Page 1

BACTRON ANAEROBIC

CHAMBERS

OPERATION MANUAL

MODELS: I, II & IV

Sheldon Manufacturing Inc. P.O. Box 627 Cornelius, Oregon 97113

EMAIL: tech@Shellab.com

1-800-322-4897 (503) 640-3000 FAX (503) 640-1366

INTERNET: http://www.Shellab.com/~Shellab

Page 2

______________________________________________________________________________

Orientation Page 3

Component Drawings Page 4 - 6

1.0 Receiving and Inspection Page 6

2.0 Installation Page 6 - 7

3.0 Controls Overview Page 8 - 9

4.0 Hose and Electrical Connections Page 9 -10

5.0 Manometer Page 11

6.0 Catalyst Cartridge Page 11 - 12

7.0 Thermoelectric Condensate Controller Page 12

8.0 Incubator Temperature Controller/Incubator Safety Page 13

9.0 Incubator Calibration Page 13 - 14

10.0 Vacuum Gauge Adjustment Page 14

11.0 Pressure Adjustment Page 15

12.0 Testing The Chamber For Gas Leaks Page 15 - 16

13.0 Making The Chamber Anaerobic/Desired Environment Page 16 - 18

14.0 Chamber Operation Page 18 - 19

15.0 Entering The Chamber Page 19 - 20

16.0 Exiting The Chamber Page 20

17.0 Maintenance Page 21

18.0 Chamber QC Sheet Page 22

19.0 Accessories Page 23

20.0 Chamber System Drawings:

A) Keeping The Chamber Anaerobic Page 24

B) The System Controller and Controls:

View From Behind Panel Page 25

C) Solenoid Page 26

D) The System Controller Indicator Guide Page 27

21.0 Troubleshooting Section Page 28 - 36

22.0 Bactron Operation Tips Page 37 - 41

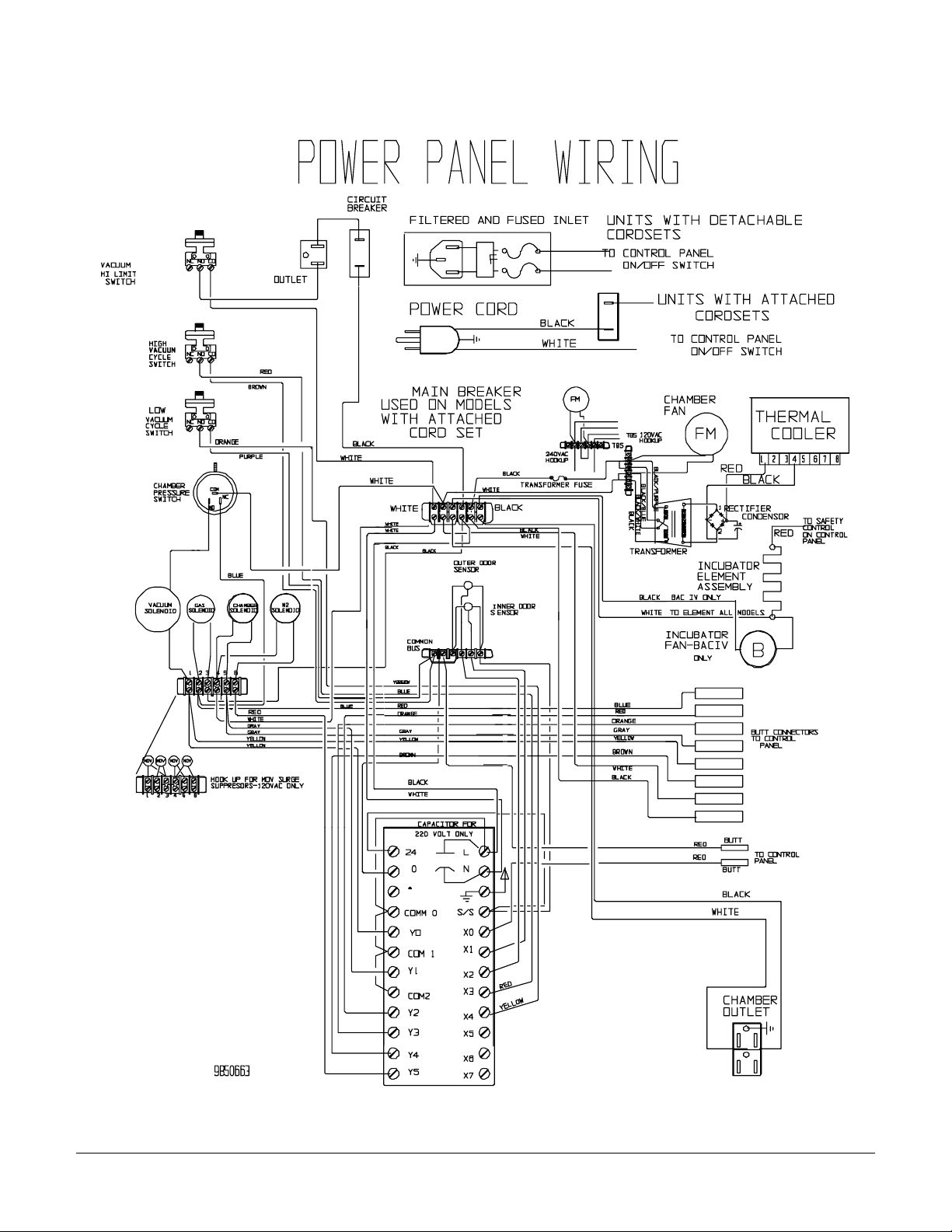

23.0 Wiring Diagrams Page 42 – 46

24.0 Parts List Page 47

25.0 Loop Sterilizer Page 48

TABLE OF CONTENTS

Rev 4/02

4861118M

Bactron Operations Manual 2

Page 3

______________________________________________________________________________

IMPORTANT: READ THIS INSTRUCTION MANUAL IMMEDIATELY.

Your satisfaction and safety require a complete understanding of this unit, including its proper

function and operational characteristics. Be sure operators are given adequate training before

attempting to put the unit in service. NOTE: This equipment must be used only for its

intended application; any alterations or modifications will void your warranty.

Orientation

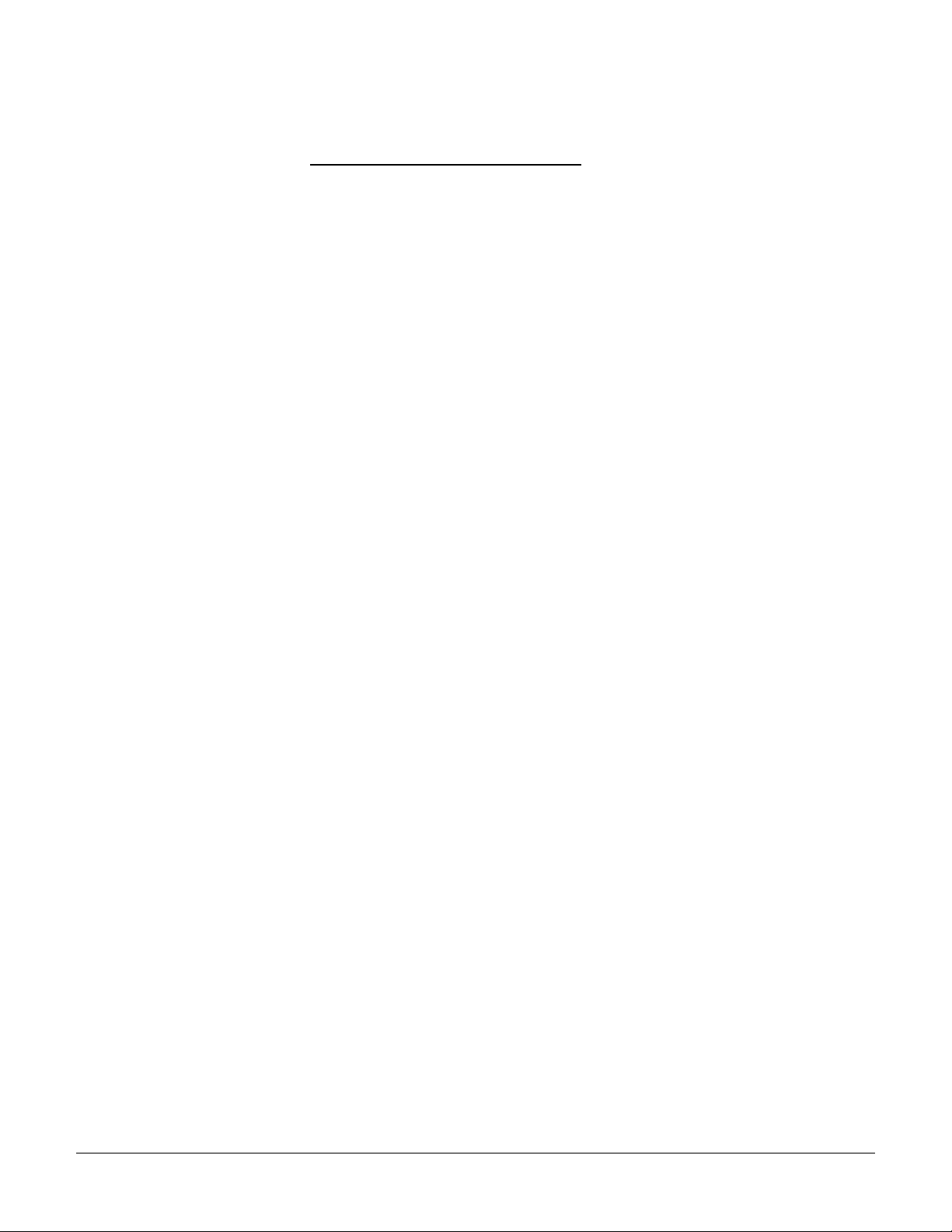

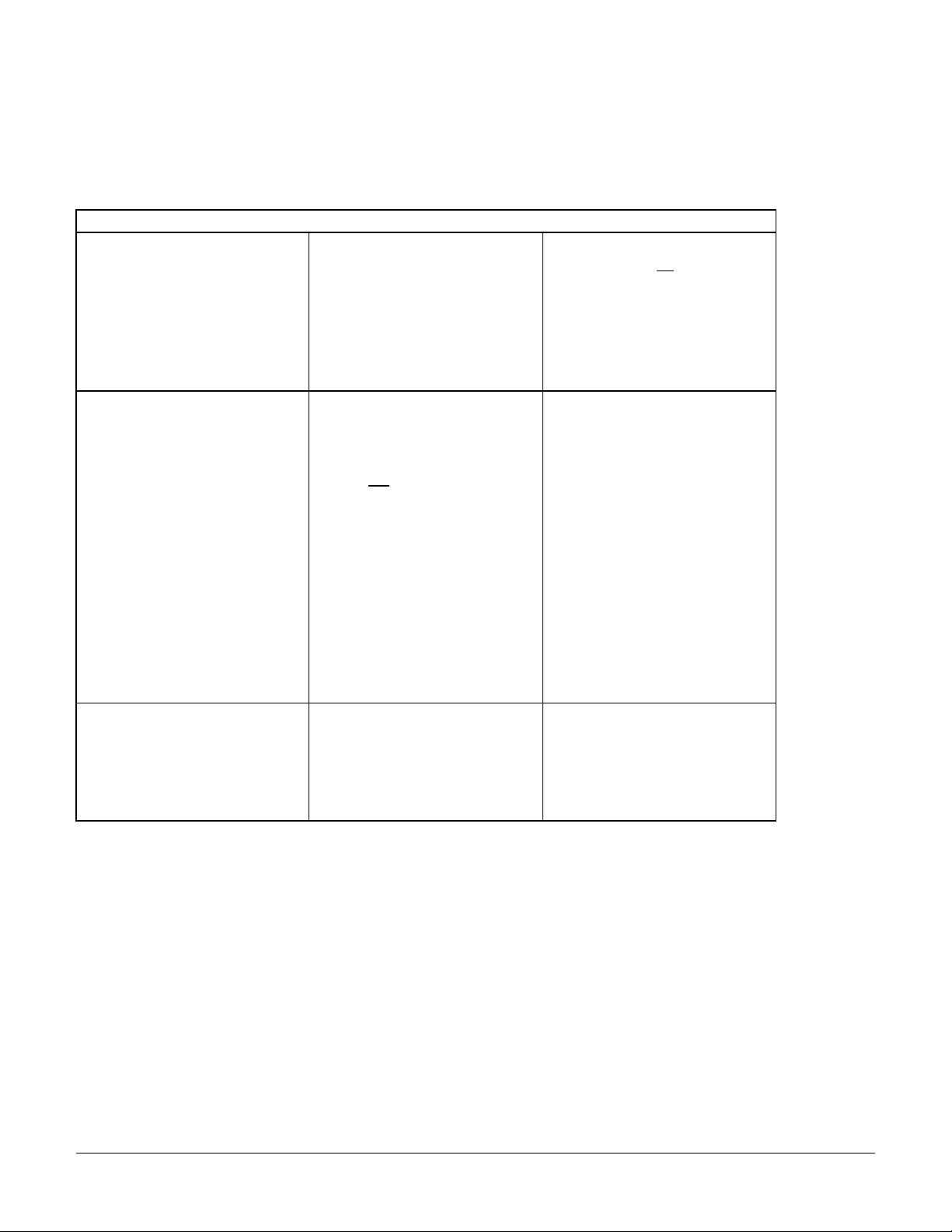

Figure 1a. Bactron II Chamber

Note: Bactron I Chamber is similar; it has three incubator compartments.

Figure 1. Bactron IV Chamber

Bactron Operations Manual 3

Page 4

______________________________________________________________________________

Component Drawings

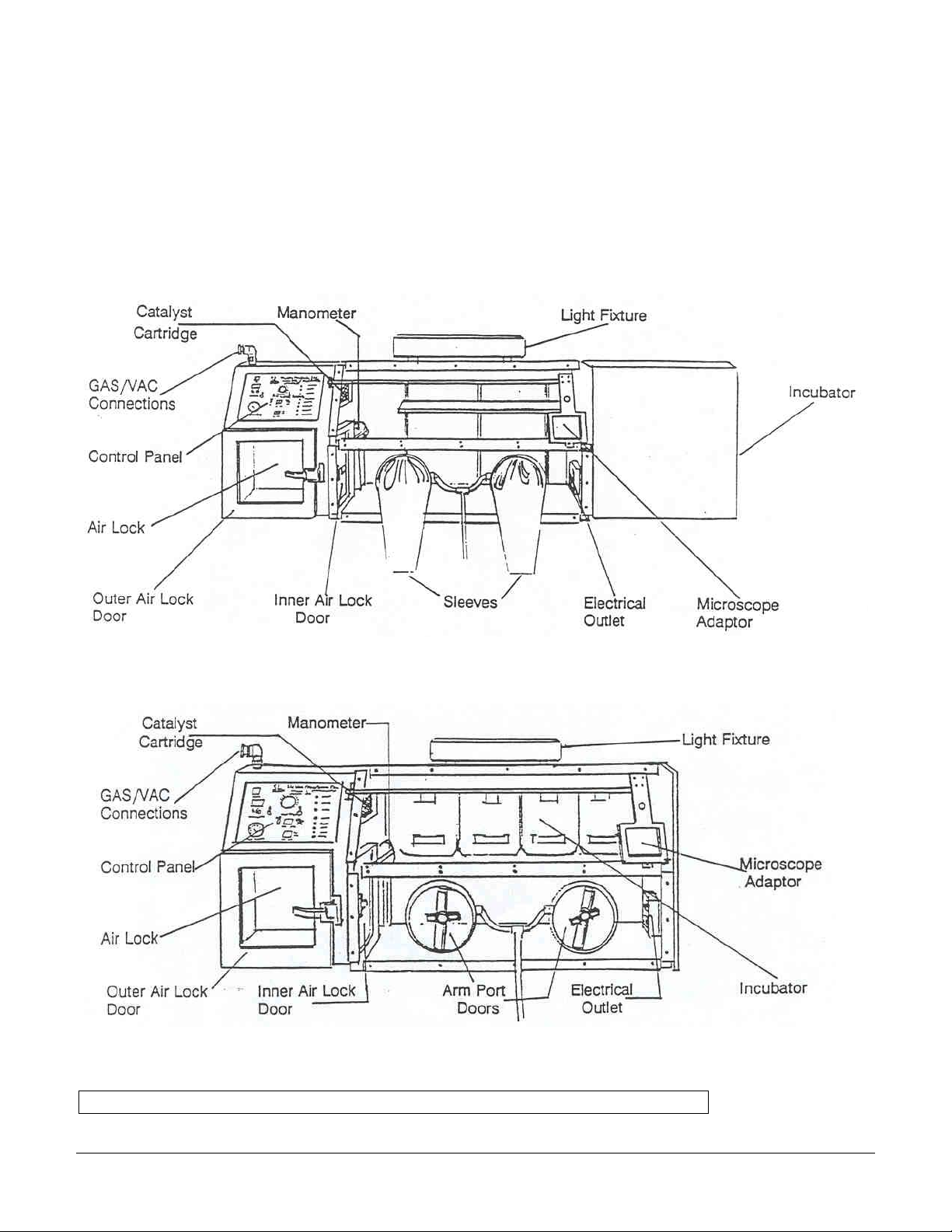

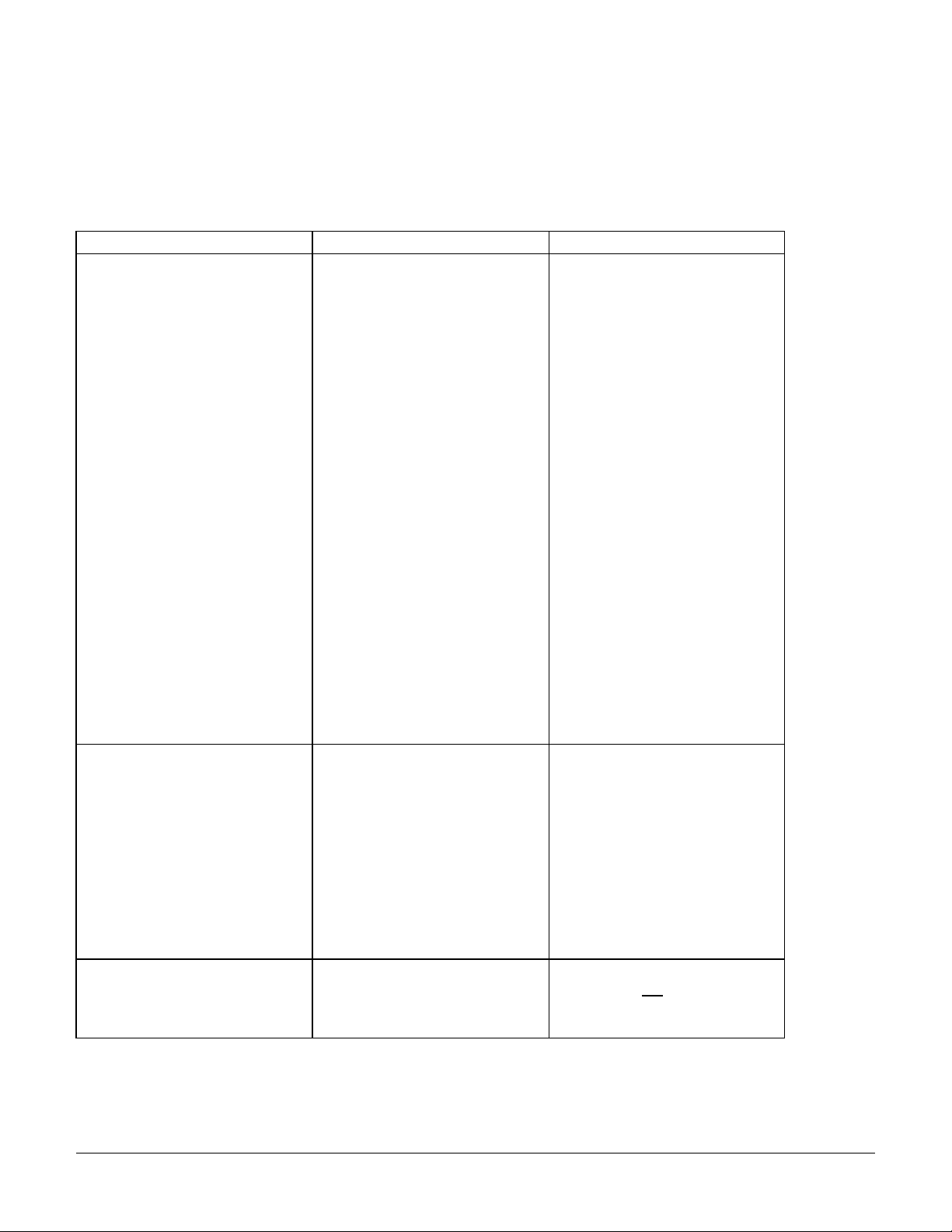

Figure 2. Sleeve/Cuff Assembly

Consists of a neoprene sleeve, a plastic cuff ring, O-Ring, and a soft rubber cuff. The assembly

allows gloveless chamber operation.

Figure 3. Armport Doors

CAUTION: The Bactron chambers have an efficient method of sealing the chamber by utilizing the

Armport doors as shown in Figure 3. The tightening knob on the armport doors should be turned

just until the knob begins to “grab”. DO NOT OVER TIGHTEN. Damage can occur if too much

force is placed on the Armport door assembly. See Section 13.5

Doors are used to seal the armports while the chamber is not in use. Doors can be stored using

the holders provided while the chamber is in use. Assembly consists of an armport door,

tightening knob and locking bar. Doors are secured by tuning the locking bars horizontally to pass

through the cutouts in chamber, then turning locking bars verticals and tightening knobs.

Bactron Operations Manual 4

Page 5

______________________________________________________________________________

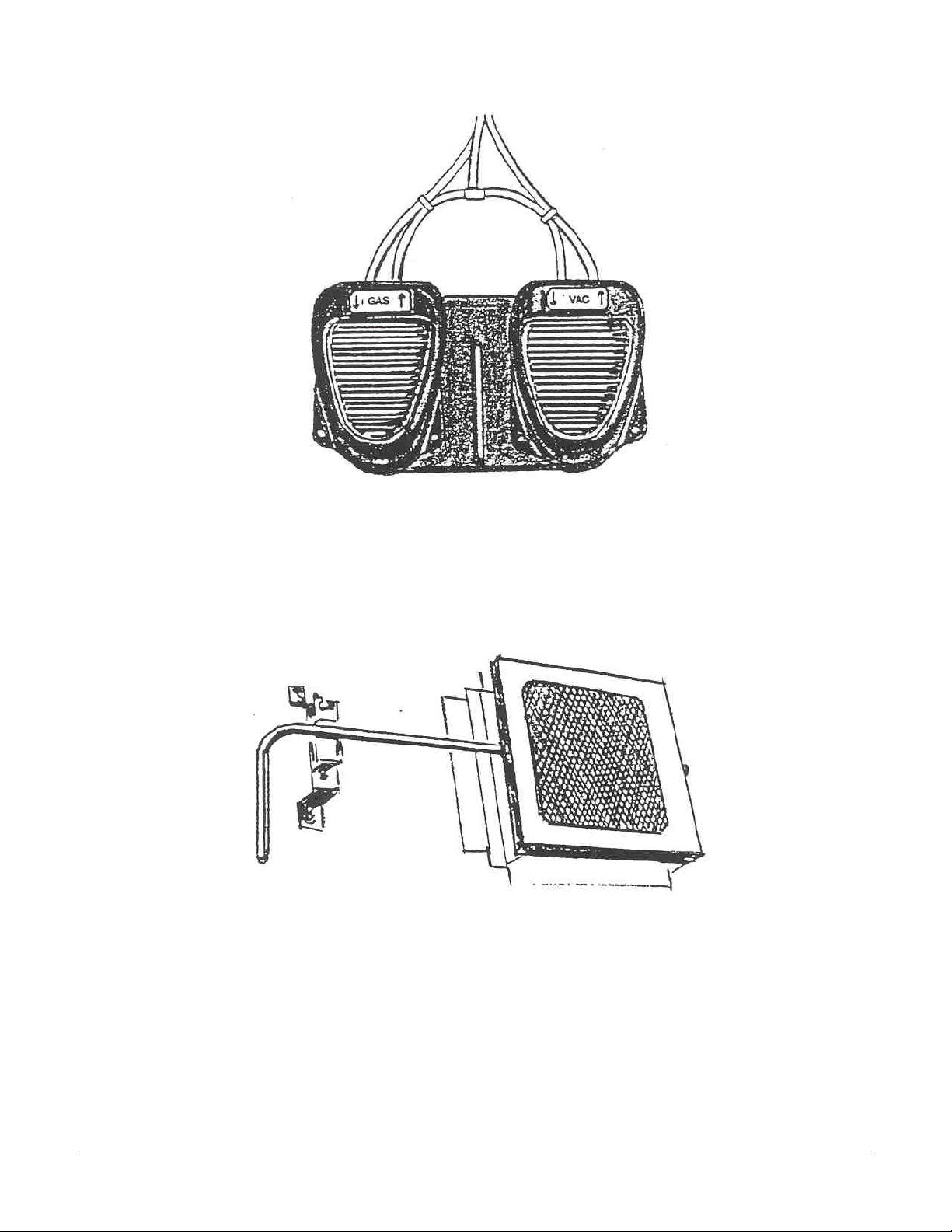

Figure 4. Foot Pedals

Utilize to exchange the sleeve atmosphere (room) with the desired chamber environment (gas

mixture). See pages 16 and 17 for further details.

Figure 5. Catalyst Cartridge

Two catalyst containing Palladium catalyst pellets are supplied to remove trace amounts of

oxygen. See page 11 and 12 for additional data.

Bactron Operations Manual 5

Page 6

______________________________________________________________________________

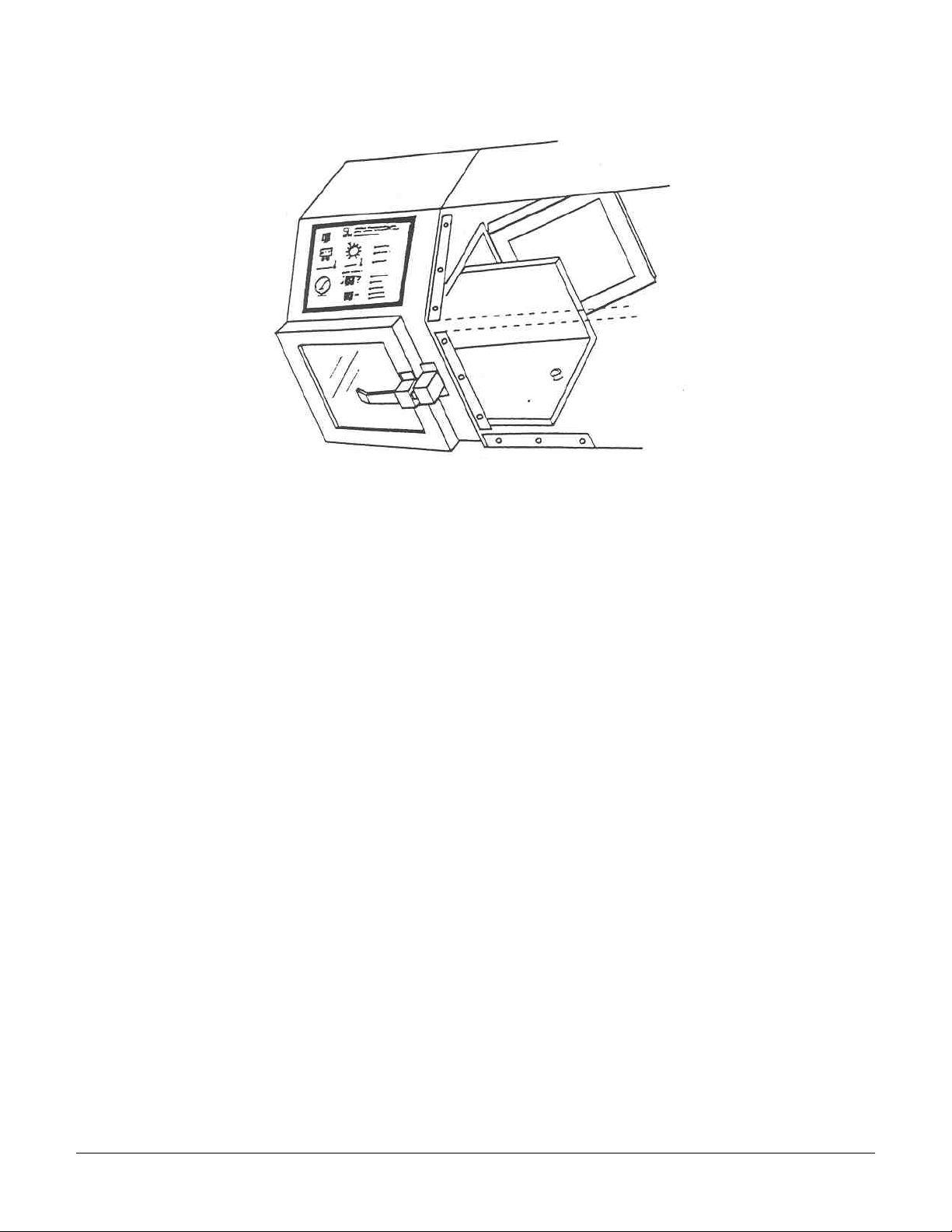

Figure 6. Air Lock

Provides ability to take material into and out of the chamber. Air Lock can be operated either

automatically or manually. The Air lock shelf (Models II and IV) allows for materials to be

conveniently rolled from the Air Lock into the chamber.

1.0 RECEIVING AND INSPECTION

1.1 The carrier, when accepting shipment, also accepts responsibility for safe delivery

and is liable for loss or damage claims. On delivery, you must inspect for visible

exterior damage. Note and describe on the freight bill any damage found and enter

your claim on the form the carrier supplies.

1.2 Inspect for concealed loss or damage on the unit itself, both interior and exterior. If

any, the carrier will arrange for official inspection to substantiate your claim. Save

the shipping crate until you are sure the unit has been delivered in good condition.

1.3 If for any reason you must return the unit, contact your sales representative for

authorization and supply nameplate data.

2.0 INSTALLATION

2.1 Local city, county, or other ordinances may govern the use of this equipment. If you

have any questions about local requirements, please contact the appropriate local

agency.

2.2 Under normal circumstances these units are intended for use indoors, at room

temperatures between 5° and 40°C, at no greater than 80% relative Humidity (at

Bactron Operations Manual 6

Page 7

______________________________________________________________________________

25°C) and with a supply voltage that does not vary by more than 10%. These ovens

should not be operated at an altitude exceeding 2000 meters. Installation category is

CAT-II.

2.3 Pollution Degree 2. Customer service should be contacted for operating conditions

outside of these limits. Installation may be performed by the end user. It is

unnecessary for this unit to be installed by a technician.

2.4 Location: When selecting a site for the unit, consider conditions which may affect

performance, such as heat from steam radiators, ovens, autoclaves, etc. Avoid

direct sun, fast-moving air currents, heating/cooling ducts, and high traffic areas. To

ensure air circulation around the unit, allow a minimum of 2” between chamber rear

and sides and any walls, partitions, or obstructions to free airflow.

2.5 Power Source: The power source must match the voltage, cycle, phase and

amperage requirements listed on the data plate. Plug the cord into a grounded

outlet. VOLTAGE OF THE OUTLET SHOULD NOT VARY MORE THAN 10%

FROM THE DATA PLATE RATING. A separate circuit is recommended to

precluded loss of product due to overloading or circuit failure. Note that the electrical

supply to the unit must conform to all national and local electrical codes.

2.6 Gas Source: Install the gas regulator(s) on the tank(s) of gas. Chain the gas

tanks(s) to a secure position on the wall. Set the regulator(s) to 10 psi.

2.7 If you are using an anaerobic gas mixture (AMG), we recommend 5% (H2), 5%

Carbon Dioxide (CO2) and 90% Nitrogen(N2).

2.8 If you are using a two gas anaerobic application, we recommend one tank of AMG

gas and the second tank of 100% Nitrogen (N2).

Figure 7. Warning Label

2.9 Cleaning: The Bactron unit was cleaned at the factory, however, a general cleaning

is recommended. Use BENZALKONIUM CHLORIDE to clean your chamber. See

page 23 for a list of cleaning products.

Bactron Operations Manual 7

Page 8

______________________________________________________________________________

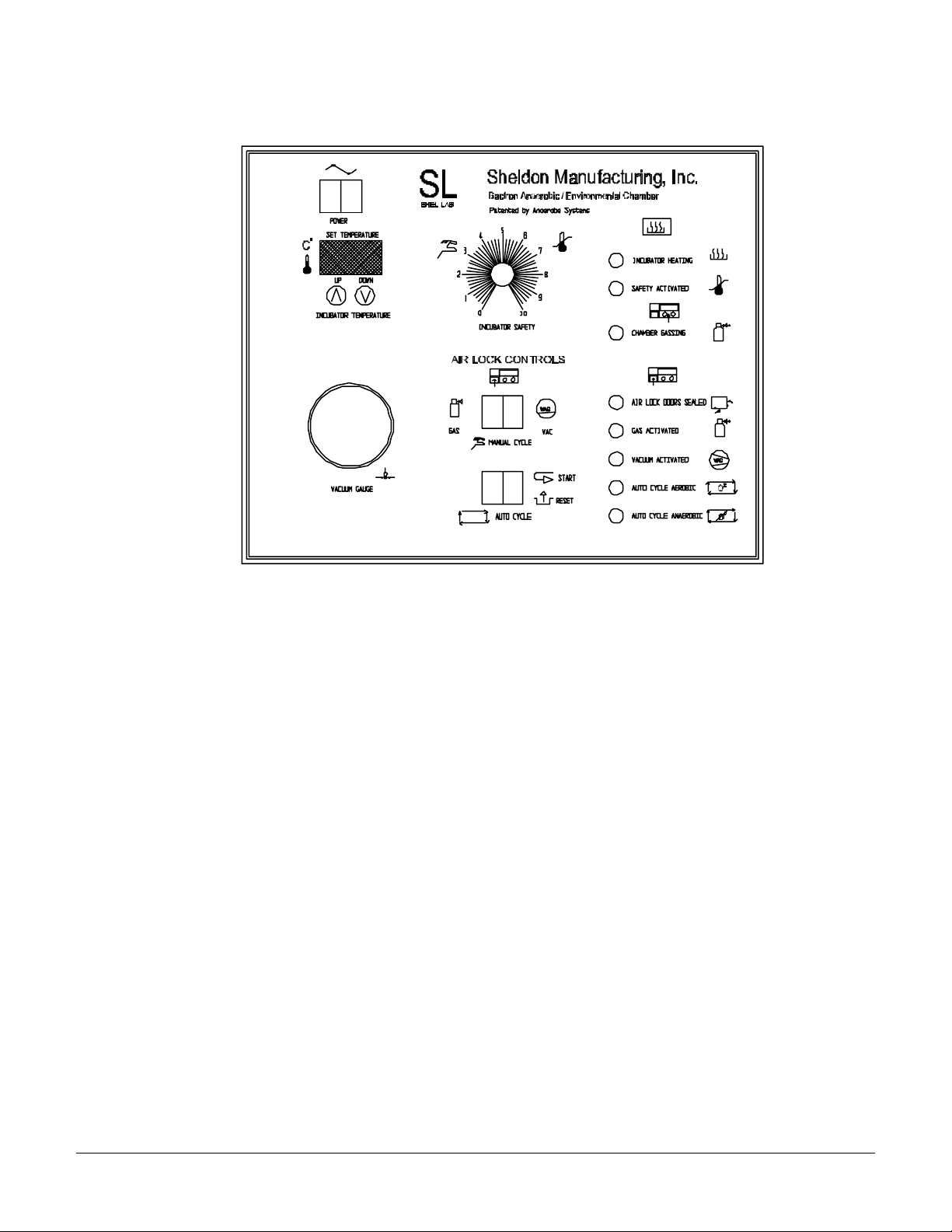

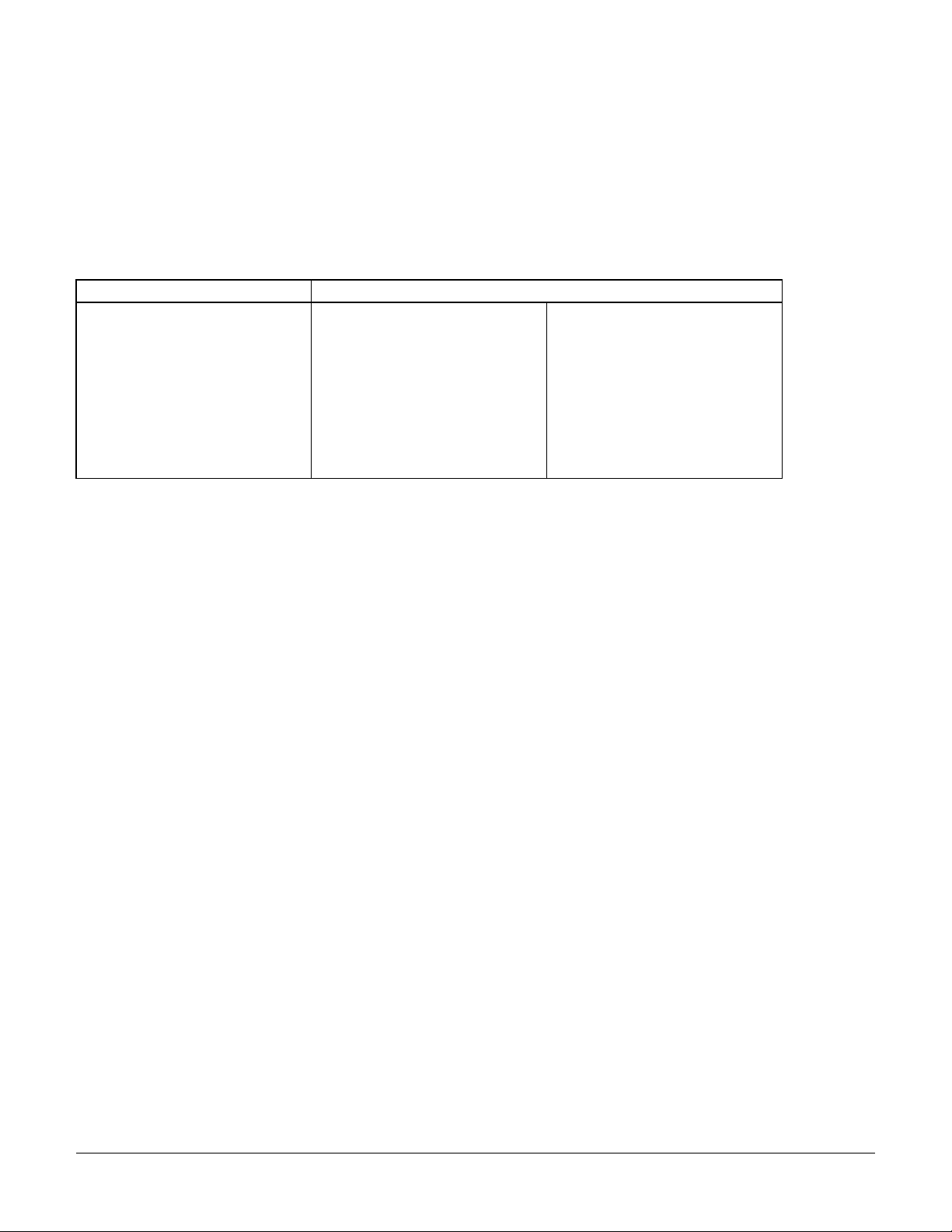

Figure 8. Control Panel

Bactron Operations Manual 8

Page 9

______________________________________________________________________________

3.0 CONTROLS OVERVIEW

3.1 Power: The lighted power “I/O” switch controls all power to the Bactron Chamber. It

must be in the “I” position before any systems are operational, including control

circuitry.

3.2 Digital Display: The actual incubator temperature will be digitally displayed to +

.1°C.

3.3 Main Temperature Control: This control consists of the Up/Down buttons and the

digital display.

3.4 Vacuum Gauge: Analog dial shows the vacuum level of the Air Lock in inches of

mercury.

3.5 Incubator Safety: The Safety is an independent thermostat that monitors incubator

temperature. It guards against any failure of the incubator controller which would

allow temperature to rise past set point. If temperature rises to the Safety set point,

the Safety will take over control of the heating element and an audible alarm will be

activated. The Safety controller allows for continued use of the chamber until service

can be arranged.

3.6 Air Lock Controls. Manual Cycle: The manual cycle switch controls the vacuum

and the gassing process of the Air Lock. Push VAC to evacuate the Air Lock then

GAS to fill the Air Lock with the desired gas mixture. This process should be done

three times.

3.7 Air Lock Controls. Auto Cycle: The automatic cycle switch will evacuate the Air

Lock and then fill the chamber with the desired gas mixture. The process will cycle

three times and upon completion the ANAEROBIC light will activate. The cycle can

be aborted by pressing the switch to the START/RESET and holding it down for five

seconds.

3.8 Incubator Heating: Light indicates that the heating element is activated and that the

incubator is heating.

3.9 Safety Activated: Light indicates that the Incubator Safety audible alarm is activated

and controlling the incubator temperature.

3.10 Chamber Gassing: Light indicates that the chamber is demanding gas. The light

activates when the operating the Air Lock and sleeves, in addition to maintaining

positive pressure in the working chamber.

3.11 Air Lock Doors Sealed: Light indicates that both the Air Lock doors are closed.

Bactron Operations Manual 9

Page 10

______________________________________________________________________________

3.12 Gas Activated: In the manual cycle the GAS light indicates that the Gas switch is

activated. In the automatic cycle, third cycle, light indicates that the GAS is activated

in the Air Lock.

3.13 Vacuum Activated: Light indicates that the VAC switch of the manual cycle Air

Lock is activated. Light is also on during automatic vacuum cycles.

3.14 Auto Cycle Aerobic: Light indicates that the Auto cycle has not been activated.

When the automatic cycle has been activated, the Auto Cycle Anaerobic lights will

alternate.

3.15 Auto Cycle Anaerobic: Light indicates that the Auto Cycle has been activated and

is complete. When the automatic cycle has been activated, the Auto Cycle

Anaerobic lights will alternate.

Indicates “Earth Ground”

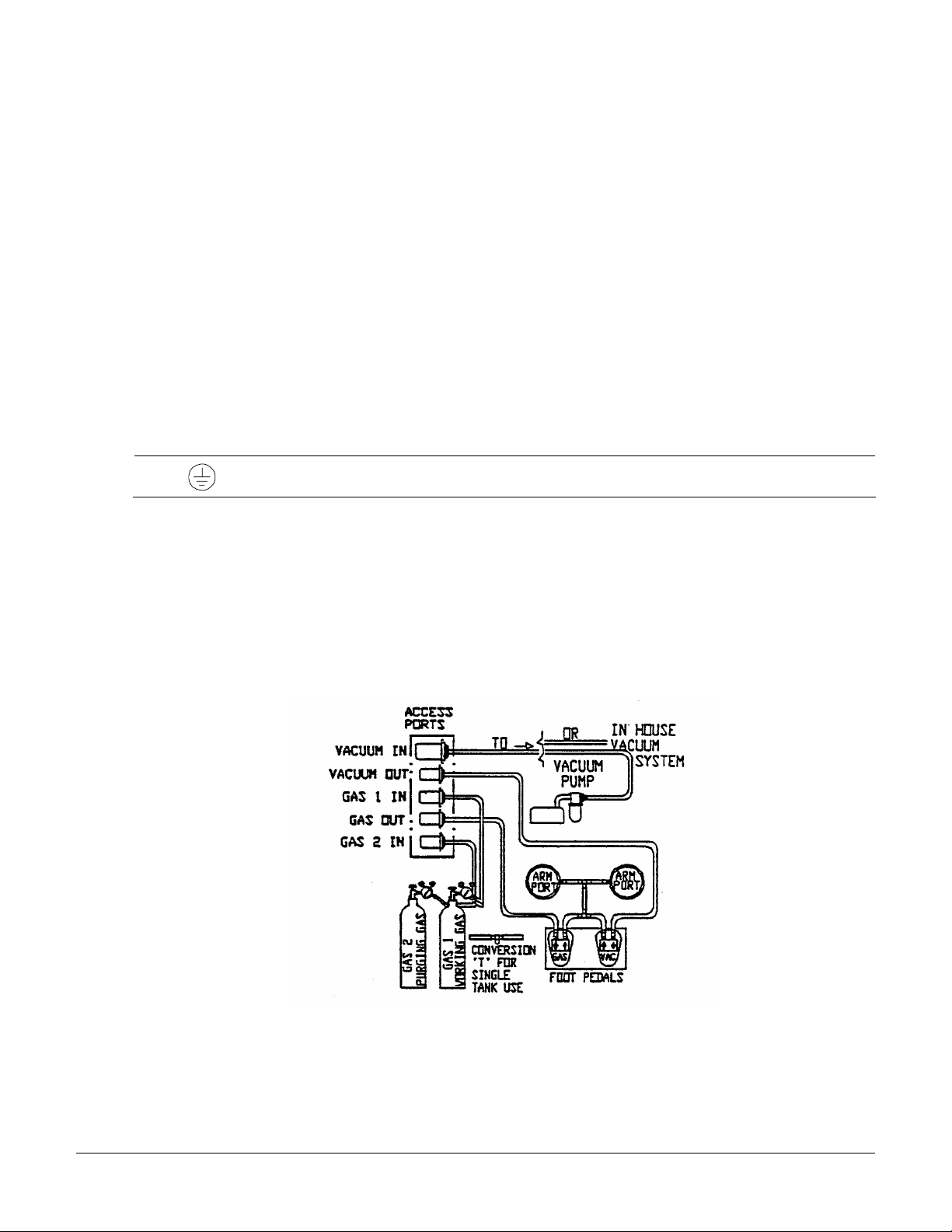

4.0 HOSE AND ELECTRICAL CONNECTIONS

4.1 Hose ports for the gas and vacuum supplies and foot pedal controls are provided on

the top back left side of the control module section. The Bactron models have five access

ports. (Older models have four access ports.) Figure 9 shows a typical hose connection for

a five port model.

Figure 9. Hose Connections

4.2 Install the hose from the gas regulator of the working gas, for example AMG, (GAS

1) tank to the port marked “GAS 1” on the chamber module.

Bactron Operations Manual 10

Page 11

______________________________________________________________________________

4.3 Install the hose from the gas regulator of the purging gas, for example Nitrogen,

(GAS 2) tank to the port marked “GAS 2” on the chamber module.

NOTE: If using only one gas supply, install the “T” tube/fitting assembly (provided in

the accessory pack) between the “GAS 1 IN” port and the “GAS 2 IN” port on the

control module. Then attach the hose from GAS 1 tank regulator, as in 4.2, to the

unused brass “T” tube end. Failure to follow this procedure will render the purging

cycles of a single gas system inoperative.

4.4 Connect the 3/8” hose from the vacuum pump or a 3/8” hose from a suitable in-

house vacuum system, to the port marked VAC IN. In-house vacuum systems must

be capable of evacuating to a minimum of 25 inches of mercury.

4.5 Plug the vacuum pump power cord into the outlet receptacle at the top left of the

control module. This outlet is marked “5 AMPS” (installations using in-house

vacuum supplies will not follow this step).

NOTE: CONNECTING HOSES.

the hose into the appropriate connector until the hose stops. Pull back slightly to

ensure hose will stay in place. Reinsert if hose pulls out.

4.6 Connect the center “T” section from the foot pedal assembly to the tube fittings

located on the inner sides of the armport access openings on the front of the

chamber.

4.7 Connect the tube from the GAS side of the foot pedal assembly to port marked GAS

OUT on the control module section.

4.8 Connect the tube from the VAC side of foot pedal assembly to the port marked VAC

OUT on the control module section.

4.9 Plug power cord from Chamber into a 115 VAC, 60 Hz (220 volt units are also

available) electrical outlet. Turn the power switch on to verify power to the system.

4.10 When the main power switch is turned on, the vacuum pump should come on for a

few seconds and then go off. If the pump does not come on, or comes on and will

not go off, consult the Troubleshooting Guide for adjustment.

4.11 When the power switch to the Chamber is turned on, you should see Power ON,

CHAMBER GASSING, AIR LOCK DOORS SEALED and AUTO CYCLE AEROBIC

lights illuminate, along with a readout of the incubator temperature. If any of these

appear not to work, consult the Troubleshooting Guide.

Hose connections are intended to be simple. Insert

Bactron Operations Manual 11

Page 12

______________________________________________________________________________

5.0 MANOMETER

5.1 Located below the right end of the control panel and inside the chamber, the

Manometer provides a visual way to measure pressure in the chamber. It also

functions as a pressure release system to prevent damage to the chamber in

the event over-pressurization occurs. By measuring the difference between

the inner and outer water levels one can obtain the chamber pressure in

inches of water. If pressure becomes too great, excess gas will push out

through the inner tube and bubble through the water thus releasing pressure

from the chamber.

5.2 Purpose: The function of the manometer is two-fold:

a. Provides visual way to measure the pressure in the chamber. As the

pressure inside the chamber increases, the water level in the inner tubes

moves down a distance proportional to the pressure increase. By measuring

the difference of the inner and outer water levels, the user can obtain the

chamber pressure in inches of water. A water level indicator notifies user that

water is high or low.

b. It acts as a pressure release system to prevent damage to the chamber in

case of inadvertent over-pressurization. If the pressure becomes too great,

the excess gas simply bubbles through the water and out the back of the

chamber.

5.3 Filling Procedure: Use a pipette or plastic wash bottle to fill the manometer with

distilled water to a level of two or three inches. Lines on the manometer provide a

guide. Fill water to the top line. This may be done from the top of the manometer

inside the chamber.

6.0 CATALYST CARTRIDGE

6.1 The catalyst cartridge removes ant trace amounts of oxygen from the chamber. Two

catalyst cartridges containing Palladium catalyst pellets are provided. See drawing

pg. 4

6.2 One cartridge should always be in the chamber. The second spare cartridge is

provided so that reactivation of the catalyst can be done after each chamber usage.

6.3 The catalyst cartridge is installed on the left wall inside the chamber. To install slide

the cartridge into the metal tracks and secure the handle into the bracket.

6.4 Reactivate spare catalyst daily by heating for a minimum of 1 –1/2 to 2 hours at

160°C (320°F). You may keep the unused cartridge in the heating oven at 160° prior

Bactron Operations Manual 12

Page 13

______________________________________________________________________________

to its use. (NOTE: Catalyst cartridge should be reactivated for the first time before

installing into the unit.)

6.5 Quality control catalyst monthly by flowing anaerobic gas over the reactivated pellets.

If the pellets become warm to hot, they are working properly and are ready for use in

the chamber. If they do not heat up when the gas is applied, reheat to 180° to 200°C

and flow gas over catalyst again to remove any buildup of sulfides that might hinder

its effectiveness.

6.6 The entire catalyst cartridge can be placed in the heating oven for reactivating.

However, if necessary, the handle on the cartridge can be removed.

6.7 A catalyst cartridge can also be placed inside the Air Lock to remove any trace

amounts of oxygen.

7.0 THERMOELECTRIC CONDENSATE CONTROLER

7.1 The thermoelectric condensate controller collects excess humidity and eliminates

chamber condensation. Moisture is funneled into a tube for collection inside your

chamber.

7.2 The thermoelectric condensate controller is located on the left side of the chamber

interior behind the catalyst cartridge. A plastic tube drains excess moisture into the

working chamber, on the back left side.

7.3 Place a container, e.g., glass flask or beaker, under the tube for collection. Empty

the container DAILY.

7.4 Desiccants are not recommended in the chamber. Desiccants are drying agents that

can regrettably pull moisture from your samples.

Bactron Operations Manual 13

Page 14

______________________________________________________________________________

8.0 INCUBATOR TEMPERATURE CONTROLLER/INCUBATOR SAFETY

8.1 Setting Incubator Controller: The INCUBATOR TEMPERATURE controller

regulates the incubator temperature by use of Up/Down buttons. To enter set point

mode on the control, press either the Up or Down button one time. The digital

display will start to blink, going from bright to dim. While blinking, the Digital Display

is showing the set point. To change the set point, use the Up and Down buttons. If

the buttons are not pressed for five (5) seconds, the display will stop blinking and will

read the temperature of the unit. Note that the INCUBATOR SAFETY should be

turned to its maximum position, (clockwise) until the unit has stabilized at desired set

point temperature. Allow the incubator at least 24 hours to stabilize. Then recalibrate the digital display to your reference thermometer, follow the calibration

instructions given in Section 9. This incubator was calibrated at the factory at 37°C.

8.2 Setting Incubator Safety: Set the control to the desires incubator temperature.

Then set the INCUBATOR SAFETY to its maximum position. Allow 24 hours for

stabilization before proceeding.

If, after 24 hours the temperature is not at desired level, adjust the INCUBATOR

TEMPERATURE up or down until the precise desired temperature is achieved. (See

Section 9 for calibration procedures)

When stabilization at the desired temperature has been achieved, turn the

INCUBATOR SAFETY control knob counter-clockwise until the INCUBATOR

SAFETY ACTIVATED light comes on and audible alarm is activated. Next, carefully

turn the INCUBATOR SAFETY knob clockwise until the light is just off. The Safety is

now set; the INCUBATOR SAFETY ACTIVATED light should remain OFF during

normal operation.

NOTE: An accurate thermometer should be used inside the incubator

as a reference when setting and calibrating the incubator temperature.

8.3 It is a good idea to mark the INCUBATOR SAFETY label with the desired

setting or position as a backup in case the knob is moved accidentally. If the

SAFETY ACTIVATED light is on and audio alarm is activated at any time,

check the INCUBATOR TEMPERATURE controller setting to be sure that it is

not set above the INCUBATOR SAFETY setting.

9.0 INCUBATOR CALIBRATION

9.1 Compare the reading of the digital temperature display to an accurate reference

thermometer. If there is a difference, put the display into calibrate mode by pressing

both the Up and the Down buttons at the same time and holding them in for about

five (5) seconds or until the two outside decimal points start to flash on and off.

Bactron Operations Manual 14

Page 15

______________________________________________________________________________

When the decimal points are flashing, the display can be calibrated to match the

reference thermometer by pressing the Up or Down button until the display reads

correctly.

10.0 VACUUM ADJUSTMENT

10.1 The vacuum gauge for the Automatic Air Lock Cycle is factory calibrated. It is

recommended that customers note the setting of the vacuum gauge during Auto Air

Lock Cycle to ensure that the setting is correct. Evacuation and the vacuum pump

capabilities can effect the calibration.

10.2 The vacuum setting for the Auto Air Lock Cycle are factory set at the High Limit 18

and the Low at 4.

10.3 Vacuum calibration procedure:

High Limit

A) Activate the Auto Air Lock Cycle and note the high level reached by the

vacuum gauge. If the vacuum gauge is not at the desired High setting of

18, adjust the high vacuum switch located on the left outside if the control

housing box.

B) This switch is illustrated in the “CONTROLS: View From Behind Control

Panel” Page 25, #10.

C) Adjust the High setting by turning the large knob until the desired value of

18 is reached. (Black notch on knob toward 0 to decrease or toward 30 to

increase). See page 25.

D) Activate the Auto Air Lock Cycle and observe the vacuum gauge on the

high level reached.

E) Repeat steps C and D.

Vacuum calibration procedure:

Low Limit

A) Activate the Auto Air Lock Cycle and note the low level reached by the

vacuum gauge. If the vacuum is not at the desired Low setting of 4,

adjust the Low vacuum switch located in the same area as the high

vacuum switch noted above.

B) Repeat the procedure noted above under High vacuum to adjust the low

Vacuum setting except adjust for the lower value of 4.

Bactron Operations Manual 15

Page 16

______________________________________________________________________________

11.0 PRESSURE ADJUSTMENT

11.1 The chamber pressure of your unit is factory calibrated but local elevations may

make adjustment of this value necessary.

11.2 If the manometer is bubbling when no one is working inside the chamber or the water

level of the manometer is less than ½ inches, the pressure should be adjusted. See

manometer diagrams on page 11 for a reference. Following is the adjustment

procedure:

A) The chamber pressure switch is located on the outer left side of the

control housing box. It is adjusted by means of an Allen wrench

adjustment screw (clockwise to increase/counterclockwise to

decrease) see page 25.

B) Adjust the setting of this valve only if the manometer level is above the

½ inch mark or is bubbling as noted above.

C) Repeat the adjustment, if necessary, observing carefully the result,

until the proper performance is obtained.

12.0 TESTING THE CHAMBER FOR GAS LEAKS

12.1 Each chamber is individually tested at the factory before shipping. The following

procedure, however, should still be followed to detect any possible damage due to

shipping.

12.2 Make sure the catalyst is removed from the chamber during initial leak testing.

12.3 Check to ensure Manometer is filled.

12.4 Close the outer and inner air Lock doors.

12.5 Secure the Armport doors. Turn the locking bars horizontally to pass through the

cutouts in the chamber, then turn bars so they are vertical, tighten knobs. Do not

over tighten. See Note at the end of Section 13.0

12.6 Open the gas tank valve all the way on and set the gas regulator to 10 psi.

12.7 Turn the power switch on. As before, with the power switch on, you should see the

POWER SWITCH, INCUBATOR TEMPERATURE display, CHAMBER GASSING,

AIR LOCK DOORS SEALED, and AUTO CYCLE AEROBIC light illuminate.

12.8 The CHAMBER GASSING light will turn OFF when the water level in the manometer

reaches a level of approximately ½” of water. The AIR LOCK DOORS SEALED

light will turn ON when the inner and outer Transfer Module doors are both closed. If

Bactron Operations Manual 16

Page 17

______________________________________________________________________________

this light is not ON, either the doors are not closed properly or one or both of the door

sensors are improperly adjusted (See Troubleshooting Guide).

12.9 If there are no leaks in the system, the CHAMBER GASSING light will remain OFF,

and the water level in the manometer will remain stable at approximately ½” water.

Normally, a “leak-tight” chamber will go from 15 to 30 minutes without the

CHAMBER GASSING light coming on again.

12.10 If the system has a gas leak, the CHAMBER GASSING light will flash ON and

OFF. Flashing every 10-30 seconds indicates a very large leak, whereas flashing

every 10 minutes or so indicates a small leak. This is accompanied by a “clicking”

sound (originating from the chamber gas solenoid). In this case, check the

following:

A) Armport doors for adequate seal of O-rings.

B) Air Lock outer/inner door gaskets for adequate contact with doors.

12.11 If the system still has a leak, refer to:

A) Chamber Maintenance: Leak Detection

B) Trouble Shooting: Excessive Gas Consumption

13.0 MAKING THE CHAMBER ANAEROBIC/DESIRED ENVIROMENT

Prior To Purging The Chamber

13.1 Turn Power switch to the “O” (Off) position.

13.2 Place about six oxygen indicators inside the system. Place one unopened indicator

in the incubator, and place one unopened indicator in the work area. The others can

be stores in the work are for future use.

13.3 Place catalyst in the chamber. For more information about the correct placement of

the catalyst, see Section 6.0. Catalyst Cartridge page 11 and 12.

13.4 Open the incubator doors before leaving the chamber. This allows the incubator to

become anaerobic also.

13.5 Put armport doors in place.

NOTE: The Bactron chambers have an efficient method for sealing the chamber by

utilizing the Armport doors as shown in Figure 3 on page 4 . The tightening knob on

the Armport doors should be snug, DO NOT OVER TIGHTEN

too much force is placed on the Armport door assembly. When the knob just begins

to “grab”, the tightening bolt has reached its maximum point. Over tightening will

cause the bolt to slip inside the handle and cause leakage.

. Damage can occur if

Bactron Operations Manual 17

Page 18

______________________________________________________________________________

Purging the Chamber

13.6 Turn Power Switch to the “I” (On) position.

13.7 Note the reading on the gas regulator.

13.8 Loosen the right armport door to create a small leak. (Remove sleeves from the

armports if they have been placed there. This will make it easier to adjust the

armport doors to create the proper leak.) Adjust the doors so that the CHAMBER

GASSING light flashes ON and OFF for equal periods. It is important that the gas

flows into the chamber in “pulses” rather than as a “stream”. If the gas “streams”, it

tends to go to the open door only.

13.9 Bleed the gas mixture through the chamber until the reading on the tank regulator

gauge is 300-400 psi less than the original reading. Normally, it takes 1-1/2 to 2

hours to flush out all atmosphere from the chamber.

13.10 After the gas purge, tighten the armport doors to prevent leaking. The CHAMBER

GASSING light will turn off, flow of gas into the chamber will stop, and the water

level difference in the manometer should again be approximately ½” and should

remain stable.

13.11 At this point it is important to check if the chamber is completely anaerobic before

using it. Check this by first replacing the sleeves on the armports, and the entering

the chamber. For more information about entering the chamber see Section 15.0,

Entering the Chamber page 19.

13.12 A) Once inside the chamber, open one indicator strip in the incubator, and one

strip in the work area.

NOTE: Please note and follow the directions for use for the type of indicator

strip you are using.

B) If the strips indicate that the atmosphere is anaerobic, the chamber is ready

for use.

C) If the strips indicate an aerobic or slightly aerobic atmosphere, then exit the

chamber. Create a small leak as detailed in Step 13.8. Flush an additional

100-200 psi through the chamber. After this step, proceed to step 13.11, until

indicator strips indicate an anaerobic atmosphere.

D) The gas flowing through the chamber may cause previous indicator strips to

dry out. Use fresh indicator strips stored in step 13.2 each time you test the

atmosphere.

Bactron Operations Manual 18

Page 19

______________________________________________________________________________

NOTE: During the initial purge you may notice heavy condensation within the chamber.

This is due to catalytic formation of water from hydrogen gas and oxygen initially in the

chamber. Most of this condensation will dissipate by the end of the gas purge cycle.

CAUTION: The catalyst cartridge will be HOT at this point. If you must touch it for any

reason, use extreme care.

Summary

The chamber is ready when:

A) The CHAMBER GASSING light remains off indicating no gas leaks.

B) The incubator doors are OPEN.

C) Oxygen indicators are in the chamber.

D) The catalyst cartridge is in place.

14.0 CHAMBER OPERATION

Air Lock Operation

14.1 Load the Air Lock with samples, materials, supplies, etc.

14.2 Close the outer and inner Air Lock Doors.

14.3 Activate the Air Lock by one of two methods:

A) Manual Cycle (Manual Gas/Vacuum Switch):

i. Locate the 3 position Manual Gas/Vacuum Cycling Switch which should be in

the middle.

ii. Turn the Manual GAS/VAC switch to VAC until a vacuum of 17 to 20-in. Hg is

reached, as indicated by the VACUUM GAUGE.

iii. Flip the GAS/VAC switch to GAS to refill the Air Lock with the gas mixture

until the AIR LOCK VACUUM GAUGE reads approximately 4-in. Hg on the

first two cycles. On the third and last cycle leave the gas on until the gauge

reaches zero to ensure that there is no vacuum still present in the Air Lock,

then return the switch to the middle or off position.

iv. It is essential to perform the cycle at least three times. Once this is done, you

may enter the chamber through the armports, using the procedure specified in

the next section, and take your materials into the chamber through the inner

Air Lock door.

Bactron Operations Manual 19

Page 20

______________________________________________________________________________

NOTE: When cycling the Air Lock manually, the AUTO CYCLE ANAEROBIC light on the

control panel will not illuminate when the cycle is completed, as it does at the end

of the automatic cycle.

B) Automatic Cycle:

i. Make sure both Air Lock doors are closed. The automatic cycle will not start

otherwise.

ii. Press the “AUTO CYCLE START/RESET” button to initiate the cycle. The

AUTO CYCLE AEROBIC/AUTO CYCLE ANAEROBIC lights will alternately

flash on and off, indicating the cycle is in progress. When the cycle is

complete, the system will stop automatically with the AUTO CYCLE

ANAEROBIC light on.

iii. If the cycle does not follow the sequences in the previous section on manual

operation (eg: cycle won’t start, cycle does not go through three times, cycle

cot within specified limits, door won’t open upon completion, etc.), consult the

Troubleshooting Guide for adjustments.

NOTE: Do not hold Auto Cycle Start Switch down. Simply Press the

button and let go to activate.

iv. If you WANT TO abort the cycle, press and hold the “AUTO CYCLE

START/RESET” switch for 5 seconds. The vacuum gauge will go to 0 and

stop. Then the AUTO CYCLE AEROBIC/AUTO CYCLE ANAEROBIC light

will stop flashing.

15.0 ENTERING THE CHAMBER

15.1 The rubber cuffs of the sleeve should be secured around your arm as opposed to

clothing. Remove watches, bracelets, etc., as they may damage the cuffs.

15.2 Insert your hands and forearms into the sleeves. The cuffs must be firmly secured

around your bare forearms. Keep your hands four to six inches away from the

armport doors.

15.3 Depress the VAC foot pedal (this procedure evacuated both sleeves), and continue

depressing until the sleeves have collapsed completely and firmly around your

forearms.

15.4 Flush the sleeves with the gas mixture by depressing the GAS foot pedal. Do not

overfill the sleeves. Stop when you feel a small separation of space between your

hands and the sleeves.

Bactron Operations Manual 20

Page 21

______________________________________________________________________________

15.5 Repeat steps 15.3 – 15.4 three more times to ensure that the sleeves are completely

anaerobic/desired atmosphere before entering the chamber.

NOTE: ALWAYS enter the chamber with both arms simultaneously.

15.6 Loosen the armport door knobs a few turns and rotate the locking bars to a

horizontal position. The armport doors can now be pushed forward into the chamber

interior and can be secured on the armport door holders.

NOTE: Arm movements that are to forceful may cause the sleeves to dislodge from

the armports.

16.0 EXITING THE CHAMBER

16.1 Before leaving the chamber the incubator doors and the inner Air Lock door must be

closed.

16.2 Depress the GAS foot pedal to allow the sleeves to fill with gas. This procedure

keeps the sleeves from collapsing as you move outward, making it easier to

reposition the doors.

16.3 Hold the locking bars in a horizontal position, and close the doors. Rotate the locking

bars to a vertical position, and gently tighten both armport door knobs, just until they

“grab”.

16.4 Before removing arms from the sleeves:

A) Check to be sure that armport doors are securely sealed by slowly pushing

both arms forward (this action generates a pressure within the sleeves).

B) If the Manometer bubbles when the arms are pushed forward, this indicates

that the doors are improperly sealed. Loosen the armport door knobs again,

remove the doors. Check the O-rings for any particulate matter on the sealing

areas, and repeat Step “A”. If Manometer remains stable, the doors are

sealed properly.

16.5 When the armport doors are properly sealed, slowly and carefully withdraw both

arms from the sleeves.

Bactron Operations Manual 21

Page 22

______________________________________________________________________________

17.0 MAINTENANCE

DAILY/ROUTINELY:

1. Before using any cleaning or decontamination method except those recommended by the

manufacturer, users should check with the manufacturer that the proposed method will not

damage the equipment.

2. Exchange chamber catalyst cartridge with reactivated one.

3. Remove & empty condensate collection container.

4. Change oxygen indicators.

5. Disinfect the chamber interior.

6. Check the cuffs on the sleeve system. If the cuffs have holes or any tears, replace.

7. Check incubator temperature. See Example Checklist page 22.

8. Record gas tank reading.

9. Change/Rejuvenate anatox.

Anatox absorbs volatile fatty acids and hydrogen sulfide in the chamber. Recommended

use is 250 grams placed in a beaker in the chamber.

Anatox-1000 grams (packaged in 250 gram packages)

Instructions:

A. Empty two 250gram packages into two separate 500 ml Pyrex beakers.

B. Day one – place one beaker in the chamber (new anatox can be placed directly into

the chamber).

C. Day two – remove beaker in the chamber and replace with the second beaker of

anatox (also new).

D. Day three – reactivate the first beaker of anatox by heating at 160°C for 2 hours.

Then replace the beaker in the chamber with this reactivated beaker.

E. Day four – six months – continue switching the reactivated beakers daily until six

months is complete, then discard the old anatox and repeat the procedure again.

Bactron Operations Manual 22

Page 23

______________________________________________________________________________

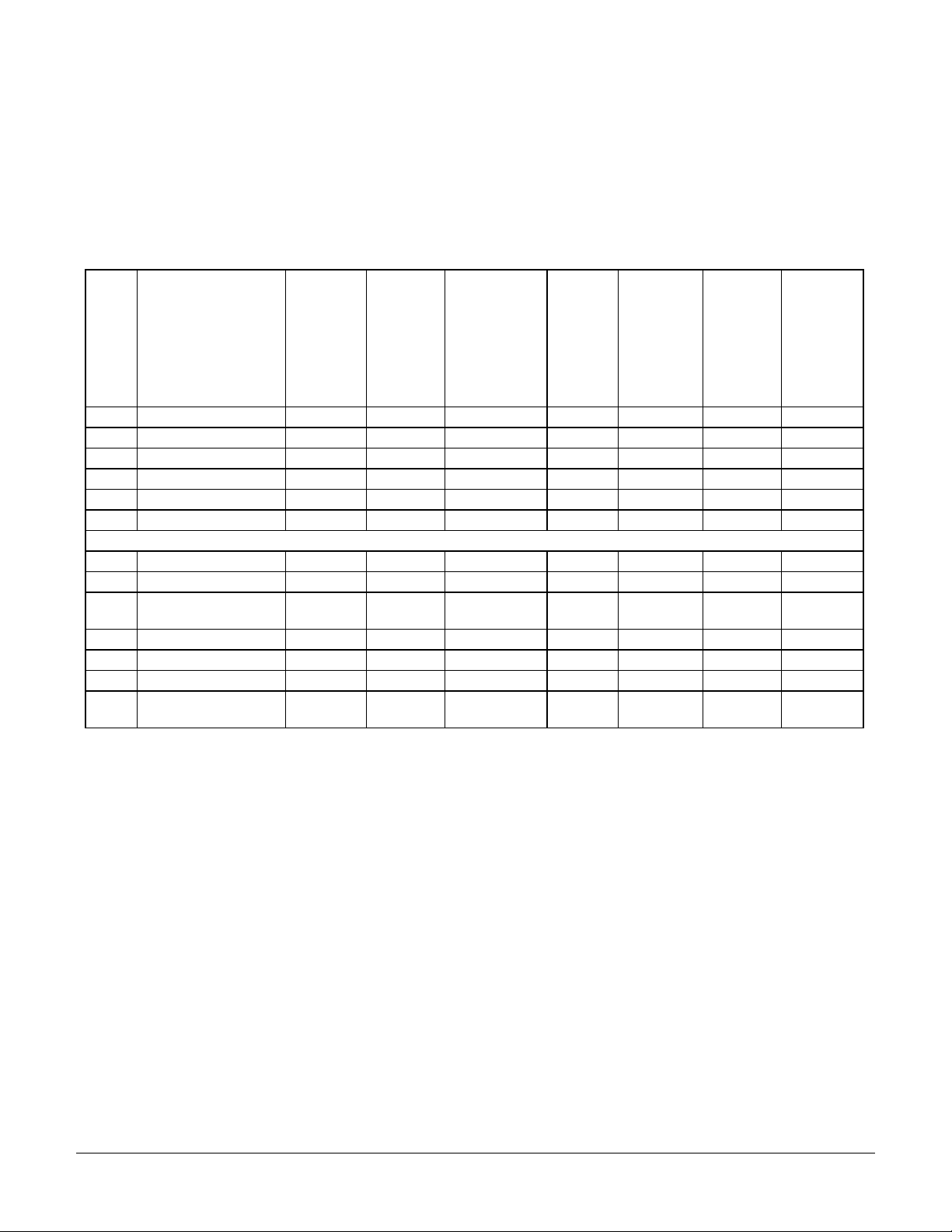

18.0 CHECKLIST

Month

Record Change Change Drain Record

Temperature Catalyst Indicator Condensate Tank Pressure

Gauge Reading

Date

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

CHAMBER QC SHEET

Bactron Operations Manual 23

Page 24

______________________________________________________________________________

19.0 ACCESSORIES

Tank Switch Chamber Stand

Switches and monitors dual gas tank supply. Provides work bench to support Bactron

Provides automatic switch-over to second gas chambers. Chamber Stand height 30”.

tank alarm sounds when both tanks are empty. Stands feature locking casters and storage

Tanks can be switched manually at any time. Space.

Model # 2002-B Model: Bactron I, II, and IV

Nitrogen Gas Regulator Microscope Recommendation

Optional accessory used in a two gas chamber The LEICA brand of microscope is a

commonly used unit with Bactron System.

Model # 7150500 Microscope: # 9990516

Illuminator: # 4650502

Extended Service Contracts

A LUKAS illumination system is also

The contract offers a twelve month warranty on available, which includes a 250 watt

parts and labor. Ensures customer of product fiber optic light, light ring, 250 watt

satisfaction and optimal performance. Lamp house, and 0.3x lens.

Cleaner Illumination system: #4650503

Spare Lamp: # 4650504

Benzalkonium Chloride

#AS-972V recommended to use in Manometer. Parts

From Anaerobe Systems Co. #408/782-7557

Catalog No.

Anatox

9990502 Catalyst Holder Filled

#B90010 From Anaerobe Systems Co. 5110730 Petri-Plate Rack 2x13

#408/782-7557 9490513 Light Fixture

9990514 Sleeves, Complete

Plexiglass Cleaner 9490507 UV Light Source

9490512 Start Up Kit-MDL I

8oz size; # 1060503 9490511 Start Up Kit-MDL II,IV,X

3600500 Rubber Cuffs, Sm Size 7

3600501 Rubber Cuffs, Med Size 8

Plexiglass Scratch Remover 3600502 Rubber Cuffs, Lrg Size 9

6000504 O-Ring For Cuff

6000501 O-Ring For Door

8oz size: # 1060504 3450506 Gasket-Airlock, Bactron I

3450507 Gasket-Airlock, Bactron

II,IV,X

Product

Bactron Operations Manual 24

Page 25

______________________________________________________________________________

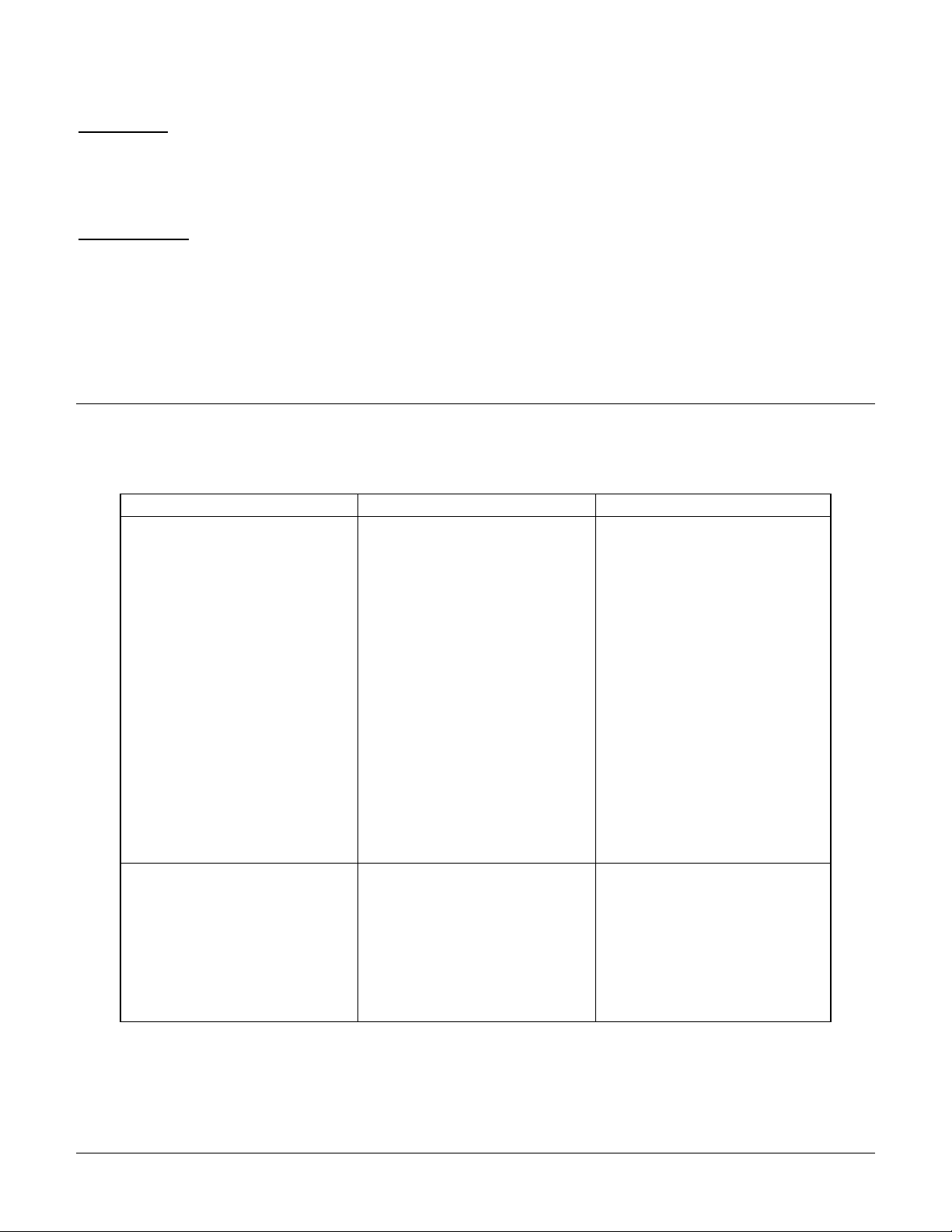

20.0 CHAMBER SYSTEM DRAWINGS

Gas

Anaerobic mixture is 5% hydrogen, 5% carbon Dioxide, and 90% nitrogen. Do not exceed

5% hydrogen for safety reasons. Test for the presence of hydrogen in the gas mixture by

flowing the gas over the active catalyst. The catalyst will get hot if hydrogen is present.

Catalyst

Reactive by heating for 2 hours at 160° C. Test by flowing the anaerobic gas mixture over

the catalyst. If the catalyst is active, it will get hot. The catalyst can be “cleaned” by heating

to 200°C, then flowing the anaerobic gas mixture over the catalyst.

Positive Pressure

The Manometer will indicate if positive pressure is present in the chamber.

Bactron Operations Manual 25

Page 26

______________________________________________________________________________

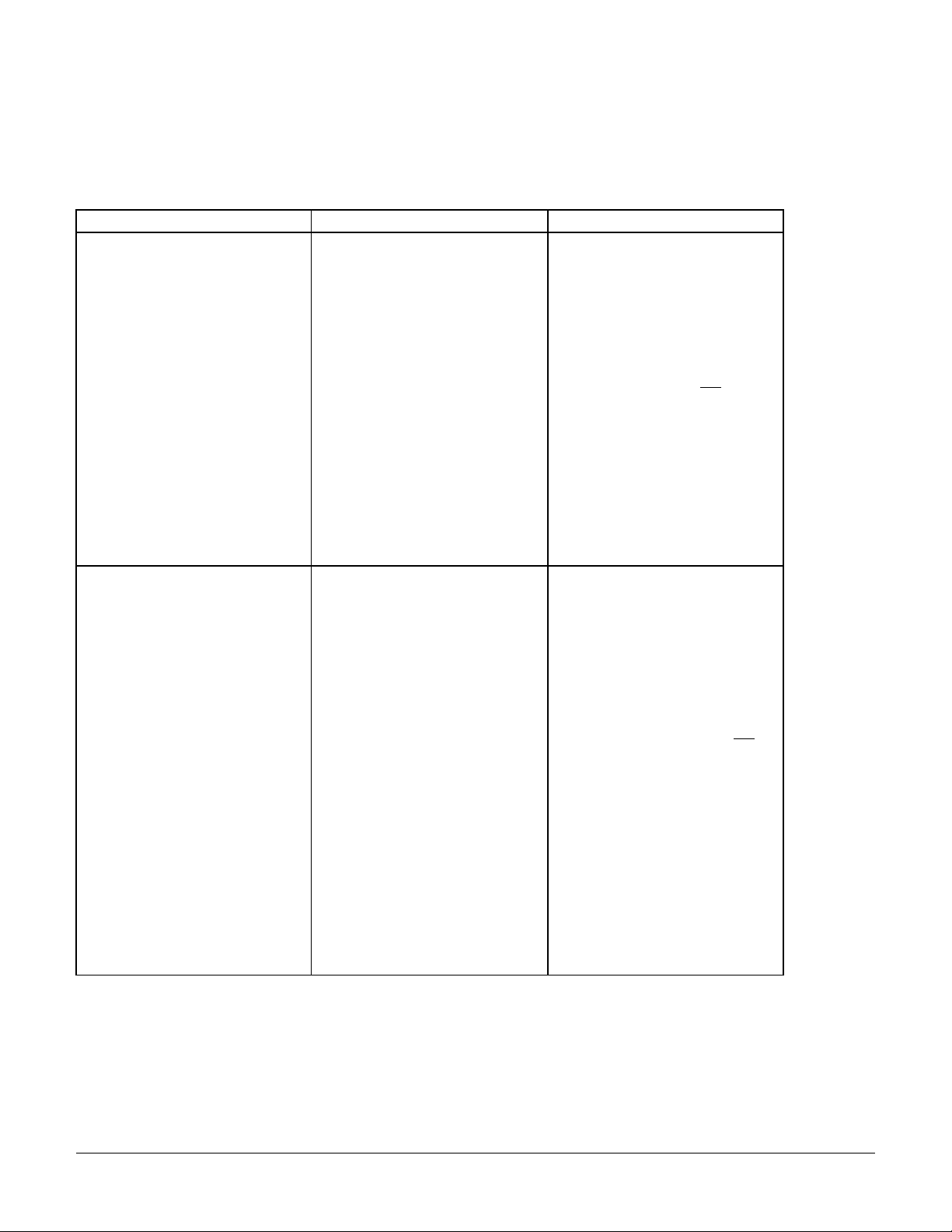

System Controller And Controls: View From Behind Panel

Bactron Operations Manual 26

Page 27

______________________________________________________________________________

Solenoid

J:\0100000\100016EX.PLT

Bactron Operations Manual 27

Page 28

______________________________________________________________________________

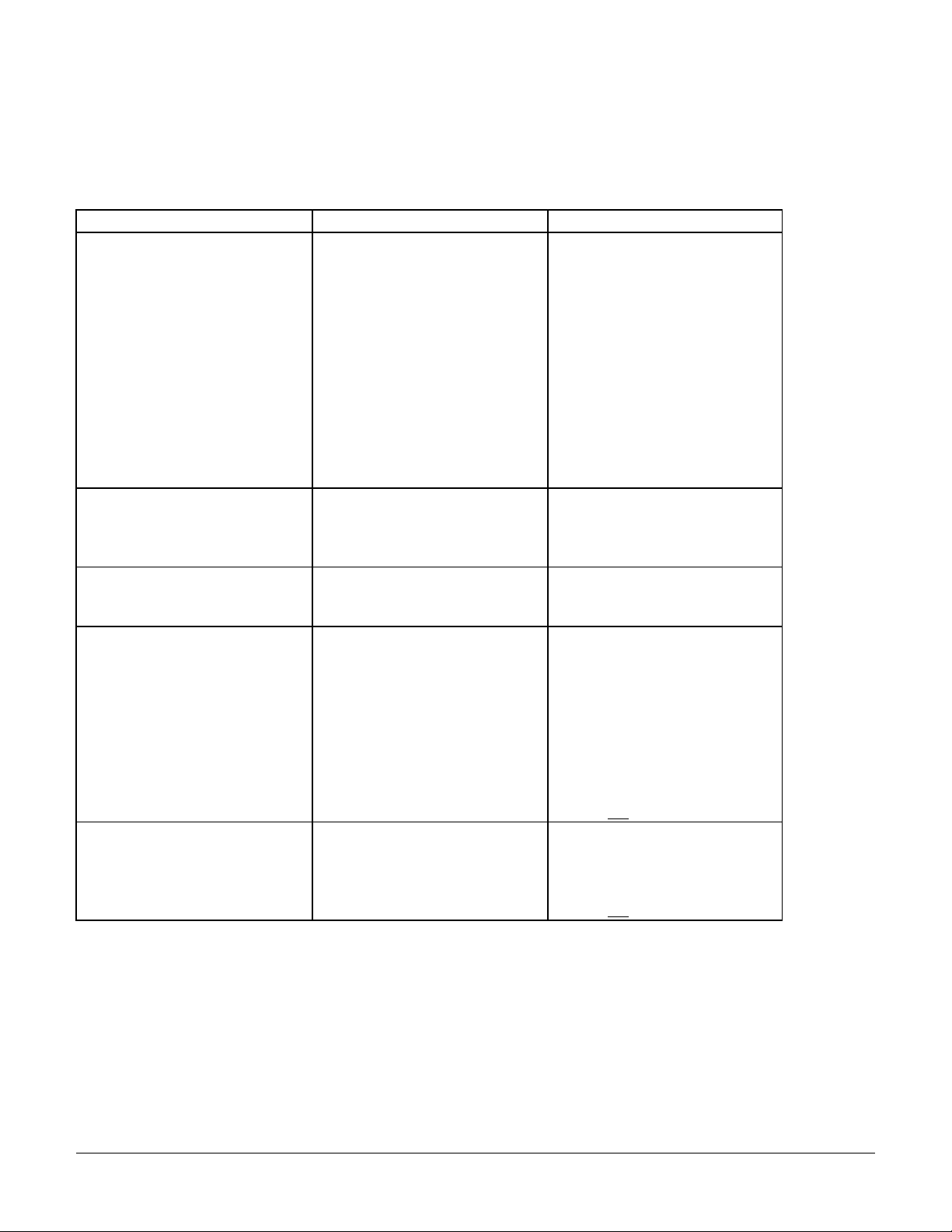

System Controller Indicator Guide

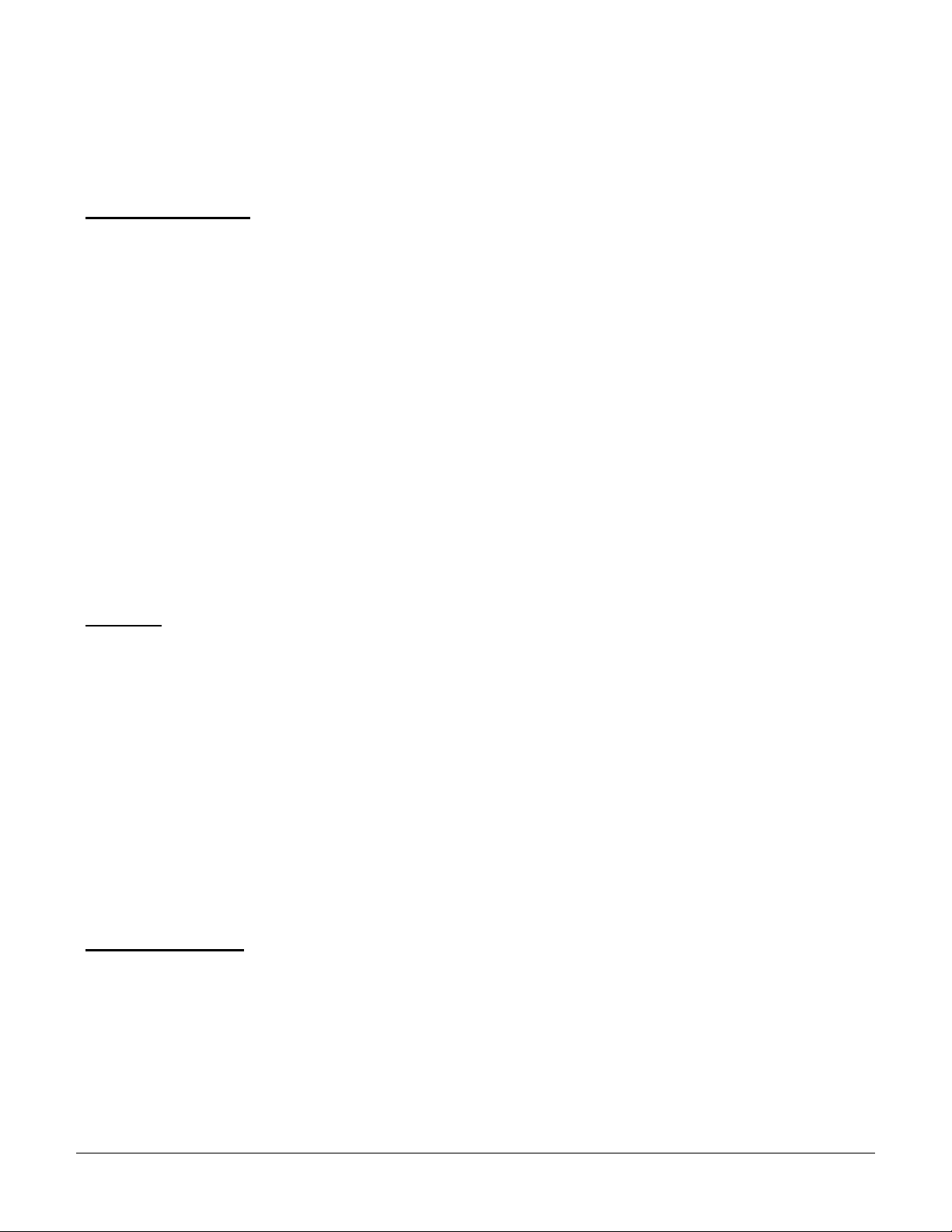

Function At Rest Start Vacuuming High Gassing Low Completed

Vacuum Vacuum

No action. Start Vacuum on. Switch Gas on. Switch Airlock

Both doors button Vacuum Point Vacuum Point anaerobic

closed. pressed.* Going up. Reached going down Reached

Airlock Lights Lights Lights

aerobic. flashing Flashing flashing

Inputs

x0 Start Off On* Off Off Off Off Off

x1 Outer Door On On On On On On On

x2 Inner Door On On On On On On On

x3 High Vacuum On On On Off** On On On

x4 Low Vacuum On On to Off Off Off Off On On

Output

y0 Vacuum Solenoid Off On On On to Off Off Off to On Off

y1 Gas (AMG) Solenoid Off Off Off Off to On

(1)

y2 Anaerobic Light Off Flashing Flashing Flashing Flashing Flashing On

y3 Aerobic Light On Flashing Flashing Flashing Flashing Flashing Off

y4 Door Light On On On On On On On

y5 Nitrogen** Off Off Off Off to On

(2)

*Input 0 is only when the start button is pushed

** Input 3 comes on only for a short moment

(1) Gas comes on for the last cycle only.

(2) Nitrogen comes on for the first two cycles.

On

(1)

On

(2)

On to Off

(1)

On to Off

(2)

Off

Off

Bactron Operations Manual 28

Page 29

______________________________________________________________________________

CAUTION: Extreme caution must be exercised any time access is made into areas housing

electrical components. Repair, replacement or adjustment of components in these areas

must only be done by qualified technicians familiar with electrical circuitry and the

operation of the anaerobic chamber.

ATTENTION: Des Précautions extrèmes sont requises à chaque fois que vous accédez à

des endroits qui abritent les composantes électriques. La réparation, le remplacement oi

ìajustement de composanted dans ces endroits ne doivent être effectués que par un

technicien qualifié familier avec les circuits électriques et ì opération des étuves

anaérobiques.

21.0 Troubleshooting

General Troubleshooting Guide

I. GAS CONSUMPTION

Problem Possible Cause Solution

CHAMBER GASSING A. Armport door not sealing.

light comes on every

five (5) minutes or less

B. Leak in seams.

panel with leak detector.

C. Manometer leak, indicated

by very large leak out

manometer hole. ( Confirm

with soap solution)

D. Oxygen present-hydrogen

being consumed by

combing with oxygen.

CHAMBER GASSING A. Inner door gasket not

light comes on more sealing-check with leak

often with the outer door detector.

open than with it

closed

A. Tighten knob until it

"grabs", Check for worn

O-rings.

B. Check front plexiglass

Call for service.

C. Seal inner tube to

block, and block to

mounting plate with

solvent cement.

D. No action necessary.

A. Check for worn gasket.

Bactron Operations Manual 29

Page 30

______________________________________________________________________________

General Troubleshooting Guide Continued

I. Gas Consumption

Problem Possible Cause Solution

Chamber pressure A. Chamber pressure A. Tap switch to jar

Increase, Manometer sensor switch stuck in contacts loose, then

Bubbles, CHAMBER "on" position. replace switch.

GASSING light on.

B. Pressure set too B. Turn adjustment

high. Adjust pressure screw counter sensor. See diagram clockwise to

page 25. decrease pressure.

Excessive gas usage - A. Foot pedal leaking. A. Disassemble and clean

no chamber leaks GAS valve or replace.

B. Gas regulator/gas B. Check for and repair

input connections any leaks. Check

leaking. regulator for 10 psi

C. Leak in supply line. C. Check all gas lines

Chamber pressure increases, A. Chamber gassing A. Disassemble and clean

Manometer bubbles. Solenoid leaking, inlet or replace solenoid valve

CHAMBER GASSING gas pressure normal. if necessary. See

light off. Pinch hose to chamber Diagram pg. 26.

to see that bubbling

stops.

B. Chamber gassing B. Set inlet gas pressure

solenoid leaking, inlet to 10 psi.

gas pressure too high.

C. Chamber gassing C. See Figure 9, pg. 9.

solenoid hosed

incorrectly.

D. Air Lock gas solenoid D. Disassemble and clean

leaks. Pinch hose to or replace solenoid

module, see if it stops. valve. See pg. 26.

E. Incubator temperature E. No action necessary.

increase on startup.

maximum output.

for leaks.

Bactron Operations Manual 30

Page 31

______________________________________________________________________________

General Troubleshooting Guide Continued

Problem Possible Cause Solution

Indicator strips are A. Low chamber pressure. A. Adjust chamber pressure

Activated , I.e. - turn color. sensor by turning

clockwise to increase.

See diagram pg. 25.

B. Catalyst inactive. B1. Use freshly heated

catalyst, flush chamber

with approx. 50 to 100

psig of gas depending

on how long chamber

has been aerobic and

size of chamber.

B2. Check to see that gas

makes catalyst hot. If

not, heat to 200 C and

blow gas mix through

to remove sulfide layer.

C. Circulating blower not C. Replace fan.

functioning.

D. Air lock not evacuating D. Turn High side switch

to high enough vacuum clockwise to increase.

( 17 - 18 inches Hg ). See diagram on page 25.

E. Outer Air Lock door not E. Check for damaged

sealing properly. gasket - replace if

necessary.

F. User did not perform F. Check technique of all

sleeve technique chamber users.

properly upon entering

chamber.

G. Gas tank mixture G1. Check for very low

contains an insufficient or empty tank.

concentration of

Hydrogen. G2. Check label for at

least 5% Hydrogen.

II. AEROBIC CHAMBER CONDITIONS

Bactron Operations Manual 31

Page 32

______________________________________________________________________________

General Troubleshooting Guide Continued

Problem Possible Cause Solution

Air Lock does not hold A. Split gasket inner & A. Check gasket. If split,

Vacuum. outer door. replace.

B. Inlet fitting to module B. Tighten/reseal with

not sealed. teflon tape if necessary.

C. Air Lock solenoids hosed C. See diagram pg. 26.

incorrectly.

D. Vacuum solenoid leaking D. Disassemble and clean

Pinch hose to module solenoid - replace if

and see if leak stops. necessary. WD40 can

be used to clean

solenoid.

E. Defective vacuum gauge. E. Replace gauge.

Automatic cycle will not start. A. Input/output terminal A. Press down on the

buss is not seated terminal buss so that it

correctly. snaps into place.

NOTE: Power should be

turned off.

B. User pushed start switch B. Push start switch once

& held inadvertently held then release. See pg. 19.

down. Thus aborting

Auto Cycle.

C. Make sure both doors C. Adjust location of the

are closed. Door sensors door sensor so that

not making contact-check DOORS light is on

that DOORS light is ON. when both doors are

If not, check programmable closed.

Controller input display IN

0001 (outer door) and IN

0002 (inner door) should

be on.

III. AIR LOCK

Bactron Operations Manual 32

Page 33

______________________________________________________________________________

General Troubleshooting Guide Continued

Problem Possible Cause

Automatic cycle will not D. Start button inoperative - D. Replace start button.

start. (Continued) check input display - IN

0000 should be on when

start button is pushed,

OFF when not.

E. No power to controller - E1. Check for 24 volt DC

check power light on out of power supply.

Controller.

E2. Check for continuity

between power supply

and controller.

Chamber pressure goes A. Inner door gasket not A. Replace door gasket

down ( Manometer level rises) Making proper seal. if necessary

when cycle is started.

Cycle only goes through A. System Controller A. Replace System

two cycles. Malfunction. Controller.

Switch will not go from A. Insufficient vacuum A. Adjust switch on VAC

Vacuum to Gas. supply. pump to allow higher

vacuum before shut off,

around 20 inches Hg.

B. High vacuum set point B. Turn High side switch

too high, it should be counterclockwise to

around 17 - 18 inches Hg. decrease. See diagram

pg. 25.

Doors difficult to open A. Low vacuum set point A. Turn Low side switch

upon completion of cycle. too high. Counter clockwise to

Decrease. See diagram

pg. 25.

III. AIR LOCK

Solution

Bactron Operations Manual 33

Page 34

______________________________________________________________________________

General Troubleshooting Guide Continued

IV. INCUBATOR

Problem Possible Cause Solution

Steady digital readout A. Temperature Controller A. Turn to pg. 13 to follow

Matches set point, but out of calibration. Complete Temperature

actual temperature does not. Controller instruction.

B. Incubator door open. B. Close incubator door

and allow incubator to

stabilize.

Digital readout and actual A. Incubator fan not A. Replace fan, Model

Temperature continue to functioning. Model Bactron IV.

Increase past set point. Bactron IV, See drawing

pg. 44.

B. Output relay stuck - B. Replace Temperature

Check to see if Controller.

" Incubator Heating"

Indicator light stays on

while temperature is

Increasing.

C. Incubator door open. C. Close incubator door

and allow incubator to

stabilize.

Audible alarm sounds. A. Temperature has risen A. Determine cause of

Beyond the set range temperature increase

for the High Limit Safety. from prior section and

take appropriate action.

Call for service.

Bactron Operations Manual 34

Page 35

______________________________________________________________________________

General Troubleshooting Guide Continued

V. VACUUM PUMP

Problem Possible Cause Solution

Pump continually turns on A. Leaking check valve - A. Disassemble check valve

off in rapid succession. Normally due to debris clean off any debris from

Ideally, pump should remain Between poppet and O - poppet, O - ring,

off for 30 minutes or more ring seal. reassemble.

Before coming on again.

B. Vacuum foot pedal valve B. Remove hose barbs

may be leaking. Check from valve - there may

to see if pinching its hose be some debris holding

Stops problem. valve open. Replace

valve if necessary.

C. Leak in pump plumbing - C. Tighten any loose

pipe fitting switch, hose, fittings, check hoses

etc. for cuts, holes, leaks

around hose barbs.

D. Air Lock vacuum D1. Disassemble solenoid,

Solenoid leaking. clean plunger, O - ring

spring, etc. and

reassemble.

D2. Make sure vacuum

hose from pump is

not pinched.

Vacuum motor does A. Broken vanes in A. Remove the end of

turn on. Pumping section ( the the pump and replace

end of pump with filter any broken vanes.

jars. )

B. Electrical problem with B. Replace pump.

Motor.

C. Check pump power C. Check circuit breaker

Supply. on back of chamber.

Pump runs continuously A. Set point on pump A. See pg. 25, " Setting

when there is no demand Vacuum switch set too vacuum High switch".

for vacuum. high.

Bactron Operations Manual 35

Page 36

______________________________________________________________________________

General Troubleshooting Guide Continued

VI. MISCELLANEOUS

Problem Possible Cause Solution

Excessive moisture A. Thermoelectric A. Replace fan.

buildup in chamber. condensate controller

fan is not operating.

B. Ambient room B1. Maintain room

temperature too low. temperature a bit

higher.

B2. Cover chamber with

a blanket overnight

as means of

installation.

C. Air conditioner unit C. Relocate chamber,

directly above

chamber.

conditioning duct.

D. Thermoelectric D. Empty thermoelectric

condensate controller condesate controller

not emptied regularly. container daily.

as means of

Loop sterilizer does A. Loop covered with A. Use a new loop.

not work. oxidized layer which

insulates from power

supply.

redirect the air

installation.

Bactron Operations Manual 36

Page 37

______________________________________________________________________________

General Troubleshooting Guide Continued

VI. MISCELLANEOUS

Problem Possible Cause Solution

Loop sterilizer does B. Sterilizer unit not getting B1. See that the unit is

not work. ( Continued) power. Plugged into internal

Outlet.

B2. See that the internal

Outlet is getting power.

B3. Replace.

Bactron Operations Manual 37

Page 38

______________________________________________________________________________

22.0 BACTRON OPERATION TIPS

Keeping the Bactron

Chamber Anaerobic: The Bactron chamber will be anaerobic if it has the following three

things: Hydrogen, Positive Pressure, and an Active Catalyst. See

Instruction Manual drawing on page 24.

User should place oxygen indicators inside the chamber or an oxygen

meter to ensure that they have an anaerobic environment. One

indicator should be placed inside the working chamber and another in

the incubator. The indicators turn color in the presence of oxygen,

and are available through distributors and supply companies.

If the indicators appear “very blue” purge the chamber with 100 PSI

and wait for 30 minutes. The open a new indicator. If the new

indicator is “white” in color your chamber in anaerobic. The greater

the color of the indicator, the more gas to purge through the chamber

and the longer users should wait before re-checking system.

Gas Source: Sheldon Manufacturing, Inc. recommends an AMG, Anaerobic Mixed

Gas, mixture of 5% CO2, 5% Hydrogen, and 90% Nitrogen for

anaerobic applications.

This mixture is available marked “NON-FLAMMABLE”.

Two national sources of AMG gas are AIRCO and Air Products.

How much gas will a

Bactron chamber use?: Gas usage is dependent upon two things; the number of times a user

enters their chamber daily and operating technique.

Our product literature states the Air Lock uses approximately 96 liters

of gas and the sleeve system uses approximately 3 liters of gas. A

standard tank contains 2,200 PSI of gas. During chamber installation,

300 PSI of gas is used. There is about 70-80 Air Lock cycle uses per

tank of gas.

Methods to

Conserve Gas:

Users can utilize the Air Lock as a holding station. As samples are

received they can be stored in an anaerobic environment by placing

them in the Air Lock and activating either the automatic or manual Air

Lock cycle.

Bactron Operations Manual 38

Page 39

______________________________________________________________________________

1. Users should evaluate and try to limit the number of times the Air Lock

is opened. For example, placing samples in the Air Lock once in the

morning and once in the afternoon as opposed to four times a day is

desirable.

2. Gas is also conserved by bringing samples in through the sleeve

system. Easy samples to transport through the sleeves are transport

tubes as well as plates that are sealed.

3. Placing an object in the Air Lock will reduce the amount of cubic area

therefore reducing the amount of atmosphere exchanged and gas

utilized.

4. Good sleeve system technique. During the first vacuum cycle, remove

all the atmosphere from the sleeve. Users should be able to see the

outline of their fingers. Next, bring enough gas in to the sleeve (by

pressing the GAS foot pedal) as to eliminate the definition of the

fingers or when the sleeve is nor clinging to the arm.

Users should not “balloon” the sleeve out when flushing with gas. This

action will waste gas.

5. The bubbling of the manometer and the activation of the “chamber

gassing” indicator light on the control panel notifies the user of usage

will working in the chamber.

When a user is in the “working Area” they should be aware of the

effects their movements have on gas consumption.

Gas consumption can be reduced by balancing arm movements. For

example, when extending the right arm into the chamber, bring the left

arm close to the front of the chamber, thus balancing the pressure and

reducing gas displaced by area.

Aborting Auto-Cycle:

How much does

AMG gas cost?:

Sheldon recommends that customers get competitive bids on their gas

The automatic Air Lock can be aborted by pressing and holding the

“Auto Start/Reset” button for five (5) seconds. If a user forgets to place

a sample in the Air Lock the cycle can be aborted in order to eliminate

the unnecessary use of gas.

The price that a gas supplier charges is often determined by the

amount of the gas the customer uses. The price per tank will decrease

as the quantity ordered decreases.

to ensure that they are receiving the “best” market price.

Bactron Operations Manual 39

Page 40

______________________________________________________________________________

The average cost of AMG gas is $30.00 per tank, and $10.00 for

nitrogen in the United States. The cost range of AMG gas is between

$8.00 and $58.00 per tank.

Dual Gas Systems:

Refer to the Instruction Manual “Gas Connections” for installation

A dual gas system, the nitrogen gas is utilized in the first two flushes of

Therefore, in a dual gas system, less AMG gas is used. AMG gas is

Customers using a dual gas system need to have two regulators. An

Catalyst:

Customers need to place a reactivated catalyst in their chamber each

The catalyst can be tested to ensure it is activated by flowing

The catalyst can be “cleaned” by heating to 200° Celsius, then flowing

Positive Pressure:

The manometer provides users with a visual indication that they have

Two catalyst cartridges containing palladium pellets are provided with

The Bactron product line comes standard with the capability to operate

a chamber with a single gas or a dual gas system. This is an exclusive

feature that provides customer flexibility.

details.

the automatic cycle of the Air Lock. The third and final flush is AMG

gas. The sleeve system always utilizes AMG gas.

more expensive than nitrogen, and the users overall gas expense is

reduced.

AMG regulator is supplied with the Bactron Chamber. A nitrogen

regulator is listed in the Instruction Manual accessory parts list.

the Bactron Chamber. The catalyst must be active in order to ensure

an anaerobic environment.

day the chamber is used. The catalyst can be reactivated by heating

for a minimum of 1-1/2 to 2 hours at 160° Celsius.

anaerobic gas over the pellets. If the pellets become warm or hot, they

are working properly and are ready for use in the chamber.

the anaerobic gas mixture over the catalyst.

If the chamber is installed properly and is connected to a gas supply

the system will have positive pressure.

positive pressure. When the manometer bubbles, for example when a

user enters the chamber, it is releasing chamber atmosphere/pressure.

Bactron Operations Manual 40

Page 41

______________________________________________________________________________

Role of Condensate

Controller: The Condensate Controller is an exclusive Bactron feature of Sheldon

Manufacturing, Inc. Our competitors use desiccants. Desiccants are a

drying agent and often dry out samples.

The Condensate Controller ensures the following:

1. Eliminates condensation in the chamber.

2. Samples will not dry out.

3. Chamber will not fog.

The Condensate Controller system is located on the left side of the

chamber interior behind the catalyst cartridge. Excess moisture is

drained into a tube for easy removal.

Place a container i.e. a flask or beaker under the tube for collection.

Customers should empty the container routinely.

Chamber Checklist: It is recommended that customers review a checklist before they enter

the Bactron Chamber. The checklist serves as a reminder of supplies

and samples they need to bring into the unit.

Common items listed on a checklist are: re-activated catalyst, samples

and loops. The checklist can be placed on the front Plexiglass panel.

How to Determine if

A Chamber is Leaking: Users should note the level of their gas tank(s) on a routine basis. This

provides a way to monitor chamber gas consumption.

Users can perform the following check before they exit the chamber

through the sleeve system to ensure the chamber is closed properly.

Upon closing the arm port doors and before removing arms form the

sleeves, user should push on the sleeves. If the arm port doors are

not closed properly, the manometer will bubble.

Hand Held Leak

Detector: If a chamber leak is suspected use the hand held leak detector

provided to identify where the leak is located. The detector senses

hydra-carbons, in our case hydrogen.

Be aware that when using the leak detector, the manometer vent hole

on the back of the chamber will activate the detector. This is because

hydrogen is being release from the chamber through the manometer.

Bactron Operations Manual 41

Page 42

______________________________________________________________________________

To check the manometer for leaks, use a soap and water solution over

the manometer and observe for bubbles.

Amount of Water

Collected in the

Dehumidifier: The amount of water collected in the dehumidifier depends on the

Size of Sleeve Cuffs: It is critical that the sleeve cuffs seal around the user’s arm during

The location that the cuffs seal on the user’s arm is determined by

The size of the cuffs that come standard with the Bactron Chamber is

Replacement of Cuffs: When and how often the cuffs on the sleeve need to be replaced

Customers should watch for small holes that can appear where the

Electrical

Model Volts Amps VA Cycles

BacI 120 8 1100 50/60 hz

240 4 1100 50/60 hz

BacII 120 8 1100 50/60 hz

240 4 1100 50/60 hz

BacIV 120 11 1350 50/60 hz

240 6 1350 50/60 hz

number and types of samples in the chamber. The typical amount

collected is around 50cc each day of chamber use.

chamber operation to ensure the desired anaerobic environment.

individual preference.

medium, size 8 glove. Other sizes are available; large size 9, and

small size 6 ½.

depends on customer care and technique. Typically the cuffs are

replaced about every three months.

cuffs are placed on the “ring cuff”. If holes are present the cuffs should

be replaced to avoid gas leak. Watches and jewelry can damage the

cuffs and are not recommended to be worn during chamber use.

Bactron Operations Manual 42

Page 43

______________________________________________________________________________

23.0 Wiring Diagram

Bactron Operations Manual 43

Page 44

______________________________________________________________________________

Bactron Operations Manual 44

Page 45

______________________________________________________________________________

Bactron Operations Manual 45

Page 46

______________________________________________________________________________

Bactron Operations Manual 46

Page 47

______________________________________________________________________________

Bactron Operations Manual 47

Page 48

______________________________________________________________________________

24.0 BACTRON PARTS LIST

DESCRIPTION PART NUMBER PART NUMBER QUANTITY

115 VOLT 220 VOLT

Gasket 9x9 Soft Lt. Blue (Bac I)

Gasket 12x12 Soft Lt. Blue (Bac II,

IV)

3450506 3450506 1

3450507 3450507 1

Power Cord 1800516 101990 1

Main Circuit Breaker 1100505 1100505 1

Main Switch 103351 103351 1

Incubator Safety Alarm 250501 250502 1

Incubator Safety Thermostat 1750500 1750500 1

Incubator Safety Indicator 200020 200020 1

Heating Element

Bactron I, II 2350502 2350502 2

Bactron IV 890081 1

Bacrton IV 890081 2

Vacuum Pump Ckt Bkr 1100505 1100505 1

Incubator Fan (Bac IV) 210002 210001 1

Vacuum Pump Outlet 100020 101483 1

Door Sensors 103208 103208 1

Start Switch 101970 101970 1

Vacuum Control Switch 7850502 7850502 3

System Control Switch 103207 103207 1

Gas/Vacuum Switch X1000411 X1000411 1

Gas 2 Solenoid Valve 8600528 8600529 1

Door Indicator 200020 200020 1

Aerobic Indicator 200020 200020 1

Anaerobic Indicator 200020 200020 1

Gas Indicator 200020 200020 1

Vacuum Indicator 200020 200020 1

Gas 1 Solenoid 8600528 8600529 1

Chamber Gas Solenoid 8600528 8600529 1

Chamber Gas Indicator 200020 200020 1

Vacuum Solenoid 8600509 8600508 1

Thermoelectric

Condesensate Controller 1070502 1070502 1

Cooling Fan X1000300 X1000300 1

Chamber Pressure Switch 7850508 7850508 1

Bacloop / Light Box Switch X1000124 X1000124 1EA

Bacloop / Light Box Cord 100014 101990 1EA

Bacloop / Light Box Breaker 1100505 1100505 1EA

Light Fixture X1000292 X1000751 1

Bacloop Pilot Light 200020 200020 1

Bacloop Transformer 103352 103352 1

Bactron Operations Manual 48

Page 49

______________________________________________________________________________

25.0 Loop Sterilizer

Directions For Use

1. Touch the end of in inoculator loop or needle to the

front and rear shorting posts as shown.

2. As soon as the inoculator needle or loop glows red,

remove it from the contact with the shorting bars.

3. Allow the needle or loop to cool before putting into use

or setting aside.

Bactron Operations Manual 49

Loading...

Loading...