Page 1

SHELDON

MICROBIOLOGICAL

INCUBATORS

MODELS: SMI31 SMI31-2

SMI39 SMI39-2

Previously designated as

RI28, RI28-2

RI40, RI40-2

11/2013

4861573

INSTALLATION AND OPERATIONAL MANUAL

Sheldon Manufacturing Inc. P.O. Box 627 Cornelius, Oregon 97113

EMAIL: tech@Shellab.com INTERNET: http://www.Shellab.com/~Shellab

1-800-322-4897 (503) 640-3000 FAX (503) 640-1366

Page 2

2

These units are TUV CUE listed as General Incubators for professional, industrial or educational use

where the preparation or testing of materials is done at approximately atmospheric pressure and no

flammable, volatile or combustible materials are being heated. These units have been tested to the

following requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010 + R:2009

UL 61010-1:2004 + R:2005-07 + R:2008-10

UL 61010A-2-010:2002

UL 61010-1:2012

EN 61010-1:2010

EN 61010-2-010:2003

IEC 61010-1:2010

IEC 61010-2-010:2003

Page 3

3

TABLE OF CONTENTS

SECTION 1.0 RECEIVING AND INSPECTION

SECTION 2.0 INSTALLATION

SECTION 3.0 GRAPHIC SYMBOLS

SECTION 4.0 CONTROL OVERVIEW

SECTION 5.0 OPERATION

SECTION 6.0 CHART RECORDER INSTALLATION

SECTION 7.0 MAINTENANCE

SECTION 8.0 TROUBLESHOOTING

SECTION 9.0 PARTS LIST

UNIT SPECIFICATIONS

SCHEMATICS

Page 4

4

RECEIVING AND INSPECTION

Section

Your satisfaction and safety require a complete understanding of this unit. Read

the instructions thoroughly and be sure all operators are given adequate training

before attempting to put the unit in service. NOTE: This equipment must be used

only for its intended application; any alterations or modifications will VOID your

warranty.

1.1 Inspection: The carrier, when accepting shipment, also accepts responsibility

for safe delivery and is liable for loss or damage. On delivery, inspect for visible

exterior damage, note and describe on the freight bill any damage found, and

enter your claim on the form supplied by the carrier.

1.2 Inspect for concealed loss or damage on the unit itself, both interior and exterior.

If necessary, the carrier will arrange for official inspection to substantiate your

claim.

1.3 Return Shipment: Save the shipping crate until you are sure all is well. If for

any reason you must return the unit, first contact your customer representative

for authorization. Supply nameplate data, including model number and serial

number. Please see the manual cover for information on where to contact

customer service.

1.4 Accessories: Verify that all of the equipment indicated on the packing slip is

included with the unit. Carefully check all packaging before discarding. These

units are equipped with 6 shelves, 24 shelf clips and 4 leveling feet.

Page 5

5

INSTALLATION

Section

Local city, county or other ordinances may govern the use of this equipment. If you have any questions

about local requirements, please contact the appropriate local agency. Installation may be performed by

the end user.

Under normal circumstances this unit is intended for use indoors, at room temperatures between 5 and

40C, at no greater than 80% Relative Humidity (at 25C) and with a supply voltage that does not vary by

more than 10%. Customer service should be contacted for operating conditions outside of these limits.

2.1 Power Source: The electrical supply circuit to the incubator must conform to all national and

local electrical codes. Consult the incubator’s serial data plate for the voltage and ampere

requirements before making connection. VOLTAGE SHOULD NOT VARY MORE THAN 10%

FROM THE SERIAL PLATE RATING. This unit is intended for 50/60 Hz application. A separate

circuit is recommended to prevent possible loss of product due to overloading or failure of other

equipment on the same circuit.

2.2 Location: When selecting a site for the incubator, consider all conditions which may affect

performance, such as extreme heat from steam radiators, stoves, ovens autoclaves, etc. Avoid

direct sun, fast-moving air currents, heating/cooling ducts, and high traffic areas. To ensure air

circulation around the unit allow a minimum of 10cm between the unit and any walls or partitions

which might obstruct free airflow.

2.3 Lifting / Handling: These units are heavy and care should be taken to use appropriate lifting

devices that are sufficiently rated for these loads. Units should only be lifted from their bottom

surfaces. Doors, handles and knobs are not adequate for lifting or stabilization. The unit should

be completely restrained from tipping during lifting or transport. All moving parts, such as shelves

and trays should be removed and doors need to be positively locked in the closed position during

transfer to prevent shifting and damage.

2.4 Leveling: The unit must sit level and solidly. Leveling feet (supplied) are to be installed in the

2.5 Cleaning: The incubator was cleaned at the factory, but not sterilized. Remove all interior parts,

holes at the base of the incubator. Turn the leveling feet counterclockwise to raise level. If the

unit must be moved, turn the leveling feet in all the way to prevent bending of the feet.

including shelves and shelf clips and clean all parts and the chamber with a disinfectant that is

appropriate for your application. A thorough periodic cleaning is strongly recommended.

WARNING: Never clean the unit with alcohol or flammable cleaners with the unit connected to the

electrical supply. Always disconnect the unit from the electrical service when cleaning and assure

all volatile or flammable cleaners are evaporated and dry before reattaching the unit to the power

supply.

Page 6

6

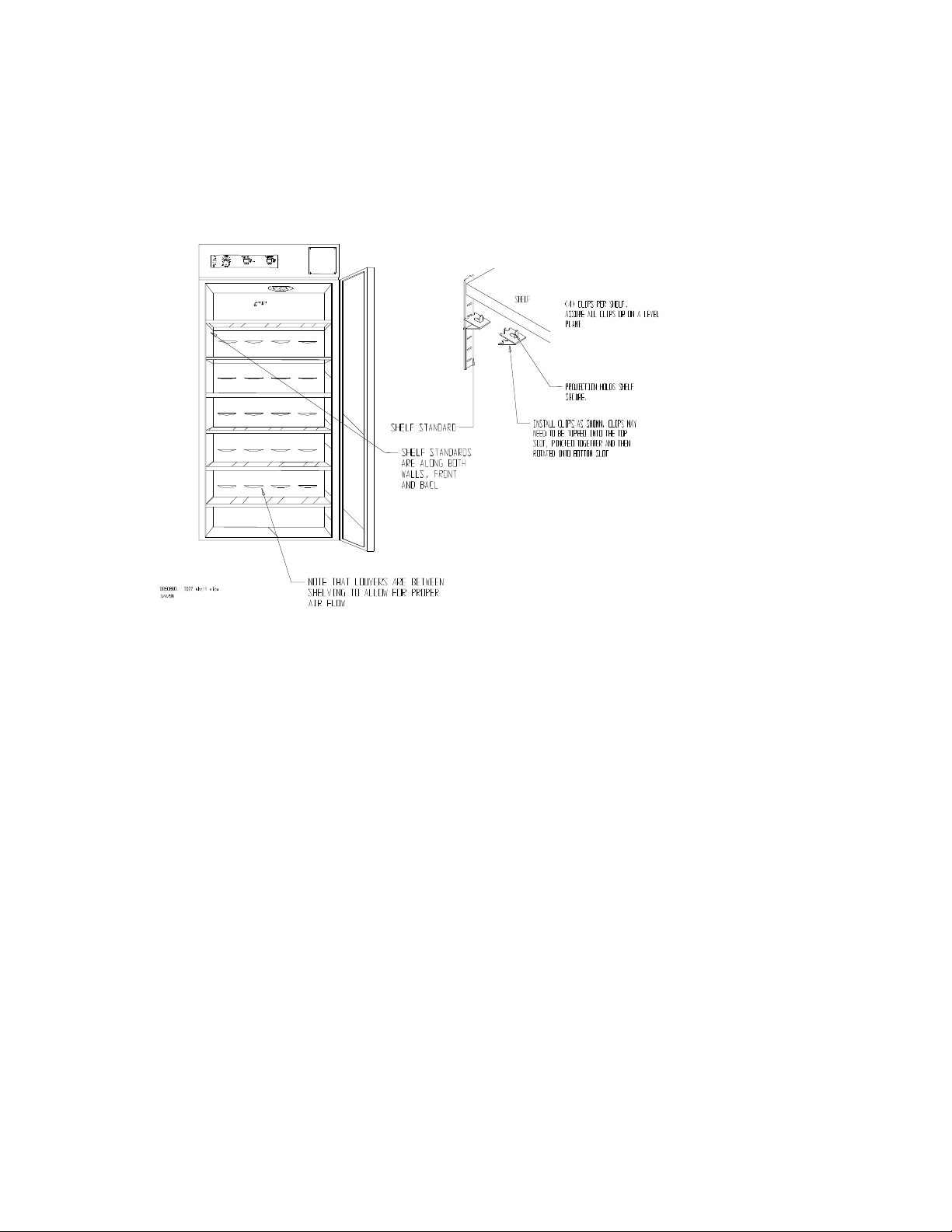

2.6 Place shelves into chamber at desired position. See Figure 1.

Figure 1

Page 7

7

GRAPHIC SYMBOLS

Section

Your incubator is provided with a display of graphic symbols on the control panel which

are designed to help identify the use and function of the adjustable components.

1. Indicates that you should consult your manual for further

description and discussion of a control or user item.

2. Indicates “Temperature”

3. Indicates “Overtemperature”

4. C Indicates “Degrees Centigrade”

5. Indicates “AC Power”

6. Indicates “Manual Adjustment”

7. Indicates “Potential Shock Hazard” behind partition

8. Indicates “Earth Ground”

9. Indicates “Unit should be recycled” (Not disposed of in

land-fill)

Page 8

8

CONTROL PANEL OVERVIEW

Section

4.1 Power Switch: The main power I/O (on/off) switch controls all power to the unit

and must be in the I/ON position before any systems are operational.

4.2 Main Temperature Control: The Main Temperature Control consists of the

digital display and UP/DOWN arrow pads for inputting set point temperatures and

calibration.

4.3 HEATING Lamp: This green pilot lamp in ON when the unit is heating up to set

point and is blinking when controlling temperature at set point.

4.4 Overtemperature Thermostat: Marked SET OVERTEMPERATURE, the

Thermostat is a completely independent control that acts as an override in the

event that the Main control fails in the ON position. The Thermostat will regulate

chamber temperature at approximately 1C above the set point of the Main

controller.

4.5 OVER TEMP Lamp: This red pilot lamp is On when the Overtemperature

4.6 Circuit Breaker: (Non-CE units) Located adjacent to the power cord, the circuit

4.7 Fuse: (CE units) Located adjacent to the power cord in place of the circuit

Thermostat has taken control of the unit. Under normal operating conditions this

lamp should never be on.

breaker is an added measure of protection against power source variations that,

if tripped, can be reset by pushing in the button once the reason for the

interruption has been cleared.

breaker. The fuse is an added measure of protection against power source

variations, and if blown must be replace once the source of the interruption has

been cleared.

Page 9

9

OPERATION

Section

5.1 Check power supply against unit data plate, they must match. Plug service cord into the

grounded electrical outlet, and turn the unit on.

5.2 Turn the Overtemperature Thermostat to its maximum position, clockwise, using a coin

or a flat edged tool.

5.3 There are four (4) electrical outlets inside the chamber for use with electrical equipment

not exceeding 1 amp.

5.4 Operating Electrical Apparatus Inside Chamber: Place the shaker, roller, spinner,

etc. inside the incubator chamber. Plug apparatus into 1 amp outlet at rear of chamber.

Be sure apparatus draws 1 amp or less (the power switch turns power on & off to outlets

inside chamber).

5.5 Set Main Temperature Controller: Enter desired set point temperature. To enter set

point mode on the controller, press either the Up or Down arrow pad one time. The

digital display will start to blink, going from bright to dim. While blinking, the digital

display is showing the set point. To change the set point, use the Up and Down arrow

pads. If the arrow pads are not pressed for five (5) seconds, the display will stop

blinking and will read the chamber temperature. Note that the Overtemperature

Thermostat should be turned to its maximum position, (clockwise) until the unit has

stabilized at desired set point temperature. Allow the incubator at least 24 hours to

stabilize.

5.6 Calibration: It is recommended that calibration is done once the unit is installed in its

5.7 Set Overtemperature Thermostat: As mentioned in step 5.2, the Overtemperature

working environment and has been stabile at set point for several hours. Place a

certified reference thermometer in the chamber where it can be easily viewed through

the window. Be certain the thermometer is not touching any shelving. Allow the

temperature to stabilize again until the thermometer reads a constant value for one hour.

Compare the digital display with the reference thermometer. If there is an unacceptable

difference, put the display into calibration mode by pressing both the Up and Down

arrow pads at the same time for five (5) seconds until the two outside decimal points

begin to flash. While the decimal points are flashing the display can be calibrated by

pressing the Up or Down arrow pads until the display reads the correct value. Allow the

incubator temperature to stabilize again, and recalibrate if necessary.

Thermostat should be initially set to its maximum position, to allow the unit to stabilize.

Once the incubator is stabile at the desired set point, turn the Thermostat

counterclockwise until the OVER TEMP light turns on. Next, turn the Thermostat

clockwise just until the light turns off. Then turn the Thermostat clockwise two of the

smallest divisions on its scale past the point where the light went out. This will set the

Overtemperature Thermostat at approximately 1C above Main temperature set point.

Page 10

10

CHART RECORDER INSTALLATION

Section

Please note that the following information is a general guide for installation.

Chart recorders are available from your dealer. Before attempting installation

please read the instructions provided with your chart recorder thoroughly for

specific installation instructions. Note: Unplug unit from the power supply before

installing the Chart Recorder.

6.1 Remove cover for Chart Recorder, located on the right side of control panel.

6.2 Remove steel plate from the back of the Chart Recorder.

6.3 Open the front glass door on the Chart Recorder and loosen the two screws on

the face of the recorder. (Screws are on the top and bottom right of the face.)

6.4 Inside the unit, behind the cover plate, you will see two wires that say “Recorder

Power”. Cut off the butt connectors and strip the wires about 3/8 inch.

6.5 Put the Recorder Power wires through the hole in back of your Chart Recorder

and connect the Recorder power wires to the terminal inside.

6.6 Run the Chart Recorder probe through the probe hole and slide into probe clips

provided inside the chamber of the unit.

6.7 Inside the Chart Recorder you will see a piece of masking tape and a metal clip;

remove these; screw face bolts back in; screw in Chart Recorder; shut the glass

door on the Chart Recorder; plug unit into power supply; then turn on the unit.

6.8 In moving or mounting a chart, the pen arm and stylus must be raised by

6.9 To remove and replace a chart, unscrew the hub knob and swing it 90

6.10 Now the pen arm may be gently released and the chart knob rotated

pressing on the tab at the uppermost end of the arm. Even if the recorder is not

to be used, a fresh chart should be mounted or some sort of padding placed

under the stylus to protect the sapphire tip.

clockwise, or to the 3 o’clock position. Press the upper tab on the pen arm; lift

the chart forward off the hub and slide down and away. DO NOT release the pen

arm, but install a new chart.

counterclockwise back to the hub. Align the proper chart time with the chart plate

index.

Page 11

11

MAINTENANCE

Section

NOTE: Disconnect the power cord from the power source before performing any

service or maintenance on this unit.

7.1 Cleaning: Clean the incubator interior and remove and clean shelves on a

regular basis. Use a disinfectant that is suitable for your application. A thorough

periodic cleaning is strongly recommended. Use care when cleaning the door

gasket to prevent damage which could impair the positive door seal.

WARNING: Never clean the unit with alcohol or flammable cleaners with the unit

connected to the electrical supply. Always disconnect the unit from the electrical

service when cleaning and assure all volatile or flammable cleaners are

evaporated and dry before reattaching the unit to the power supply.

7.2 Storage: To prepare the unit for storage, remove all shelves and shelf clips and

disconnect the power supply. Be certain that the chamber is clean and dry and

the door is positively locked in the closed position. See Section 2.3,

Lifting/Handling, for proper transport procedures.

7.3 No maintenance is required on the electrical components. If electrical or

temperature problems occur, please see the Troubleshooting guide, Section 8.0,

before calling for service.

Page 12

12

TROUBLESHOOTING

TEMPERATURE

Temperature too high-display and

reference thermometer don’t match

1/ Controller set too high-see section 5.5.

2/ Controller failed on – call Customer Service.

3/ Wiring error – call Customer Service.

Display reads "HI" or "400"+

Probe is unplugged, is broken or wire to sensor is broken – trace wire

from display to probe; move wire and watch display to see intermittent

problems.

Chamber temperature spikes over set

point and then settles to set point

Recalibrate – see section 5.6.

Temperature too low-display and

reference thermometer don’t match

1/ High limit set too low - see section 5.7

2/ Controller set too low – see section 5.5.

3/ Unit not recovered from door opening – wait for display to stop

changing.

4/ Unit not recovered from power failure or being turned off – incubators

will need 24 hours to warm up and stabilize.

5/ Element failure – see if HEATING light is on; compare current draw to

data plate.

6/ Controller failure – confirm with front panel lights that controller is

calling for heat.

7/ Overtemperature failure – confirm with front panel lights that

Thermostat is operating correctly.

8/ Wiring problem – check all functions and compare wiring to owner’s

manual – especially around any areas recently worked on.

9/ Loose connection – call Customer Service.

Display reads "LO"

1/ If ambient temperature is lower than range of unit – compare set

points and ambient temperature to rated specifications in section 9.0.

2/ Sensor is plugged in backwards – call Customer Service.

Unit will not heat over a temperature that

is below set point

1/ Confirm that fan moving and that amperage and voltage match data

plate – check fan motor motion by removing top panel of the unit.

2/ Confirm that set point is set high enough –turn Thermostat all the way

clockwise and see if HEATING light or OVERTEMP light comes on.

Section

FOR PERSONAL SAFETY, ALWAYS DISCONNECT THE POWER BEFORE

SERVICING.

Always make a visual inspection of the incubator and control panel when

troubleshooting. Look for loose or disconnected wires that may be the source of

trouble.

Page 13

13

3/ Check connections to sensor.

4/ Check calibration – using independent thermometer, follow

instructions in section 5.6.

Unit will not heat up at all

1/ Verify that controller is asking for heat by looking for HEATING light –

if pilot light is not on continuously during initial start up, there is a

problem with the controller.

2/ Check amperage – amperage should be virtually at maximum rated

(data plate) amperage.

3/ Do all controller functions work?

4/ Is the Overtemperature set high enough? – for diagnostics, should be

fully clockwise with the pilot light never on.

5/ Has the fuse/circuit breaker blown?

Indicated chamber temperature unstable

1/ ±0.1 may be normal.

2/ Is fan working? – remove top panel and verify movement of cooling

fan.

3/ Is ambient radically changing – either door opening or room airflow

from heaters or air conditioning? – stabilize ambient conditions.

4/ Sensor miss-located, damaged or wires may be damaged - check

mounts for control and Overtemperature sensors, then trace wires or

tubing between sensors and controls.

5/ Calibration sensitivity – call Customer Service.

6/ Overtemperature set too low – be sure that its setting is more than 5

degrees over desired set point; check if pilot light is on continuously;

turn controller knob completely clockwise to see if problem solved then

follow instructions in section 5.7 for correct setting.

7/ Electrical noise – remove nearby sources of RFI including motors,

arcing relays or radio transmitters.

8/ Bad connection on temperature sensor or faulty sensor – check

connectors for continuity and mechanical soundness while watching

display for erratic behavior; check sensor and wiring for mechanical

damage.

9/ Bad connections– check connectors for mechanical soundness and

look for corrosion around terminals or signs of arcing or other visible

deterioration.

Will not maintain set point

1/ Assure that set point is at least 5 degrees over ambient.

2/ See if ambient is fluctuating – check for adjacent open doors or

HVAC duct openings, stabilize ambient conditions.

Display and reference thermometer don’t

match

1/ Calibration error – see section 5.6.

2/ Temperature sensor failure – evaluate if pilot light is operating

correctly.

3/ Controller failure – evaluate if pilot light is operating correctly.

4/ Allow at least 24 hours to stabilize at set point temperature.

5/ Verify that reference thermometer is certified.

Can't adjust set points or calibration

1/ Turn entire unit off and on to reset.

2/ If repeatedly happens, call Customer Service.

Calibrated at one temperature, but not at

another

This can be a normal condition when operating temperature varies

widely. For maximum accuracy, calibration should be done at or as

close to the set point temperature as possible.

MECHANICAL

Door not sealing

1/ Check physical condition of gasket.

Page 14

14

2/ Assure that gasket is in original location.

3/ Adjust hinge blocks or twist the door.

4/ Confirm that unit has not been damaged and body is square.

Motor doesn't move

1/ If shaft spins freely: check connections to motor and check voltage to

motor.

2/ If shaft rubs or is frozen, relieve binding and retest.

Motor makes noise

1) Make sure that the fan or blower wheel is not contacting its housing.

Adjust the motor mounting bracket position to re-center the fan or

blower wheel, if necessary.

2) Check the fan or blower wheel for damage or out of balance

condition. Replace the fan or blower wheel if it is damaged or out of

balance.

3) Turn the motor shaft to make sure that it spins freely. If it binds or the

bearings make a rubbing or scrapping sound then replace the motor.

OTHER

Controller on at all times - "locked-up"

1/ Turn unit off and on to reset.

2/ If cannot change any condition on the front panel, call Customer

Service.

Front panel displays are all off

Check for wire damage.

Unit or wall fuse/circuit breaker is blown

1/ Check wall power source.

2/ Compare current draw and compare to specs on data plate.

3/ See what other loads are on the wall circuit.

Unit will not turn on

1/ Check wall power source.

2/ Check fuse/circuit breaker on unit or in wall.

3/ See if unit is on, e.g., fan or heater, and just controller is off.

4/ Check all wiring connections, especially around the on/off switch.

Unit is smoking – Out of box

This is not an uncommon occurrence when first operating new units.

Put unit under vent and run at full power for one hour. – smoking is

normal during first cycle to temperature.

Contamination in chamber

1/ See cleaning procedure in section 2.5.

2/ Develop and follow standard operating procedure for specific

application; include definition of cleaning technique and maintenance

schedule.

If following these troubleshooting suggestions does not solve the problem call your customer service

representative for assistance. Please see the manual cover for information on where to contact customer

service.

Page 15

15

PARTS LIST

Description

115V

220V

Blower Motor

4880548

4880548

Blower Wheel

2600535

2600535

Cooling Fan, Control Panel

4880564

4880563

Cord Set

1800510

1800500

EMI Filter

2800503

2800503

Fuse 10 Amp

N/A

3300516

Fuse 16 Amp

3300513

N/A

Heating Element, SMI31 SMI31-2

(RI28 RI28-2)

2350563

2350554

Heating Element, SMI39 SMI39-2

(RI40 RI40-2)

2350557

2350566

Overtemperature Thermostat

1750982

1750983

I/O (On/Off) Power Switch

7850579

7850579

Moisture Proof Plug

1650530

1650530

Main Control w/Sensing Probe

1750582

1750583

Outlet, Interior

1650531

1650531

Pilot Light, Green

4650554

4650554

Pilot Light, Red

4650553

4650553

Shelf, SMI31 SMI31-2 (RI28 RI28-2)

5400500

5400500

Shelf, SMI39 SMI39-2 (RI40 RI40-2)

5401146

5401146

Section

Page 16

16

UNIT SPECIFICATIONS

Weight

Shipping

Net

SMI31 SMI31-2

(RI28 RI28-2)

610 lbs.

500 lbs.

SMI39 SMI39-2

(RI40 RI40-2)

730 lbs.

850 lbs.

Dimensions

Exterior WxDxH

Interior WxDxH

SMI31 SMI31-2

(RI28 RI28-2)

38.5x34.0x75.3

30.5x26x62

SMI39 SMI39-2

(RI40 RI40-2)

41x34x87

35x26x76.5

Capacity

SMI31 SMI31-2

(RI28 RI28-2)

28 Cubic Feet

SMI39 SMI39-2

(RI40 RI40-2)

40 Cubic Feet

Temperature

Range

Uniformity

Sensitivity

SMI31 SMI31-2

(RI28 RI28-2)

Amb. +8 to 70C

+ .5C @ 37

+ .05C

SMI39 SMI39-2

(RI40 RI40-2)

Amb. +8 to 70C

+ .5C @ 37

+ .05C

Page 17

17

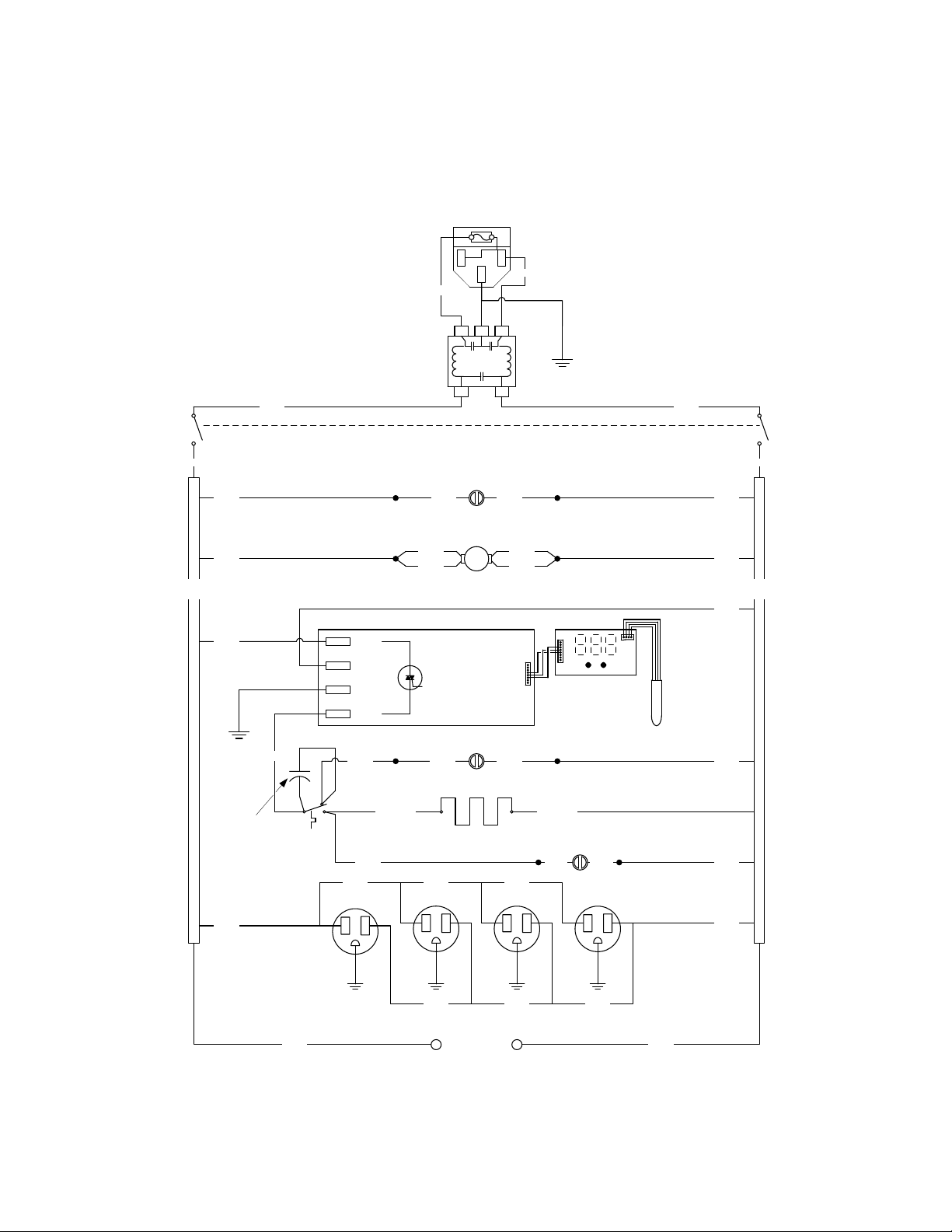

MAIN POWER SWITCH CHERRY ROUND

7850532

POWER LIGHT ~ 4650554 (G)

OTP LIGHT 4650553

(R)

HEAT LIGHT 4650554(G)

CHAMBER FAN ~ 4880548

½ TB1

L1

½ TB1

L2

1 2

4

OTP

1750862

CONVENIENCE

OUTLETS

6100525 x4

DESIGN = 750W / 120V / 19.2

BLK BLK

BLK WHT

WHT

BLK

BLK HT WHT HT

BLK

BLK

WHT

WHT

BLK

BLK BLK

BLK

BLK BLK

BLK

WHT

WHT

WHT

WHT

BLK WHT

CHART RECORDER

CONNECTIONS

RED

BLUWHT

BLK

WHT

BLK

BLK

WHT

BLK BLK

0900503

0.47 F / 250 VAC

HOT

NEUTRAL

GROUND

LOAD

TEMPERATURE

CONTROL

1750982

2800503

IEC FUSED INLET

4200505

BLK

WHT

BLK WHT

WIRE DIAGRAM

SMI31 (RI28) 120V

(9851242)

Page 18

18

2800503

MAIN POWER SWITCH CHERRY ROUND

7850532

POWER LIGHT ~ 4650554 (G)

OTP LIGHT 6540553

(R)

HEAT LIGHT 4650554 (G)

CHAMBER FAN ~ 4880548

½ TB1

L1

½ TB1

L2

IEC FUSED INLET

4200505

1 2

4

12

4

½ OTP

1750813

½ OTP

1750813

WHTRED

BLU & BLK

EURO OUTLETS

6100531 x4

DESIGN = 750W 83

0900503

0.47 F / 250 VAC

BLK

WHT

WHT

BLK

WHT

BLK BLK

BLK WHT

WHT

BLK

BLK HT WHT HT

WHT

BLK

BLK

BLK

WHT

BLK

BLK BLK

BLK

BLK BLK

BLK

WHT

WHT

WHT

WHT

BLK

WHT

CHART RECORDER

CONNECTIONS

HOT

NEUTRAL

GROUND

LOAD

TEMPERATURE

CONTROL

1750983

WIRE DIAGRAM

SMI31-2 (RI28-2) 230V

(9851243)

Page 19

19

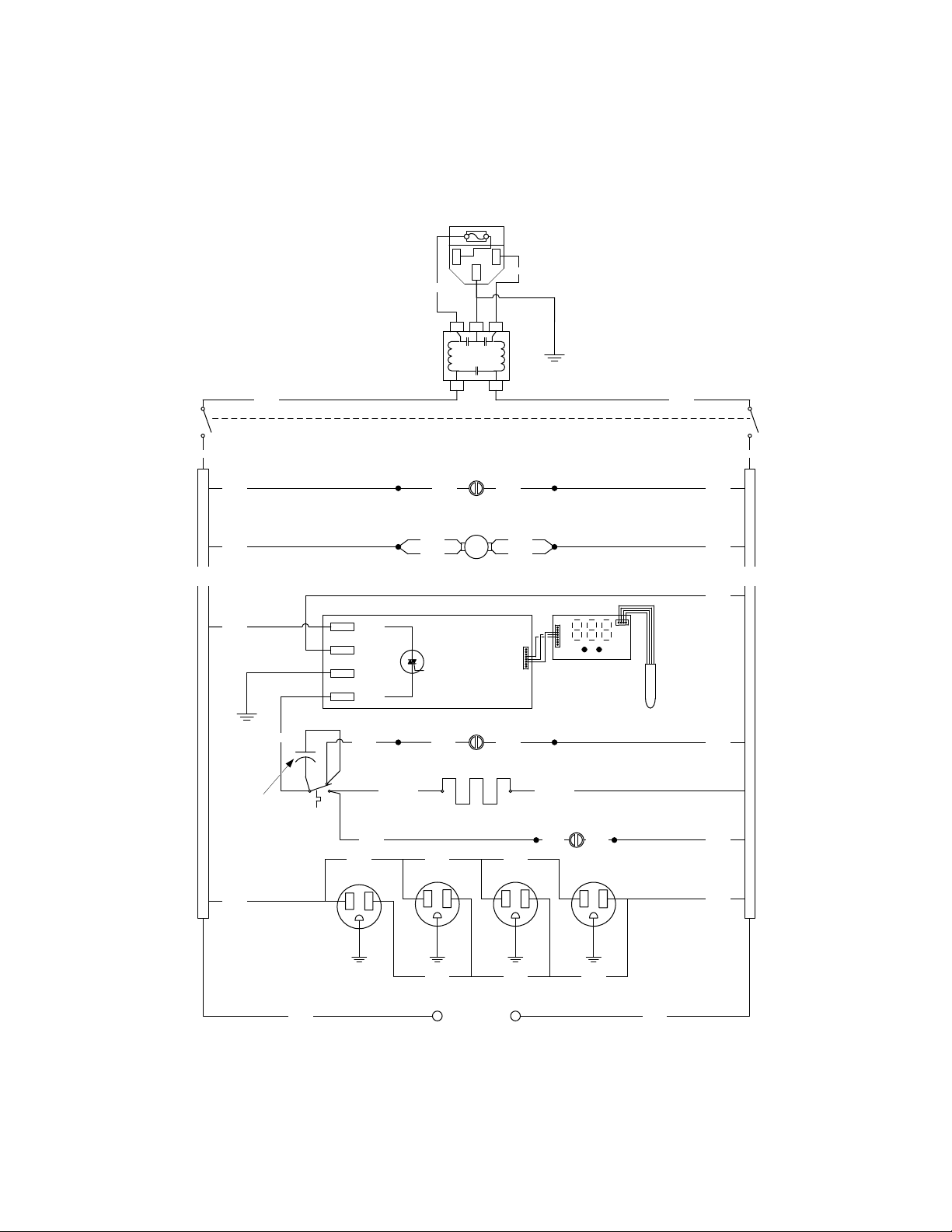

MAIN POWER SWITCH CHERRY ROUND

7850532

POWER LIGHT ~ 4650554 (G)

OTP LIGHT 4650553

(R)

HEAT LIGHT 4650554(G)

CHAMBER FAN ~ 4880548

½ TB1

L1

½ TB1

L2

1 2

4

OTP

1750862

CONVENIENCE

OUTLETS

6100525 x4

DESIGN = 1000W 12.4

BLK BLK

BLK WHT

WHT

BLK

BLK HT WHT HT

BLK

BLK

WHT

WHT

BLK

BLK BLK

BLK

BLK BLK

BLK

WHT

WHT

WHT

WHT

BLK WHT

CHART RECORDER

CONNECTIONS

RED

BLUWHT

BLK

WHT

BLK

BLK

WHT

BLK BLK

0900503

0.47 F / 250 VAC

HOT

NEUTRAL

GROUND

LOAD

TEMPERATURE

CONTROL

1750982

2800503

IEC FUSED INLET

4200505

BLK

WHT

BLK

WHT

WIRE DIAGRAM

SMI39 (RI40) 120V

(9851244)

Page 20

20

2800503

MAIN POWER SWITCH CHERRY ROUND

7850532

POWER LIGHT ~ 4650554 (G)

OTP LIGHT 6540553

(R)

HEAT LIGHT 4650554 (G)

CHAMBER FAN ~ 4880548

½ TB1

L1

½ TB1

L2

IEC FUSED INLET

4200505

1 2

4

12

4

½ OTP

1750813

½ OTP

1750813

WHTRED

BLU & BLK

EURO OUTLETS

6100532 x4

DESIGN = 1000W 58.7

0900503

0.47 F / 250 VAC

BLK

WHT

WHT

BLK

WHT

BLK BLK

BLK WHT

WHT

BLK

BLK HT WHT HT

WHT

BLK

BLK

BLK

WHT

BLK

BLK BLK

BLK

BLK BLK

BLK

WHT

WHT

WHT

WHT

BLK

WHT

CHART RECORDER

CONNECTIONS

HOT

NEUTRAL

GROUND

LOAD

TEMPERATURE

CONTROL

1750983

WIRE DIAGRAM

SMI39-2 (RI40-2) 230V

(9851245)

Loading...

Loading...