Page 1

Installation - Operation Manual

VACUUM OVENS

110 – 120 Volts

SVAC1 SVAC2 SVAC4

Page 2

Pictured on the front cover, left to right: SVAC1, SVAC2, SVAC4

48TWarning:48T This product contains chemicals, including triglycidyl isocyanurate, known to the State of

California to cause cancer as well as birth defects or other reproductive harm. For more information,

go to

33Twww.P65Warnings.ca.gov33T.

48T¡Advertencia! Este producto contiene sustancias químicas, incluido el triglicidil isocianurato, que el

estado de California sabe que causa cáncer, así como defectos de nacimiento u otros daños

reproductivos. Para obtener más información, visite www.P65Warnings.ca.gov

48T.

Avertissement! Ce produit peut vous exposer à des produits chimiques, dont l'isocyanurate de

triglycidyle, reconnu par l'État de Californie pour provoquer le cancer, des anomalies congénitales

ou d'autres problèmes de reproduction. Pour plus d'informations, visitez le site

www.P65Warnings.ca.gov.

2 | Page

Page 3

Benchtop Vacuum Ovens

110 – 120 Voltage

Part Number (Manual): 4861835

Revision: January 14, 2020

Sheldon Part ID Numbers:

Model SVAC1 SVAC2 SVAC4

Part ID SLV122 SLV222 SLV422

The Part ID denotes the specific build version of the model.

SH

EL LAB is a brand of Sheldon Manufacturing, INC, an ISO 9001

certified manufacturer.

Safety Certifications

ese units are CUE listed by TÜV SÜD as vacuum ovens for professional, industrial or educational

Th

use where the preparation or testing of materials is done at an ambient air pressure range of 22.14 –

31.3 inHg (75 – 106 kPa), and no flammable, volatile or combustible materials are being heated.

These units have been tested to the following requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010/2015

UL 61010-1:2012

UL 61010A-2-010:2015

EN 61010-1:2010

EN 61010-2-010:2014

3 | Page

Page 4

TABLE OF CONTENTS

INTRODUCTION ......................................................................................................................................................... 7

Read this Manual .................................................................................................................................................................... 7

Safety Considerations and Requirements ...................................................................................................................... 7

Contacting Assistance .......................................................................................................................................................... 8

Manufacturing Warranty ...................................................................................................................................................... 8

Engineering Improvements.................................................................................................................................................. 8

Vacuum Supply Requirements ........................................................................................................................................... 9

Reference Sensor Device .................................................................................................................................................. 10

Oven Chamber Gaskets ...................................................................................................................................................... 11

RECEIVING YOUR UNIT .......................................................................................................................................... 13

Inspect the Shipment ........................................................................................................................................................... 13

Orientation.............................................................................................................................................................................. 14

Dimension Visuals ............................................................................................................................................................... 20

Record Data Plate Information ........................................................................................................................................ 23

INSTALLATION ........................................................................................................................................................ 25

Installation Procedure Checklist ..................................................................................................................................... 25

Required Ambient Conditions .......................................................................................................................................... 26

Required Clearances .......................................................................................................................................................... 26

Power Source Requirements ............................................................................................................................................27

Lifting and Handling ........................................................................................................................................................... 28

Leveling .................................................................................................................................................................................. 28

Install the Oven .................................................................................................................................................................... 29

Deionized and Distilled Water ......................................................................................................................................... 29

Installation Cleaning and Disinfecting .......................................................................................................................... 29

Shelving Installation............................................................................................................................................................ 30

Connect to the Vacuum Supply ...................................................................................................................................... 32

GRAPHIC SYMBOLS ............................................................................................................................................... 33

CONTROL OVERVIEW ............................................................................................................................................ 35

OPERATION.............................................................................................................................................................. 37

Operating Precautions ........................................................................................................................................................ 37

Theory of Operation ........................................................................................................................................................... 38

Put the Oven into Operation ............................................................................................................................................ 40

Set the High Temperature Limit ...................................................................................................................................... 42

Evacuating and Backfilling the Oven Chamber ......................................................................................................... 43

Setting the Constant Temperature Setpoint ............................................................................................................... 45

Temperature Programs ..................................................................................................................................................... 45

High Temperature Limit Activated ................................................................................................................................. 46

Changing the Unit of Measurement ................................................................................................................................ 47

Vacuum Gauge Operations ............................................................................................................................................. 48

Maximum Obtainable Vacuum ........................................................................................................................................ 49

Pressure Units Conversion Chart .................................................................................................................................... 49

Data Port ................................................................................................................................................................................ 50

Oven Cooldowns ................................................................................................................................................................. 50

USER MAINTENANCE .............................................................................................................................................. 51

Cleaning .................................................................................................................................................................................. 51

Maintaining Atmospheric Integrity ................................................................................................................................. 52

Electrical Components ....................................................................................................................................................... 52

Vacuum Pump Maintenance ............................................................................................................................................ 52

Storage ................................................................................................................................................................................... 52

Calibrating the Temperature Display ............................................................................................................................ 53

Unlocking the Temperature Controller ..........................................................................................................................57

Heating Issues — Diagnostic Questionnaire ............................................................................................................... 60

Vacuum Leak Issues – Diagnostic Questionnaire ..................................................................................................... 65

4 | Page

Page 5

UNIT SPECIFICATIONS ........................................................................................................................................... 71

Weight ....................................................................................................................................................................................... 71

Dimensions .............................................................................................................................................................................. 71

Capacity ................................................................................................................................................................................... 71

Shelf Capacity by Weight ...................................................................................................................................................72

Vacuum ...................................................................................................................................................................................72

Temperature ..........................................................................................................................................................................72

Power ....................................................................................................................................................................................... 73

PARTS LIST ............................................................................................................................................................... 75

Replacement Gaskets .........................................................................................................................................................76

5 | Page

Page 6

TABLE OF CONTENTS

6 | Page

Page 7

INTRODUCTION

Thank you for purchasing a SHEL LAB oven. We know you have many choices in today’s competitive

marketplace when it comes to constant temperature equipment. We appreciate you choosing ours. We

stand behind our products and will be here if you need us.

READ THIS MANUAL

Failure to follow the guidelines and instructions in this user manual may create a protection

impairment by disabling or interfering with the unit safety features. This can result in injury or death.

Before using the unit, read the manual in its entirety to understand how to install, operate, and

maintain the unit in a safe manner. Ensure all users are given appropriate training before the unit

begins service. Keep this manual available for use by all end-users.

SAFETY CONSIDERATIONS AND REQUIREMENTS

Follow basic safety precautions, including all national laws, regulations, and local ordinances in your

area regarding the use of this unit. If you have any questions about local requirements, please

contact the appropriate agencies.

SOPs

Because of the range of potential applications this unit can be used for, the end-user or their

supervisors must draw up a site-specific standard operating procedure (SOP) covering each

application and associated safety guidelines. This SOP must be written and available to all users in a

language they understand.

Intended Applications and Locations

SVAC ovens are engineered for constant temperature drying, curing, and baking applications under

vacuum in professional, industrial, and educational environments. The ovens are not intended for

use at hazardous or household locations.

Power

Your unit and its recommended accessories are designed and tested to meet strict safety

requirements.

• The unit is designed to connect to a power source using the specific power cord type

shipped with the unit.

• Always plug the unit power cord into a protective earth grounded electrical outlet

conforming to national and local electrical codes. If the unit is not grounded properly, parts

such as knobs and controls can conduct electricity and cause serious injury.

• Do not bend the power cord excessively, step on it, or place heavy objects on it.

• A damaged cord can be a shock or fire hazard. Never use a power cord if it is damaged or

altered in any way.

• Use only approved accessories. Do not modify system components. Any alterations or

modifications to your unit not explicitly authorized by the manufacturer can be dangerous

and will void your warranty.

7 | Page

Page 8

INTRODUCTION

CONTACTING ASSISTANCE

Phone hours for Sheldon Technical Support are 6 am – 4:30 pm Pacific Coast Time (west coast of

the United States, UTC -8), Monday – Friday. Please have the following information ready when

calling or emailing Technical Support: the model number, serial number, part number, and Part ID

(see page 23).

support@sheldonmfg.com

1-800-322-4897 extension 4

(503) 640-3000 extension 4

FAX: (503) 640-1366

Sheldon Manufacturing, INC.

P.O. Box 627

Cornelius, OR 97113

USA

MANUFACTURING WARRANTY

For information on your warranty and online warranty registration please visit:

• sheldonmanufacturing.com/warranty

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes and

improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your SHEL LAB dealer or

customer service representative for assistance.

8 | Page

Page 9

Building Vacuum Supply

Vacuum Pump

INTRODUCTION

VACUUM SUPPLY REQUIREMENTS

Pump or Building System Required

The oven does not come with a vacuum pump. A pump must be separately purchased for the oven.

Required Flow Rate

For the oven chamber door to seal, the vacuum pump or system must be able to evacuate at least 1

cubic foot per minute (cfm) for each cubic foot of oven chamber volume (CuFt).

Model Chamber Capacity Min. Pump Capacity CFM Min. Pump Capacity LPM

SVAC1 0.56 CuFt 1 cfm 28 Liters per Minute

SVAC2 1.67 CuFt 2 cfm 57 Liters per Minute

SVAC4 4.50 CuFt 5 cfm 142 Liters per Minute

The use of clamps to secure vacuum tubing is recommended.

Minimum Evacuation Level

The oven must be pumped down to -3 inHg or lower for the oven chamber door to seal. The manufacturer

recommends pumping down below -3 inHg as part of the first step in a baking recipe to ensure a good

seal. This helps safeguard the oven and pump.

Pump Type Selection

Consult a vacuum pump specialist to determine the pump type best suited to your baking application. The

correct selection of a vacuum pump is critical for evacuating the chamber to the level required for your

vacuum baking applications in a timely manner. The nature of the sample or product being heated should

drive the selection of the pump, including the types of chemicals outgassed during the baking process.

Common pump types include Chemical Duty PTFE Dry, Standard Duty Dry, and Compact Direct-Drive. The

selection of an application-specific pump can improve the overall oven performance and minimize pump

maintenance costs. All maintenance and instructional information should be obtained from the pump

manufacturer if not shipped with the pump.

Oil Trap Recommended

The use of an oil trap plumbed on the vacuum line between the oven and the pump is strongly

recommended. The trap protects the pump from any oils outgassed during your baking procedure. This

extends the life of the pump.

9 | Page

Page 10

Reference

INTRODUCTION

REFERENCE SENSOR DEVICE

Must be purchased separately

A reference sensor device is required for calibrating the unit temperature display.

Reference devices must meet the following standards:

• Accurate to at least 0.1°C

Device

Temperature Probes

Use a digital device with wire thermocouple probes that can be introduced into the unit chamber

through the unit access port. Select a probe suitable for the application temperature you will be

calibrating at.

A vacuum-rated feedthrough baseplate is required for introducing the probe through the KF-25 port.

Why Probes?

Reference readings taken outside the chamber using wire temperature probes avoid chamber door

openings. Openings disrupt the chamber temperature. Each disruption requires a minimum 1-hour wait

to allow the chamber to re-stabilize before continuing.

No Alcohol or Mercury Thermometers

Alcohol thermometers do not have sufficient accuracy to conduct accurate temperature calibrations.

Never place a mercury thermometer in the unit chamber. Always use thermocouple probes.

The device should be regularly calibrated, preferably by a third party.

10 | Page

Page 11

INTRODUCTION

OVEN CHAMBER GASKETS

Wear and Replacement

Chamber gaskets are non-warranty, high-wear consumable items subject to compression forces, heat,

and outgassed byproducts. Heavy usage rates may necessitate frequent replacements. The

manufacturer strongly recommends keeping a spare gasket on hand during operation.

Included Chamber Gasket

Each oven comes with a replaceable silicone gasket installed on the chamber liner, which seals the

oven chamber when the door is closed and the chamber is under vacuum. The gasket must be

replaced periodically and is rated to 230°C. It is vulnerable to acids and solvents. The manufacturer

also offers for sale Viton®, fluorosilicone, and Buna-N gaskets. See page 76 for information on gasket

type suitability for baking applications.

Do Not Use Vacuum Grease

• These ovens do not require vacuum grease to seal.

• The use of grease may contaminate the chamber and samples and can foul vacuum pumps.

• Silicone vacuum grease will damage silicone gaskets. Do not use silicone grease with

silicone gaskets.

11 | Page

Page 12

INTRODUCTION

12 | Page

Page 13

2 1 1

3 12 1 4

RECEIVING YOUR UNIT

INSPECT THE SHIPMENT

When a unit leaves the factory, safe delivery becomes the responsibility of the carrier. Damage

sustained during transit is not covered by the manufacturing defect warranty. When you receive

your unit, inspect it for concealed loss or damage to its interior and exterior. If you find any damage

to the unit, follow the carrier’s procedure for claiming damage or loss.

Save the shipping carton until you are certain that the unit and its accessories function properly.

1. Carefully inspect the shipping carton for damage.

2. Report any damage to the carrier service that delivered the unit.

3. If the carton is not damaged, open the carton and remove the contents.

4. Inspect the unit for signs of damage. See the orientation depictions on the next pages as a

reference.

5. The unit should come with an Installation and Operation Manual and a Temperature Program

Manual.

6. Verify that the correct number of accessories has been included.

7. Carefully check all packaging for accessories before discarding.

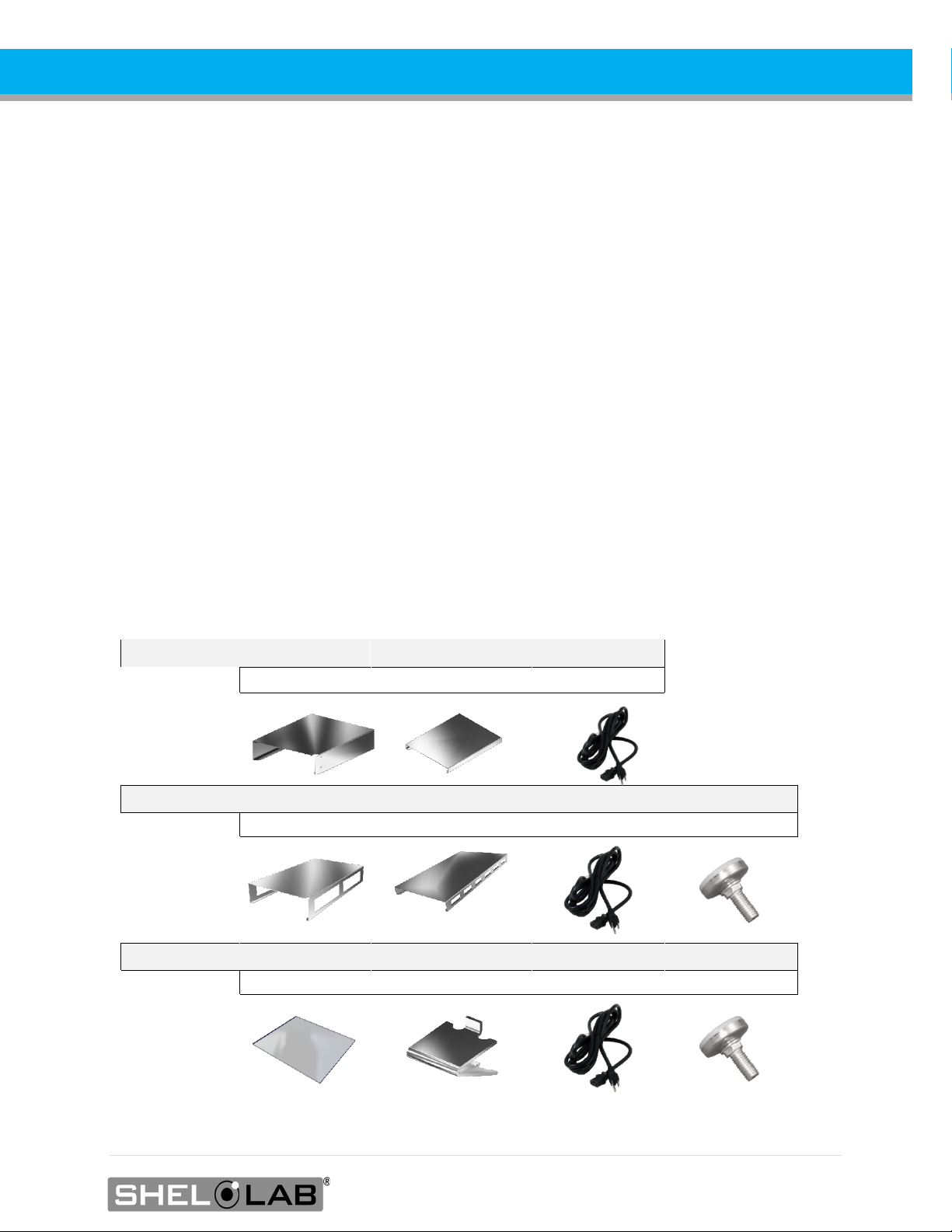

Included Accessories:

SVAC1 Tall Shelves Short Bottom Shelf Power Cord

SVAC2 Tall Shelves Short Bottom Shelf Power Cord Leveling Feet

2 1 1 4

SVAC4 Shelves Shelf Clips Power Cord Leveling Feet

13 | Page

Page 14

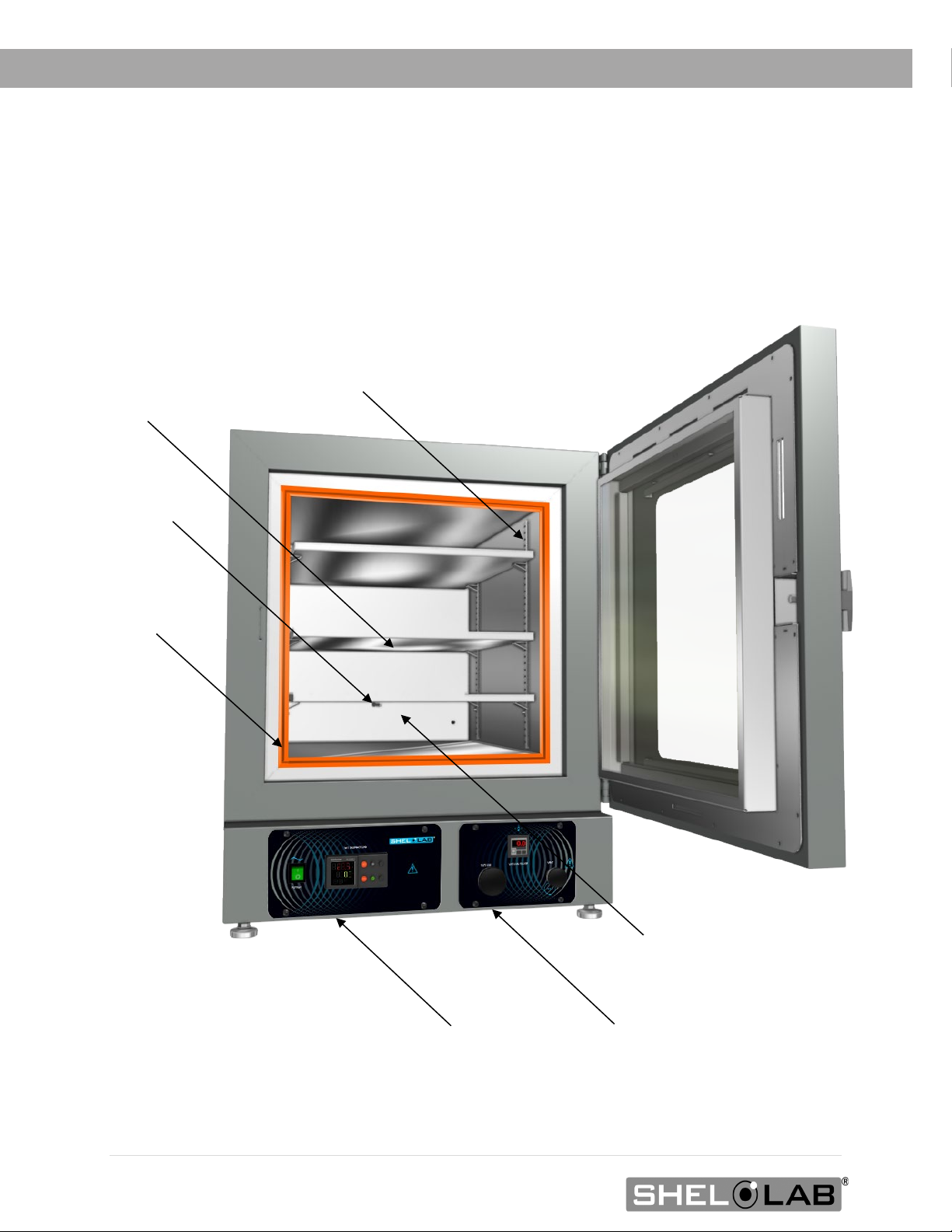

SVAC4

Chamber Door

Chamber

Oven Chamber

Shelf Standard Rail

Main Control Panel

Vacuum Control Panel

Temperature

Access Port (hidden

image)

RECEIVING

ORIENTATION

by the shelf in this

Probe

Gasket Seal

14 | Page

Page 15

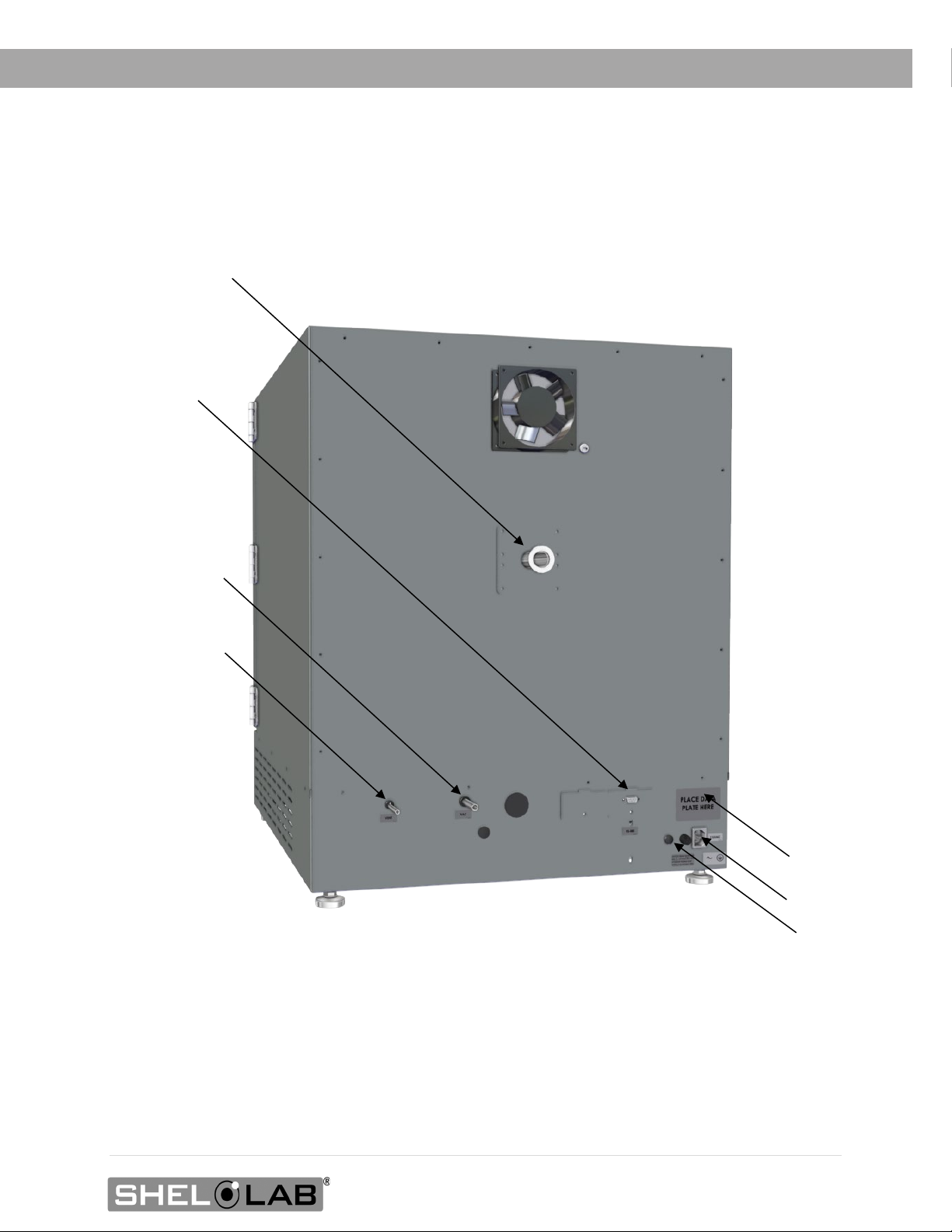

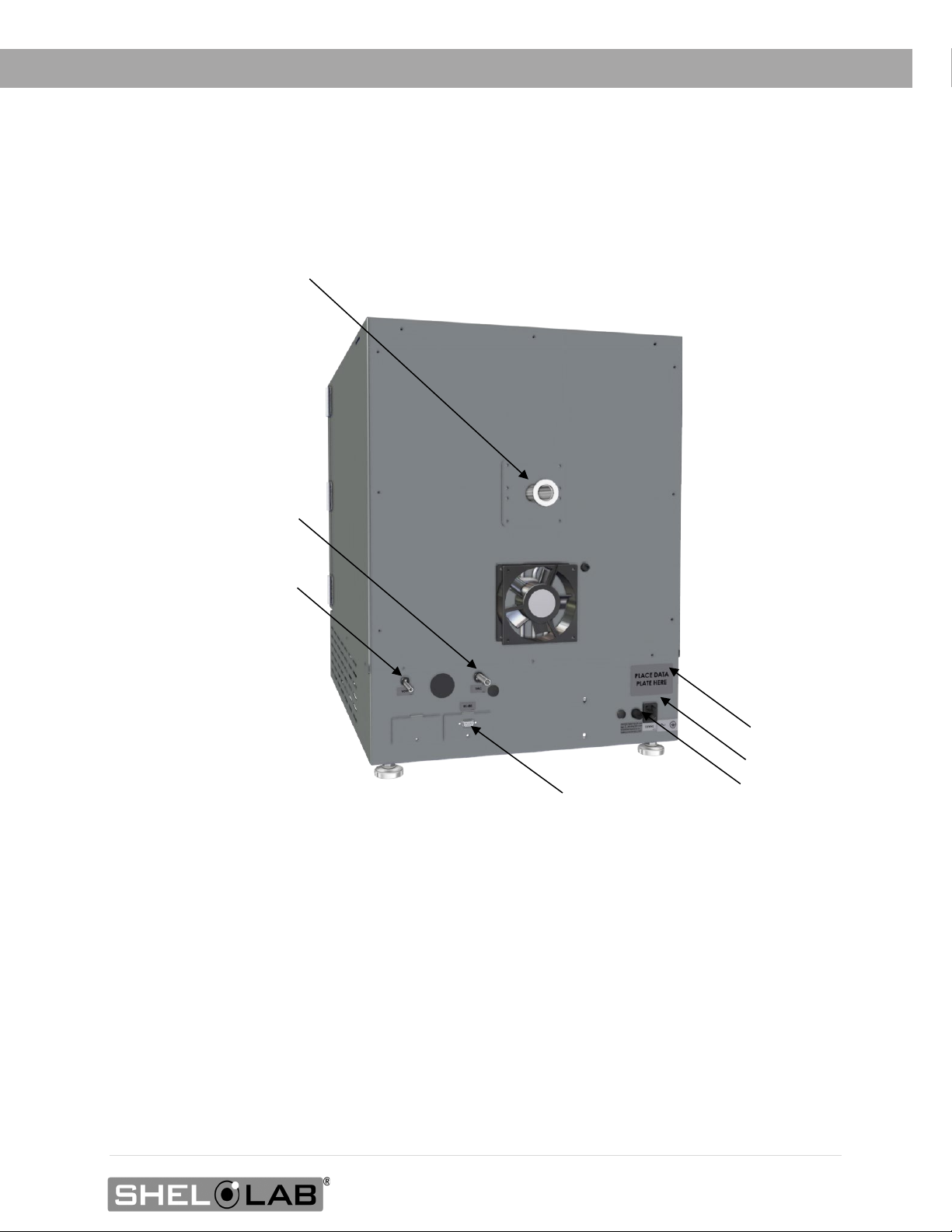

KF-25 Access Port (Includes Blank and Clamp, not pictured here)

Vacuum Port, 3/8

Chamber Vent

Power Cord

Fuse Holder

RS485 Data

Data Plate

RECEIVING

Port 9-Pin

Back of SVAC4

inch (9.52 mm)

Inlet Port ¼

inch (6.35 mm)

Inlet

15 | Page

Page 16

Temperature

the Short Shelf

Tall Shelf

Access Port

Tall Shelf

Chamber Door

Chamber

Main Control Panel

Vacuum Control Panel

RECEIVING

SVAC2

Probe Clip on

Gasket Seal

(KF-25 Fitting)

16 | Page

Page 17

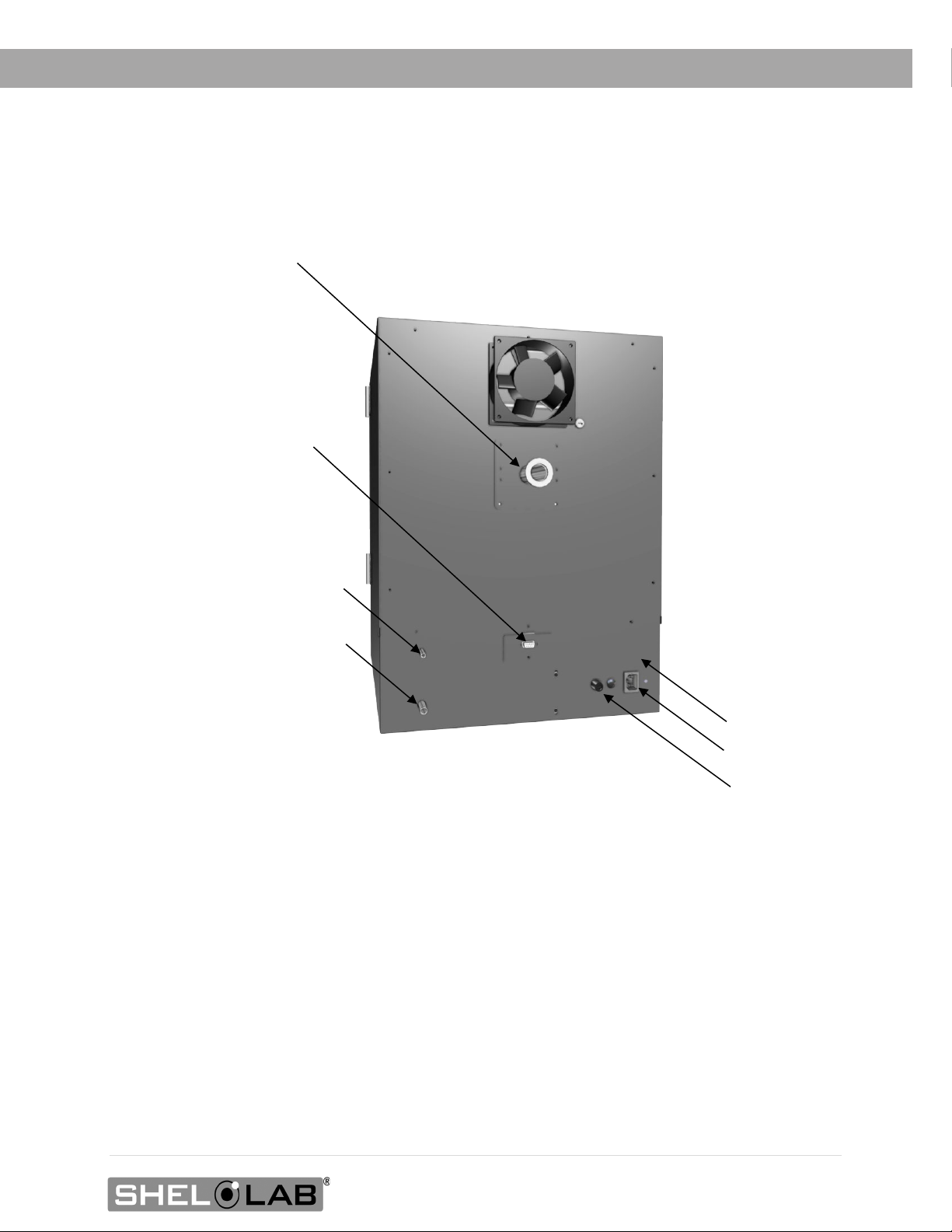

KF-25 Access Port (Includes Blank and Clamp, not pictured here)

Vacuum Port, 3/8

Chamber Vent

RS485 Data Port 9-Pin

Power Cord

Fuse Holder

Data Plate

RECEIVING

Back of SVAC2

inch (9.52 mm)

Inlet Port ¼

inch (6.35 mm)

Inlet

17 | Page

Page 18

Short Shelf

Tall Shelf

Access Port (KF-25 Fitting)

Door Latch

Tall Shelf

Chamber Door

Chamber

Control Panel

Temperature Probe Clip

RECEIVING

SVAC1

(Bottom)

Gasket Seal

18 | Page

Page 19

KF-25 Access Port (Includes Blank and Clamp, not pictured here)

Vacuum Port, 3/8

Chamber Vent

RS485 Data

Power Cord

Fuse Holder

Data Plate

RECEIVING

Port 9-Pin

Back of SVAC1

Inlet Port ¼

inch (6.35 mm)

inch (9.52 mm)

Inlet

19 | Page

Page 20

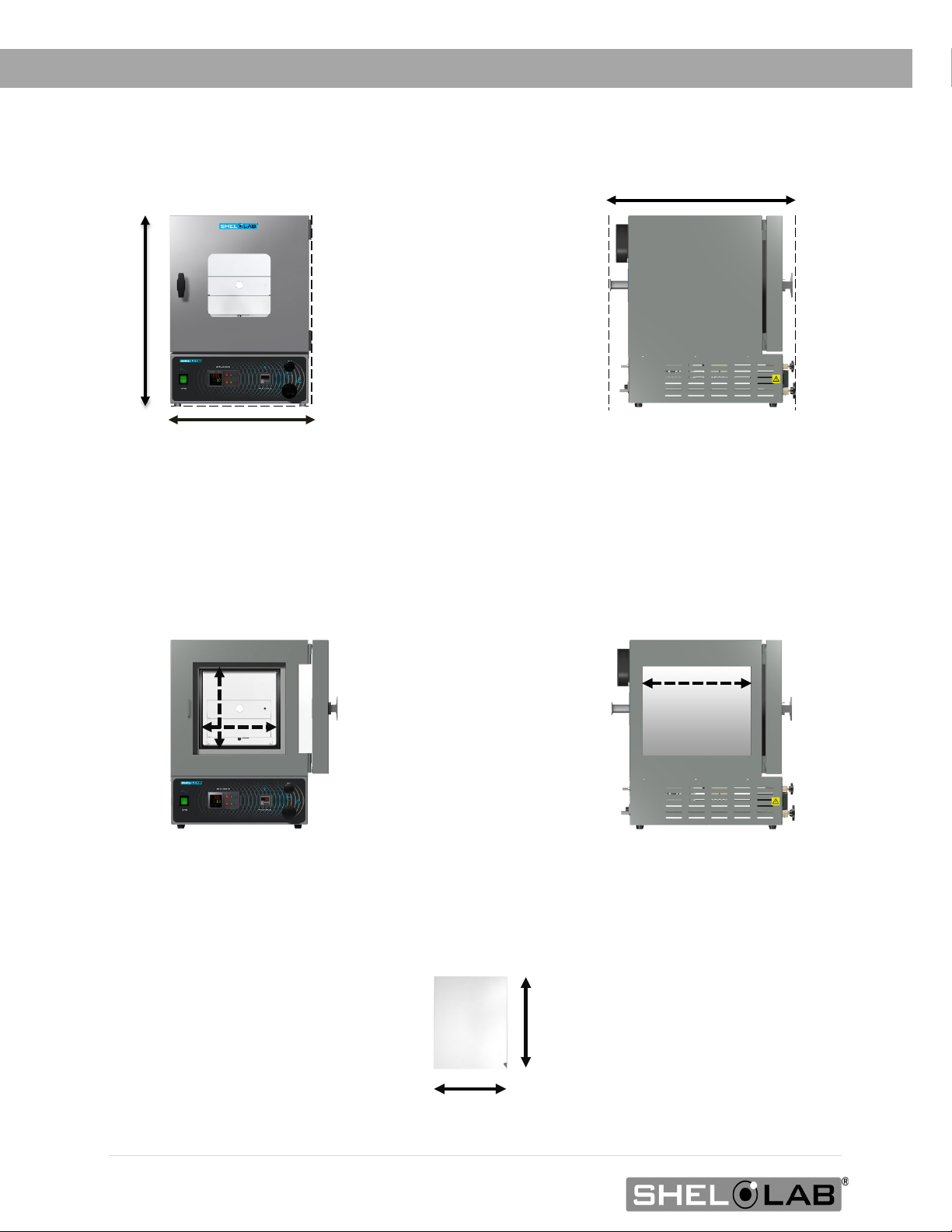

Shelf Width: 17.2 inches (437 mm)

Shelf Depth: 22.9 inches

Width: 27.0 inches (686 mm)

Depth: 35.2 inches (894 mm)

Exterior

Interior

Chamber Height: 18.0 inches (457 mm)

Chamber Width: 18.0 inches (457 mm)

Chamber Depth: 24.0 inches (610 mm)

Shelves

Height: 32.8 inches (833 mm)

RECEIVING

DIMENSION VISUALS

SVAC4

See page 26 for the required ventilation clearances.

20 | Page

(582 mm)

Page 21

Width: 20.8 inches (528 mm)

Exterior

Interior

Tall Shelves

Shelf Depth: 19.0 inches

Chamber Height: 12.0 inches (304 mm)

Chamber Width: 12.0 inches (304 mm)

Chamber Depth: 20.0 inches (508 mm)

Height: 26.8 inches (681 mm)

Shelf Width: 11.3 inches (223 mm)

Depth: 31.3 inches (795 mm)

RECEIVING

SVAC2

See page 26 for the required ventilation clearances.

(483 mm)

21 | Page

Page 22

Interior

Tall Shelves

Shelf Depth: 11.0 inches

Width: 17.5 inches (444 mm)

Chamber Height: 9.0 inches (228 mm)

Chamber Width: 9.0 inches (228 mm)

Chamber Depth: 12.0 inches (304 mm)

Height: 23.7 inches (602 mm)

Shelf Width: 8.8 inches (223 mm)

Depth: 23.0 inches (584 mm)

Exterior

RECEIVING

SVAC1

See page 26 for the required ventilation clearances.

22 | Page

(279 mm)

Page 23

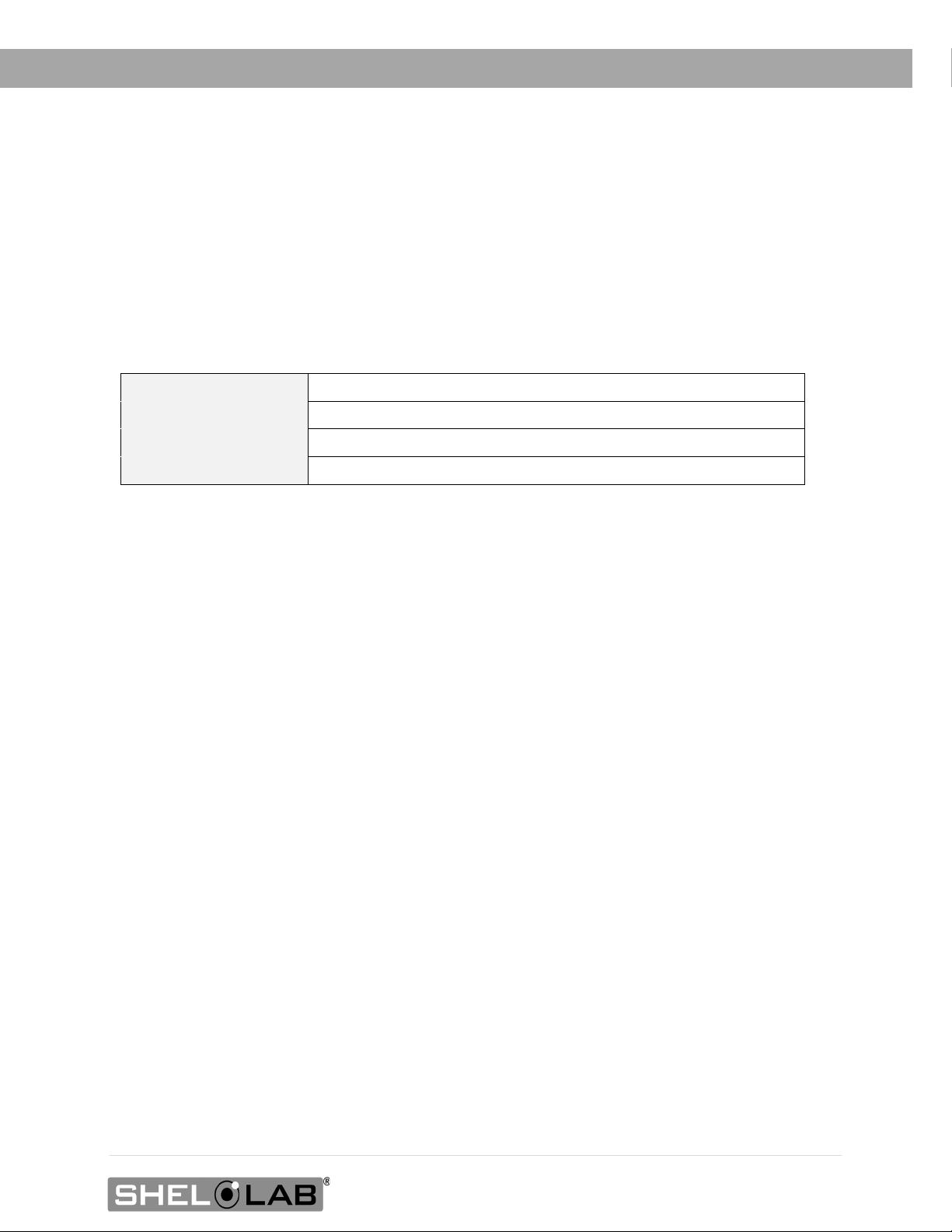

RECEIVING

RECORD DATA PLATE INFORMATION

The data plate contains the unit model number, serial number, part number, and part ID. Tech

Support will need this information during any support call. Record it below for future reference.

• The data plate is located on the back of the oven, above the power cord inlet.

Data Plate Information

MODEL NO:

SERIAL NO:

PART NO:

PART ID:

23 | Page

Page 24

RECEIVING

24 | Page

Page 25

INSTALLATION

INSTALLATION PROCEDURE CHECKLIST

For installing the unit in a new workspace location.

Pre-Installation

Verify that a vacuum supply source suitable for your application is available

and can be connected to the oven, page

• See page 32 for the oven gas and vacuum port locations.

Check that the required ambient conditions for the unit are met, page 26.

Check that the spacing clearance requirements are met, page 26.

9.

• Unit dimensions may be found on page 71.

Check that a suitable electrical outlet and power supply is present, page 27.

Install the oven in a suitable workspace location

Review the lifting and handling instructions, page 28.

SVAC2 and SVAC4, install the leveling feet, page 28.

Install the oven in its workspace location, page 29.

Set up the oven for use

Clean the oven shelving. Clean the chamber if needed, page 29.

Install the shelving in the oven chamber, page 30.

Connect the oven to its vacuum supply source along with any optional backfill gas

supply, page

32.

25 | Page

Page 26

6” (152 mm) Fan

KF-25 Port

6” (152 mm)

Door Swing

12” (305 mm)

12” (305 mm)

12” (305 mm)

6” (152 mm)

SVAC1: 17.6” (447 mm)

INSTALLATION

REQUIRED AMBIENT CONDITIONS

This oven is built for use indoors at room temperatures between 15°C and 40°C (59°F and 104°F), at no

greater than 80% Relative Humidity (at 25°C / 77°F). The ambient temperature should not change by

2°C (3.6°F) or more during operation.

Operating outside these conditions may adversely affect the oven temperature performance.

When selecting a location to install the unit, consider all environmental conditions that can adversely

impact its temperature performance. These include:

• Proximity to other ovens, autoclaves, and any device that produces significant radiant heat

• Heating and cooling vents or other sources of fast-moving air currents

• High-traffic areas

• Direct sunlight

REQUIRED CLEARANCES

These clearances are required to provide airflows for ventilation and cooling.

6 inches (152 mm) of clearance is required on the sides.

SVAC2: 20.8” (528 mm)

SVAC4: 27.0” (686 mm)

12 inches (305 mm) of headspace clearance is required between the top of the unit and any

overhead partitions.

Do not place objects on top of the oven.

A KF-25 vacuum port is located on the back of the oven for introducing vacuum-rated thermocouple

feedthroughs into the chamber or connecting to an external vacuum supply source. Leave sufficient

clearance for users to safely access this port.

26 | Page

Page 27

INSTALLATION

POWER SOURCE REQUIREMENTS

When selecting a location for the unit, verify each of the following requirements is satisfied.

Power Source: The wall power outlet must meet the power requirements listed on the unit data

plate.

Model AC Voltage Amperage Frequency

SVAC1

110 – 120 7.0 50/60 Hz

SVAC2 110 – 120 10.0 50/60 Hz

SVAC4 110 – 120 13.0 50/60 Hz

• Supplied voltage must not vary more than 10% from the data plate rating. Damage to the

unit may result if the supplied voltage varies more than 10%.

• The wall power source must be protective earth grounded.

• Use a separate circuit to prevent loss of the unit due to overloading or circuit failure.

• The recommended wall circuit breakers for these units are 15 amps.

• The wall power source must conform to all national and local electrical codes.

Power Cord

The unit must be positioned so that all end-users can quickly unplug the oven in the event of an

emergency.

• Each unit comes provided with a 125-volt, 15-amp, 9ft 5 in (2.86 m) NEMA 5-15P power

cord.

• Always use this cord or an identical replacement.

Fuses

Each unit comes with a fuse installed in a fuse holder immediately adjacent to the power cord inlet.

• The fuse must be installed and intact for the unit to operate.

• Always find and fix the cause of a blown fuse prior to putting the unit back into operation.

• Fuse type:

o T16A 250V 5x20mm

27 | Page

Page 28

INSTALLATION

LIFTING AND HANDLING

The oven is heavy. Use appropriate lifting devices that are sufficiently rated for these loads. Follow

these guidelines when lifting the oven:

• Lift the oven only from its bottom surface.

• Doors, handles, and knobs are not adequate for lifting or stabilization.

• Restrain the oven completely while lifting or transporting so it cannot tip.

• Remove all moving parts, such as shelves and trays, and lock doors in the closed position

during transfers to prevent shifting and damage.

LEVELING

All ovens must be level and stable for safe operation.

SVAC2 and SVAC4: Install the 4 leveling feet in the 4 corner holes in the bottom of the oven.

Note: To prevent damage when moving the unit, turn all 4 leveling feet so that the leg of each foot

sits inside the unit.

SVAC1: The rubber leveling feet are non-adjustable.

28 | Page

Page 29

INSTALLATION

INSTALL THE OVEN

Install the unit in a workspace location that meets the criteria discussed in the previous entries of the

Installation section.

• Do not connect the oven to its power source at this time.

DEIONIZED AND DISTILLED WATER

Do not use deionized water to clean the unit, even if DI water is readily available in your laboratory.

• The use of deionized water may corrode metal surfaces and voids the manufacturing

warranty.

• The manufacturer recommends the use of distilled water in the resistance range of 50K

Ohm/cm to 1M Ohm/cm, or a conductivity range of 20.0 uS/cm to 1.0 uS/cm, for cleaning

applications.

INSTALLATION CLEANING AND DISINFECTING

The manufacturer recommends cleaning the shelving and oven chamber prior to the installation of

the shelving in the chamber. The unit was cleaned at the factory but may have been exposed to

contaminants during shipping.

• Remove all wrappings and coverings from shelving prior to cleaning and installation.

• See the 33TCleaning and Disinfecting33T topic in the User Maintenance section (see page 51) for

more information on how to clean the oven chamber and shelving.

• Do not clean with deionized water.

29 | Page

Page 30

INSTALLATION

SHELVING INSTALLATION

In a pumped down oven chamber, heat flows in part from oven elements through the chamber walls

and floor and into the shelves. Install the shelves as described below to ensure proper heat

conduction and temperature measurement in a vacuum environment.

Never place samples or products on the oven chamber floor. The floor runs hotter than the shelf

temperatures. All oven heating specifications are for shelving temperatures.

SVAC1 and SVAC2

Temperature Probe Shelf Clip

Bottom of Short Shelf

1. Carefully slide the short shelf into position on the chamber floor, sliding the clip on the bottom

of the shelf onto the oven temperature probe.

• The shelf clip should be on the side of the shelf closest to the oven door. This ensures

the best measurement position for the probe.

• The oven probe extends from the back wall near the floor of the chamber.

• The short shelf must be on the bottom of the shelf-stack to ensure the oven

accurately measures and controls the shelving temperature.

2. Place the 2 tall shelves on top of the short shelf.

Continued on next page

30 | Page

Page 31

Rocking Motion

Probe

Shelf

Install 4 Shelf Clips

Place the Shelf

INSTALLATION

Shelving Installation Continued

SVAC4 Shelving

To ensure accurate temperature measurement, one shelf bottom must be in close proximity to the

oven temperature probe. This probe extends out from the chamber back wall. Do not place the

shelf in direct contact with the probe.

1. Install the shelf clips in the slots of the shelf standard mounting rails located on the sides of the

chamber interior, 4 clips per shelf.

a. Squeeze each clip, insert the top tab first, and then the bottom tab using a

rocking motion.

2. Set the shelves on the clips.

a. Verify the shelves are level.

31 | Page

Page 32

KF-25 Vacuum Port

Vacuum Line Connected

to the 3/8 inch Vacuum

Port

1. Vacuum Supply: Connect

Optional: Connect a

INSTALLATION

CONNECT TO THE VACUUM SUPPLY

Use clamps to secure the tubing to the Vacuum and Vent Ports.

to the 3/8 inch (9.52 mm)

Vacuum Port.

clean gas supply to the

Vent Port (Backfill Inlet).

The maximum allowed

gas pressure is 15 psi.

Oven Chamber Ports – Left to Right

• Vent Port (Backfill Inlet) – 1/4 inch (6.35 mm) OD

o External atmosphere backfills the oven chamber through this port when the Vent

Valve control on the front control panel is opened.

o A clean or inert gas supply source may be connected to this port. The maximum

allowed delivery pressure at the port is 15 psi.

• Vacuum Port – 3/8 inch (9.52 mm) OD

o The chamber atmosphere is evacuated through this port. Connect the vacuum

source to the oven here.

o This port is opened and closed by the Vacuum Valve control on the front control

panel.

• KF-25 Vacuum Port

o Comes with a clamp and blank.

Vacuum and Gas Backfill Connections

32 | Page

o Used for introducing thermocouple probes through a vacuum-rated feedthrough.

o A vacuum supply can be connected to the KF-25 port for increased efficiency in

vacuuming down the chamber. However, the Vacuum Valve control on the front

control panel will not affect the level of vacuum and must be set to Closed to

prevent atmosphere from entering the chamber through the 3/8-inch Vacuum Port.

Page 33

GRAPHIC SYMBOLS

The unit is provided with graphic symbols on its exterior. These identify hazards and adjustable

components as well as important notes in the user manual.

Symbol Definition

Consult the user manual

Consulter le manuel d'utilisation

Over Temperature Limit system

Thermostat température limite contrôle haute

AC Power

Repère le courant alternatif

I/ON O/OFF

I indique que l'interrupteur est en position marche.

O indique que le commutateur est en position d'arrêt.

Potential shock hazard

Risque de choc électrique

Recycle the unit. Do not dispose of in a landfill.

Recycler l'unité. Ne jetez pas dans une décharge

Protective earth ground

Terre électrique

33 | Page

Page 34

SYMBOLS

34 | Page

Page 35

Top Line (Red): Present chamber shelving

CONTROL OVERVIEW

Control Panels

Power Switch

The switch illuminates when in the ON ( I ) position.

Temperature Controller - Display on Homepage

While on the homepage, the Up and Down arrow buttons adjust the constant temperature setpoint.

Pressing and holding both buttons navigates from the homepage to menu pages. On the menu

pages, the buttons adjust calibration offsets and temperature program variables.

When starting on the homepage, the green Advance button navigates forward through parameter

option pages including and Units of Measurement (Celsius or Fahrenheit). The button also advances

forward in menus and parameter lists when programming a temperature recipe in the oven

controller.

The gray Reset button returns the display to the previous page or menu. Pushing the Reset button

repeatedly returns the display to the homepage.

temperature

Middle Line (Green): The constant

temperature setpoint

Bottom Line: Flashing “2” indicates active

heating

The EZ1 button launches temperature Program 1. Pushing EZ1 again while running aborts Program 1.

The EZ2 button launches temperature Program 2 (Step 11). Pushing EZ2 again while running aborts

Program 2.

35 | Page

Page 36

Close

Close

CONTROL OVERVIEW

Vacuum Gauge

As set at the factory, this gauge shows the chamber vacuum level relative to sea level

atmospheric pressure in inches of mercury (inHg). The display range is 0 to -29.9inHg. Zero

is the room atmosphere pressure at sea level and -29.9inHg a near-perfect vacuum. See

page 48 for how to display other units of measurement or zero the gauge to your local

altitude.

Vacuum Valve Control

This valve adjusts the level of vacuum draw applied to the oven chamber through the

Vacuum Port on the back of the oven.

• In the open position, this valve allows the connected vacuum supply to pump down

the oven chamber.

• In the closed position, the valve closes off the vacuum draw.

This valve should always be closed before a vacuum pump attached to the oven is turned off.

This safeguards the pump from external atmosphere being drawn through it and into the oven. If

an attached oil pump is turned off while the valve is open and the chamber is under vacuum, oil

may be pulled out of the pump and into the oven.

Vent Valve Control (Chamber Backfill)

This valve controls the oven chamber inlet Vent Port on the back of the oven.

• In the open position, the oven chamber is open to external atmosphere through the

vent intake port on the back of the oven.

• Optional: An inert or clean backfilling gas supply connected to the Vent Port will

flow gas from the pressurized supply to the oven chamber when the Vent Valve is

open.

• When the valve control is in the closed position, the chamber is cut off from external

atmosphere and any backfill gas supply.

o The vent must be closed before pumping down the chamber. Failure to

do so may result in damage to the vacuum pump.

36 | Page

Page 37

OPERATION

Safe operation of the oven depends on the actions and behavior of the oven end-user. Operating

personnel must read and understand the Operating Precautions in this section prior to operating

the oven. The end-user must follow these instructions to prevent injuries and to safeguard their

health, environment, and the materials being treated in the oven, as well as to prevent damage to

the oven. Failure to adhere to the Operating Precautions, deliberately or through error, is a

hazardous behavior on the part of the end-user.

Le fonctionnement sûr du four dépend des actions et du comportement des opérateurs du four. Le

personnel d'exploitation doit lire et comprendre les consignes de sécurité et les précautions

d'utilisation de cette section avant d'utiliser le four. Les opérateurs doivent suivre ces instructions

pour prévenir les blessures et protéger leur santé, leur environnement et les matériaux traités dans

le four, ainsi que pour éviter d'endommager le four. Le non-respect des consignes de sécurité et des

précautions d'utilisation, délibérément ou par erreur, est un comportement dangereux de la part de

l'opérateur.

OPERATING PRECAUTIONS

• Do not use this oven in unsafe improper applications that produce flammable or combustible

gases, vapors, liquids, or fuel-air mixtures in quantities that can become potentially explosive.

• Outgassed byproducts may be hazardous to or noxious for operating personnel. Vacuum

pump exhaust should be vented to a location outside the workspace in a safe manner in

accordance with all applicable laws, ordinances, and regulations. Do not operate the oven in

an unsafe area with noxious fumes.

• Do not use this oven for applications heating hazardous fibers or dust. These materials can

become airborne and come into contact with hot surfaces.

• Individual ovens are not rated to be explosion proof. Follow all building certification

requirements and laws for Class I, II, or III locations as defined by the US National Electric

Code.

• The bottom surface of the chamber should not be used as a work surface. It runs hotter than

the shelf temperatures. Never place samples or product on the oven chamber floor.

• Do not place sealed or filled containers in the oven. These may burst open when the

chamber is under vacuum.

• Do not place alcohol or mercury thermometers in the oven. With improper use, they can

rupture.

• Do not move the oven until it has finished cooling.

Burn hazard: Use proper personal protective equipment to minimize the risk of burns when the oven door

is open and the chamber door interior, chamber surfaces, and shelving are hot.

Risques de brûlure: Utilisez un équipement de protection individuelle approprié pour minimiser le

risque de brûlures lorsque la porte du four est ouverte et que l'intérieur de la porte de la chambre, les

surfaces de la chambre et les étagères sont chauds.

37 | Page

Page 38

OPERATION

THEORY OF OPERATION

Vacuum

Vacuum is supplied by an external vacuum supply (a pump or building system) connected to the

vacuum port on the back of the oven. Vacuum levels obtained in the oven chamber are dependent

on pump type and performance, valve settings, and the nature of the application or process,

including the volume of materials outgassed.

The chamber atmospheric pressure is displayed on the Vacuum Gauge on the main control panel.

The chamber should be sealed and evacuated at the start of a vacuum baking application. The oven

is not built to operate with the chamber exposed to atmosphere. Running the oven with the door or

the vent open risks destroying the vacuum pump, damaging the integrity of the oven chamber, and

may oxidize chamber surfaces.

Vacuum pumps and door gaskets should be selected on the basis of the application type or process.

Pumps vary in suitability and safety depending on the outgassed byproduct types and moisture

levels produced in the oven chamber. Gasket types are both resistant to and vulnerable to different

chemicals.

Gas Backfill

A gas or clean air supply can be connected to the vent port (backfill inlet) or KF-25 port located on

the back of the oven. Nitrogen or other inert gases are typically used to avoid particulate

contamination or the oxidation of product that has not cooled down. The maximum allowed backfill

pressure is 15 psi of delivery at the port.

Heating Options

The oven can either heat to and run at a constant temperature setpoint or execute a programmable

multistep temperature program with ramp up, heat soak, and ramp down intervals.

38 | Page

Page 39

OPERATION

Heating in a Vacuum

In conventional ovens, powered elements transfer heat into the chamber air. The heated air then

circulates by natural convection or blower fan action and surrounds the product on the shelves,

gradually bringing it to temperature. In a vacuum oven, heat transfer takes place in part through

direct infrared radiation. A significant portion, however, takes place through conduction. The oven

heating elements located inside the chamber walls and floor transfer heat to the shelves via metalon-metal conduct. Each shelf then transports heat to the products or samples resting on it.

The displayed oven temperature may change when pumping down the oven. This reflects the

chamber probe transitioning from measuring air temperature to shelf temperature, followed by a

redistribution of thermal energy in the vacuum environment. This may present as a drop in

temperature followed by an apparent rise. The drop may take place even if the oven is actively

heating.

Heating Control

The controller monitors the oven chamber shelving temperature using a thermocouple temperature

probe extending into the chamber from the back wall. In a vacuum environment, the probe senses

the temperature of the shelf placed immediately above it. Placement of a shelf in close proximity to –

but not in contact with the probe — is crucial for accurate measurement of the shelving temperature

in the vacuum chamber.

The unit uses Proportional – Integral – Derivative (PID) control to avoid significantly overshooting the

setpoint. The rate of heating will slow as the chamber temperature approaches the target temperature. If

the chamber temperature is above the setpoint, the unit uses minimum heating to control the rate of

cooling and avoid dipping below the setpoint.

PID loops also optimize heating rates to compensate for the temperature environment around the

unit. If the unit is operating in a cool room, the controller will increase the length of the heating

pulses. Likewise, when operating in a warm room the unit uses shorter pulses. If the ambient

temperature conditions change significantly, there may be minor over or undershoots as the unit

adapts.

The oven relies on natural heat radiation for cooling. It can achieve a low-end operating temperature

of the ambient room temperature plus the oven waste heat.

High Limit Control System

The temperature controller contains a heating cutoff system with independent circuitry connected to a

redundant solid-state temperature sensor probe inside the oven chamber. This high limit system depowers

the oven heating elements whenever the chamber shelving temperature exceeds the current limit setting.

This safeguards the oven in the event of a failure of the main temperature control circuitry or main

temperature sensor probe.

The high limit is set by the end-user to a minimum of 10˚C above the highest temperature of the application

process the oven is currently being used for. Failure to set the high limit control system voids the oven

manufacturing defect warranty in the event of an overtemperature event.

39 | Page

Page 40

1.

Attach the Power Cord

3. Verify the Door and Valves are Closed

4. Turn on the Oven

Place the oven Power Switch in the ON ( I ) position.

5. Set the High Limit Temperature

6.

OPERATION

PUT THE OVEN INTO OPERATION

Perform the procedures below after the unit has been installed in a new workplace location. These

verify the integrity of the vacuum system and prepare the oven for normal use.

2.

Attach the power cord that came with the unit to the power inlet

receptacle on the back of the oven.

Plug the power cord into the workspace electrical supply.

Verify the oven chamber door is closed and latched, and

that the vent intake valve and vacuum valve are in the

closed position (turned all the way clockwise).

This safeguards your vacuum pump from exposure to

streaming atmosphere.

• The controller display will illuminate and default to its

homepage.

• The vacuum display will illuminate.

Plug in the Vacuum Pump

40 | Page

Use the 33TSet the High Temperature Limit procedure on33T

page 42 to set 33Tto the Limit heating cutoff at least 10°C above

the highest intended temperature of your application33T.

Plug the vacuum pump power cord into a wall power source.

Continued next page

Page 41

7.

8.

Setting the Operating Temperature

OPERATION

Continued from the previous page

Verify Vacuum Integrity

10 Minutes Minimum

Use the 33TEvacuating the Chamber33T procedure on page 43 to

pump down33T and hold the oven chamber under vacuum 33Tfor 10

minutes to verify the integrity of the vacuum supply system.

Read these procedures and descriptions.

33TSet the constant temperature setpoint33T. See the

procedure on page 45.

Or

33TProgram multistep heating recipes33T. See the

description on page 45.

The oven is now ready for use

41 | Page

Page 42

1.

OPERATION

SET THE HIGH TEMPERATURE LIMIT

Note: Test the high limit system once per year for functionality.

Set the high-temperature limit at least 10°C above the highest temperature the oven will run at during

your recipe program or constant-temperature application. See the High Temperature Limit system

explanation on page 39.

Advance to the Limit High Setpoint, starting on the homepage

Push Advance

Multiple Times

Push the Advance button until “Lh.S1” (Limit High

Setpoint) shows in the green mid-level display line.

2. Adjust the high limit to at least 10°C above the highest temperature of your application

Adjust

• The oven will automatically save and apply the

new High Limit setting after you have stopped

adjusting.

Note: If you are just checking the current hightemperature limit setting, push the Reset button to

exit the Limit High Setpoint menu and return to the

homepage without saving any changes.

3. Return to the homepage

Push Reset

•

Returned to homepage

End of Procedure

42 | Page

Page 43

Evacuate the Oven Chamber

1. Verify the Vacuum and Vent Valve controls are in the closed position

3. Open the oven Vacuum Valve

4. Close the Vacuum Valve

Turn the Vacuum Valve control back to the closed position (clockwise) to

• The pump may remain on.

VACUUM

VENT

VACUUM

OPERATION

EVACUATING AND BACKFILLING THE OVEN CHAMBER

The oven chamber must be drawn down to at least -3 inHg (-76 mmHg or -10 kPa) in order to seal.

Option 1: Vacuuming down with a pump connected to the vacuum port.

• This protects your vacuum pump from exposure to streaming

atmosphere.

2. Turn on your vacuum pump

Turn the control all the way counterclockwise.

• The Vacuum Gauge on the front panel should

show the chamber pressure decreasing.

• The achievable vacuum level is dependent on

altitude above sea level as well as the vacuum

supply efficiency and the volume of outgassed

byproducts. See page 49.

Holding at Vacuum

Continue evacuating the chamber throughout the baking application

to vent outgassed byproducts.

Backfilling the Oven Chamber

protect the vacuum pump from extended exposure to streaming

atmosphere.

5. Slowly open the Vent Valve

The chamber pressure gauge will count upward to 0 inHg.

End of Procedure

43 | Page

Page 44

Evacuate the Oven Chamber

1. Verify the Vacuum and Vent Valve controls are in the closed position

3. Open the regulator on your vacuum supply system

4. Close the regulator on your vacuum supply system.

The chamber pressure gauge will count upward

VENT

OPERATION

Option 2: Vacuuming down with a vacuum supply connected to the KF-25 fitting on the

back of the oven.

2. Turn on your vacuum pump

• This protects your vacuum pump from exposure to streaming

atmosphere.

• The vacuum gauge should show a decreasing

pressure in the oven chamber.

Holding under Vacuum

• Continue evacuating the chamber throughout the baking

application to vent outgassed byproducts.

• When first putting the oven into operation, hold under

vacuum for at least ten minutes.

Backfilling the Oven Chamber

• This isolates your pump from the oven chamber.

5. Slowly open the Vent Valve

•

to 0 inHg.

End of Procedure

44 | Page

Page 45

1.

2.

OPERATION

SETTING THE CONSTANT TEMPERATURE SETPOINT

Adjust the constant temperature setpoint on the homepage

• Stay 10°C below the high

limit setpoint.

Note: Holding down an arrow

button will cause the temperature

to advance in increments of ten

Adjust

Release the arrow buttons after adjusting the setpoint

(10).

• There may be a brief pause as the oven controller

calculates the optimum power usage to achieve the

setpoint starting from the current oven chamber

temperature.

• A small illuminated 2 near the bottom of the display

indicates the temperature controller is calling for

heat.

Oven Heating

TEMPERATURE PROGRAMS

Please see the temperature program manual included with this oven for how to program automated

heating recipes. The manual provides illustrated explanations for all major program functions and

programming steps.

Pushing EZ1 launches heating Program 1. Pushing EZ1 again while running aborts Program 1.

Pushing EZ2 launches heating Program 2 (Step 11). Pushing EZ2 again while running aborts Program 2.

45 | Page

Page 46

OPERATION

HIGH TEMPERATURE LIMIT ACTIVATED

The High Limit system cuts off heating in the oven whenever the chamber temperature meets or

exceeds the Limit setting. Heating remains disabled until the oven end-user clears the Limit cutoff.

Indicators

When heating is cut off, the oven display flashes an alert screen alternating with

the homepage. Additionally, an illuminated “4” on the bottom display level

specifies that the oven should be routing electricity away from the heating

elements.

Activation of the Limit cutoff is accompanied by a click sound.

Possible Causes of High Limit Activation

• The oven temperature is set above or near the High Limit cutoff setting. The

High Limit should be set at least 10°C above the highest intended

temperature of your heating application.

• A heat source in the oven chamber is pushing the oven temperature above

the limit setting.

• Significant outgassing in the chamber may be interfering with the measured

temperature.

• Attempting to heat a significant mass of product or samples may trigger a

temperature overshoot and subsequent Limit cutoff.

• The oven temperature controller circuitry or sensor probe have failed.

Alternating Screens

Attention Screen

Heating Off

If you suspect an ignition event in the oven chamber or a hardware failure wait for the oven to

cool to room temperature before opening the chamber door. Contact

33TTechnical Support33T for

assistance.

Clearing the High Limit Heating Cutoff

• Clearing the cutoff restores power to the oven heating elements.

• The oven chamber temperature must be below the High Limit cutoff setting before

clearing the cutoff.

• Always verify it is safe to resume heating before clearing the High Limit cutoff.

1. Push the Reset button.

• The alert screens will flash 2 additional times before the oven controller clears the

cutoff, ending it.

46 | Page

Page 47

X5

⁰C ⁰F

OPERATION

CHANGING THE UNIT OF MEASUREMENT

The controller can display temperatures in either Celsius or Fahrenheit.

1. Starting on the homepage, push the green Advance button until

reaching the “C_F1” units of measurement option.

2. Use the Arrow buttons to change the measurement parameter on

the top display line to your preferred unit of measurement.

• “C” is Celsius and “F” Fahrenheit.

3. Push the Reset button to save and return to the homepage.

47 | Page

Page 48

Inches of Mercury

Kilopascals

Both

OPERATION

VACUUM GAUGE OPERATIONS

Change the Unit of Measurement

1. Place the vacuum gauge in its adjustment mode.

a. Press and hold the “M” button for approximately 3 seconds.

• The display will begin to blink and show a unit of measurement.

2. Use the arrow buttons to scroll between units.

3. Exit the adjustment mode.

a. Press and hold the “M” button for approximately 3 seconds.

• The display will cease blinking and show the current chamber

pressure.

Units of Measurement – Display Characters

kPa Kgf/cmP2 bar psi mmHg inHg mmHR

Zeroing the Gauge

As set at the factory, the vacuum gauge shows a reading of 0 inches of mercury (inHg) when the

chamber is at ambient (room) pressure. The display was set near sea level.

If the gauge does not show 0 inHg when the chamber is at room atmospheric pressure, perform the

following steps to zero the gauge.

1. With the chamber door open, press and hold both the Up and Down

arrow buttons.

RO

2

See page 72 for the zero equivalent for units of measurement other than inHg.

48 | Page

2. Release the buttons when the display shows 0.0.

Page 49

Sea Level

Sea Level

14.70 psi

-29.9 inHg

1000ft

305m

14.16 psi

-28.9 inHg

2000ft

610m

13.66 psi

-27.8 inHg

3000ft

914m

13.16 psi

-26.8 inHg

6000ft

1829m

11.77 psi

-24.0 inHg

7000ft

2134m

11.33 psi

-23.1 inHg

8000ft

2438m

10.91 psi

-22.2 inHg

10,000ft

3048m

10.10 psi

-20.6 inHg

28.9590

98.0665

1

0.9806

14.2233

735.55

10000.27

29.5300

100

1.0197

1

14.5037

750.06

10197.44

0.0028

0.0098

0.0001

0.0001

0.0014

0.0029

1

OPERATION

MAXIMUM OBTAINABLE VACUUM

The maximum vacuum obtainable, as measured by the oven gauge, is in part a function of altitude.

While a vacuum pump will evacuate the same percentage of atmosphere from the oven chamber at

higher altitudes, less overall pressure is expelled because of the reduced density.

Put differently, at sea level, there are 29.9 inches of mercury pressure that can be drawn out of the

oven chamber by a vacuum pump. At 5000ft (1524m), there are only 24.9 inches of atmospheric

pressure to be evacuated from the oven chamber.

Altitude (Feet) Altitude (Meters) Atmospheric Pressure

4000ft 1219m 12.68 psi -25.8 inHg

5000ft 1524m 12.22 psi -24.9 inHg

9000ft 2743m 10.50 psi -21.4 inHg

*In gauge pressure

PRESSURE UNITS CONVERSION CHART

Max Vac

Obtainable

InHg kPa Kgf/cmP2 bar psi mmHG mmHR

1 inHg

1 kPa

1 3.3863 0.0345 0.3386 0.4911 25.400 345.32

0.2953 1 0.0102 0.01 0.1450 7.5006 101.97

1 Kgf/cmP2

1 bar

1 psi

1 mmHG

1 mmHR

2

RO

2.0360 6.8947 0.0703 0.0689 1 51.7150 703.09

0.0394 1.3332 0.0014 0.0013 0.0193 1 13.5954

49 | Page

RO

2

Page 50

OPERATION

DATA PORT

9-Pin Port

The 9-pin RS485 data port, located on the back of the oven, connects to the oven temperature

controller. The port is primarily intended for updating the controller software but can be used for

data logging and graphical temperature recipe programming. Accessing the controller with a

computer requires a 9-pin RS485-to-USB converter cable and driver software.

Applications and Utility Software

• National Instrument LabView and Watlow SpecView — Temperature monitoring and data

logging in graphical user interface environments.

• Watlow’s EZ Zone™ Configurator — Programming temperature recipes in a drop-down

menu environment. Configurator can also be used to copy and save the controller

configuration file, which includes the currently programmed heating programs.

o Configurator is available for free on the Watlow website.

OVEN COOLDOWNS

The oven chamber is well insulated and requires a significant amount of time to cool down while

sealed and evacuated. Please see the Unit Specifications chapter for cooldown times.

• Introducing free atmosphere into the oven when the chamber temperature is above 100°C

risks oxidizing chamber surfaces.

R

• Backfilling the oven with N

R does not significantly increase the rate of cooling.

2

50 | Page

Page 51

USER MAINTENANCE

Warning: Disconnect the unit from its power supply prior to maintenance or cleaning of this unit.

Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le cordon

secteur de la source d'alimentation.

CLEANING

If a hazardous material or substance has spilled in the unit, immediately initiate your site Hazardous

Material Spill Containment protocol. Contact your local Site Safety Officer and follow instructions per

the site policy and procedures.

• Periodic cleaning is required.

• Do not use spray-on cleaners or disinfectants. These can leak through openings and coat

electrical components.

• Do not use cleaners or disinfectants that contain solvents capable of harming paint coatings

or stainless steel surfaces. Do not use chlorine-based bleaches or abrasives; these will

damage the chamber liner.

• Consult with the manufacturer or their agent if you have any doubts about the compatibility

of decontamination or cleaning agents with the parts of the equipment or with the material

contained in it.

Warning: Exercise caution if cleaning the unit with alcohol or flammable cleaners. Always allow the

unit to cool down to room temperature prior to cleaning and make sure all cleaning agents have

evaporated or otherwise been completely removed prior to putting the unit back into service.

Avertissement: Soyez prudent lorsque vous nettoyez l'appareil avec de l'alcool ou des produits de

nettoyage inflammables. Laissez toujours refroidir l'appareil à la température ambiante avant le

nettoyage et assurez-vous que tous les produits de nettoyage se sont évaporés ou ont été

complètement enlevés avant de remettre l'appareil en service.

Oven Chamber Cleaning Guidelines

1. Disconnect the unit from its power supply.

2. Remove any removable chamber accessory items such as shelving if present.

3. Use 99% isopropyl alcohol to clean chamber surfaces and shelving. Apply using lint-free

wipes.

4. Take special care when cleaning around temperature sensor probes. Do not clean the

probes.

5. Clean all removable accessories and components.

6. Verify the cleaning alcohol has evaporated completely from all chamber surfaces and

accessories prior to reconnecting the unit to its power source.

51 | Page

Page 52

MAINTENANCE

Oven Exterior Cleaning Guidelines

1. Disconnect the unit from its power supply.

2. The manufacturer recommends cleaning the unit with a mild soap and water solution.

• Do not use abrasive cleaners, these will damage metal surfaces.

• Cleaning agents must be compatible with steel and powder coat paint surfaces.

• Do not use deionized water to rinse or clean with.

3. Rinse with distilled water and wipe dry with a soft cloth.

MAINTAINING ATMOSPHERIC INTEGRITY

Periodically, inspect the door latch, trim, catch, and gasket for signs of deterioration. Failure to

maintain the integrity of the door system shortens the lifespan of the unit.

The gasket should be replaced if it is dry, cracked, or otherwise showing a loss of elasticity.

ELECTRICAL COMPONENTS

Electrical components do not require maintenance. If the oven fails to operate as specified, please

contact your distributor or

33TTechnical Support33T for assistance.

VACUUM PUMP MAINTENANCE

Refer to the operation manual supplied with your vacuum pump for recommended maintenance

routine, such as oil levels, replacement of sorbent charge, and exhaust filter change-outs. Contact

your vacuum pump supplier if you do not have an operation manual.

STORAGE

To prepare the unit for storage, remove all shelves, dry the chamber completely, and disconnect the

power supply. Be certain that the door is positively locked in the closed position.

52 | Page

Page 53

Use non-marking, heat-resistant polyamide tape to

MAINTENANCE

CALIBRATING THE TEMPERATURE DISPLAY

Note: Performing a temperature display calibration requires a temperature reference device. Please

see the33T Reference Sensor Devices entry33T on page 10 for device requirements.

Temperature calibrations match the temperature display to the actual chamber temperature inside

the oven chamber. The actual chamber temperature is supplied by a reference sensor device.

Calibrations compensate for software drifts in the controller as well as those caused by the natural

material evolution of the sensor probe in the chamber space. Calibrate as often as required by your

laboratory or production protocol, or regulatory compliance schedule. Always calibrate to the

industry or regulatory standards required for your application.

A Suggested Calibration Set-Up

1. Introduce the reference device vacuum-rated

thermocouple probe feedthrough into the KF-25

port on the back of the oven.

• There must be at least 12 inches (305

mm) of wire in the chamber to prevent

heat sinking, which would result in a

false low temperature reading.

2. Position the probe in the chamber.

• Place the probe head as close as

possible to the geometric center

point of the chamber.

• The probe head must be in direct

contact with the shelf surface.

3. Secure the probe head in position with

the non-marking, heat-resistant tape.

hold the thermocouple probe in place. The oven

manufacturer recommends Kapton brand tape,

0.5 inches width (12.7 mm), 2 mil thickness.

4. Use the KF-25 clamp to secure the

feedthrough and seal the port.

5. Close and latch the oven door. The door must

be sealed to carry out an accurate calibration.

6. Evacuate the chamber to the vacuum level of

your application or baking process. The

chamber must be under vacuum to perform an

accurate calibration.

Probe head in direct contact with the shelf surface

53 | Page

Page 54

Begin Calibration

Suggested Calibration Procedure

1

2

152.0°C

150°C

2

149.1°C

150°C

-0.9

150°C

Start

Required Stability Period

Fluctuations

See the Unit Specifications

MAINTENANCE

7. The unit temperature must be stable in order to perform an accurate calibration.

• The temperature is considered stabilized when the oven chamber has operated at your

calibration temperature for at least 1 hour with no fluctuations greater than the specified

temperature stability of the oven (see the Unit Specifications chapter).

• The manufacturer recommends calibrating at your application temperature.

chapter for the oven Time to

Temperature heat up rates.

Once the chamber has stabilized, compare the reference

temperature device and chamber temperature display readings.

• If the readings are the same, or the difference between

the two falls within the acceptable range of your protocol,

the display is accurately showing the chamber

temperature. The Temperature Calibration procedure is

now complete.

• See the next step if a difference falls outside the

acceptable range of your protocol.

43TThe display requires a calibration adjustment43T.

• The difference between the reference device and the display is

an offset value.

• Examples of offset values:

Reference Sensor

Reading

(Exaggerated)

-OR-

Oven Temp.

Display

1 Hour Minimum

Reference Device

Set Temperature

Reference Device

Set Temperature

Offset

Value

54 | Page

148.0°C 150°C -2

Note the offset value for use in Step 5.

Continued next page

Page 55

3

4

is not unlocked.

5

6

7

x2

x3

MAINTENANCE

Calibration continued

Unlock the controller.

• See the Unlocking procedure on page 57.

Note: The temperature controller must be unlocked in order to

access the Operations menu and enter a calibration offset.

Navigate to the Operations menu after unlocking the

controller.

a. Press and hold both the Up and Down arrow buttons

simultaneously for approximately 5 seconds.

b. Release the buttons when “A1” appears on the top display

line and “oPEr” appears in the mid display line.

Note: The Operations menu will not appear if the controller

Operations Menu

Advance through the Operations menu options to the

Temperature Calibration offset parameter.

a. Push the green Advance button repeatedly until “i.CA”

appears in the green mid display line and a number

value in the red top line.

Adjust the number value in the top display line to match the

offset value from step 2, using the arrow buttons.

Save the calibration offset and return to the homepage.

a. Push the Reset button 3 times so the display shows the

homepage.

• The oven will now begin heating or passively cooling to reach

the setpoint with the corrected display value.

Continued next page

55 | Page

Page 56

8

9

10

MAINTENANCE

Calibration continued

Wait for 30 minutes for the oven to stabilize, after the oven

has achieved the setpoint with the corrected display value.

• Failure to wait until the oven is fully stabilized will

result in an inaccurate reading.

Compare the reference device reading with the chamber

display again.

• If the reference device and the chamber

temperature display readings are the same, or the

difference falls within the range of your protocol,

the unit is now calibrated for temperature.

-OR-

• See the next step if the readings still fail to

match or fall outside of your protocol range.

If the two readings are not the same, and the difference

still falls outside the acceptable range of your protocol,

repeat steps 3 - 7 up to two more times.

• You may skip Step 3 by leaving the controller

unlocked until the unit is successfully calibrated.

• Three attempts may be required to

successfully calibrate units that are more

than ±2°C out of calibration.

Note: Always relock the temperature controller after a successful

calibration has been carried out. This safeguards against a user

accidentally changing the controller configuration file and

interfering with the functionality of the unit.

Reference Device

Reference Device

If the temperature difference between the unit and reference device readings fall outside your protocol

after three calibration attempts, 33Tcontact Technical Support33T or your distributor for assistance.

End Calibration Procedure

56 | Page

Page 57

1

2

3

Both

MAINTENANCE

UNLOCKING THE TEMPERATURE CONTROLLER

The oven temperature controller is software locked at the factory to ensure the integrity of its

configuration file. This safeguards against end-users accidentally altering the oven functionality or

safe operating bounds.

The controller must be unlocked in order to access the Operations menu and enter calibration

offsets.

Backing Up the Configuration File

The manufacturer recommends saving the controller configuration file prior to making any changes

to Operations options. See the Configurator software description in the

This will allow you to restore the configuration file in the event a change is made that adversely

affects the operation of the oven.

33TData Port33T entry on page 50.

Navigate to the Lock menu.

a. Press and hold both the Reset and Advance

buttons for approximately 8 – 9 seconds.

Note: If the top red line shows the “CUSt” Custom option,

use the Up or Down arrow buttons to scroll to the “Loc”

Security Setting option. Then push the Advance button as

per Step 2.

Advance to the lock “LoC.o” parameter.

a. Push the Advance button once.

Adjust the LoC.o setting from 3 to 2.

a. Push the Down arrow button.

Continued next page

57 | Page

Page 58

Unlocking the Controller Continued

4

6

7

8

x2

MAINTENANCE

Advance to the second security parameter, “LoC.P”

a. Push the Advance button once, saving the

previous parameter and advancing to the next

parameter.

5

Adjust the LoC.P setting from 2 to 3.

a. Push the Up arrow button.

Advance twice. Skip through the “PAS.E” Password Enable

parameter to “rLoc”, leaving “PAS.E” set to Off.

a. Push the Advance button twice.

Leave set to Off

Adjust the rLOC parameter from 2 to 5.

a. Push the Up arrow button.

Advance to the “SLOC” Write Security parameter.

a. Push the Advance button once.

58 | Page

Continued next page

Page 59

LoC.o

3

2

Operations Page

PAS.E

Off

Off

Password Enable

rLoC 2 5

Read Lock

SLoC

2

5

Write Security

Unlocking the Controller Continued

9

10

x2

MAINTENANCE

Change the “SLoC” parameter from 2 to 5.

a. Push the Up arrow button.

Return to the homepage to access the now unlocked

Operations page.

a. Push the Reset button twice.

Relocking the Controller

Always relock the controller after completing a calibration or other Operations menu procedure.

• To relock the controller, repeat the Unlocking procedure, only this time restore all of the

Security lock parameters to the locked settings.

• When first navigating from the homepage to the Factory menu to relock the controller, the

red top display line will show the “CUSt” Custom option.

• Use the arrow buttons to scroll to the “LoC” Security option, then push the Advance button

as per Step 2 and carry out the rest of the procedure.

Parameter Locked Unlocked Parameter Function

LoC.P 2 3 Programming Page

End of Procedure

59 | Page

Page 60

Record your observations in the SDRAP Answers Log on page 64.

Verify the Unit Conditions using the

1

2 3 4

Share the gathered information

MAINTENANCE

HEATING ISSUES — DIAGNOSTIC QUESTIONNAIRE

If the unit is experiencing heating issues, use this questionnaire to gather information on the unit prior to