Page 1

GC-2014 Gas Chromatograph

INSTRUCTION MANUAL

221-40609A

Read the instruction manual thoroughly before you use the product.

Keep this instruction manual for future reference.

Page 2

©2004-2006 Shimadzu Corporation. All rights are reserved, including those to reproduce this

publication or parts there of in any form without permission in writing from Shimadzu Corporation.

Information in this publication is subject to change without notice and does not represent a

commitment on the part of the vendor.

Any errors or omissions which may have occurred in this publication despite the utmost care

taken in its production will be corrected as soon as possible, but not necessarily immediately

upon detection.

Note that Shimadzu does not have any obligation concerning the effects resulting from the application of the contents of this manual.

Page 3

About this USER’s MANUAL

About this USER’s MANUAL

GC-2014 user's manual consists of the two separate manuals as described below.

Operation Manual Part number: 221-40607

It describes procedures necessary to operate the instrument.

Instruction Manual Part number: 221-40609 (this manual)

It describes the instrument's functions and how to use them.

Safety precautions are included in the operation manual. Please read them before using the instrument.

WARNING LABELS

WARNING LABELS

Label conventions for this manual are provided below.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in serious injury or possibly death.

CAUTION

NOTE

Indicates a potentially hazardous situation which, if not avoided,

may result in minor to moderate injury or equipment damage.

Emphasizes additional information that is provided to ensure the

proper use of this product.

I

Page 4

This page is intentionally left blank.

Page 5

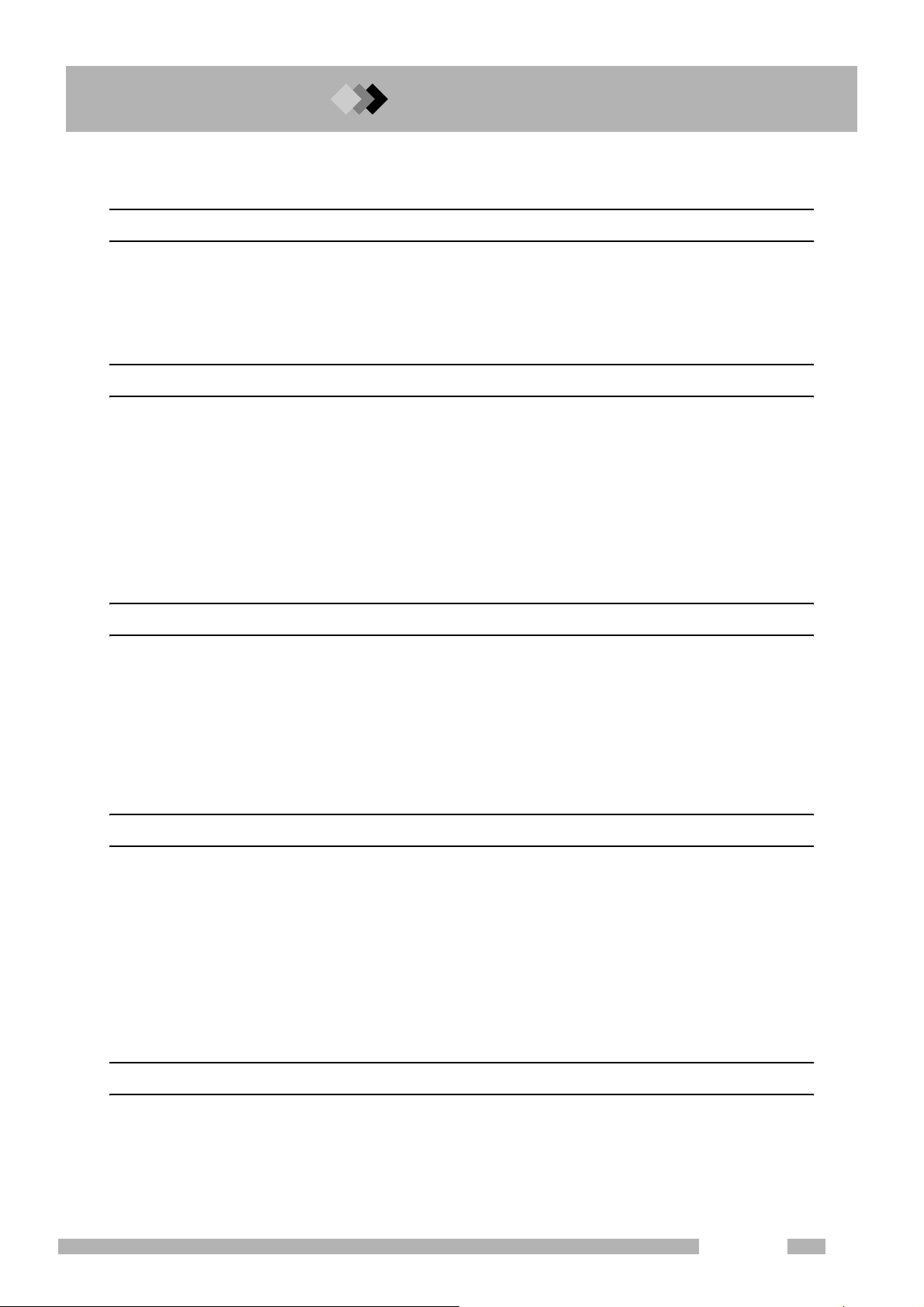

Contents

About this USER’s MANUAL

1 Installation

1.1 Verification of Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Power supply and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Gas Supply Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Before Use

2.1 Setting Analytical Flow Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Outputting Analog Signals to the Chromatopac . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Outputting Digital Signals to a Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Connecting a RS-232C Cable to the Chromatopac C-R8A . . . . . . . . . . . . . . . . . . 25

2.5 Connecting Auto Injector/Auto Sampler AOC-20 Series . . . . . . . . . . . . . . . . . . . . 27

2.6 Connecting the Relay Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3 Installing Packed Columns and Setting Analytical Flow Lines

3.1 Installation Location for Packed Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Dual-Column Packed FID Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Single-Column Packed FID Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4 Packed TCD Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.5 Packed Analysis Using the Single DET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 Installing Capillary Columns and Setting Analytical Flow Lines

4.1 Installation Location for Capillary Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Capillary Analysis Using the Dual FID

(When a detector adapter with purge is used) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.3 Capillary Analysis Using the Dual FID

(When a makeup gas flow controller is used) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4 Capillary TCD Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.5 Single DET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

5 Analysis

5.1 Analysis Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1.2 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1.3 Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

GC-2014

i

Page 6

Contents

5.2 Notes for Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Basic Key Operation

6.1 Keypad Description and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.1 Keypad operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.1.2 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.1.3 Status indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2 Adjusting The Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.3 Basic Key Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.1 Screen display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.3.2 Moving the cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.3.3 Entering numeric values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.3.4 Changing a selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.3.5 Changing item names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.4 Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7 Starting and Stopping the GC [SYSTEM]

7.1 [SYSTEM] Key Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.1 Screen Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.2 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.1.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.2 Specifying Clean Up Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.2.1 Screen Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.2.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.2.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.3 Specifying Start Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.3.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.3.3 Example: starting the system with carrier gas flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4 Specifying the Stop Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.1 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.3 System shut down examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8 Setting the Analytical Parameters and File Management

8.1 [SET] Key Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.1.1 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.1.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.1.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8.2 File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.3 Copying a file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.4 Renaming a file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.5 Initializing a file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

ii

GC-2014

Page 7

Contents

8.3 Specifying the Analytical Flow Line Components ([Line Config]) . . . . . . . . . . . . 98

8.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.4 Changing Items Displayed with [Customiz] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9 Monitoring the GC

9.1 [MONIT] key Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9.1.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9.1.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.2 Monitoring the Temperature with [Temp Mon] . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.2.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.2.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.3 Monitoring the Flow Rate with [Flow Mon] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.3.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.4 Zero Point Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10 Starting and Stopping Analysis

10.1 Making an Injecting and Starting an Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.1.1 Verifying the gas chromatograph status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

10.1.2 Making manual injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.1.3 Starting the analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.2 Terminating the Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.2.1 Terminating the analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.2.2 External devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11 Creating an Oven Temperature Program

11.1 [COL] Key Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11.1.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11.1.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

11.1.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.2 Temperature Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2.1 Isothermal analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2.2 Programmed analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2.3 Creating a temperature program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

12 Injection Port

12.1 Packed Column Injection Port (Dual INJ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

12.1.1 Setting the temperature with [INJ] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12.1.2 Setting the Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

12.1.3 Entering Columns Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

12.1.4 Creating a Flow Rate Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

12.2 Split/Splitless Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

GC-2014

iii

Page 8

Contents

12.2.1 Setting the temperature with [INJ] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

12.2.2 Setting the flow rate with [FLOW] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

12.2.3 Setting column parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.2.4 Gas saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

12.2.5 Pressure program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

12.2.6 Creating a Flow rate program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

12.2.7 Split ratio program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

12.2.8 Septum purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

12.2.9 High pressure injection and splitter fix mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.3 Direct Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.3.1 Setting the temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

12.3.2 Setting the flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12.4 AFC and APC Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

12.5 Setting the Flow Rate Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

13 Detector

13.1 Hydrogen Flame Ionization Detector (FID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

13.1.1 Principle of FID operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

13.1.2 Setting the detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

13.1.3 Setting the Detector Gas (manual flow controller) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

13.1.4 Setting the detector gas flows(APC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

13.1.5 Igniting and Extinguishing the FID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

13.2 Thermal Conductivity Detector (TCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

13.2.1 Principle of TCD operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

13.2.2 Setting the detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

13.2.3 TCD Zero Point Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

13.3 Filter Signal Time Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

13.4 Background Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

14 Diagnosis

14.1 Standard Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

14.1.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

14.1.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

14.1.3 Diagnosis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

14.1.4 Diagnosis parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

14.1.5 Starting the diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

14.1.6 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

14.1.7 Stopping/exiting the diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

14.1.8 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

14.1.9 Diagnosis results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

14.1.10 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

14.2 Log Reading Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.2.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

14.2.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

14.2.3 GC Operation log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

14.2.4 Analysis log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

14.2.5 Parameter log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

14.2.6 Error log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

14.2.7 Diagnostic log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.3 Analysis Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

iv

GC-2014

Page 9

Contents

14.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

14.3.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

14.3.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

14.4 Coolant Consumption Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

14.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

14.4.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

14.4.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

14.5 Standard Installation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

14.5.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

14.5.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

14.5.3 Test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

14.6 Peak Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

14.6.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

14.6.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

14.6.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

15 Optional Devices

15.1 Auto Injector Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

15.1.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

15.1.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

15.1.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

15.1.4 AOC priority analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

15.1.5 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

15.1.6 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

15.1.7 Other AOC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

15.1.8 Other AOC Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

15.1.9 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

15.1.10 Auto-sampler carousel and other optional parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

15.1.11 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

15.2 Setting AUX Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

15.2.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

15.2.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

15.2.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

15.2.4 On/Off setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

15.2.5 On/Off parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

15.3 Setting the AUX APC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

15.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

15.3.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

15.3.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

15.4 Setting the AUX AMC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

15.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

15.4.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

15.4.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

15.5 Setting the CRG Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

15.5.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

15.5.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

15.5.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

16 Special Functions

16.1 Time Scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

16.1.1 description Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

GC-2014

v

Page 10

Contents

16.1.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

16.1.3 Setting the mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

16.1.4 Editing a time schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

16.1.5 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

16.1.6 Creating a new time schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

16.1.7 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

16.1.8 Parameters available in the time scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

16.1.9 Changing schedule parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

16.1.10 Time schedule example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

16.1.11 Starting/stopping a time schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

16.1.12 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

16.1.13 Copying and deleting a time schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

16.2 Batch Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

16.2.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

16.2.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

16.2.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

16.2.4 Creating a new batch schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

16.2.5 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

16.2.6 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

16.2.7 Editing a batch schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

16.2.8 Batch processing Setup example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

16.3 Time Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

16.3.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

16.3.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

16.3.3 Creating a new time program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

16.3.4 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

16.3.5 Time Program parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

16.3.6 Editing a time program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

16.3.7 Time program setup example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

16.4 Pre-Run Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

16.4.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

16.4.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

16.4.3 Creating a new Pre-Run program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

16.4.4 Editing a Pre-Run program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

16.4.5 After Pre-Run program is finished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

16.4.6 Pre-Run Program set up example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

16.5 Direct Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

16.5.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

16.5.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

16.5.3 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

16.6 GC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

16.6.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

16.6.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

16.6.3 Setting the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

16.6.4 Setting the maximum temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

16.6.5 Setting transmission parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

16.6.6 Setting the Ready Check Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

16.6.7 Parameter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

16.6.8 Customizing Component Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

16.6.9 Setting the link device code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

16.6.10 Temperature offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

16.6.11 Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

16.7 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

16.7.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

16.7.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

16.7.3 INSTALLATION (POSITION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

16.7.4 INSTALLATION (PIPING) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

vi

GC-2014

Page 11

Contents

16.7.5 INITIALIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

16.7.6 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

16.8 Stopwatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

16.8.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

16.8.2 PF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

16.8.3 Timing with inverse measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

16.9 Key Lock and Parameter Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

16.9.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

16.9.2 Key locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

16.9.3 Parameter locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

16.10 ROM Version No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

16.10.1 Screen description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

16.10.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

17 Printing

17.1 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

17.1.1 Connection to Chromatopac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

17.1.2 Parameters to be printed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

17.2 AOC commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

17.3 Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

17.4 Event No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .279

18 Error Messages

18.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

18.1.1 System errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

18.1.2 Temperature control errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

18.1.3 Pressure/flow rate errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

18.1.4 Communication errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

18.1.5 Detector errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

18.1.6 Program errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .296

18.1.7 Operations errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

18.1.8 Optional device error (AOC-20i/s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

18.1.9 Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

19 Index

GC-2014

vii

Page 12

Contents

This page is intentionally left blank.

viii

GC-2014

Page 13

1 Installation

1.1

1.1.

Q Installation location requirements

Consider the following points to ensure safe and appropriate unit operation when selecting

the installation site.

1.1Verification of Installation Location

1. Ambient temperature and humidity

For optimal performance, operate this unit within the following temperature and humidity

specifications.

Temperature range: 18 °C to 28 °C

Relative humidity range: 50 % to 60 % (Avoid use under conditions where

Operating temperature range: 5 °C to 40 °C

Operating humidity range: 5 % to 90 % (Avoid use under conditions where con-

2. Installation location

Install the unit on a firm, stable and flat base.

(The GC-2014ATF model weighs approximately 50 kg.)

3. Corrosive gas and dust

Avoid exposure to corrosive gas and excessive dust to prolong the service life and maintain

optimal unit performance.

condensation forms)

densation forms)

4. Electro-magnetic fields and power supply noise

This unit should not be used near strong electro-magnetic fields. The power supply must

have little or no noise. These items can cause instrument problems.

5. Other precautions

For optimal performance, avoid the following conditions during installation:

(1) Fluctuating ambient temperature.

(2) Temperature changes from heating or air conditioning.

(3) Direct sunlight.

(4) Vibrations.

GC-2014

1

Page 14

1 Installation

1.1 Verification of Installation Location

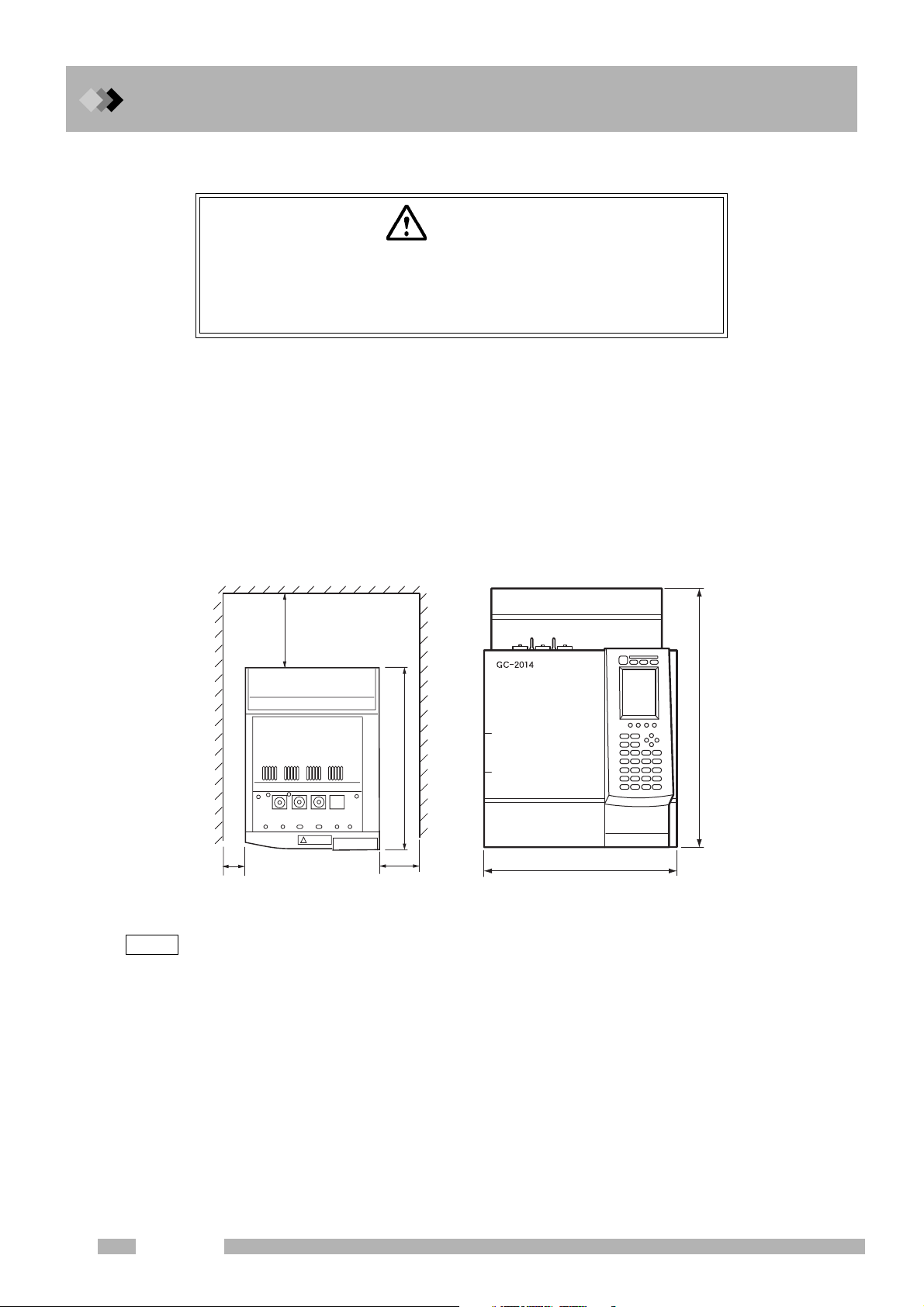

■ Installation clearances

Hot air is exhausted from the vent. Do not place flammable materials

where they will be exposed to the heat.

Hot air is vented at the back of the unit when the column oven cools. Consider the following

during installation.

1. Do not place flammable materials behind the unit.

2. Allow a clearance of 400 mm or more between the back cover and the wall.

3. Allow a clearance of 50 mm or more on the left side.

4. Allow a clearance of 100 mm or more on the right side in order to have a space to open/

close the oven door.

5. Reserve extra space for maintenance and inspection behind the unit.

WARNING

Hot air

NOTE

Minimum 400 mm

Height 690 mm

Depth 607 mm

Width 400 mm

Minimum 100 mmMinimum 50 mm

When the optional exhaust air duct (P/N 221-70675-91) is used, rear space of 200 mm or more is

required.

2

GC-2014

Page 15

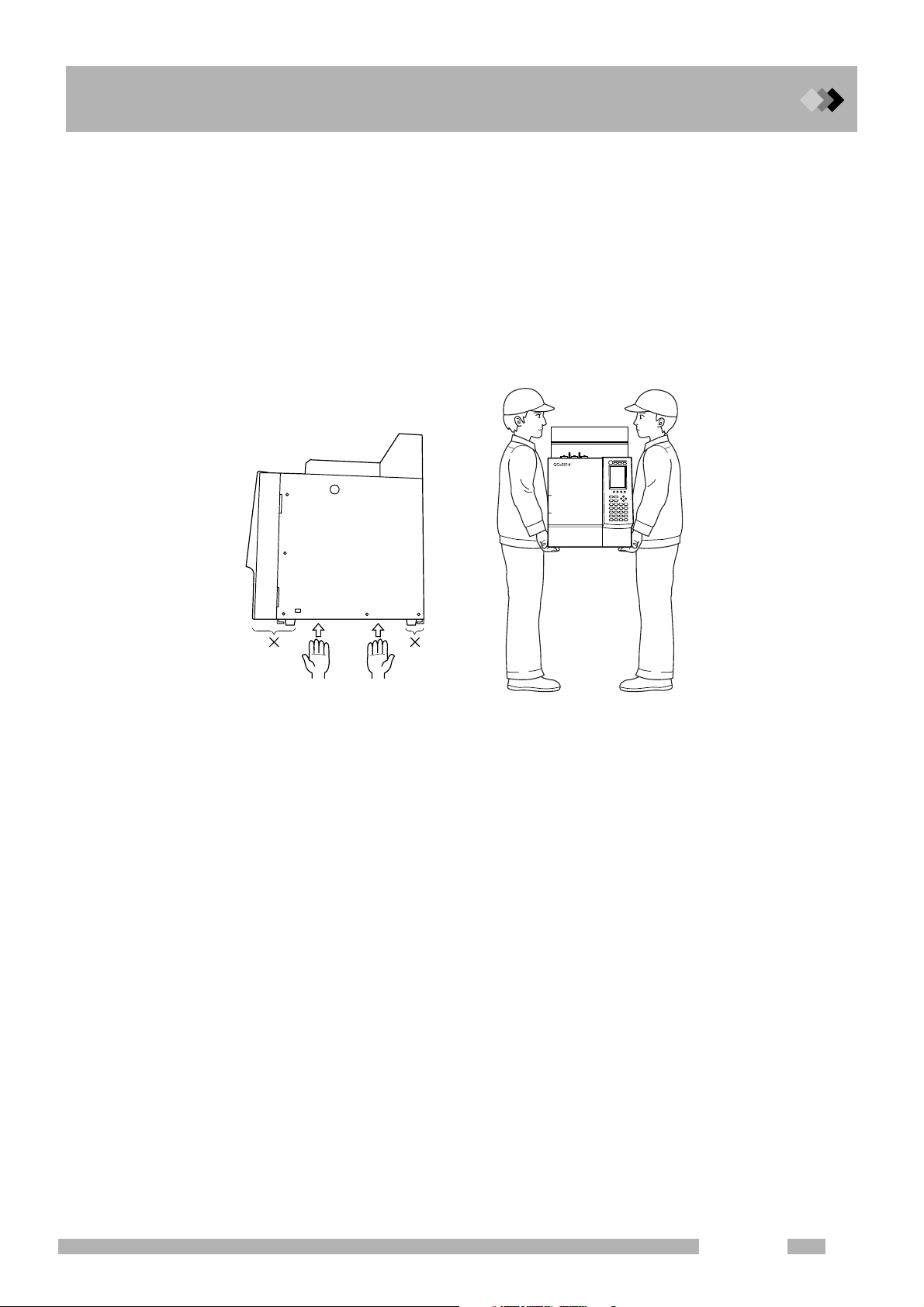

■ Moving the GC

Move the GC carefully so it does not get bumped or jarred.

1. The GC weighs approximately 50 kg (GC-2014ATF).

2. Two people must carry the GC, one on the left and one on the right, with their hands

between the rubber legs on the left and right side of the unit.

3. Do not hold the oven door when carrying the GC because it may break the door.

4. Do not put your hands on the rubber legs or along the front/rear direction of the unit

because your fingers may get trapped under the unit when placing it on a table.

1 Installation

1.1 Verification of Installation Location

GC-2014

3

Page 16

1 Installation

1.2

1.

Before connecting the power supply, verify the following items.

Q Power supply voltage

Use a power source with the following specifications to maintain optimal unit performance.

1.2Power supply and wiring

WARNING

HIGH VOLTAGE

1.Before connecting the power cable to the distribution board, turn

OFF the power to the distribution board.

2.The power supply must have a circuit breaker.

3.Do not place heavy items on the power cable.

Commended power voltage: 115 VAC ± 5 %

230 VAC ± 5 %

Frequency 50/60 Hz

Operating power voltage: 115 VAC ± 10 %

230 VAC ± 10 %

Frequency 50/60 Hz

Q Power supply capacity

Calculate the power supply capacity by considering the total power consumption of the

individual components as shown below.

Connect the power source to a terminal with sufficient capacity.

GC-2014ATF (TCD, FID models):1,950 VA (115 V model)/2,750 VA (230 V model)

Optional temperature control block (INJ, etc.): 150 VA/pc

Maximum power is 2600 VA (115 V model), 3400 VA (230 V model)

NOTE

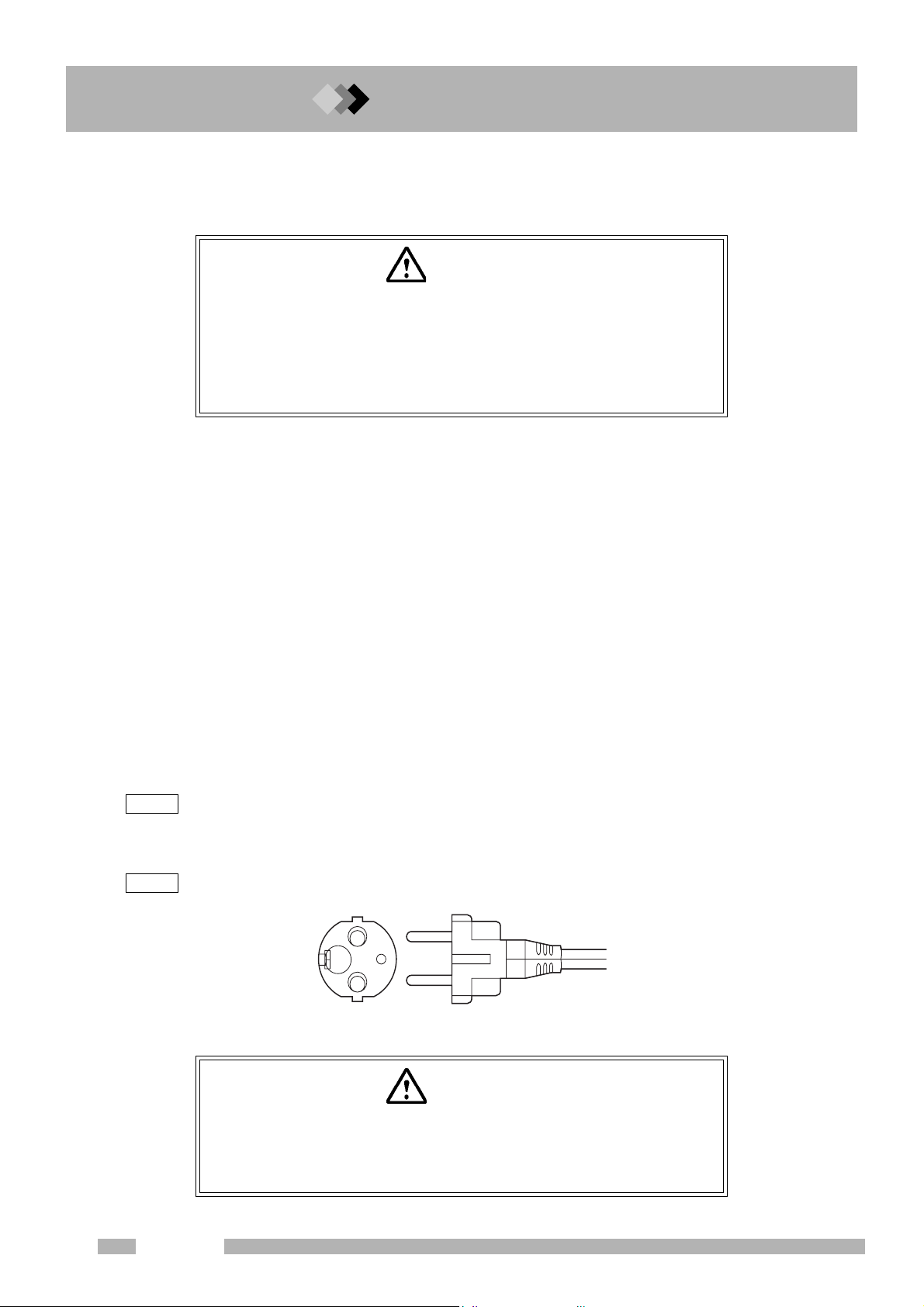

Q Connecting the power cable

NOTE

Performance of the unit may be affected if the power supply voltage fluctuates or the capacity is

insufficient.

The power cable of the 230 V model uses a plug.

Fig. 1.2.1 Plug

WARNING

Make sure to ground the cable properly. Insufficient grounding may cause an

electric shock in the event of a breakdown.

Be careful to wire the plug correctly, as outlined on the next page to avoid

damage to the unit or supply fuse.

4

GC-2014

Page 17

The power cable for 115 V model is color-coded as follows.

Black ... Connected to HOT of AC line.

White ... Connected to NEUTRAL of AC line.

Green ... Grounding (GROUND)

1 Installation

1.2 Power supply and wiring

Black

Power cable

Q Symbol conventions

~ : AC

○ : Off, Open

| : On, Close

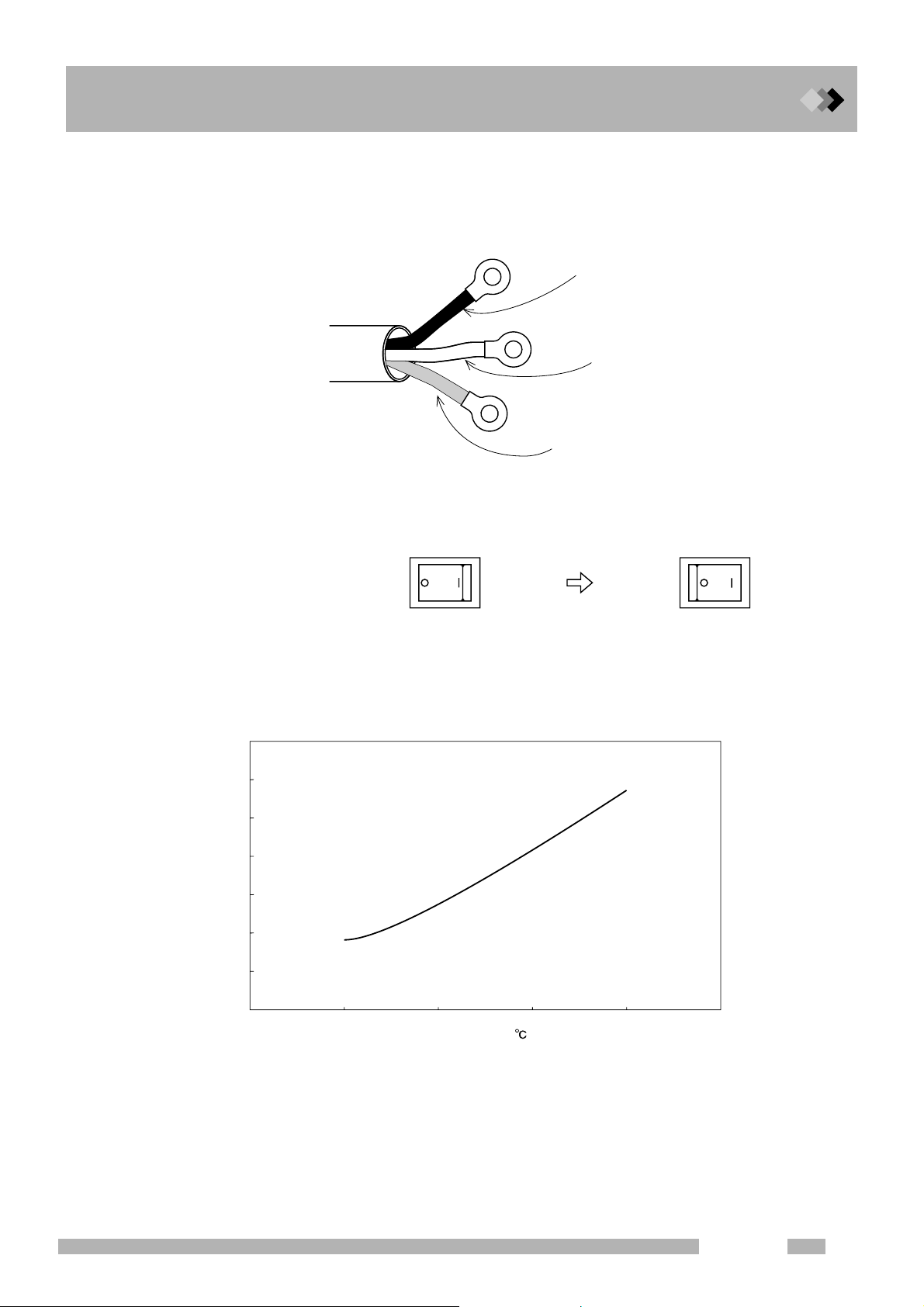

Q Heating energy generation

The following graph shows the heating values generated by the unit.

3.5

3

Fig. 1.2.2 Power cable

OFF status

White

Green

Power switch

ON status

2.5

J/hour)

6

2

1.5

1

Heat generation (×10

0.5

0

0

100 200 300 400

Temperature (

)

Fig. 1.2.3

GC-2014

5

Page 18

1 Installation

1.2 Power supply and wiring

Q Fuse

The following fuses are used in the GC-2014.

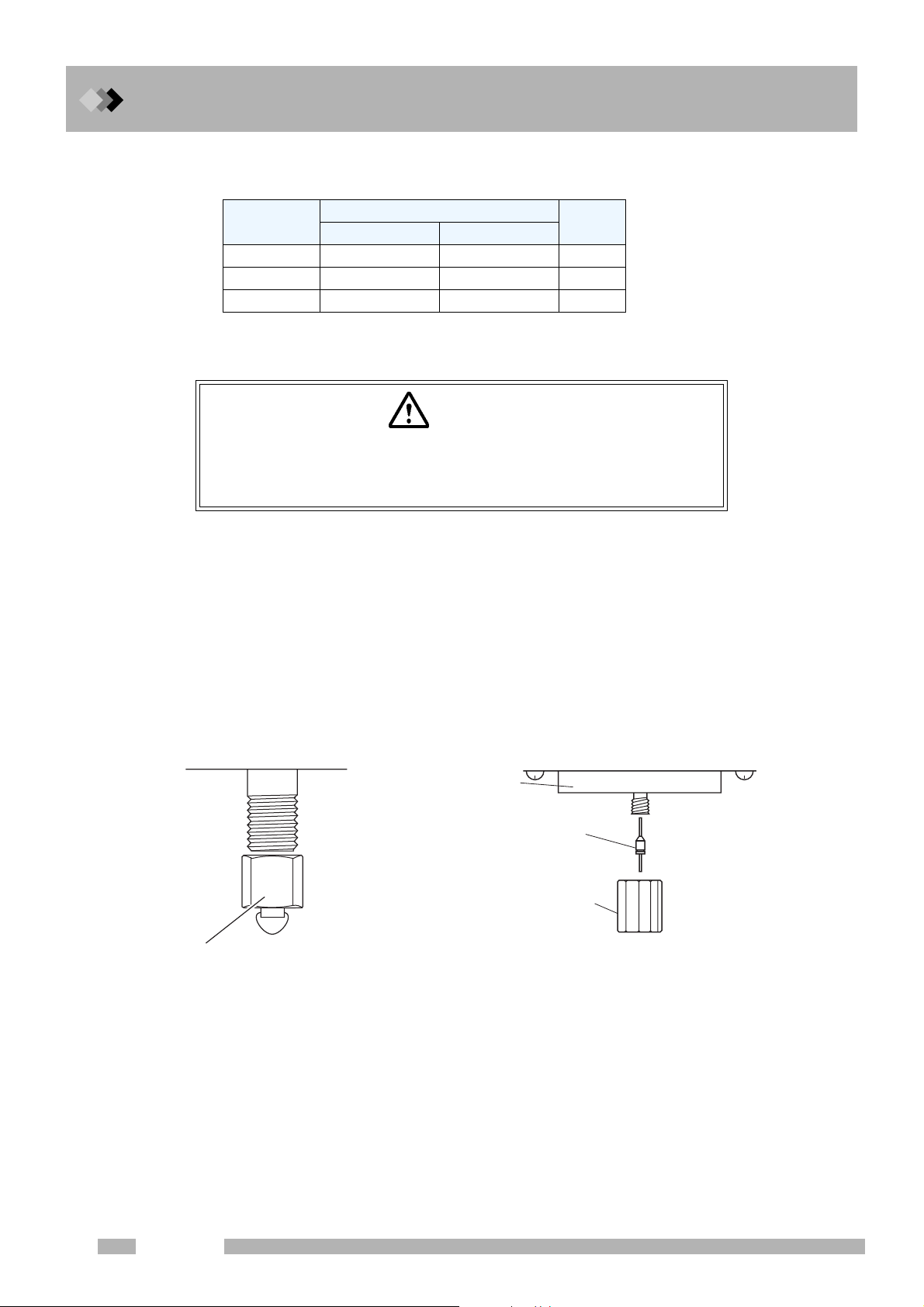

Fuse, No.

F1, F2 15 A/250 V 10 A/250 V T

F3, F4 5 A/250 V 3.15 A/250 V T

F5, F6 5 A/250 V 5 A/250 V T

Rated current/voltage

Q Allowing the GC to dry after transport.

CAUTION

GC-2010 may get wet from humidity in some transport conditions. In

such case “drying-out” is necessary to avoid a short circuit at the

heater in the injection port or the detector.

Under some transport conditions, condensation may form inside the GC components. To

avoid injection port or detector heater unit short-circuits, allow the unit sufficient time to dry

after transport, and follow the procedure below after installation.

(1) Seal the injection port and detector without attaching a column. (Refer to the figure

below.)

(2) Remove the injection ports (INJ) and detectors (DET) from all configured analytical flow

lines to prevent the heater from turning ON.

(3) Set the column oven temperature to 300 °C and start the GC.

(4) Keep the column temperature at 300 °C for 2 hours or more.

Type *

∗Classification depending

on “IEC127”.115 V model 230 V model

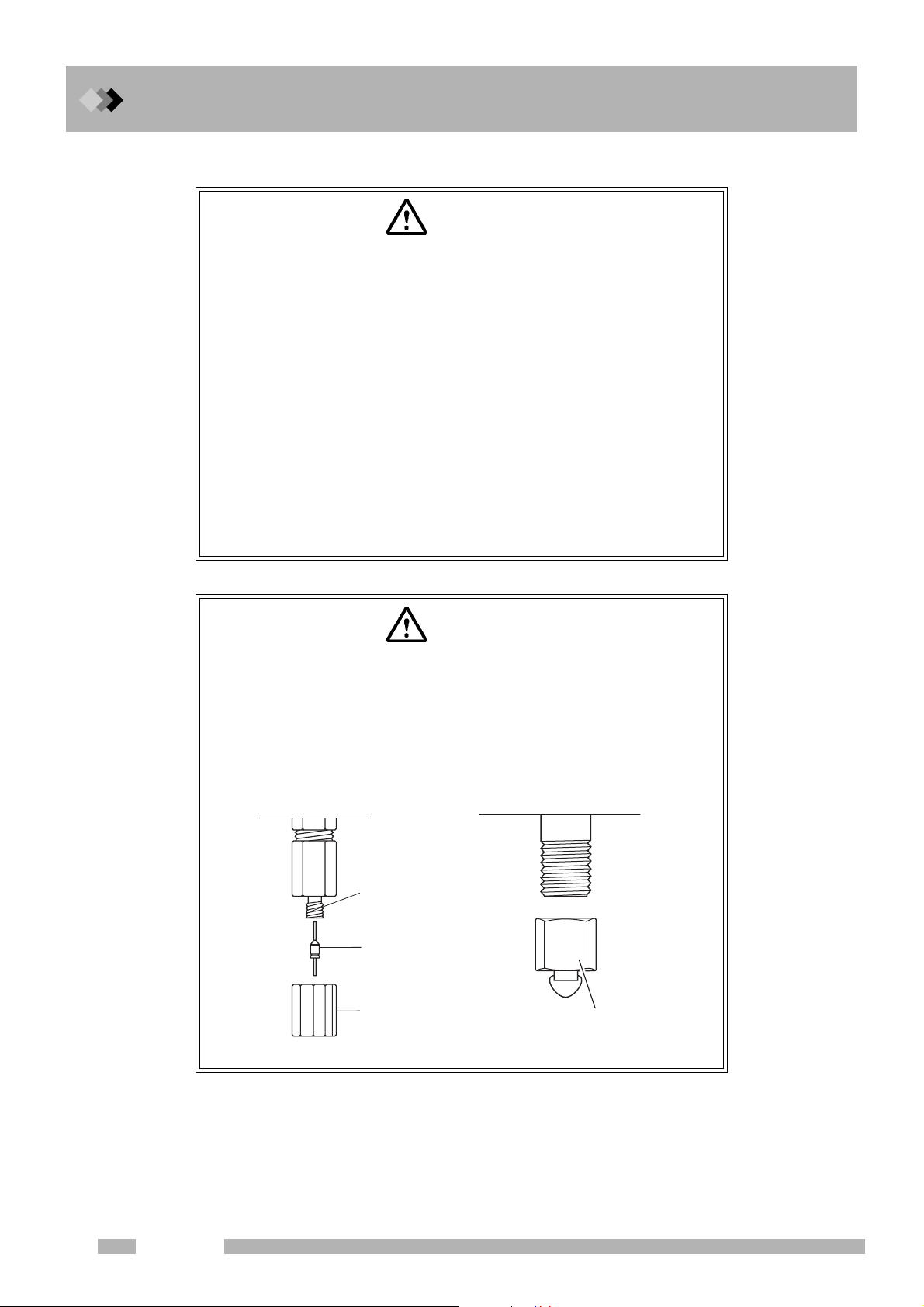

2NWI

When a packed column connecting

joint is used

Thermal

insulation cup

Graphite ferrule

with a wire

Column nut

(or Column nut

of injection port)

When a capillary column connecting

joint is used

6

GC-2014

Page 19

1 Installation

1.3

1.

Q Supply gases

The following gases and associated purity values are required to maintain the optimum

performance of the unit.

For detectors other than FID and TCD, refer to the instruction manual corresponding to each detector.

1.3Gas Supply Plumbing

CAUTION

1.Gas supply pressure should not exceed the maximum pressure

listed below.

Excessive pressure may break pressure control valve or other parts.

2.When sharing a gas source with other instruments, check

specifications of all instruments to be used including this unit and

supply gas so that requirements of all the instruments can be

satisfied at the same time.

1. Gas types

•Carrier gas types

(Packed FID analysis)

Both helium and nitrogen can be used. Nitrogen is more reasonable in terms of price.

(Packed TCD analysis)

Using helium or hydrogen as carrier gas helps analyzing other materials at high

sensitivity. Because hydrogen is flammable, helium is generally used for safety.

However, to analyze helium or hydrogen, use nitrogen or argon as carrier gas. Nitrogen

is convenient to analyze minor components in the air because the nitrogen peak is not

detected when it is used as carrier gas.

(Capillary analysis)

Helium is the most suitable for separation.

Although nitrogen, which is more reasonable than helium, can also be used, the optimum

separation conditions may not be reached.

•Makeup gas types

(Capillary FID)

Both helium and nitrogen can be used. Nitrogen has a slightly higher sensitivity.

(Capillary TCD)

The same gas is used as makeup gas and reference gas for capillary TCD.

Select a type of gas by the same method to select carrier gas.

2. Gas purity

Helium (carrier gas, makeup gas) : 99.995 % or higher

Nitrogen (carrier gas, makeup gas) : 99.995 % or higher

Argon (carrier gas, makeup gas) : 99.995 % or higher

Hydrogen (FID detector gas) : 99.995 % or higher

Air (FID detector gas) : Dry air (oil and other organic components eliminated)

Compressed air(must be suppressed by an oil-free

compressor and dehumidified)

GC-2014

7

Page 20

1 Installation

1.3 Gas Supply Plumbing

3. Gas supply pressures

Carrier gas 300 - 980 kPa (Hydrogen: 300 - 500 kPa)

Makeup gas 300 - 980 kPa

Hydrogen 300 - 500 kPa

Air 300 - 500 kPa

NOTE

The relationship of kPa and bar is as follows

100 kPa = 1 bar

Convert units between kPa and kgf/cm2 as follows.

1 kPa = 1.0

1 kgf/cm2 = 98.1 kPa

Convert the units between kPa and psi as follows.

1 kPa = 1.45 × 10

1 psi = 6.89 kPa

2

× 10-2 kgf/cm

-1

2

psi

8

GC-2014

Page 21

Q High pressure gas cylinder precautions

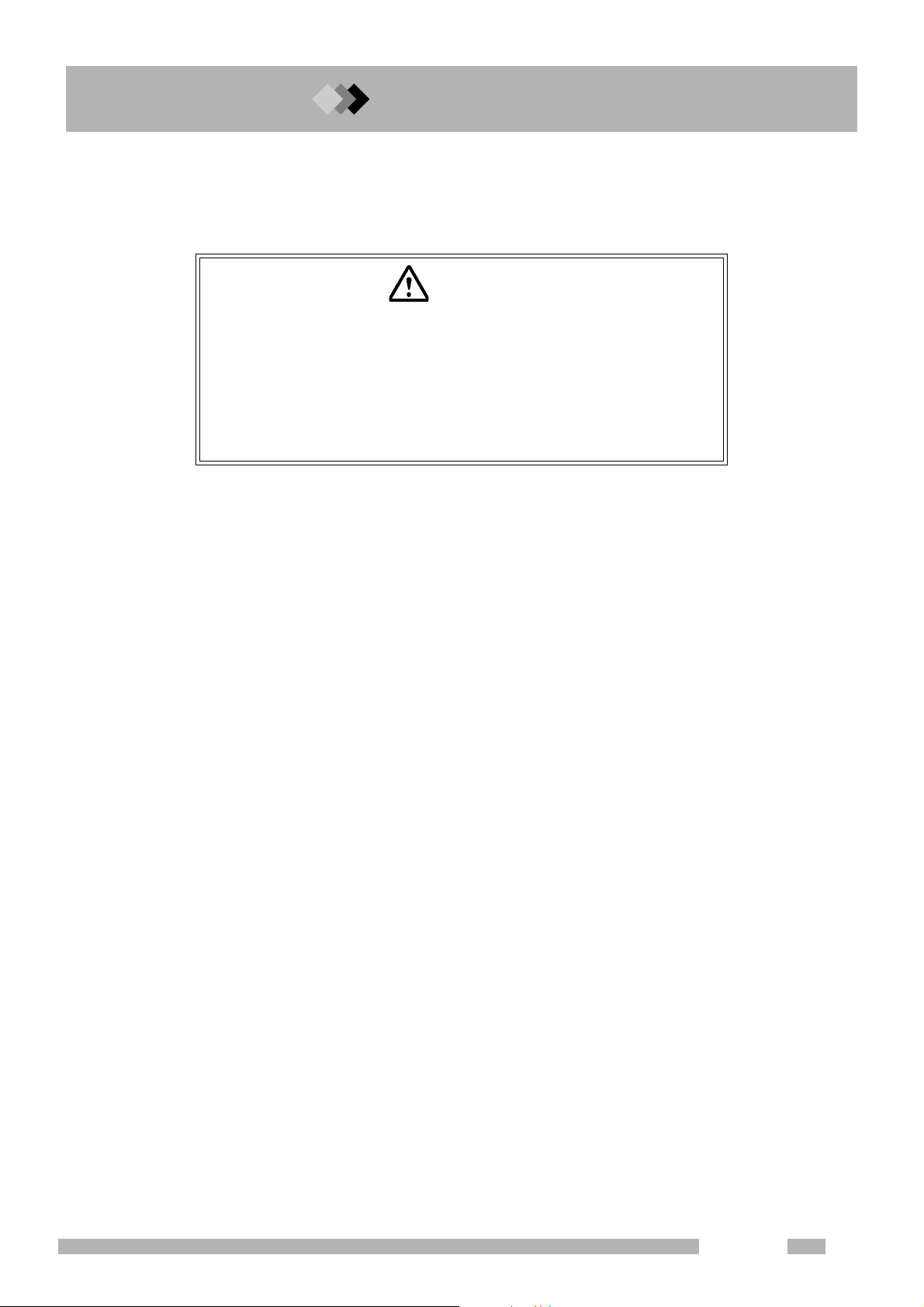

WARNING

HIGH PRESSURE

Gas cylinders are under high pressure. When handling gas cylinders,

instruction and safety measures provided by the gas supplier must be

strictly observed to prevent accidents.

General precautions are provided below.

Consult state and local regulations for specific precautions.

Keep gas cylinders away from the lab, preferably outdoors, but not exposed to direct sunlight. The area must be well-ventilated. Use tubing to bring the gases to the lab.

The temperature of gas cylinders must not exceed 40 °C. Flammable items must be kept at

least 2 m from a gas cylinder.

When using high pressure gases, pay strict attention to ventilation, and perform daily leak

checks. In particular, when using flammable gases (such as hydrogen), never smoke or

allow open flame within 5 m of the equipment. Fire extinguishers must be present.

Secure gas cylinders firmly with cylinder clamps so they cannot fall over. Use oil-free pressure valves only. Never use tubing which has contacted oil. When finished with the gas,

tighten the main valve of the cylinder immediately.

1 Installation

1.3 Gas Supply Plumbing

GC-2014

9

Page 22

1 Installation

1.3 Gas Supply Plumbing

Q Precautions on handling hydrogen gas

WARNING

HYDROGEN GAS PRECAUTIONS

Hydrogen can explode if it is allowed to accumulate in a poorly ventilated area.

1.Connect gas lines correctly. Hydrogen is released into the room if

the tubing is accidentally connected to the air inlet.

2.When the unit is not in use, close the main valve of the hydrogen

gas cylinder. Check for leaks at the main valve.

3.Every time the unit is used, check for leaks along the flow line from

gas cylinder to the unit interior.

4.To prevent an explosion due to a hydrogen gas leak, the room in

which the unit is used should be well ventilated. Prohibit the use of

open flame in this room.

5.Close the main valve of the hydrogen cylinder immediately after

completing the analyses. Then, turn OFF the unit and perform

normal shut-down procedures.

WARNING

HYDROGEN GAS HANDLING PRECAUTIONS

The accumulation of hydrogen gas inside the column oven can cause

an explosion.

Close all hydrogen regulator valves not in use and stop gas supply.

(When a manual regulator valve is used, turn its control to make the

pressure zero. For APC, turn off the APC for hydrogen gas.) Seal the

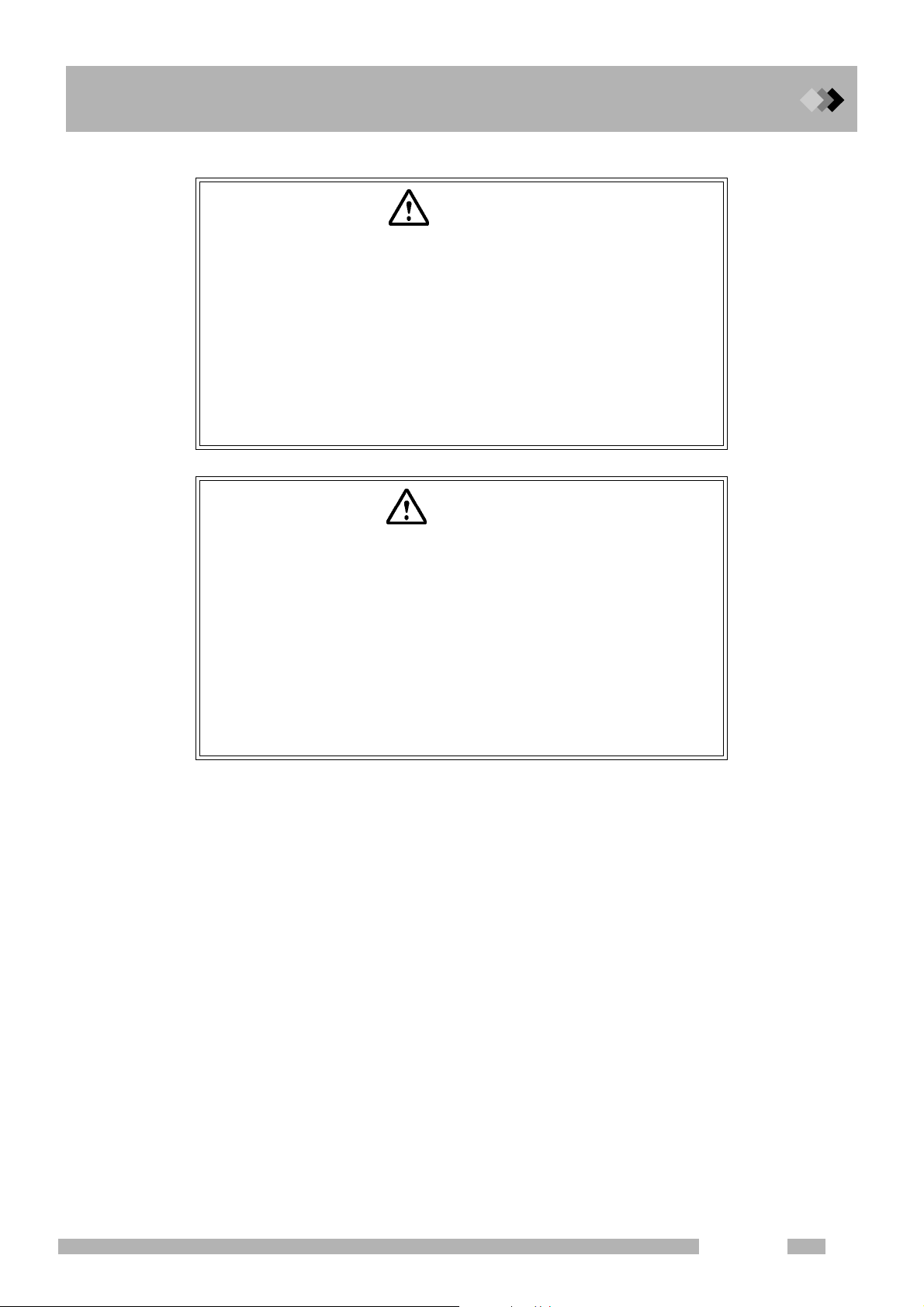

column connection.

Capillary adapter

Graphite ferrule

with a wire

Column nut

When a detector that uses hydrogen gas is not in use

Plug

10

GC-2014

Page 23

1.3 Gas Supply Plumbing

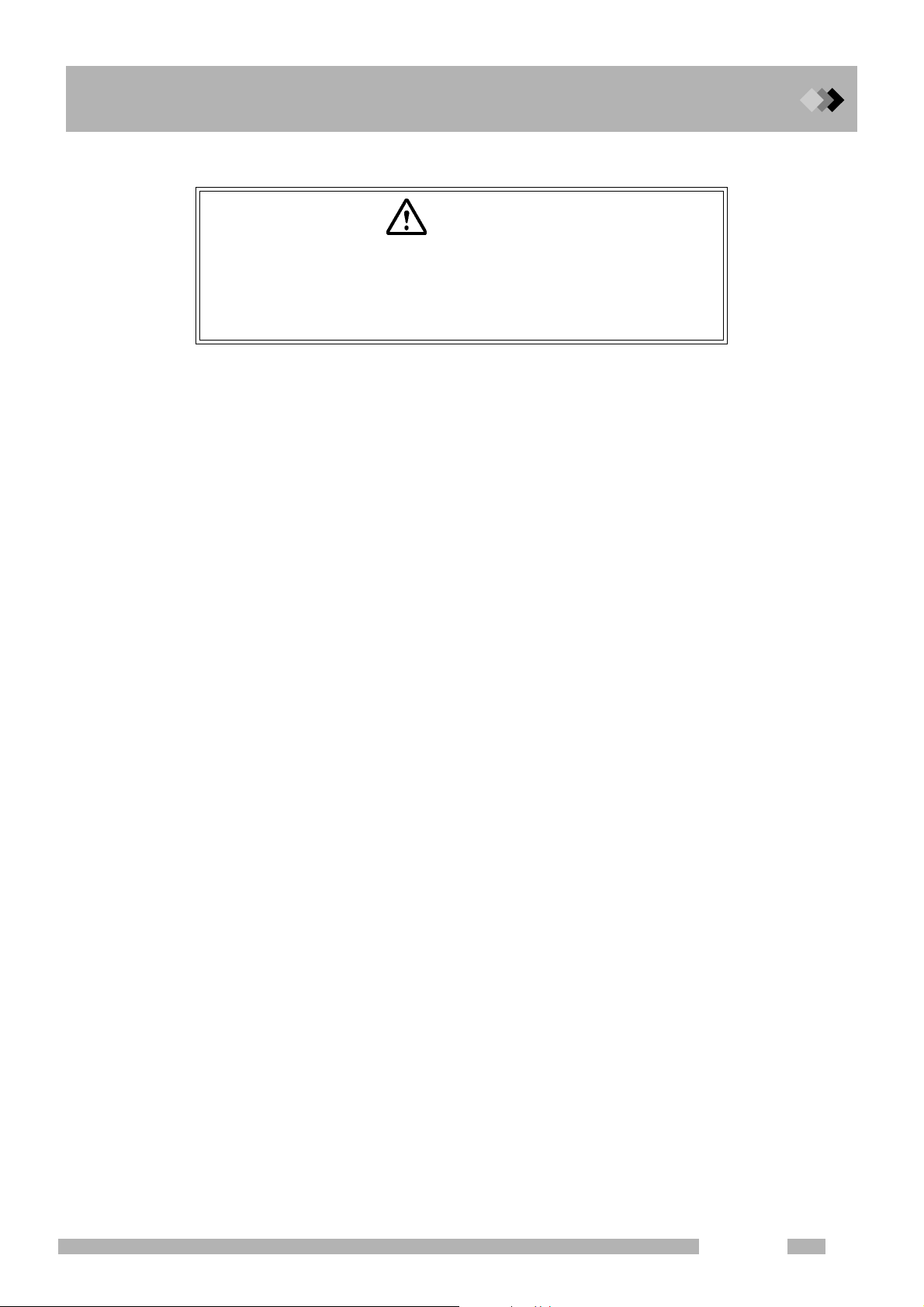

CAUTION

Hydrogen gas supply precautions

Make sure that the supply pressure to the flow controller does not

exceed 500 kPa.

If the flow controller fails with a hydrogen gas supply pressure over

500 kPa, a dangerous situation exists. Lange amounts of leaking

hydrogen could cause the FID flame to expand out of the detector.

Hydrogen gas is lighter than air. If it leaks, it can accumulate near the

ceiling. Pay strict attention to ventilation so that leaking hydrogen is

vented out of the room and cannot accumulate.

WARNING

1 Installation

Hydrogen carrier gas precautions

If much hydrogen gas is released into the poorly ventilated room, it

may cause the explosion.

1.In order to prevent hydrogen gas accumulate in the room, attach

tubes to split vent, purge vent, TCD vent and ECD vent. Discharge

the gas to open air or a ventilation equipment (such as the draft

chamber).

2.Install the GC in the well ventilated area. (Ex. in the draft chamber)

3.In order to measure hydrogen gas concentration, equip a hydrogen

gas sensor in the room. Keep the hydrogen concentration low.

GC-2014

11

Page 24

1 Installation

1.3 Gas Supply Plumbing

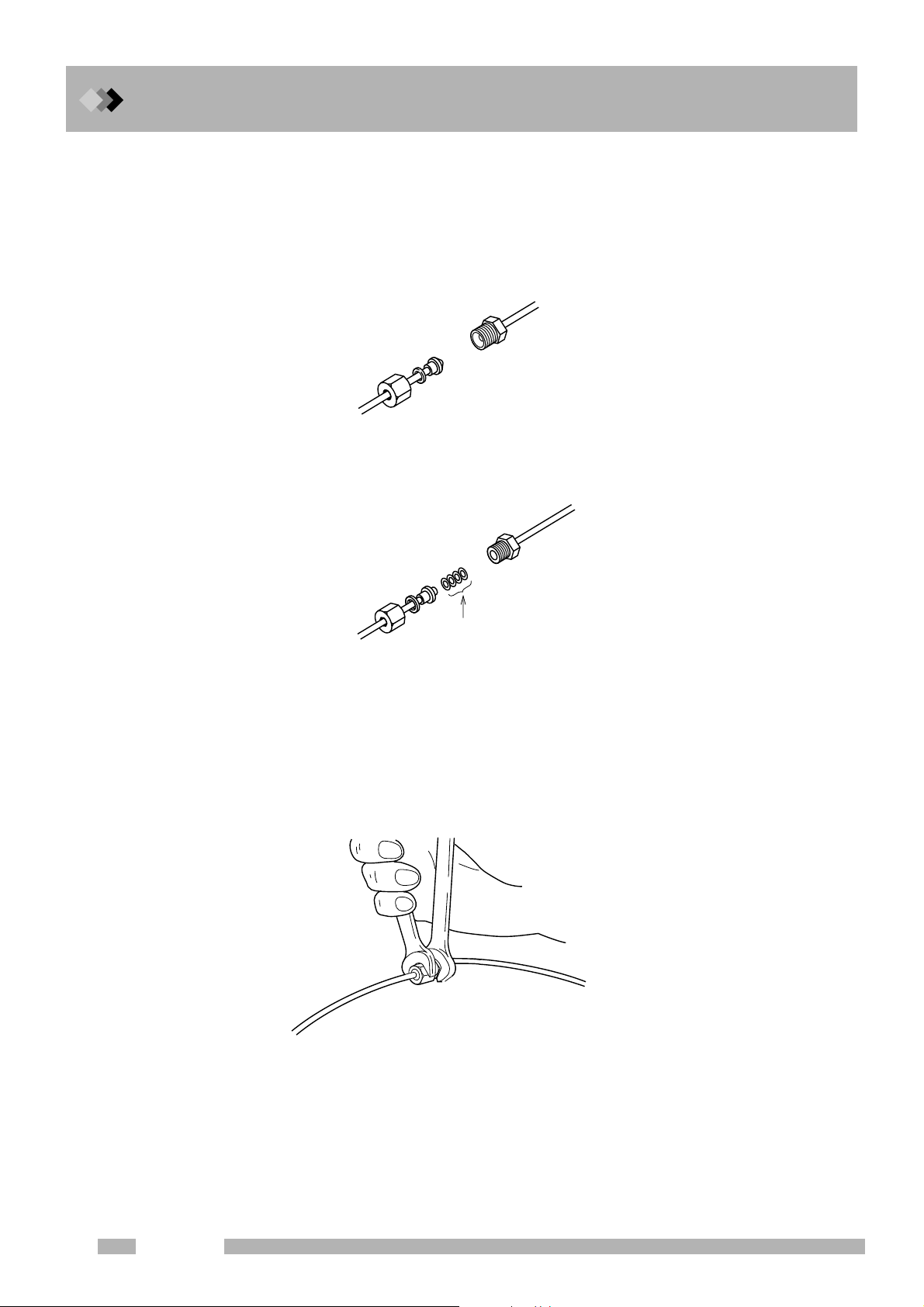

Q Supply gas tubing

There are two types connections in the Gas Chromatograph: Type M and Type G. Type M

connections are located at the main tubing connections in the instrument interior and exterior. The metal fittings contact directly.

Type G connectors, which are used in high temperature areas, are connected by tightening

three to five aluminum gaskets between the fittings.

MF fitting

MM fitting

Fig. 1.3.1 Joining Type M fittings

GF fitting

Alminum gaskets (3-5 pcs)

GM fitting

Fig. 1.3.2 Joining Type G fittings

Tightening the tubing connections

To ol s

2 wrenches 10×12 (standard accessory)

Use the 12 mm wrench for Type M connections and the 10 mm wrench for type G

connections.

12

Fig. 1.3.3 Tightening the joints

GC-2014

Page 25

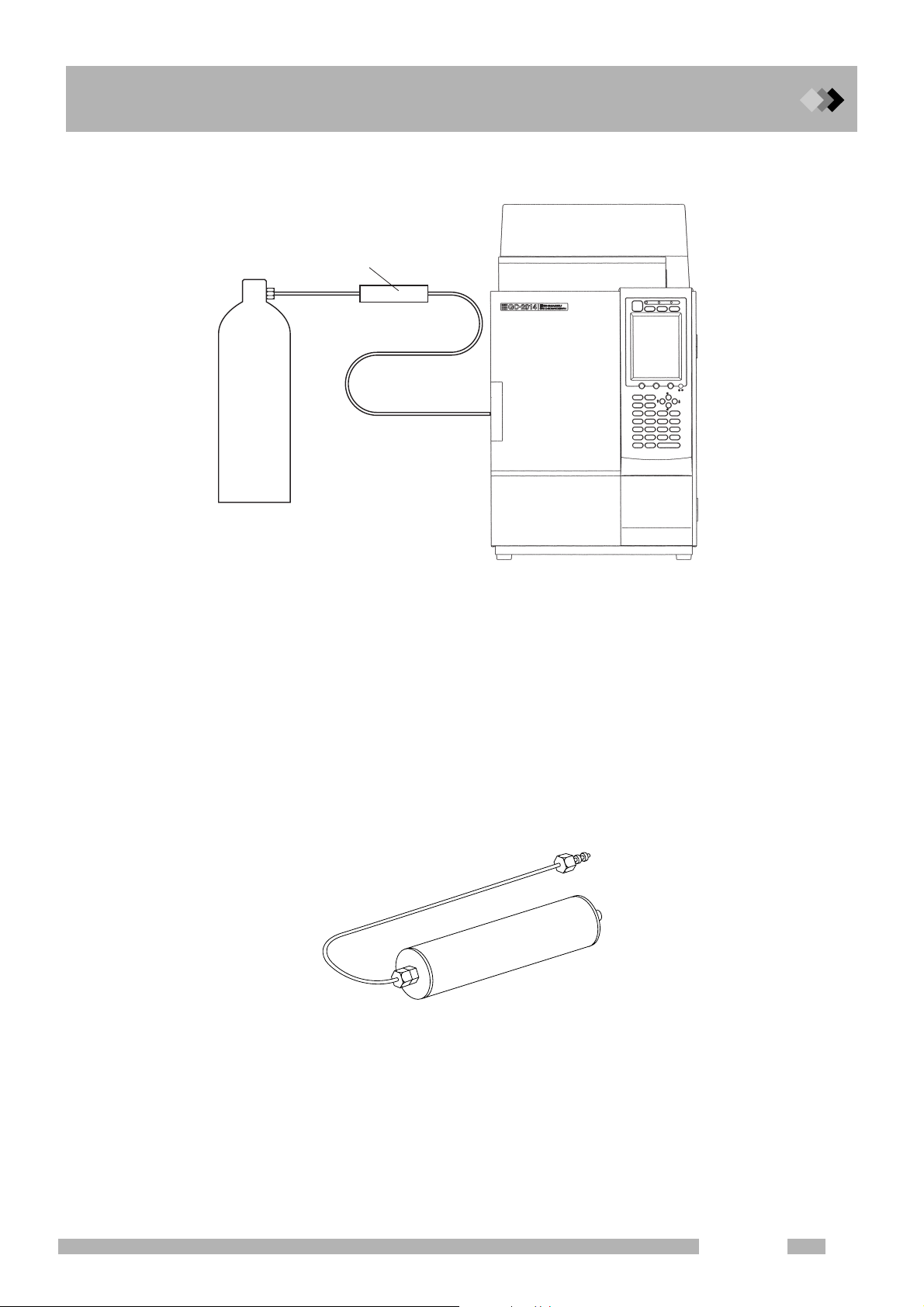

Q Tubing between the gas cylinder and gas chromatograph

Gas filter <option>

Gas

cylinder

1 Installation

1.3 Gas Supply Plumbing

Fig. 1.3.4 Tubing between the gas cylinder and gas chromatograph

Use tubing with a 3 mm O.D. and 2 mm I.D. between the gas cylinder and gas chromatograph.

The use of a gas filter is highly recommended. Contaminated tubing or poor quality gases

can interfere with baseline stability.

<Option> Gas filter (P/N 221-05619-01)

This absorbs organic compounds and moisture in the supply gas, improving its

purity. The filter can be regenerated by baking in the GC oven at 250 °C with

30 mL/min carrier gas purging the filter.

Capacity: Approx. 200 mL

Absorbent: Molecular sieve 5 A

Fig. 1.3.5 Gas filter

GC-2014

13

Page 26

1 Installation

1.3 Gas Supply Plumbing

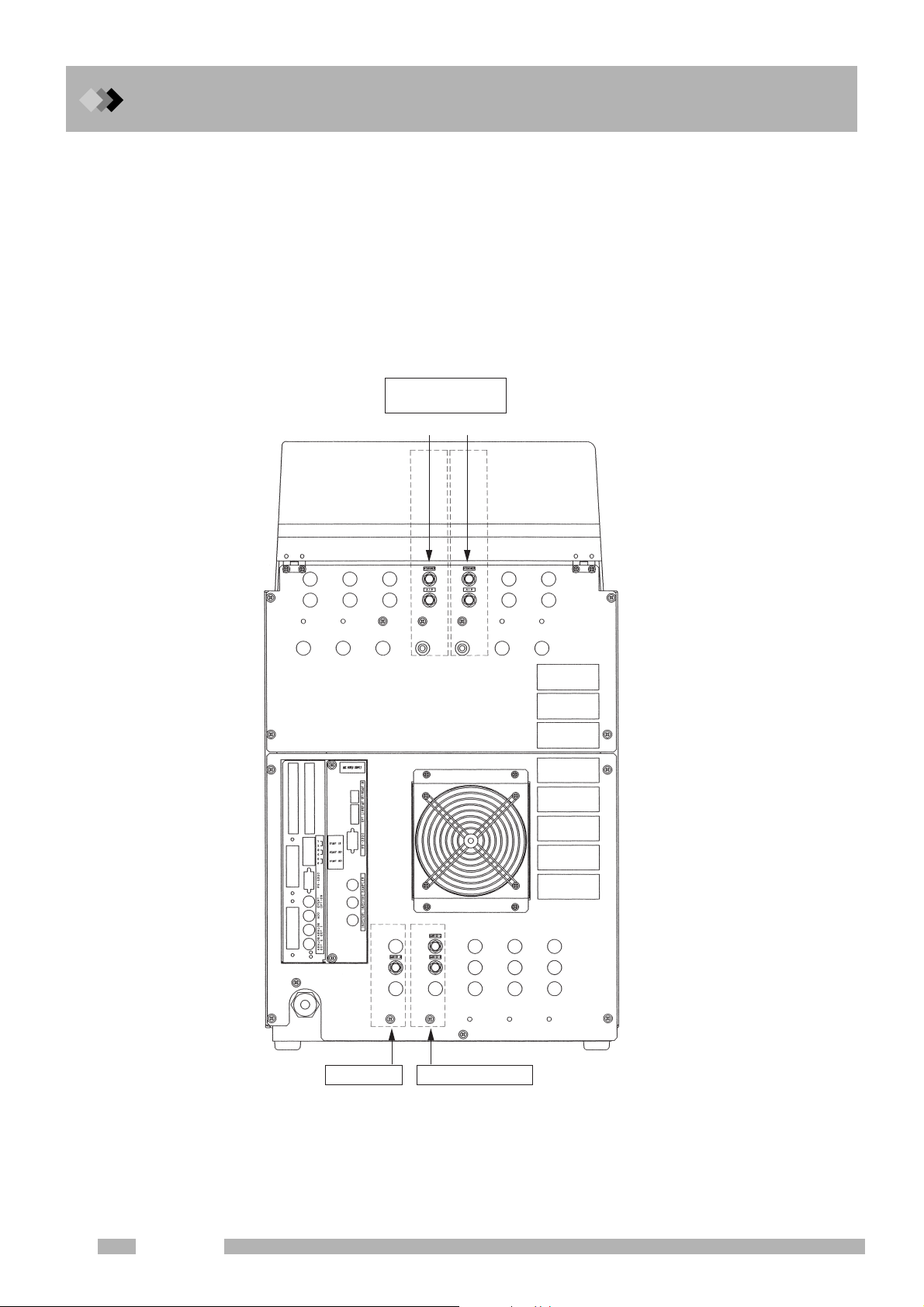

Q Gas chromatograph tubing connections

Connections are provided on the rear panel of the unit for connecting external tubing.

They are labeled as follows.

Carrier gas ..................... CARRIER

(“L” and “R” mean the left and right side of dual INJ.)

Makeup gas ................... MAKE UP

Hydrogen ....................... HYDROGEN

Air .................................. AIR

Flow controller

for the dual FID

Right Left

14

AFC for SPL AFC for the dual INJ

Supply the carrier gas for the left inlet of the dual INJ to CARRIER L

and the carrier gas for the right inlet of the dual INJ to CARRIER R.

Fig. 1.3.6 Plumbing (Example of the GC-2014ATF+SPL model)

GC-2014

Page 27

Q Checking for gas leaks

After plumbing the unit, check for gas leaks according to the following guidelines.

(1) Open the main valve of the gas cylinder.

(2) Adjust the gas supply to the specified pressures.

(3) Check for leaks with leak detecting fluid (option) or soapy water on all connections.

Bubbles can be observed if a leak exists.

(4) If a leak is detected:

• Further tighten the connection, or retighten it.

• Replace the seal material.

(5) Wipe off the leak detecting fluid or soapy water using a wet cloth.

Electronic leak detectors can also be used for hydrogen and helium leaks.

<Option> “Snoop” Gas leak detecting fluid (P/N 670-11514)

1 Installation

1.3 Gas Supply Plumbing

LIQUID LEAK DE

Fig. 1.3.7 Leak detecting fluid

GC-2014

15

Page 28

1 Installation

1.3 Gas Supply Plumbing

This page is intentionally left blank.

16

GC-2014

Page 29

2 Before Use

2.1

2.2.

2.1Setting Analytical Flow Lines

GC-2014 does not operate normally without setting analytical flow lines. Always set

analytical flow lines before using the unit. Refer to “Chapter 3. Installing Packed Columns

and Setting Analytical Flow Lines” and “Chapter 4. Installing Capillary Columns and Setting

Analytical Flow Lines” for detailed descriptions.

Setting analytical flow lines creates the following benefits during operation.

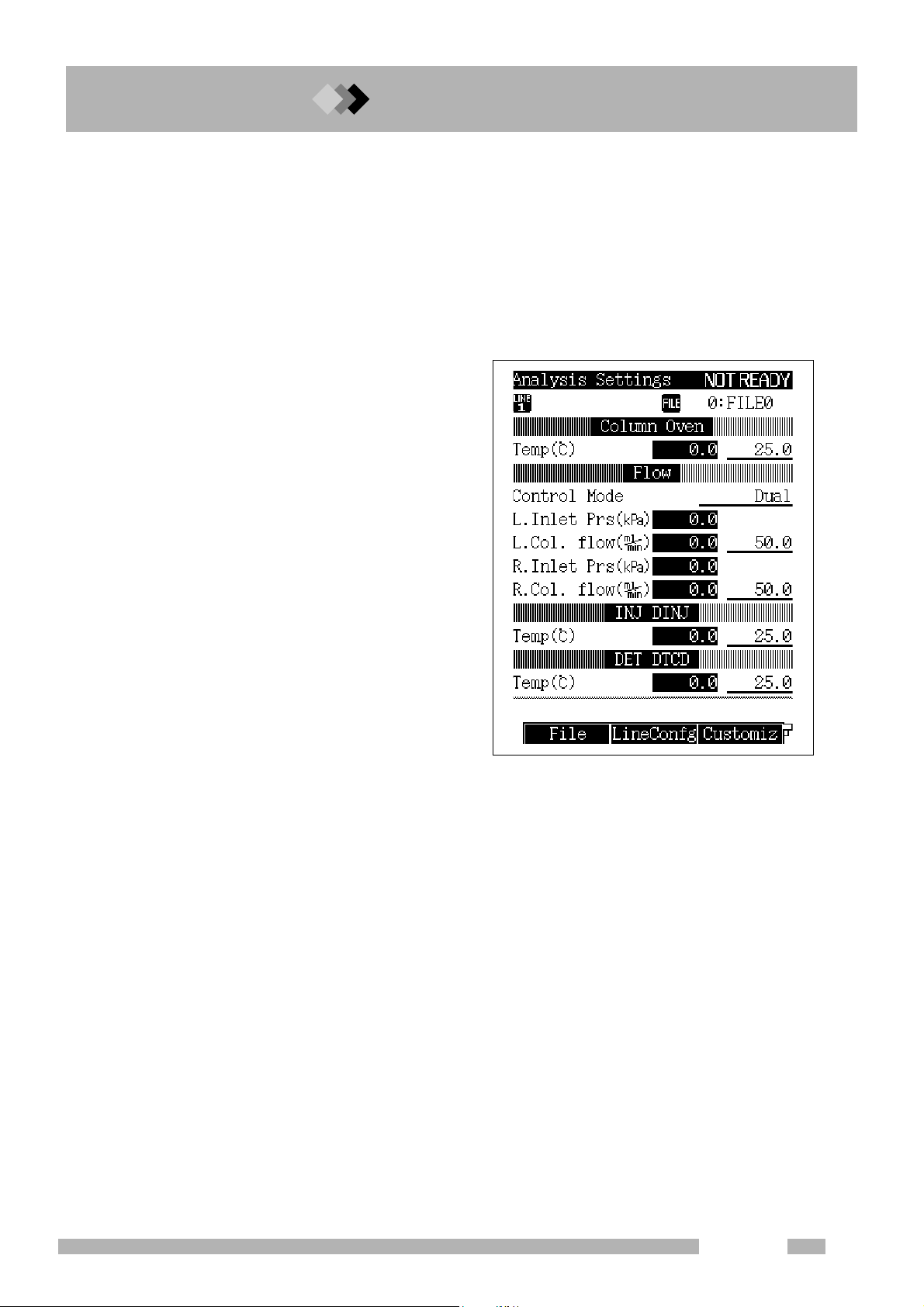

1. Conditions of analytical parameters for

each line can be set and monitored.

For example, when the [SET] key of

the gas chromatograph is pressed,

temperatures of columns, injection

ports, and detectors as well as carrier

gas flow rate can be set and monitored

on a single screen.

2. A protective mechanism operates to

foster more stable operation conditions.

For example, when a carrier gas

cylinder becomes empty while TCD is

used, the flow controller detects an

error and automatically lowers the

column temperature and stops

conduction to the TCD filament in order

to prevent damage to the column and

TCD filament.

GC-2014

17

Page 30

2 Before Use

2.1 Setting Analytical Flow Lines

Q Analytical flow lines

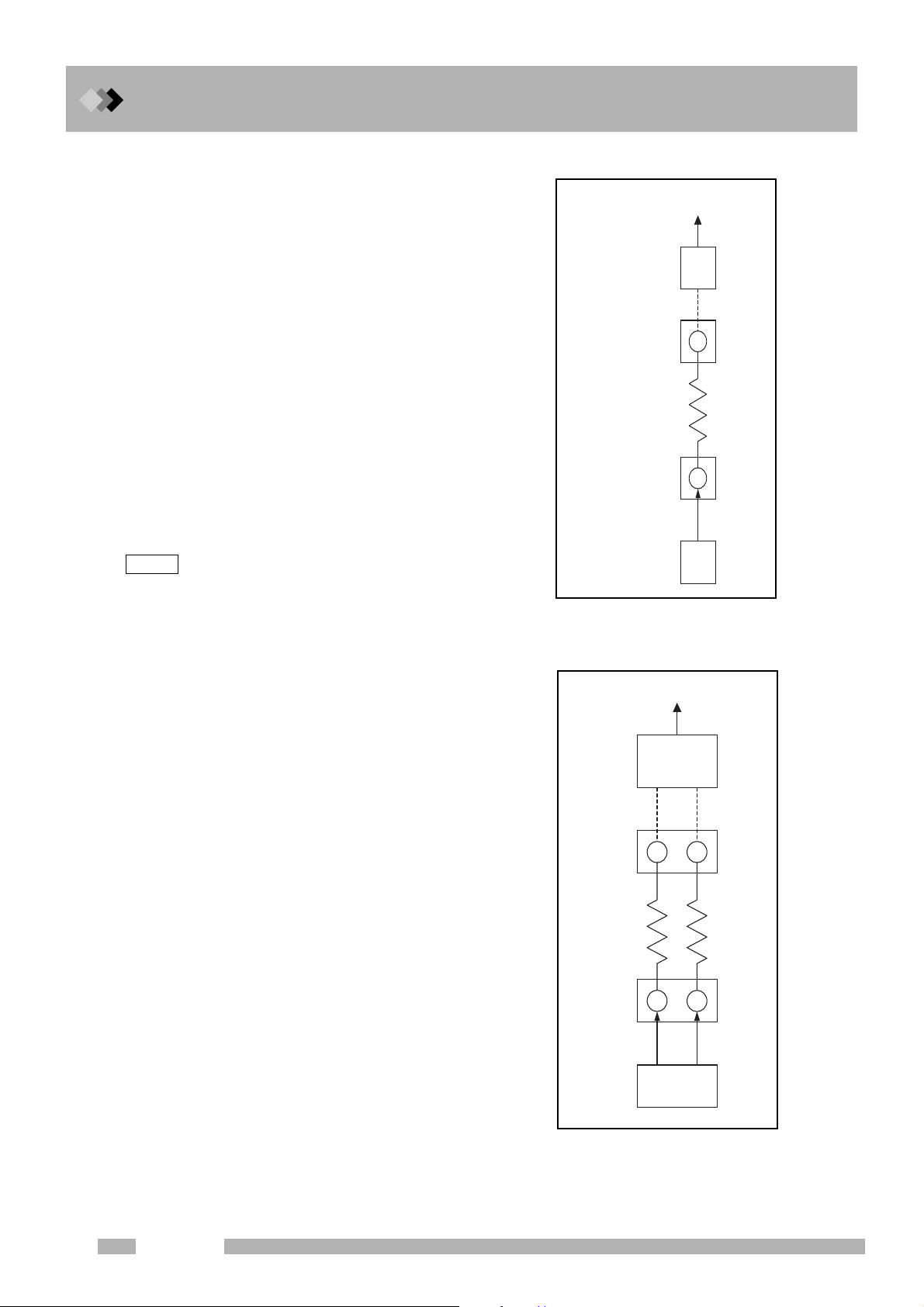

An analytical flow line consists of the flow

controller, injection port, column, detector cell,

and detector amp as shown in Fig. 2.1.1.

During analysis, the flow controller feeds

carrier gas to the injection port, a sample

injected to the injection port goes through the

column to reach to the detector cell, and a

detected signal is amplified by the detector

amp to be outputted.

In order to allow the gas chromatograph to

recognize these units as an analytical flow line,

specification for the connection between them

is necessary.

For regular analysis, specify the combination

between an injection port and detector to

which a column is connected. (Refer to the

following page for setting procedures.)

Outputted Signal

Detector

amp

Detector

cell

Column

Injection

port

NOTE

Connections of the flow controller(s) and injection

port(s) and connections of detector cell(s), and

detector amplifier(s) are specified by a serviceperson

at shipment or installation. They do not need to be

specified for regular analysis.

Fig. 2.1.2 shows a representative example of

the line configuration for packed column FID

analysis using the GC-2014.

In this example, the dual INJ and dual FID are

connected with two columns and the difference

between two FID signals is outputted from the

dual FID amp. Two columns are used because

the dual INJ and dual FID are recognized as a

single unit respectively. However, this is

considered to be a single line.

flow

comtrol

Fig. 2.1.1 Concept of

analytical flow lines

Outputted Signal

Dual FID

amp

Dual FID

Column(L) Column(R)

Dual INJ

L R

L

R

18

GC-2014

Dual AFC

(L) (R)

Fig. 2.1.2 An example of

analytical flow lines

Page 31

■ How to set lines

(1) Press the [SET] key then press the

[PF2] key (Line Config).

(2) Move the cursor to the unit to be set in a

line and select a line using [

Make sure to specify an injection port

and a detector to which a column is

connected in the same line. Any

number from LINE1 through LINE4 can

be selected.

2 Before Use

2.1 Setting Analytical Flow Lines

Y ] [ Z ] keys.

■ Precautions for setting analytical flow lines

CAUTION

Set analytical flow lines correctly.

Incorrectly set analytical flow lines hinder the unit's normal operation

and may also damage columns or detectors at worst.

1. Specify units to be used as part of a line.

Only units specified as part of a line are temperature-regulated.

Gas is controlled only for injection ports (flow controllers) specified as part of a line.

Examples

• If an injection port that a column is connected is not specified as part of a line, carrier

gas does not flow. If the column's temperature rises in this condition, the column may be

damaged.

• To keep feeding gas to units or maintain their temperature even though they will not be

used for analysis for a while, specify the units as part of a line.

2. Remove the units not in use from a line.

Examples

• If a detector without a column stays on a line, it may damage TCD filament or cause an

error such as FID ignition error.

• If the setting for the flow controller is turned OFF without removing an injector port

without a column from a line, an error is detected and the protection mechanism works

to lower the column temperature.

• If a split/splitless injection port (SPL) without a column is not removed from a line, an

error is detected and the protection mechanism works to lower the column temperature.

GC-2014

19

Page 32

2 Before Use

A

A

2.2

2.2

2.

GC-2014 can output analog signals for two channels, and detector signals to be outputted to

each channel can be set using keys. When a detector is changed, output can be changed

using keys without changing the connection on the back of the GC.

■ Connecting the Chromatopac signal cable

Connect the attached Chromatopac signal cable to the connector (ANALOG OUT1 or 2) on

the back of the GC. (Fig. 2.2.1)

Using this cable, analog signals can be outputted and the Chromatopac can be started when

the GC starts. (Refer to “16.6.9 Setting the link device code”)

Outputting Analog Signals to the Chromatopac

NALOG OUT 1=Ch1

NALOG OUT 2=Ch2

Fig. 2.2.1 Connecting the Chromatopac signal cable

1

2

3

4

5

6

232C

-

RS

EVENT

OPTION

AOC

ANALOG

OUT 1

ANALOG

OUT 2

START IN

READY OUT

START OUT

AOC POWER SUPPLY

OUT/READY IN

232C OP1 LINKSTART

RS

INJECIOR1 INJECIOR2 SAMPLER

Back of the GC

AOC built-in power source

20

GC-2014

Page 33

■ Setting analog signal output

1. Set a line

(1) Press the [SET] key then press the

[PF2] key (Line Config).

(2) Specify an injection port and detector

to which a column is connected in the

same line.

The screen on the right shows an

example where a column is connected

to the dual INJ and dual FID.

2 Before Use

2.2 Outputting Analog Signals to the Chromatopac

NOTE

Without specifying a detector in a line, the screen to set analog signal output below does not appear.

2. Set analog signal output.

(1) Press the [DET] key.

(2) The outlined part is a parameter for

analog signal output for all detectors.

Set the parameter following the

description below.

For “Background signal save/

compensation” and “Detector signal

subtraction,” refer to “Chapter 13

Detector [DET].”

“Signal Output Port”

Specify a connector number to output

analog signals.

(ANALOG OUT 1 = Ch1, ANALOG OUT 2 = Ch2)

Channel number of a detector specified at

the last is effective. (If TCD signal was

outputted to Ch1 formerly and FID signal is

newly specified to be outputted to Ch1 as

shown in the screen on the right, TCD

signal becomes OFF automatically.)

GC-2014

21

Page 34

2 Before Use

2.2 Outputting Analog Signals to the Chromatopac

“Signal Attenuation” or “Signal Range”

Names of items automatically change according to types of analog signals as listed below.

Set multiplying power (attenuation rate) of output signals for all types. Change the setting

when the peak obtained by the data processing unit is saturated.

Signal attenuation: When analog signal type is wide

Output signal becomes smaller when the setting is changed from x 1

→ x 2

-3

→ x 2

-4

Signal range: When analog signal type is linear

Output signal becomes smaller when the setting is changed from x1

→ x 10

-3

→ x 10-4

“Analog Signal Type”

Set a signal type according to the type of Chromatopac to be connected. If this is set

incorrectly, data cannot be processed correctly.

Wide : C-R8A, C-R7A, C-R7Aplus

Linear: Chromatopacs other than C-R8A, C-R7A, C-R7Aplus

■ Calibration of analog wide range signal

When the GC is connected to the Chromatopac (C-R8A, C-R7A, C-R7Aplus) with a

chromatopac signal cable and the “analog signal type” described above is set to “Wide

calibration is necessary in order to match the zero level of the GC and Chromatopac.

-1

→ x 2

→ x10-1→ x10

→ x 2

-2

-2

,”

Perform calibration in the following cases.

• When the GC and Chromatopac are connected for the first time (during installation)

• When the GC or Chromatopac is changed with other instrument.

• When a connection channel number is changed by switching a connector on the GC side

• When a two-channel board is installed on the Chromatopac and a connection channel

number is changed by switching a connector on the Chromatopac side

NOTE

Calibration is not necessary when a detector is changed (e.g. when signal to be outputted to Ch1 is

changed from TCD to FID).

The following is calibration procedures.

(1) Press the [DET] key on the GC to turn OFF the detector control.

(2) Load the BASIC calibration program.

C-R7A, C-R7Aplus: Type “LOAD “ZCALIB”” on the [Win3] key screen.

C-R8A: Type “LOAD “8.ZCALIB.BAS”” when key input is possible.

(3) Press the [RUN] key of the Chromatopac.

(4) Enter the Chromatopac channel number

when the following sentence is displayed.

C-R7A, C-R7Aplus: “Channel No. (1:CH1 2:CH2) : ?”

C-R8A: “CH No. (1:CH1 2:CH2) : ?”

(5) Enter “Y” when the sentence below is displayed to save calibration results on the

Chromatopac. If they are not saved on the disk, calibration is required again when

starting the Chromatopac after turning its power off.

C-R7A, C-R7Aplus: “Save to disk (Y: Yes N: No) : ?”

C-R8A: “Save to the disk (Y: Save N: No) : ?”

(6) Press the [DET] key of the GC to turn ON the detector control.

22

GC-2014

Page 35

2 Before Use

2.3

2.

2.3Outputting Digital Signals to a Personal

Computer

GC-2014 can be directly connected to a personal computer to output digital signals.

GCsolution software allows a PC to control the unit and take data.

For operation of GCsolution, refer to its instruction manual.

■ Connecting the RS-232C cable

Connect the RS-232C cable attached to GCsolution workstation to the connector on the

back of the GC. (Fig. 2.3.1)

To connect one PC with more than one GCs, separate RS-232C cables are necessary and

an expanded COM port needs to be attached to the PC.

NOTE

AOC built-in power source has the same connector. Connect the cables correctly.

RS-232C

AOC POWER SUPPLY

Back of the GC

1

2

3

4

5

6

232C

-

RS

EVENT

OPTION

AOC

ANALOG

OUT 1

ANALOG

OUT 2

START IN

READY OUT

START OUT

OUT/READY IN

232C OP1 LINKSTART

RS

INJECIOR1 INJECIOR2 SAMPLER

AOC built-in power source

Fig. 2.3.1 Connection of RS-232C cable

GC-2014

23

Page 36

2 Before Use

2.3 Outputting Digital Signals to a Personal Computer

■ Setting transmission parameters

(1) Select “6. GC CONFIGURATION” on

the [FUNC] key screen and then select

“3. TRANSMISSION PARAMETER.”

(2) Set transmission parameters.

Protocol = LEVEL3

Baud rate (bps) = 115200

(3) Press the [PF2] key (Apply).

NOTE

Turning ON the power of the GC is not

necessary.

24

GC-2014

Page 37

2 Before Use

2.4

2.

2.4Connecting a RS-232C Cable to the

Chromatopac C-R8A

Connecting the GC-2014 and Chromatopac C-R8A with a RS-232C cable allows for various

functions such as printing out parameters of the GC.

For detailed information about C-R8A, refer to its instruction manual.

■ Connecting RS-232C cable

Connect an optional RS-232C cable to the connector on the back of the GC. (Fig. 2.4.1)

NOTE

AOC built-in power source has the same connector. Connect the cables correctly.

AOC POWER SUPPLY

RS-232C

1

2

3

4

5

6

232C

-

RS

EVENT

OPTION

AOC

ANALOG

OUT 1

ANALOG

OUT 2

START IN

READY OUT

START OUT

OUT/READY IN

232C OP1 LINKSTART

RS

INJECIOR1 INJECIOR2 SAMPLER

Back of the GC

AOC built-in power source

Fig. 2.4.1 Connection of RS-232C cable

GC-2014

25

Page 38

2 Before Use

2.4 Connecting a RS-232C Cable to the Chromatopac C-R8A

■ Setting transmission parameters

Set transmission parameters when performing digital-transmission between the GC and

Chromatopac for the first time. (This is not required for each operation.)

1. Set transmission parameters for the GC

(1) Select “6. GC CONFIGURATION” on

the [FUNC] key screen and then select

“3. TRANSMISSION PARAMETER.”

(2) Set transmission parameters.

Protocol = LEVEL2

Baud rate (bps) = 9600

Stop bit = 1 bit

Parity = EVEN

(3) Press the [PF2] key (Apply).

NOTE

Turning ON the power of the GC is not

necessary.

2. Set transmission parameters for the C-R8A

(1) Press the [CONFIG] key and then press the [T] key (T:TRS).

(2) Press the [ ↓ ] key until the STD2 Port (RS-232C) Setup screen appears.

[PORT | MODE | #No. | BPS ]

STD2 | 12917 | 8 | 9600

(3) Set transmission parameters.

MODE = 12917 (Protocol LEVEL2, Stop bit 1 bit, Parity EVEN)

#No. = 8 (logical port number)

BPS = 9600 (baud rate)

(4) After completing setting, press the [EXIT] key and then press the [Y] key to save the

settings.

(5) After changing transmission parameters, reboot the C-R8A to enable the new settings.

■ Procedures to start digital transmission

After setting transmission parameters, start digital transmission.

1. Start digital transmission.

(1) Type “OPEN TRS 8” using the C-R8A keyboard and press the [Enter] key.

(2) The transmission port will open and transmission between the GC and C-R8A will start.

NOTE

26

To turn OFF the power of the GC or Chromatopac after opening the transmission port, type “CLOSE

TRS 8” using the C-R8A keyboard and press the [Enter] key.

GC-2014

Page 39

2 Before Use

2.5

2.

2.5Connecting Auto Injector/Auto Sampler

AOC-20 Series

Connecting the GC-2014 and the auto injector/auto sampler power source unit using an

AOC RS-232C cable allows AOC parameters to be set using the GC’s keyboard.

Refer to AOC-20 user’s manual for details about AOC-20.

■ Cable connections

Connect the READY/START cable attached to the AOC built-in power source and the AOC

RS-232C cable to the connectors on the back of the GC. (Fig. 2.5.1)

Connect the AOC power cable to the connector on the back of the GC and the auto injector

or auto sampler.

NOTE

There are two identical RS-232C connectors. Make sure to make the correct connections.

READY/START cable

Wire the cables according to the

numbers on them. Press the

buttons on the terminal when

inserting or removing cables.

ButtonCable inlet

1

2

3

4

5

6

AOC RS-232C cable

Connect the cable to the "AOC"

connector and "RS-232C"

connector on the AOC built-in

power source.

Fig. 2.5.1 Connection of the AOC-20 series

1

2

3

4

5

6

232C

-

RS

EVENT

OPTION

AOC

ANALOG

OUT 1

ANALOG

OUT 2

START IN

READY OUT

START OUT

AOC POWER SUPPLY

OUT/READY IN

232C OP1 LINKSTART

RS

INJECIOR1 INJECIOR2 SAMPLER

Back of the GC

SMAPLER=auto sampler

AOC power cable

INJECTOR1=auto injector

AOC built-in power source

GC-2014

27

Page 40

2 Before Use

2.5 Connecting Auto Injector/Auto Sampler AOC-20 Series

■ Setting AOC parameters

1. Set a line.

(1) Press the [SET] key and then press the

[PF2] key (Line Config).

(2) Specify “AOC1” on the line with the

injection port that the auto injector has

been attached to.

(3) The GC and AOC built-in power source

will be automatically linked.

2. Set AOC parameters.