Page 1

1-800-322-4897

(503) 640-3000

FAX (503) 640-1366

LOW TEMPERATURE

DIURNAL ILLUMINATION

INCUBATOR

SRI21D SRI21D-2

Previously designated as:

LI15 LI15-2

INSTALLATION AND OPERATION MANUAL

Revised 11/2013

4861575

Sheldon Manufacturing Inc. P.O. Box 627 Cornelius, Oregon 97113

EMAIL: tech@Shellab.com INTERNET: http://www.Shellab.com/~Shellab

Page 2

2

TABLE OF CONTENTS

SECTION 1.0 RECEIVING AND INSPECTION

SECTION 2.0 INSTALLATION

SECTION 3.0 GRAPHIC SYMBOLS

SECTION 4.0 CONTROL PANEL OVERVIEW

SECTION 5.0 OPERATION

SECTION 6.0 MAINTENANCE

SECTION 7.0 TROUBLESHOOTING

SECTION 8.0 PARTS LIST

UNIT SPECIFICATIONS

WIRE DIAGRAMS

These units are general purpose Biochemical Oxygen Demand (BOD) incubators for

professional, industrial or educational use where the preparation or testing of materials is done

at approximately atmospheric pressure and no flammable, volatile or combustible materials are

being heated. These units are not intended for hazardous or household locations or use.

Page 3

3

RECEIVING AND INSPECTION

Section

Your satisfaction and safety require a complete understanding of this unit. Read the instructions

thoroughly and be sure operators are given adequate training before attempting to put the unit into

service. This equipment must be used only for its intended application; any alterations or

modifications will void your warranty.

1.1 Inspection: The carrier, when accepting shipment, also accepts responsibility for safe

delivery and is liable for loss or damage. On delivery, inspect for visible exterior damage,

note and describe on the freight bill any damage found, and enter your claim on the form

supplied by the carrier.

1.2 Inspect for concealed loss or damage on the unit itself, both interior and exterior. If

necessary, the carrier will arrange for official inspection to substantiate your claim.

1.3 Return Shipment: Save the shipping crate until you are sure all is well. If for any reason

you must return the unit, first contact your customer representative for authorization. Supply

nameplate data, including model number and serial number. Please see the manual cover

for information on where to contact Customer Service.

1.4 Accessories: Verify that your accessory package is complete. Each unit is equipped with

a key and four (4) shelves.

WARNING: Never use this unit for the growth, cultivation, incubation or storage of fruit flies

(drosophila melanogaster). This unit is not designed for use with fruit flies. Improper use of

this unit, including use with fruit flies, will void any warranty. Other units are specifically

manufactured for fruit fly application, and you should consult your dealer or the manufacturer

in order to identify another model suitable for your application.

Page 4

4

INSTALLATION

Section

Local city, county, or other ordinances may govern the use of this equipment. If you have any questions about local

requirements, please contact the appropriate local agency. Installation may be performed by the end user. It is

unnecessary for this unit to be installed by a technician.

Under normal circumstances this unit is intended for use indoors, at room temperatures between 18 and 28C, at no

greater than 80% Relative Humidity ( at 25C ) and with a supply voltage that does not vary by more than 10%.

Customer service should be contacted for operating conditions outside of these limits.

This unit should remain upright for 24 hours prior to operating. This will allow the oil to settle in the compressor.

2.5 Power Source: See the incubator's serial/data plate for the voltage, cycle, phase and

ampere requirements. VOLTAGE SHOULD NOT VARY MORE THAN 10% FROM THE

DATA PLATE RATING. These units are intended for 50/60 Hz application. Electrical

supply to the unit must conform to all national and local electrical codes. A separate circuit

is recommended to avoid overloading or failure of other equipment on the same circuit.

2.6 Location: When selecting a site for the incubator, consider all conditions which may

affect performance, such as extreme heat from steam radiators, stoves, ovens,

autoclaves, etc. Avoid direct sun, fast-moving air currents, heating/cooling ducts, and high

traffic areas. To ensure air circulation around the unit allow a minimum of 20cm between

incubator and any walls or partitions which might obstruct free air flow.

2.7 Lifting / Handling: These units are heavy and care should be taken to use appropriate

lifting devices that are sufficiently rated for these loads. Units should only be lifted from

their bottom surfaces. Doors, handles and knobs are not adequate for lifting or

stabilization. The unit should be completely restrained from tipping during lifting or

transport. All moving parts, such as shelves and trays should be removed and doors need

to be positively locked in the closed position during transfer to prevent shifting and

damage.

2.8 Leveling: The unit must sit level and solidly. Turn the leveling feet counterclockwise to

raise level. If the unit must be moved, turn the leveling feet in all the way to prevent

bending or damage.

2.9 Cleaning: The incubator's interior was cleaned at the factory, but not sterilizied. Remove

all interior parts, including shelves and clean thoroughly with a disinfectant that is

appropriate for your application. Regular periodic cleaning is required. Special care

should be taken when cleaning around sensing heads to prevent damage. DO NOT USE

chlorine based bleaches as this may damage the incubator interior. DO NOT USE spray

cleaners that might leak through cracks and openings and get on electrical components,

or that may contain solvents that will harm coatings.

WARNING: Never clean the unit with alcohol or flammable cleaners with the unit connected to

the electrical supply. Always disconnect the unit from the electrical service when cleaning and

assure all volatile or flammable cleaners are evaporated and dry before reattaching the unit to the

power supply.

Page 5

5

GRAPHIC SYMBOLS

Section

Your incubator is provided with a display of graphic symbols on the control panel which

are designed to help identify the use and function of the adjustable components.

1. Indicates that you should consult your manual for further

description and discussion of a control or user item.

2. Indicates “Temperature”

3. Indicates “Overtemperature”

4. C Indicates “Degrees Centigrade”

5. Indicates “AC Power”

6. Indicates “Manual Adjustment”

7. Indicates “Potential Shock Hazard” behind partition

8. Indicates “Earth Ground”

9. Indicates “Unit should be recycled” (Not disposed of in

land-fill)

Page 6

6

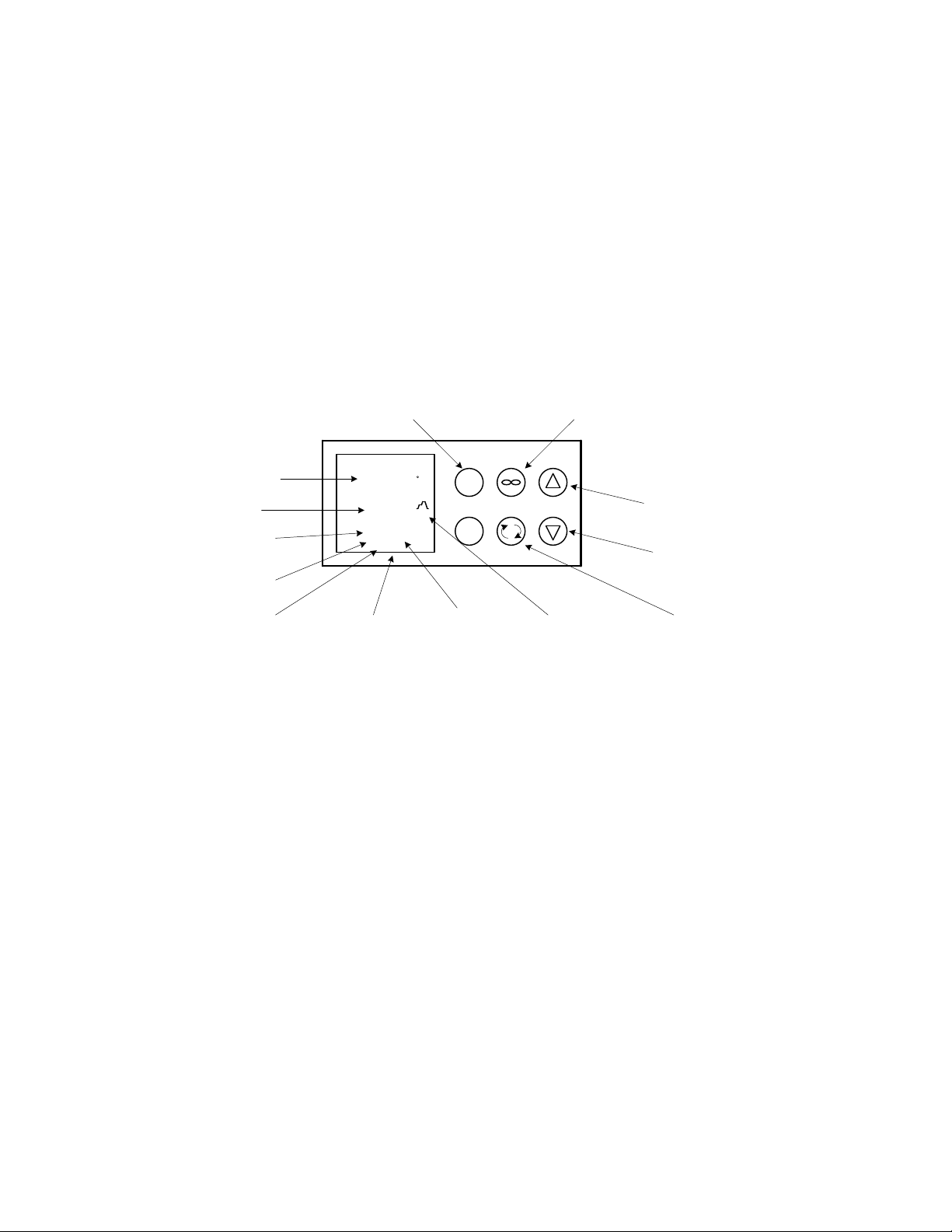

CONTROL PANEL OVERVIEW

Section

The SRI21D (LI15) comes with one control (Watlow PM) that can be set to do all light and

temperature setting functions. It has an ON/OFF Power Switch to turn the unit ON or OFF and

one Over Temperature Protection for High Temperature Limit.

4.1 Power Switch: The main power I/O (on/off) switch controls all power to the unit and must

be in the I/On position before any systems are operational.

4.2 Main Temperature Control: This control is marked SET TEMPERATURE and AM/PM

LIGHT CONTROL. It has two digital displays. Top Display reads PROCESS

TEMPERATURE and bottom display reads SET POINT TEMPERATURE. The control is a

40-Step Ramp and Soak Programmable Control with two (2) Event Outputs.

4.3 Over Temperature Thermostats: This control are marked SET OVER TEMPERATURE

4.4 HEATING Light: Marked HEATING ACTIVATED, this pilot light indicates when the Main

4.5 OVERTEMP Light: Marked OVER TEMPERATURE ACTIVATED, this pilot light indicates

4.6 Circuit Breaker: Located on the rear bottom next to the cord inlet provides protection

and are equipped with adjustment knob and graduated dial. Completely independent of the

Main Controller, the Thermostat guards against any failure which would allow temperature

to rise past the Main Controllers set point. If temperature rises to the Over Temperature set

point, this thermostat takes control of the heating element and allows continued use of the

incubator until the problem can be resolved or service can be arranged. It is not

recommended that the unit be allowed to operate for an extended period of time using only

the Over Temperature thermostat as temperature uniformity will suffer.

Controller has activated the heating elements to reach and maintain set point temperatures.

when the Over Temperature Thermostat has been activated. Under normal operating

conditions this pilot light should never come on.

against power source variations. Protection is in addition to the automatic high temperature

limit designed into the heating element. If the Circuit breaker opens, the unit will shut down

and the cause should be determined and corrected before resetting the circuit breaker.

Page 7

7

OPERATION

Section

The refrigeration system, heater, and air circulating fan are used in conjunction with the

temperature control circuit to achieve sensitive temperature control. The temperature sensor

located in the air stream senses any temperature deviation from the control point, and heat is

provided to maintain desired temperature. The circulating fan provides even air distribution

throughout the chamber and assures temperature uniformity.

Regardless of the temperature maintained, the refrigeration system operates continuously. This

constant operation minimizes component failures which are more frequently associated with a

cycling type operation. Note that a factory set Low-Limit Thermostat will shut off the compressor

when temperatures reach around 1C so samples will not freeze.

5.1 Plug incubator into electrical service corresponding to data plate rating located on the side

of the unit. Turn the power switch to the ON position and turn the Overtemperature

Thermostat to its maximum position, clockwise using a coin or flat edged tool.

5.2 Place a certified reference thermometer (not supplied) in the center of the chamber. Be

certain the thermometer is not touching any shelving or chamber walls. Taping the

thermometer to a petri dish raises it off the shelf and keeps the scale in view. Placing a

reference thermometer in the chamber at this stage of operation will allow for calibrating

the control without the loss of processing time.

5.3 Loading Procedure: Adequate spacing should be allowed between items whenever

possible. Proper spacing will allow maximum air circulation, which is necessary for

temperature uniformity.

5.4 Frost Buildup: Excessive frost buildup on the evaporator coil located on the lower rear

wall can affect temperature uniformity. Liquid containers should never be placed in the

chamber without covers. The evaporation of moisture within the chamber will only add

frost and hasten the need for defrosting. Defrosting instructions are available in

Maintenance Section 6.

Page 8

8

WATLOW PM CONTROLLER START GUIDE

20.0

20.0

EZ1

EZ2

1 2 3

C

ACTUAL PROCESS

TEMPERATURE DISPLAY

PROCESS SETPOINT

DISPLAY

OUTPUT 1 INDICATES

HEATING ELEMENT ON

OUTPUT 2 INDICARES

LIGHTS ON

OUTPUT 3 INDICATES

CALIBRATION OFFSET

ON FOR DAY CYCLE

RAMPING SYMBOL

INDICATES PROGRAM

RUNNING WHEN ACTIVE

ADVANCE KEY

ALLOWS TO SCROLL

THROUGH PARAMETER LIST

DOWN ARROW KEY

ALLOWS TO LOWER SETPOINT

OR CHANGE PARAMETERS

UP ARROW KEY

ALLOWS TO RAISE SETPOINT

OR CHANGE PARAMETERS

INFINITE KEY

ALLOWS TO BACK UP

ONE LEVEL OR RETURN

TO HOME PAGE

EASY ZONE KEY 1

STARTS AND STOPS

PROGRAM

CONTROLLER KEYS AND DISPLAYS

5 6

OUTPUT 5 INDICATES

DAY OPERATION

OUTPUT 6 INDICATES

NIGHT OPERATION

Easy Zone Key 1

Starts and stops program

Infinite Key

Backs up one level or returns to normal display

mode

Up Arrow Key

Raises Setpoint or changes parameters

Ramp Symbol

Indicates program is running when active

Down Arrow Key

Lowers Setpoint or changes parameters

Advance Key

Scrolls through parameter list

Easy Zone Key 2

Not in use but can be programmed

Output 1

Active Heating Element

Light On

Indicates heating element is ON

Output 3

Active Calibration

Indicates calibration is ON for Day Cycle

Output 5

Day Cycle is active

Output 6

Night Cycle is active

Process Setpoint Display

Factory preprogrammed Setpoint

Actual Process

Temperature Display

Factory preprogrammed Setpoint

The SRI21D (LI15) comes from the factory preprogrammed to run a 12 hour day and 12 hour night cycle

using one setpoint. The setpoint from the factory is 20 degrees C and the program is set to start the day

cycle first.

Before Getting Started

Before getting started, it’s a good idea to become familiar with the control display and keys, terms, and

factory steps. Doing so will make getting started easier.

Controls

Normal Display Mode

Keys

Page 9

9

Terms

A1

Analog 1 input menu

CLoC

Setting hour, minutes, seconds for run time

dOW

Day Of Week

ED

Every Day

ENT1

Event output 1

ENT2

Event output 2

Event Timer

Factory installed timer (internal)

gLbL

Global menu

HoUr

Hour of day / night

i.CA

Calibration offset

JC

Jump Count

JL

Jump Loop

JS

Jump Step

Min

Minutes

SoAH

Soak

oPEr

Operation page

P1 PROF

Profile 1 of 4

rtCSet

Real Time Clock Set

SEC

Seconds

S.tyP

Active step type

Ti

Time

t.SPI

Target set point

Usr.s

User set

UStp

Unused Step

1P1, 2P1, 3P1, etc.

# indicates step, P1 indicates Profile 1

Page 10

Getting Started

There are four parts to setting up and running your SRI21D (LI15). Each part has instructions for powering

up the unit, setting the temperature setpoint, calibrating the offset value for day cycle and storing it into

memory, and calibrating the offset value for the night cycle and storing it into memory.

Powering Up Unit

To power up the unit, do the following:

On the front panel, turn the power OFF.

Plug the unit into a dedicated power source.

Turn the power ON.

The Power On light appears.

Turn the Set Over Temperature knob clockwise all the way over.

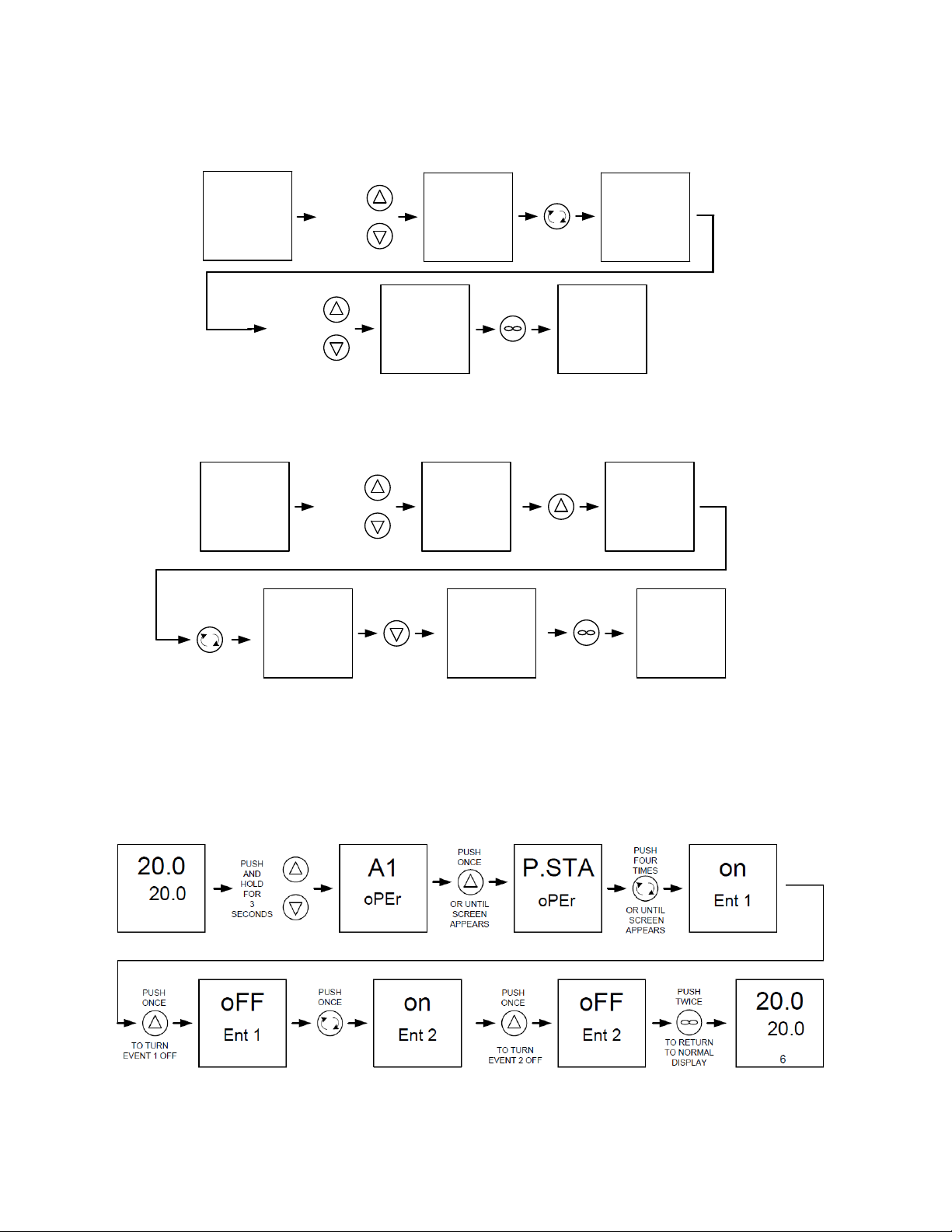

SETTING AND CALIBRATING DAY CYCLE

Use the up/down arrows to choose desired Setpoint. After Setpoint is entered, turn ON both Event Outputs.

To simulate Day Cycle, turn on Event Outputs following direction below.

Outputs 2,3, and 5 should be illuminated in the Bottom Display and light in incubator should be on. Allow unit

to stabilize for several hourse before calibrating.

Page 11

11

BEFORE CALIBRATION IS MADE MAKE SURE THAT INDICATOR 2, 3, 5, AND RAMP SYMBOL ARE ON INDICATING DAY

CYCLE ACTIVE. FIGURE OUT # VALUE OF OFFSET (ACTUAL TEMPERATURE MINUS PROCESS DISPLAY TEMPERATURE).

BELOW SHOWS WHERE AND HOW TO ENTER THE OFFSET # VALUE.

20.0

20.0

PUSH

AND

HOLD

FOR

5

SECONDS

PUSH

THREE

TIMES

i.CA

# VALUE

USE

UP AND

DOWN

BUTTONS

TO

ENTER

CALIBRATION

# VALUE

i.CA

# VALUE

PUSH

TWICE

20.0

20.0

TO RETURN

TO NORMAL

DISPLAY

A1

oPEr

OR UNTIL

SCREEN

APPEARS

AFTER THE OFFSET HAS BEEN ENTERED ALLOW UNIT TO STABALIZE. RECHECK TEMPERATURE AGAIN

AND IF CALIBRATION IS WITHIN EXCEPTABLE LIMITS THE OFFSET # VALUE NEEDS TO BE STORED INTO

MEMERY OR IT WILL REVERT BACK TO THE LAST # VALUE ON THE NEXT SWITCHING CYCLE.

BELOW SHOWS HOW TO STORE OFFSET # VALUE FOR THE DAY CYCLE

A1

SET

20.0

20.0

PUSH

AND

HOLD

FOR

10

SECONDS

PUSH

THREE

TIMES

LbL

g

SET

PUSH

FOUTEEN

TIMES

OR UNTIL

SCREEN

APPEARS

nonE

Usr.S Usr.S

SET 2

PUSH

ONCE

PUSH

TWICE

20.0

20.0

TO RETURN

TO NORMAL

DISPLAY

SELECTING SET 2 UNDER Usr.S SAVES THE OFFSET CALIBRATION FOR THE DAY CYCLE.

SETTING AND CALIBRATING NIGHT CYCLE

Use the up/down arrows to choose desired Setpoint. After Setpoint is entered, turn ON both Event Outputs.

To simulate Day Cycle, turn Event Outputs OFF to simulate Night Cycle. To turn OFF the Event Outputs,

follow directions below.

Outputs 2,3, and 5 should be OFF and 6 should be illuminated in the bottom of display. The lights inside

incubator should be off. Allow unit to stabilize for several hours before calibration.

Page 12

12

BEFORE CALIBRATION IS MADE MAKE SURE THAT INDICATOR 2, 3, 5, AND RAMP SYMBOL ARE ON INDICATING DAY

CYCLE ACTIVE. FIGURE OUT # VALUE OF OFFSET (ACTUAL TEMPERATURE MINUS PROCESS DISPLAY TEMPERATURE).

BELOW SHOWS WHERE AND HOW TO ENTER THE OFFSET # VALUE.

20.0

20.0

PUSH

AND

HOLD

FOR

5

SECONDS

PUSH

THREE

TIMES

i.CA

# VALUE

USE

UP AND

DOWN

BUTTONS

TO

ENTER

CALIBRATION

# VALUE

i.CA

# VALUE

PUSH

TWICE

20.0

20.0

TO RETURN

TO NORMAL

DISPLAY

A1

oPEr

OR UNTIL

SCREEN

APPEARS

AFTER THE OFFSET HAS BEEN ENTERED ALLOW UNIT TO STABALIZE. RECHECK TEMPERATURE AGAIN

AND IF CALIBRATION IS WITHIN EXCEPTABLE LIMITS THE OFFSET # VALUE NEEDS TO BE STORED INTO

MEMERY OR IT WILL REVERT BACK TO THE LAST # VALUE ON THE NEXT SWITCHING CYCLE.

BELOW SHOWS HOW TO STORE OFFSET # VALUE FOR THE DAY CYCLE

A1

SET

20.0

20.0

PUSH

AND

HOLD

FOR

10

SECONDS

PUSH

THREE

TIMES

LbL

g

SET

PUSH

FOUTEEN

TIMES

OR UNTIL

SCREEN

APPEARS

nonE

Usr.S Usr.S

SET 2

PUSH

ONCE

PUSH

TWICE

20.0

20.0

TO RETURN

TO NORMAL

DISPLAY

SELECTING SET 2 UNDER Usr.S SAVES THE OFFSET CALIBRATION FOR THE DAY CYCLE.

SETTING OVER TEMPERATURE LIMIT (OTL)

If using two different temperatures, pick the cycle with the higher Setpoint.

1. Allow unit to stabilize.

2. Turn OTL counter clockwise slowly until the OTL Light illuminates.

3. Turn OTL clockwise slowly until the OTL light goes out.

4. OTL is now set.

Page 13

13

20.0

20.0

USE UP OR

DOWN ARROWS

TO SELECT HOUR OF

DAY IN TOP

DISPLAY

hoU1

HOUR OF DAY

Mi1

ENTER REAL TIME

IN HOUR OF DAY

MINUTE OF HOUR

ENTER REAL TIME

IN MINUTE OF HOUR

TO SELECT MINUTE

OF HOUR IN TOP

DISPLAY

hoU2

HOUR OF DAY

hoU1

Mi1

TO SELECT

HOUR OF DAY IN TOP

DISPLAY

ENTER DAY CYCLE

START TIME IN

HOUR OF DAY

hoU2

Mi2

Mi2

TO SELECT HOUR

OF DAY IN TOP

DISPLAY

MINUTE OF HOUR

ENTER DAY CYCLE

START TIME IN

MINUTE OF HOUR

t.SP3

DAY CYCLE SET

POINT VALUE

TO SELECT DAY

CYCLE SET POINT

IN TOP DISPLAY

t.SP3

ENTER DAY CYCLE

SET POINT

hoU4

HOUR OF DAY

TO SELECT MINUTE

OF HOUR IN TOP

DISPLAY

hoU4

ENTER NIGHT

CYCLE START TIME

IN HOUR OF DAY

Mi4

MINUTE OF HOUR

TO SELECT MINUTE

OF HOUR IN TOP

DISPLAY

Mi4

ENTER NIGHT

CYCLE START TIME

IN MINUTE OF HOUR

t.SP5

NIGHT CYCLE

SET

POINT VALUE

TO SELECT NIGHT

CYCLE SET POINT

IN TOP DISPLAY

t.SP5

ENTER NIGHT

CYCLE

SET POINT

20.0

20.0

EZ1

20.0

20.0

PROGRAMING THE DAY AND NIGHT CYCLE

PROGRAMING THE DAY AND NIGHT CYCLE IS DONE IN JUST 8 EASY STEPS. THE FIRST TWO STEPS IS ENTERING THE REAL TIME IN HOURS

AND MINUTES OF THE DAY. THE NEXT THREE STEPS IS ENTERING THE DAY CYCLE START TIME IN HOUR AND MINUTES OF THE DAY PLUS

THE SET POINT IN WHICH THE DAY CYCLE WILL RUN. THE LAST THREE STEPS IS ENTERING THE NIGHT CYCLE START TIME IN HOUR AND

MINUTES OF THE DAY PLUS THE SET POINT WHICH THE NIGHT CYCLE WILL RUN.BELOW ARE INSTRUCTIONS ON HOW TO SCROLL

THROUGH THE 8 STEPS AND HOW TO CHANGE THE TIMES AND SET POINTS FOR THE REAL TIME, DAY CYCLE, AND NIGHT CYCLE.

PUSH

ONCE

PUSH

ONCE

USE UP OR

DOWN ARROWS

PUSH

ONCE

USE UP OR

DOWN ARROWS

PUSH

ONCE

USE UP OR

DOWN ARROWS

PUSH

ONCE

USE UP OR

DOWN ARROWS

PUSH

ONCE

USE UP OR

DOWN ARROWS

PUSH

ONCE

USE UP OR

DOWN ARROWS

USE UP OR

DOWN ARROWS

PUSH

ONCE

TO START

DAY/NIGHT

CYCLE

PROGRAM

PUSH

ONCE

PUSH

ONCE

TO RETURN

TO HOME

PAGE

HOME PAGE IS WHERE THE

CONTROL IS IN NORMAL CONTROL

MODE MEANING UPPER DISPLAY

IS PROCESS AND LOWER DISPLAY

IS SET POINT. TO START THE DAY

AND NIGHT CYCLE PROGRAM

PUSH THE EZ1 BUTTON ONCE.

PROGRAM IS

RUNNING WHEN

THE RAMP

SYMBOL IS

ILLUMINATED ON

THE RIGHT HAND

SIDE OF THE

DISPLAY

WHEN STARTING THE DAY AND NIGHT CYCLE IT WILL ALWAYS WAIT FOR THE DAY CYCLE FIRST. IF THE DAY TIME ENTERED IS EARLIER

THAN THE PROGRAM START TIME ( THE TIME YOU PUSH THE EZ1 BUTTON) THE PROGRAM WILL WAIT TILL THE NEXT DAY TO START.

Hou1 = REAL TIME IN HOURS OF DAY

Mi1 = REAL TIME IN MINUTES OF DAY

Hou2 = DAY CYCLE START TIME IN HOURS OF DAY

Mi2 = DAY CYCLE START TIME IN MINUTES OF THE HOUR

t

.SP3 = DAY CYCLE SET POINT VALUE

Hou4 = NIGHT CYCLE START TIME IN HOURS OF THE DAY

Mi4 = NIGHT CYCLE START TIME IN MINUTES OF THE HOUR

.SP5 = NIGHT CYCLE SET POINT VALUE

t

Page 14

14

MAINTENANCE

Section

The design of the chamber is such that periodic maintenance is kept to a minimum. NO

lubrication or adjustments of components is needed. If the incubator is used frequently at

temperatures below ambient room temperature or in any manner that increases moisture buildup within the chamber, a frequent defrosting schedule is recommended.

6.1 Defrosting: Frost can appear inside the unit due to moisture accumulating and

condensing on the coldest surface. The unit should be defrosted and cleaned on a

regular basis. The unit can be defrosted either manually or automatically. The water

drains from the chamber into an evaporation pan. Make sure to completely dry out the

interior when defrosting is complete.

A. Manual Defrost: Turn the unit off, open the door and allow the frost to melt. Then

clean the chamber following the directions in 6.2.

B. Automatic Defrost: the automatic defrost switch is located on the back of the unit.

It is an ON/OFF switch. In the ON position, the frost sensor is activated once every

twelve (12) hours. If the sensor detects frost, the compressor is shut down until the

frost has melted, and then the compressor is reactivated. The amount of time the

compressor is shut down is roughly one-half hour. During this time, the temperature

in the chamber will spike and the Main temperature Controller will cycle off, shutting

down the heating element. When the compressor is activated, the temperature will

stabilize at set point.

6.2 Cleaning: Clean the incubator chamber on a regular basis. Remove all interior parts

WARNING: Never clean the unit with alcohol or flammable cleaners with the unit connected to

the electrical supply. Always disconnect the unit from the electrical service when cleaning and

assure all volatile of flammable cleaners are evaporated and dry before reattaching the unit to

the power supply.

6.3 Compressor Compartment: Located at the back bottom of the unit, the compressor

6.4 Electrical Components: There is NO maintenance to electrical components. If the

and clean thoroughly with a disinfectant that is appropriate for your application.

Shelving should be cleaned with the same solution. Special care should be taken when

cleaning around sensing heads. DO NOT USE chlorine based bleaches or abrasives as

this can damage the interior. DO NOT USE spray cleaners that might leak through

openings and cracks and get on electrical parts or that may contain solvents that will

harm coatings.

compartment can collect dust which will inhibit proper air flow. This compartment should

be vacuumed out at least once every six (6) months to ensure maximum efficiency.

incubator fails to operate as specified, please review Section 7.0 Troubleshooting, prior to

calling for service.

Page 15

15

TROUBLESHOOTING AND SERVICE

TEMPERATURE

Temperature too high

1/ controller set too high-see section 5.5

2/ controller failed on – call Customer Service

Temperature too low

1/ Overtemperature Thermostat set too low – see section 5.8

2/ controller set too low – see section 5.5

3/ unit not recovered from door opening – wait for display to stop

changing.

4/ element failure – see if HEATING light is on; compare current

draw to data plate.

5/ controller failure – confirm with front panel lights that controller is

calling for heat.

6/ Overtemperture Thermostat failure – confirm with front panel

lights that Thermostat is operating correctly.

7/ loose connection – check shadow box for loose connections.

Unit will not heat over a temperature

that is below set point

1/ confirm that fan is moving and that amperage and voltage

match data plate – check fan motor and feel for air movement in

chamber

2/ confirm that set point is set high enough –turn Thermostat all

the way clockwise and see if HEATING light or OVERTEMP light

comes on

3/ check calibration – using independent certified thermometer,

follow instructions in section 5.6

Unit will not heat up at all

1/ verify that controller is asking for heat by looking for controller

light – if pilot light is not on continuously, there is a problem with the

controller.

2/check amperage – amperage should be virtually at maximum

rated (data plate) amperage.

3/ do all controller functions work?

4/ is the Thermostat set high enough? – for diagnostics, should be

fully clockwise with the pilot light never on.

5/ has the fuse/circuit breaker blown?

Indicated chamber temperature

unstable

Section

When troubleshooting, always make a visual inspection of the incubator and it’s control console to

find loose or disconnected wires which may be the source of the trouble. In the event the

incubator does not operate properly, check the following before calling for service.

Page 16

16

1/ ±0.1 may be normal

2/ is fan working? – fan must operate for uniformity

3/ is ambient room temperature radically changing – either door

opening or room airflow from heaters or air conditioning ? –

stabilize ambient conditions.

4/ sensor miss-located, damaged or wires may be damaged check mounts for control and Thermostat sensors, then trace wires

or tubing between sensors and controls.

5/ calibration sensitivity – call Customer Service

6/ Overtemperature set too low – be sure that Thermostat is more

than 5 degrees over desired set point; check if OVERTEMP pilot is

on continuously; turn controller knob completely clockwise to see if

problem solved then follow instructions in owner’s manual for

correct setting – see section 5.8

7/ electrical noise – remove nearby sources of RFI including

motors, arcing relays or radio transmitters.

8/ bad connection on temperature sensor or faulty sensor – check

connectors for continuity and mechanical soundness while

watching display for erratic behavior; check sensor and wiring for

mechanical damage.

9/ bad connections or faulty relay – check connectors for

mechanical soundness and look for corrosion around terminals or

signs of arcing or other visible deterioration.

Display and reference thermometer

don’t match

1/ calibration error – see section 5.9

2/ controller failure – evaluate if pilot light is operating correctly

3/ allow at least two hours to stabilize.

4/ see if reference thermometer is certified.

Calibrated at one temperature, but

not at another

Refer to Section 5.9

REFRIGERATION

Temperature can't get up to set point

1/ assure that power is going to heating coils.

2/ confirm that evaporator is calling for heat (check front panel

light).

3/ if light not coming on, check control set point and Thermostat

set point .

4/ confirm that fan is operating and airflow is not blocked.

5/ reset by turning unit off and on.

Unit won't cool

Page 17

17

If the compressor is running:

1/ see if condenser is cold but free of ice.

2/ be sure that fan is circulating air in the chamber and over the

compressor.

3/ confirm proper sensor location and operation.

4/ look for leaks in the chamber or around the door gasket.

5/ assure ample room around the unit as described in Installation

section 2.2

6/ If 1 through 7 has been tried and still not functioning correctly,

call customer service.

If compressor isn’t running:

1/ if too cold inside adjust “cold control”

located outside on bottom right rear

2/ check for non-operating relay

3/ confirm that compressor cooling fan motor is operable.

4/ check if motor has voltage to it.

5/ see if refrigeration is running too hot and thermal cutoff

activated:

a- dirty coil or poor circulation

b- coil next to heat source

c- ambient temperature too high

Ice build up in chamber

1/ Remove any open or exposed water in the chamber

2/ Search for leak in door gasket.

3/ Door being opened too often.

4/ Open container inside the chamber.

5/ Check tightness of seal around all chamber wire and plumbing

access to outside.

6/ Turn defrost switch on, Note: defrost switch must be turned off

for best temperature uniformity; If no defrost option available,

call Customer Service.

Making noise

1/ assure that fan is not miss-aligned.

2/ Steady internal clicking may be broken spring or valve – call

Customer Service.

MECHANICAL

Motor doesn't move

1/ if shaft spins freely: check connections to motor and check

voltage to motor.

2/ if shaft rubs or is frozen, relieve binding and retest.

Motor makes noise

1) Make sure that the fan or blower wheel is not contacting its

housing. Adjust the motor mounting bracket position to re-center

the fan or blower wheel, if necessary.

2) Check the fan or blower wheel for damage or out of balance

condition. Replace the fan or blower wheel if it is damaged or out

of balance.

3) Turn the motor shaft to make sure that it spins freely. If it binds

or the bearings make a rubbing or scrapping sound then replace

the motor.

Door not sealing

1/ Confirm that unit has not been damaged and body is square.

Page 18

18

OTHER

Unit heating all the time

1/ Adjust set point to room temperature. If the light goes out but is

still heating, replace the solid state relay.

2/ if cannot change any condition on the front panel, call Customer

Service.

Front panel displays are all off

Check for wire damage.

Unit or wall fuse/circuit breaker is

blown

1/ check wall power source.

2/ compare current draw and compare to specs on data plate.

3/ see what other loads are on the wall circuit.

Unit will not turn on

1/ check wall power source.

2/ check fuse/circuit breaker on unit or in wall.

3/ see if unit is on, e.g., fan or heater, and just controller is off.

4/ check all wiring connections, especially around the on/off

switch.

Contamination in chamber

1/ see cleaning procedure in operator’s manual

2/ develop and follow Standard operating procedure for specific

application; include definition of cleaning technique and

maintenance schedule.

Service

If none of the suggestions listed above have solved the problem, Customer Service should be

contacted for assistance.

Call 1-800-322-4897 and have the model number, serial number and voltage (listed on the data

plate on the side of the incubator) as your service representative will require it.

Page 19

19

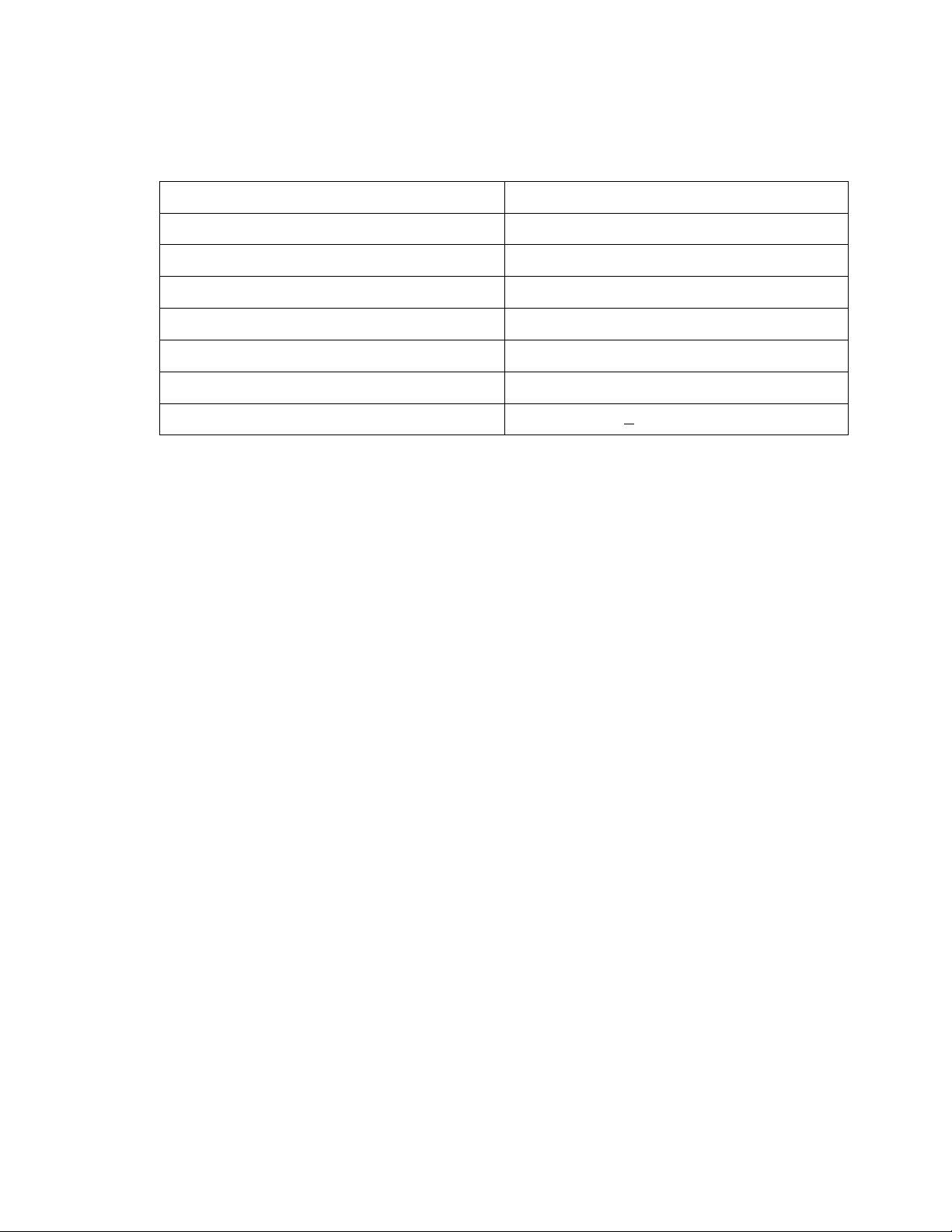

PARTS LIST

Description

115V

220V

Circuit Breaker (20 amp)

1100500

1100500

Control Relay

7030536

7030536

Cooling Fan

4880564

4880564

Cord Set, European

NA

1850500

Cord Set, USA

1800529

1800537

Defrost Switch

7850579

7850579

Defrost Heater

2350536

2350536

Florescent Bulbs

4650538

4650538

Florescent Light Ballast

4660505

4660505

High Limit Control

1750862

1750862

Interior Outlet

6100525

6100526

Interior Outlet, European

NA

6100531

Low Limit Control

1750538

1750538

Main Temperature Control

9660513

9660513

Pilot Light, Green

4650554

4650554

Pilot Light, Red

4650553

4650553

Power Switch

7850532

7850532

Relay

7030511

7030520

Step Down Transformer

NA

8350521

System Logic Relay SSR

7030533

7030533

Thermal Limit Control, Non-Adjustable

1750506

1750506

Timer Defrost

8250507

8250507

Venting Fan

4880550

4880550

Section

Page 20

20

Unit Specifications

Shipping Weight

400 lbs.

Net Weight

280 lbs.

Exterior LxDxH (in.)

34.5 x 32 x 77

Interior LxDxH (in.)

27 x 23.5 x 57

Capacity

20.3 Cubic Ft

Capacity

257 Bottles

Temperature Range

0 to 45C

Temperature Uniformity

+.5 @ 20C

Page 21

21

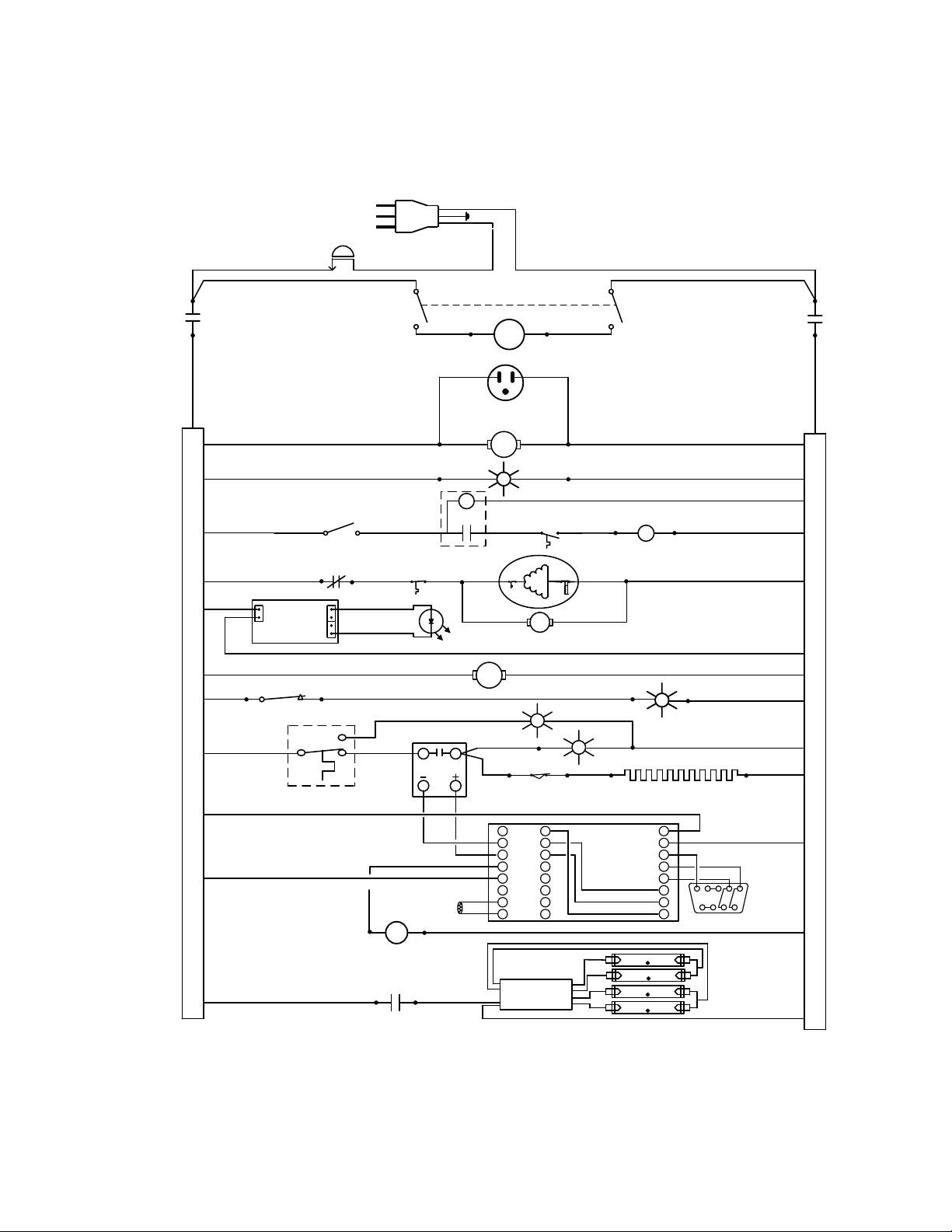

TIMER

DEFROST

TIMER

8250507

1 2

3

14 13

MANUAL

DEFROST SWITCH

7850579

CF

CF

LOW LIMIT

THERMOSTAT

1750538

DOOR SWITCH

INTERIOR LIGHT

CF

9 1

RELAY

CONTACT

FOR 7030536

RELAY COIL FOR

7030536

COMPRESSOR

CONTROL COOLING FAN

4880550

COMPRESSOR

COOLING FAN

4880564

DEFROST

THERMOSTAT

R1

T1

S1

R1

X1

W1

Y1

L3

K3

J3

98

99

CF

CD

CE

WATLOW PM

9660513

RTD

SENSOR

6600520

14

13

RELAY COIL FOR

7030536

RC2

RELAY CONTACT

FOR 7030536

R2

34

21

1

2

4

OTP 1750862

4 TUBE

ELECTR ONIC BA LLAST

4660565

FLUORE SCE NT

FLUORE SCE NT

FLUORE SCE NT

FLUORE SCE NT

L2

K2

B5

D6

D5

1 2 3 4 5

6 7 8 9

SUB D 9 PIN

CONNECTOR

1650537

4

2

8

6

10

5

9

C1

C3

R3

R3

POWER CORD

1800529

CIRCUIT

BREAKER

1100500

POWER SWITCH 7850553

RELAY COIL

FOR 7030511

½ POWER RELAY

7030511

½ POWER RELAY

7030511

CHAMBER FAN

4880555

POWER ON LIGHT

4650554

OTL INDICATOR

4650553

HEATING LIGHT

4650554

LIMIT THERMOSTAT

43°C 1750506

SOLID STATE

RELAY

7030523

HEATING ELEMENT

2350536

12VDC

POWER

SUPPLY

6750507

LED LOGO

1750742

RED 22G

BLACK 22G

BLACKBLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BLACK

BLUE BLUE

YELLOW YELLOW

GREY

BROWN

BROWN

ORANGE

ORANGE

ORANGE

RED

RED 22G

RED 22G

RED 22G

BLACK 22G

BLACK 22G

BLACK 18G

WHITE 18G

INTERIOR OUTLET

6100525

Wire Diagram

SRI21D (LI15) 100-120V

Page 22

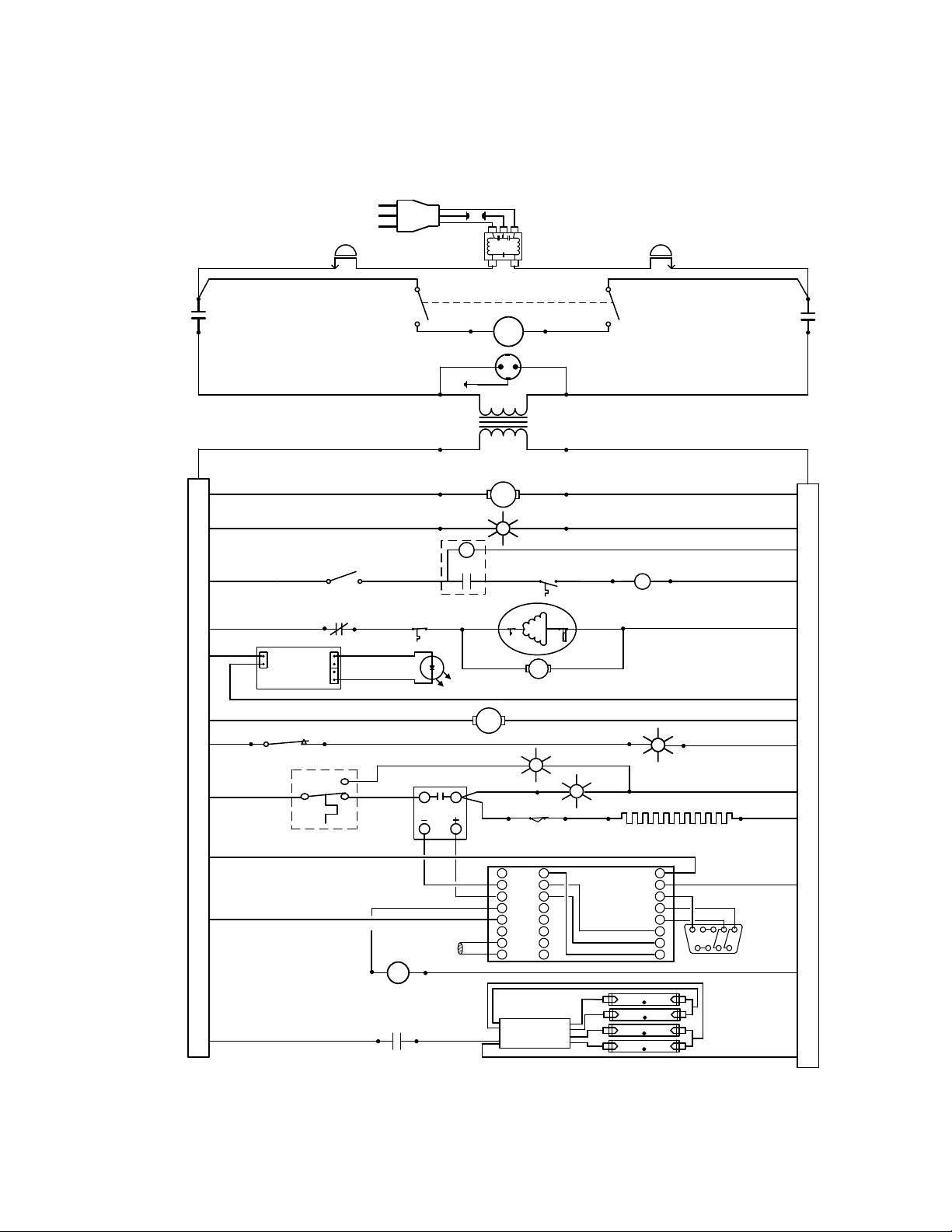

22

Wire Diagram

TIMER

DEFROST

TIMER

8250507

1 2

3

14 13

MANUAL

DEFROST SWITCH

7850579

CF

CF

LOW LIMIT

THERMOSTAT

1750538

DOOR SWITCH

INTERIOR LIGHT

CF

9 1

RELAY

CONTACT

FOR 7030536

RELAY COIL FOR

7030536

COMPRESSOR

CONTROL COOLING FAN

4880550

COMPRESSOR

COOLING FAN

4880564

DEFROST

THERMOSTAT

R1

T1

S1

R1

X1

W1

Y1

L3

K3

J3

98

99

CF

CD

CE

WATLOW PM

9660513

RTD

SENSOR

6600520

14

13

RELAY COIL FOR

7030536

RC2

RELAY CONTACT

FOR 7030536

R2

34

21

1

2

4

OTP 1750862

4 TUBE

ELECTRONIC BALLAST

4660565

FLUORESCENT

FLUORESCENT

FLUORESCENT

FLUORESCENT

2800502

EMI

FILTER

L2

K2

B5

D6

D5

1 2 3 4 5

6 7 8 9

SUB D 9 PIN

CONNECTOR

1650537

4

2

8

6

10

5

9

C1

C3

R3

R3

POWER CORD

1800541

CIRCUIT

BREAKER

1100500

CIRCUIT

BREAKER

1100500

POWER SWITCH 7850553

RELAY COIL

FOR 7030520

INTERIOR OUTLET

6100532

STEP DOWN

TRANSFORMER

8350321

½ POWER RELAY

7030520

½ POWER RELAY

7030520

CHAMBER FAN

4880555

POWER ON LIGHT

4650554

OTL INDICATOR

4650553

HEATING LIGHT

4650554

LIMIT THERMOSTAT

43°C 1750506

SOLID STATE

RELAY

7030523

HEATING ELEMENT

2350536

12VDC

POWER

SUPPLY

6750507

LED LOGO

1750742

RED 22G

BLACK 22G

BLACKBLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BLACK

BLUE BLUE

YELLOW YELLOW

GREY

BROWN

BROWN

ORANGE

ORANGE

ORANGE

RED

RED 22G

RED 22G

RED 22G

BLACK 22G

BLACK 22G

BLACK 18G

WHITE 18G

SRI21D-2 (LI15-2) 220-240V

Loading...

Loading...