Page 1

Installation and

Operation Manual

BACTRON300, BACTRON600, BACTRON900

Previously Designated:

BACTRONII, BACTRONIV, BACTRONIV-900

BACTRON® 110 – 120 Volts

Page 2

BACTRON Anaerobic Workstation 110 - 120 Volts

Installation and Operation Manual

Part number (Manual): 4861700-1

Revision: August 27, 2014

Pictured on Cover: BACTRON900 (BACTRONIV-900)

BACTRON600 (BACTRONIV)

BACTRON300 (BACTRONII)

These units are TÜV CUE listed as Climactic Chambers (Anaerobic Chambers) for professional,

industrial, or educational use where the preparation or testing of materials is done at approximately

atmospheric pressure and no flammable, volatile, or combustible materials are being heated.

These units have been tested to the following requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010 + R:2009

UL 61010A-2-010:2002

UL 61010-1:2012

EN 61010-1:2010

EN 61010-2-010:2003

2 | P a g e

Page 3

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 5

General Safety Considerations ................................................................................................................. 5

Engineering Improvements ....................................................................................................................... 6

Contacting Assistance ............................................................................................................................... 6

RECEIVING YOUR BACTRON .................................................................................................................... 7

Inspecting the Shipment ............................................................................................................................ 7

Returning the Shipment ............................................................................................................................ 8

Recording Data Plate Information ............................................................................................................. 8

GRAPHIC SYMBOLS ................................................................................................................................... 9

INSTALLATION .......................................................................................................................................... 11

Ambient Conditions ................................................................................................................................. 11

Location ................................................................................................................................................... 11

UV Lighting .............................................................................................................................................. 11

High Altitude Locations ........................................................................................................................... 12

Power Source .......................................................................................................................................... 12

Lifting and Handling ................................................................................................................................ 13

Leveling ................................................................................................................................................... 13

Gas Source ............................................................................................................................................. 14

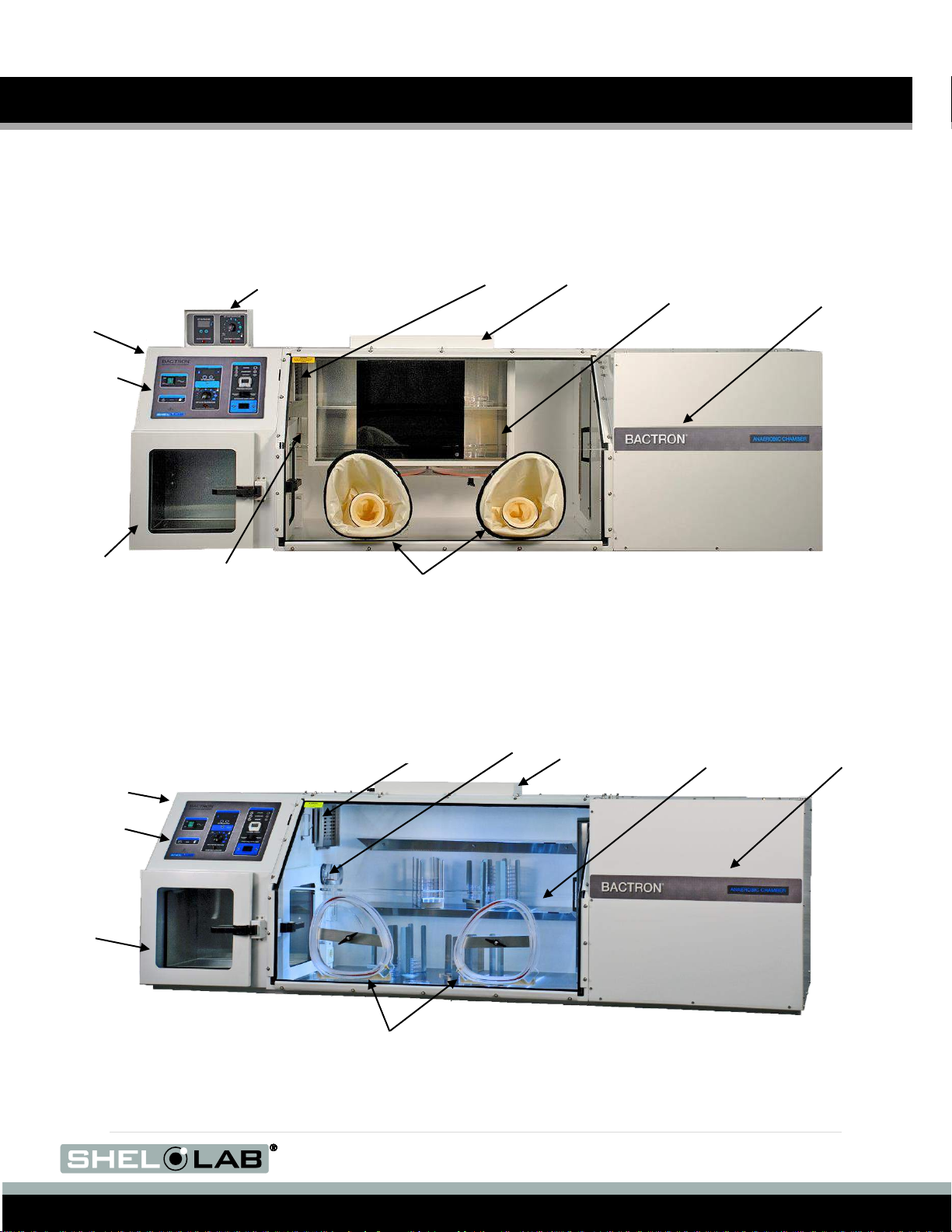

BACTRON900 Orientation ...................................................................................................................... 15

BACTRON600 Orientation ...................................................................................................................... 15

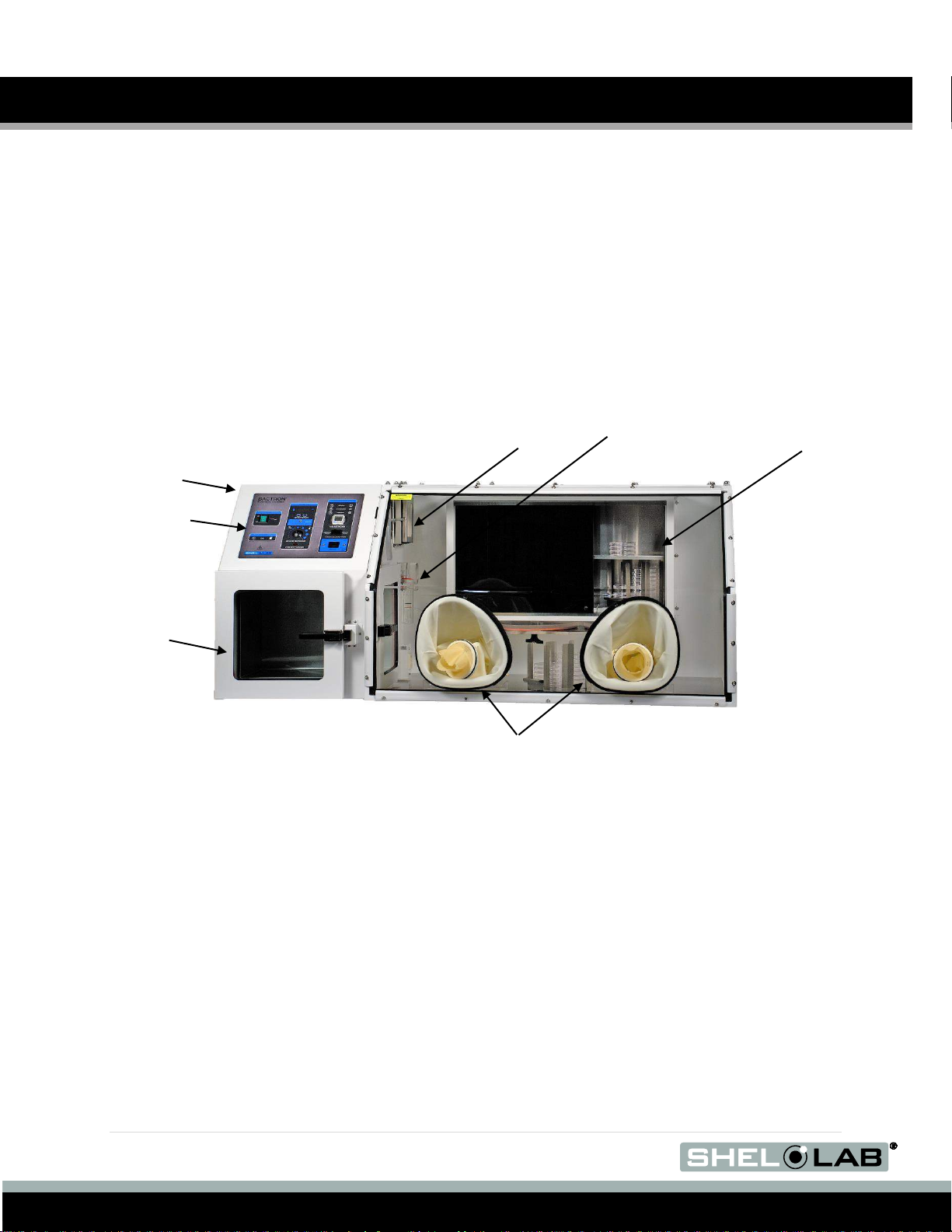

BACTRON300 Orientation ...................................................................................................................... 16

Workspace Chamber Orientation (All Units) ........................................................................................... 17

Pass Box Orientation .............................................................................................................................. 17

Cleaning .................................................................................................................................................. 18

CONTROL PANEL OVERVIEW ................................................................................................................. 19

OPERATION ............................................................................................................................................... 24

Theory of Operation and Major Component Functions ........................................................................... 24

Setting up the BACTRON ....................................................................................................................... 27

Set up the Gas Supply ............................................................................................................................ 29

Single Gas Connection ........................................................................................................................... 30

Dual Gas Connection .............................................................................................................................. 30

Connecting To an In-House Vacuum System ......................................................................................... 31

Connecting the Vacuum Pump ............................................................................................................... 31

Filling the Manometer .............................................................................................................................. 31

Installing the Arm Port Doors .................................................................................................................. 31

Connecting the Foot Pedal Assembly ..................................................................................................... 32

Shelving Installation BACTRON300 and BACTRON900 ........................................................................ 33

Power the BACTRON ............................................................................................................................. 33

Establishing an Anaerobic environment .................................................................................................. 34

Installing the Sleeve Assemblies ............................................................................................................. 36

Chamber Entry ........................................................................................................................................ 37

Moving in the Pressurized Chamber ....................................................................................................... 37

Verifying an Anaerobic Atmosphere........................................................................................................ 38

Troubleshooting The Presence of Oxygen ............................................................................................. 39

Exiting the Chamber ................................................................................................................................ 40

Setting the Incubator Temperature ......................................................................................................... 41

Setting the Over Temperature Limit ........................................................................................................ 41

Operating the Pass Box .......................................................................................................................... 42

Loading the Workstation ......................................................................................................................... 44

3 | P a g e

Page 4

Reactivating the Catalyst Cartridge......................................................................................................... 45

Calibrate the Incubator Temperature display .......................................................................................... 46

Gas Conservation Methods ..................................................................................................................... 47

Activated Charcoal Scrubber and Rejuvenation Cycle ........................................................................... 48

Attaching Equipment to the Chamber Accessory Outlets ....................................................................... 48

Deionized and Distilled Water ................................................................................................................. 49

Humidifying the Incubator ....................................................................................................................... 49

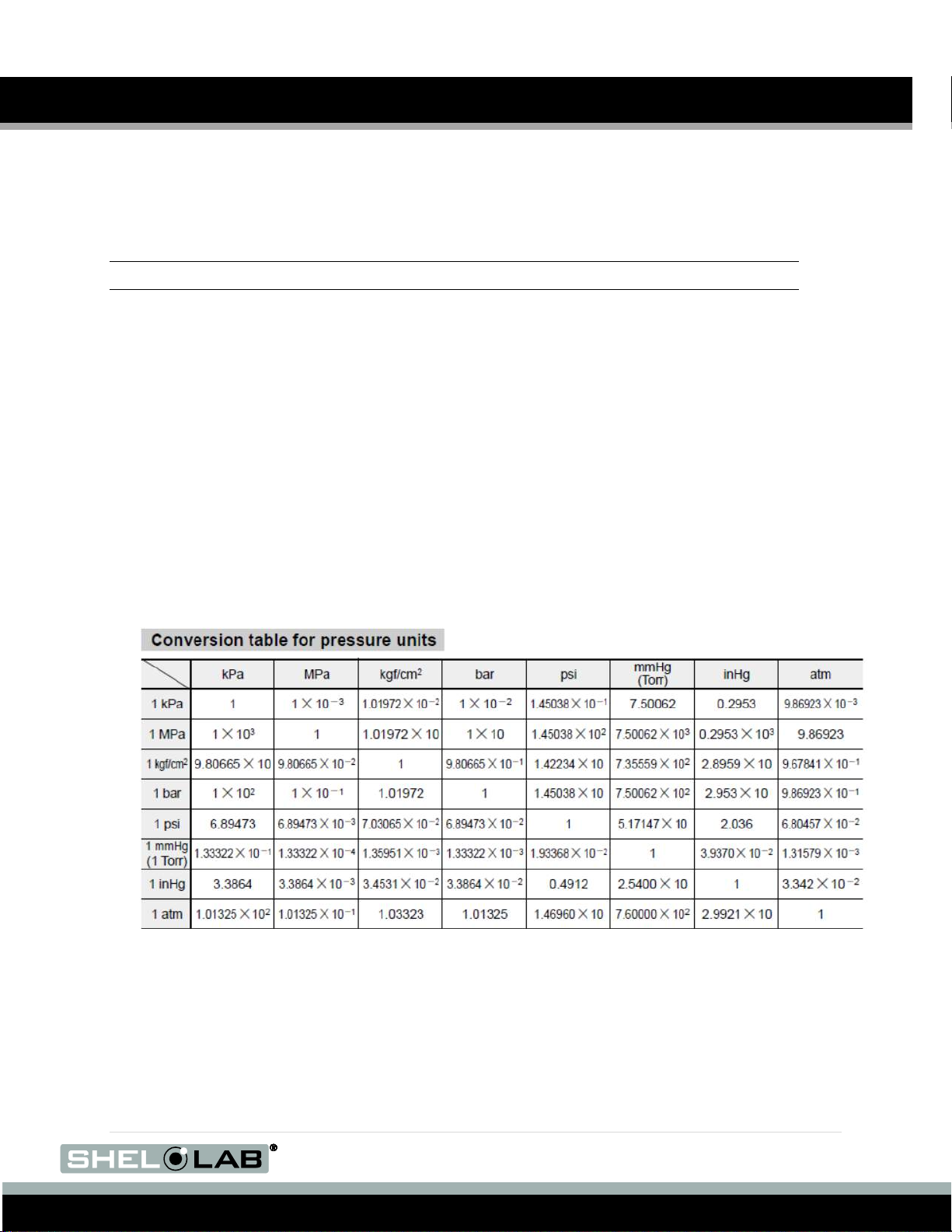

Pressure Unit Conversion ....................................................................................................................... 49

USER MAINTENANCE ............................................................................................................................... 50

Daily Maintenance ................................................................................................................................... 51

Normal Gas Consumption ....................................................................................................................... 51

Leak Diagnosis – Unit Full ...................................................................................................................... 52

Leak Check – Empty Unit ........................................................................................................................ 53

Door Gasket Maintenance and Usage .................................................................................................... 54

Sleeves Maintenance and Usage ........................................................................................................... 54

Replacing the Sleeve Cuffs ..................................................................................................................... 55

Cleaning .................................................................................................................................................. 56

Disinfecting .............................................................................................................................................. 57

Vacuum Pump Maintenance ................................................................................................................... 57

Maintaining the Acrylic Glass Panels ...................................................................................................... 58

Electrical Components ............................................................................................................................ 58

Condensation and the Dew Point ............................................................................................................ 59

UNIT SPECIFICATIONS ............................................................................................................................. 60

Weight ..................................................................................................................................................... 60

Workstation Dimensions ......................................................................................................................... 60

Stand Dimensions ................................................................................................................................... 61

Pass Box Interior Dimensions ................................................................................................................. 61

Pass Box Plate Capacity ......................................................................................................................... 61

Incubator Dimensions ............................................................................................................................. 61

Capacity .................................................................................................................................................. 62

Total Plate Capacity ................................................................................................................................ 63

Temperature ............................................................................................................................................ 63

Power ...................................................................................................................................................... 63

PARTS LIST ............................................................................................................................................... 64

Ordering Parts and Consumables ........................................................................................................... 65

ACCESORIES ............................................................................................................................................ 66

4 | P a g e

Page 5

INTRODUCTION

Thank you for purchasing a Shel Lab BACTRON Anaerobic Chamber Workstation. We know that in

today’s competitive marketplace, customers have many choices when it comes to constant

temperature equipment. We appreciate you choosing ours. Our continued reputation as a leading

laboratory product manufacturer rests with your satisfaction. Sheldon Manufacturing, Inc. stands

behind our products, and we will be there if you need us.

BACTRON workstations are intended for professional, industrial, and educational applications as

anaerobic workstations suitable for the cultivation of clinical bacteria. These units are not intended

for use at hazardous or household locations. Only use this equipment for its intended spectrum of

applications; any alterations or modifications void the warranty.

Before using the BACTRON read this entire manual carefully to understand how to install, operate,

and maintain the workstation in a safe manner. Keep this manual available for use by all

workstation operators. Ensure that all operators are given appropriate training prior to using the

BACTRON.

GENERAL SAFETY CONSIDERATIONS

Note: Failure to follow the guidelines and instructions in this manual may create a protection

impairment by disabling or interfering with the unit’s safety features. This can result in injury

or death.

Your BACTRON and its recommended accessories are designed and tested to meet strict safety

requirements. The workstation is built to connect to a wall power source using the specific power

cord type shipped with the unit.

For continued safe operation of your BACTRON, always follow basic safety precautions including:

Follow all local or regional ordinances in your area regarding the use of this unit. If you

have any questions about local regulations, please contact the appropriate agency.

Use only approved accessories. Do not modify system components. Any alterations or

modifications to your BACTRON can be dangerous and void your warranty.

Always plug the BACTRON power cord into an earth grounded electrical outlet that

conforms to national and local electrical codes. If the workstation is not grounded properly,

parts such as knobs and controls can conduct electricity and cause serious injury.

Avoid damaging the power cord. Do not bend it excessively, step on it, or place heavy

objects on it. A damaged cord can be a shock or fire hazard. Never use a power cord if it is

damaged.

Do not position the workstation in such a manner as to make it difficult to unplug the unit in

the event of an emergency.

Ensure that the vacuum line from the vacuum pump to the workstation is not kinked, and

that the pump is placed in a location with adequate ventilation to avoid overheating.

Do not attempt to move the workstation while in operation.

5 | P a g e

Page 6

INTRODUCTION (CONTINUED)

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes

and improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your Shel Lab dealer or

distributor for assistance.

CONTACTING ASSISTANCE

If you are unable to resolve a technical issue with the BACTRON, please contact Sheldon

Technical Support. Phone hours for Sheldon Technical Support are 6am – 4:30pm Pacific Coast

Time (west coast of the United States, UTC -8).

Please have the following information ready when calling or emailing Technical Support: the model

number and the serial number. These will be found on the unit’s data plate, which is located in the

workspace chamber next to the inner pass box door. See page 8.

EMAIL: tech@shellab.com PHONE: 1-800-322-4897 extension 4 or (503) 640-3000 FAX: (503)

640-1366

Sheldon Manufacturing INC.

P.O. Box 627

Cornelius, OR 97113

6 | P a g e

Page 7

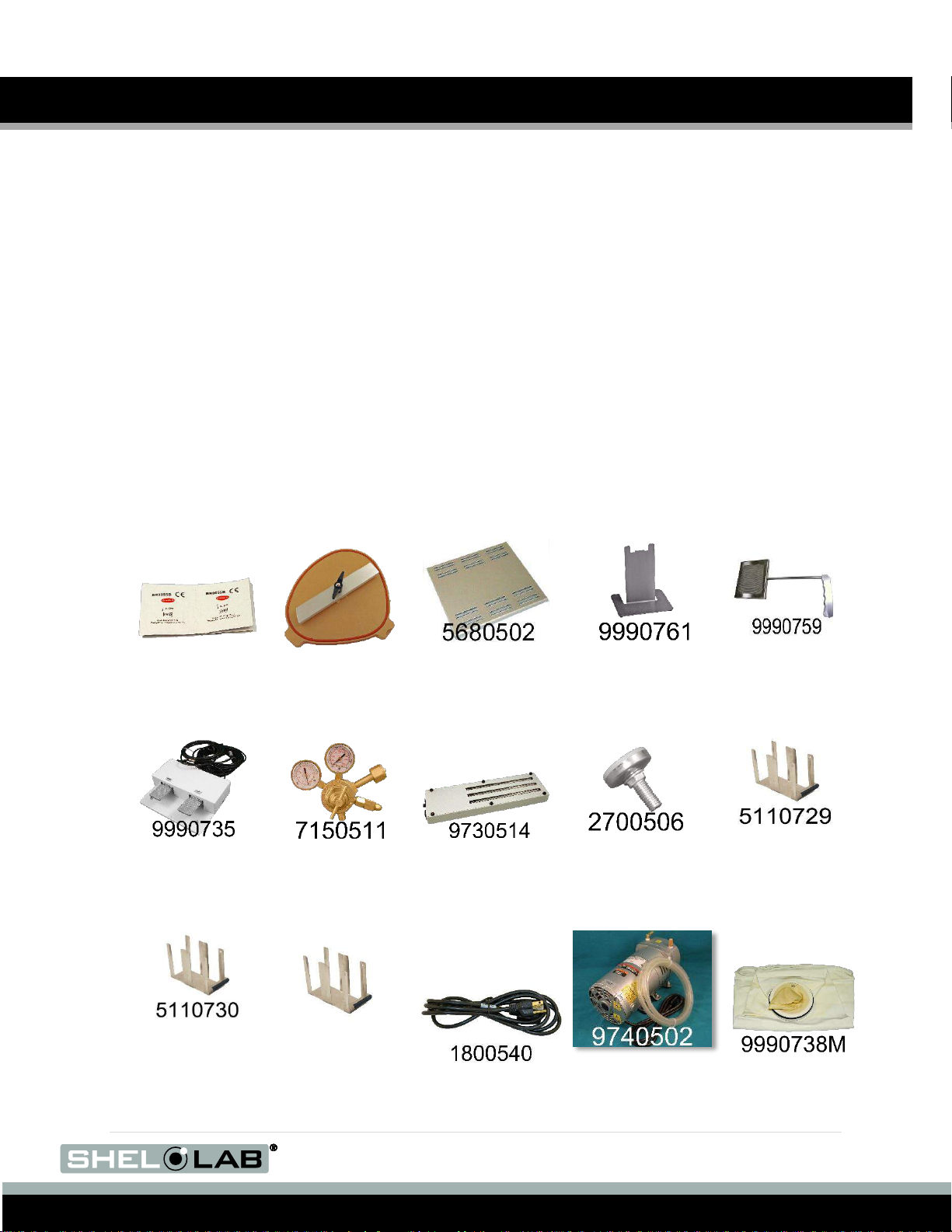

Anaerobic Indicator

Strips (5 packets)

Arm Port Door

Left and Right

PN 9900699 / PN 9900698

BACTRON300 / 900

Shelf Spacers

BACTRON600

Arm Port Door Stands

Catalyst Cartridges

(2)

Foot Pedal Unit

Gas Regulator, AMG

LED Lamp Unit

Leveling Feet

(4)

BACTRON300

Petrie Dish Rack

7 (2 x 11)

BACTRON600

Petrie Dish Rack

10 (2 x 13)

BACTRON900

Petrie Dish Racks

7 (2 x 11) 10 (2 x 13)

Power Cord 5-15

NEMA

Vacuum Pump

Sleeve Cuff

Assemblies

2 (Size 8 Medium)

RECEIVING YOUR BACTRON

Before leaving our factory, all BACTRONs are packaged in high-quality shipping materials to

provide protection from transportation-related damage. When the unit departs the factory, safe

delivery becomes the responsibility of the carrier. Damage sustained during transit is not covered

by the BACTRON’s warranty.

This makes it important that you inspect your BACTRON for concealed loss or damage to its

interior and exterior when receiving it. If you find any damage to the workstation, follow the carrier’s

procedure for claiming damage or loss.

INSPECTING THE SHIPMENT

Carefully inspect the shipping carton for damage. Report any damage to the carrier service that

delivered the BACTRON. If the carton is not damaged, open the carton and remove the contents.

The unit should come with an Installation and Operation Manual, warranty card, and a Certificate of

Compliance.

Verify that the correct number of components are included with the unit:

7 | P a g e

Page 8

Model Number

Serial Number

RECEIVING YOUR BACTRON (CONTINUED)

Carefully check all packaging before discarding. Save the shipping carton until you are certain that

the unit and its accessories function properly.

RETURNING THE SHIPMENT

If you must return the BACTRON for any reason, contact your Shel Lab service representative for a

return of material authorization (RMA). You must provide the unit’s data plate information for an

RMA. See Recording Data Plate Information below. Returns without RMAs will not be accepted.

BACTRONs that have been exposed to contaminants such as, pathogenic microorganisms or toxic

substances, are required to undergo a decontamination procedure prior to the issuance of an RMA

and shipping. Contact your service representative for details.

RECORDING DATA PLATE INFORMATION

Locate the data plate in the workspace chamber above the inner pass box door. The data plate

contains the BACTRON’s model number and serial number. Enter this information below for future

reference.

Date Plate Information

8 | P a g e

Page 9

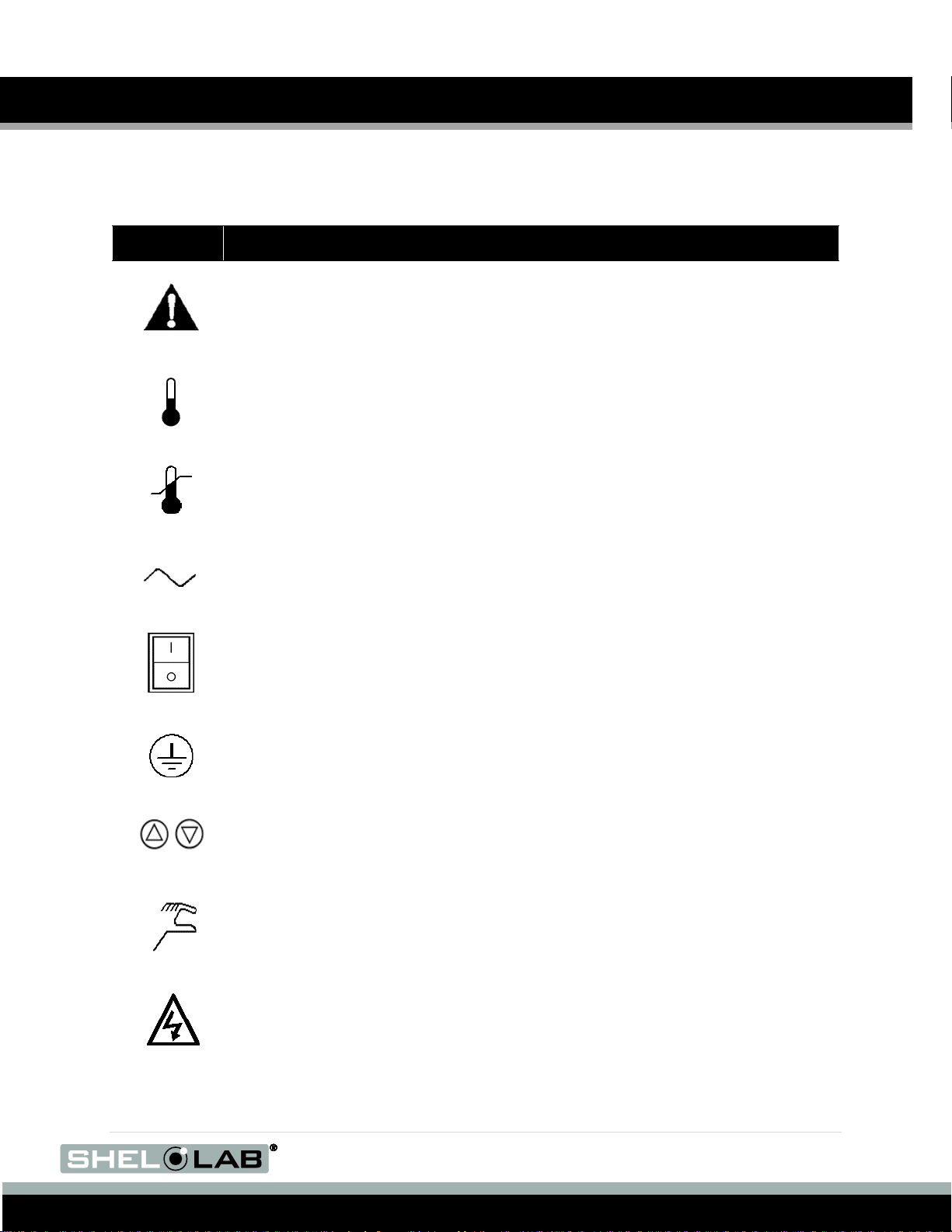

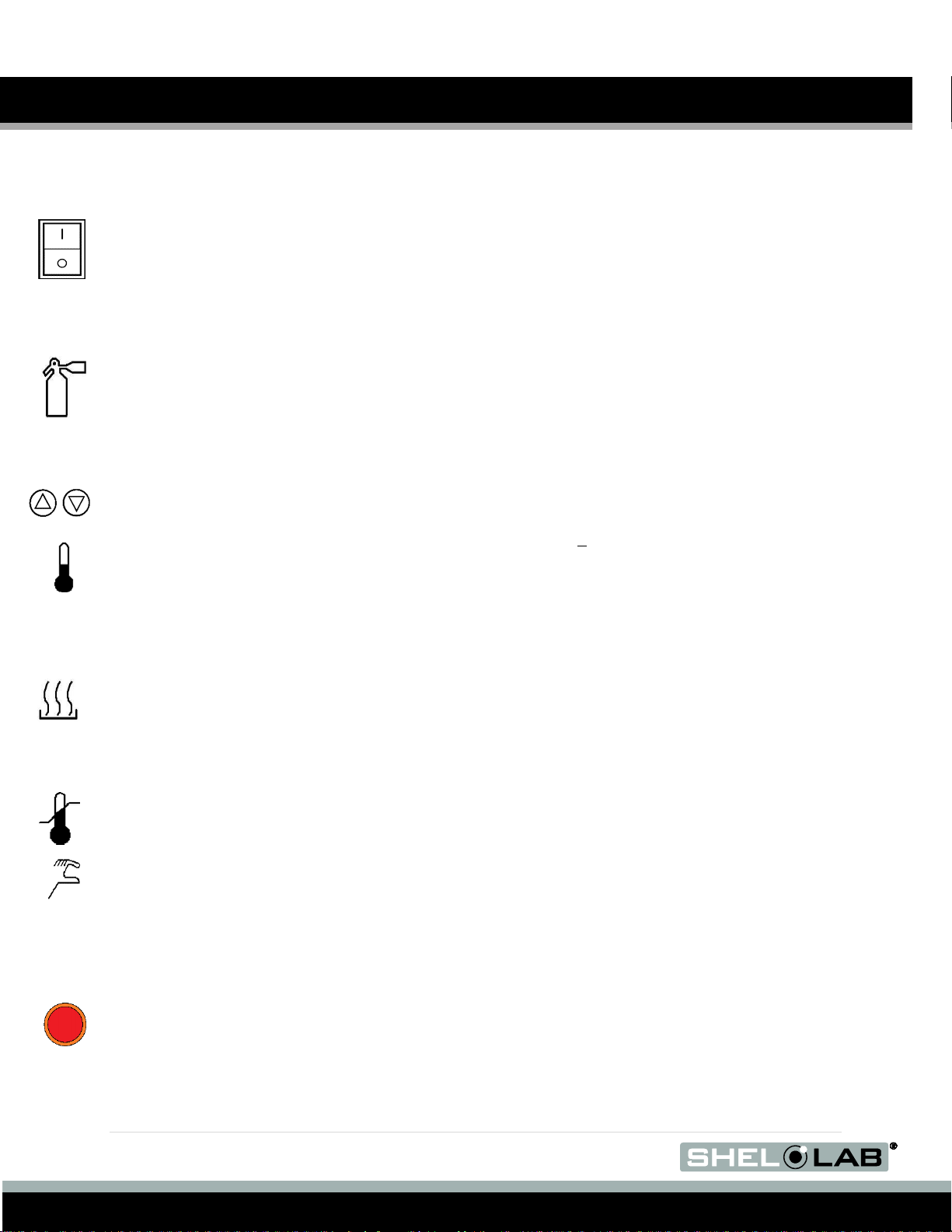

Symbol

Definition

Indicates that you should consult your service manual for further instructions.

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires.

Indicates Temperature

Repère température

Indicates the Over Temperature Limit system

Indique le système de dépassement de temperature

Indicates AC Power

Repère le courant alternatif

Indicates I/ON and O/OFF

I repère de la position MARCHE de l'interrupteur d'alimentation

O repère de la position ARRÊT de l'interrupteur d'alimentation

Indicates protective earth ground

Repère terre électrique

Indicates UP and DOWN respectively

Touches de déplacements respectifs vers le HAUT et le BA

Indicates Manually Adjustable

Indique un bouton réglable manuellement

Indicates Potential Shock Hazard

Signale danger électrique

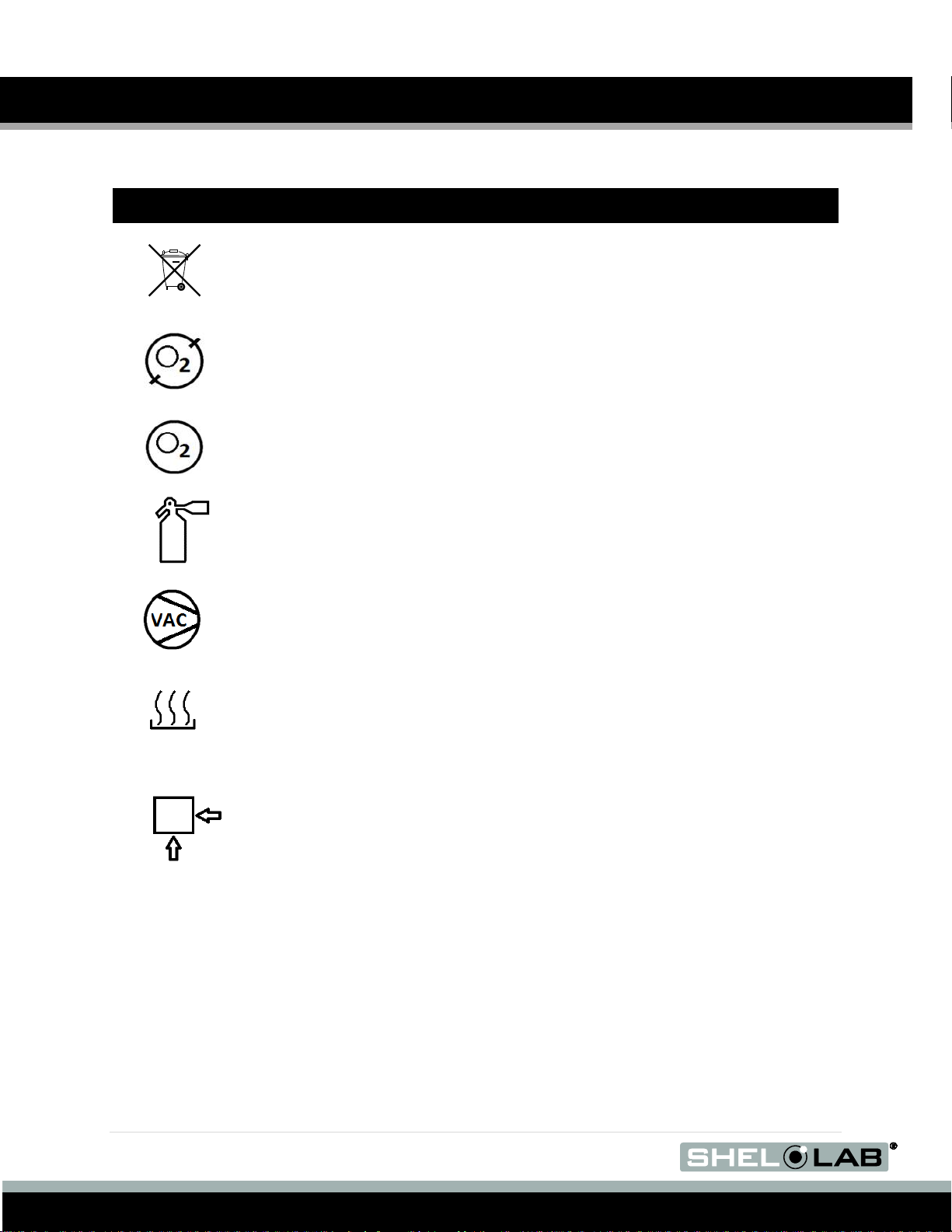

GRAPHIC SYMBOLS

The BACTRON is provided with multiple graphic symbols located on its exterior and interior

surfaces. The symbols identify hazards and the functions of the adjustable components, as well as

important notes found in the user manual.

9 | P a g e

Page 10

Symbol

Definition

WEEE Directive compliant logo

Indicates the unit should be recycled (Not disposed of in land-fill)

Indique l’appareil doit être recyclé (Ne pas jeter dans une décharge)

Indicates an anaerobic environment in the pass box

Indique un environnement anaérobie dans le sas

Indicates an aerobic environment in the pass box

Indique un environnement aérobie dans le sas

Indicates a injection of gas

Indique un flux de gazeux

Indicates the vacuum pump is evacuating the pass box

Indique la pompe à vide se vide dans le sas

Indicates the incubator heater is active

L'élément chauffant est la production de chaleur

Indicates the pass box doors are closed

Indique les portes du sas sont fermés

GRAPHIC SYMBOLS (CONTINUED)

10 | P a g e

Page 11

INSTALLATION

AMBIENT CONDITIONS

This workstation is intended for use indoors, at room temperatures between 15C and 30C (59F

and 86F), at no greater than 80% Relative Humidity (at 25C / 77F). Allow a minimum of 4

inches (10cm) between the workstation and walls or partitions, and 2 inches (5cm) of clearance

above the top of the workstation for unobstructed airflow.

Operating the unit outside of these conditions may adversely affect the unit’s temperature

range and stability.

For conditions outside of those listed above, please contact your distributor or Sheldon Sales to

explore other unit options suited to your laboratory or production environment.

LOCATION

When selecting a location to install your BACTRON, consider environmental conditions that can

affect the workstation’s temperature and atmospheric integrity:

Ovens, autoclaves, and any device that produces significant radiant heat

Heating and cooling ducts, or other sources of fast moving air currents

High-traffic areas

Direct sunlight

Note: Direct exposure to air conditioning vents or other sources of cold air can result in

condensation or fogging on the workstation’s acrylic glass panels, depending on humidity

and other ambient conditions. Prolonged exposure to cold air flows may adversely affect the

temperature performance of the incubator.

UV LIGHTING

Check if your laboratory or workspace contains sources of UV lighting. Sustained exposure to direct

sunlight, UVC or UV germicidal lighting around 254nm, will cause a rapid aging of BACTRON

acrylic glass panels and arm port sleeves. Periodic use of long-wave (365nm) UV hand lamps for

bacterial identification should not damage the acrylic glass. See the Maintaining the Acrylic Glass

Panels entry on page 58 for more details.

11 | P a g e

Page 12

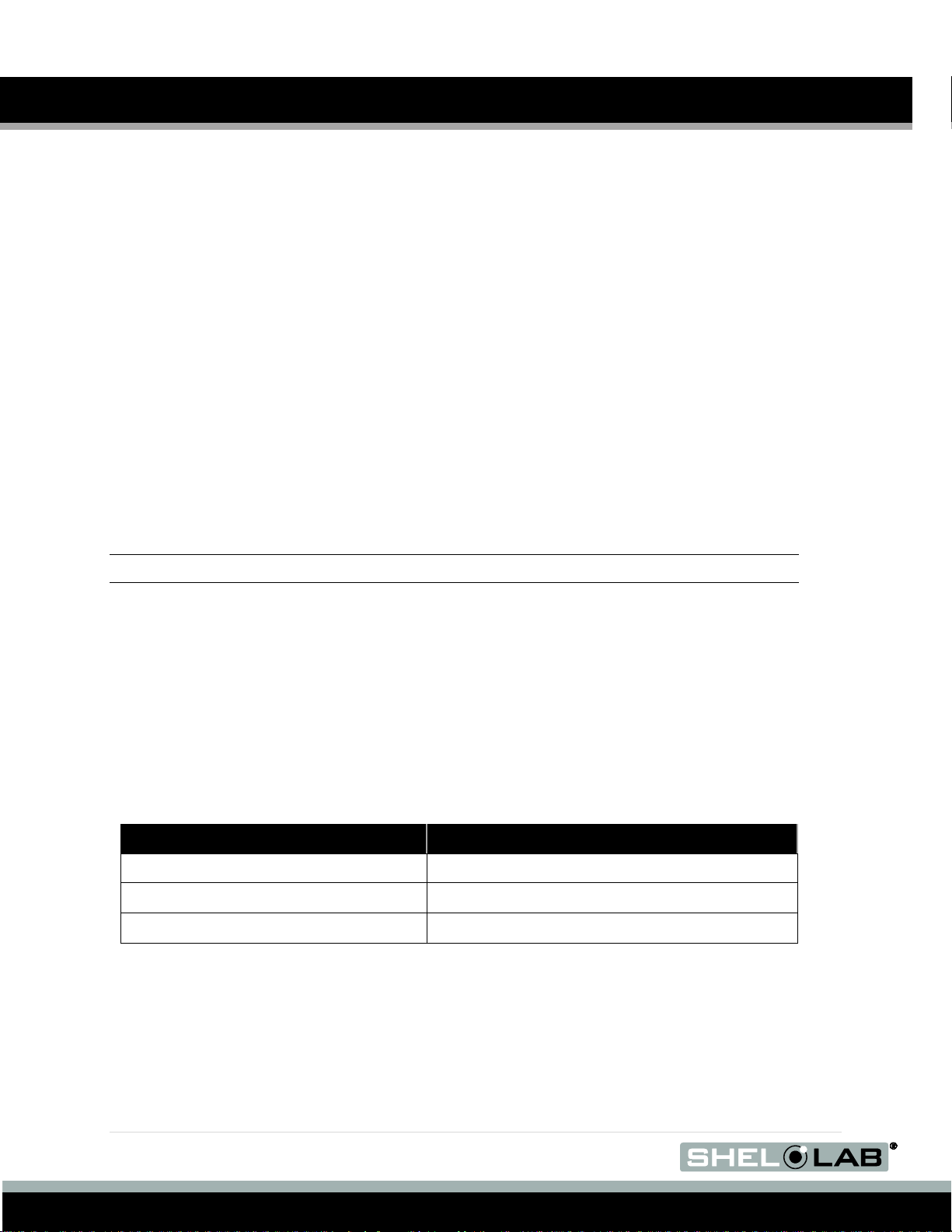

Model

Amperage

BACTRON300 (BACTRONII)

9 Amps

BACTRON600 (BACTRONIV)

11 Amps

BACTRON900 (BACTRONIV-900)

14 Amps

INSTALLATION (CONTINUED)

HIGH ALTITUDE LOCATIONS

BACTRON anaerobic workstations are equipped with two (2) digital vacuum controller - display

units that control the atmospheric cycling operations of the pass box and the vacuum pump line

pressure. These devices are calibrated at the factory at an altitude of 179 feet (54.5m) above sea

level, and read gauge pressure rather than absolute pressure. Altitudes around 6500 feet (2000m)

or higher may affect the operation of the vacuum system, depending on ambient conditions. If the

vacuum pump runs continuously or near continuously when installed at a high altitude location,

contact Sheldon Technical Support (see page 6) for assistance in adjusting the vacuum gauge

settings.

POWER SOURCE

Note: The electrical supply to the BACTRON must conform to all national and local electrical codes.

Always position the workstation so that the users have access to the power cord and can quickly

unplug it in the event of an emergency.

When choosing a location for the BACTRON check that the voltage and ampere requirements on

the workstation’s data plate match those of your wall source. The source must be an earth

grounded outlet The supplied voltage must not vary more than 10% from the data plate rating.

Damage to the workstation may result if supplied voltage varies more than 10%. Each

BACTRON workstation is provided with a 110 – 120VAC 8ft (2.5m) 5-15 NEMA power cord.

These incubators are intended for a 50/60 Hz, 110 - 120 volt applications at the following

amperages:

Use a separate circuit to prevent loss of the unit due to overloading or circuit failure.

12 | P a g e

Page 13

INSTALLATION (CONTINUED)

LIFTING AND HANDLING

The BACTRON is heavy, and care should be taken to use appropriate lifting devices that are

sufficiently rated for these loads. Follow these guidelines when lifting and handling the BACTRON

workstation:

Lift the BACTRON only from its bottom surface.

Doors, handles, and knobs are not adequate for lifting or stabilization.

Restrain the BACTRON completely while lifting or transporting so it cannot tip.

Remove all moving parts, such as shelf spacers and trays, and secure all doors in the

closed position during transfer to prevent shifting and damage.

Note: To prevent damage when moving the BACTRON, turn each of the four leveling feet

completely clockwise.

LEVELING

The BACTRON must be level and stable for safe operation. Each BACTRON ships with four

leveling feet. Insert one leveling foot into each of the four holes in the bottom corners of the

workstation. Adjust the foot at each corner until the workstation stands level and solid without

rocking. To raise a foot, turn it in a counterclockwise direction; to lower a foot, turn it in a clockwise

direction.

13 | P a g e

Page 14

INSTALLATION (CONTINUED)

GAS SOURCE

Warning: Never exceed a 5% hydrogen concentration inside the unit’s chamber.

Avertissement: La concentration d’hydrogène ne doit pas dépasser 5% dans la chambre anaérobie.

The BACTRON requires an anaerobic gas mixture with 5% hydrogen to drive the oxygen-capturing

catalytic process in the workspace chamber. To reduce anaerobic gas consumption during auto

cycle pass box purges, the BACTRON may also be connected to a second compressed gas

cylinder containing an inert gas such as, nitrogen (N2), for use in the first two stages of the threestage auto cycle. Manual cycles of the pass box will only draw from the anaerobic mixed gas

cylinder attached to the GAS 1 In port.

For a single cylinder of anaerobic mixed gas (AMG), Sheldon Manufacturing recommends

5% hydrogen (H2), 5% Carbon Dioxide (CO2), and 90% Nitrogen (N2).

If you are using a two gas anaerobic application, Sheldon recommends one cylinder of

AMG gas at the above ratios, and a second cylinder of 100% Nitrogen (N2).

Gas regulators for BACTRON applications will need to be set at 15 - 20 psi. Please see the

Pressure Unit Conversion table on page 49 in the Operation Section for working with

units other than Pounds per Square Inch.

Anaerobic Mixed Gas is often sold by gas suppliers under the category of Anaerobic Incubation

Mixtures or Biological Atmospheres. Contact your site safety officer and review your institutional

safety protocols for handling, storing, and using compressed gasses. Follow all local ordinances

and national regulations regarding compressed gases in research, clinical, or production

environments.

14 | P a g e

Page 15

Gas and

Vacuum Ports

Main Control

Panel

Manometer

Side Storage

Incubator

Pass Box

Arm Ports

LED

Lamp

Catalyst

Cartridge

Workspace

Chamber

Workspace

Chamber

Incubator

Catalyst

Cartridge

Gas and

Vacuum

Ports

Workspace Incubator

Control Panel

Manometer

Side

Storage

Incubator

Pass Box

Arm Ports

LED Lamp

Main Control Panel

(Side Storage

Incubator)

INSTALLATION (CONTINUED)

BACTRON900 ORIENTATION

BACTRON600 ORIENTATION

15 | P a g e

Page 16

Manometer

Main Control

Panel

Pass Box

Arm Ports

Workspace Chamber

Incubator

Catalyst

Cartridge

Gas and Vacuum

Ports

INSTALLATION (CONTINUED)

BACTRON300 ORIENTATION

16 | P a g e

Page 17

Catalyst

Cartridge

Data Plate

INSTALLATION (CONTINUED)

WORKSPACE CHAMBER ORIENTATION (ALL UNITS)

Figure 1: Workspace Chamber Layout

PASS BOX ORIENTATION

Figure 2: Pass Box Inner Door and Sliding Shelf

The pass box is provided with an integral sliding shelf to facilitate material transfers. Small items

may be introduced into the chamber via the Arm Port Doors and Sleeve Assemblies using proper

sleeve technique.

17 | P a g e

Page 18

INSTALLATION (CONTINUED)

CLEANING

The BACTRON interior was cleaned and disinfected at the factory, but not sterilized. See the

Cleaning procedure in the User Maintenance section for more information.

18 | P a g e

Page 19

CONTROL PANEL OVERVIEW

Figure3: Main Control Panel

Main Control Panel BACTRON300

The main control panel on the BACTRON300 controls the heater and the Over Temperature Limit

System of the workspace chamber incubator. Controls for cycling the pass box atmosphere,

along with the power switch for the BACTRON, and the workstation gas injection light are also

located on this panel.

Main Control Panel BACTRON600

The main control panel on the BACTRON600 controls the heater and the Over Temperature Limit

System of the side storage incubator. Controls for the purging the pass box atmosphere, along

with the power switch for the BACTRON, and the workstation gas injection light are also located on

this panel.

Main Control Panel BACTRON900

The main control panel on the BACTRON900 controls the heater and the Over Temperature Limit

System of the side storage incubator. The controls for the workspace chamber incubator are

located on the workspace control panel (see page 23). The controls for the pass box, along with

the power switch for the BACTRON, and the workstation gas injection light are also located on the

main panel.

19 | P a g e

Page 20

CONTROL PANEL OVERVIEW (CONTINUED)

Main Control Panel Continued

Power Switch

The main power switch on the control panel controls all power to the workstation and must be in the

on ( I ) position before any of the BACTRON’s systems are powered. The switch will illuminate

when on.

Chamber Gas Light

This light indicates that anaerobic mixed gas is being injected into the workspace chamber.

Main Temperature Control and Green Digital Display

Labeled INCUBATOR, this control consists of a green digital display and up and down arrow

buttons used to adjust the incubator’s operating temperature (set point). In its default mode the

display shows the current incubator temperature, accurate to within + 0.1C. The arrow buttons can

also place the unit in its calibration mode. During temperature calibrations, the controls used to

enter temperature offsets to match the displayed temperature to the temperature detected by an

independent reference thermometer.

Heating Activated Light

The clear pilot light located beneath the label HEATING ACTIVATED illuminates whenever the

heating elements are powered and warming the incubator.

Set Over Temperature

This graduated dial sets the incubator’s temperature limit for the Over Temperature Limit backup

system. The OTL System operates independently of the Main Temperature Controller, and

prevents uncontrolled heating of the incubator in the event of a failure of the Main Controller while

in its heating mode. For more details, please see the explanation of the Over Temperature Limit

System in the Operation section’s Theory of Operation.

OTL Light

This pilot light is marked OVERTEMPERATURE ACTIVATED and is directly below the Over

Temperature Limit control. The light will turn on when the OTL System has taken control of the

incubator, and will be accompanied by a buzzer alarm. Under normal operating conditions this light

should not illuminate.

20 | P a g e

Page 21

CONTROL PANEL OVERVIEW (CONTINUED)

Pass Box Doors Light

The clear Doors pilot light indicates that both pass box doors are closed. This light must be on in

order to cycle the pass box.

Anaerobic Light

This is light activates after the completion of a full auto cycle of the pass box Interior.

Aerobic Light

This light activates when the outer pass box door has been opened, exposing the pass box to

aerobic atmosphere. It remains on until the next completion of a full auto cycle.

Pass Box Vacuum Controller and Digital Display

The main control panel vacuum gauge-controller displays the level of vacuum in inches of mercury

in the pass box interior. It controls the application of vacuum to the pass box during the pass box

auto cycle.

Figure 4: Pass Box Vacuum

Controller and Display

21 | P a g e

Page 22

CONTROL PANEL OVERVIEW (CONTINUED)

Automatic Start / Reset Switch

The all black Automatic Start / Reset switch initiates or aborts the pass box’s auto vacuum-andgas-recharge cycle used to remove aerobic atmosphere from the pass box. Pressing then releasing

on the left (Start) the will initiate the auto cycle. Pressing and holding on the right (Reset) for three

seconds will abort and then restore the pass box to a near standard atmospheric pressure sufficient

that the pass box doors can be easily opened.

Pass Box Gas Light

This light indicates that the anaerobic mixed gas is being injected into the pass box during the auto

cycle. The pass box Gas light does not illuminate during manually gas injections.

VAC Light

The clear VAC pilot light indicates that the vacuum pump is in operation when the auto cycle is

vacuuming down the pass box chamber. The Vac Light does not turn on during manual

vacuuming.

Manual GAS / OFF / VAC Switch

The all black GAS / OFF / VAC switch allows the user to manually initiate a flow of AMG from the

GAS 1 IN port into the pass box by depressing the switch to the left. Pressing the switch to the right

activates the vacuum pump, lowering the atmospheric pressure inside pass box. A combination of

vacuum followed by injections of anaerobic mixed gas can be used to manually cycle the pass box

atmosphere.

Fuse

Located on the inside the power cord inlet on the back of the workstation, the fuse protects against

over current conditions. If the fuse blows, the BACTRON will shut down. For your safety and the

safety of laboratory personnel, the cause of a blown fuse should be determined prior to replacing it.

22 | P a g e

Page 23

CONTROL PANEL OVERVIEW (CONTINUED)

Workspace Incubator Control Panel (BACTRON900 / BACTRONIV-900 Only)

Figure 5: BACTRON900 Workspace Control Panel

The workspace incubator control panel on the BACTRON900 controls the operations of the

workspace chamber incubator and the incubator’s Over Temperature Limit system.

Main Temperature Control and Green Digital Display

The BACTRON900’s workspace SET TEMPERATURE control panel comes with a green digital

display that shows the temperature of the incubator accurate to within + 0.1C. The control consists

of up and down arrow keys for adjusting set point temperatures or placing the display in its

calibration mode.

Heating Activated Light

The clear pilot light located beneath the label HEATING ACTIVATED illuminates whenever the

heating elements are powered and warming the BACTRON900’s workspace chamber Incubator

Set Over Temperature

This graduated dial sets the temperature set point for the Over Temperature Limit backup system in

the workspace chamber of the BACTRON900. The OTL System operates independently of the

Main Temperature Controller, and prevents uncontrolled heating of the workspace incubator in the

event of a temperature control board failure. For more details, please see the explanation of the

Over Temperature Limit System in the Operation Section.

OTL Light

This pilot light is marked OVERTEMPERATURE ACTIVATED and is located directly below the

Over Temperature Limit control. The light will turn on and a buzzer alarm will activate when the

OTL System has taken control of the incubator. Under normal operating conditions this light should

not illuminate.

23 | P a g e

Page 24

No

Oxygen

Hydrogen

Positive

Pressure

Active

Catalyst

OPERATION

THEORY OF OPERATION AND MAJOR COMPONENT FUNCTIONS

Achieving Anaerobic Conditions

Figure 6: Atmosphere Control Measures

The BACTRON workstation is designed to establish and maintain a strict anaerobic environment

suitable for the cultivation of clinical anaerobic bacteria. This is achieved through injections of an

anaerobic mixed gas (AMG) with a 5% hydrogen concentration, and a subsequent catalytic reaction

between the hydrogen, free oxygen in the air, and the activated palladium of the workstation’s

catalyst scrubber. This results in the oxygen being captured in the formation of water vapor.

A palladium catalyst must be kept clean and active by baking the catalyst cartridge at 200°C after

each 24 hours of usage.

A mild chamber overpressure is maintained using a workspace pressure switch sensor, AMG, and

a gas injection solenoid to help prevent infiltration by outside atmosphere.

The presence of oxygen in the workstation can be detected through the use of color-changing

Oxoid brand indicator strips. Microbiological controls such as, Clostridium novyi or Pseudomonas

aeruginosa, may also be used to indicate anaerobic or aerobic conditions. Use of an activated

charcoal scrubber in the chamber can help absorb volatile fatty acids and hydrogen sulfides

generated by cultivation processes or applications.

Condensation Management

Sample media evaporation from petri dishes and water vapor from the oxygen-capturing catalytic

reaction is trapped on the cold plate of a Peltier-effect condensate chiller located behind catalyst

cartridge. Condensed moisture is then channeled into a drain tube that empties into a receptacle

placed in the workspace chamber by the end-user. The receptacle must be drained regularly. The

Peltier condensate chiller eliminates the need to use chemical desiccants to control humidity levels

inside the chamber, which can retain condensate and dry out culture media.

24 | P a g e

Page 25

OPERATION (CONTINUED)

Accessing the Workstation

Items such as media containers and laboratory equipment can be introduced to or removed from

the BACTRON’s anaerobic environment through the pass box. The pass box creates a near

anaerobic environment through three cyclic applications of the BACTRON’s vacuum pump to

reduce air volume in the pass box, followed by gas replenishment injections. The pass box

operates in one of two modes: A user-initiated three stage auto-cycle, or through use of the manual

control switch to cycle the pass box atmosphere three times. The option to manually cycle the pass

box is primarily intended as a backup for the auto cycle system.

Users can access and work glove-free in the workspace chamber by donning the sleeve

assemblies attached to the front panel arm ports. The sleeve assemblies are also compatible with

exam gloves for handling pathogenic samples inside the workspace. After being donned – but prior

to opening the arm port doors – the sleeve assemblies are purged by using the foot pedal assembly

to apply reduced pressure to the sleeves with the vacuum pump, then to charge the sleeves with

AMG.

Purging, sealing, and effective use of the sleeve assemblies requires bare skin contact between the

widest part of the user’s forearms and the cuff ring of the sleeve assembly. Smooth, small items

held in hand may be introduced into the workspace chamber through the sleeve assemblies.

Incubators

BACTRON300 and BACTRON900 are each provided with a cabinet style incubator in the

workspace chamber. The BACTRON600 and BACTRON900 come with a rotating tray (Lazy

Susan) in a side storage incubator.

Each incubator’s temperature is controlled by a digital controller board using a solid state

temperature sensor probe attached to the incubator body and a heating element. When heating the

incubator, the controller uses Proportional – Integral – Derivative (PID) analytic functions to slow

the rate of heating as it approaches the user-selected set point. This is done to avoid overshooting,

and to correct for naturally occurring measurement errors.

The digital controller also uses PID learning functions to optimize its warming rates for hotter or

cooler environments. If the BACTRON is moved to a new location with a significant temperature

difference from its previous surroundings, it may require 24 hours of incubator run time for the

controller to fully adapt to the new thermal environment and obtain its previous high level of

temperature stability. This is why the incubator should be run at its application set point for 24 hours

prior to calibration. Additionally, the heat loss from leaving the incubator doors open for long

periods of time (an hour or more) can trick the controller into thinking it is operating in a cool

environment. This can result in a period of temperature overshooting.

25 | P a g e

Page 26

OPERATION (CONTINUED)

The Over Temperature Limit System

The OTL is a mechanical heating control backup system included with each incubator, and which

operates independently of the incubator’s digital temperature controller board. The OTL is intended

to be set to approximately 1°C above the user-selected temperature set point stored in digital

controller board. The OTL prevents runaway heating in the event that the main controller fails while

in its heating mode.

If the incubator’s temperature exceeds to the OTL limit setting, a red pilot light indicator will

illuminate and an audible alarm will buzz. The OTL System will depower the incubator’s heating

element, and continue to do so as long as the temperature remains higher than the OTL setting.

Manometer Pressure Gauge and Check Valve

The water-filled manometer in the workspace chamber serves as a visual pressure gauge, as well

as a venting check valve during instances of excess overpressures.

Figure 7: Manometer Components

An increase in atmospheric pressure inside the workstation drives down water within the

Manometer relative to a pair of reference and refill rings. Under normal operating conditions the

workstation’s overpressure displaces a-half inch of water (0.5cm). Excessive pressure will cause

the water to bubble as chamber atmosphere is vented through the manometer and out of the

workstation. This helps prevents damage to workstation gaskets. The manometer exhaust vent is a

port consisting of a transparent tube and black O-ring located on the back, right side of the

BACTRON.

26 | P a g e

Page 27

PN 9900699 / PN 9900698

Figure 8: Arm Port

Doors

Figure 9: Incubator

Shelf Spacers

Figure 10: Petri Dish

Racks

Figure 11: Oxoid

Anaerobic

Indicator Strips

OPERATION (CONTINUED).

SETTING UP THE BACTRON

Perform the following steps to set up the BACTRON workstation for use:

1. Remove all protective wrappings from accessories and the workstation.

2. Disinfect the workstation to the standards of your laboratory or production

environment protocol. The BACTRON was disinfected at the factory prior to

shipment. However, Sheldon Manufacturing cannot guarantee that the BACTRON

was not exposed to contaminants en route, or that the factory procedure matches the

standards of your institutional protocols. See the Cleaning procedure in the User

Maintenance section on page 56 for more information about cleaning and disinfecting

the BACTRON. Also see step 3 of this procedure.

3. Clean, disinfect, and place the following items in the workspace chamber:

a. Arm port doors

b. The incubator bottom shelf spacers (BACTRON300 and BACTRON900).

Remove the protective shipping wrappings prior to placing the spacers in

the chamber.

c. The petri dish racks. These can be placed on the top shelf of the

workspace chamber incubator or (BACTRON600) shelves during the

setup.

d. At least five unopened Oxoid brand anaerobic indicator strips.

e. A glass flask or beaker placed under the plastic condensation tube on

the left side of the chamber.

f. One or two 500ml beakers of purified water.

g. Any equipment and other aerobic-tolerant items that you plan on

introducing into the workspace chamber. Doing so now saves time and

AMG usage by eliminating future pass box cycles.

4. Verify that the wall power supply and incubator electrical requirements match (See the

Installation Section, page 12).

5. Do not place a catalyst cartridge in the chamber at this time!

6. Partly open both doors of the workspace chamber incubator (BACTRON300 and

BACTRON900), and the door to the side storage incubator (BACTRON600 and

BACTRON900). Only open the doors by approximately 1 cm (0.5 inches). Failure

to open the doors during the setup will leave reservoirs of aerobic atmosphere after

the workstation’s chamber space has been purged of oxygen. Opening the doors all

the way at the start of the BACTRON setup will cause an incubator heater to

significantly overshoot its set point when the doors are finally closed.

Procedure continued on the following page

27 | P a g e

Page 28

OPERATION (CONTINUED).

7. Perform the following procedures to setup the unit for use.

Setup the Gas Supply page 29

Single Gas Connection or Dual Gas Connection procedure page 30

Connecting to an In-House Vacuum System or Connect the Vacuum Pump page 31

Filling the Manometer page 31

Installing the Arm Port Doors page 31

Connecting the Foot Pedal Assembly page 32

Power the BACTRON page 33

Establishing an Anaerobic Atmosphere page 34

Installing the Sleeve Assemblies page 36

Chamber Entry page 37

Verifying Anaerobic Atmosphere page 37

Exiting the Chamber page 39

Setting the Incubator Temperature page 41

Setting the Over Temperature Limit page 41

28 | P a g e

Page 29

Figure 13: Hose

Connections

Figure 14: Hydrogen

Warning Label

To Vacuum Pump or

In-House Source

To Foot Pedal VAC

Port

To Foot Pedal

GAS Port

To AMG Cylinder

(Single Gas

Application)

OPERATION (CONTINUED)

Figure 12: Gas and Vacuum Ports

SET UP THE GAS SUPPLY

See the Gas Source entry in the Installation section on page 14 for Sheldon

Manufacturing’s recommended gas applications.

1. Install the gas regulator or regulators on the compressed gas cylinders

you will be using.

2. The regulators should be set to 15 to 20 psi. Please see the Pressure

Unit Conversion table in the Operation Section for working with units

other than Pounds per Square Inch.

Warning: Never exceed a 5% hydrogen concentration inside the unit’s chamber.

Avertissement: La concentration d’hydrogène ne doit pas dépasser 5% dans la chambre anaérobie.

29 | P a g e

Page 30

AMG

GAS 1

IN

GAS 2

IN

Figure 16: Dual Gas Connections

OPERATION (CONTINUED)

SINGLE GAS CONNECTION

Follow these steps to connect a single cylinder of anaerobic mixed gas.

1. Locate the T-shaped brass fitting included with the BACTRON’s AMG gas regulator

(normally shipped in the regulator box).

Figure 14: T-Fitting AMG Figure 15: Single Gas Connections

2. Using the attached short lengths of black OD tubing, connect the fitting to the GAS 1 IN

and GAS 2 IN ports on the top left side of the BACTRON. See figure 13 on the previous

page.

3. Connect a barb adaptor on the T-fitting to the AMG gas regulator using the length of black

OD included with the regulator.

Note: Failure to connect the T-fitting to both the GAS 1 and 2 ports will prevent the pass box auto

cycle from cycling the pass box.

DUAL GAS CONNECTION

To connect AMG and an inert recharging gas such as, nitrogen

(N2), complete the following steps:

1. Connect the AMG regulator’s tubing to the

BACTRON’s GAS 1 IN port.

2. Connect the inert recharging gas cylinder regulator line

to the BACTRON’s GAS 2 IN port.

Note: When plumbed in this configuration, the BACTRON will draw twice from the GAS 2 IN port,

and once from the GAS 1 IN port during pass box auto cycles. This is intended to reduce

pass box AMG consumption. The BACTRON will not draw from the GAS 2 IN port during

manual gas injections, sleeve assembly purges, or other operations.

30 | P a g e

Page 31

Figure 17: Vacuum

Pump

Figure 18: Manometer

PN 9900699 / PN 9900698

Figure 19: Arm Port

Door

OPERATION (CONTINUED)

CONNECTING TO AN IN-HOUSE VACUUM SYSTEM

Carry out this procedure to connect the BACTRON to an in-house vacuum system. An in-house

system must be capable of evacuating a minimum of 25 inches (63.5 cm) of mercury.

1. Connect a 3/8 inch hose from the in-house system to the VAC IN port on the back, on the

right side of the BACTRON.

CONNECTING THE VACUUM PUMP

Use this procedure to connect the vacuum pump included with the BACTRON.

1. Connect the 3/8 inch hose from the vacuum pump to the BACTRON’s VAC IN

port.

Note: Plug the vacuum pump into the circular grey power outlet located on the back

of the BACTRON at the top right. Do not plug into a wall outlet! Plugging the

pump into a wall outlet will run the pump non-stop, rather than only when

needed by the BACTRON.

2. Ensure that the vacuum pump is placed in a ventilated location to prevent

overheating. An overheated vacuum pump can become a fire hazard.

3. Make sure there are no kinks in the vacuum line running from the pump to the

BACTRON.

FILLING THE MANOMETER

1. Fill the manometer located in the workspace chamber with distilled water to the

refill ring (the top of the two reference rings). This can be done by unscrewing

and removing the manometer bottle, or pouring water in through the hole on

the top of the manometer assembly.

2. Distilled water is preferable to tap water to avoid long-term scaling deposits

from waterborne minerals.

INSTALLING THE ARM PORT DOORS

The arm port doors should already be inside the workspace chamber.

1. Turn the silver locking bar to a roughly 45° position.

2. Install each door bottom first, inserting the tabs into the slots on the arm ports.

3. Tilt the door cover up so that it fits securely within the arm port.

4. Turn the locking bar to the horizontal position:

5. Secure the door by turning the black arm port door knob clockwise, using wrist

strength only, until the knob grabs and feels snug. Tightening too much may compromise

the integrity of the door by pulling the post that the knob and locking bar are mounted on

out of position.

31 | P a g e

Page 32

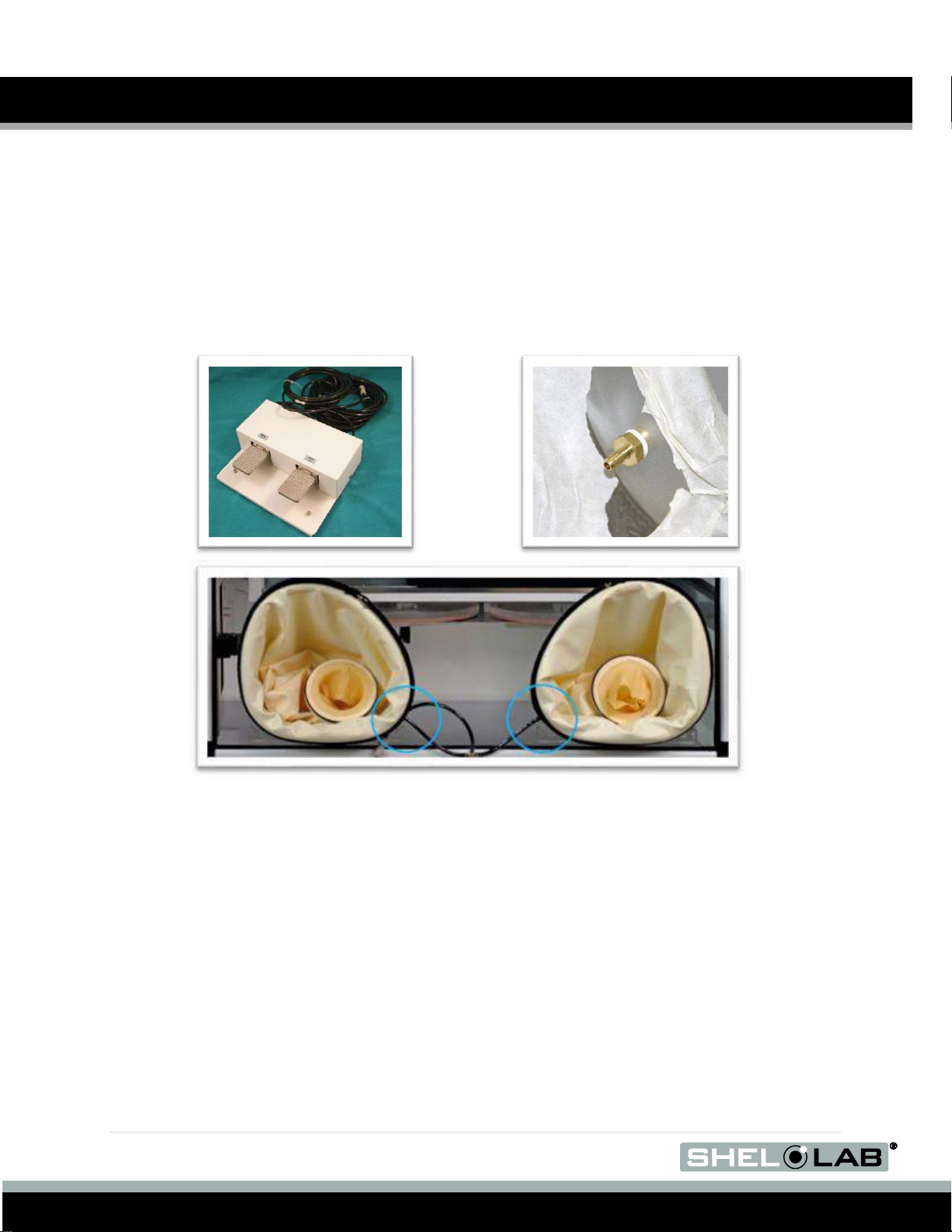

Figure 20: Foot Pedal Line Connection

with the Arm Port Door Assemblies

OPERATION (CONTINUED)

CONNECTING THE FOOT PEDAL ASSEMBLY

1. Place the foot pedal assembly on the floor below the arm port doors.

2. Locate the center line on the back of the foot pedal assembly.

3. Connect the branching lines from the center line’s T-fitting to the two brass barb adaptor

fittings on the inner sides of the arm port door assemblies. See figure below.

4. Connect the line labeled VAC on the right side of the pedal assembly to the VAC OUT port

on the BACTRON. This supplies vacuum for reducing atmosphere in the sleeve assemblies

prior to charging with AMG.

VAC VAC OUT

5. Connect the line labeled GAS on the left side of the pedal assembly to the GAS OUT port

on the BACTRON. This supplies AMG for charging the sleeve assemblies.

GAS GAS OUT

32 | P a g e

Page 33

Figure 21: Incubator

Shelf Spacer

OPERATION (CONTINUED)

SHELVING INSTALLATION BACTRON300 AND BACTRON900

Install the three (3) metal bottom spacers included with the BACTRON600 and 900 on the

bottom shelf of the workspace chamber incubator. These spacers shield sample containers

from direct contact with the warm surface of the incubator, and ensure heat dissipation and

uniformity.

1. Set the spacers on the bottom shelf of the workspace chamber incubator, side by

side, with the “SPACER” label facing outwards toward you.

2. Make sure to leave the incubator doors only partly open (1cm / 0.5 inches) after

installing the shelf spacers while setting up the BACTRON for use.

3. An empty plate or dish placed at the bottom of each sample stack can provide additional

shielding for anaerobes that are heat sensitive, or if the incubator is being run at high

temperatures.

POWER THE BACTRON

1. Plug the workstation power cord into a suitable outlet (page 12).

2. Turn the power switch ON to verify that the workstation will power up.

3. The vacuum pump should turn on for a few seconds, and then turn off. If the pump does

not run, consult Sheldon Technical Support. If the vacuum pump runs for a long period of

time at higher altitudes it will require adjustment.

4. The following lights and displays should illuminate.

a. The Green power switch.

b. The Chamber Gassing pilot light will illuminate for a few seconds, if all doors

are closed and the gas supply is turned on.

c. The Pass Box Doors sealed pilot light if the doors are closed.

d. The Auto Cycle Aerobic pilot light.

e. The green LED Set Temperature display on the main control panel.

f. The green LED Set Temperature Display on the workspace control panel of the

BACTRON900 (BACTRONIV-900).

33 | P a g e

Page 34

Figure 22: Catalyst Cartridge

Installed

OPERATION (CONTINUED)

ESTABLISHING AN ANAEROBIC ENVIRONMENT

Carry out the following steps to purge the aerobic atmosphere from the workstation and establish

an anaerobic environment. If the BACTRON has previously been in use, remove the right arm port

sleeve prior to starting the procedure. This procedure requires approximately 1 to 4 hours to

complete.

1. Verify the following:

a. The interior and exterior pass box doors are closed and secured.

b. The manometer is filled to the fill line (upper ring) with water.

c. The foot pedal assembly center line is securely connected to the brass barb

adaptors on both arm port door assemblies.

d. The foot pedal assembly GAS and VAC lines are connected to the GAS OUT

and VAC OUT ports on the BACTRON.

e. Gas input lines are attached to the BACTRON’s GAS IN 1 and GAS IN 2 ports.

2. Note the reading on the AMG gas regulator.

a. The BACTRON300 (BACTRONII) will require approximately 200 psi of AMG

for a setup purge.

b. The BACTRON600 (BACTRONIV) and BACTRON900 (BACTRONIV-900)

need around 400 psi of AMG for a setup purge.

3. Make sure the AMG cylinder regulator is set to 15 to 20 psi. Open the valve all the way to

start a flow of gas to the BACTRON

a. Nitrogen and other inert gasses should not be used to purge the workstation.

4. Turn on the workstation, if it is not already powered up.

5. Open the right arm port door.

6. Verify that all incubator doors are slightly open to avoid

leaving reservoirs of aerobic atmosphere.

7. Unwrap and install a fresh catalyst cartridge on the left wall

inside the workspace chamber. See Figure 22 to the right.

a. Catalyst cartridges come ready for use from

the factory. However, if you have stored the

cartridges for longer than six months, it is

strongly recommended that you reactivate prior

to first use. Please see Reactivating the

Catalyst Cartridge section on page 45.

34 | P a g e

b. The catalyst cartridge will grow warm in the presence of

oxygen and AMG.

Procedure continued on next page

Page 35

OPERATION (CONTINUED)

Establishing an Anaerobic Environment Continued

Note: If you have opened the left armor port door to install the catalyst, reinstall and secure the

door now. Leaving the left arm port unsecured may cause AMG to “stream” through the

chamber directly to the door, rather than building up and pushing out aerobic atmosphere,

from the left side of the chamber to the right.

8. Reinstall the right arm port door and secure it. From the snugly tightened positioned,

loosen the knob on the on the right arm port door by about half a turn. This should create a

small leak that aerobic atmosphere can be pushed out through.

a. AMG should pulse rather than flow continually into the chamber. The Chamber

Gas light should activate for 1 to 2 seconds before deactivating for 1 to 2

seconds. This will be accompanied by a clicking sound that is the gas solenoid

opening and closing.

b. If the interval between pulses are longer than 1 to 2 seconds, or if there is no

pulsing, slowly loosen the arm port knob until the interval decreases.

c. If gas continually pulses into the chamber, tighten the right arm port door knob

until an injection interval of 1 to 2 seconds is established. Continual streaming

means that gas is likely streaming through the chamber directly to a door,

rather than accumulating and creating the turbulence necessary to purge the

chamber atmosphere.

Note: Depending on ambient conditions (temperature of the room and humidity) there may be mild

or heavy condensation on the inside of the chamber during the gas purge. This is due to the

formation of water vapor during the catalytic reaction. Condensation should dissipate by the

end of the purge as oxygen decreases and the condensate controller removes water vapor

from the chamber atmosphere.

9. End state:

a. BACTRON300 (BACTRONII). When the purge process has gone through 200

psi of AMG or gone on for 2 hours (whichever happens first), tighten and

secure the right arm port door. Then carry out the Installing the Sleeve

Assemblies, Chamber Entry, and Verifying Anaerobic Atmosphere

procedures on the following pages.

b. BACTRON600 (BACTRONIV) and BACTRON900 (BACTRONIV-900). When

the purge process has used 400 psi of AMG or gone on for 4 hours (whichever

happens first), tighten and secure the right arm port door. Then carry out the

Installing the Sleeve Assemblies, Chamber Entry, and Verifying

Anaerobic Atmosphere procedures on the following pages.

35 | P a g e

Page 36

Figure 23: Mounted Sleeve Assemblies

OPERATION (CONTINUED)

INSTALLING THE SLEEVE ASSEMBLIES

Prior to verifying the achievement of an anaerobic atmosphere, install the arm sleeve assemblies in

order to access the chamber without introducing oxygen.

Start with either side.

1. Unroll the large opening of a sleeve over the plastic lips of the arm port door opening. The

sleeve should at least stretch to the base of the barb adaptor.

2. Secure the sleeve to the arm port using the 48 inch (121cm) self-griping strap included with

the sleeve assembly. Place the strap between the outside lip and the brass gas-andvacuum line barb adaptor

3. Repeat the process for the 2nd sleeve assembly and arm port.

Note: Sleeve assemblies can be left attached to the BACTRON when not in use. No stowing

procedure is required.

36 | P a g e

Page 37

OPERATION (CONTINUED)

CHAMBER ENTRY

Perform these steps to access and work in the workspace chamber without drawing in aerobic

atmosphere. See the Exiting the Chamber procedure on page 39 for how to withdraw your arms

from the chamber and sleeve assembly without compromising the anaerobic atmosphere.

1. Remove watches, bracelets, large rings, and any sharp objects that might damage the

cuffs or sleeves.

2. Place your hands in the sleeve assemblies so that the cuff rings are secure around the

bare skin of the widest part of your forearms.

a. The BACTRON comes with mid-size size 8 cuff. Size 6 cuffs are available for

users with smaller forearms; size 9 for larger users. Please see the Parts List

on page Error! Bookmark not defined..

3. Keep your hands approximately 4 – 6 inches (10 cm – 15 cm) away from the arm port

doors, and slightly to either side. This helps prevent the collapsing sleeves from pulling

your hands into the arm port doors during the next step.

4. Depress the VAC foot pedal (right). Both sleeves will deflate simultaneously. Continue

deflating until can see the definition of your fingernails through the sleeves.

5. Flush the sleeves with AMG mixture by depressing the gas foot pedal (left). Stop as soon

as you can no longer see the definition of your fingers through the sleeve, and the sleeve

material does not cling to your forearms. Do not overfill the sleeves. “Ballooning” the

sleeves wastes gas, and risks compromising the seals around the cuff rings and arm ports.

6. Repeat steps 4 and 5 for a minimum of three (3) complete evacuation and replacement

cycles.

7. Loosen both arm port door knobs by two or three turns.

8. Rotate the locking bars to a roughly 45° diagonal:

9. Slowly push one door in to the chamber, then the second. The Arm port doors can be hung

in the arm port door holders on the bottom of the workspace chamber incubator

(BACTRON300 and BACTRON900) or placed in the arm port door stands included with the

BACTRON600.

MOVING IN THE PRESSURIZED CHAMBER

There is a minor, but noticeable feeling of resistance while working in the overpressure

environment of the workspace chamber. Moving in the chamber will temporarily increase the

chamber pressure. Large and fast movements can cause the manometer to bubble as anaerobic

atmosphere is forced out of the BACTRON. Move deliberately and steadily. Withdrawing one

sleeved arm partly into the arm port while reaching in with the other (a movement combination that

looks something like swimming) can help reduce pressure and gas consumption. Additionally, use

of the vacuum foot pedal can help reduce any ballooning of the sleeves while working in the

chamber.

37 | P a g e

Page 38

Figure 23: Pink indicating

the presence of oxygen in

an office environment

OPERATION (CONTINUED)

VERIFYING AN ANAEROBIC ATMOSPHERE

This procedure verifies that an anaerobic atmosphere has been established prior to placing

anaerobe samples in the workstation.

1. After entering the workspace chamber, open one (1) of the Oxoid brand

anaerobic indicator strip packages.

a. Do not touch the indicator strip. Doing so risks contaminating the

strip and creating a false positive.

b. For the best accuracy, and to lengthen the amount of usable time,

the strip should be left in the packet, partly exposed, to avoid

contamination from surfaces, and to wick oxygen detecting fluid

from bottom of the packet.

c. Bending the edges or partly folding the packet will allow it to stand

upright.

d. Once an indicator strip has dried out, it can no longer indicate the

presence of oxygen.

e. There should be one, opened, moist anaerobic indicator strip in the workspace

chamber at all times while maintaining anaerobic conditions. Place the strip

where it will be clearly visible.

2. If the strip remains white, the chamber atmosphere is free of oxygen and ready to use. Exit

the chamber using the steps described in the Exiting the Chamber procedure on page

39.

3. If the strip turns partly or completely pink, exit the chamber using the Exiting the Chamber

procedure steps to avoid introducing more oxygen into the chamber.

a. Loosen the right arm port door to create a slight leak that aerobic atmosphere

can be expelled through. See Step 11 of the Establish an Anaerobic

Environment procedure on page 35.

b. Flush an additional 50 psi or 30 minutes worth of AMG through the chamber.

Note: The sleeve assemblies can be left on the BACTRON during this second purge.

c. When 30 minutes has elapsed or 50 psi of AMG have been flushed through

the chamber (whichever comes first), re-enter the chamber using correct entry

procedures, and open a second anaerobic indicator strip.

d. If the second anaerobic indicator strip shows less pink than before, repeat

steps b and c to finish purging the chamber.

38 | P a g e

e. If the second strip turns completely pink or shows the same degree of coloring

as the first, contact Sheldon Technical Support for assistance. See page 6.

Also, see the optional troubleshooting procedure on the next page for steps to

identify possible sources of oxygen in the workstation.

Page 39

OPERATION (CONTINUED)

TROUBLESHOOTING THE PRESENCE OF OXYGEN

1. Verify that proper sleeve donning, entry, and exiting procedures have been used

2. Check if closed containers are being introduced through the pass box. Closed containers

can hold significant volumes of oxygen.

3. Seek to reduce amount of daily pass box usage.

4. Make sure that the arm port doors and sleeve assemblies are correctly installed.

5. Verify that the manometer is filled to the fill line with water.

6. Verify that gas input lines are attached to the BACTRON’s GAS IN 1 and GAS IN 2 ports.

7. Make sure the foot pedal assembly center GAS / VAC line is securely connected to the

brass barb adaptors on both arm ports.

8. Check that the foot pedal assembly GAS and VAC lines are connected to the GAS OUT

and VAC OUT ports on the BACTRON.

9. Turn the AMG cylinder regulator to 20 psi.

10. Uninstall the catalyst cartridge. If the cartridge is not warm, it may not be active, or it has

not been exposed to AMG and oxygen. Replace it with the second catalyst cartridge

included with the BACTRON. Reactivate the first cartridge. Please see the Reactivating

the Catalyst procedure on page 45.

Note: Use caution when uninstalling the catalyst cartridge. The catalyst may have grown hot during

the anaerobic atmosphere establishment procedure.

11. Make sure that the anaerobic indicator strip packets have not been opened prior to being

placed in the oxygen-free atmosphere of the chamber

39 | P a g e

Page 40

Figure 24: Securing the Arm

Port Doors

OPERATION (CONTINUED)

EXITING THE CHAMBER

The following steps are used to exit the chamber without pulling in aerobic

atmosphere.

1. Check that the exterior and interior pass box doors are both closed

and secured, to avoid drawing aerobic atmosphere through the pass

box.

2. Depress the GAS foot pedal (left) for one or two seconds. Charging

the sleeves with gas will help prevent them from constricting while

withdrawing from the chamber.

3. Grasp the arm port doors by the silver locking bars, and slowly

withdraw one arm, then the other. Inset the tabs on the doors into the

slots of the arm port assembly. Then tilt the doors toward you so that

they sit securely in the ports. Rotate both locking bars from the

diagonal to horizontal position.

4. Tighten the arm port door knobs until the knobs start to grab, using

wrist strength only.

5. Withdraw both hands from the cuffs. Exit the sleeves.

Door Check

6. Grasp both sleeves tightly, approximately three (3) to four (4) inches (7

– 10cm) behind the cuffs.

7. Gently and slowly push both sleeves towards the doors. This will

cause the sleeves to balloon up.

8. This creates pressure in the sleeves. If the manometer bubbles in

response, the doors are not sealed.

Note: Never physically press on the arm port doors to test the seal! Doing so,

especially doing so repeatedly, may warp front panel or damage the

doors.

9. If the manometer bubbles, renter the sleeves, and re-secure both arm

port doors.

10. When the arm port doors are sealed, slowly withdraw both arms from

the sleeves.

40 | P a g e

Page 41

OPERATION (CONTINUED)

SETTING THE INCUBATOR TEMPERATURE

1. Using a coin or other flat metal implement, turn the Over Temperature Limit control dial

clockwise to the maximum position indicated by the largest dot. This prevents the Over

Temperature Limit System from interfering with setting a new temperature for the incubator.

2. Press either the Up or Down key one time on the Temperature Control sub-panel to

activate the temperature set point mode.

3. The Set Temperature digital display will briefly flash the letters “SP” for Set Point. The

display will then go from bright to dim, and start to blink. The display will now show an

adjustable temperature set point.

4. Use the Up or the Down Arrow keys to adjust the set point to the temperature you want

the incubator to run at.

5. If neither key is pressed within 5 seconds, the Set Temperature display stops blinking and

returns to displaying the current temperature of the incubator.

6. After selecting your set point, wait 5 seconds. The display will stop flashing, and the set

point is now saved in the temperature controller. The incubator will now adjust to match

your set point.

7. Set the Over Temperature Limit System, using the procedure below.

Note: Sheldon Manufacturing recommends waiting for 24 hours for the incubator temperature to

stabilize prior to loading samples.

SETTING THE OVER TEMPERATURE LIMIT

Perform the following steps to set up the Over Temperature Limit system for use.

1. If you have not done so already, turn the Set Over Temperature Limit control dial clockwise

to the maximum position. This allows the Set Temperature control to stabilize.

2. Turn the Over Temperature Limit control dial co unterclockwise until the Over Temp Limit

Activated light illuminates and the audible alarm buzzes.

3. Slowly turn the Over Temperature Limit control dial clockwise until the light and audible

alarm turn off.

4. This adjusts the Over Temperature Limit control to approximately 1˚C above the

temperature configured by the Set Temperature control.

The Over Temperature Limit System will activate if the incubator temperature exceeds the

temperature setting of the OTL System. If the main temperature controller system has failed, or the

OTL is set below your chosen temperature set point, the OTL alarm will buzz and continue to turn

on and off indefinitely. Contact Sheldon Technical Support. See page 6.

41 | P a g e

Page 42

OPERATION (CONTINUED)

OPERATING THE PASS BOX

The pass box is used to introduce items into or remove items from the workspace chamber.

Automatic Cycle

1. Make sure the inner pass box door is closed and secured.

2. Open the outer pass box door. If not already on, the Pass Box Aerobic light will illuminate,

indicating that the pass box has been exposed to the aerobic atmosphere of the room.

3. Load the pass box slider shelf with items to be introduced in the workspace chamber.

4. Close and secure the outer door. The Pass Box Doors light will then illuminate. The light

will only do so when both the inner and outer doors are closed. The Doors light must be

on for the auto cycle to initiate.

Note: Contact Sheldon Technical support if the Air Lock Doors light will not illuminate when both

doors are closed and secured.

5. Briefly depress the Auto Cycle Start / Reset Switch to the left (Start) to initiate the auto

cycle.

6. The Aerobic and Anaerobic indicator lights will alternately flash on and off, indicating that a

cycle is in process. The vacuum pump will cycle the air pressure inside the pass box three

times (from -18 inHg to -4 inHg), refilling twice from the GAS 2 IN port, and on the final

cycle from the GAS 1 IN port.

7. The anaerobic light will illuminate once the cycle has finished. The inner pass box door

may now be opened, and items introduced into the workspace chamber.

8. Do not open the outer pass box door while the inner pass box door is opened!

9. After removing items from the slider shelf, return the shelf to the pass box chamber. Close

the inner pass box door. This safeguards against inadvertently introducing oxygen into the

workspace chamber if someone opens the outer door later on.

Vacuum Interruption: The Chamber Gas light illuminates when the BACTRON is injecting AMG

into the workspace chamber. Chamber injections are made in response to the workspace

atmospheric pressure falling below a factory-set threshold. If the light illuminates while the vacuum

pump is active, the BACTRON will briefly depower the vacuum pump. If the Chamber Gas light

illuminates frequently during auto cycle, abort the cycle (see below). There may be a leak along the

inner pass box door, which is allowing the pass box to pull atmosphere out of the workspace

chamber and into the vacuum lines. Contact Sheldon Technical support.

Aborting: To abort the automatic cycle, depress and hold the Auto Cycle Start / Reset switch to the

right for three (3) seconds. The BACTRON will cease vacuuming and automatically restore

pressure to the pass box. The vacuum gauge must rise to at least -2 inHg (near room pressure)

before the Pass Box Aerobic and Anaerobic lights will stop flashing, and the inner pass box door

can be opened.

42 | P a g e

Page 43

OPERATION (CONTINUED)

Manual Cycle

The manual cycle is intended as a backup for use in the event the auto cycle is not functioning.

1. Verify that the inner pass box door is closed and secured.

2. Open the outer pass box door. The Pass Box Aerobic Light will illuminate, indicating that

the pass box chamber has been exposed to the aerobic atmosphere of the room.

3. Load the pass box slider shelf with items to be introduced into the workspace chamber.

4. Close and secure the outer door. The Pass Box Doors light will illuminate when both doors

are closed. Do not manually cycle the pass box if the Pass Box Doors light is not

illuminated!