Page 1

Gas Chromatograph

GC-8A Series

C184- E016 B

Page 2

GC-8A Series

Dedicated Single Detector

Gas Chromatograph

GC that meets increasing analytical requirements…

GC that can analyze instantaneously…

GC that is tough and useful…

The GC-8A is a gas chromatograph that makes these dreams come true.

GC-8AIT GC-8AIF

Simple design with emphasis on functionality

Tough an d stron g die cast fr ame

Reliability backed by years of experience

Self-diagnostic monitor / thermometer for easy maintenance

Accommodates a range of stable, high-sensitivity d etector s (TC D, FI D, ECD, FP D)

Easy-to-use digital settings

Comprehensive accessor ies

Contents

P 3

Column Oven

P 4

Sample Injection Ports

P 5

Detectors

P 7

GC-8AIT

P 8

GC-8AIF

P 9 GC-8AIE

P 10

GC-8APFp

P 11

Accessories

Page 3

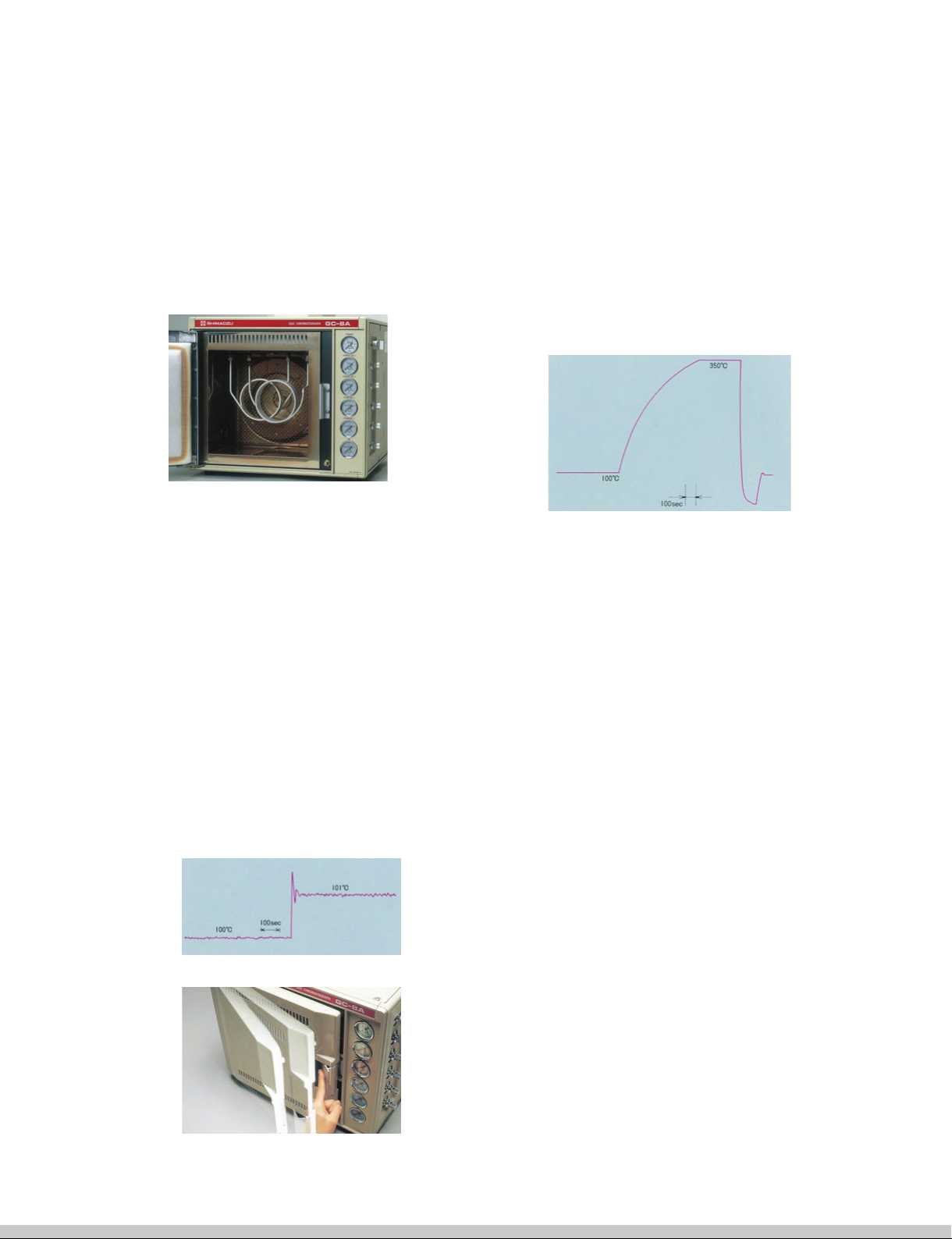

Column Oven

Large-capaci ty, cubi c ove n

Almost cubic in shape, the column oven opens entirely at the

front, making changing columns simple and easy. The column

oven's door opens and closes by a simple one-touch operation.

The lightweight door moves extremely smoothly.

Fig. 1 Column Oven

Two-stage ov erheat prevention

for pro tection o f colum ns

If the temperature exceeds the programmed (preset)

temperature by 30°C, the heater will be automatically turned

o. If the temperature reaches about 420°C, the heater will be

automatically turned o.

Rapid he at ing and cool in g

ch aracteristi cs

Rapid heating and cooling characteristics of the column oven

are also important for a gas chromatograph. Fig. 4 shows that

heating from 100°C to 350°C requires just 12 minutes, while

cooling takes less than one minute and re-stabilizing at the

initial temperature takes about three minutes.

Fig. 4 Heating and Cooling Curve

Tempe rature contro l oers

ex ce llent stabil it y a nd r espons e

Excellent temperature control of the column oven is essential

for a gas chromatograph. Fig. 2 shows the response and stability

when the column oven's temperature setting is changed from

100°C to 101°C. It shows that the oven responds rapidly to a

changed temperature setting and is able to immediately achieve

stable temperature control.

Fig. 2 Temperature Stability

Fig. 3 Operation of Column Oven Door

3

Page 4

Sample Injection Ports

Easy-to-use on-column sample

injection ports

The standard injection ports are on-column type. Since sample

solution is directly injected into the head of a glass column, the

decomposition and adsorption of sample components are

minimized.

Carrier gas

Fig. 6 On-Column Sample Injection Port

Capillary column adapter

Adding the optional CLH-800 capillary column holder allows

simple mounting of the capillary column for both split and

splitless sample injection.

Fig. 7 Quartz Capillary Column Mounted with CLH-800

GC-8A Series

Gas Chromatograph

4

Page 5

Detectors

Thermal Conductivity Detector (GC-8AIT, GC-8APT)

Highly stable and sensitive filaments

The rhenium-tungsten filaments, each of which has a resistance

of 100Ω, ensure the highest sensitivity and stability.

Constant current system

The bridge current is kept constant even when the detector

temperature is changed. It is not necessary therefore to readjust

the current after the detector temperature is stabilized.

Carrier gas

Filament

Filament protection

If some air should flow into the TCD cell, for example, at the

time of column replacement, the bridge current will

automatically be turned off and the warning lamp will be lit.

Flame Ionization Detector (GC-8AIF, GC-8APF)

Cylindrical collector

Combustion gases from the hydrogen flame pass from the

nozzle straight through the cylindrical collector to be

discharged externally. This reduces contamination of the

detector to extremely low levels.

On-detector system

The dead space is eliminated at the connection of the column

and the detector. Excellent repeatability is provided even in

analysis of trace components.

Fig. 8 TCD Cell (GC-8APT)

Quartz jet

Collector electrode

High voltage electrode

Air

H

2

External igniter

Column

The flame igniter is mounted external to the detector to

significantly reduce wire damage due to corrosive combustion

components and to make replacement of the igniter filament

cheap and simple.

Carrier gas

Fig. 9 FID Cell

5

Page 6

Electron Capture Detector (GC-8AIE)

Linear ECD with high sensitivity and wide dynamic range

The constant-current ECD maintains a constant current flow in

the detector. It offers excellent performance of a linear dynamic

range of 10,000 and 0.2 pg (Υ-BHC) minimum limit of detection,

and greatly restricts peak abnormalities such as negative peaks.

Switchable detector current

The standing current flowing in the detector can be switched in

three stages for convenient analysis of samples across a wide

concentration range.

Exhaust

Carrier gas

Fig. 10 ECD Cell

Electrode

63

Ni source

Purge gas

Column

Comprehensive contamination countermeasures

The system features a programmed heating system to prevent

detector contamination (column oven heating starts only after

the detector reaches the set temperature) and a purge system

to maintain carrier gas purging and keep the detector in

standby status even when the detector is not being used for

analysis.

Purge flow line reduces stabilization time

The purge flow line allows purging of the interior of the

detector by carrier gas when the detector remains mounted in

the gas chromatograph but is not used.

This prevents oxidation by oxygen in the air and ensures stable

operation the next time the detector is used.

Flame Photometric Detector (GC-8APFp)

Flame

The FPD cell is designed so that the flame will not be

extinguished by a solvent overload.

FID monitor electrode

The FID monitor electrode in the detector permits extraction of

the FID signal.

*Requires the FID monitor kit (Special Accessory: P/N 221-23950-91)

Forced cooling system

To ensure a low noise level and long service life, the

photomultiplier tube is kept cool by a blower when the

detector is maintained at a high temperature.

Complete safety

The photomultiplier tube is protected against damage from

exposure to high light levels by a sensing circuit which cuts

power to the tube if anomalous conditions are detected.

Chloroform 7.5ppb

Dichlorobromomethane

6.4ppb

1,1,1-

Chlorodibromomethane

2ppb

Fig. 11 Chromatogram of Trihalomethane

Quartz cylinder

Nozzle

Quartz tube

H

2

Thiophene

(2ng)

Fig. 13 Analysis of Trace Thiophene

in Benzene (S mode)

trichloroethane

Carrier gas

Fig. 12 FPD Cell

Tetrachloromethane

Trichloroethylene

1,1,2-trichloroethane

Tetrachloroethylene

1,1,1,2-

Chloroform

Electrode for FID monitor (option)

Cooling fan

Photomultiplier

Interference filter

Quartz window

Air

Column

Fig. 14 Analysis of Organophosphorus

tetrachloroethane

1,1,2,2tetrachloroethane

Methyl parathion (20ng)

Ethyl parathion (20ng)

EPN (20ng)

FID monitor

Pesticides (P-mode)

FPD

GC-8A Series

Gas Chromatograph

6

Page 7

GC-8AIT

Column Oven

Temperature range

Temperature control

Temperature control accuracy

Temperature

Readout (Monitor)

Heating speed

Cooling speed

Column

Overheat Protection

: Room temperature to 399°C

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: When the temperatures of the column

oven and the injection port/detector have

reached the set points, the respective

READY lamps are lit.

From room temperature to 350°C in 13 minutes.

:

: From 350°C to 100°C in 3.5 minutes.

: Stainless steel: 6m x 2

Glass: 5.4m x 2

: Two-stage protection:

(1) If the temperature exceeds the

programmed (preset) temperature by 50°C,

the heater will be automatically turned off.

(2) If the temperature reaches about 420°C,

the heater will be automatically turned off.

Temperature of Injection Port/Detector

Temperature range

Temperature control

Temperature control accuracy

Temperature

Readout (Monitor)

Overheat Protection

Injection Port

: Room temperature to 400°C (10°C steps)

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: When the temperatures of the column

oven and the injection port/detector have

reached the set points, the respective

READY lamps are lit.

: If the temperature reaches about 420°C,

the heater will be automatically turned off.

: On-column injection ports

Flow Control

Carrier gas : Two pressure regulators

Two column inlet pressure gauges

Thermal Conductivity Detector (TCD)

Detector

Maximum temperature

Bridge current

Filament protection circuit

: Differential type of semi-diffusion flow system

Four rhenium-tungsten filaments (100Ω each)

: 400°C

: Constant current system (OFF, 60, 70, 80,

90, 100, 120, 140, 160, 180, 200mA)

: Incorporated

Others

Dimensions

Weight

Power Requirements

Others

: 440W x 405D x 435Hmm

: 26.5kg

: AC100/115V or 220V as ordered.

1500VA max. 50/60Hz.

: (1) Column oven heating starts after the

injection port / detector reaches the set

temperature.

(2) Cannot be used with a preparative system.

7

Page 8

GC-8AIF

Column Oven

Temperature range

Temperature control:

Temperature control accuracy

Heating speed

Cooling speed

Column

Overheat Protection

: Room temperature to 399°C

: Proportional-integration type of zero cross

switching system

: ±0.1°C

From room temperature to 350°C in 13 minutes.

:

: From 350°C to 100°C in 3.5 minutes.

: Stainless steel: 6m x 2

Glass: 5.4m x 2

: Two-stage protection:

(1) If the temperature exceeds the

programmed (preset) temperature by 30°C,

the heater will be automatically turned off.

(2) If the temperature reaches about 420°C,

the heater will be automatically turned off.

Temperature of Injection Port/Detector

Temperature range

Temperature control

Temperature control accuracy

Overheat Protection

Injection Port

: Room temperature to 400°C (10°C steps)

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: If the temperature reaches about 420°C,

the heater will be automatically turned off.

: On-column injection ports

Temperature Readout

The three temperatures (injection port/detector, column oven, and

auxiliary) are selectively indicated on the pyrometer, the selection being

made by pushbuttons.

Flow Control

Carrier gas

Hydrogen

Air

: Two pressure regulators

Two column inlet pressure gauges

: Two pressure regulators

Two pressure gauges

: One pressure regulator

One pressure gauge

Flame Ionization Detector (FID)

Detector

Maximum temperature

Detection limit

Dynamic range

Jet

: Dual cell with cylindrical collectors

: 400°C

-12

g/s for diphenyl

: 3 x 10

7

: 10

: Mode of quartz

Electrometer

-12

Sensitivity

Noise

Drift

Input attenuation

Output attenuation

Linearity

Background suppression

Signal output

: 1 x 10

A/mV

-14

: Below 10

: Below 2 x 10

(Constant room temperature)

: 1, 10, 10

: 1 to 1024 (binary step) and ∞

: Wider than 10

: ±6.4 x 10

: 0 to 1mV for recorder

0 to 1V for data processor

A

-14

2

, 103, 10

-10

A (NORM mode)

Others

Dimensions

Weight

Power Requirements

Carrier gas

GC-8AIF Flow Chart

: 440W x 405D x 570Hmm

: 34.5kg

: AC100/115V or 220V as ordered.

1500VA max. 50/60Hz.

Column

Inlet

A/h

4

5

(fixed input attenuation)

Air

H

2

GC-8A Series

Gas Chromatograph

8

Page 9

GC-8AIE

Column Oven

Temperature range

Temperature control

Temperature control accuracy

Temperature

Readout (Monitor)

Heating speed

Cooling speed

Column

Overheat Protection

: Room temperature to 399°C

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: When the temperatures of the column

oven and the injection port/detector have

reached the set points, the respective

READY lamps are lit.

From room temperature to 350°C in 13 minutes.

:

: From 350°C to 100°C in 3.5 minutes.

: Stainless steel: 12m x 1

Glass: 5.4m x 1

: Two-stage protection:

(1) If the temperature exceeds the

programmed (preset) temperature by 50°C,

the heater will be automatically turned off.

(2) If the temperature reaches about 420°C,

the heater will be automatically turned off.

Temperature of Injection Port/Detector

Temperature range

Temperature control

Temperature control accuracy

Temperature

Readout (Monitor)

Overheat Protection

Injection Port

: Room temperature to 350°C (10°C steps)

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: When the temperatures of the column

oven and the injection port/detector have

reached the set points, the respective

READY lamps are lit.

: If the temperature reaches about 350°C,

the heater will be automatically turned off.

: On-column injection ports

Flow Control

Carrier gas One pressure regulator

One column inlet pressure gauge

Electron Capture Detector (ECD)

Detector

Radiation source

Detection limit

Dynamic range

Maximum temperature

Standing current

: Coaxial type cell and purge flow line

63

Ni 370MBq

:

: 0.2pg/s for Υ-BHC

4

: 10

: 350°C

: 0.5, 1.0, 2.0mA

Others

Dimensions

Weight

Power Requirements

Other

: 440W x 405D x 435Hmm

: 26.0kg

: AC100/115V or 220V as ordered.

1500VA max. 50/60Hz.

: Column oven heating starts after the

injection port / detector reaches the set

temperature.

9

Page 10

GC-8APFp

Column Oven

Temperature range

Temperature control

Temperature control accuracy

Heating speed

Cooling speed

Column

Overheat Protection

: -100°C to 400°C (The optional cryogenic

work attachment and cryogenic valve

unit are necessary for sub-ambient

temperature operation.)

: Proportional-integration type of zero

cross switching system

: ±0.1°C

From room temperature to 350°C in 13 minutes.

:

: From 350°C to 100°C in 3.5 minutes.

: Stainless steel: 12m x 1

Glass: 5.4m x 1

: Two-stage protection:

(1) If the temperature exceeds the

programmed (preset) temperature by 30°C,

the heater will be automatically turned off.

(2) If the temperature reaches about 420°C,

the heater will be automatically turned off.

Temperature Programmer/Timer

Initial temperature

Final temperature

Programming rate

: -100°C to 399°C (1°C steps)

: 0°C to 400°C (10°C steps)

: 0.5, 1, 2, 3, 4, 5, 6, 8, 10, 16, 20, 32°C/min.

Temperature of Injection Port/Detector

Temperature range

Temperature control

Temperature control accuracy

Overheat Protection

Injection Port

Room temperature to

:

: Proportional-integration type of zero cross

switching system

: ±0.1°C

: If the temperature reaches about 420°C,

the heater will be automatically turned off.

: On-column injection ports

400°C (10°C steps)

Temperature Readout

The three temperatures (column oven, injection port/detector, and

auxiliary) are selectively indicated on the pyrometer, the selection being

made by pushbuttons.

Flow Control

Carrier gas

Hydrogen

Air

: One primary pressure regulator

One primary column inlet pressure gauge

One differential flow controller

One column inlet pressure gauge

: One pressure regulator

One pressure gauge

: One pressure regulator

One pressure gauge

Flame Photometric Detector (FPD)

Selective detection of sulfur and phosphorus (by filter interchange)

Optional filter

Detection limit

Power supply

Maximum temperature

: 394nm (S), 526nm (P)

-11

gS/s for S in thiophene

: 5 x 10

1.4 x 10-12 gP/s for P in DDVP or parathion

: -700V, stabilized

: 350°C (air cooling)

Electrometer

Sensitivity

Noise

Drift

Input attenuation

Output attenuation

Linearity

Background suppression

Signal output

-10

A/mV

: 1 x 10

: Below 10

:

: 1, 10, 102, 10

: 1 to 1024 (binary step) and ∞

: Wider than 10

: ±6.4 x 10

: 0 to 1mV for recorder

0 to 1V for data processor

-12

Below 2 x 10

-8

A

A

-12

A/h (Constant room temperature)

3

5

(fixed input attenuation)

Others

Dimensions

Weight

Power Requirements

Special accessories

: 440W x 405D x 650Hmm

(Electric control: 440W x 330D x 135Hmm)

: 35.0kg

: AC100/115V or 220V as ordered.

1500VA max. 50/60Hz.

: FID monitor and electrometer for monitor

(P/N 221-23950-91)

Filter for S (P/N 221-00892-01)

Filter for P (P/N 221-00897-01)

GC-8A Series

Gas Chromatograph

10

Page 11

Accessories

Hydrogen Generator

Compact hydrogen generator by ion exchange membrane water electrolysis.

High-purity hydrogen is formed through electrolysis of pure water. The compact design

fits perfectly beside a GC-8A gas chromatograph. Requires deionized water with a

specific resistance of 5 MΩcm min.

Model

P/N

Max. delivery flow rate

Max. delivery pressure

OPGU-2200S

221-45131-91 (115V)

221-45131-93 (230V)

225 mL/min

20 to 400kPa

Air Compressors

These supply clean (oil mist free) compressed air to support combustion in FID and FPD.

Output: 1/4HP

Delivery pressure: 400±50kPa

Maximum delivery flow rate: 20L/min. (NTP)

Model

P/N

Weight

Noise

Oil-less

221-72380

16kg

—

Oil-less, silent

670-12138

44kg

58db

PPR Series Pressure Regulator for High Purity Gases

Dedicated GC gas pressure regulator that provides a high-purity, high-accuracy supply of

carrier gas or hydrogen from the gas cylinder. The air-purge valve on the primary side

prevents ingress of air when the cylinder is changed. This ensures rapid baseline

recovery after cylinder replacement and extends the column life by restricting oxidative

degradation of the solid phase.

Oil-less type

11

Model

PPR-N2

PPR-H2

PPR-He

Nitrogen and Argon (Blue)

Hydrogen (Red)

Helium (Yellow)

P/N

221-35999-01

221-35999-02

221-35999-03

Accessory/Supply Set (P/N 221-38650-90)

Contains all the items required to operate the gas chromatograph.

Major contents: a carrier gas supply pipe, a gas filter, leak check fluid, tools, a mirror

for flame checking, a microliter syringe, column tags, quartz beads, color markers, a

power outlet, a case, etc.

The separate FID accessories set (P/N 221-38651-90) is also required for a gas

chromatograph with FID.

Page 12

Economy Set of Microsyringes

A range of analytical syringes is available.

· Economy type 10 µL (6 per pack)

· Standard microsyringe 25 to 100 µL

· Gas-sealed microsyringe 25 to 100 µL

· Plunger-guide microsyringe 5 to 25 µL

· Plunger-in-needle microsyringe 0.5 to 5 µL

· Large-capacity gas-tight syringe 1 to 100 mL

Set of Devices for Packing Columns (P/N 221-37387-91)

Contains all the items required to fill or re-pack the column.

It allows the column to be easily repacked. Includes detailed

instructions and a convenient carrying case.

Major contents: funnels, aspirator, vibrator (electric engraver),

trap bottles, column tags, silica wool, column packing, rubber

tubes, connectors, etc.

Columns (Tube for packed column)

Length (m)

0.5

1.0

1.5

2.0

2.5

3.0

* Columns exceeding 3 m also available. Consult your Shimadzu representative for details.

Stainless Steel Columns

3mm ID, 4mm OD

201-48705-05

201-48705-10

201-48705-15

201-48705-20

201-48705-25

201-48705-30

3.2mm ID, 5mm OD

221-22949-05

221-22949-10

221-22949-15

221-22949-20

221-22949-25

221-22949-30

Glass Columns

2.6mm ID, 5mm OD

221-22950-05

221-22950-10

221-22950-15

221-22950-20

221-22950-25

221-22950-30

GC-8A Series

Gas Chromatograph

12

Page 13

GC-8A Series

www.shimadzu.com/an/

Company names, product/service names and logos used in this publication are trademarks and trade names of Shimadzu Corporation or its

affiliates, whether or not they are used with trademark symbol “TM” or “®”.

Third-party trademarks and trade names may be used in this publication to refer to either the entities or their products/services. Shimadzu

disclaims any proprietary interest in trademarks and trade names other than its own.

For Research Use Only. Not for use in diagnostic procedures.

The contents of this publication are provided to you “as is” without warranty of any kind, and are subject to change without notice. Shimadzu

does not assume any responsibility or liability for any damage, whether direct or indirect, relating to the use of this publication.

© Shimadzu Corporation, 2012

Printed in Japan 3655-10216-20ANS

Loading...

Loading...