Shimano SI-R650F Service Instructions

A

A'

Technical Service Instructions SI-R650F

1

2

®

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai, Osaka 590-8577, Japan

H

Y

P

E

R

G

L

I

D

E

-

C

J

A

P

A

N

U

.

S

.

P

A

T

4

2

6

8

2

5

9

L

O

C

K

4

0

0

k

g

/

c

m

O

N

A

M

I

H

S

H

Y

P

E

R

G

L

I

D

E

-

C

J

A

P

A

N

U

.

S

.

P

A

T

4

2

6

8

2

5

9

L

O

C

K

4

0

0

k

g

/

c

m

O

N

A

M

I

H

S

H

Y

P

E

R

G

L

I

D

E

-

C

J

A

P

A

N

U

.

S

.

P

A

T

4

2

6

8

2

5

9

L

O

C

K

4

0

0

k

g

/

c

m

O

N

A

M

I

H

S

H

Y

P

E

R

G

L

I

D

E

-

C

J

A

P

A

N

U

.

S

.

P

A

T

4

2

6

8

2

5

9

L

O

C

K

4

0

0

k

g

/

c

m

O

N

A

M

I

H

S

a

c

-

1

4

T

A

1

1 2

2

1

2

1 2

2

1

1

2

1 2

Rear Drive System

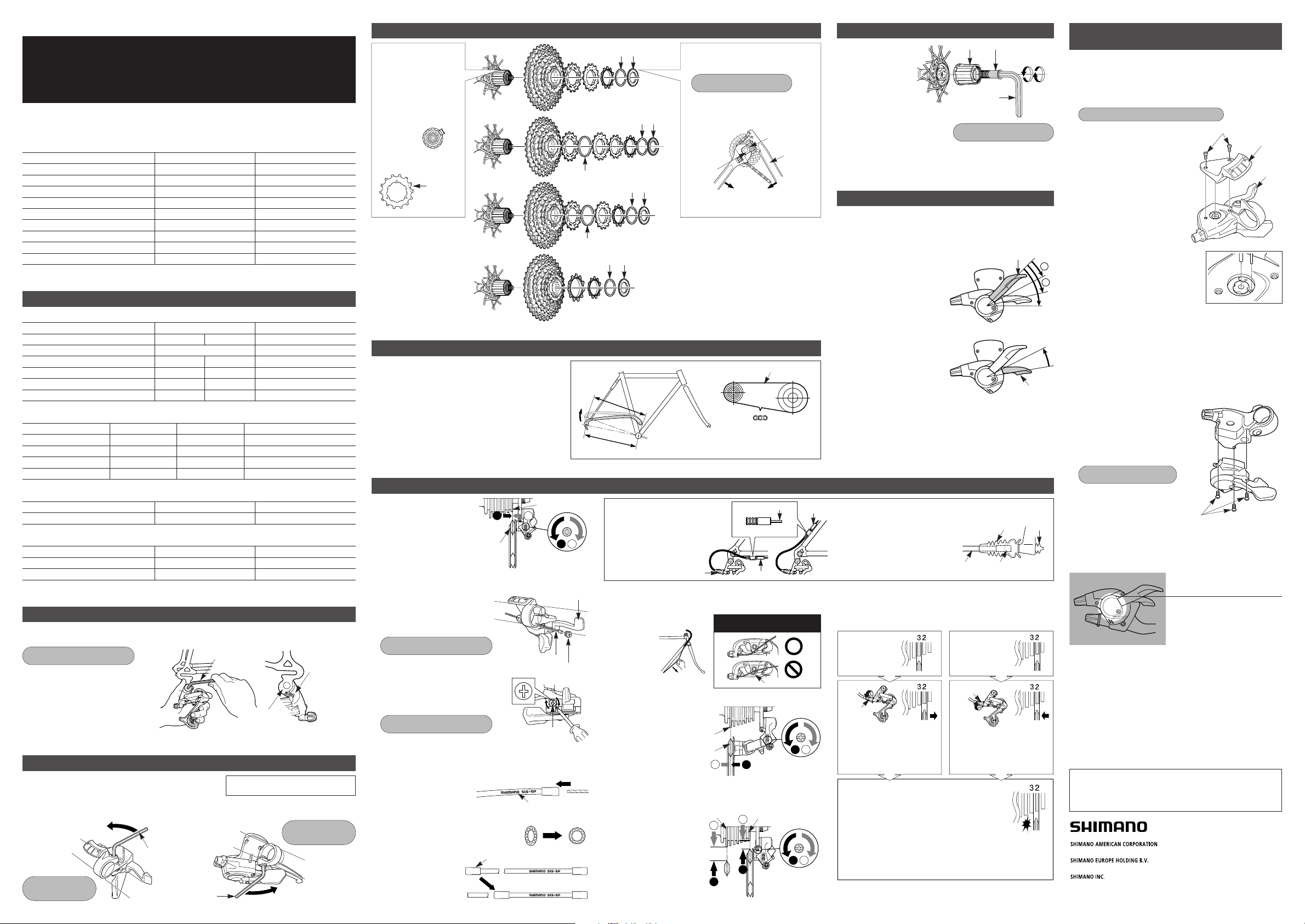

In order to realize the best performance, we recommend that the following combination be

used.

Series

Rapidfire M9 (Shifting lever)

Outer casing

Rear derailleur

Type

Freehub

Gears

Cassette sprocket

Chain

Bottom bracket guide

Specifications

Rear Derailleur

Model number

Type

Gears

Total capacity

Largest sprocket

Smallest sprocket

Front chainwheel tooth difference

Cassette sprocket tooth combination

Model number

CS-M750

CS-M750

CS-M750

CS-HG70-9

Group name Gears

as

Q

a

ap

ar

Shifting lever

Model number

Gears

Freehub

Model number

Gears

No. of spoke holes 36 / 32 36 / 32

Installation of the rear derailleur

When installing, be careful that deformation is not caused by the B-tension adjustment screw coming into

contact with the dropout tab.

Bracket spindle Tightening torque :

8 - 10 N·m {70 - 86 in. lbs.}

Installation of the lever

SL-M750 / SL-M570

Install the brake lever in a position where it will not obstruct

brake operation. Do not use in a combination which causes

brake operation to be obstructed.

SL-M750 /

SL-M570

Tightening torque :

5 N·m

{44 in. lbs.}

5 mm Allen key

DEORE XT DEORE LX

ST-M750 / SL-M750 ST-M570 / SL-M570

SP40 sealed SP40 sealed

RD-M750 RD-M570

SGS / GS SGS

FH-M750 FH-M570

99

SGS GS

43T

34T

11T

22T

ST-M750 / SL-M750

ST-M750 /

ST-M570

5 mm Allen key

CS-M750

CN-HG93

SM-SP17

RD-M750

9

9

9

9

9

9

FH-M750

9

5 mm Allen key

33T

34T

11T

22T

11, 13, 15, 17, 20, 23, 26, 30, 34T

11, 12, 14, 16, 18, 21, 24, 28, 32T

12, 14, 16, 18, 20, 23, 26, 30, 34T

11, 12, 14, 16, 18, 21, 24, 28, 32T

Use a handlebar grip with a maximum

outer diameter of 32 mm.

CS-HG70-9

CN-HG73

SM-SP17

RD-M570

Tooth combination

ST-M570 / SL-M570

FH-M570

Dropout tab

Tightening torque :

SGS

9

43T

34T

11T

22T

9

9

{53 - 69 in. lbs.}

B-tension

adjustment screw

6 - 8 N·m

Installation of the sprockets

For each sprocket, the

surface that has the group

mark should face outward

and be positioned so that

the wider part of each

sprocket and the A part

(where the groove width is

wide) of the freewheel

body are aligned.

The groove is

wide at one

place only.

Wide part

CS-M750 (as)

CS-M750 (aQ)

CS-M750 (ap)

CS-HG70-9

Lock ring spacer Lock ring

Sprocket spacers (2.56 mm)

Sprocket spacers (2.56 mm)

Lock ring spacer Lock ring

Chain length on bicycles with rear suspension

The length of A will vary depending on the movement of the

rear suspension. Because of this, an excessive load may

be placed on the drive system if the chain length is too

short. Set the length of the chain by adding two links to the

chain when the rear suspension is at a position where

dimension "A" is longest and the chain is on the largest

sprocket and the largest chainring. If the amount of

movement of the rear suspension is large, the slack in the

chain

may not be taken up properly when the chain is on the

smallest chainring and smallest sprocket.

SIS Adjustment

1. Top adjustment

Turn the top adjustment

screw to adjust so that the

guide pulley is in line with

the outer line of the

smallest sprocket when

looking from the rear.

2. Connecting and securing the inner cable

Operate lever (B) eight times or

more, and check on the indicator

that the lever is at the highest

position. Then remove the inner

hole cover and connect the inner cable.

Tightening torque :

5 - 7 N·m {44 - 60 in. lbs.}

Install the inner hole cover by turning it

as shown in the illustration until it stops.

Do not turn it any further than this,

otherwise it may damage the screw

thread.

Tightening torque :

0.3 - 0.5 N·m {3 - 4 in. lbs.}

Inserting the inner cable

Insert the inner cable into the outer casing from the end with the

marking on it. Apply grease from the end with the marking in

order to maintain cable operating efficiency.

Cutting the outer casing

When cutting the outer casing, cut the

opposite end to the end with the marking.

After cutting the outer casing, make the

end round so that the inside of the hole

has a uniform diameter.

Attach the same outer

end cap to the cut end of

the outer casing.

Guide pulley

Outer end cap

Outer line of

smallest sprocket

Top adjustment

Inner cable

Inner hole cover

Inner hole cover

Marking

screw

Lever (B)

• For installation of the sprockets, use

the special tool (TL-HG16) to tighten

the lock ring.

Tightening torque:

30 - 50 N·m {261 - 434 in. lbs.}

• To replace the sprockets, use the

Lock ring spacer

Lock ring

special tool (TL-HG16) and TL-SR20

to remove the lock ring.

Lock ring

Tool

(TL-SR20)

TL-HG16

Lock ring spacer Lock ring

Note regarding the sealed cap with

tongue, rubber shield and outer

casing adjustment barrel cover

1. The sealed cap with tongue and

the rubber shield should be

installed to the outer casing

stopper of the frame.

Outer casing

adjustment barrel cover

Connect the cable to the rear derailleur and, after taking up the

initial slack in the cable, re-secure to the front derailleur as shown

in the illustration.

Disassembly

Largest

sprocket

Add 2 links (with the chain on

both the largest sprocket and

the largest chainring)

Be careful not to bend

Note: Be sure that the cable is

Chain

Sealed cap with tongue

Rubber shield

securely in the groove.

Pull

Groove

3. Low adjustment

Turn the low adjustment screw

so that the guide pulley moves

to a position directly in line with

the largest sprocket.

4. How to use the B-tension adjustment screw

Mount the chain on the smallest chainring and the largest

sprocket, and turn the crank arm backward. Then turn the

B-tension adjustment

screw to adjust the guide

pulley as close to the

sprocket as possible but not

so close that it touches.

Next, set the chain to the

smallest sprocket and

repeat the above to make

sure that the pulley does

not touch the sprocket.

Largest

sprocket

Guide pulley

Largest sprocket Smallest sprocket

Low adjustment

adjustment screw

Largest

chainring

screw

B-tension

Rubber shield

Replacement of the freewheel body

After removing the hub

axle, remove the freewheel

body fixing bolt (inside

the freewheel body),

and then replace the

freewheel body.

Note: Do not attempt to

disassemble the

freewheel body, because it

may result in a malfunction.

Freewheel body

Freewheel body fixing bolt

Disassembly

Assembly

10 mm Allen key

(TL-WR37)

Tightening torque :

35 - 50 N·m {305 - 434 in. lbs.}

Gear shifting operation

Both lever (A) and lever (B) always return to the initial position when

they are released after shifting. When operating one of the levers,

always be sure to turn the crank arm at the same time.

To shift from a small sprocket to a larger sprocket

To shift one step only, press lever

(A) to the (1) position. To shift two

steps at one time, press to the (2)

position.

A maximum three-step shift can be

made in this manner.

To shift from a large sprocket to a smaller sprocket

Press lever (B) once to shift one

step from a larger to a smaller

sprocket.

2. Pass the outer casing through the

outer casing adjustment barrel

cover. At this time, check that the

outer casing fits securely into the

outer casing holder on the rear

derailleur side.

5. SIS Adjustment

Operate the shifting lever several times to move the chain to the

2nd sprocket. Then, while pressing the lever just enough to take

up the play in the lever, turn the crank arm.

When shifting

to 3rd

Outer casing

adjustment

barrel

Tighten the outer casing adjustment

barrel until the chain returns to the

2nd sprocket. (clockwise)

* Turn the outer casing adjustment

barrel together with the outer casing

adjustment barrel cover.

Best setting

The best setting is when the shifting lever is

operated just enough to take up the play and the

chain touches the 3rd sprocket and makes noise.

* Return the lever to its original position (the position where

the lever is at the 2nd sprocket setting and it has been released) and

then turn the crank arm clockwise. If the chain is touching the 3rd

sprocket and making noise, turn the outer casing adjustment barrel

clockwise slightly to tighten it until the noise stops and the chain runs

smoothly.

For the best SIS performance, periodically lubricate all

power-transmission parts.

Lever (A) initial position

Lever (B)

Outer casing adjustment

barrel cover

Outer casing

When no

sound at all

is heard

Outer casing

adjustment barrel

Loosen the outer casing adjustment barrel

until the chain touches the 3rd sprocket

and makes noise. (counter clockwise)

* Turn the outer casing adjustment

barrel together with the outer casing

adjustment barrel cover.

Outer casing

holder

Rubber

shield

Replacement of the shifting lever unit

and indicator

Removal of the indicator

Disassembly and reassembly should only be carried out when

replacing the indicator.

1. Remove the two indicator set screws which are securing the

indicator.

Tightening torque : 0.3 - 0.5 N·m {3 - 4 in. lbs.}

2. Remove the indicator unit as

shown in the illustration.

3. Operate lever (B) at least eight

times to set the lever to the

highest position.

4. After checking that the indicator needle

is at the left edge, install the indicator

as shown in the illustration.

5. Check the operation of the indicator. If it does not operate

correctly, re-install the indicator while taking particular note of

steps 3. to 4.

Replacement of the shifting lever unit

Disassembly and reassembly should only be carried out when

replacing the shifting lever unit.

1. Loosen the cable fixing bolt (nut) of the rear derailleur, and then

pull the inner cable out of the shifting lever unit in the same way

as when installing the inner cable.

2. Carry out steps 1 - 2 for replacement

of the indicator.

3. Remove the three shifting lever

mounting screws, and then remove

the shifting lever unit as shown in the

illustration.

Tightening torque :

0.5 - 0.8 N·m {4 - 7 in. lbs.}

Shifting lever mounting screws

4. To assemble, align the shifting lever unit and the brake lever

bracket and then secure the shifting lever mounting screws.

5. Carry out steps 3 - 4 for replacement of the indicator.

Do not disassemble the

indicator and shifting lever unit,

as this may damage them or

cause mis-operation.

This service instruction explains how to use and maintain the

Shimano bicycle parts which have been used on your new bicycle.

For any questions regarding your bicycle or other matters which

are not related to Shimano parts, please contact the place of

purchase or the bicycle manufacturer.

Please note: specifications are subject to change for improvement without notice.(English)

© Apr. 2003 by Shimano Inc. XBC SZK Printed in Japan

Indicator set screws

Indicator

Lever (B)

These service instructions are

printed on recycled paper.