6

Afloje el botón de la tapa del filtro de

1.

aire y retire la tapa del filtro de aire.

Consulte la figura 6.

Afloje la tuerca de seguridad en el cable

2.

ajustador. Consulte la figura 7.

F222

Mango

Tornillos de

cabeza allen

Figura 8B

Tubo

Exterior

Gire el cable ajustador hacia dentro o

3.

fuera como sea requerido para obtener

la holgura apropiada 3/16-1/4 pulgadas

(4.6 mm). Consulte la figura 7.

Apriete las tuercas de seguridad.

4.

Cable

ajustador

Tuerca de

seguridad

Figura 7

Reinstale la tapa del filtro de aire.5.

La fabrica instala el mango en el tubo

1.

exterior y es posicionado verticalmente.

Consulte la figura 8A.

Afloje los cuatro tornillos de cabeza

2.

hueca y rote el mango 90 grados.

Consulte la figura 8B.

Posicione el mango hacia adelante a la

3.

posición más cómoda para el operador

(usualmente a 10 pulgadas más allá de la

caja del acelerador).

Asegure el mango ajustando

4.

alternadamente los cuatro tornillos de

cabeza allen en forma diagonal o cruzada.

SP_6

Page 23

26013

Ensamblaje y Ajustes

Protector del accesorio de corte

Tornillo de

cabeza

hexagonal

Soporte

Tubo

Exterior

Espaciador

T222

Protector del

accesorio

de corte

F222

Tubo

Exterior

Espaciador

Tornillo de la

abrazadera

Placa de

Retén

Figura 9

montaje del

accesorio de

corte

Instale el protector del accesorio

de corte T222

Inserte el protector del accesorio de

1.

corte entre el tubo exterior y la placa de

montaje. Consulte la figura 9.

NOTA:

Pueda que sea necesario aojar el retén y

el tornillo sujetador para ajustar la placa de

montaje del protector del accesorio de corte.

Coloque los dos espaciadores y el

2.

soporte sobre el tubo exterior e instale

sin ajustar los cuatro tornillos de cabeza

allen y apriete los cuatro tornillos.

Consulte la figura 9.

Tuercas

Cuchia de corte

Tornillos

Figura 9A

hexagonales

¡PRECAUCIÓN!

Asegurese de que el tornillo sujetador y

el retén estén debidamente apretados

antes de apretar los cuatro tornillos de

cabeza allen.

Apriete los cuatro tornillos de cabeza

3.

allen para asegurar el protector del

accesorio de corte.

Volver a apretar el tornillo de la abraza-

4.

dera al igual que la tuerca.

Soporte

Tornillos de

cabeza hexagonal

Instale el protector del accesorio

de corte F222

1.

2.

3.

Español

Protector del accesorio

de corte

Instale el protector y abrazadera como

se demuestra en la figura 9.

Alinee el agujero con el tubo externo

con el localizador en la tapa; instale los

dos (2) tornillos con la mano.

Apriete los tornillos alternativamente

para asegurar que el protector del

implemento de corte este en su lugar.

¡ADVERTENCIA!

NUNCA opere la unidad sin

el protector del accesorio de corte

instalado y asegurado rmemente.

Ensamblaje

Cabezal de Corte

Cabezal de corte

Voltee la maquina de tal forma que el eje

1.

de salida de la caja de cambios esté cara

arriba.

Retire y deseche la tapa protectora de

2.

plástico negro del eje de salida. Consulte la figura 10.

Gire el soporte hasta que el hueco en

3.

el soporte se alinie con la muesca en la

caja de cambios. Use el lado largo de la

llave hexagonal para asegurar el soporte

y el eje de salida. Consulte la figura 10.

Mientras sostiene la llave hexagonal, en-

4.

rosque el cabezal de corte sobre el eje

de salida, girando en dirección contraria

a las agujas del reloj. Usando presión

manual solamente, apriete el cabezal de

recorte firmemente en el eje de salida.

Tapón

Sujetador

Eje de

salida

Figura 10

Retire la llave hexagonal.

5.

Ajuste el largo de la línea de corte para

6.

que alcance no más allá de la cuchilla

de corte en el protector. Recorte el

largo correcto si es necesario.

Llave

hexagonal

La unidad debe ahora estar

completamente ensamblada y

lista para ser usada con

un cabezal.

¡ADVERTENCIA!

Una podadora de grama normal

con mango circular NUNCA debe ser

operada con accesorios tipo cuchilla.

SP_7

Page 24

222013

Mezcla de Combustible

¡PRECAUCIÓN!

Algunas gasolinas contienen alcohol

como un oxigenante. Combustibles

oxigenados pueden aumentar la

temperatura del motor durante

su funcionamiento. Bajo ciertas

condiciones, combustible con alcohol

puede reducir la calidad lubricante de

Español

algunos aceites de mezcla. Nunca use

ningún combustible que contenga más

de 10% de alcohol por volumén!

Aceites genéricos y algunos aceitespara

motores fuera de borda puedaque

no sean para el uso en motoresde 2

tiempos, de alto rendimiento, y no deben

ser usados en su motor Shindaiwa!

¡PRECAUCIÓN!

Este motor está diseñado solamente

para funcionar con una mezcla de

50:1 de gasolina sin plomo y aceite de

mezclar para motores de 2 tiempos. ISOL-EGD o JASO FC. El uso de aceites de

mezclar no autorizados puede conducir

a excesos de depósitos de carbón.

Use solamente gasolina fresca, limpia

■

y sin plomo, con índice de octanaje de

87 o superior.

Mezcle todo el combustible con aceite

■

de mezclar para motores de 2 tiempos

enfriados por aire que cumpla o exceda

aceites clasificados ISO-L-EDG y/o JASO

FC a proporción de 50:1 gasolina/aceite.

Llenando el Tanque de Combustible

¡ADVERTENCIA!

Disminuya el riesgo de

incendios!

Pare el motor antes de volver a llenar el

■

tanque.

Siempre deje enfriar el motor antes de

■

volver a llenar el tanque!

Limpie todo derrame de combustible y

■

aleje el motor por lo menos 10 pies (3

metros) del depósito de combustible

antes de volver a prender el motor!

Nunca comienze u opere esta máquina

■

si existe una périda de combustible.

Nunca encienda u opere esta máquina si

■

el carburador, líneas de combustible y/o

tapa de tanque o tanque de combustible

se encuentran dañados.

Nunca fume o encienda fuegos cerca

■

del motor o del combustible!

Nunca coloque material inamable

■

cerca del silenciador del motor!

Nunca opere el motor sin antes

■

comprobar que el silenciador y el

guardachispas estén funcionando

adecuadamente.

Ejemplos de cantidades de

mezcla a proporción de 50:1

1 galón de gasolina por 2.6 onzas de

■

aceite de mezclar.

5 litros de gasolina por 100 ml de aceite

■

de mezclar.

¡IMPORTANTE!

Mezcle solamente el combustible necesario para

uso inmediato! De ser necesario almacenar el

combustible por más de 30 días, y si no se está

usando aceite con estabilizador de

combustible, entonces el combustible debe ser

tratado primero con un estabilizador como por

ejemplo STA-BIL™.

El Aceite es un aceite registrado de JASO

FC clasificado y tambien cumple o excede los

requisitos de rendimiento de ISO-L-EGD. Shindaiwa

One es recomendado para el uso en todo los

motores Shindaiwa de baja emisión. Shindaiwa One

tambien incluye el estabilizador de combustible.

Posicione la maquina sobre una super-

1.

ficie plana y nivelada.

Retire cualquier suciedad o despojos

2.

alrededor de la tapa de combustible.

Retire la tapa de combustible y llene el

3.

tanque con combustible fresco y limpio.

Reinstale la tapa de combustible y

4.

apriete firmemente.

Arranque del Motor

¡IMPORTANTE!

El encendido del motor está controlado por un interruptor de dos posiciones montado en el mango del acelerador indicado “I”

(encendido o arranque) y “O” (apagado o pare).

Encendido

Figura 11

Deslice el interruptor hacia la posición

1.

“I” (motor encendido).

Presione la bombilla de cebado hasta

2.

que vea pasar combustible por el tubo

de retorno transparente.

Bombilla de Cebado

Tubo de Retorno

Figura 12

SP_8

La bomba de cebado solamente empuja

combustible a travéz del carburador.

Presionando repetidamente la bomba

de cebado no ahogará el motor con

combustible.

Figura 13

Posicione la palanca del cebador en la

3.

posición CLOSED (cerrado) si el motor

está frío.

¡IMPORTANTE!

Cerrado

Cerciórese de que

el accesorio de

corte esté libre de

obstrucciones!

Figura 14

Mientras sostiene el tubo exterior firme-

4.

mente con una mano, jale despacio la

cuerda del arrancador recular hasta que

sienta resistencia, luego jale rápidamente para arrancar el motor.

¡PRECAUCIÓN!

No jale el arrancador recular hasta

el nal de la cuerda. De lo contrario,

puede dañar el arrancador.

Page 25

Arranque del Motor (continuación)

¡ADVERTENCIA!

El accesorio de corte pueda

que gire cuando encienda el motor!

Cuando arranque el motor, mueva

5.

despacio la palanca del cebador a la

posición “OPEN” (abierto). Consulte la

figura 15. (Si el motor para después del

arranque inicial, cierre la palanca del

cebador y vuelva arrancar).

Abierto

Figura 15

la posición de operación.

Si el motor falla en arrancar después de

varios intentos con la palanca del cebador

en posicion cerrada, puede que el motor

esté ahogado con combustible. Si esto se

sospecha, mueva la palanca del cebador a

la posición abierta y repetidamente jale el

arrancador recular para remover el exceso

de combustible y para arrancar el motor. Si

aún falla en arrancar el motor, consulte el

guía diagnóstico de este manual.

¡ADVERTENCIA!

Nunca arranque el motor desde

¡IMPORTANTE!

Cuando arranca el motor…