Page 1

Installation and

Operation Manual

SCO6WE

Previously Designated:

2406

ECONOMY WATER-JACKETED CO2 INCUBATOR

110 - 120 Voltage

Page 2

Page left blank

2 | P a g e

Page 3

SCO6WE WATER-JACKETED CO2 INCUBATOR

Installation and Operation Manual

Part Number (Manual): 4861748

Revision: March 21, 2016

These units are TÜV CUE listed as water jacket incubators for professional, industrial, or

educational use where the preparation or testing of materials is done at an ambient air pressure

range of 22.14 – 31.3 inHg (75 – 106 kPa) and no flammable, volatile, or combustible materials are

being heated.

These units have been tested to the following requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010:2004 Reaffirmed: 2014-07

UL 61010-1:2012-05

UL 61010A-2-010:2002-03

EN 61010-1:2010

EN 61010-2-010:2014

Supplemented by: UL 61010-2-010:2015

3 | P a g e

Page 4

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 6

General Safety Considerations ................................................................................................................. 6

Engineering Improvements ....................................................................................................................... 7

Contacting Assistance ............................................................................................................................... 7

RECEIVING YOUR UNIT .............................................................................................................................. 8

Inspect the Shipment ................................................................................................................................ 8

Orientation Photo ...................................................................................................................................... 9

Regulator ................................................................................................................................................. 10

Recording Data Plate Information ........................................................................................................... 10

Reference Sensor Devices ..................................................................................................................... 10

INSTALLATION .......................................................................................................................................... 11

Installation Checklist ............................................................................................................................... 11

Required Ambient Conditions ................................................................................................................. 12

Environmental Disruption Sources .......................................................................................................... 12

Power Source Requirements .................................................................................................................. 12

Lifting and Handling ................................................................................................................................ 13

Install Incubator in Location .................................................................................................................... 13

Leveling ................................................................................................................................................... 13

Deionized and Distilled Water ................................................................................................................. 13

Installation - Clean and Disinfect ............................................................................................................. 14

Install the Chamber Air Duct ................................................................................................................... 14

Shelving Installation ................................................................................................................................ 15

Connect to the CO2 Supply ..................................................................................................................... 16

Access Port Stopper ............................................................................................................................... 17

Fill the Water Jacket ................................................................................................................................ 17

GRAPHIC SYMBOLS ................................................................................................................................. 19

CONTROL PANEL OVERVIEW ................................................................................................................. 21

OPERATION ............................................................................................................................................... 23

Theory of Operation ................................................................................................................................ 23

Put the Incubator into Operation ............................................................................................................. 26

Humidify the Incubator ............................................................................................................................ 27

Set the Temperature Set Point ................................................................................................................ 28

Muting the Audible Temperature Alarm .................................................................................................. 29

Automatic Door Cutoff ............................................................................................................................. 29

Set the CO2 Set Point .............................................................................................................................. 30

Muting the Audible CO2 Alarm ................................................................................................................ 31

No Gas Supply Alarm (NGS) .................................................................................................................. 31

Temperature Accuracy Verification ......................................................................................................... 32

CO2 Accuracy Verification ....................................................................................................................... 34

Set the Over Temperature Limit .............................................................................................................. 36

Load the Incubator .................................................................................................................................. 37

Accessory Compatibility .......................................................................................................................... 37

Data Output Capabilities ......................................................................................................................... 37

Condensation and the Dew Point ............................................................................................................ 38

USER MAINTENANCE ............................................................................................................................... 39

Cleaning and Disinfecting ....................................................................................................................... 39

Minimizing Contamination Exposure ....................................................................................................... 40

Gas Lines and HEPA Filters ................................................................................................................... 41

4 | P a g e

Page 5

Storage of the Incubator .......................................................................................................................... 41

Maintaining Atmospheric Integrity ........................................................................................................... 41

Electrical Components ............................................................................................................................ 41

Calibrate the Temperature display .......................................................................................................... 42

Calibrate the CO2 Display ........................................................................................................................ 46

Anode and Water Quality ........................................................................................................................ 50

UNIT SPECIFICATIONS ............................................................................................................................. 52

Weight ..................................................................................................................................................... 52

Dimensions .............................................................................................................................................. 52

Capacity .................................................................................................................................................. 53

CO2 .......................................................................................................................................................... 53

Temperature ............................................................................................................................................ 53

Power ...................................................................................................................................................... 53

PARTS LIST ............................................................................................................................................... 54

Ordering Parts and Consumables ........................................................................................................... 55

Accessories ............................................................................................................................................. 55

5 | P a g e

Page 6

INTRODUCTION

Thank you for purchasing a Shel Lab product. We know that in today’s competitive marketplace

customers have many choices when it comes to constant temperature equipment. We appreciate

you choosing ours. Our continued reputation as a leading laboratory product manufacturer rests

with you. We stand behind our products and will be here for you if you need us.

These incubators are intended for laboratory, industrial, and educational microbiological cultivation

applications. These incubators are not intended for use in hazardous or household locations.

Before using the unit, read this manual in its entirety to understand how to install, operate, and

maintain the incubator in a safe manner. Keep this manual available for use by all operators.

Ensure that all operators are given appropriate training before the incubator begins service.

GENERAL SAFETY CONSIDERATIONS

Note: Failure to follow the guidelines and instructions in this manual may create a protection

impairment by disabling or interfering with the unit safety features. This can result in injury or

death.

Your unit and its recommended accessories are designed and tested to meet strict safety

requirements. It is designed to connect to a power source using the specific power cord type

shipped with the unit.

For continued safe operation of your unit, always follow basic safety precautions including:

Always plug the unit power cord into a protective earth grounded electrical receptacle

(outlet) that conforms to national and local electrical codes. If the unit is not grounded

properly, parts such as knobs and controls can conduct electricity and cause serious injury.

Do not bend the power cord excessively, step on it, or place heavy objects on it.

A damaged cord can be a shock or fire hazard. Never use a power cord if it is damaged or

altered in any way.

Always position the unit so that end-users can quickly unplug it in the event of an

emergency.

Do not attempt to move the unit while in operation or before the unit has cooled.

Do not stack the unit without a factory-approved stacking rack or adaptor.

Use only approved accessories. Do not modify system components. Any alterations or

modifications to your incubator can be dangerous and void your warranty.

Follow all local ordinances in your area regarding the use of this unit. If you have any

questions about local requirements, please contact the appropriate agencies.

6 | P a g e

Page 7

INTRODUCTION (CONTINUED)

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes

and improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit operating characteristics or

appearance differs from those described in this manual, please contact your Shel Lab dealer or

distributor for assistance.

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue with the incubator, please contact Sheldon Technical

Support. Phone hours for Technical Support are 6am – 4:30pm Pacific Coast Time (west coast of

the United States, UTC -8). Please have the following information ready when calling or emailing:

the model number and the serial number (see page 9).

EMAIL: tech@shellab.com PHONE: 1-800-322-4897 extension 4, or (503) 640-3000 FAX: (503)

640-1366

Sheldon Manufacturing INC.

P.O. Box 627

Cornelius, OR 97113

7 | P a g e

Page 8

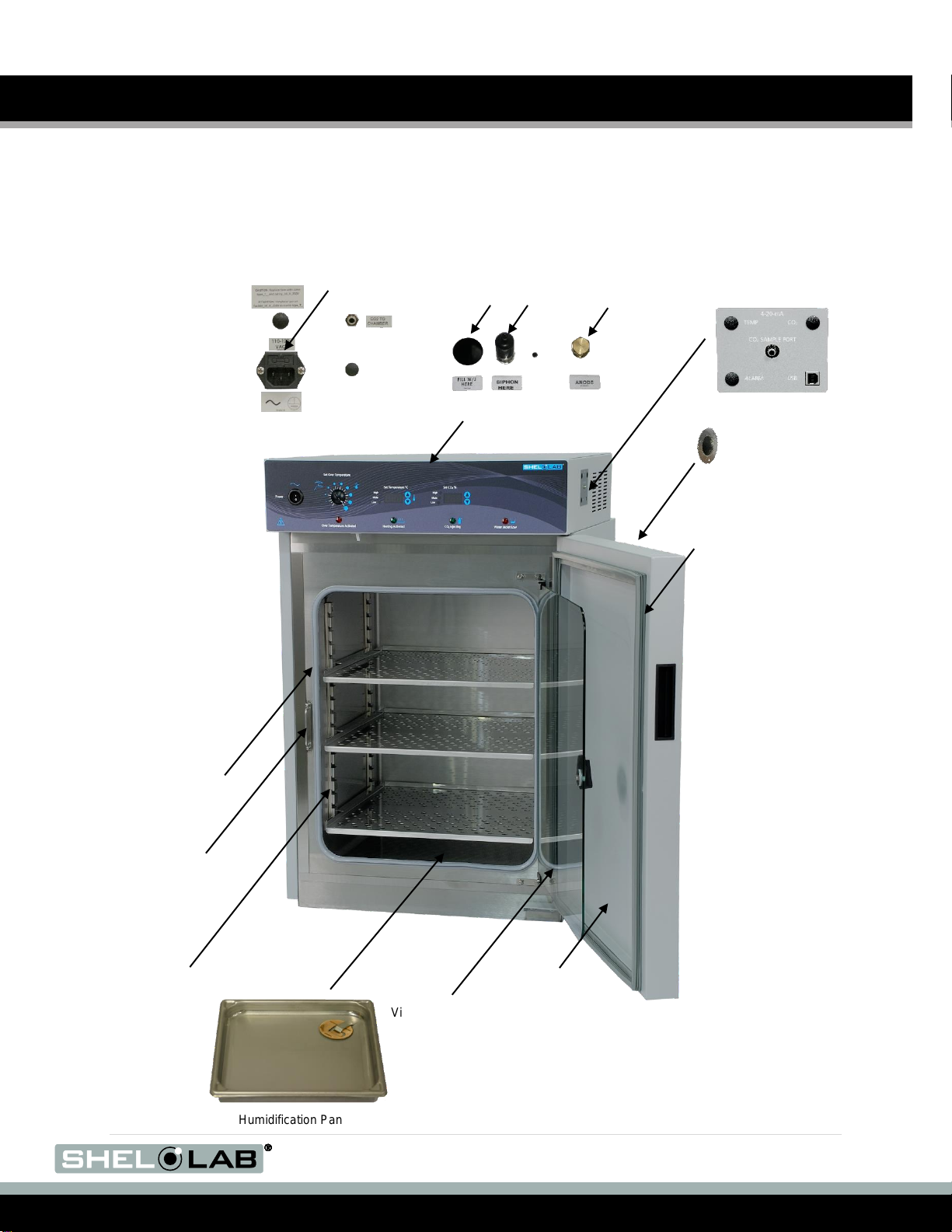

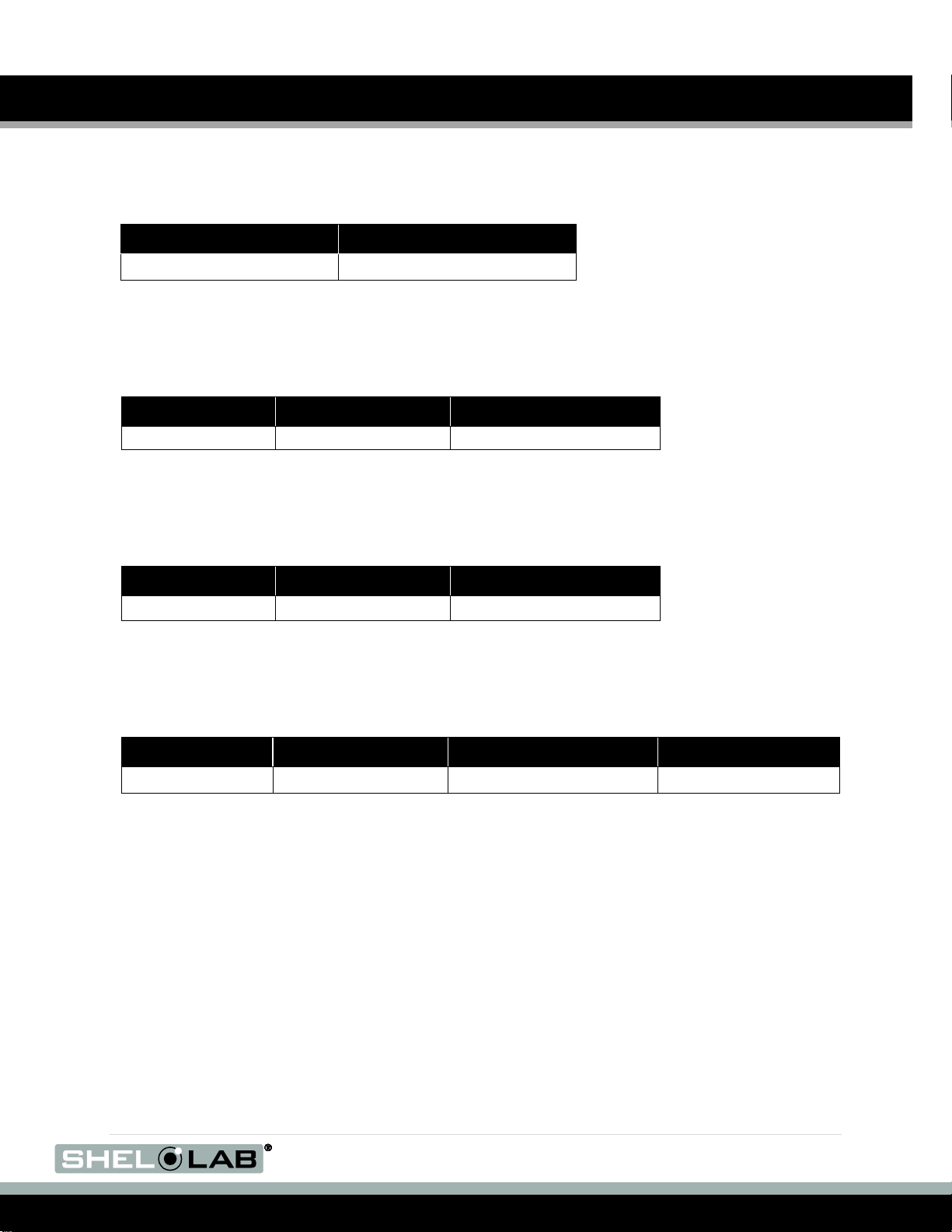

1 Copper Pan Token

1 Access Port

Stopper*

1 Ceiling Air Duct

CO2 Tubing Kit

5800529

7750514

5121514

9710500

1 Humidification Pan

4 Leveling Feet

1 Power Cord

Fill Port Stopper*

995-00015

PN 2700506

PN 1800510

7750513

6 Shelf Slides

4 Shelf Standards

3 Shelves

5121028

5170646

5121777

RECEIVING YOUR UNIT

INSPECT THE SHIPMENT

When a unit leaves the factory, safe delivery becomes the responsibility of the carrier.

Damage sustained during transit is not covered by the manufacturing defect warranty.

When you receive your unit, inspect it for concealed loss or damage to its interior and exterior. If

you find any damage, follow the carrier’s procedure for claiming damage or loss.

1. Carefully inspect the shipping carton for damage.

2. Report any damage to the carrier service that delivered the unit.

3. If the carton is not damaged, open the carton and remove the contents.

4. The unit should come with an Installation and Operation Manual.

5. Verify that the correct number of accessories have been included.

Included Accessories SCO6WE

*The access and water fill stoppers ship installed in their respective ports on the unit.

8 | P a g e

Page 9

Figure 1: SCO6WE

Chamber

Gasket

Door Latch

Viewing Door (Glass)

Chamber Door

Chamber Door

Handle

Access Port

Door Gasket

Control Panel

Back of Unit

Fuse in Cord Inlet

Back of Unit

Fill Port

Water Jacket Ports

Siphon Port

Anode Top

Shelf Standard Rail

Humidification Pan

Side of Unit

CO2 Sample Port and USB Port

Side of Unit

CO2 Gas In Port

RECEIVING (CONTINUED)

ORIENTATION PHOTO

9 | P a g e

Page 10

Model Number

Serial Number

Figure 2: CO2 Regulator

RECEIVING (CONTINUED)

REGULATOR

The incubator must be connected to either a building CO2 gas supply system or a

supply cylinder (tank). A cylinder regulator is not included with the incubator, and

must be purchased separately. Please see the Accessories section on page 55 if

you wish to order one from Shel Lab.

RECORDING DATA PLATE INFORMATION

Locate the data plate inside the incubation chamber, on the top right corner of the chamber door.

The data plate contains the incubator model number and serial number. Enter this information

below for future reference.

Date Plate Information

REFERENCE SENSOR DEVICES

Reference sensor devices or a combined device must be purchased separately in order to perform

accuracy verifications or calibrations of the incubator temperature and CO2 displays.

Reference devices must be accurate to at least 0.1°C and 0.1% CO2. The devices should be

regularly calibrated, preferably by a third party. For best temperature results, use a digital device

with a wired-connected temperature sensing probe that can be placed in the incubation chamber

through the unit access port. For example: a wire thermocouple probe. For best CO2 accuracy, use

a calibrated digital gas analyzer with sample tubing that can be connected to the incubator external

CO2 sample port.

Reference readings that avoid chamber door openings during verification and calibration eliminate

subsequent waits for the chamber temperature and gas levels to re-stabilize before proceeding.

This also allows temperature and gas verifications or calibrations to be performed simultaneously.

Select probes suitable for the application temperature you will be calibrating or verifying the

incubator displays at.

Alcohol thermometers are insufficient for conducting accurate temperature verifications and

calibrations. Do not use a mercury thermometer. Never place a mercury thermometer in the

incubation chamber.

10 | P a g e

Page 11

INSTALLATION

INSTALLATION CHECKLIST

Carry out the steps and procedures listed below to install the unit in a new workspace location and

prepare it for use. All procedures are found in the Installation section of this manual.

Pre-Installation

Procure a CO

Always use medical grade CO2.

gas supply for the incubator with a concentration suitable for your application.

2

Check that the required ambient conditions, ventilation, and spacing for the incubator are met,

page 12.

Unit dimensions may be found on page 52

Check for performance-disrupting heat and cold sources in the environment, page 12

Check that a suitable electrical outlet and power supply is present, page 26

Install the Incubator in a suitable location

Review the lifting and handling instructions, page 13

Install the incubator in its workspace location, page 13

Make sure the incubator is level, page 13

Set up the Incubator for use

Clean and disinfect the incubator and accessories that will be placed in the incubation

chamber, page 14

Do not use deionized water to clean the unit or fill the water jacket, see page 13

Install the ceiling air duct in the incubation chamber, page 14

Install the shelving in the incubation chamber, page 15

Connect the incubator to the CO

gas supply source, page 16

2

Verify that the rubber stopper is installed in the access port inside the incubation chamber,

page 17

Fill the water jacket with 9.5 gallons (36 liters) of water, page 17

11 | P a g e

Page 12

INSTALLATION (CONTINUED)

REQUIRED AMBIENT CONDITIONS

SCO incubators are intended for use indoors at room temperatures between 15C and 30C (59F

and 86F), at no greater than an ambient 80% Relative Humidity (at 25C / 77F).

4 inches (10cm) minimum ventilation clearance between the incubator and walls or partitions.

2 inches (5cm) minimum clearance above the top of the incubator for unobstructed airflow.

Operating the unit outside these conditions may adversely affect its temperature range and

stability. For conditions outside of those listed above, please contact your distributor to explore

other unit options suited to your laboratory or production environment.

ENVIRONMENTAL DISRUPTION SOURCES

When selecting a location to install the incubator, consider all environmental conditions that can

affect the unit temperature performance. For example:

Proximity to ovens, autoclaves, and any device that produces significant radiant heat

Heating and cooling ducts, or other sources of fast-moving air currents

High-traffic areas

Direct sunlight

POWER SOURCE REQUIREMENTS

When selecting a location for the unit, verify that each of the following requirements are satisfied:

The wall power source must match the power requirements listed on the unit data plate. These

units are intended for 110 – 120 VAC 50/60 Hz applications at 6.0 amps.

Supplied voltage must not vary more than 10% from the data plate rating. Damage to

the unit may result if supplied voltage varies more than 10%.

Wall power sources must be protective earth grounded and conform to all national and

local electrical codes.

Use a separate circuit to prevent loss of product due to overloading or circuit failure. The

circuit must match or exceeded the amperage requirement listed on unit the data plate.

The unit must be positioned so that all end-users can quickly unplug the power cord in the event of

an emergency.

The unit is provided with a 115 volt 15 Amp, 9ft 5 in (2.86m) NEMA 5-15P power cord.

The unit is provided with a 250V time-lag T 10 amp 5x20mm fuse located in the power cord

receptacle (inlet).

12 | P a g e

Page 13

Figure 3:

Leveling Foot

INSTALLATION (CONTINUED)

LIFTING AND HANDLING

The unit is heavy. Use appropriate powered lifting devices. Follow these guidelines when lifting and

handling the unit:

Lift the unit only from its bottom surface.

Doors, handles, and knobs are not adequate for lifting or stabilization.

Restrain the unit completely while lifting or transporting so it cannot tip.

Remove all removable components, such as shelving, and secure all doors in the closed

position during transfer to prevent shifting and damage.

INSTALL INCUBATOR IN LOCATION

Install the unit in a workspace location that meets the criteria discussed in the previous entries of

the Installation section.

LEVELING

Install the leveling feet shipped with the unit. The unit must be level and stable for safe

operation.

Insert one leveling foot into each of the four holes in the bottom corners of the

unit.

Adjust the foot at each corner until the unit stands level and solid without rocking.

To raise a foot, turn it in a counterclockwise direction.

To lower a foot, turn it in a clockwise direction.

Note: To prevent damage when moving the unit, turn each of the four leveling feet completely

clockwise.

DEIONIZED AND DISTILLED WATER

Do not use deionized water to clean or humidify the incubator, or fill the water jacket. Use of

deionized water may corrode metal surfaces and voids the warranty. The manufacturer

recommends the use of distilled water in the resistance range of 50K Ohm/cm to 1M Ohm/cm, or a

conductivity range of 20.0 uS/cm to 1.0 uS/cm, for cleaning, humidifying, and water-jacketing

applications.

13 | P a g e

Page 14

Back

Step 2

Front

Step 1

Step 3

Chamber Ceiling Air Duct

Figure 4: Chamber Air

Duct Installation

INSTALLATION (CONTINUED)

INSTALLATION - CLEAN AND DISINFECT

Cleaning and disinfecting the unit incubation chamber, shelving components and ceiling air duct now

reduces the risk of contamination. The chamber and shelving were cleaned and disinfected at the factory,

however, the unit may have been exposed to contaminants during shipping.

Remove all protective wrappings from shelving components and

the ceiling air duct prior to cleaning.

See the Cleaning and Disinfecting entry on page 39 for

information on how to clean and disinfect without damaging the

incubator or its components.

INSTALL THE CHAMBER AIR DUCT

Note: Exercise caution to avoid striking the sensors and blower fan

wheel on the chamber ceiling when installing the duct.

Note: The incubator must be turned off and unplugged when

carrying out this procedure.

Install the ceiling air duct to ensure the even flow of air throughout

the chamber space. This is essential for meeting the unit

temperature uniformity specs in the chamber.

Carry out the following steps:

Place the duct in the chamber.

a. The back of the duct should be toward the rear of

the chamber

b. The legs on the duct should face down toward the

chamber ceiling, next to the left and right chamber

walls

Move the air duct to the top of the chamber.

Seat the duct-mounting legs carefully in the shelf-standard

clips.

14 | P a g e

Page 15

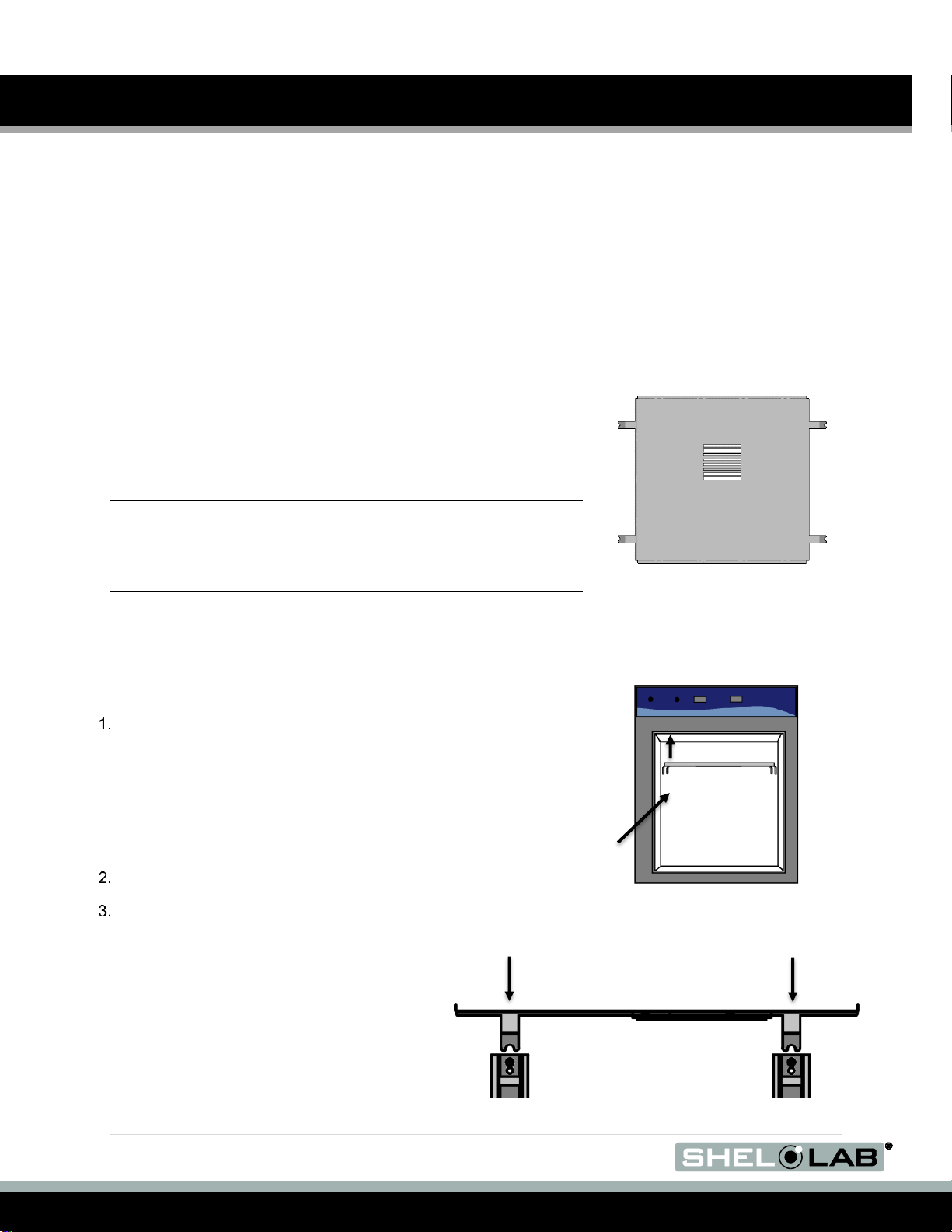

Figure 5: Shelving Installation

INSTALLATION (CONTINUED)

SHELVING INSTALLATION

Note: Always install the copper token in the humidification pan. Copper is known to have

antimicrobial properties that retard the growth of microorganisms in the pan.

Install the shelving and humidification pan in the in the

incubation chamber.

Install the shelf standard rails.

a. Align the keyhole slot of the standard with the

mounting peg on the side of the chamber wall.

b. Mount the shelf standard.

Install the shelf slides.

a. Insert the shelf slide into the shelf standard

using a rocking motion.

b. The shelf slide will sit level when correctly

installed.

Install the shelves.

a. Slide into position.

Install the humidification pan.

a. Place the copper token in the humidity pan.

b. Secure the token using the clip on the bottom

of the pan.

c. Place the pan on the chamber floor.

15 | P a g e

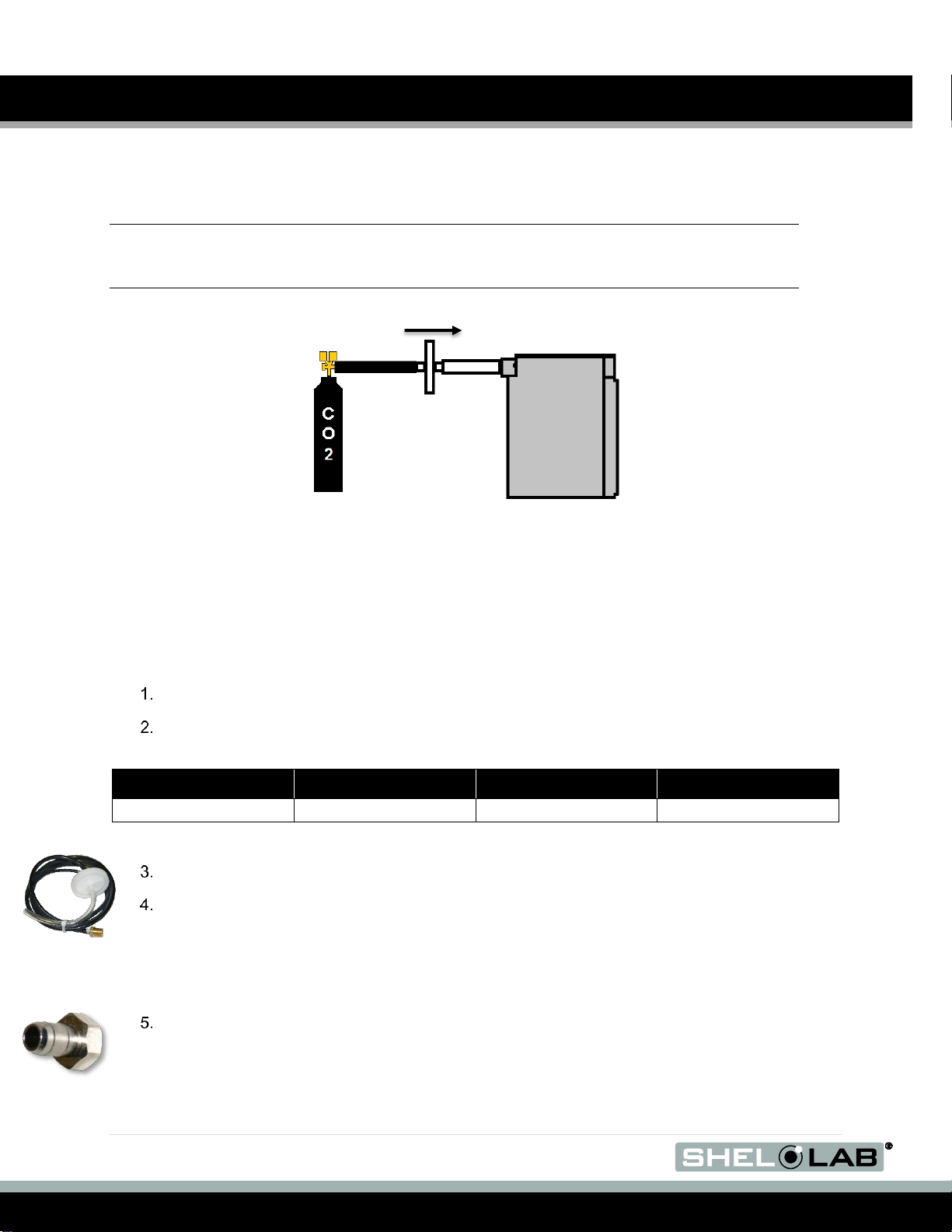

Page 16

PSI

Megapascals

Kilopascals

Bar

15 - 20 psi

0.103 - 0.137 Mpa

103.42 - 137.89 Kpa

1.03 - 1.378 bar

Figure 8: CO2

to Chamber

SCO6WE

Figure 7: Gas

Tubing Kit

Figure 6: CO2 Cylinder

Connection

CO2 Regulator

HEPA Filter

INSTALLATION (CONTINUED)

CONNECT TO THE CO

Note: Always use medical grade CO2. Use of non-medical grade CO2 risks introducing

contaminants into the chamber may damage the incubator, and voids the manufacturing

defect warranty.

The incubator may be connected to either a building supply source or a supply cylinder.

Two-Stage Regulators: If connecting to a supply cylinder always use a two-stage CO2 pressure

regulator. Be aware that some single-stage regulators have 2 gauges. Make certain your regulator

is a two-stage regulator. Precise regulation of the gas input flow is vital for the incubator

performance.

2

SUPPLY

Connect to the CO2 supply

Attach the CO2 regulator to a medical grade CO2 cylinder, if using a cylinder supply.

Set the wall source control or cylinder regulator to 15 - 20 Pounds per Square Inch (psi).

Do not exceed 25 psi.

Remove the dust cover from the CO2–to-Chamber port on the back of the unit.

Connect the gas tubing to the incubator and regulator or wall source.

a. Connect the black tubing to the regulator or wall source.

b. Connect the clear tubing to the CO2 to Chamber port on the back of the

incubator.

Do not initiate a flow of CO2 to the incubator at this time.

End of procedure

16 | P a g e

Page 17

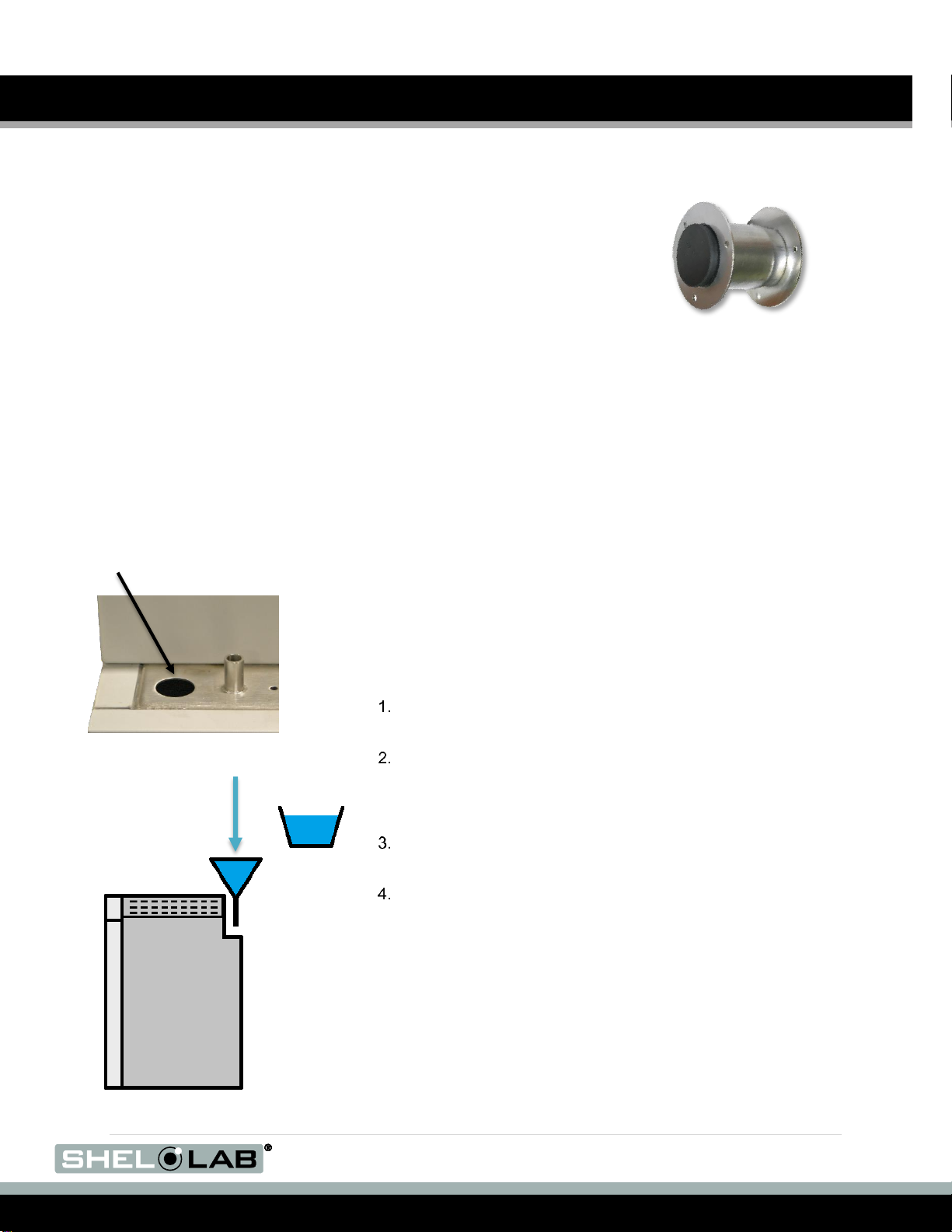

Figure 9: Port Stopper

in the Access Port

Fill Port

19 Gallons

(72 Liters)

INSTALLATION (CONTINUED)

ACCESS PORT STOPPER

Verify that that a port stopper is installed in the access port on the right side

of the unit.

A rubber access port stopper is shipped in the port. The stopper must be

installed inside the chamber to obtain the best temperature uniformity and

prevent condensation from forming inside the port.

FILL THE WATER JACKET

The water jacket requires 19 gallons (72 liters) to provide sufficient thermal insulation for the incubator

to operate at its stated temperature specifications.

The manufacturer recommends the use of distilled water or

filtered tap water if possible. Please see the Anode and

Water Quality entry in the maintenance section on page 50.

Use of a funnel or hose while filling the jacket is strongly

recommended.

Locate the water fill port on the back right side of the

incubator.

Remove the port stopper.

a. Place the port stopper in a location where it will be easy to

find.

Fill the jacket with 19 gallons (72 liters) by pouring water in

through the fill port.

Place the stopper back in the port.

17 | P a g e

Page 18

INSTALLATION (CONTINUED)

This page left blank

18 | P a g e

Page 19

Symbol

Definition

Indicates that you should consult your user manual for further instructions

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires

Indicates temperature

Repère température

Indicates the Over Temperature Limit system

Indique le système de dépassement de temperature

Indicates AC Power

Repère le courant alternatif

Indicates I/ON and O/OFF

I repère de la position MARCHE de l'interrupteur d'alimentation

O repère de la position ARRÊT de l'interrupteur d'alimentation

Indicates protective earth ground

Repère terre électrique

Indicates Up and Down respectively

Touches de déplacements respectifs vers le HAUT et le BA

Indicates Potential Shock Hazard

Signale danger électrique

Indicates the unit should be recycled (Not disposed of in land-fill)

Indique l’appareil doit être recyclé (Ne pas jeter dans une décharge)

GRAPHIC SYMBOLS

Each incubator is provided with multiple graphic symbols on its exterior and internal surfaces.

These symbols identify hazards, and the functions of the adjustable components, as well as

important notes in the user manual.

19 | P a g e

Page 20

Symbol

Definition

Indicates relative humidity

Indique humidité relative

Indicates water level low

Indique faible niveau d'eau

Indicates CO2 gas

Indique gaz CO2

Indicates the incubator heater is active.

L'élément chauffant est la production de chaleur.

GRAPHIC SYMBOLS (CONTINUED)

20 | P a g e

Page 21

Figure 10: Control

Panel

CONTROL PANEL OVERVIEW

Power Switch

The round, black main power switch controls all power to the incubator and its systems. “I” is the on

position, and “O” the off.

Over Temperature Limit

This graduated dial sets the heating cut off point for the OTL temperature limit system. The OTL

system prevents unchecked heating of the chamber in the event of a failure of the main digital

controller. For more details, please see the Over Temperature Limit System description in the

Theory of Operations (page 25).

The red Over Temp Activated light illuminates when the Over Temperature Limit system cuts off

heating by rerouting power away from the heating elements.

Temperature Control and Display

Labeled Set Temperature °C, this display shows the current air temperature in the incubation

chamber accurate to within 0.1C. The arrow buttons can be used to adjust the temperature set

point, or place the display in its temperature calibration mode and then enter a display value

correction.

Red LED alarm indicators marked High and Low illuminate when the temperature deviates by ±1°C

or greater from the current set point. The yellow LED marked Mute illuminates whenever an audible

deviation alarm is being muted. See the Muting the Audible Temperature Alarm entry on page

29 of the Operations section for more information.

The green indicator labeled Heating Activated illuminates whenever the temperature control system

is heating the incubation chamber.

21 | P a g e

Page 22

CONTROL PANEL OVERVIEW (CONTINUED)

CO2 Display

Labeled Set CO

percentage of the chamber atmosphere. The display has a range of OFF to 20% and an accuracy

of 0.1%. The display shows “LO” until the CO2 sensor registers a concentration in the chamber

greater than 0%. When initially injecting CO2 into the chamber a few minutes may be required to

build up a sufficient concentration to register.

The UP / DOWN arrow pad can be used to adjust the CO2 concentration set point and to mute

audible gas deviation alarms. The control can also place the CO2 display in its calibration mode,

and be used to enter a calibration adjustment.

Red LED alarm indicators marked High and Low illuminate whenever CO2 deviations of ±1% or

greater from the set point take place. The yellow LED marked Mute illuminates whenever an

audible deviation alarm is being muted. See the Muting the Audible CO2 Alarm entry on page 31

of the Operations section for more information.

The green CO2 Injecting indicator illuminates when the incubator is injecting CO2 into the incubation

chamber. Injections are accompanied by a click that is the CO2 solenoid opening and then closing.

Water Jacket Low

The red indicator marked Water Jacket Low illuminates when the water level of the jacket has fallen

to a level that impacts the incubator temperature uniformity and stability. Add water to the waterjacket as soon as this light illuminates. Fill until the light turns off. See page 17 in the Installation

section for instructions.

this display shows the concentration of CO2 in the incubation chamber as a

2

,

22 | P a g e

Page 23

OPERATION

THEORY OF OPERATION

The SCO6WE is engineered to provide constant temperature CO2 incubation environments that is

passively humidified to prevent the premature drying of sample media. The incubator can obtain a

stable, uniform temperature in its chamber, ranging from the room temperature (ambient) +5°C up

to 60°C for incubation applications. The CO2 range is a 0 – 20% concentration. Filling the

humidification pan will result in a relative humidity (RH) of 90 – 95% in the chamber.

Each incubator features a glass viewing door that allows visual inspection of samples without

compromising the chamber CO2 or humidity environment.

Heating

When powered, the unit heats to and maintains the incubation chamber air temperature at the

currently programed temperature set point. An internal microprocessor stores the temperature set

point. The microprocessor board is wired to a solid-state temperature probe located on the

chamber interior right wall. When the processor detects that the chamber temperature has dropped

below the temperature set point, it pulses power to heating elements on the surface of the waterjacket insulation space, and in the outer chamber door. Heat from the elements on the jacket

propagates through water inside the jacket to the chamber wall, and then to the chamber airspace.

During normal operations, with the doors closed, most heating pulses correct for deviations of less

than 0.1°C.

The processor employs proportional-integral-derivative analytical feedback-loop functions when

measuring and controlling the chamber air temperature. PID-controlled heating pulse intensities

and lengths are proportional to the difference between the measured chamber temperature and the

current set point. The frequency of pulses are derived from the rate of change in that difference.

The integral function slows the rate of pulses when the temperature nears the set point to avoid

overshooting.

Each incubator relies on natural heat radiation for cooling. The incubator can achieve a low-end

temperature of the ambient room temperature +5°C.

The chamber door is self-heating to bolster the thermal uniformity and stability of the chamber, and

to minimize condensation on the inner glass viewing door. The protection provided by the viewing

door against temperature and CO2 disruptions is of limited duration. Minimize sample viewing times

with chamber door open, when possible.

Insulation – Water Jacket

Insulation is provided by the water-filled jacket surrounding the incubation chamber on the top,

bottom, back, and left and right sides. The mass of the water, once heated to the set point, provides

a high degree of temperature uniformity in the chamber, as well as thermal inertia. In other words,

the chamber will retain heat in the event of a power outage for significantly longer than an airjacketed incubator. However, the water jacket does require a longer time to come up to

temperature when placing the unit in operation from a cold state.

23 | P a g e

Page 24

OPERATION (CONTINUED)

CO2 Atmosphere

The same microprocessor board that controls the chamber temperature also manages the gas

concentration of CO2 in the chamber atmosphere by operating an internal injection solenoid valve

connected to the gas input ports. The processor monitors CO2 concentration level in the incubator

using an infrared sensor located behind the chamber ceiling duct. The sensor operates on the

principle that a specific frequency set of infrared light is absorbed by CO2. The more CO2 present in

chamber, the more of that band of infrared is absorbed. The sensor is only sensitive to CO2, so

measurement accuracy is consistent, regardless of the presence of other gasses in the incubator.

The processor employs proportional-integral-derivative analytic feedback-loop functions when

measuring and controlling the CO2 concentration. When the PID are active, injection lengths are

proportional to the difference between the measured concentration and the set point. The

frequency of injections is derived from the rate of change in the difference. Integrator feedback

slows the rate of injection as the concentration approaches the set point, which helps prevent

overshoots. When the chamber concentration is stable CO2 injections take place in small bursts to

correct for deviations less than 0.1%. The incubator is not provided with a means to actively

remove CO2 from the chamber atmosphere.

Humidification

Passive humidification is provided by filling the humidification pan included with the unit. The pan is

then placed on the heated chamber floor. Evaporation driven in part by heating raises the relative

humidity percentage (RH%) of the chamber. A copper token included with the pan helps to

significantly slow the growth of microbiological populations in the humidification water supply.

The incubator must be operated humidified in order to achieve its stated temperature uniformity

specification.

Physical and Data Access

An access port on the right side of the unit allows sensors such as, thermocouples and humidity

meter solid state probes, to be inserted and left in the chamber without compromising the CO2

atmosphere or temperature performance. An atmosphere sample port for independently verifying

the CO2 concentration in the chamber is provided on the left side of the control panel. A USB-style

serial port outputs CO2 and temperature levels once per minute as a digital log line. Please see the

Data Output entry on page 37 for more details.

24 | P a g e

Page 25

OPERATION (CONTINUED)

The Over Temperature Limit System (OTL)

When set, the mechanical OTL heating cutoff system prevents runaway heating in the incubation

chamber. The OTL operates independently of the microprocessor and is provided with a separate,

hydrostatic temperature sensor probe located in the chamber. In the event the chamber air

temperature exceeds the current OTL setting, the OTL routes power away from the heating

elements. The OTL will continue to prevent heating until the temperature drops below its limit

setting. The Over Temperature Limit is set by the end-user, typically at approximately 1°C above

the application temperature set point.

25 | P a g e

Page 26

OPERATION (CONTINUED)

Note: From a cold start, the incubator requires 12 hours to come up to and stabilize at temperature

and humidity levels prior to loading samples. Stabilization safeguards samples.

PUT THE INCUBATOR INTO OPERATION

Carry out the following steps and procedures to put the incubator into operation after installing it in

a new workspace environment:

Optional: A clean and disinfected thermocouple probe for performing the optional

temperature display accuracy verification may be inserted through the access port now.

a. This saves time by allowing the incubation chamber temperature to stabilize

undisturbed prior to the verification procedure.

b. See the Temperature Display Accuracy Verification procedure on page 32

for the correct introduction and placement of the thermocouple probe.

Verify that the workspace power supply and the incubator power requirements listed on the

unit data plate have been matched.

a. See the Power Source Requirement entry on page 26.

Attach the power cord that came with the incubator to the power inlet receptacle on the

back of the unit.

Plug the power cord into the workspace supply outlet.

Place the Power switch in the on ( I ) position.

Perform the following procedures in sequence to finish preparing the incubator:

Humidifying the Incubator page 27

Set the Temperature Set Point page 25

Allow the incubator to heat undisturbed for 10 hours before continuing.

Open the CO2 supply control or gas regulator so it supplies a flow of

15 - 20 psi, as per the supply description on page 16.

Set the CO2 Set Point page 30

After setting the set point, wait for an additional 2 hours for a CO2

concentration to establish and stabilize in the chamber, and for the

unit to finish stabilizing thermally undisturbed with the doors closed.

Optional, Verify Temperature Display Accuracy page 32

26 | P a g e

Optional, Verify CO2 Display Accuracy page 34

Set the Over Temperature Limit page 36

Load the Chamber page 37

Page 27

OPERATION (CONTINUED)

HUMIDIFY THE INCUBATOR

Note: Humidifying the chamber helps slow the drying of samples in open, “breathable” containers

Fill the humidification pan in the incubation chamber.

The humidification pan must be filled in order for the incubator to achieve its stated

temperature uniformity specification.

The pan must be placed on the chamber floor. The floor is heated and helps evaporation to

raise the humidity level to 90 – 95% relative humidity.

Always place and secure the copper token in the pan to slow the growth of microbiological

populations in humidification water supply.

Regularly clean and disinfect the pan.

Refill as needed, and change the water in the pan at least once per week.

Use of chemical disinfectants added to the pan may alter the surface tension of the water.

This may significantly reduce the rate of evaporation and impact the humidity level of the

incubator chamber.

Never use deionized water to humidify the incubator.

27 | P a g e

Page 28

Set Temperature Set Point

Turn the OTL control clockwise to the maximum, if not already set to max.

a. This prevents the Over Temperature system from interfering

with setting the set point.

Push and release the Up or Down button on the Set Temperature control

panel to activate the temperature set point mode.

a. The temperature display will briefly flash the letters “SP” to

indicate a Set Point is about to be displayed.

b. The digital display will then dim and showing the blinking,

adjustable temperature set point.

Set Temperature °C

Set Point Indicator

Set Temperature °C

Initial Set Point

Use the Up and the Down button to enter a new set point.

a. If neither button is pressed within 5 seconds, the temperature

display will stop blinking and return to displaying the current

temperature of the incubator.

Set Temperature °C

New Set Point

Wait 5 seconds after entering the new set point.

a. The display will stop flashing. The new set point is now saved

in the microprocessor controller.

b. The incubator will automatically heat or cool adjust to achieve

the new set point.

c.

Set Temperature °C

Heating to Adjusted Set Point

See the Set the OTL procedure on page 36 for how to set the OTL system once

the incubation chamber has stabilized at your application temperature set point,

and after you have performed any display verifications or calibrations.

OPERATION (CONTINUED)

SET THE TEMPERATURE SET POINT

Perform the steps below to change the set point to the operational temperature you will be using

during your incubation application. The incubator comes from the factory with a set point of 37°C.

Note: The visual example below depicts adjusting the incubator set point from 35°C to a 37°C

application temperature.

28 | P a g e

End of Procedure

Page 29

Figure 11: High

Alarm Muted

OPERATION (CONTINUED)

MUTING THE AUDIBLE TEMPERATURE ALARM

An audible and visual deviation alarm activates if the incubation chamber

temperature deviates by 1°C above or below the temperature set point. The low

deviation audible alarm has a delay of 15 minutes. This prevents the low alarm from

sounding whenever the chamber doors are opened, causing a short drop in

temperature.

Carry out the following step to mute active high or low deviation alarms.

Press and hold either the Up or Down arrow on the Temperature Control

panel, until the amber Mute LED illuminates and the audible alarm shuts off.

The audible alarm component will remain muted for the duration of the

current temperature deviation. The visual alarm indicator will remain

illuminated.

Any new deviation of ±1°C or greater will reactivate the audible alarm.

AUTOMATIC DOOR CUTOFF

Whenever the incubation chamber outer door is opened, the incubator stops the flow of CO2 into

the chamber, depowers the heater element, and ceases operation of the internal blower fan. This

limits the amount of CO2 released into the workspace around the incubator. It also prevents the

heater from attempting to counteract the continual inflow of cooler air, which would cause a

significant heat spike once the door is closed. Normal CO2 injections, heating, and fan operation all

resume automatically when the outer door is closed.

29 | P a g e

Page 30

Set CO2 Set Point

Press either the Up or Down arrow button on the CO2 panel.

a. The display will flash the letters “SP” for set point

b. A flashing, adjustable CO2 set point will appear in the display

Note: The display will automatically exit the adjustment mode after 5 seconds of

inactivity, with the last shown set point value saved.

Set CO2 %

Set CO2 %

Initial Set Point

Use the Up or the Down arrow keys to adjust the set point to

your application CO2 concentration.

Set CO2 %

New Set Point

Wait 5 seconds after entering the set point.

a. The display will stop flashing, and the set point is now saved in

the controller processor

b. The chamber will now automatically inject CO2 or allow the

current level to decay in order to achieve your set point

c. The display will revert to showing the current chamber

concentration

Set CO2 %

CO2 Injecting to achieve

the new set point.

Note: The CO2 display and injections can be set to off when in the set point

adjustment mode. Hold the down arrow after the blinking set point appears until the

display reads “OFF”. The incubator will then cease injecting CO

2

.

OPERATION (CONTINUED)

SET THE CO

The incubator comes from the factory set to Off. Set the CO2 set point to that of your application.

The gas supply must continually deliver 15 - 20 psi while establishing and maintaining a CO2enriched chamber atmosphere. A CO2 flow to the chamber must be started a minimum of 2 hours

prior to the start of a display verification or calibration, or prior to loading samples in the chamber.

The CO2 display will read “LO” until enough CO2 has built up for the sensor to register a

concentration greater than 0%.

Note: The example below represents adjusting the CO2 set point from off to 5%.

SET POINT

2

30 | P a g e

End of procedure

Page 31

Figure 12: Low

Gas Alarm Muted

Figure 14: No Gas

Supply

SET CO2

OPERATION (CONTINUED)

MUTING THE AUDIBLE CO

Visual indicator alarms illuminate if the chamber CO2 level deviates 1% above or below the CO2 set

point. An audible alarm sounds immediately for a high deviation. The low deviation audible alarm

will sound after the visual low indicator alarm has been continually illuminated for 15 minutes. This

delay prevents the alarm from sounding whenever a door opening creates a short-lived drop in gas

concentration.

Carry out the step below to mute an active audible deviation alarm.

To mute an alarm, press and hold the CO2 Up or the Down arrow button until the amber

Mute LED illuminates.

The alarm will stay muted for the duration of the current temperature deviation.

Another deviation of 1% will reactivate the audible alarm.

ALARM

2

Figure 13: Gas Alarm Timeline

NO GAS SUPPLY ALARM (NGS)

If the Low Gas deviation indicator is active for longer than 20 minutes, a second alarm

will activate.

The letters “ngS” will appear in the CO

The alarm will remain active even if the incubator is turned off and turned back on.

The NGS Alarm will remain on until CO2 is restored to the chamber. It may take 2 or

more minutes of CO2 inflow to establish a concentration percentage (%) high enough to

deactivate the alarm.

display to indicate No Gas Supply.

2

31 | P a g e

Page 32

Figure 15: Introducing a

sensor probe through the

access port.

Figure 16: Probe End 2

inches (5cm) From Shelf

Surface

OPERATION (CONTINUED)

TEMPERATURE ACCURACY VERIFICATION

Note: Performing a temperature accuracy verification requires a temperature reference device.

Please see the Reference Sensor Devices entry on page 10 for the device requirements.

Optional: This procedure verifies the accuracy of the incubator temperature display against the

actual chamber air temperature as measured by a reference sensor device. Perform the procedure

if required by your laboratory or production protocol. The unit was calibrated at the factory at 37ºC.

If a difference between the actual and displayed temperatures is discovered, perform a temperature

calibration. Please see the Calibrate Temperature Display procedure on page 42 in the User

Maintenance section.

Humidity

Perform the verification with the chamber fully humidified. The humidity level of the chamber

impacts its temperature uniformity. 8-hours are required for the unit to achieve and stabilize at its

operational relative humidity level of 90 – 95%, from a dry state.

CO2

A CO2 display verification may be performed concurrently with the temperature verification.

Probes

Reference device sensing probes may be introduced through the access

port. Carefully place the port stopper over any probe wires. The probe may

also be introduced through the chamber door space. Use non-stick, nonmarking tape to secure the wires and probe head, and to seal any gaps.

The door must close and latch fully.

Place the sensor probe head of the temperature reference device as close

as possible to the geometric center of the incubation chamber. A

thermocouple sensor probe sleeve may be taped to the shelving, as long

as the exposed copper end is 2 inches (5cm) away from the shelf (see

Figure 16). An exposed sensor probe in direct contact with the shelving

may experience heat sinking, which can result in an inaccurate

temperature reading.

Temperature Stability

After introducing and placing the temperature probe, allow the incubator to

operate undisturbed and humidified for at least 24-hours prior to

performing the verification.

The incubator must operate humidified at its verification temperature set

point for at least 1 hour with no fluctuations of ±0.1°C or greater in order

to be considered stabilized. Failure to wait for stabilization will result in an

inaccurate verification. If the chamber door is opened during the verification

the chamber must be allowed to re-stabilize before continuing.

32 | P a g e

Page 33

Verifying the Temperature Display Accuracy

Once the chamber temperature has stabilized, compare the reference

temperature device and incubator display readings.

a. If the readings are the same, or if a difference between the

two (2) falls within the acceptable range of your protocol, the

display is accurately showing the chamber air temperature.

The Temperature Verification procedure is now

complete.

b. See step 2 if a difference falls outside the acceptable range

of your protocol.

Reference Device

Set Temperature °C

If there is an unacceptable difference, a display temperature

calibration must be performed to match the display to the reference

device.

a. Please see page 42 in the User Maintenance section.

Reference Device

Set Temperature °C

OPERATION (CONTINUED)

End of procedure

33 | P a g e

Page 34

Figure 17: CO

2

Sample Port

OPERATION (CONTINUED)

CO

ACCURACY VERIFICATION

2

Note: Performing a CO2 display accuracy verification requires a gas reference device. Please see

the Reference Sensor Devices entry on page 10 for the device requirements.

Optional: The CO2 display was calibrated at the factory at a 5% concentration. A display accuracy

verification may be performed when preparing the incubator for use, or if required by your

laboratory or production protocol. The verification procedure compares the chamber CO2 level as

measured by the incubator with the actual level, as provided by a calibrated reference device.

If a difference between the actual and displayed CO2 concentrations is discovered, perform a CO2

display calibration. Please see the Calibrate CO2 Display procedure on page 46 in the User

Maintenance section.

Temperature

A CO2 display verification may be performed simultaneously with the temperature display

verification, as long as the chamber door is not opened during either procedure. The incubation

chamber should be heated to and running at your application temperature, as temperature drives

gas diffusion in the chamber.

Humidity

The incubator should be allowed to come up to humidity in the chamber prior to performing a CO

verification. Relative humidity affects CO2 distribution due to its influence on the chamber

atmosphere temperature.

Probes

Connect a CO2 reference device sample tube to the sample port, located on the left side

of the control panel.

Gas Stability

Allow the unit to operate undisturbed to run for at least 12 hours for heat and humidity

stability (for example, overnight) prior to performing the verifications. A CO2 flow to the

chamber may be started 2 hours prior to the start of the verification.

Prior to a verification, the chamber must operate at its CO2 set point for at least 1 hour with no

fluctuations of ±0.1% or greater in order to be considered stabilized. Failure to wait for stabilization

will result in an inaccurate verification. If the chamber door is opened during the verification the

chamber must be allowed to re-stabilize before continuing.

Continued on next page

2

34 | P a g e

Page 35

Verifying the CO2 Display Accuracy

Once the chamber has stabilized with no fluctuations, compare the gas

reference device and chamber CO2 display readings.

a. If the readings are the same, or if a difference between the

two (2) falls within the acceptable range of your protocol, the

display is accurately showing the chamber CO2

concentration. The CO2 Verification procedure is now

complete.

b. See step 2 if a difference falls outside the acceptable range

of your protocol.

Reference Device

Set CO2

If there is an unacceptable difference, a CO2 calibration must be

performed to match the display to the reference device.

a. Please see page 46 in the User Maintenance section.

Reference Device

Set CO

2

OPERATION (CONTINUED)

End of procedure

35 | P a g e

Page 36

Set OTL

Example

Turn the Set Over Temperature Limit control dial clockwise to the

maximum position, if it is not already set to maximum.

Turn the Over Temperature Limit control dial co unterclockwise until the

red Over Temperature Limit Activated light illuminates.

Slowly turn the dial clockwise until the Over Temperature Limit

Activated light turns off. Stop turning the control.

a. The Over Temperature Limit is now set approximately 1˚C

above the current chamber temperature.

Optional: You may turn the dial slightly to the left to bracket in closer to

the set point temperature. This sets the OT Limit nearer to the current

chamber temperature.

Leave the OTL dial set just above the activation point.

OPERATION (CONTINUED)

Note: Test the OTL system at least once per year for functionality.

SET THE OVER TEMPERATURE LIMIT

This procedure sets the Over Temperature Limit heating cutoff to approximately 1˚C above the

current chamber temperature. Perform the steps below once the incubator has run with no

temperature fluctuations at your application temperature set point for at least 1 hour.

If the OTL activates sporadically, turn the dial very slightly to the right (clockwise) one time.

If the OTL continues activating, check for ambient sources of heat or cold that may be adversely

impacting the unit temperature stability. Check if any powered accessories in the chamber are

generating heat. If you can find no sources of external or internal temperature fluctuations, contact

Tech Support or your distributor for assistance.

End of Procedure

36 | P a g e

Page 37

Channel

Parameter

C1

Temperature

C3

CO2

OPERATION (CONTINUED)

LOAD THE INCUBATOR

Place items on the shelves inside the incubation chamber as evenly spaced as possible. Proper

spacing allows for maximum air circulation and a high degree of temperature uniformity. Leave 1

inch (2.5cm) between sample containers and the chamber walls.

This is the final step in the Preparing the Incubator procedure.

ACCESSORY COMPATIBILITY

Make sure any accessory equipment used inside the incubation chamber can safely and effectively

operate within your selected range of temperature, humidity, and CO2 levels. Some equipment

types such as, stirrers or shakers, can generate heat sufficient to disrupt the thermal uniformity and

stability of the chamber.

DATA OUTPUT CAPABILITIES

The incubator generates data outputs describing temperature and CO2 levels as a digital

log line, once per minute. These outputs are transmitted through a USB-style RS232

serial port located on the left side of the incubator.

USB-Style Serial Port Output

Example logline output: C1=37.0 C3=5.0

A software driver and data logging package for the port can be downloaded from the Shel Lab

website. To download the software, visit the product page of any Shel Lab SCO incubator, and click

on the large USB bar icon titled “USB Software for CO2 Incubators” located approximately halfway

down the page.

http://shellab.com/product/sco6we-shel-lab-basic-co2-water-jacketed-incubator-infrared-irsensor-6-cu-ft-120v/

37 | P a g e

Page 38

OPERATION (CONTINUED)

CONDENSATION AND THE DEW POINT

Relative humidity inside the incubator chamber should never be allowed to exceed 95%.

Exceeding this thresholds will likely result in condensation, possible leaks around the incubator,

and may cause corrosion damage, if allowed to continue for any significant length of time

Condensation takes place whenever the humidity level in the incubator chamber reaches the dew

point. The dew point is the level of humidity at which the air cannot hold more water vapor. The

warmer the air, the more water vapor it can hold.

As the level of humidity rises in an incubation chamber, condensate will first appear on surfaces

that are cooler than the air temperature. Near the dew point, condensate forms on any item or

exposed surface even slightly cooler than the air. When the dew point is reached, condensate

forms on nearly all exposed surfaces.

Managing condensation primarily depends on either lowering the humidity level or increasing the air

temperature in the incubator chamber.

Note: Rising or falling air pressure from weather will adjust the dew point up and down in small

increments. If the relative humidity in the incubation chamber is already near the dew point,

barometric fluctuations may push it across the dew point threshold.

Note: Thin air at higher altitudes holds less humidity than the denser air found at or near sea level.

If excessive condensate has appeared in the incubation chamber, dry the chamber interior and

check the following.

Verify that the access port stopper is in place, on the inside of the incubation chamber and

not the unit exterior.

Make sure samples on the shelves are evenly spaced to allow for good airflow.

Ensure the chamber door is closing and latching properly.

Are frequent or lengthy chamber door openings causing significant temperature disruptions

and chilling the chamber surfaces? If so, reduce the number of openings.

Are there are too many open containers of evaporating sample media in the chamber? If

so, reduce the number of open sample containers.

Does the ambient humidity in the room exceed the stated operating range of 80% relative

environmental humidity? If so, lower the room humidity.

Is the incubator exposed to an external flow of cold air such as, an air-conditioning vent or

a door to a cooler hallway or adjacent room? Block or divert the air, or reposition the unit.

Check the door gaskets for damage, wear, or signs of brittleness or dryness. Arrange for

replacement of the gaskets if damaged or excessively worn.

38 | P a g e

Page 39

USER MAINTENANCE

Warning: Prior to any maintenance or cleaning of this unit, disconnect the power cord from the power

supply.

Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le

cordon secteur de la source d'alimentation.

CLEANING AND DISINFECTING

If a hazardous material or substance has spilled in the incubator, immediately initiate your site’s

Hazardous Material Spill Containment protocol. Contact your local Site Safety Officer and follow

instructions per the site policy and procedures.

The incubator chamber should be cleaned and disinfected prior to first use.

Periodic cleaning and disinfection are required to prevent microbiological contamination.

Do not use spray on cleaners or disinfectants. These can leak through openings and coat

electrical components.

Do not use cleaners or disinfectants that contain solvents capable of harming paint

coatings or stainless steel surfaces.

Do not use chlorine-based bleaches or abrasives; these will damage the chamber

liner.

Consult with the manufacturer or their agent if you have any doubts about the compatibility

of decontamination or cleaning agents with the parts of the equipment or with material

contained in it.

Warning: Never clean the unit with alcohol or flammable cleaners.

Avertissement: Ne jamais nettoyer l'appareil à l'alcool ou avec des nettoyants inflammables.

Cleaning

Remove all removable chamber components and accessories (shelves, racks, and any

additional items).

Clean the chamber interior with a mild soap and water solution, including all corners.

Take special care when cleaning chamber sensor probes located at the rear of the

chamber on the back wall.

Clean all removable accessories and components.

Clean and disinfect any attached sample tubing and replace if discoloring is present.

Rinse the chamber surfaces and shelving with distilled water and wipe dry with a soft cloth.

Do not use deionized water.

39 | P a g e

Page 40

USER MAINTENANCE (CONTINUED)

Disinfecting

Note: Contact your local Site Safety Officer for detailed information on the disinfectants compatible

with your cultivation or culturing applications.

Disinfect the incubation chamber on a regular basis. For maximum effectiveness, disinfection

procedures are typically performed after cleaning and removal of gross matter contamination.

Perform the following steps to disinfect the incubator:

Turn the unit off. Open all doors and carry out your laboratory, clinical, or production space

disinfection protocol.

If permitted by your protocol, remove all interior accessories (shelving and other non-

attached items) from the chamber when disinfecting.

Gas concentrations from evaporating disinfecting agents can inhibit growth or cause

metabolic symptoms in microbiological sample populations.

a. Make sure chlorines, amphyls, quaternary ammonias, or any other overtly

volatile disinfecting agents have been rinsed or otherwise removed from the

chamber surfaces, prior to placing samples in the chamber.

Disinfect the incubation chamber using commercially available disinfectants that are non-

corrosive, non-abrasive, and suitable for use on stainless steel surfaces.

a. Disinfect all surfaces in the chamber, making sure thoroughly disinfect the

corners.

b. Do not disinfect the sensor heads.

When disinfecting external surfaces use disinfectants that will not damage painted metal or

plastic.

MINIMIZING CONTAMINATION EXPOSURE

The following are suggestions for minimizing exposure of the incubator chamber to potential

contaminants.

Maintain a high air quality in the laboratory workspaces around the incubator.

Avoid placing the incubator near sources of air movement such as doors, air vents, or high

traffic routes in the workspace.

Minimize the number of times the incubator chamber door is opened during normal

operations.

40 | P a g e

Page 41

“IN”

Figure 18: In-Line Gas Filter

“IN”

USER MAINTENANCE (CONTINUED)

GAS LINES AND HEPA FILTERS

Replace the in-line gas HEPA filter once per year or when a filter is noticeably

discolored.

HEPA filters are directional, and must be installed facing in the

correct direction. The word “IN” is stamped on the rim of the filter

assembly on the side that faces toward the gas supply.

Gas lines should be replaced when cracking, brittleness,

permanent kinking, or other signs of damage are present. Please

see the Parts List on 54.

STORAGE OF THE INCUBATOR

Perform the following steps if the incubator will be out of use for more than 24 hours to prevent

microbiological contamination such as, fungus or mold.

Depower the incubator.

Disinfect and clean if required by your laboratory protocol, or if the chamber has been

exposed to pathogenic microorganisms.

Use a soft cloth to dry the chamber surfaces.

MAINTAINING ATMOSPHERIC INTEGRITY

Periodically, inspect the door latch, trim, catch, and gaskets for signs of deterioration. Failure to

maintain the integrity of the door system shortens the life span of the incubator.

ELECTRICAL COMPONENTS

Electrical components do not require maintenance. If the incubator fails to operate as specified,

please contact your distributor or Technical Support for assistance (please see page 7).

41 | P a g e

Page 42

Figure 19: Introducing a

sensor probe through the

access port.

Figure 20: Probe End 2

inches (5cm) From Shelf

Surface

USER MAINTENANCE (CONTINUED)

CALIBRATE THE TEMPERATURE DISPLAY

Note: Performing a temperature display calibration requires a temperature reference device.

Please see the Reference Sensor Devices entry on page 10 for device requirements.

Temperature calibrations are performed to match the incubator temperature display to the actual air

temperature inside the incubation chamber. The actual air temperature is supplied by a calibrated

reference sensor device. Calibrations compensate for drifts in the unit microprocessor controller as

well as those caused by the natural material evolution of the sensor probe in the humidified and

heated chamber space. Calibrate as often as required by your laboratory or production protocol, or

regulatory compliance schedule.

Humidity

Humidity affects temperature uniformity and stability in the incubation chamber. The chamber must

be humidified for at least 24 hours in order to conduct an accurate calibration.

CO

2

A CO2 calibration may be conducted simultaneously with a temperature calibration as long as the

chamber doors are not opened during either procedure.

Probe

A reference device sensor probe may be introduced through the access port.

Carefully place the port stopper over any probe wires (see Figure 19). Probes

may also be introduced through the chamber door space. Use non-stick, nonmarking tape to secure the wires and probe heads and seal any gaps. The door

must close and latch fully.

Place the sensor probe of the temperature reference device inside as close as

possible to the geometric center of the chamber. A thermocouple sensor probe

sleeve may be taped to the shelving, as long as the exposed copper end is 2

inches (5cm) away from the shelf (see Figure 20). An exposed sensor probe in

direct contact with the shelving may experience heat sinking, which can result in

an inaccurate temperature reading.

Stability

From a cold start, the incubator must operate humidified and at its application

temperature set point for at least 24 hours in order to stabilize. Prior to a

calibration it must operate for at least 8 hours undisturbed with the both doors

closed. A common practice is to place the temperature sensor probe in the

chamber, allow the unit to operate and stabilize overnight, and then conduct the

calibration the next morning.

The chamber is considered stabilized when it has operated for 1 hour with no

fluctuations ±0.1°C or greater. Failure to wait for stabilization will result in an

inaccurate calibration and incubator temperature display reading.

42 | P a g e

Page 43

Temperature Calibration

Once the chamber temperature has stabilized, compare the reference

device and temperature display readings.

a. If the readings are the same, or if a difference between the

two (2) falls within the acceptable range of your protocol, the

display is accurately showing the chamber air temperature.

The Temperature Calibration procedure is now complete.

b. If a difference falls outside of your protocol range, advance to

step 2.

Reference Device

Set Temperature °C

A display calibration adjustment must be entered to match the display to

the reference device. See next step.

Reference Device

Set Temperature °C

Place the temperature display in its calibration mode.

a. Press and hold both the UP and DOWN temperature arrow

buttons simultaneously for approximately 5 seconds.

b. Release the buttons when the temperature display shows the

letters “CO”. The display will then begin flashing the current

temperature display value.

Note: If an arrow button is not pressed for five seconds, the display will cease

flashing, and store the last displayed value as the new current chamber

temperature value.

Set Temperature °C

Set Temperature °C

USER MAINTENANCE (CONTINUED)

Continued on next page

43 | P a g e

Page 44

Temperature Calibration (Continued)

Use the Up or Down arrows to adjust the flashing current

temperature display value until it matches the reference device

temperature reading.

Reference Device

Set Temperature °C

After matching the display to the reference device, wait 5

seconds.

a. The temperature display will cease flashing and store the

corrected chamber display value.

b. The incubator will now begin heating or passively cooling in

order to reach the set point with the corrected display value.

Set Temperature °C

Adjusting to Set Point

Allow the incubator to operate undisturbed for at least one 1

hour to stabilize after it has achieved the set point with the

corrected display value.

a. Failure to wait until the incubation chamber is fully

stabilized will result in an inaccurate reading.

Set Temperature °C

Compare the reference device reading with the incubator temperature

display again.

a. If the reference device and the incubator temperature display

readings are the same or the difference falls within the range of your

protocol, the incubator is now calibrated for temperature.

b. See the next step if the readings fail to match or fall outside of your

protocol range.

Reference Device

Set Temperature °C

USER MAINTENANCE (CONTINUED)

44 | P a g e

Continued on next page

Page 45

Temperature Calibration (Continued)

If a difference still falls outside the acceptable range of your protocol,

repeat steps 3 – 7 up to two more times.

Three calibration attempts may be required to successfully calibrate units that are

more than ±2°C out of calibration.

Reference Device

Set Temperature °C

If the temperature readings of the incubator and the reference device still

fall outside your protocol after three calibration attempts, contact your

distributor or Technical Support for assistance.

USER MAINTENANCE (CONTINUED)

End of procedure

45 | P a g e

Page 46

Figure 21: CO2

Sample Port

USER MAINTENANCE (CONTINUED)

CALIBRATE THE CO2 DISPLAY

Note: Performing a CO2 display calibration requires a gas reference device. Please see the

Reference Sensor Devices entry on page 10 for the device requirements.

CO2 calibrations are performed to match the incubator CO2 display to the actual gas concentration

in the incubation chamber. The actual concentration is supplied by a calibrated reference sensor

device. Calibrations compensate for drifts in the unit microprocessor controller, as well as those

caused by the natural material evolution of the IR CO2 sensor when continually exposed to a

heated and humidified atmosphere with elevated CO2 concentrations. Calibrate as often as

required by your laboratory or production protocol, or regulatory compliance schedule.

CO2 Supply

The incubator must be powered, the CO2 set point set, and the chamber supplied with CO2 for at

least two hours prior to the calibration.

Temperature

Temperature drives gas diffusion in the chamber. CO2 calibrations must be performed with the

chamber fully heated and stable at your operational temperature set point. A CO2 display

calibration may be performed during a temperature calibration as long as the chamber door is