Page 1

Installation and

Operation Manual

SRI6PF, SRI20PF

Previously designated as

LI6P-FLY, LI20P-FLY

FLY INCUBATORS 100 - 120 Voltage

Page 2

Sheldon Fly Refrigerated Incubators 100 - 120 Voltage

Peltier

Installation and Operation Manual

Part Number (Manual): 4861674-1

Revision: March 12, 2014

Pictured on Cover: SRI6PF Left, SRI20PF Right

These units are TÜV CUE listed as incubators and radiant warmers for professional, industrial, or

educational use where the preparation or testing of materials is done at approximately atmospheric

pressure and no flammable, volatile, or combustible materials are being heated.

These units have been tested to the following requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010 + R:2009

UL 61010A-2-010:2002

UL 61010-1:2012

EN 61010-1:2010

EN 61010-2-010:2003

IEC 61010-1:2010

IEC 61010-2-010:2003

Page | 2

Page 3

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 4

General Safety Considerations ................................................................................................................. 4

Engineering Improvements ....................................................................................................................... 5

Contacting Assistance ............................................................................................................................... 5

RECEIVING YOUR INCUBATOR ................................................................................................................ 6

Inspecting the Shipment ............................................................................................................................ 6

Recording Data Plate Information ............................................................................................................. 7

Contacting Assistance ............................................................................................................................... 7

GRAPHIC SYMBOLS ................................................................................................................................... 8

INSTALLATION ............................................................................................................................................ 9

Location ..................................................................................................................................................... 9

Lifting and Handling .................................................................................................................................. 9

Leveling ..................................................................................................................................................... 9

Install Side Air Ducts SRI20PF ............................................................................................................... 10

Shelving Installation ................................................................................................................................ 11

Power Source .......................................................................................................................................... 13

Cleaning .................................................................................................................................................. 13

CONTROL PANEL OVERVIEW ................................................................................................................. 14

OPERATION ............................................................................................................................................... 16

Theory of Operation ................................................................................................................................ 16

Door Alarm .............................................................................................................................................. 16

Setting up the Incubator .......................................................................................................................... 17

Control Setup and Operation .................................................................................................................. 17

Set the Current Time ............................................................................................................................... 18

Set the Day Time Phase Start Point ....................................................................................................... 18

Set the Night Phase Start Point .............................................................................................................. 19

Set the Day Time Phase Temperature Set Point .................................................................................... 19

Set the Night Time Phase Temperature Set Point .................................................................................. 20

Calibrate the Temperature Display ......................................................................................................... 21

Set the Over Temperature Limit Control ................................................................................................. 23

Starting the Auto Cycle ........................................................................................................................... 23

Ending the Auto Cycle ............................................................................................................................. 23

Silencing the Door Ajar Alarm ................................................................................................................. 24

Loading the Incubator ............................................................................................................................. 24

Attaching equipment to the Interior Accessory Outlet ............................................................................. 24

Humidifying the Incubator ....................................................................................................................... 24

USER MAINTENANCE ............................................................................................................................... 25

Cleaning .................................................................................................................................................. 25

Disinfecting .............................................................................................................................................. 25

UNIT SPECIFICATIONS ............................................................................................................................. 27

Weight ..................................................................................................................................................... 27

Dimensions .............................................................................................................................................. 27

Capacity .................................................................................................................................................. 27

Shelf Capacity by Weight ........................................................................................................................ 28

Temperature ............................................................................................................................................ 28

Power ...................................................................................................................................................... 28

PARTS LIST ............................................................................................................................................... 29

3 | P a g e

Page 4

INTRODUCTION

Thank you for purchasing a Sheldon Refrigerated Peltier Fly Incubator. We know that in today’s

competitive marketplace, customers have many choices when it comes to constant temperature

equipment. We appreciate you choosing ours. Our continued reputation as a leading laboratory

product manufacturer rests with your satisfaction. Sheldon Manufacturing, Inc. stands behind our

products, and we will be here if you need us.

These incubators are intended for professional, industrial, or educational use for fruit fly cultivation.

They are not designed for use in hazardous or household locations.

Before using the incubator read this entire manual carefully to understand how to install, operate,

and maintain the unit in a safe manner. Keep this manual available for use by all workstation

operators. Ensure that all operators are given appropriate training prior to using the incubator.

Note: This unit is designed for the growth, cultivation, incubation, and storage of fruit flies

(Drosophila melanogaster). Improper use of this unit will void any warranty. Other units are

specifically manufactured for BOD application, and you should consult your Shel Lab dealer

or customer service representative in order to identify another model suitable for your

application.

GENERAL SAFETY CONSIDERATIONS

Note: Failure to follow the guidelines and instructions in this manual may create a protection

impairment by disabling or interfering with the unit’s safety features. This can result in injury

or death.

Your incubator and its recommended accessories are designed and tested to meet strict safety

requirements. Only use this equipment for its intended application; any alterations or modifications

void the warranty.

For continued safe operation of your incubator, always follow basic safety precautions including:

Follow all local or regional ordinances in your area regarding the use of this unit. If you

have any questions about local regulations, please contact the appropriate local agency.

Use only approved accessories. Do not modify system components. Any alterations or

modifications to your incubator can be dangerous and void your warranty.

Always plug the incubator power cord into an earth grounded electrical outlet that conforms

to national and local electrical codes. If the incubator is not grounded properly, parts such

as knobs and controls can conduct electricity and cause serious injury.

Avoid damaging the power cord. Do not bend it excessively, step on it, or place heavy

objects on it. A damaged cord can be a shock or fire hazard. Never use a power cord if it is

damaged.

Do not position the incubator in such a manner as to make it difficult to unplug the unit in

the event of an emergency.

Do not attempt to move the incubator while in operation.

Page | 4

Page 5

INTRODUCTION (CONTINUED)

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes

and improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your Shel Lab dealer or

distributor for assistance.

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue with your incubator, please contact Sheldon Technical

Support. Phone hours for Sheldon Technical Support are 6am – 4:30pm Pacific Coast Time (west

coast of the United States, UTC -8). Please have the following information ready when calling or

emailing Technical Support: the model number and the serial number (see page 7).

EMAIL: tech@shellab.com PHONE: 1-800-322-4897 extension 2, or (503) 640-3000 FAX: (503)

640-1366

Sheldon Manufacturing INC.

P.O. Box 627

Cornelius, OR 97113

5 | P a g e

Page 6

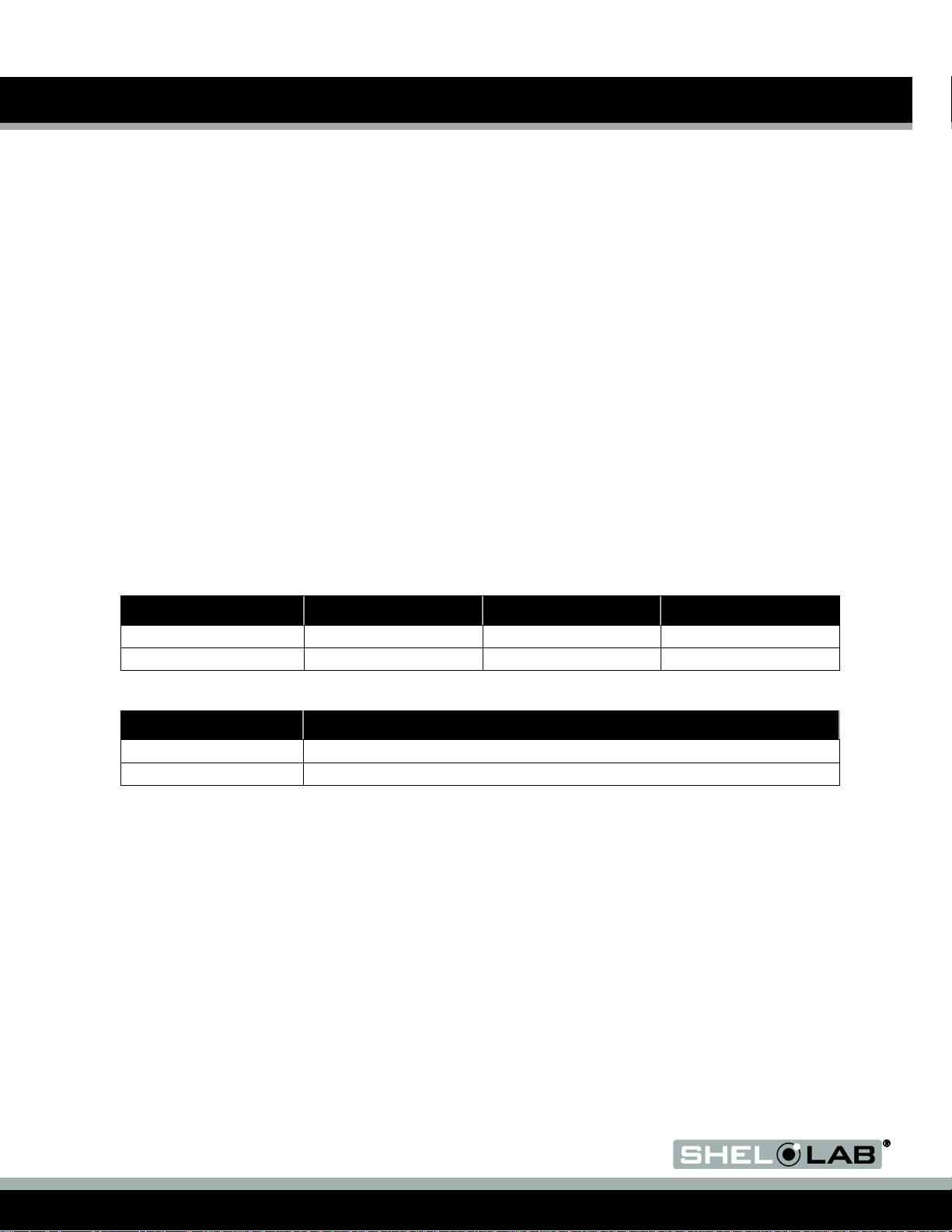

Model

Standard Shelves

Sliding Shelves

Leveling Feet

SRI6PF

2 0 4

SRI20PF

4 1 4

Model

Side Air Ducts

SRI6PF

0

SRI20PF

2

RECEIVING YOUR INCUBATOR

Before leaving the factory, all incubators are packaged in high-quality shipping materials to provide

protection from transportation-related damage.

When an incubator leaves the factory, safe delivery becomes the responsibility of the carrier.

Damage sustained during transit is not covered by the warranty.

When you receive your incubator, inspect it for concealed loss or damage to its interior and

exterior. If you find any damage to the incubator, then follow the carrier’s procedure for claiming

damage or loss.

INSPECTING THE SHIPMENT

Carefully inspect the shipping carton for damage. Report any damage to the carrier service that

delivered the incubator. If the carton is not damaged, open the carton and remove the contents.

Verify that the correct number of shelves, shelf slides, and leveling feet have been included (see

the following table for quantities).

Included accessories

Carefully check all packaging before discarding. Save the shipping carton until you are sure

everything works properly.

If you must return the incubator for any reason, first contact your service representative for

authorization (RMA). You must provide the unit’s data plate information. See Recording Data Plate

Information below.

Page | 6

Page 7

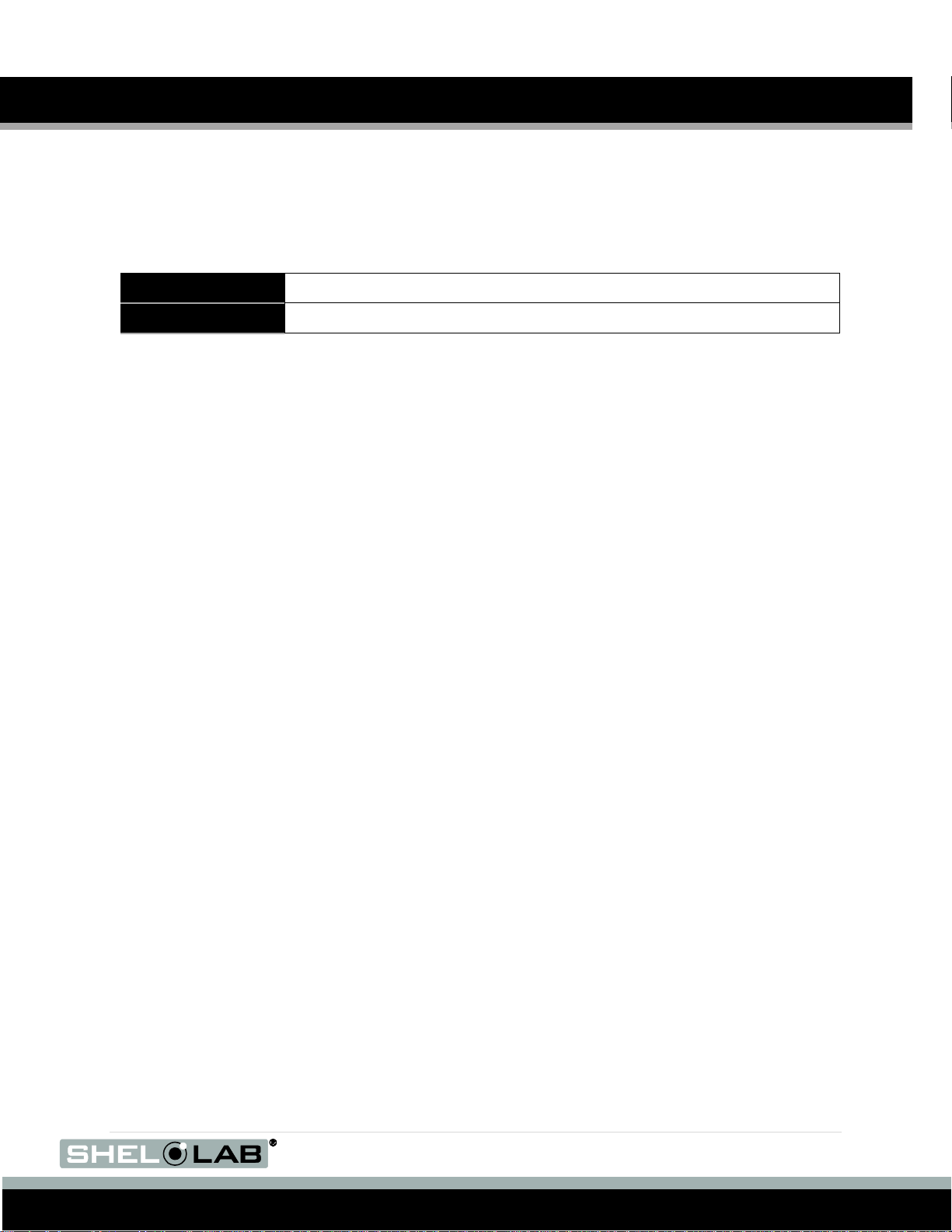

Model Number

Serial Number

RECEIVING (CONTINUED)

RECORDING DATA PLATE INFORMATION

Locate the data plate on the back of the incubator at the top right. The data plate contains the

incubator model number and serial number. Enter this information below for future reference.

Date Plate Information

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue your incubator, please contact Sheldon Technical

Support. Phone hours for Sheldon Technical Support are 6am – 4:30pm Pacific Coast Time (west

coast of the United States, UTC -8). Please have the following information ready when calling or

emailing Technical Support: the model number and the serial number.

EMAIL: tech@shellab.com PHONE: 1-800-322-4897 extension 2, or (503) 640-3000 FAX: (503)

640-1366

Sheldon Manufacturing INC.

P.O. Box 627

Cornelius, OR 97113

7 | P a g e

Page 8

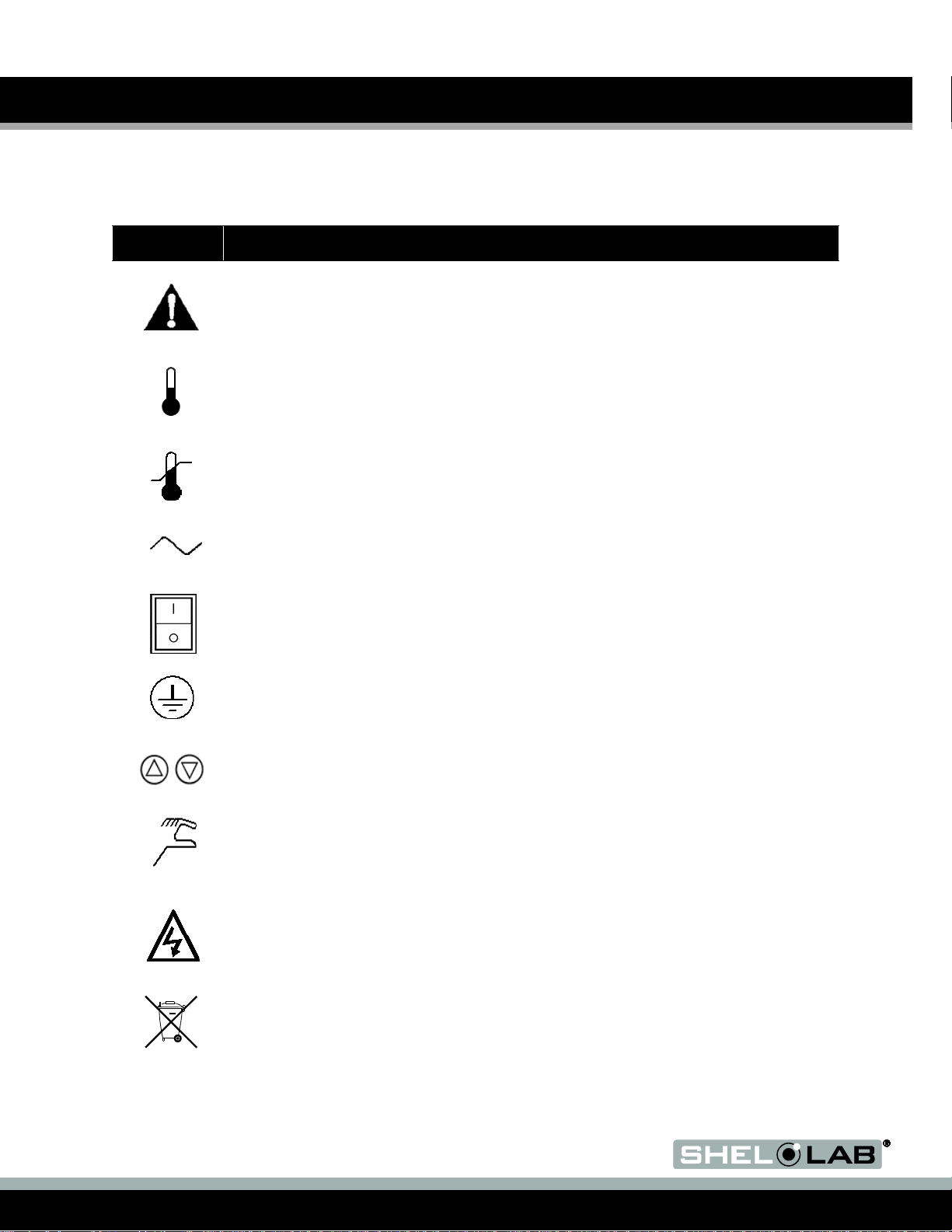

Symbol

Definition

Indicates that you should consult your service manual for further instructions.

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires.

Indicates Temperature

Repère température

Indicates the Over Temperature Limit system

Indique le système de dépassement de temperature

Indicates AC Power

Repère le courant alternatif

Indicates I/ON and O/OFF

I repère de la position MARCHE de l'interrupteur d'alimentation

O repère de la position ARRÊT de l'interrupteur d'alimentation

Indicates protective earth ground

Repère terre électrique

Indicates UP and DOWN respectively

Touches de déplacements respectifs vers le HAUT et le BA

Indicates Manually Adjustable

Indique un bouton réglable manuellement

Indicates Potential Shock Hazard

Signale danger électrique

WEEE Directive compliant logo

Indicates the unit should be recycled (Not disposed of in land-fill)

Indique l’appareil doit être recyclé (Ne pas jeter dans une décharge)

GRAPHIC SYMBOLS

The incubator is provided with graphic symbols on its interior and exterior surfaces. The symbols

identify hazards and the functions of the adjustable components, as well as important notes in the

user manual.

Page | 8

Page 9

INSTALLATION

This incubator is intended for use indoors, at room temperatures between 15C and 30C (59F

and 86F), at no greater than 80% Relative Humidity at 25C (77F). Allow a minimum of 4

inches (10cm) between the incubator and walls or partitions and 2 inches (5cm) of clearance

above the top of the incubator for unobstructed airflow.

Operating the unit outside of these conditions may adversely affect the temperature range

and stability.

For conditions outside of those listed above, please contact your distributor or Sheldon Sales to

explore other incubator options suited to your laboratory or production environment.

LOCATION

When selecting a location to install the incubator, consider all environmental conditions that can

affect unit’s effective temperature range, uniformity, and stability. For example:

Ovens, autoclaves, and any device that produces significant radiant heat

Heating and cooling ducts, or other sources of fast moving air currents

High-traffic areas

Direct sunlight

LIFTING AND HANDLING

The incubator is heavy and care should be taken to use appropriate lifting devices that are

sufficiently rated for these loads. Follow these guidelines when lifting and handling the incubator.

Lift the incubator only from its bottom surface.

Doors, handles, and knobs are not adequate for lifting or stabilization.

Restrain the incubator completely while lifting or transporting so it cannot tip.

Remove all moving parts, such as shelves and trays, and secure the doors in the closed

position during transfer to prevent shifting and damage.

LEVELING

You must make sure that the incubator is level and stable. Each incubator ships with four leveling

feet. Insert one leveling foot into each of the four holes in the bottom corners of the incubator.

Stand the incubator upright. Then, adjust the foot at each corner until the incubator stands level and

solid without rocking. To raise a foot, turn it in a counterclockwise direction; to lower a foot, turn it in

a clockwise direction.

Note: To prevent damage when moving the incubator, turn each of the four leveling feet completely

clockwise.

9 | P a g e

Page 10

INSTALLATION (CONTINUED)

INSTALL SIDE AIR DUCTS SRI20PF

Two (2) side air ducts are packed with the accessories of the SRI20PF. Install the air ducts from the

corner top and bottom hooks into the provided slots on the sides of the chamber. The SRI6PF

incubator does not use side ducts.

Figure 1: SRI20PF

Air Duct Panel

Note: The air duct panels play an important role maintaining even heat distribution inside the

SRI20PF’s incubation chamber. Failure to install both air duct panels may adversely impact

the incubator’s temperature uniformity.

Page | 10

Page 11

Figure 4: Standard Shelf Hung From

Mounting Bracket

Figure 3: Standard Mounting Bracket In

Place

INSTALLATION (CONTINUED)

SHELVING INSTALLATION

SRI6PF and SRI20PF Standard Shelving Installation

Perform the following steps to install the SRI6PF and SRI20PF incubator standard shelves:

Figure 2: Standard Shelf Mounting Bracket Installation

1. Laterally insert the mounting bracket’s 2 pairs of twin tabs (front and back) into the slots on

the sides of the incubator chamber.

2. Slide the bracket down so that the tabs are securely seated in the mounting slots.

3. Repeat the process on the opposite side of the chamber with the second mounting bracket.

4. Hang 1 shelf off the 2 installed mounting brackets.

11 | P a g e

Page 12

Figure 5: Sliding Shelf Mounting

Bracket Installation

Figure 6: Sliding Shelf Mounting

Bracket Installation

Figure 7: Sliding Mounting Bracket

Screws

Figure 8: Sliding Mounting Bracket

Front Screw Installed

INSTALLATION (CONTINUED)

SRI6PF and SRI20PF Sliding Shelf Installation

Note: The SRI6PF does not come with a sliding shelf. Sliding shelves for the SRI6PF must be

purchased separately.

1. Laterally insert the sliding mounting bracket’s 2 pairs of twin tabs (front and back) into the

slots on the sides of the incubator chamber. See Figure 5.

2. Slide the bracket down so that the tabs are securely seated in the mounting slots. See

Figure 6.

3. Secure the bottom flange of the sliding mounting bracket to the side of the chamber interior

by threading and screwing in 2 screws, at the front and back of the flange. See Figures 7

and 8.

Page | 12

Page 13

INSTALLATION (CONTINUED)

4. Repeat the process on the opposite side of the chamber with the second sliding mounting

bracket.

5. Hang 1 shelf from the 2 installed sliding mounting brackets.

POWER SOURCE

Always position the unit so the end-user has access to the power plug.

Check the data plate for voltage and ampere requirements before making a connection. If the

requirements match your power source, plug the power cord into an earth grounded outlet. This

incubator comes provided with a 100 – 120V 9ft, 5 in (2.86m) Nema 5-15P power cord. Supplied

voltage must not vary more than 10% from the data plate rating. Damage to the incubator

may result if supplied voltage varies more than 10%.

These incubators are intended for a 50/60 Hz application. Use a separate circuit to prevent loss of

product due to overloading or circuit failure.

Note: Electrical supply to the incubator must conform to all national and local electrical codes.

CLEANING

The incubator interior was cleaned at the factory but not sterilized. See the Cleaning topic in the

User Maintenance section for more information.

13 | P a g e

Page 14

CONTROL PANEL OVERVIEW

Figure 9: SRI6PF and SRI20PF Control Panel

Main Display

The main display consists of 4 operational elements. These are: The Time Display, time mode

indicator lights, the Temperature Display, and temperature mode indicator lights. The

functions of these indicators vary depending on the incubator’s current mode of operation, such as

temperature calibration or when setting the Current Time. The indicator functions for the Auto

Cycle’s day – night temperature programming and operation modes are explained in the Operation

Section.

Time Display: The green LED number display on the left side of the Main Display shows time in a

24 hour format. It can display one of three different times: Current Time, the Day-Time cycle start

time, and the Night-Time cycle start time. The default display is Current Time.

Time Mode Indicators: Just below the Time display are three LED indicators. The indicators are

for: Current Time, Day Time, and Night Time. The default indication is Current Time. The Day

Time and Night Time indicators illuminate when the user is setting up the Auto Cycle’s cycle day

and night start times, and when the unit is running in the Auto Cycle’s programmed day – night

cycle mode.

Temperature Display: The green LED number display on the right side of the Main Display shows

the temperature within the chamber, as well the current user-selected set point when prompted. It

will also display the Day-Time and Night-Time temperature set points when programing the Auto

Cycle.

Temperature Mode Indicators: Just below the Temperature Display are two LED indicators. The

indicators are: Day Temp and Night Temp. The Day Temp and Night Temp indicators are

illuminated when programing the Auto Cycle’s day and night cycle start times, and when the

incubator is running in the Auto Cycle’s programmed day - night cycle mode.

Power Switch

The main power switch on the control panel (green lighted I/O) controls all power to the unit and

must be in the I/ON position before any systems are operational. The switch will be lighted when in

the I/ON position.

Page | 14

Page 15

CONTROL PANEL (CONTINUED)

Main Temperature and Timer Control

The control consists of an UP/DOWN arrow pad. It is used to enter temperature set points when in

set point mode. In the calibration mode it is used to enter offsets. It is also used to adjust the

current time.

Enter Button

The ENTER button is used to enter time values for cycle start points and the current time, and to

scroll through the time setup menu.

Mode Button

This button is used to enter the time setup menu. It is also lets the user scroll between the day and

nighttime temperature modes.

Cycle Start Button

This button starts and ends the programmable automatic day – night cycle. The green PROGRAM

ACTIVE LED indicator to the right of the button will be illuminated when the Auto Cycle is running

the unit in the day – night cycle.

Heating and Cooling Light

The green pilot light located beneath the label TEC ACTIVATED should be ON whenever the

Peltier TEC device is actively heating or cooling the chamber. This light should be ON nearly all of

the time.

Set Over Temperature

This graduated dial sets the temperature set point for the Over Temperature Limit backup system.

The OTL System operates independently of the Main Temperature Controller, and prevents

uncontrolled heating of the Main Chamber in the event of a Main Temperature Controller failure.

For more details, please see the explanation of the Over Temperature Limit System in the

Operation Section.

OTL Light

The red pilot light marked OVER TEMPERATURE ACTIVATED will illuminate when the Over

Temperature Limit Thermostat has taken control of the incubator. Under normal operating

conditions this pilot lamp should never turn on.

Fuse

Located on the top back of the unit inside the cord inlet, the fuse protects against over current

conditions. If the fuse blows, the unit will shut down. For your safety and the safety of laboratory

personnel the cause of a blown fuse should be determined prior to replacing it.

15 | P a g e

Page 16

OPERATION

THEORY OF OPERATION

Each SRIPF incubator uses a Peltier thermoelectric cooling-and-heating device and an air

circulating fan in conjunction with a Proportional-Integrative-Derivative feedback temperature

controller board to achieve precise control over temperature levels within the incubator chamber.

The temperature sensor located in the air stream senses temperature deviations from the set point.

The PID Controller Board uses feedback from the sensor and error calculation functions to ensure

a high degree of thermal stability – avoiding overshooting or undershooting the user-selected set

point when heating or cooling the chamber. This results in precise and highly efficient cooling and

heating operations with minimum of power use. The circulating fan provides even air distribution

throughout the chamber and assures temperature uniformity around the unit’s shelf space.

An SRIPF Fly incubator can be set to run in a steady state Manual Mode, or in a programmable

Auto Cycle Mode with day – night variations in temperature and lighting automatically initiated when

user-selected start times are reached. In Manual Mode the incubator runs constantly in either the

Day Time or Night Time phase, as selected by the user. During Day Time phase operations the

Main Temperature Controller Board compensates for extra heat generated by the LED light bars in

the incubator chamber.

DOOR ALARM

The SRIP incubator is equipped with a magnetic induction door alarm which activates when the

door is open and the sensor components are out of range of one another for more than sixty

seconds (1 minute). When the alarm system is active an audio alarm will sound and the control

panel display will flash. Leaving the door open for extended periods will disrupt temperature

uniformity within the incubator chamber, and may result in significantly increased power use as the

temperature controller board attempts to compensate for the disruption.

ACCESSORY COMPATIBILITY

Make sure that any accessory equipment you will be using inside an SRIP incubator can safely and

effectively operate within your selected temperature range.

THE OVER TEMPERATURE LIMIT SYSTEM

The OTL is a backup heating control system that operates independently of the unit’s digital Main

Temperature Controller board. In the event of a failure of the controller board while in its heating

mode, the OTL system prevents runaway heating by depowering the peltier thermal electric heating

and cooling unit.

The OTL will not prevent a rise in heat caused by a failure of the peltier itself.

Note: The OTL system should be tested at least once per year using the Set The Over

Temperature Limit procedure.

Page | 16

Page 17

OPERATION (CONTINUED)

SETTING UP THE INCUBATOR

Perform the following steps each time the incubator is installed in a new location:

1. Verify that the power supply and incubator data plate match.

2. Check that the fuses are installed in the power inlet of the incubator and the fuse holder

next to the inlet.

3. Turn the Set Over Temperature Limit control dial to its maximum position clockwise. This

is to prevent the OTL from accidently interfering with the control setup and calibration

processes.

4. Plug the power cord into an earth grounded electrical outlet.

5. Place the Power switch in the ON position.

CONTROL SETUP AND OPERATION

The SRIPF incubators operate in a constant temperature Manual Mode or the programmable

day – night Auto Cycle Mode. At initial power up, the unit will be in Manual Mode and show the

current time and current temperature in its displays. All SRIPF incubators come factory set to

US Pacific Time Zone time, with the Day Time phase start point set at 08:00, and the Day Time

Temp set point set at 20˚C (calibrated to 20˚C), Night Time phase start point is set at 20:00,

and Night Temp set point at 20˚C (calibrated to 20˚C).

The Mode button is used to manually change between the Day Time and Night Time phases,

and to enter a Set Time Mode. To switch between the Day Time and Night Time phases, press

and hold the Mode Button for 5 seconds. To enter the Time Set Mode, press and release the

Mode button normally.

There are seven (7) procedures required to set up the SRIPF Drosophila incubator for use. In

order, these are:

1. Set the Current Time

2. Set the Day Time Phase Start Point

3. Set the Night Time Phase Start Point

4. Set the Day Time Phase Temperature Set Point

5. Set the Night Time Phase Temperature Set Point

6. Calibrate the Temperature Display

7. Set the Over Temperature Limit Control

17 | P a g e

Page 18

OPERATION (CONTINUED)

Figure 10: Details of the SRI6PF and SRI20PF Controls and Displays

SET THE CURRENT TIME

1. To change the clock to your current local time, press and release the Mode button.

2. The Current Time LED will stay lit, the Temperature Display will go out, and the Time

Display will begin flashing, displaying an adjustable time setting.

3. It will not matter if the Day or Night Temp LED’s are illuminated. Neither will affect setting

the clock.

4. Set the current time in the 24 hour clock day using the UP and DOWN arrows. 24 hour

clock PM afternoon and evening times are twelve hours greater than their normal 12-hour

clock equivalents. Example: 1 PM = 13:00; 6 PM = 18:00; 9 PM = 21:00. 12 AM will be

00:00. 12 AM is the point where the 24 clock cycle starts over.

5. After adjusting the clock to local time, press and release the Enter button. This will enter

your selected time into the incubator as the Current Time. It will also automatically advance

the unit to the Day Time phase Start Point selection mode.

SET THE DAY TIME PHASE START POINT

This procedure selects a time start point at which the unit will automatically switch to illuminated

Day Time phase lighting and temperature operations when running in the Auto Cycle Mode.

1. After pressing the Enter button at the end of setting the Current Time, the unit will advance

to its select Day Time Start mode. The Temperature Display will remain dark, and the Time

Display will continue to flash, displaying an adjustable Day Time start point.

2. The Current Time indicator LED will extinguish.

3. The Day Time LED indicator will turn on.

4. Using the UP and DOWN arrow keys, set the Day Time start point.

5. Press the Enter button. This will enter the Day Time phase Start Point, and automatically

advance the unit to its Night Time phase Start Point selection mode.

Page | 18

Page 19

OPERATION (CONTINUED)

SET THE NIGHT PHASE START POINT

1. The Temperature Display will remain dark. The Day Time indicator LED will extinguish, and

the Night Time indicator will illuminate.

2. The Time Display will continue to flash, now displaying an adjustable Night Time phase

start point.

3. Use the UP and DOWN arrows to set the Night Time start point, when the unit will

automatically transition from day time temperature and lighting to the night time

temperature and no lighting in the incubator chamber.

4. After selecting the Night Time start point, press the Enter button. This will enter the Night

Time phase start point into the unit, and return the display to its Current Time mode.

5. The Night Time LED should extinguish.

6. The Current Time LED should illuminate.

7. The Unit will now be running in Manual Mode with both phase’s Start Times, and the

Current Time stored in its memory.

SET THE DAY TIME PHASE TEMPERATURE SET POINT

1. If the Day Temp indicator is not already illuminated, select the Day Temp Mode by

pressing and holding the Mode button for 5 seconds. Otherwise start at step 2.

2. To set the Day Time Temp set point, press and release the UP or DOWN arrow once. The

Time Display will turn off, the current time LED will extinguish. The letters “SP” for set point

will briefly flash in the Temperature Display. The Temperature Display will then start

flashing an adjustable set point value.

3. To change the adjustable set point value press the UP arrow to increase the set point and

the DOWN arrow to decrease the set point.

4. Select the temperature you will be using during daytime operations.

5. After the desired temperature set point is reached, release the control. The incubator will

automatically return to Manual Mode after 5 seconds if no buttons are pushed, with the new

Day Temp set point entered.

6. The Temperature Display will resume showing the current chamber temperature, and the

Time Display will turn back on, showing the current time.

19 | P a g e

Page 20

OPERATION (CONTINUED)

SET THE NIGHT TIME PHASE TEMPERATURE SET POINT

1. Select the Night Temp Mode by pressing and holding the Mode button for 5 seconds. The

Day Temp light should go out, and the Night Temp light should turn on.

2. To set the Night Time Temp set point press, and release the UP or DOWN arrow once. The

Time Display will turn off, the current time LED will extinguish. The letters SP will briefly

flash in the Temperature Display. The Temperature Display will then start flashing an

adjustable set point value.

3. To change the adjustable set point value press the UP arrow to increase the set point and

the DOWN arrow to decrease the set point.

4. Select the temperature you will be using during nighttime operations. This can be same as

the Day Time temperature set point.

5. After the desired set point is reached, release the control. The incubator will automatically

return to Manual Mode after 5 seconds if no buttons are pushed, with the new Night Time

temperature set point entered.

6. The Temperature Display will resume showing the current chamber temperature, and the

Time Display will turn back on, showing the current time.

7. The user can cycle between the Day Temp and Night Temp temperature as needed by

pushing and holding the Mode button for 5 seconds.

Note: If setting up the incubator for the first time as part of the installation process, set the unit to

its Day Temp and leave undisturbed for 24 hours to prepare it for calibration.

Note: Before beginning use of the incubator, it is essential that you calibrate the unit’s temperature

display to match the actual air temperature of the chamber at the set points you will be

using during regular operations. Please see the following section.

Page | 20

Page 21

OPERATION (CONTINUED)

CALIBRATE THE TEMPERATURE DISPLAY

Allow the incubator at least 24 hours to stabilize at its operational set point before performing a

calibration. Always use a certified temperature sensing reference device that is regularly calibrated

to 0.1°C by a third party to conduct temperature verifications or calibrations. For best results use a

remote sensing device.

Part 1: Calibrate the Day Time Temperature

1. Place the incubator Manual Mode, with the Day Time Temperature indicator LED

illuminated.

2. Place the temperature sensor of a calibrated reference device inside the incubator as close

as possible to the chamber’s geometric center.

Note: A thermocouple sensor probe’s sleeve may be taped to the shelving, as long as the exposed

copper end is 2 inches (5cm) above the shelf. An exposed sensor probe in direct contact

with the shelving may experience heat sinking, which can result in an inaccurate temperature

reading.

3. Allow the temperature to re-stabilize after closing the door. The reference device’s

temperature measurement should not change for at least one (1) hour after a significant

disruption for the chamber to be considered stabilized.

4. If the reference device’s and the incubator’s temperature readings are the same, or the

difference between the two falls within the acceptable range of your laboratory protocol

after one (1) hour of stability, the incubator is calibrated.

5. If there is a difference between the two (2) readings, and that offset falls outside your

laboratory protocol’s acceptable range, adjust the incubator’s temperature display to match

the reference device’s reading. See the next step. If the door was briefly opened to take a

reading, wait fifteen minutes for the temperature to stabilize before correcting for the offset.

6. Press and hold both the UP and DOWN arrows simultaneously. The Temperature Display

will begin flashing and display the current temperature value. Adjust the current value

until it matches the reference device’s temperature reading. This will enter the offset into

the unit’s temperature controller board.

7. After matching the unit’s current value to that of the reference device, wait five seconds.

The incubator’s Temperature Display will cease flashing, and the incubator will now begin

heating or cooling to compensate for the entered temperature offset.

8. Allow the incubator one (1) hour to stabilize after reaching the new temperature.

9. Compare the reference device’s reading with the incubator’s. If the reference device’s and

the incubator’s temperature readings are the same or fall within the range of your

laboratory protocol, the incubator is now calibrated.

10. If the two readings are not the same or fall outside your laboratory protocol, repeat steps 5

– 8.

11. If the temperature readings of the incubator and the reference device still fall outside your

laboratory protocol after three calibration attempts, contact Sheldon Technical Support

for assistance.

21 | P a g e

Page 22

OPERATION (CONTINUED)

Part 2: Calibrate the Night Time Temperature

Note: The SRI6PF and SRI20PF must be calibrated to separate Day Time temperature and Night

Time temperature set points. In the Day Time heating and lighting mode, the LED interior

lights give off heat. As a result Day and Night calibration offsets will differ.

1. Change the unit to its Night Time mode by pressing and holding the Mode button for five

seconds. The Day Time Temp indicator LED should extinguish, and the Night Time Temp

indicator should turn on.

2. Allow the temperature to stabilize at the Night Time set point for at least one (1) hour with

no changes in the reference device’s reading. Do not disturb the incubator or open the door

during this time.

3. If the reference device’s and the incubator’s temperature readings are the same, or the

offset between the two falls within the acceptable range of your laboratory protocol after

one (1) hour of stability, the incubator is calibrated.

4. If there is a difference between the two (2) readings, and that offset falls outside your

laboratory protocol’s acceptable range, adjust the incubator’s temperature display to match

the reference device’s reading. See the next step. If the door was briefly opened to take a

reading, wait fifteen minutes for the temperature to stabilize before correcting for the offset.

5. Press and hold both the UP and DOWN arrows simultaneously. The Temperature Display

will begin flashing and display the current temperature value. Adjust the current value

until it matches the reference device’s temperature reading. This will enter the offset into

the unit’s temperature controller board.

6. After matching the unit’s current value to that of the reference device, wait five seconds.

The incubator’s Temperature Display will cease flashing, and the incubator will now begin

heating or cooling to compensate for the entered temperature offset.

7. Allow the incubator one (1) hour to stabilize after reaching the new temperature.

8. Compare the reference device’s reading with the incubator’s. If the reference device’s and

the incubator’s temperature readings are the same or fall within the range of your

laboratory protocol, the incubator is now calibrated.

9. If the two readings are not the same or fall outside your laboratory protocol, repeat steps 5

– 8.

10. If the temperature offset between the readings of the incubator and the reference device

still falls outside your laboratory protocol after three calibration attempts, contact Sheldon

Technical Support for assistance.

Page | 22

Page 23

OPERATION (CONTINUED)

SET THE OVER TEMPERATURE LIMIT CONTROL

Perform the following steps to set up the Over Temperature Limit system for use after calibrating

the unit.

1. If you have not done so already, turn the Set Over Temperature Limit control dial

clockwise to the maximum position. This allows the Set Temperature control to stabilize.

2. Then turn the Over Temperature Limit control dial counterclockwise until the Over Temp

Limit Activated light illuminates.

3. Slowly turn the Over Temperature Limit control dial clockwise until the light turns off.

4. This adjusts the Over Temperature Limit control to approximately 1˚C above the

temperature configured by the Set Temperature control.

Note: Test the Over Temperature feature annually

STARTING THE AUTO CYCLE

To start the incubator’s day – night Auto Cycle Mode carry out the following step:

1. Press and hold the Cycle Start button for two seconds.

2. The Program Active LED indicator next to the Cycle Start button should illuminate and stay

lit.

ENDING THE AUTO CYCLE

To end the Auto Cycle perform the following step:

1. Push and hold the Cycle Start button for two seconds

2. The Program Active indicator next to the Cycle Start button should extinguish.

Note: In the event of a power outage, the unit will restart in the last mode it was operating in, with

the Current Time display automatically adjusted to compensate. If running in the Auto Cycle

mode, the incubator will advance itself to the correct Day Time or Night Time phase of the

automatic temperature and illumination cycle.

23 | P a g e

Page 24

OPERATION (CONTINUED)

SILENCING THE DOOR AJAR ALARM

If the door alarm needs to be silenced, close the door, which will reset the timer. For prolonged

periods with the door open, the unit should be switched to the OFF position. If the door alarm

continues to sound when the door is fully closed, the position of the black tab-like door alarm

sensor, mounted on the front left side of the door frame overhang, can be adjusted using a

screwdriver. Loosen the screws just enough to slide the sensor and adjust. Do not remove the

screws.

LOADING THE INCUBATOR

Place items on the shelves inside the incubator chamber as evenly spaced as possible. Good

spacing allows for maximum air circulation and a higher degree of temperature uniformity.

ATTACHING EQUIPMENT TO THE INTERIOR ACCESSORY OUTLET

The incubator has a 1A (maximum) accessory outlet located inside the chamber. The power switch

on the front panel controls power to the accessory outlet. This outlet can power equipment such as

magnetic stirrers, rockers, etc. Do not attach any equipment drawing more than 1A to this outlet.

Accessory equipment may produce additional heat. This heat could affect the temperature range

and uniformity of this incubator. If you are using the interior accessory outlet, you should check that

the incubator operates within required temperatures when the accessory equipment is installed and

operating.

HUMIDIFYING THE INCUBATOR

Placing only a small number of petri dishes or open media containers in the incubator chamber may

lead to excessive drying of sample media. Unusually dry environmental conditions may also

contribute to sample drying. To counteract this, Sheldon Manufacturing offers an optional humidity

collection pan and tubing accessory kit: Part Number 9900708. The kit redirects moisture that

normally condenses on the heat sink fins of the Peltier TEC heating and cooling device, and uses it

to humidify the incubator. After ordering and receiving the kit, place the stainless steel pan on the

lowest chamber surface. Connect the tubing that comes with the kit to the port on the back of the

Peltier duct cover. Run the tubing down the back of the incubator behind the shelves, and secure

the end of the tubing inside the pan. The pan is supplied with a copper slug to help prevent

microbial contamination.

The humidifying kit is intended for use while running small loads. High workspace ambient

humidity, or applications that generate high levels of humidity, may result in excessive

condensation on the Peltier TEC unit. Overloading the unit with culture media can also generate

excessive humidity from sample media evaporation and blocking air flow pathways through the

shelf space. Water dripping from the Peltier duct cover at the top of the chamber onto the shelf

space and floor is symptomatic of excessive chamber humidity, and may damage the incubator.

Page | 24

Page 25

USER MAINTENANCE

Warning: Prior to any maintenance or service on this unit, disconnect the power cord from the power

supply.

Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le

cordon secteur de la source d'alimentation.

If a hazardous material/substance has spilled in the incubator immediately initiate your site’s

Hazardous Material Spill Containment protocol. Contact your local Site Safety Officer and follow

instructions per the site policy and procedures.

Periodic cleaning and disinfection are required to prevent microbiological contamination.

CLEANING

Note: The incubator chamber should be cleaned and disinfected prior to use.

Perform the following steps to clean incubator.

1. Remove all of the interior parts (shelves, racks, and any additional items), if assembled.

2. Clean the incubator with a mild soap and water solution, including all corners.

3. Rinse with distilled water and wipe dry with a soft cloth. Do not use deionized water.

4. Take special care when cleaning around the door alarm and temperature sensor heads,

and the chamber’s electrical outlet to prevent damage.

Warning: Never clean the unit with alcohol or flammable cleaners.

Avertissement: Ne jamais nettoyer l'appareil à l'alcool ou avec des nettoyants inflammables.

Note: Do not use spray cleaners or disinfectants that might leak through openings and cracks and

coat electrical components, or that contain solvents that will harm coatings. Do not use

chlorine-based bleaches or abrasives; they will damage the chamber liner.

DISINFECTING

Disinfect the incubator on a regular basis. Perform the below steps to disinfect the incubator:

1. Remove all of the interior parts (shelves, racks, and any additional items), if assembled.

Disinfect the Incubator, including all corners and the access port, using a suitable

disinfectant. Take special care when cleaning around sensing heads to prevent damage

and around the door gasket so as not to impair the positive seal.

2. Disinfect the incubator using commercially available disinfectants that are non-corrosive,

non-abrasive, and suitable for use on stainless steel, aluminum, painted steel surfaces.

Contact your local Site Safety Officer for detailed information for the proper disinfectants

suitable for your operation and laboratory protocol.

25 | P a g e

Page 26

MAINTENANCE (CONTINUED)

Periodically, inspect the door latch, trim, catch, and gasket for signs of deterioration. Failure to

maintain the integrity of the door system shortens the life span of the incubator.

Electrical components do not require maintenance. If the incubator fails to operate as specified,

please contact Sheldon Technical Support for help.

Page | 26

Page 27

Model

Shipping

Net Weight

SRI6PF

245lbs / 111.1kg

125lbs / 56.7kg

SRI20PF

405lbs / 183.7kg

246lbs / 111.6kg

Model

Exterior W × D × H

Interior W × D × H

SRI6PF

30 x 31.5 x 33.5 in

25.5 x 24.0 x 18.5 in.

SRI20PF

30 x 31.5 x 69.5 in

25.5 x 24.0 x 54.5 in.

Model

Exterior W × D × H

Interior W × D × H

SRI6PF

76.2 x 80.01 x 85.09 cm

64.8 x 61.0 x 47.1 cm

SRI20PF

76.20 x 80.01 x 176.53 cm

64.77 x 60.96 x 138.43 cm

Model

Cubic Feet

Liter

SRI6PF

6.55

185.53

SRI20PF

19.30

546.57

UNIT SPECIFICATIONS

These incubators are 100 - 120 voltage units. Please refer to each incubator’s data plate for its

electrical specifications.

Technical data specified applies to units with standard equipment at an ambient temperature of

25°C and a voltage fluctuation of ±10%. The temperatures specified are determined in accordance

to factory standard following DIN 12880 respecting the recommended wall clearances of 10% of the

height, width, and depth of the inner chamber. All indications are average values, typical for units

produced in the series. We reserve the right to alter technical specifications at all times.

WEIGHT

DIMENSIONS

In inches

In Centimeters

CAPACITY

27 | P a g e

Page 28

Model

Per Shelf

Total

SRI6PF

75lbs / 34kg

150lbs / 34kg

SRI20PF

75lbs / 34kg

375lbs / 170kg

Model

Temp Range

Uniformity

Stability

SRI6PF

15 to 40C

+/-0.5 @ 20C

+/-0.1C @ 20C

SRI20PF

15 to 40C

+/-0.5 @ 20C

+/-0.1C @ 20C

Model

Voltage

Amperage

Frequency

SRI6PF

100 - 120VAC

4.0 Amps

50/60 Hz

SRI20PF

100 – 120VAC

5.5 Amps

50/60 Hz

UNIT SPECIFICATIONS (CONTINUED)

SHELF CAPACITY BY WEIGHT

TEMPERATURE

POWER

Page | 28

Page 29

Description

Part Number

Gasket, Magnetic Door SRI6PF (29 inches X 26 inches)

3450743

Gasket, Magnetic Door SRI20PF (29 inches X 62 inches)

3450732

Feet, Adjustable Glide

2700506

Power Cord, USA

1800510

Shelf

6800525

Static Shelf Mount Bracket

5220942

Sliding Shelf Mounting Kit (2 Brackets)

9490560

Fuse 6.3A

3300515

Lab Stopper

7750517

LED Light Bars

4650547

Optional Humidity Reservoir Pan and Tubing

9900708

PARTS LIST

29 | P a g e

Page 30

Loading...

Loading...