Page 1

Installation and

Operation Manual

SMO5CR-2

Previously designated as

CR1-2

Sheldon Clean Room Oven 230 Voltage

Page 2

Sheldon Manufacturing Oven Clean Room 230 Voltage

Installation and Operation Manual

Part Number (Manual): 4861580

Revision: July 28, 2014

These units are forced air ovens for professional, industrial, or educational use where the

preparation or testing of materials is done at approximately atmospheric pressure and no

flammable, volatile, or combustible materials are being heated.

These units are compliant with the following standards:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010 + R:2009

UL 61010A-2-010:2002

UL 61010-1:2012

EN 61010-1:2010

EN 61010-2-010:2003

2 | P a g e

Page 3

TABLE OF CONTENTS

General Safety Considerations ................................................................................................................. 4

Engineering Improvements ....................................................................................................................... 5

Contacting Assistance ............................................................................................................................... 5

RECEIVING YOUR OVEN ............................................................................................................................ 6

Inspecting the Shipment ............................................................................................................................ 6

Returning the Shipment ............................................................................................................................ 6

Recording Data Plate Information ............................................................................................................. 6

Orientation ................................................................................................................................................. 7

GRAPHIC SYMBOLS ................................................................................................................................... 8

INSTALLATION ............................................................................................................................................ 9

Ambient Conditions ................................................................................................................................... 9

Location ..................................................................................................................................................... 9

Lifting and Handling .................................................................................................................................. 9

Leveling ................................................................................................................................................... 10

Power Source .......................................................................................................................................... 10

Shelving Installation ................................................................................................................................ 11

Cleaning .................................................................................................................................................. 11

Burn In ..................................................................................................................................................... 11

CONTROL PANEL OVERVIEW ................................................................................................................. 12

OPERATION ............................................................................................................................................... 14

Operating Precautions ............................................................................................................................ 14

Theory of Operations .............................................................................................................................. 14

Setting up the Oven ................................................................................................................................ 15

Set the Over Temperature Limit .............................................................................................................. 16

Set the Temperature Controller Set Point ............................................................................................... 16

HEPA Filter Burn-In ................................................................................................................................. 17

Calibrating the Unit For Your Application ................................................................................................ 19

Closed Vents ........................................................................................................................................... 21

Over Temperature Limit Active ............................................................................................................... 21

Positive Venting of Exhaust .................................................................................................................... 22

USER MAINTENANCE ............................................................................................................................... 24

Cleaning .................................................................................................................................................. 24

Disinfecting .............................................................................................................................................. 24

Door Latch and Electronics ..................................................................................................................... 25

Door Gaskets .......................................................................................................................................... 25

HEPA Filter Lifespan ............................................................................................................................... 25

Replacing the HEPA Filter Assembly ...................................................................................................... 26

UNIT SPECIFICATIONS ............................................................................................................................. 28

Weight ..................................................................................................................................................... 28

Dimensions .............................................................................................................................................. 28

Capacity .................................................................................................................................................. 28

Shelf Capacity by Weight ........................................................................................................................ 28

Temperature ............................................................................................................................................ 29

Airflow Performance ................................................................................................................................ 29

Power ...................................................................................................................................................... 29

REPLACEMENT PARTS ............................................................................................................................ 30

Ordering Parts and Consumables ........................................................................................................... 30

3 | P a g e

Page 4

INTRODUCTION

Thank you for purchasing a Sheldon Manufacturing Clean Room Oven. We know that in today’s

competitive marketplace, customers have many choices when it comes to constant temperature

equipment. We appreciate you choosing ours. Our continued reputation as a leading laboratory

product manufacturer rests with your satisfaction. Sheldon Manufacturing, Inc. stands behind our

products, and we will be here if you need us.

These ovens are intended for professional, industrial, and educational clean room applications

requiring horizontal shelf space airflows. The ovens are not designed for use at hazardous or

household locations.

Before you use your oven read this entire manual carefully to understand how to install, operate,

and maintain the oven in a safe manner. Keep this manual available for use by all oven operators.

Ensure that all operators are given appropriate training before the oven begins service.

GENERAL SAFETY CONSIDERATIONS

Note: Failure to follow the guidelines and instructions in this manual may create a protection

impairment by disabling or interfering with the unit’s safety features. This can result in injury

or death.

Your oven and its recommended accessories have been designed and tested to meet strict safety

requirements. For continued safe operation of your oven, always follow basic safety precautions

including:

Follow all local or regional ordinances in your area regarding the use of this unit. If you

have any questions about local regulations, please contact the appropriate agency.

Use only approved accessories. Do not modify system components. Any alterations or

modifications to your oven may be dangerous and will void your warranty.

Always hardwire the unit’s power feed to an earth grounded electrical source that conforms

to national and local electrical codes. If the unit is not grounded, parts such as, knobs and

controls may conduct electricity and cause serious injury.

Avoid damaging the power feed. Do not bend it excessively, step on it, place heavy objects

on it. A damaged power feed can easily become a shock or fire hazard. Never use a power

feed after it has been damaged.

Do not position the equipment in such a manner as to make it difficult to disconnect or

uncouple the power feed.

Do not attempt to move the unit while in operation or before the unit has cooled.

4 | P a g e

Page 5

INTRODUCTION (CONTINUED)

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes

and improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your Shel Lab dealer or

customer service representative for assistance.

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue with the oven, please contact Sheldon Technical

Support. Phone hours for Sheldon Technical Support are 6am – 4:30pm Pacific Coast Time (west

coast of the United States, UTC -8).

Please have the following information ready when calling or emailing Technical Support: the model

number and the serial number. These will be found on the unit’s data plate, which is located on

the back of the unit at the top right, next to the power supply as mandated by regulatory

requirement.

EMAIL: tech@shellab.com PHONE: 1-800-322-4897 extension 2, or (503) 640-3000 FAX: (503)

640-1366

5 | P a g e

Page 6

Shelves (2)

Shelf Slides (4)

Leveling Feet (4)

Model Number

Serial Number

RECEIVING YOUR OVEN

Before leaving our factory, all Clean Room Ovens are packaged in high-quality shipping materials

to provide protection from transportation-related damage. When an oven leaves our factory, safe

delivery becomes the responsibility of the carrier. Damage sustained during transit is not

covered by the oven’s warranty. When you receive your High Performance Oven, inspect it for

concealed loss or damage to its interior and exterior. If you find any damage to the oven follow the

carrier’s procedure for claiming damage or loss.

INSPECTING THE SHIPMENT

Carefully inspect the shipping carton for damage. Report any damage to the carrier service that

delivered the oven. If the carton is not damaged, open the carton and remove the contents. The

unit should come with an Installation and Operation Manual, warranty card, a Certificate of

Compliance, and the Programming Guide – Watlow EZ-Zone Heating Profiles.

Verify that the correct number of shelves, shelf slides, and leveling feet have been included (see

the following table for quantities).

Included accessories

Carefully check all packaging before discarding. Save the shipping carton until you are certain that

the unit and its accessories function properly.

RETURNING THE SHIPMENT

If you must return the oven for any reason, first contact your service representative for a return of

material authorization (RMA). You must provide the unit’s data plate information. See Recording

Data Plate Information below.

RECORDING DATA PLATE INFORMATION

Locate the data plate on the back of the oven next to the power inlet. The data plate contains the

oven model number and serial number. Enter this information below for future reference.

Date Plate Information

6 | P a g e

Page 7

Figure 1: Orientation Photo

Fuse

Holders

External Power

Outlet

Nitrogen Gas

Inlet

Permanent Connect Wire Braid

14 gauge, 6 inches (15 cm)

Intake Vent

Exhaust Vent

Control Panel

Power Switch

Intake Vent Valve

Control

Exhaust Vent Valve

Control

Outer Door

Gasket

Chamber Ceiling

Liner

Right Wall

Chamber Liner

HEPA Filter

Assembly

Left Wall

Chamber Liner

Door Latch

Door Latch

Chamber Gasket

Note: The external

power outlet type

varies by country and

voltage.

RECEIVING (CONTINUED)

ORIENTATION

Back Panel

7 | P a g e

Page 8

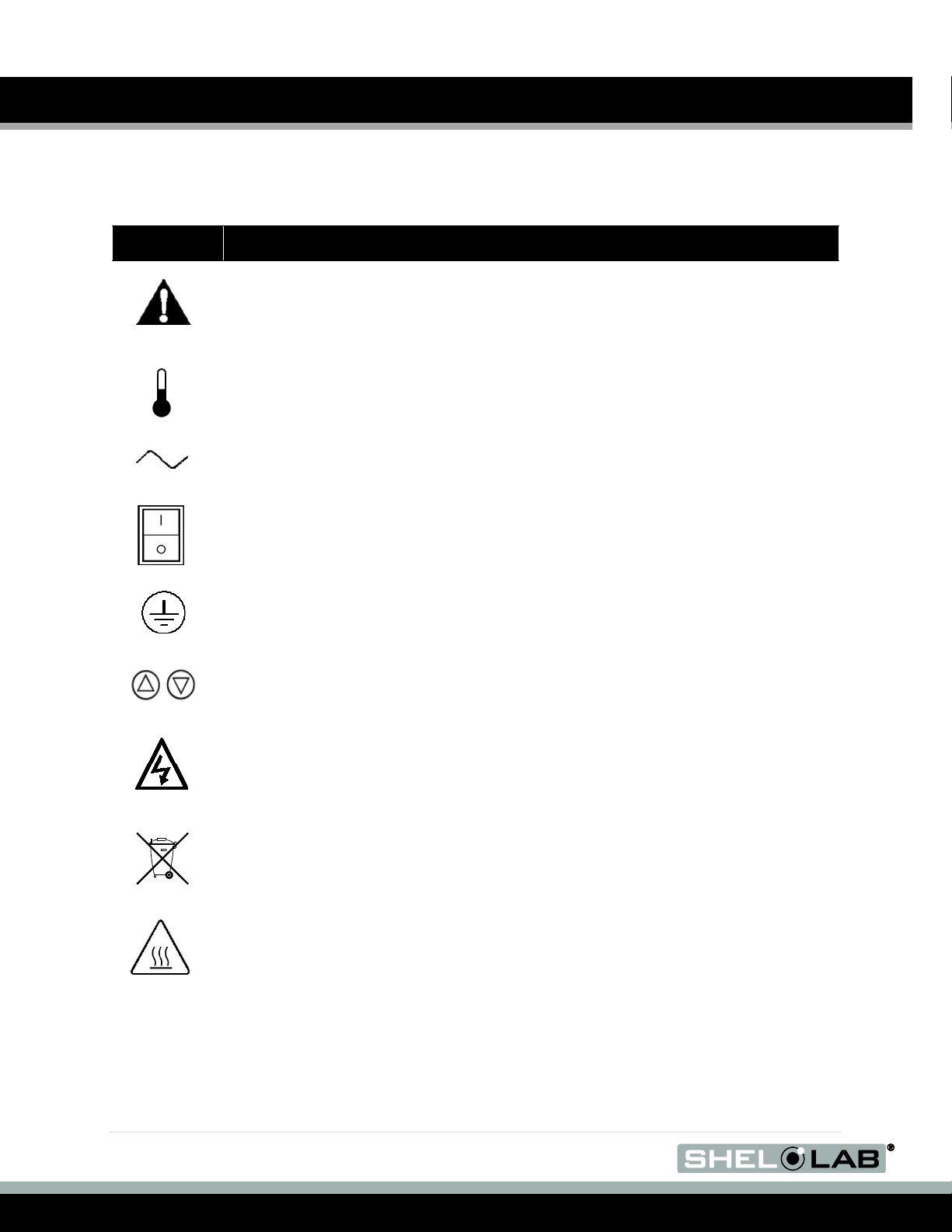

Symbol

Definition

Indicates that you should consult your service manual for further instructions.

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires.

Indicates Adjustable Temperature

Indique température réglable

Indicates AC Power

Repère le courant alternative

Indicates I/ON and O/OFF

I repère de la position MARCHE de l'interrupteur d'alimentation

O repère de la position ARRÊT de l'interrupteur d'alimentation

Indicates protective earth ground

Repère terre électrique

Indicates UP and DOWN respectively

Touches de déplacements respectifs vers le HAUT et le BA

Indicates a Potential Shock Hazard

Signale danger électrique

WEEE Directive compliant logo

Indicates the unit should be recycled (Not disposed of in land-fill)

Indique l’appareil doit être recyclé (Ne pas jeter dans une décharge)

Indicates: Caution hot surface

Indique: Avertissement symbole de surface chaude

GRAPHIC SYMBOLS

The oven is provided with multiple graphic symbols on its external and internal surfaces. The

symbols identify hazards and the functions of the adjustable components, as well as important

notes found in the user manual.

8 | P a g e

Page 9

INSTALLATION

Installation of an SMO5CR-2 requires permanent connect wiring (commonly known as hardwiring),

and must be performed by a qualified electrical technician. All other installation steps can be

performed by the end user.

AMBIENT CONDITIONS

This oven is intended for use indoors, at room temperatures between 15C and 40C (59F and

104F), at no greater than 80% Relative Humidity (at 25C / 77F). Allow a minimum of 12 inches

(30cm) between the oven and any walls or partitions, and 24 inches (60cm) of vertical headspace

clearance above the top of the oven for unobstructed airflow and cooling. If the oven’s exhaust will

be vented from the workspace through a duct or other channeling, 12 inches (30cm) of vertical

clearance will suffice. Make sure the intake and exhaust vent remain unobstructed. Do not place

objects on top of oven, aside from the power exhaust accessory described in the manual.

Operating the unit outside these conditions may adversely affect the oven’s temperature

range, uniformity, and stability.

For conditions outside of those listed above, please contact your distributor or Shel Lab Sales to

explore other ovens suited to your production of laboratory environment.

LOCATION

When selecting a location to install the oven, consider all conditions that can affect temperature

performance. For example:

Ovens, autoclaves, and any device that produces significant radiant heat

Heating and cooling ducts, or other sources of fast moving air currents

High-traffic areas

Direct sunlight

LIFTING AND HANDLING

The oven is heavy. Use appropriate lifting devices that are sufficiently rated for these loads. Follow

these guidelines when lifting the oven:

Lift the oven only from its bottom surface.

Doors, handles, and knobs are not adequate for lifting or stabilization.

Restrain the oven completely while lifting or transporting so it cannot tip.

Remove all moving parts, such as shelves and trays, and secure the door in the closed

position during transfers to prevent shifting and damage.

9 | P a g e

Page 10

INSTALLATION (CONTINUED)

LEVELING

The oven must be level and stable for safe operation. Each Clean Room Oven ships with four

leveling feet. Insert one leveling foot into each of the four holes in the bottom corners of the oven.

Stand the oven upright. Then, adjust the foot at each corner until the oven stands level and solid

without rocking. To raise a foot, turn it in a counterclockwise direction; to lower a foot, turn it in a

clockwise direction.

Note: To prevent damage when moving the oven, turn each of the four leveling feet completely

clockwise.

POWER SOURCE

The oven is intended for 230 volt, 50/60 Hz applications at 12 Amps.

Check the oven’s data plate to verify voltage and ampere requirements before wiring to a power

source.

The oven’s power feed must be wired into an earth grounded source. The oven comes provided

with an integral 6 inch (15 cm) wire braid of two 14 gauge high-temperature (300°C) hot wires and a

14 gauge earth ground. See the Orientation figure on page 7.

The power source for the oven must conform to all national and local electrical codes Supplied

voltage must not vary more than 10% from the data plate rating. Damage to the oven may

result if supplied voltage varies more than 10%.

Before energizing the oven it must be earth grounded using the protective conductor terminal

(green with yellow stripe wire. Do not remove the protective conductor (earth connection).

Removing the protective conductor will negate the oven’s protections against potentially dangerous

electric shocks and create a possible fire hazard.

A separate circuit is recommended to prevent possible loss of product due to overloading

or failure of other equipment on the same circuit.

A switch or circuit-breaker must be used in the building installation.

The required circuit-breaker is 20 Amps.

The wires for power source connection should be in accordance with the following for all

units: Green/Yellow – Earth; Black – Hot; Red – Hot.

The power feed Disconnect must be in close proximity to the equipment and within easy

reach of the operator.

The power feed Disconnect must be marked as the disconnecting device for the

equipment.

10 | P a g e

Page 11

INSTALLATION (CONTINUED)

SHELVING INSTALLATION

The horizontal airflow within the chamber moves from the HEPA filter housing on the right-hand

side of the chamber, to the large holes on the left side. Place the shelves so they do not obstruct

the duct holes on the left in order to maximize airflow across the shelf space.

1. Install shelf slide hangers on opposites of the oven by inserting the slider’s tabs into the

chamber’s mounting slots, then pushing down gently to secure the slider.

2. Hang the shelf from the two installed sliders.

Figure 2: Installed Sliding Shelf, SMO5CR-2

CLEANING

The oven interior was cleaned at the factory but not sterilized. See the Cleaning and Disinfection

topics in the User Maintenance section on page 24 for more information.

BURN IN

The SMO5CR-2 requires a burn in of its HEPA Filer. Please see the HEPA Filter Burn-In

procedure on page 17 in the Operation Sections.

11 | P a g e

Page 12

CONTROL PANEL OVERVIEW

Figure 3: Control Panel

Power Switch

The main power switch on the control panel (green lighted I/O) controls all power to the oven. It

must be in the illuminated I (ON) position before any systems or components are operational.

Temperature, Profile, and OTL Controller

The temperature controller for the oven is labeled TEMPERATURE AND HIGH LIMIT CONTROL

and consists of a Watlow EZ-Zone Controller. The control is provided with a digital display and up

and down arrow keys for adjusting the oven’s temperature set point, performing a calibration, and

choosing pages and adjusting parameter settings while setting up heating profiles. The arrow keys

also control the operations of the oven’s Over Temperature Limit system (OTL).

Figure 4: Temperature Controller

The EZ1 button is used to quick launch Profile 1 or abort any running heating profile (see the

Programmed Operations section on page 22). The EZ2 button does not have function associated

with it in the SMO5CR-2.

The green advance button is used to scroll forward through menus and parameters lists.

The reset button is used to scroll the display back to a previous page or menu while programing

heating profiles. Pressing the reset button repeatedly returns the display to the home page.

Note: On some older Watlow Controllers the Reset button may be labeled with an infinite ∞ symbol

rather than RESET.

A small flashing “2” toward the center bottom of the display indicates when the controller is

powering the oven’s heating elements. A small flashing “1” indicates internal communications

functions within the controller.

12 | P a g e

Page 13

CONTROL PANEL OVERVIEW (CONTINUED)

Vent Valves

The SMO5CR-2 comes provided with two vent valve controls on its front control panel. These open

or close the intake and exhaust valves located on the top of the unit.

Purge Valve

The SMO5CR-2 comes with a purge valve located on the back of the unit. The valve can be

connected to a cylinder of nitrogen (N2) or other neutral gas to purge the oven chamber.

Fuses

The SMO5CR-2 is provided with two (2) 20 amp fuses. These are located in holders adjacent to the

power feed braid on the back power panel of the unit. Please see the Orientation photo on page

7. The fuses protect against overcurrent conditions related to the operation of the oven. If one fuse

blows, the oven will shut down. For safe operation, the cause of a blown fuse should be determined

prior to replacing it.

The oven is also provide with a pair (2) of 2 amp fuses installed adjacent to the external power

outlet. Please see the Orientation photo on page 7. The fuses protect against overcurrent

conditions related to the operation of the outlet and an attached power exhaust blower. If one fuse

blows, the outlet will depower. The cause of a blown fuse should be determined prior to replacing it.

13 | P a g e

Page 14

OPERATION

OPERATING PRECAUTIONS

Warning: The SMO5CR-2 is not an explosion proof unit! The oven is not designed to safely contain

combustible gasses. Do not place explosive, combustible, or flammable materials into the chamber.

1. The SMO5CR-2 not designed for use in Class I, II, or III locations as defined by the US

National Electric Code.

2. Do not operate the oven in an environment with noxious fumes.

3. Outgassed byproducts maybe hazardous to or noxious for operating personal. If either is

the case, oven exhaust should be positively ventilated to a location outside workspace in

accordance with national and local regulations.

4. Do not place sealed or filled containers in the oven.

5. Do not place mercury thermometers in the oven.

6. The bottom surface of the chamber should not be used as a work surface

Warning: The vent dampers may be hot to the touch. These areas are marked with Hot Surface labels.

Proper PPE should be employed to minimize risk to burn.

Avertissement:Les clapets d'aération peuvent être chauds au toucher. Ces zones sont marqués avec

des étiquettes de Surface chaude. Les EPI approprié devraient être employée pour réduire au minimum

le risque de brûler.

THEORY OF OPERATIONS

Heating

Operation of the Sheldon Clean Room Oven is controlled by a Watlow EZ digital controller through

the use of user-selected temperature set points or user-programed heating profiles. When heating

the oven, the controller users Proportional – Integrative – Derivative (PID) feedback functions to

avoid overshooting temperature set points and profile levels. The controller does so by gradually

decreasing the amount of power to the heating elements in response to measurements and PID

analysis.

The Watlow controller can store up to four heating profiles, each with ten steps. Please see the

Programed Operations section on page 22, and the Watlow EZ-Zone Profile Programing Guide

for more details.

The heating rates given in this manual’s unit specification section are for a 25°C environment. The

ambient temperature of the workspace around the oven will affect the oven’s heating and cooling

The SCMO5CR-2 should be calibrated as required by your production or laboratory protocol, or

regulatory requirements, to verify that it is accurately measuring and displaying the oven chamber

air temperature. If a measurement error (offset) is detected the, display can be calibrated to the

actual temperature by placing the oven in its calibration mode (see page 19.)

14 | P a g e

Page 15

Home Page

Temp in Red

Set Point in Green

OPERATION (CONTINUED)

Airflow and Applications

During normal operations an internal blower fan motor pulls air in through the intake vent. The

captured air is blown across heating elements and then forced down through a duct on the right

side of the oven chamber. The air exits the duct through the HEPA filter.

Upon leaving the filter, the heated air blows horizontally across the shelf space, helping to create

temperature uniformity and enhance drying. After crossing the shelves, the air enters a duct on the

left side of the chamber, and is then pulled back into the heater space above the oven chamber.

During each minute of operation some air exits through the open exhaust vent on the top right of

the unit. Lost air is replaced through the intake vent. The rate of atmosphere exchange on several

variable factors. These include: ambient conditions, position of the vent valves, the volume of

material in the oven chamber, and if a power exhaust unit is connected to the exhaust vent.

Over Temperature Limit

The Watlow controller contains a backup temperature control system with independent circuitry

connected to a redundant temperature sensor probe inside the oven chamber. To set up this

system for use, the user enters an over temperature limit into the Watlow controller — typically 5°C

above the application or process temperature set point. In the event the oven temperature exceeds

the over temperature limit, the backup system will depower the heating element. This provides

redundant heating control the event of a failure of the primary circuitry or the main temperature

sensor probe.

Power Exhaust Outlet

SMO5CR-2 Ovens come provided with a power outlet that can be used to power an exhaust blower

unit attached to the oven’s exhaust vent. The power outlet and attached fan can be activated by the

Watlow controller as part of a heating profile. The primary application of the power exhaust fan is to

channel or positively vent exhaust out of the workspace around the oven.

SETTING UP THE OVEN

1. After the oven has been installed in the location where it will be used, open the

oven’s intake and the exhaust vents.

2. Push the Power Switch to the ON position. The Temperature Display will illuminate.

3. Set up the oven for use by carrying out the following procedures found in this

manual’s Operation section:

Set the Over Temperature Limit (pg. 16)

Set the Temperature Controller Set Point (pg. 16)

HEPA Filter Burn-In (pg. 17)

Calibrating the Unit (pg. 19)

15 | P a g e

Page 16

OPERATION (CONTINUED)

SET THE OVER TEMPERATURE LIMIT

This procedure sets the Over Temperature Limit backup system. This is typically 5°C above the set

point temperature you will be using during your application or process, or 5°C above the hottest

temperature of your heating profile.

Note: If this is the first use of the oven, set the Over Temperature Limit to 325°C or higher to

prepare for the Burn In procedure. This helps ensures the OTL system will not interfere

with the Burn In procedure.

1. Press the green Advance button until “Lh.S1” (Limit High Set Point) shows in the greencolored mid-level display.

2. Use the Up and Down arrows to enter a temperature limit in the red top display.

3. After entering the temperature limit, press the Advance button. The red display will show

“SAFE”, indicating that the temperature limit has been set.

4. Press the Reset button to scroll the display back to the home page.

SET THE TEMPERATURE CONTROLLER SET POINT

This procedure sets a new temperature set point for the oven.

Note: Set the oven to 125°C if you will be manually running the HEPA Filter Burn-In procedure prior

to its first use (see page 17).This procedure may also be run by programing and launching it

as a heating profile.

1. On the home page, use the Up and Down Arrow keys to adjust the set point in the green

display to your baking application or process temperature set point.

a. Holding down an arrow key will cause the temperature to advance in

increments of ten (10) rather one (1).

2. Release the Arrow Button once you have reached your required set point. There may be

a brief pause before the oven starts heating.

a. A small flashing 2 in the Watlow display indicates when the temperature

controller is calling for heat.

Note: Please see the Quick Start – SHEL LAB Vacuum Oven Basic Video at

http://www.shellab.com/store/virtual-tour-vac-oven.html for a demonstration of how to enter

a temperature set point. The video applies to all ovens with the EZ-Zone Watlow controller.

Note: The Reset Button on the controller of your Watlow is referred to as the Infinite Button in the

video.

End procedure

16 | P a g e

Page 17

OPERATION (CONTINUED)

HEPA FILTER BURN-IN

The HEPA filter must be burned in prior to its first use. The HEPA filter will fill with gas and produce

significant smoke during the burn-in. The oven’s intake and exhaust vents must be open throughout

the procedure. The burn-in process requires approximately thirteen hours. Remove shelving from

the oven prior to the burn-in.

Burn-in:

1. 125°C for 1 hour

2. 150°C for 4 hours

3. 175°C for 1 hour

4. 200°C for 1 hour

5. 225°C for 1 hour

6. 250°C for 1 hour

If the operating temperature will exceed 250°C, continue the cycle of one hour at 25°C increments

until the operating temperature is reached (maximum 300°C). The filter must be burned-in to the

highest operating temperature.

If manually running the burn-in process, be sure to allow time for the oven to ramp up (heat) to

each temperature level and ramp down (cool) afterward. Under most ambient conditions a-half hour

(30 minutes) should suffice for ramping up.

Procedure continued on next page

17 | P a g e

Page 18

Step

Step Type

Set Point

Time Interval

Event Option

Step 1

Time Interval “Ti”

125°C

30 Minutes

Off

Step 2

Soak “SoAh”

1 Hour

Off

Step 3

Time Interval “Ti”

150°C

30 Minutes

Off

Step 4

Soak “SoAh”

4 Hours

Off

Step 5

Time Interval “Ti”

175°C

30 Minutes

Off

Step 6

Soak “SoAh”

1 Hour

Off

Step 7

Time Interval “Ti”

200°C

30 Minutes

Off

Step 8

Soak “SoAh”

1 Hour

Off

Step 9

Time Interval “Ti”

225°C

30 Minutes

Off

Step 10

Soak “SoAh”

1 Hour

Off

Step 11

Time Interval “Ti”

250°C

30 Minutes

Off

Step 12

Soak “SoAh”

1 Hour

Off

Step 13

End

Off

OPERATION (CONTINUED)

The table below shows the burn-in process as a programed heating profile for the Watlow controller

in a 25°C ambient environment. Please consult the Programing Guide – Watlow EZ-Zone

Controller Heating Profiles document for the details of how to program a heating profile.

Post-Burn Cleaning:

Note: Do not remove or disturb the HEPA filter assembly cover after the burn-in. A burnt filter is

fragile and easy to damage. Only remove the HEPA filter housing cover when replacing the

filter.

1. Shutdown and unplug the oven. Allow the oven to cool to room temperature.

2. Clean the oven’s shelving and interior surfaces to remove the exhaust from the HEPA filter.

3. Take care not to damage the temperature sensor probes when cleaning. These are located

on the back wall of the oven chamber, adjacent to the HEPA filter.

4. Reinstall shelving when the oven is

18 | P a g e

Page 19

OPERATION (CONTINUED)

CALIBRATING THE UNIT FOR YOUR APPLICATION

The oven should be calibrated at the temperature set point it will be run at. For heating profiles, the

oven should be calibrated to the average temperature of the profile.

1. Close the exhaust vent if your application or process calls for the exhaust vent to be

closed. Otherwise leave the vent open. The intake vent should always be open.

2. Place the temperature sensor of a certified reference device inside the oven, secured to the

center of the center-most shelf.

Note: Always use an independently certified temperature reference device that is regularly

calibrated to 0.5°C accuracy or better to conduct temperature calibrations or verifications.

. For best results, using a remote sensing reference device.

3. Enter an Over Temperature Limit of 325°C to safeguard against the OTL System

interfering with the calibration procedure, if you have not already done so.

4. Enter the temperature set point you will use during your application or process.

5. Allow the chamber to heat to up the set point, and then stabilize with no change in

temperature for at least a-half hour (30 minutes) prior to performing a temperature

calibration. This is to ensure the best possible temperature uniformity and accuracy in

the oven chamber.

6. Read the reference temperature device’s display. Compare its reading with the red

temperature shown in the Watlow Controller’s Temperature Display.

7. If the reference device’s and the Watlow’s temperature readings are the same or fall within

the range of your laboratory or manufacturing protocol, the oven is now calibrated.

8. If there is a temperature difference between reference device and the Watlow, and that

difference falls outside your laboratory or manufacturing protocol’s acceptable range, adjust

the Watlow to match the reference device’s reading by entering a temperature offset. See

the next step.n

Procedure continued on next page

19 | P a g e

Page 20

Reference Sensor

Reading

Watlow Temp.

Display

Offset

Value

152°C

150°C

2

148°C

150°C

-2

OPERATION (CONTINUED)

Note: The accuracy of the calibration process is limited by the accuracy of your reference

temperature device.

The difference between the reference device and oven’s display is called an offset.

Examples of offsets:

Note: If the door was opened to check the reference device’s reading, allow the oven

temperature ten minutes to stabilize before entering the offset.

9. Enter the temperature offset into the Watlow Controller. To do so, push and hold both

the Up and Down Arrow Button simultaneously for three (3) seconds or until “Ai”

appears in the Upper Display and “oPEr” appears in the Lower Display.

10. Push the green Advance Button repeatedly unit “i.CA” appears in the green middle

display and a number value in the red top display.

11. Adjust the number value in the top display using the Up or Down Arrow Buttons to

match the offset value.

12. Once the Offset Calibration Number is entered, push the Reset Button repeatedly to

exit the calibration, save the set point, and return to the Home Page. The current

temperature will show on the top display and the set point in the bottom.

13. Wait for a half hour and compare the reading of the reference device and the Watlow

Controller. Enter an offset if the readings are still different and fall outside your laboratory

protocol range.

14. If the temperature readings of the display and the reference device still do not fall close

enough to be acceptable by your laboratory protocol after three calibration attempts,

contact Sheldon Technical Support for assistance.

Note: After calibrating the oven to your process or application temperature, set the Over

Temperature Limit to 5°C above the process / application’s set point. If you will be running a

programed heating profile, set the Over Temperature Limit to 5°C above the profile’s highest

set point.

End of procedure

20 | P a g e

Page 21

Alternating OTL

Alert Screens

OPERATION (CONTINUED)

CLOSED VENTS

The oven can be run with the exhaust vent closed if required for your application or process.

However, running the oven with a closed exhaust will likely decrease drying efficiency in the

chamber.

OVER TEMPERATURE LIMIT ACTIVE

When the oven chamber air temperature exceeds the user-programed Over Temperature

Limit, the OTL system will depower the heating elements. This is normally accompanied by a

loud “click.” The display will flash two (2) alternating alert screens. “FAiL” in red, “L.st1” in

green. Then “Li.h1” in red, and “Attn” for attention in green. A small “4” will show in the bottom

display, indicating that the controller has depowered the heating elements.

The Over Temperature Limit will activate if one of two events happens.

You have set the Over Temperature Limit below the temperature set point you are

using for your application or process.

The main controller circuitry or sensor probe has failed, and must be replaced in

order to maintain safe and accurate oven operations.

If you have set the Over Temperature Limit too low, perform the following steps to take the unit

out of shutdown:

1. Press the advance key until Ignore “i9nr” shows in the top display, and Limit High

“Lih1” in the green display.

2. Press the green advance key again. Limit High Set Point “LhS1” will now show in the

green display, and the Over Temperature Limit setting in the red top display.

3. Adjust the Over Temperature Limit to above your set point using the Up Arrow Button.

4. Push the Reset Button to save the new OTL setting.

If the Over Temperature Limit has activated and the red oven temperature is higher than

your green temperature set point, the main controller circuitry or temperature sensor may

have failed. Cease using the oven and contact Sheldon Technical Support for assistance

21 | P a g e

Page 22

Figure 5: High

Performance Power

Exhaust (Part Number

9990741)

OPERATION (CONTINUED)

PROGRAMMED OPERATIONS

The Watlow controller can hold four (4) ten-step heating profiles. Additionally, profiles may be

combined by programing profile steps sequentially to run as a single profile of between two (2) and

forty (40) steps.

Please see the Programing Guide – Watlow EZ-Zone Controller Heating Profiles document,

which comes included with the SMO5CR-2 oven, for instructions on how to program heating

profiles. The guide is intended as simplified explanation for all major heating profile functions and

programing steps. The guide is also available on the Shel Lab website in PDF format.

The How to Program Ramp & Soak Profiles video at http://www.shellab.com/store/virtual-

tour-vac-oven.html shows how to program a three-step profile that will ramp the oven up to 150°C

over a one (1) hour period; then hold (“soak”) at 150°C for four (4) hours; then end the profile. The

video applies to the SMOHP family.

Refer to Chapter 7 of the “EZ-Zone PM User’s Manual” for highly detailed instructions on how to

program the EZ Watlow Controller.

POSITIVE VENTING OF EXHAUST

Exhaust ducting can be connected to the oven’s exhaust port to

channel or positively vent exhaust out of the workspace around the

oven. Additionally, Sheldon Manufacturing sells a 230 volt High

Performance Power Exhaust that can be mounted directly on the

exhaust vent, and powered by the oven. An exhaust duct should not

extend straight up from the oven, but should include a steep bend

sufficient to stop condensation within the ducting from sliding down

into the oven.

Mounting the Power Exhaust

1. Remove the screws on the cover of the exhaust vent assembly

on the top of the oven, but leave the assembly in place.

2. Mount the power exhaust blower on the exhaust vent cover assembly, aligning the blower

and the assembly’s screw holes. The open side of the blower’s mounting body should go

over the handle of the exhaust port’s sliding vent cover.

3. Reinstall the screws.

4. Plug in the power exhaust into the 230 volt outlet on the back of the oven.

22 | P a g e

Continued on next page

Page 23

OPERATION (CONTINUED)

Activating and Deactivating the Power Exhaust

To activate the power exhaust as part of a heating profile step, do the following:

1. While selecting the parameters for the step, choose Event 1 On (“Ent1” “on”).

a. The Event 1 parameter is located after the Time parameter when scrolling

through a step menu using the green Advance Key.

b. Use either of the Arrow Keys to toggle “oFF” to “on”.

2. Press the Advance key to scroll to the next event and save Event 1 as On.

3. Next time the profile runs, the 230 volt outlet on the back of the oven will power up

when the controller reaches this step.

4. The plugged in power exhaust will run until the next step in which Event 1 Off is selected

(“Ent1” “oFF”), or until the oven shuts down.

5. By default the Event 1 parameter is set to Off. It must be switched to On for each

successive step that you want the blower to run during the execution of the profile

23 | P a g e

Page 24

USER MAINTENANCE

Warning: Prior to any maintenance or service on this unit, disconnect the power feed from the power

supply.

Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le

cordon secteur de la source d'alimentation.

If a hazardous material/substance has spilled in the oven, immediately initiate your site’s

Hazardous Material Spill Containment protocol. Contact your local Site Safety Officer and follow

instructions per the site policy and procedures.

CLEANING

Note: The oven’s chamber should be cleaned and disinfected prior to use.

Perform the steps below to clean the oven:

1. Remove the shelves and sliders. Do not remove or disturb the HEPA filter housing cover if

a burnt-in filter is installed.

2. Clean the oven with a mild soap and water solution, including all corners. Do not use an

abrasive cleaner that will damage stainless steel surfaces.

3. Rinse with distilled water and wipe dry with a soft cloth. Do not use deionized water.

4. Take care not to damage the temperature sensor probes when cleaning. These are located

on the back wall of the oven chamber, adjacent to the HEPA filter.

Warning: Never clean the oven with alcohol or flammable cleaners.

Avertissement: Ne jamais nettoyer l'appareil à l'alcool ou avec des nettoyants inflammables.

Note: Do not use spray cleaners or disinfectants that might leak through openings and cracks and

get on electrical components, or that contain solvents that will harm coatings. Do not use

chlorine-based bleaches or abrasives; they will damage the chamber’s interior surfaces.

DISINFECTING

Disinfect the oven on a regular basis if required by your production or laboratory protocol, or if mold

or fungus is an issue in your region. Perform the below steps to disinfect the oven:

1. Remove the shelves and sliders. Do not remove or disturb the HEPA filter housing cover if

a burnt-in filter is installed.

2. Disinfect the oven, including all corners and the access port, a using commercially available

disinfectant that is non-corrosive, non-abrasive, and suitable for use on stainless steel

surfaces. Contact your local Site Safety Officer for detailed information for the proper

disinfectants compatible with your application or process.

3. Take special care when cleaning around sensing heads to prevent damage and around the

door gasket so as not to impair the positive seal.

24 | P a g e

Page 25

MAINTENANCE (CONTINUED)

DOOR LATCH AND ELECTRONICS

Periodically, inspect the door latch, trim, catch, and gasket for signs of deterioration. Failure to

maintain the integrity of the door system shortens the life span of the Oven.

Electrical components do not require maintenance. If the oven fails to operate as specified, please

contact your Shel Lab distributor or Sheldon Manufacturing Technical Support for assistance.

DOOR GASKETS

The Sheldon Clean Room Oven is provided with a high temperature silicon door gasket. See the

Parts Section on page 28 for ordering replacement gaskets.

HEPA FILTER LIFESPAN

The lifespan of the HEPA filter can vary greatly depending on ambient conditions such as humidity

and temperature, as well as the processes or applications the oven is being used for. The dirtier the

bake out process, the faster the filter will become clogged and constrict airflow through the oven.

A useable life of one ( 1 ) year is common for many cleanroom applications. Replace the filter at

least once per year. Replace more often if the exhaust output is noticeably reduced, or if required

by your production or laboratory protocol, or regulatory requirements.

25 | P a g e

Page 26

1, 2, 3)

Remove

Shelves,

Nuts, and

Door Gasket

4) Ceiling

Liner

Removed

5) Right

Air Duct

and HEPA

Filter

Assembly

Removed

1 2 3

4

5

MAINTENANCE (CONTINUED)

REPLACING THE HEPA FILTER ASSEMBLY

To replace the HEPA filter assembly, it is necessary to

remove or at least partly remove the door gasket. Replacing

the HEPA filter assembly is an opportune time to replace

the door gasket.

Note: Door removed in illustrations for clarity. Do not remove the

door from the oven.

1. Remove all shelves and shelf sliders from the oven.

2. Unscrew the nuts located at the top of the back wall of the

oven chamber. Remove the nuts and washers.

3. Remove the chamber gasket so that there is room to pull

the ceiling liner out through the door space. The gasket

may be fully or partially removed.

4. Remove the chamber ceiling liner by pulling it out through

the oven door space. The liner may require some side-toside motion to free up.

5. Remove the right wall air duct that the HEPA filter assembly

is mounted on by pulling it out through the door space.

Procedure continued on next page

26 | P a g e

Page 27

6) Loosen the Mounting

Bracket Screws

Mounting Bracket

Screw

HEPA Filter Pin Nut

and Washer

7) Remove the HEPA Filter

Pin Nuts and Washers

8) Slide the HEPA Filter

Out of the Air Duct

MAINTENANCE (CONTINUED)

6. Loosen but do not remove the six (6) mounting bracket screws on the

right air duct.

a. This creates play (looseness) in the mounting bracket that

will make it easier to slide out the HEPA filter.

7. Unscrew and remove the 12 HEPA filter pin nuts and washers.

8. Slide the old HEPA filter assembly out of the air duct’s mounting

bracket.

9. Slide the new HEPA filter assembly into the air duct assembly.

a. Screw in the 12HEPA filter pin screws and washers.

b. Retighten the six (6) mounting bracket screws.

10. Reinstall the air duct assembly on the right wall.

11. Reinstall the oven chamber ceiling liner.

12. Screw in the back wall nuts and washers to secure the ceiling liner.

13. Reinstall the chamber gasket.

27 | P a g e

Page 28

Shipping

Net Weight

425 lbs

325 lbs

Exterior W × D × H

Interior W × D × H

35 x 29 x 38

17 x 20 x 20

Exterior W × D × H

Interior W × D × H

89 x 73.7 x 96.5

43.2 x 50.8 x 51

Cubic Feet

Liters

3.9

110

Pounds

Kilograms

50 lbs. per shelf

22.8 kg per shelf

UNIT SPECIFICATIONS

The SMO5CR-2 is a 230 voltage unit. Please refer to the oven’s data plate for individual electrical

specifications.

Technical data specified applies to ovens with standard equipment at an ambient temperature of

25°C and a voltage fluctuation of ±10%. The temperatures specified are determined in accordance

to factory standard following DIN 12880 respecting the recommended wall clearances of 10% of the

height, width, and depth of the inner chamber. All indications are average values, typical for units

produced in the series. We reserve the right to alter technical specifications at all times.

WEIGHT

DIMENSIONS

By Inches

By centimeters

CAPACITY

SHELF CAPACITY BY WEIGHT

28 | P a g e

Page 29

Range

Uniformity

Stability

Ambient + 15 to

300C

+ 1.7C @ 110

0.1°C

Heat Up Time to 110°C

Heat Up Time to 180°C*

10 minutes

35 minutes

Recovery to 110°C*

4 minutes after closing the door

Cubic Feet

Per Minute

Cubic Liters

Per Minute

Air Exchanges

Per Minute

6.2

175.56

1.6

AC Voltage

Amperage

Frequency

230

12

50/60 Hz

UNIT SPECIFICATIONS (CONTINUED)

TEMPERATURE

All temperature performance data for 25°C ambient conditions

AIRFLOW PERFORMANCE

Airflow performance data is for both the intake and exhaust vents fully open.

POWER

29 | P a g e

Page 30

Description

Parts Number

Adjustable Feet SMO5CR-2

2700512

Chamber Gasket Silicone (unit is per foot, requires 8

feet)

3750626

Door Gasket SMO5CR-2 Silicone (unit is per foot,

requires 11 feet)

3450587

Fuse 20 Amp

3300538

HEPA Filter Assembly

9990503

Shelf Slide SMO5CR-2

5121189

Shelf SMO5CR-2

512195

Power Exhaust Blower Unit 230 Volt

9990741

REPLACEMENT PARTS

ORDERING PARTS AND CONSUMABLES

If you have the Part Number for an item, you may order it directly from Sheldon Manufacturing by calling

1-800-322-4897 extension 1. If you are uncertain that you have the correct Part Number, or if you need

that specific item, please contact Sheldon Technical Support for help at 1-800-322-4897 extension 2 or

(503) 640-3000. Please have the model number and serial number of the oven ready, as Tech Support

will need this information to match your workstation with its correct part.

30 | P a g e

Page 31

Loading...

Loading...