Page 1

XV-Z2000

DT-400

SERVICE MANUAL

SERVICE-ANLEITUNG

SY4C6XV-Z2000

PROJECTOR

PROJEKTOR

XV-Z2000

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

DT-400

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XV-Z2000

DT-400

• SPECIFICATIONS ............................................ 3

• IMPORTANT SERVICE SAFETY

NOTES (for USA) .............................................. 4

• NOTE TO SERVICE PERSONNEL .................. 6

• OPERATION MANUAL ................................... 10

• DIMENSIONS ................................................. 16

• REMOVING OF MAJOR PARTS .................... 17

• RESETTING THE TOTAL LAMP TIMER ........ 22

• THE OPTICAL UNIT OUTLINE ....................... 24

• ELECTRICAL ADJUSTMENT ......................... 26

• TROUBLE SHOOTING TABLE ....................... 33

CONTENTS

Page Page

• BLOCK DIAGRAM .......................................... 88

• OVERALL WIRING DIAGRAM ....................... 90

• WAVEFORMS ................................................. 92

• PRINTED WIRING BOARD ASSEMBLIES .... 93

• PARTS LIST

Ë

ELECTRICAL PARTS...............................101

Ë

CABINET AND MECHANICAL PARTS .... 114

Ë

ACCESSORIES PARTS ........................... 118

Ë

PACKING PARTS..................................... 118

• PACKING OF THE SET ................................ 119

• SCHEMATIC DIAGRAM ....................... D1~D35

Seite Seite

• TECHNISCHE DATEN .................................... 47

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................48

• BEDIENUNGSANLEITUNG ............................ 50

• ABMESSUNGEN ............................................ 56

• ENTFERNEN DER HAUPTTEILE .................. 57

• RÜCKSTELLUN DES

LAMPEN-TIMERS .......................................... 62

• BESCHREIBUNG DER OPTIK-EINHEIT ....... 64

• ELEKTRISCHE EINSTELLUNG ..................... 66

• FEHLERSUCHTABELLE ................................ 74

• BLOCKSCHALTBILD ......................................88

INHALT

• GESAMTSCHALTPLAN..................................90

• WELLENFORMEN .......................................... 92

• LEITERPLATTENEINHEITEN ........................ 93

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ........................ 119

• SCHEMATISCHER SCHALTPLAN....... D1~D35

Ë

ELEKTRISCHE BAUTEILE ....................... 101

Ë

GEHÄUSE UND MECHANISCHE

BAUTEILE ................................................. 114

Ë

ZUBEHÖRTEILE....................................... 118

Ë

VERPACKUNGSTEILE ............................. 118

2

Page 3

SPECIFICATIONS

Product type

Model

Video system

Display method

DLP panel

Lens

Projection lamp

Video input signal

S-video input signal

Component input signal

(INPUT 1, 2)

Analog RGB/Digital

(INPUT 5/DIGITAL)

Horizontal resolution

Pixel clock

Vertical frequency

Horizontal frequency

Computer control signal

Rated voltage

Input current

Rated frequency

Power consumption

Power consumption (standby)

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

Projector

XV-Z2000, DT-400

PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43

DTV 480

I

/480P/540P/576I/576P/720P/1080

I

Single Panel Digital Micromirror Device (DMD™) by Texas Instruments

Panel size: 0.8"

Drive method: Digital Light Processing (DLP™)

No. of dots: 921,600 dots (1,280 [H] ⋅ 720 [V])

1–1.5 ⋅ zoom lens, F2.0–2.5 f=21.3–31.6 mm

275 W DC lamp

RCA Connector: VIDEO (INPUT 4), composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

4-pin Mini DIN connector (INPUT 3)

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

RCA Connector

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B (CB): 0.7 Vp-p, 75 Ω terminated

P

R (CR): 0.7 Vp-p, 75 Ω terminated

29-pin DVI-I terminal

<Digital>

Input impedance 50 Ω

Input level 250-1000 mV

<Analog>

Input impedance 75 Ω

Input level 0.7 Vp-p

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B (CB): 0.7 Vp-p, 75 Ω terminated

P

R (CR): 0.7 Vp-p, 75 Ω terminated

<Synchronization signal>

•

Separate sync/Composite sync

Input level TTL level

Input impedance 1 KΩ

• Green on sync

Input level (Synchronizing input) 0.286 Vp-p

Input impedance 75 Ω

720 TV lines (DTV 720P input)

12–80 MHz

43–75 Hz

15–70 kHz

9-pin D-sub connector (RS-232C Port)

AC 100–240 V

3.65 A (When using AC 100 V)

50/60 Hz

360 W (When using AC 100 V)

6 W (When using AC 100 V)

1,350 BTU/hour

41°F to 95°F (+5°C to +35°C)

–4°F to 140°F (–20°C to +60°C)

Plastic

38 kHz

12

7

/32" ⋅ 3 33/64" ⋅ 11 7/64" (310 (W) ⋅ 89 (H) ⋅ 282 (D) mm)

9.5 lbs. (4.3 kg)

Remote control, Two AA size batteries, Power cord, Lens cap (attached on the body),

Operation manual

Lamp unit (Lamp/cage module) (AN-K2LP), Remote control (RRMCGA334WJSA), AA

size batteries, Power cord (QACCBA036WJPZ:XV-Z2000, for U.K., Hong Kong and

Singapore), (QACCDA007WJPZ:XV-Z2000, for U.S.A., Canada and DT-400),

(QACCLA018WJPZ:XV-Z2000, for Australia and New Zealand),

(QACCVA011WJPZ:XV-Z2000, for Europe, except U.K.) Lens cap (PCAPHA021WJSA),

Operation manual (TINS-B529WJZZ:XV-Z2000, for U.S.A., and Canada),

(TINS-B530WJZZ:XV-Z2000, for European 7 Laguges),

(TINS-B531WJZZ:XV-Z2000, for Hong Kong and Korean), (TINS-B532WJZZ:DT-400)

Operation manual, for 21pin RCA Conversion Adaptor (TCADH1018CEN1:XV-Z2000,

for Europe) Video cable (QCNWGA001WJZZ:XV-Z2000, except U.S.A., Canada and

DT-400), 21pin RCA conversion adaptor (QSOCZ0361CEZZ:XV-Z2000, for Europe)

XV-Z2000

DT-400

As a part of policy of continuous improvement, SHARP reserves the right to make design and

specification changes for product improvement without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

3

Page 4

XV-Z2000

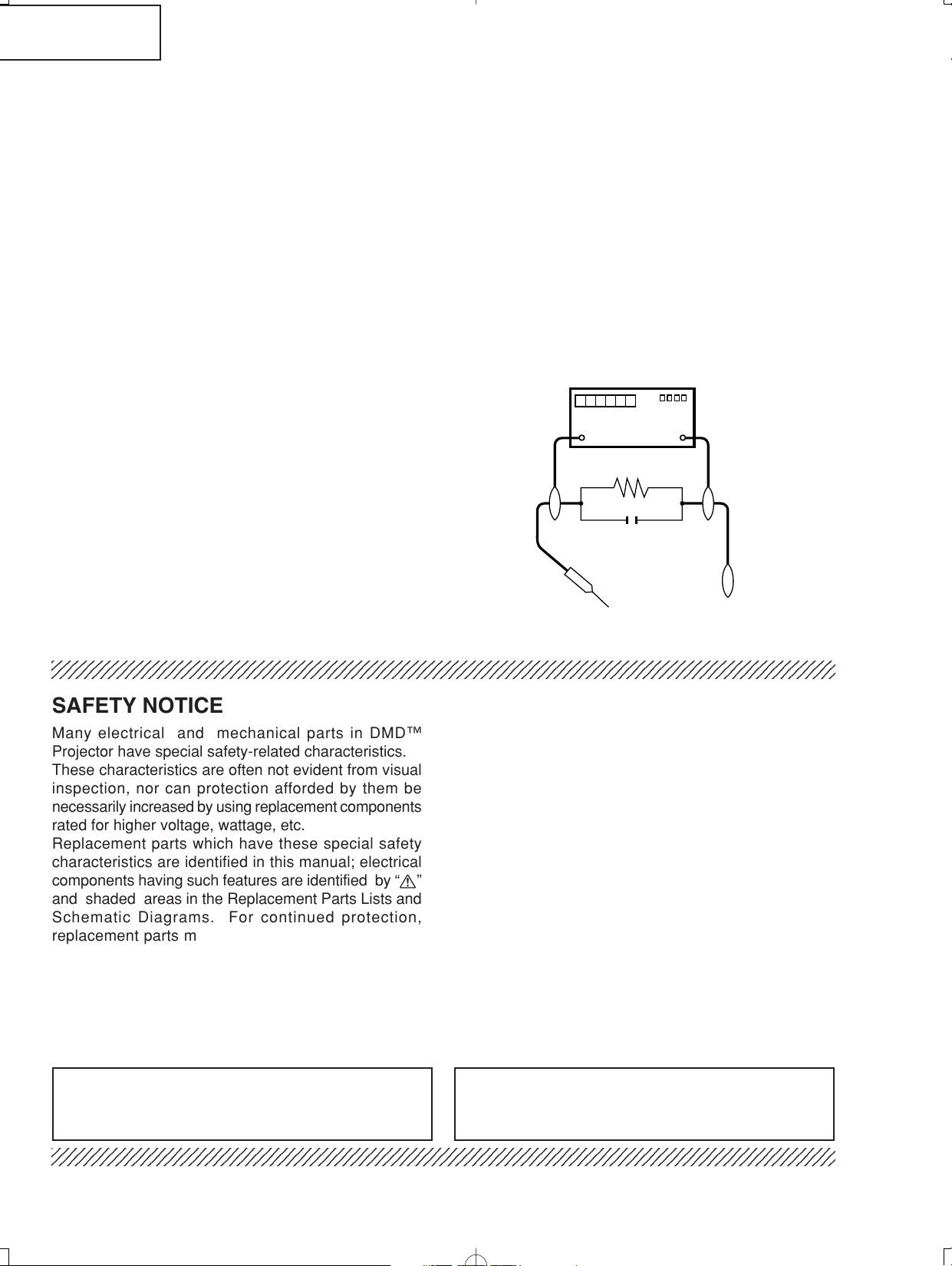

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15 µF

TEST PROBE

DT-400

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 100-240 volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

SAFETY NOTICE

Many electrical and mechanical parts in DMD™

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DMD™ présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

4

Page 5

XV-Z2000

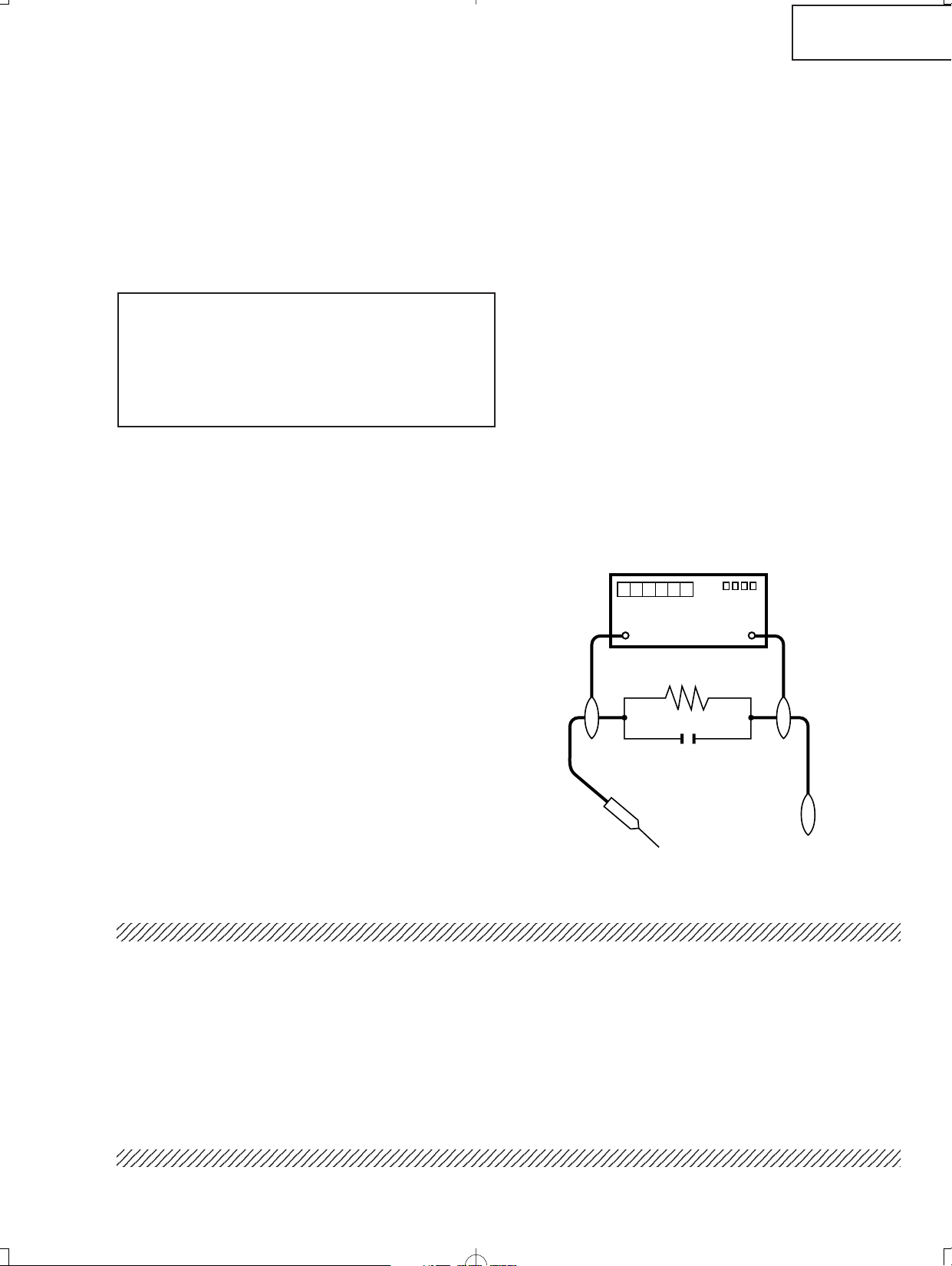

DVM

ECHELLE CA

1.5k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

DT-400

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LA

PROTECTION CONTINUE CONTRE

LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F701 (T6.3AH, AC250V)

VERIFICATIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants, le

dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

• Brancher le cordon d'alimentation directem-ent à une

prise de courant de 100-240V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

• A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer la

chute de tension CA en-travers de la résistance. Toutes

les vérifications doivent être refaites après avoir inversé

la fiche du cordon d'alimentation. (Si nécessaire, une

prise d'adpatation non polarisée peut être utilisée dans

le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser 0.5

mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces caractéristiques sont identifiées dans ce manuel; les pièces électriques

qui présentent ces particularités sont identifiées par la marque " å " et hachurées dans la liste des pièces de

remplacement et les diagrammes schématiques.

Pour assurer la protection, ces pièces doivent être identiques à celles utilisées dans le circuit d'origine. L'utilisation

de pièces qui n'ont pas les mêmes caractéristiques que les pièces recommandées par l'usine, indiquées dans ce

manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

5

Page 6

XV-Z2000

DT-400

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the projector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide, dans

le projecteur émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-K2LP

rated 275W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

AN-K2LP, caractéristique 275W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

6

Page 7

XV-Z2000

1

2

1

2

DT-400

UV-RADIATION PRECAUTION (Continued)

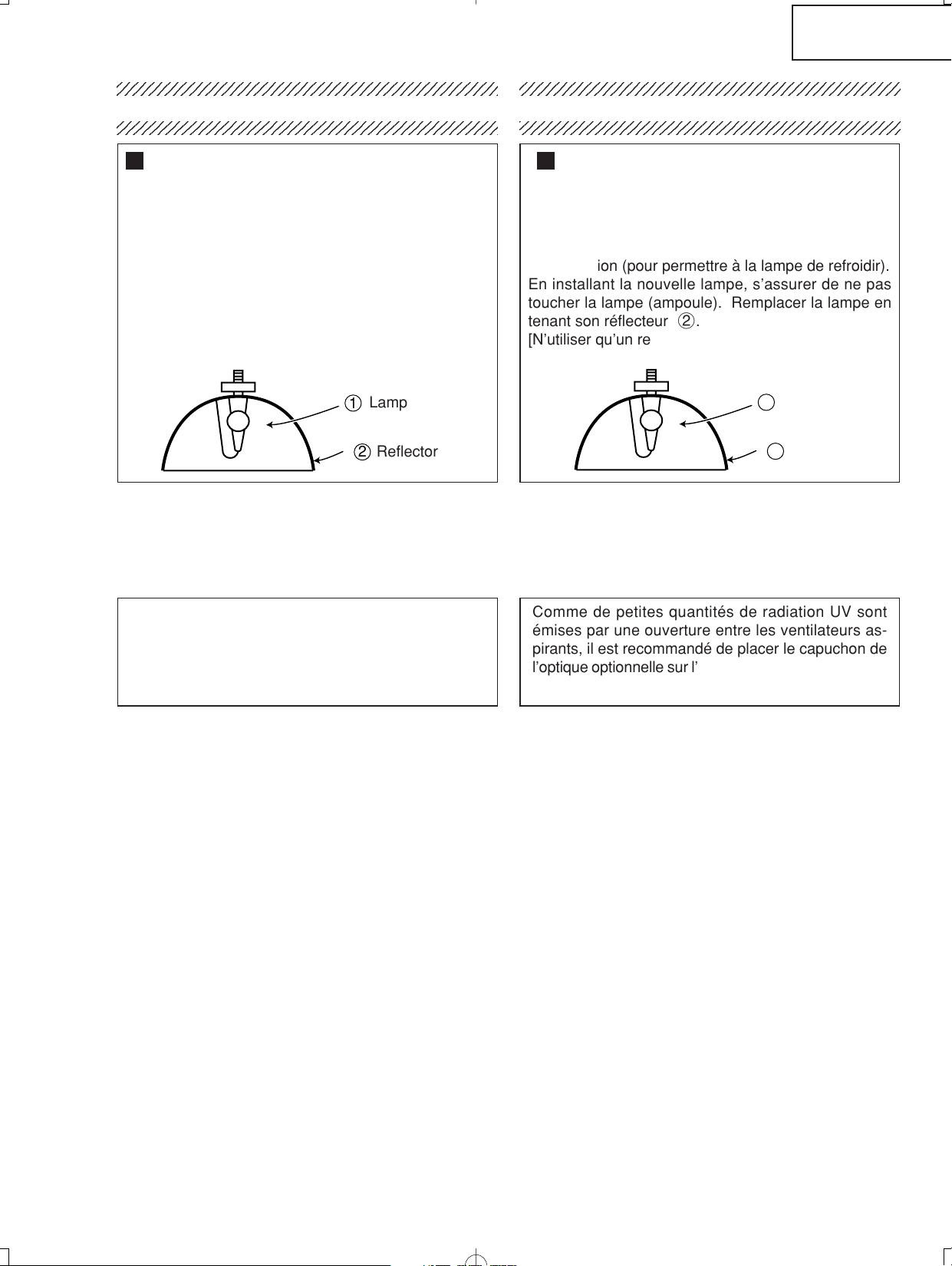

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

Reflector

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

Lampe

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans, it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

7

Page 8

XV-Z2000

DT-400

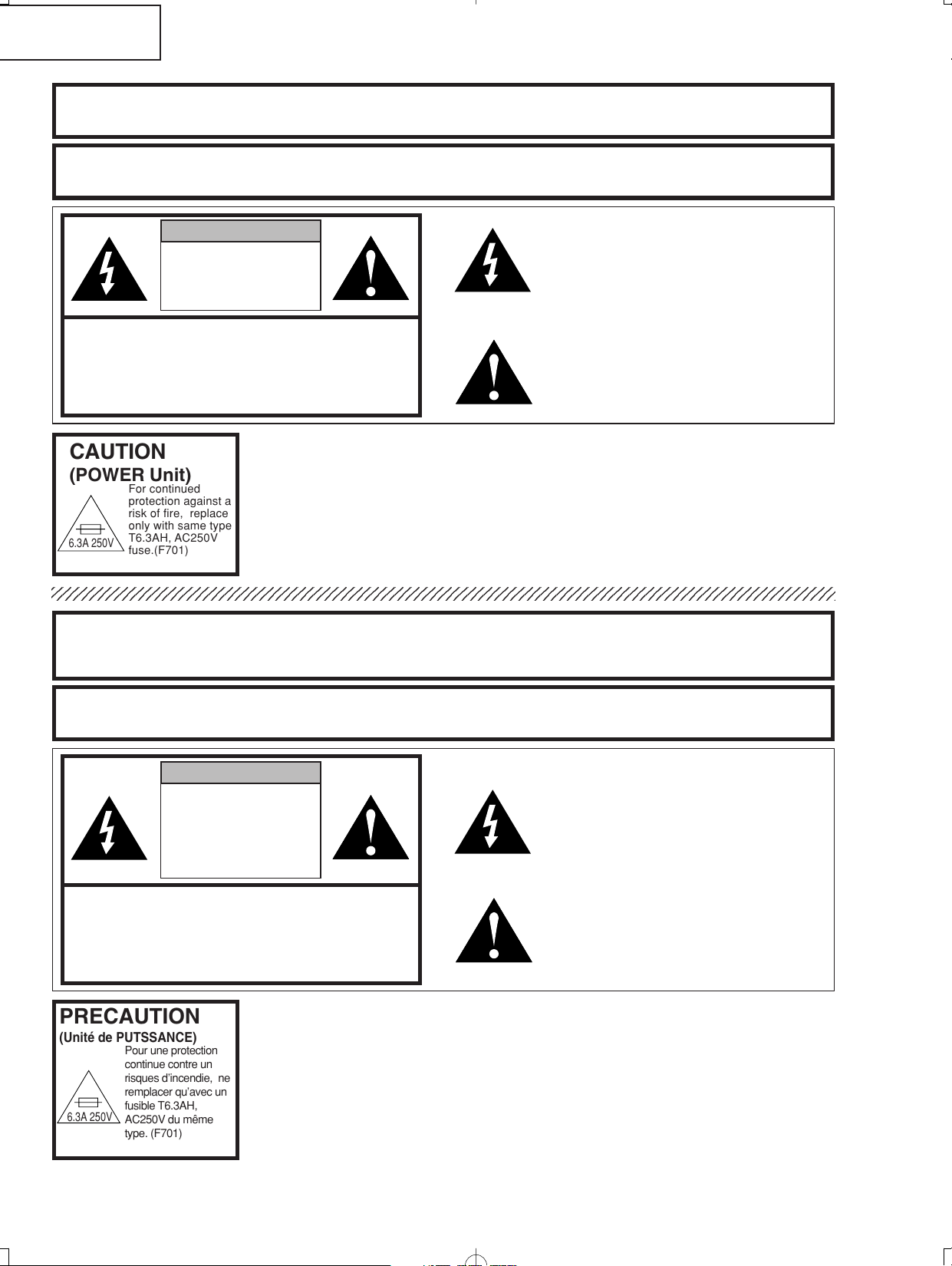

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

6.3A 250V

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

For continued

protection against a

risk of fire, replace

only with same type

T6.3AH, AC250V

fuse.(F701)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

PASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de PUTSSANCE)

6.3A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible T6.3AH,

AC250V du même

type. (F701)

8

Page 9

XV-Z2000

L Fa

DT-400

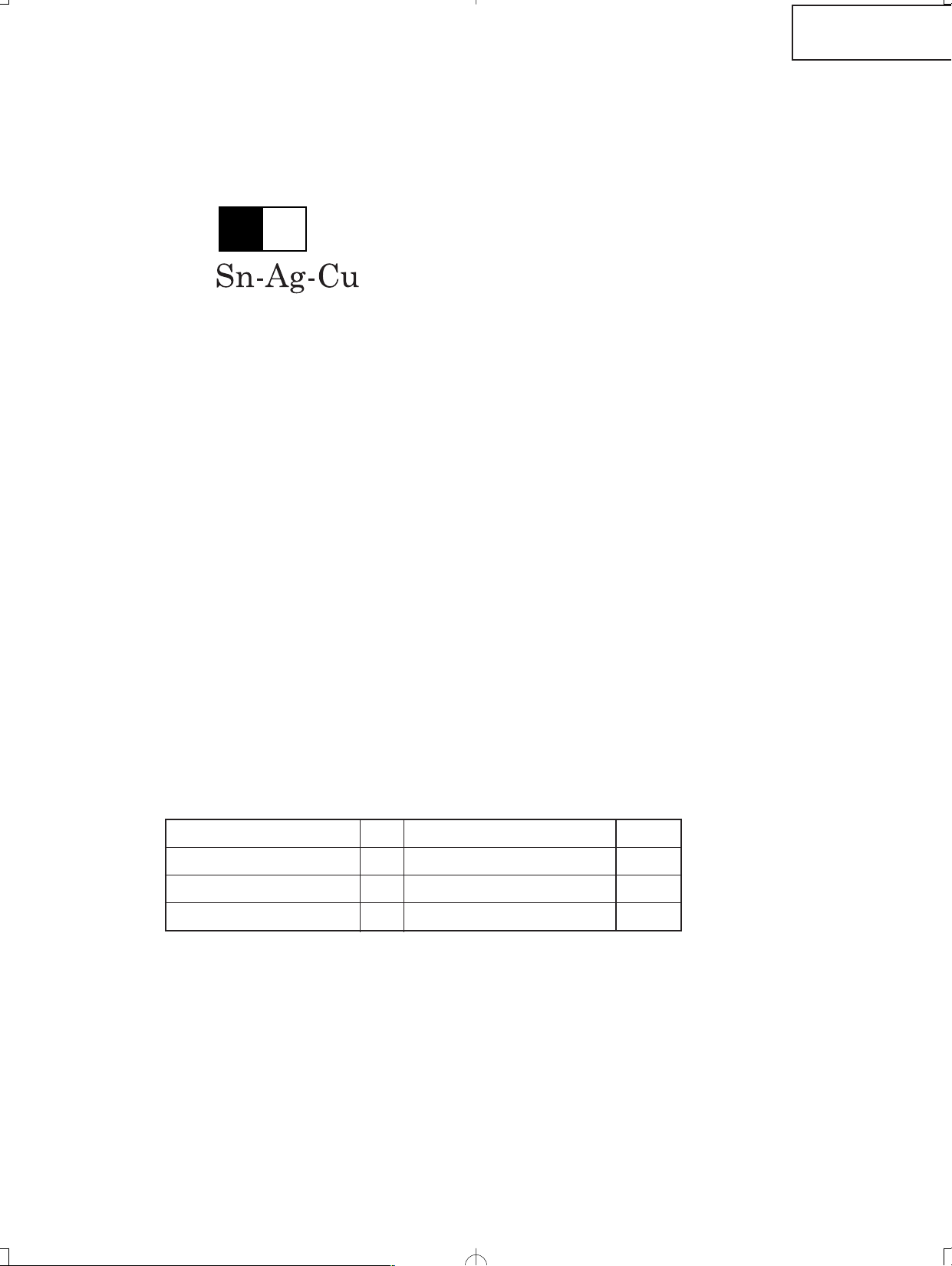

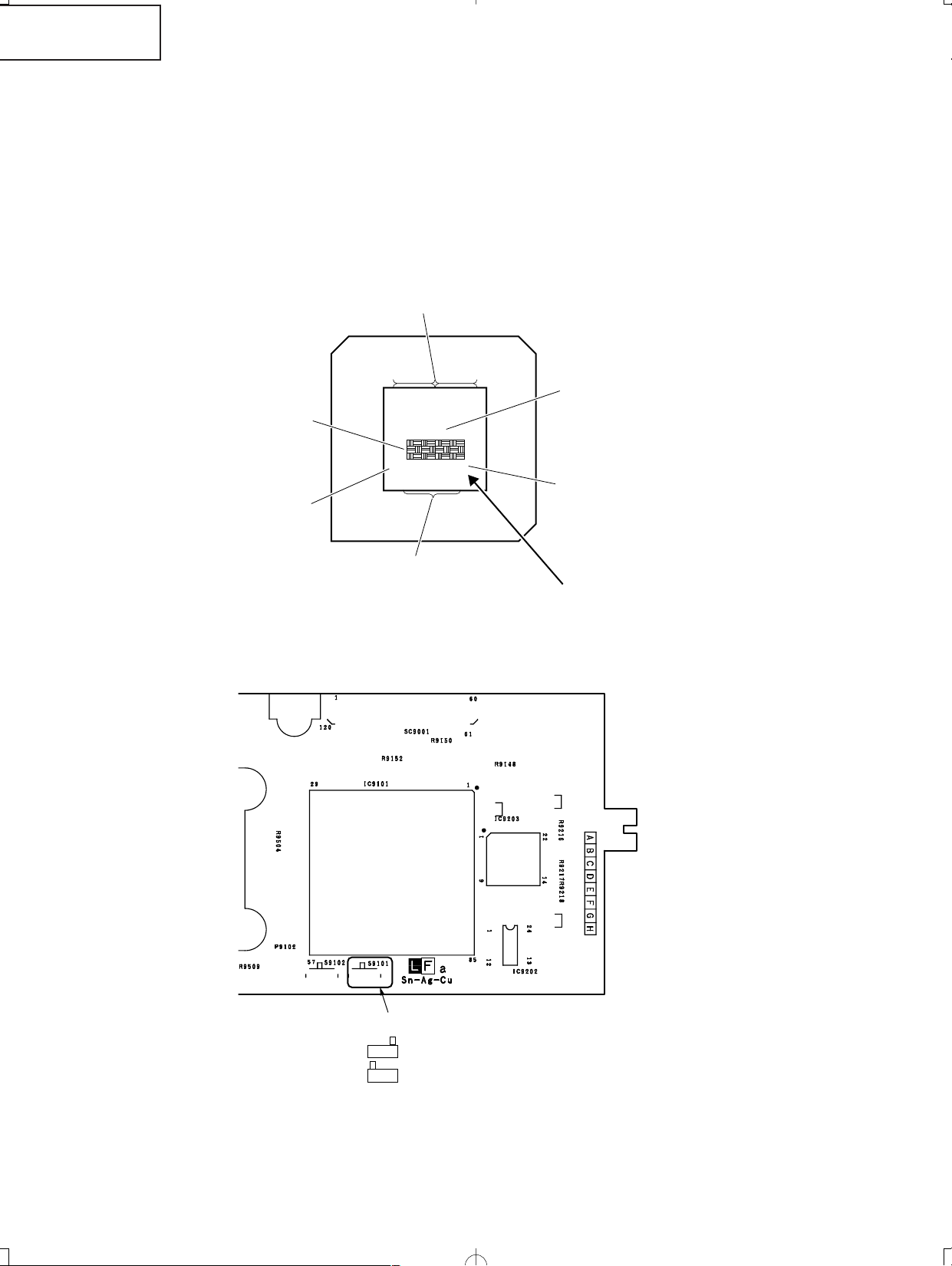

Precautions for using lead-free solder

1 Employing lead-free solder

"PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the

PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. However, since the land may be peeled off or the maximum heat-resistance temperature

of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

9

Page 10

XV-Z2000

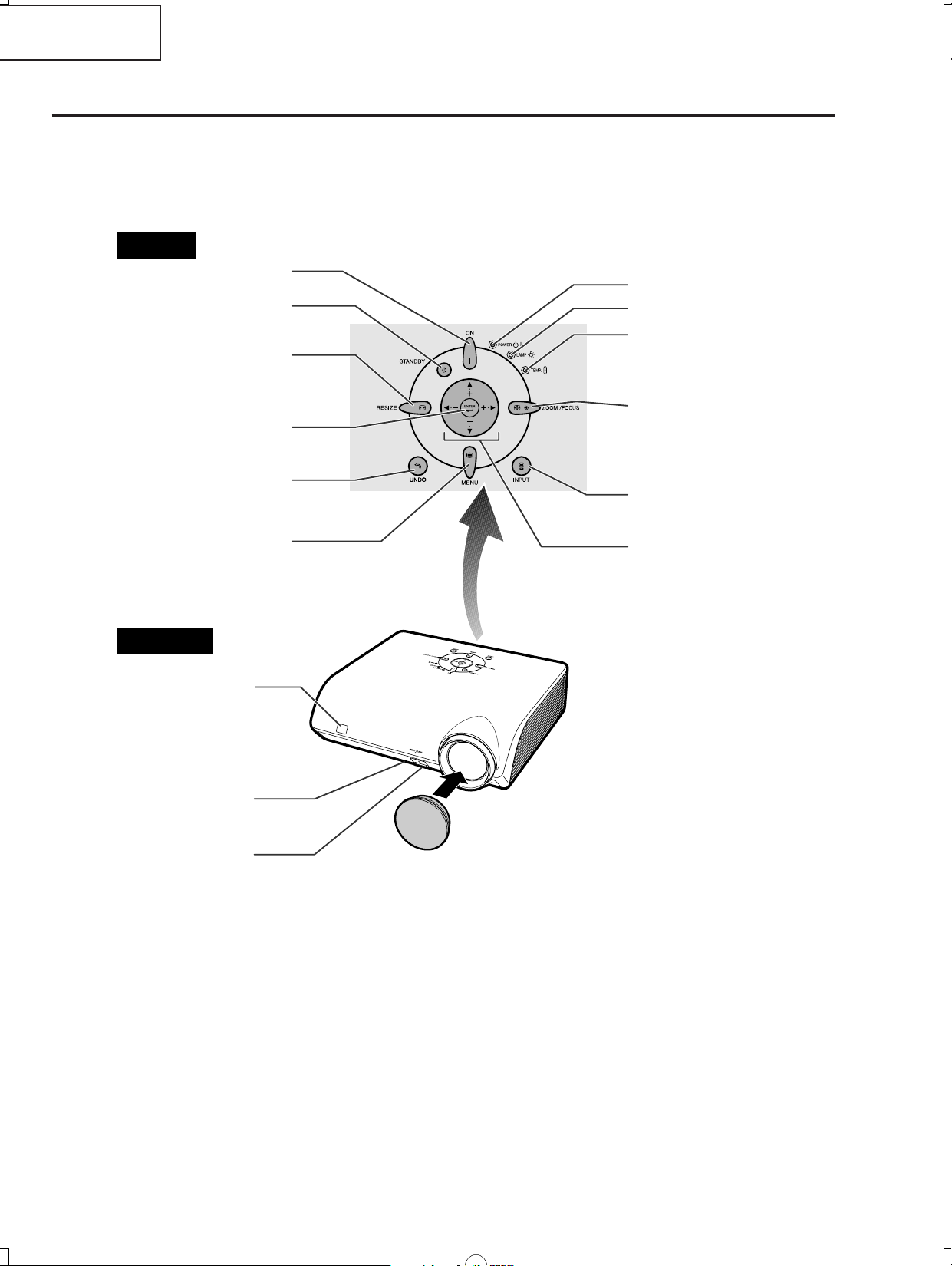

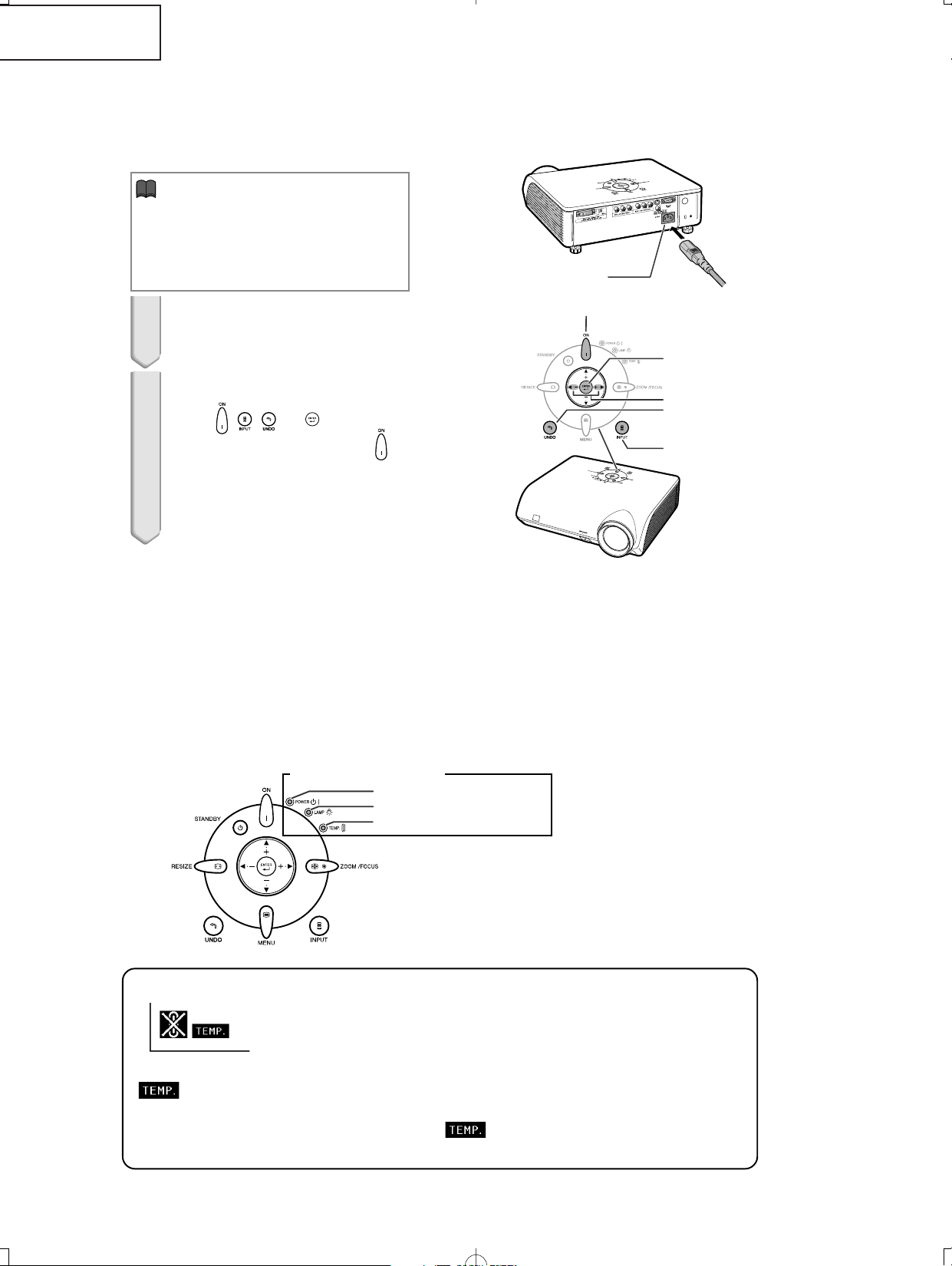

Adjustment buttons

('/"/\/|)

Select menu items and other

settings.

INPUT button

Switch input mode 1, 2, 3, 4,

5 or DIGITAL.

ZOOM/FOCUS button

Adjust the projected image

size or adjust the focus.

Temperature warning

indicator

Lamp indicator

Power indicator

Remote control sensor

HEIGHT ADJUST button

Front adjustment foot

(on the bottom of

the projector)

MENU button

Display adjustment and

setting screens.

ENTER button

Set items selected or

adjusted on the menu.

UNDO button

Undo an operation or

returning to the previous

display.

STANDBY button

Put the projector into standby

mode.

RESIZE button

Switch the picture display

(STRETCH, SIDE BAR, etc.).

ON button

Turn the power on.

Projector

• Attaching the lens cap

Push the lens cap on until it clicks

into position.

• Removing the lens cap

Pull the lens cap directly outward.

Top View

Front View

DT-400

OPERATION MANUAL

10

Page 11

XV-Z2000

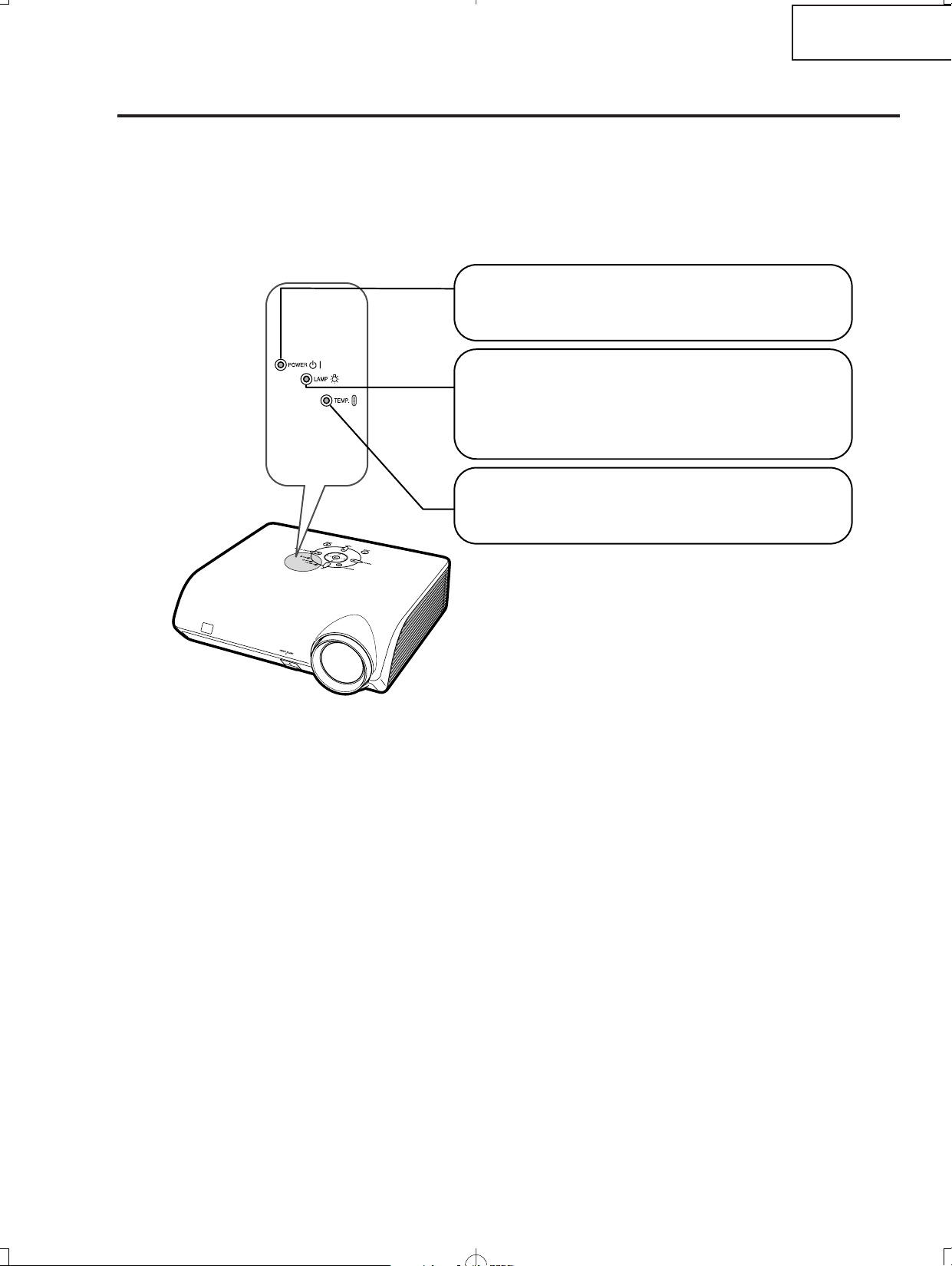

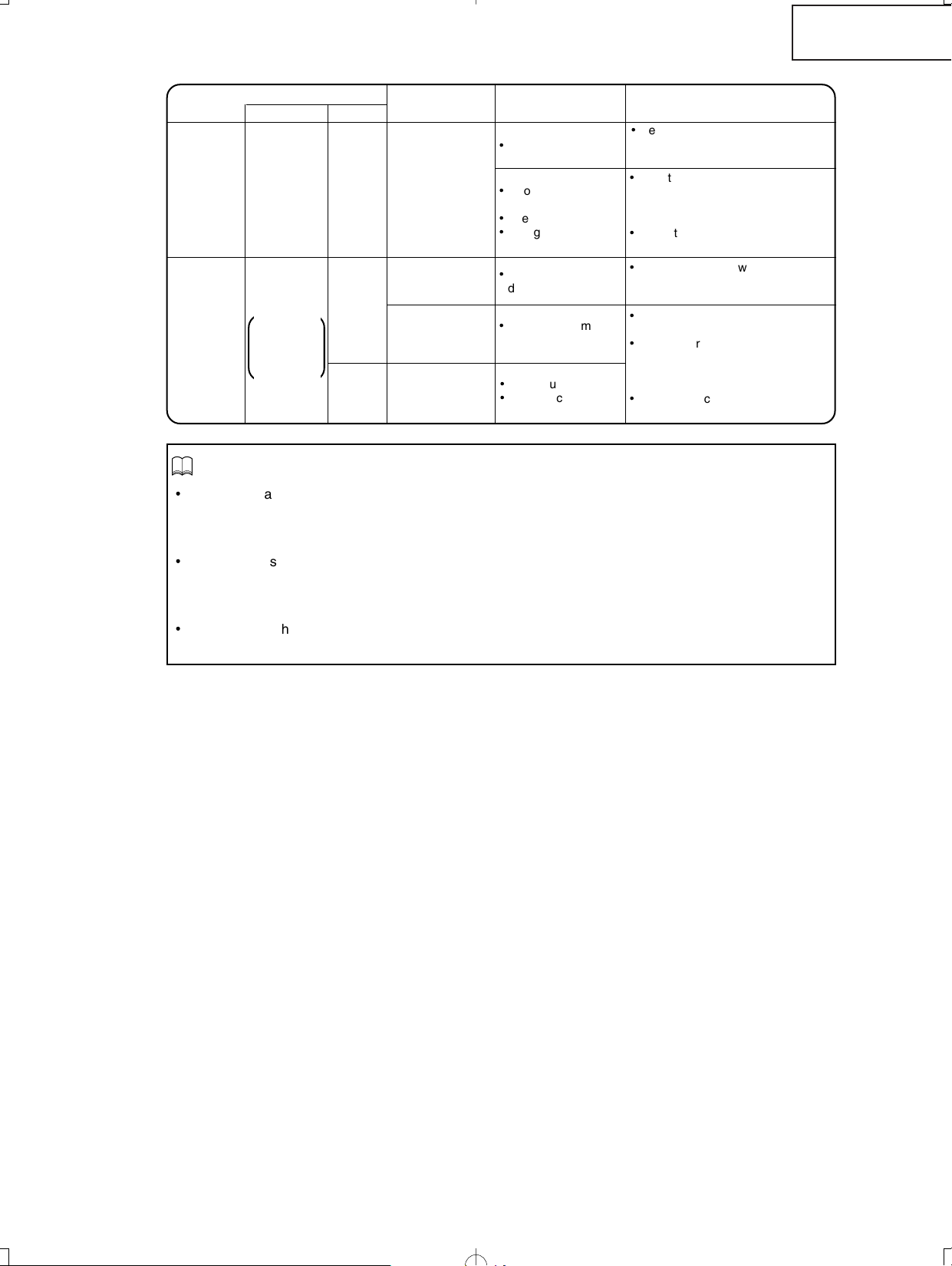

About the Indicators on the Projector

Power indicator

Red on

...

Normal (Standby)

Green on

...

Normal (Power on)

Temperature warning indicator

Off

...

Normal

Red on

...

The internal temperature is abnormally high.

Lamp indicator

Green on

...

Normal

Green blinks

...

The lamp is warming up or shutting down.

Red on

...

The lamp has been shut down abnormally or

needs to be changed.

DT-400

11

Page 12

XV-Z2000

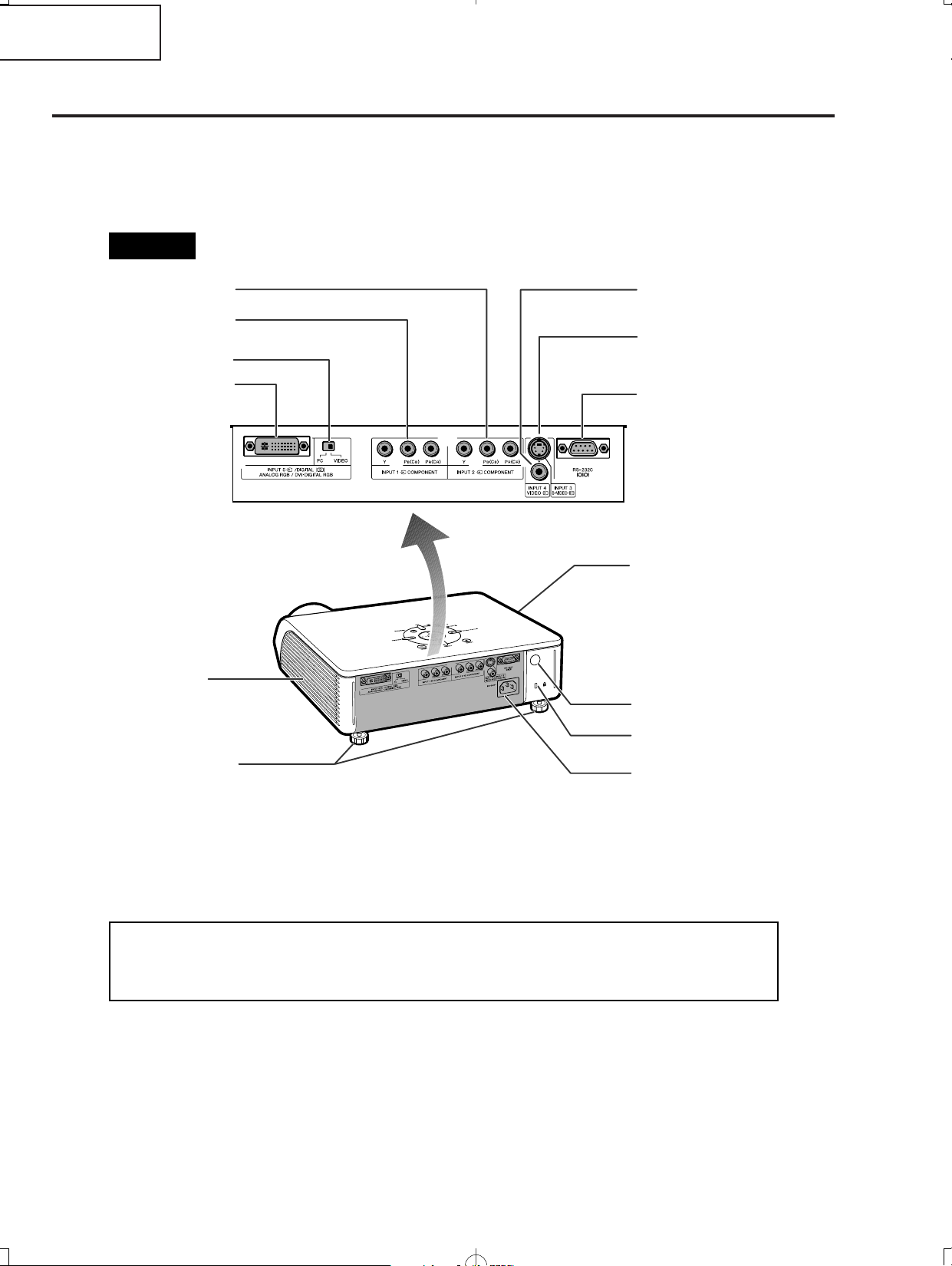

Projector (Rear View)

Using the Kensington Lock

• This projector has a Kensington Security Standard connector for use with a Kensington MicroSaver Security

System. Refer to the information that came with the system for instructions on how to use it to secure the

projector.

Remote control sensor

AC socket

Connect the supplied

Power cord.

Kensington Security

Standard connector

Rear adjustment feet

Intake vent

Exhaust vent

The speed and pitch of

the cooling fan may

change during operation

in response to internal

temperature changes.

This is normal operation

and does not indicate a

malfunction.

INPUT 2 terminal

Component signals.

Digital input type switch

INPUT 5/DIGITAL

terminal

INPUT 1 terminal

Component signals.

INPUT 4 terminal

Connect video

equipment.

INPUT 3 terminal

Connect video

equipment with an

S-video terminal.

RS-232C terminal

Control the projector using a

computer.

Terminals

DT-400

12

Page 13

XV-Z2000

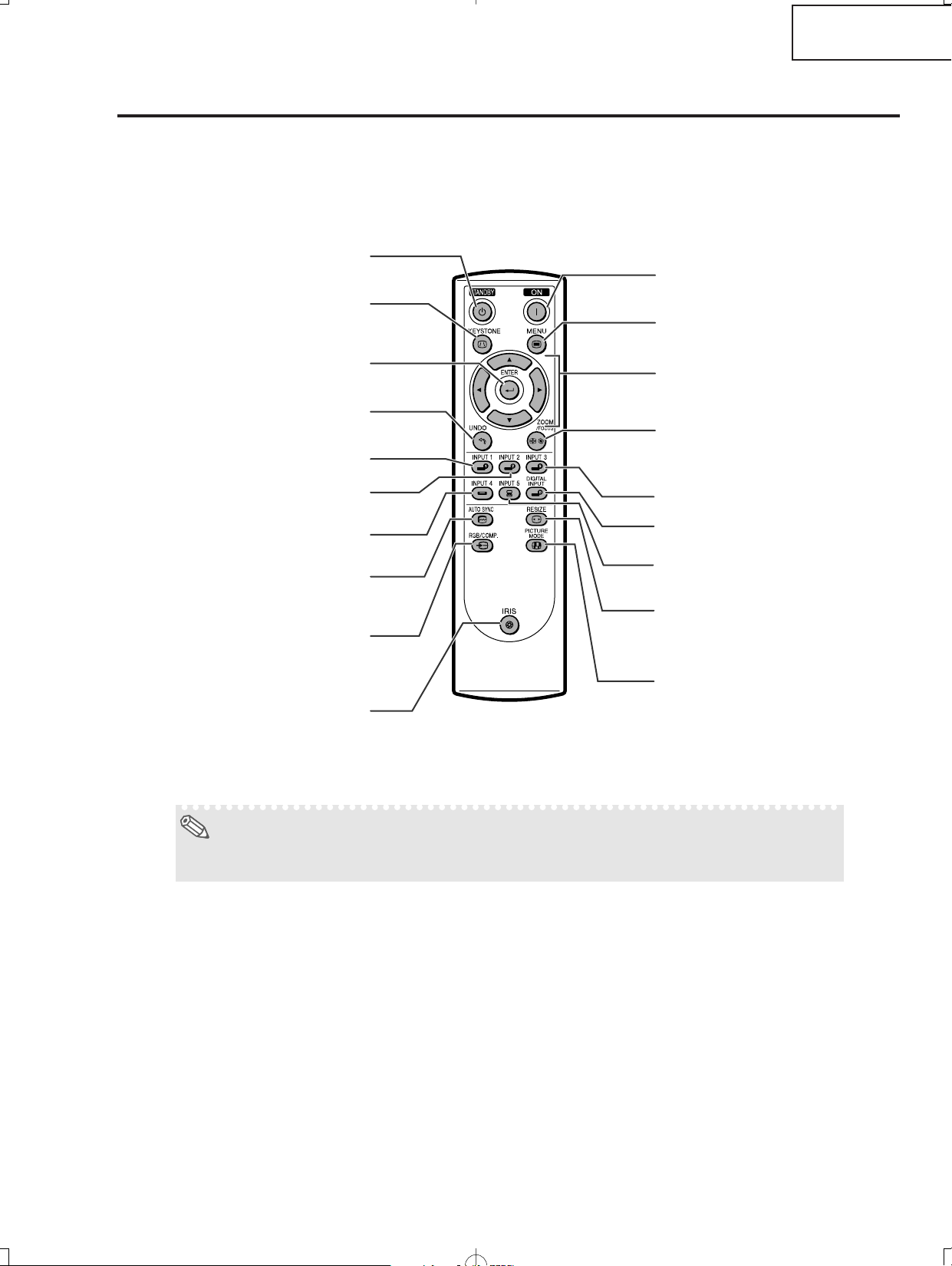

Remote Control

Adjustment buttons

('/"/\/|)

MENU button

Display adjustment and setting

screens.

ON button

Turn the power on.

ZOOM/FOCUS button

Adjust the projected image

size or adjusting the focus.

INPUT 3 button

INPUT 5 button

RESIZE button

Switch the picture display

(STRETCH, SIDE BAR, etc.).

DIGITAL INPUT button

PICTURE MODE button

Select the picture setting (Memory)

stored in “Picture Mode” on the

“Picture” menu.

STANDBY button

Put the projector into standby

mode.

KEYSTONE button

Enter the Keystone

Correction mode.

ENTER button

Set items selected or

adjusted on the menu.

UNDO button

Undo an operation or returning to

the previous display.

INPUT 1 button

INPUT 2 button

INPUT 4 button

AUTO SYNC button

Automatically adjust images when

connected to a computer.

RGB/COMP. button

Switch the signal type

(RGB or Component).

IRIS button

Switch “HIGH BRIGHTNESS

MODE” or “HIGH CONTRAST

MODE”.

Note

• All the buttons on the remote control are made of luminous material that is visible in the dark. Visibility will

diminish over time. Exposure to light will recharge the luminous buttons.

DT-400

13

Page 14

XV-Z2000

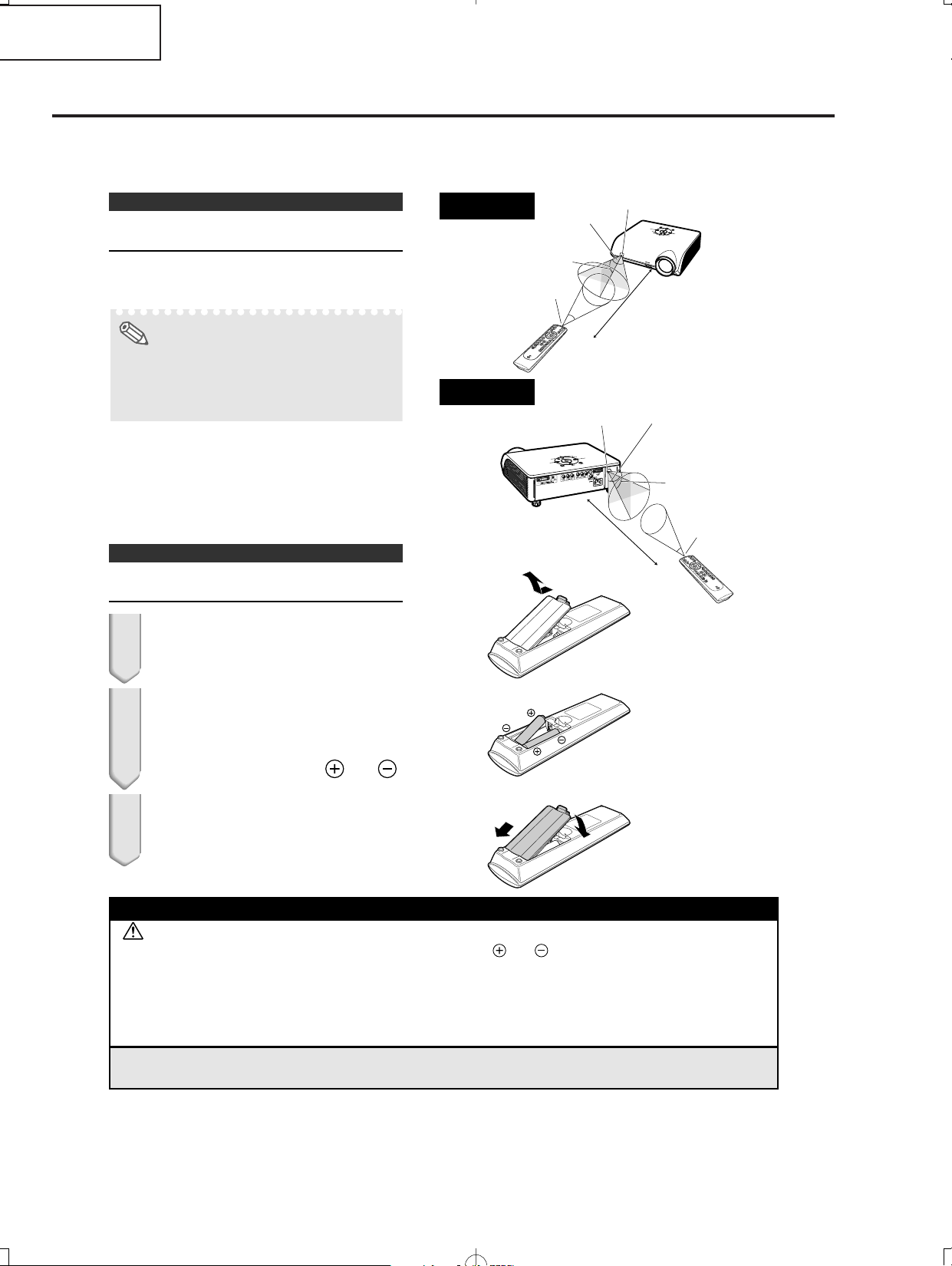

Inserting the Batteries

1

Pull down the tab on the cover

and remove the cover towards

the direction of the arrow.

2

Insert the included batteries

(two “AA” size).

• Insert the batteries making sure the polarities correctly match the

and

marks inside the battery compartment.

3

Insert the lower tab of the cover

into the opening, and lower the

cover until it clicks in place.

Incorrect use of the batteries may cause them to leak or explode. Please follow the precautions below.

Caution

• Insert the batteries making sure the polarities correctly match the and marks inside the battery compartment.

• Batteries of different types have different properties, therefore do not mix batteries of different types.

• Do not mix new and old batteries.

This may shorten the life of new batteries or may cause old batteries to leak.

• Remove the batteries from the remote control once they have run out, as leaving them in can cause them to leak.

Battery fluid from leaked batteries is harmful to skin, therefore ensure to first wipe them and then remove them using a cloth.

• The batteries included with this projector may run down in a short period, depending on how they are kept.

Ensure to replace them as soon as possible with new batteries.

Usable Range

The remote control can be used to control the

projector within the ranges shown in the

illustration.

Note

•

The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the signal may

differ depending on the screen material.

When using the remote control:

• Ensure not to drop, expose to moisture or high

temperature.

• The remote control may malfunction under a

fluorescent lamp. In this case, move the projector away from the fluorescent lamp.

Remote control sensor

Remote

control

signal

transmitters

Remote control

23' (7 m)

30°

30°

30°

Front View

Remote control

30°

30°

Remote control sensor

23' (7 m)

Remote

control

signal

transmitters

30°

Rear View

DT-400

14

Page 15

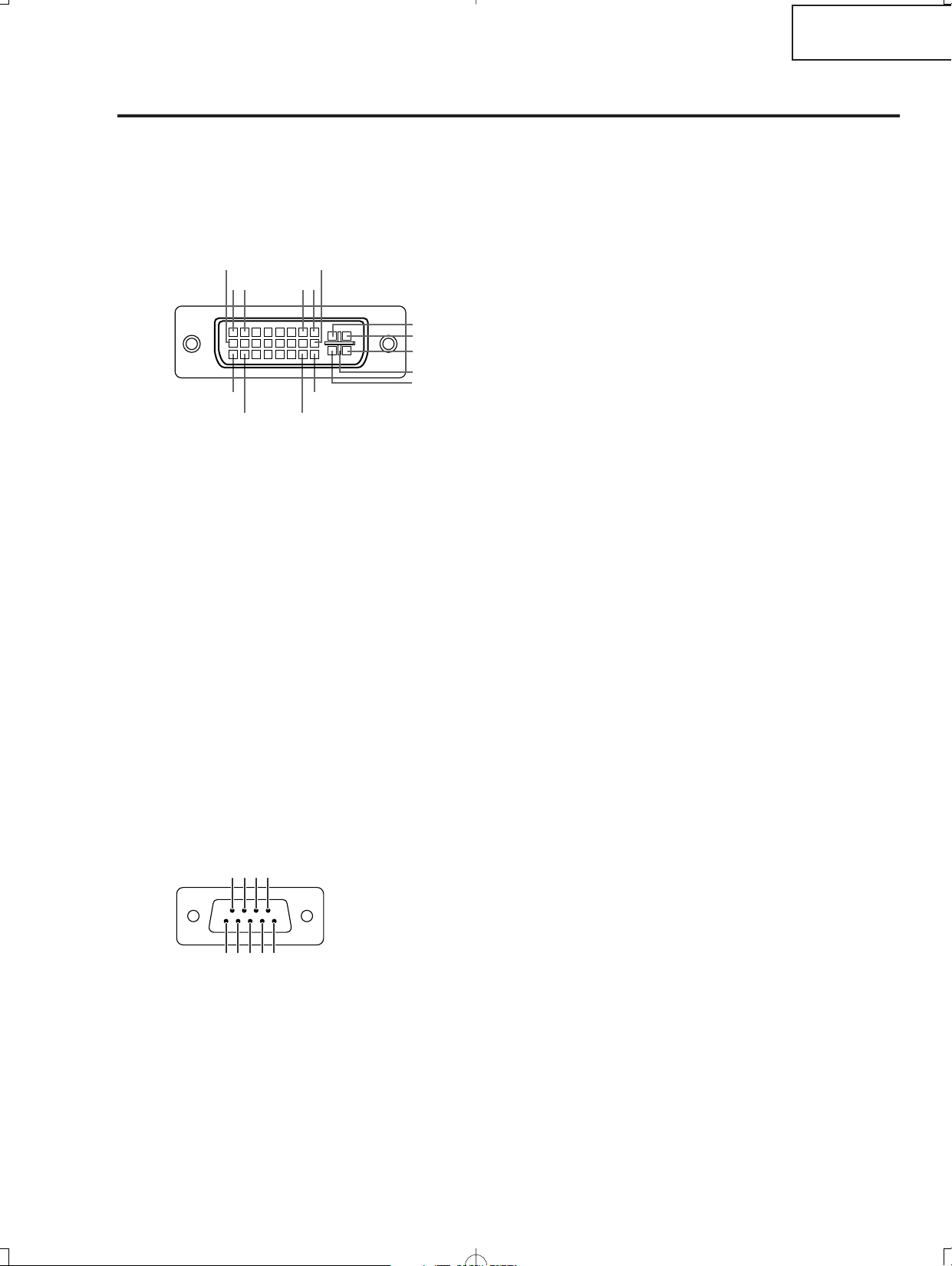

Connection Pin Assignments

RS-232C Port: 9-pin D-sub male connector

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Reserved Connected to internal circuit

5 SG Signal Ground Connected to internal circuit

6 Reserved Connected to internal circuit

7 Reserved Connected to internal circuit

8 Reserved Connected to internal circuit

9 Not connected

DVI-I (INPUT 5) port : 29 pin connector

•

DVI Digital INPUT

Pin No. Signal Pin No. Signal

1 T.M.D.S data 2– 16 Hot plug detection

2 T.M.D.S data 2+ 17 T.M.D.S data 0–

3 T.M.D.S data 2 shield 18 T.M.D.S data 0+

4 Not connected 19 T.M.D.S data 0 shield

5 Not connected 20 Not connected

6 DDC clock 21 Not connected

7 DDC data 22 T.M.D.S clock shield

8 Not connected 23 T.M.D.S clock+

9 T.M.D.S data 1– 24 T.M.D.S clock–

10 T.M.D.S data 1+ C1 Not connected

11 T.M.D.S data 1 shield C2 Not connected

12 Not connected C3 Not connected

13 Not connected C4 Not connected

14 +5V power C5 Ground

15 Ground

•

DVI Analog RGB Input

Pin No. Signal Pin No. Signal

1 Not connected 16 Hot plug detection

2 Not connected 17 Not connected

3 Not connected 18 Not connected

4 Not connected 19 Not connected

5 Not connected 20 Not connected

6 DDC clock 21 Not connected

7 DDC data 22 Not connected

8 Vertical sync 23 Not connected

9 Not connected 24 Not connected

10 Not connected C1 Analog input Red

11 Not connected C2 Analog input Green

12 Not connected C3 Analog input Blue

13 Not connected C4 Horizontal sync

14 +5V power C5 Ground

15 Ground

•

DVI Analog Component Input

Pin No. Signal Pin No. Signal

1 Not connected 16 Not connected

2 Not connected 17 Not connected

3 Not connected 18 Not connected

4 Not connected 19 Not connected

5 Not connected 20 Not connected

6 Not connected 21 Not connected

7 Not connected 22 Not connected

8 Not connected 23 Not connected

9 Not connected 24 Not connected

10 Not connected C1 Analog input P

R/CR

11 Not connected C2 Analog input Y

12 Not connected C3 Analog input P

B/CB

13 Not connected C4 Not connected

14 Not connected C5 Ground

15 Ground

17

∞∞∞∞∞∞∞∞∞

~

∞∞∞∞∞∞∞∞∞

∞∞∞∞

~

∞∞∞∞

∞∞∞∞

~

∞∞∞∞

24

18 23

C3

21

9

16

C1

C2

C4

C5

87

6789

1

2345

XV-Z2000

DT-400

15

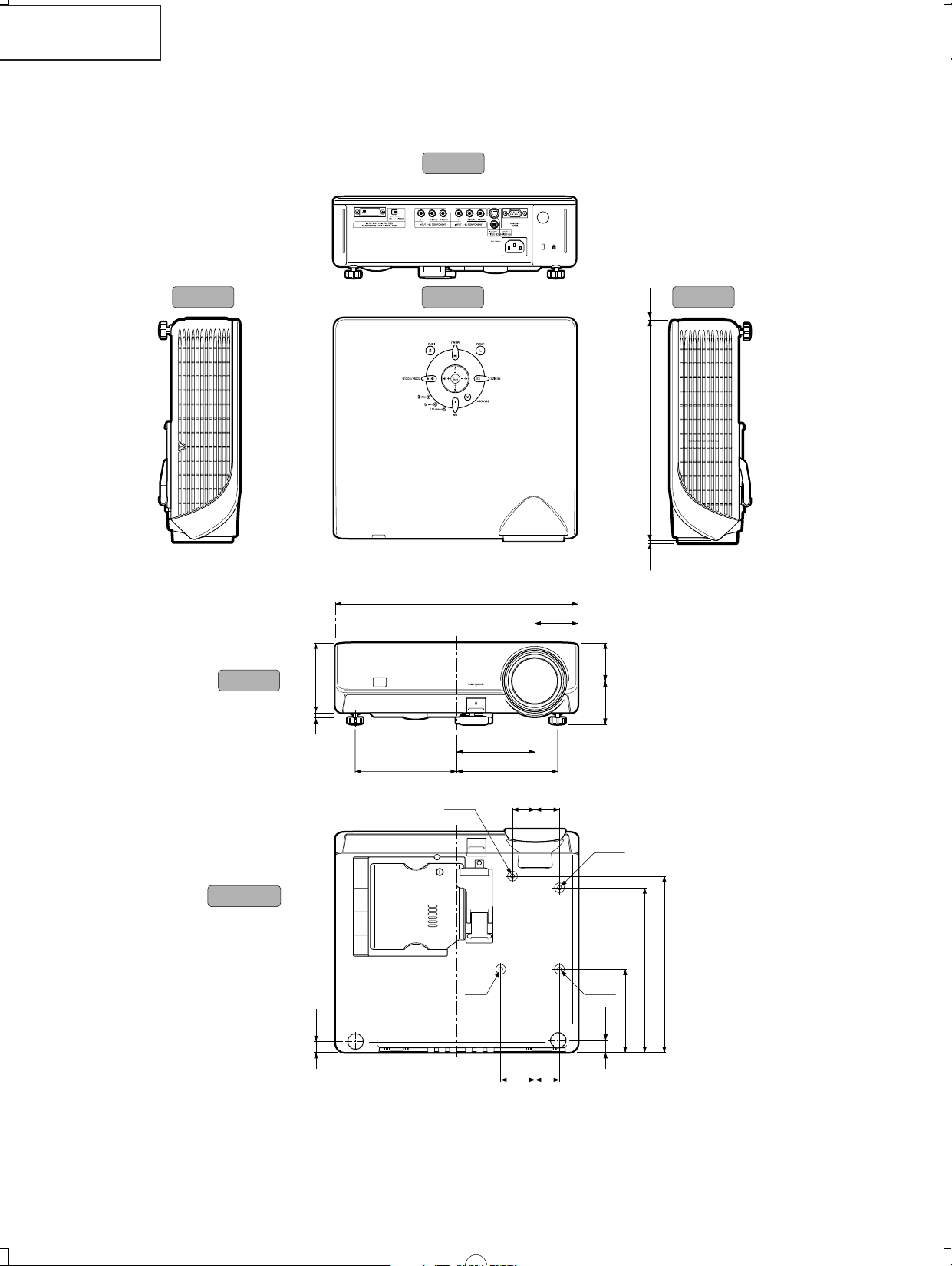

Page 16

XV-Z2000

Units: inches (mm)

Side View Side View

Top View

Rear View

Front View

Bottom View

M4

M4

M4

M4

9

/

64

(3.25)

11

7

/

64

(282)

1

/

16

(1.5)

2

11

/64 (55.05)

12

7

/32 (310)

1

59

/

64

(48.5)

3

33

/

64

(89)

13

/

64

(5)

2

3

/

16

(55.5)

3

15

/16 (99.95)

5

7

/64 (129.5)5 7/64 (129.5)

5

/

8

(15.5)

9

/

16

(14)

4

3

/

16

(106.3)

8

9

/

32

(210.3)

8

7

/

8

(225.3)

1 7/

32

(30.9)

1

5

/

32

(29.1)

1

7

/

32

(30.9)

1

3

/

4

(44.1)

DT-400

DIMENSIONS

16

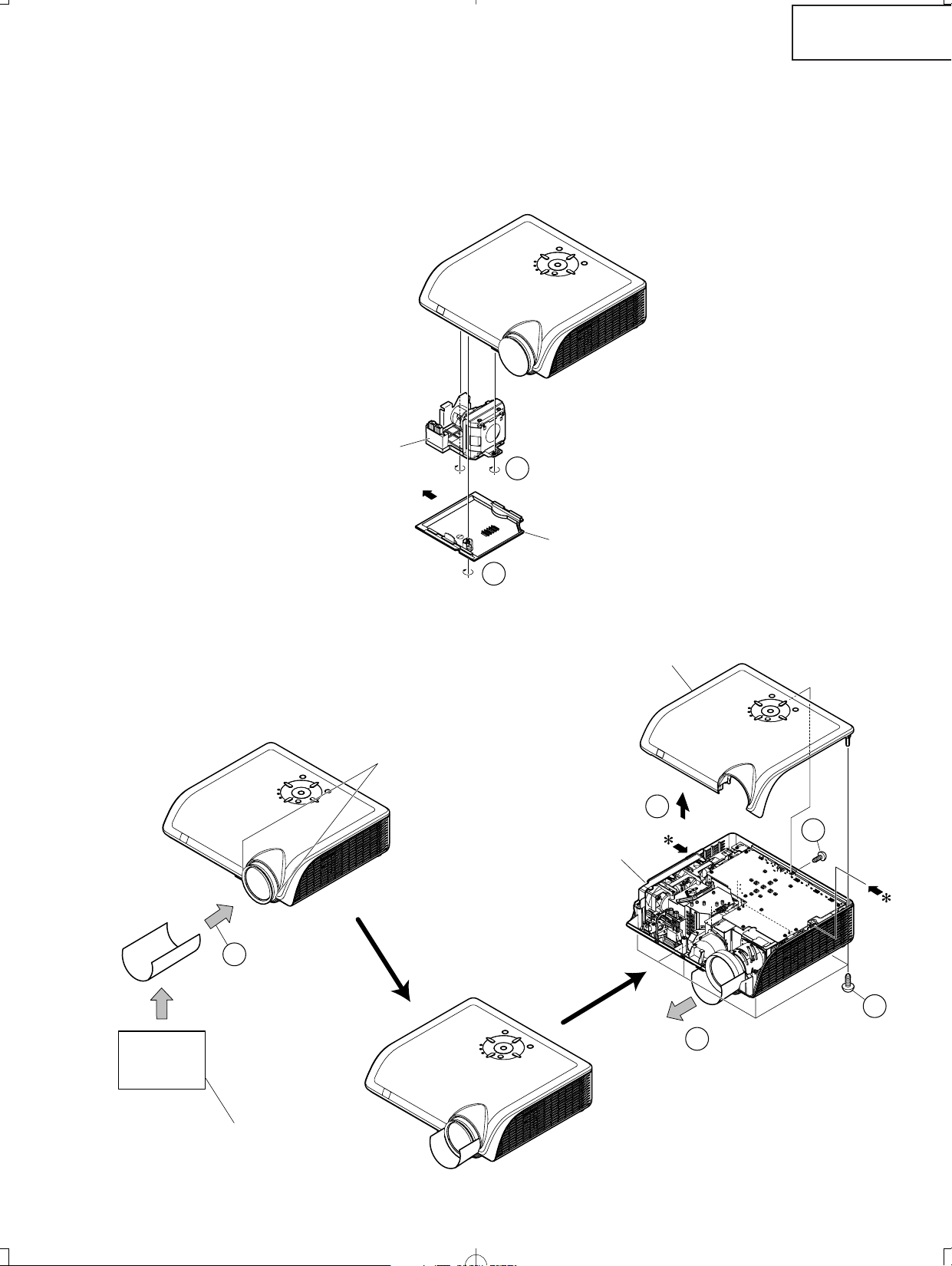

Page 17

XV-Z2000

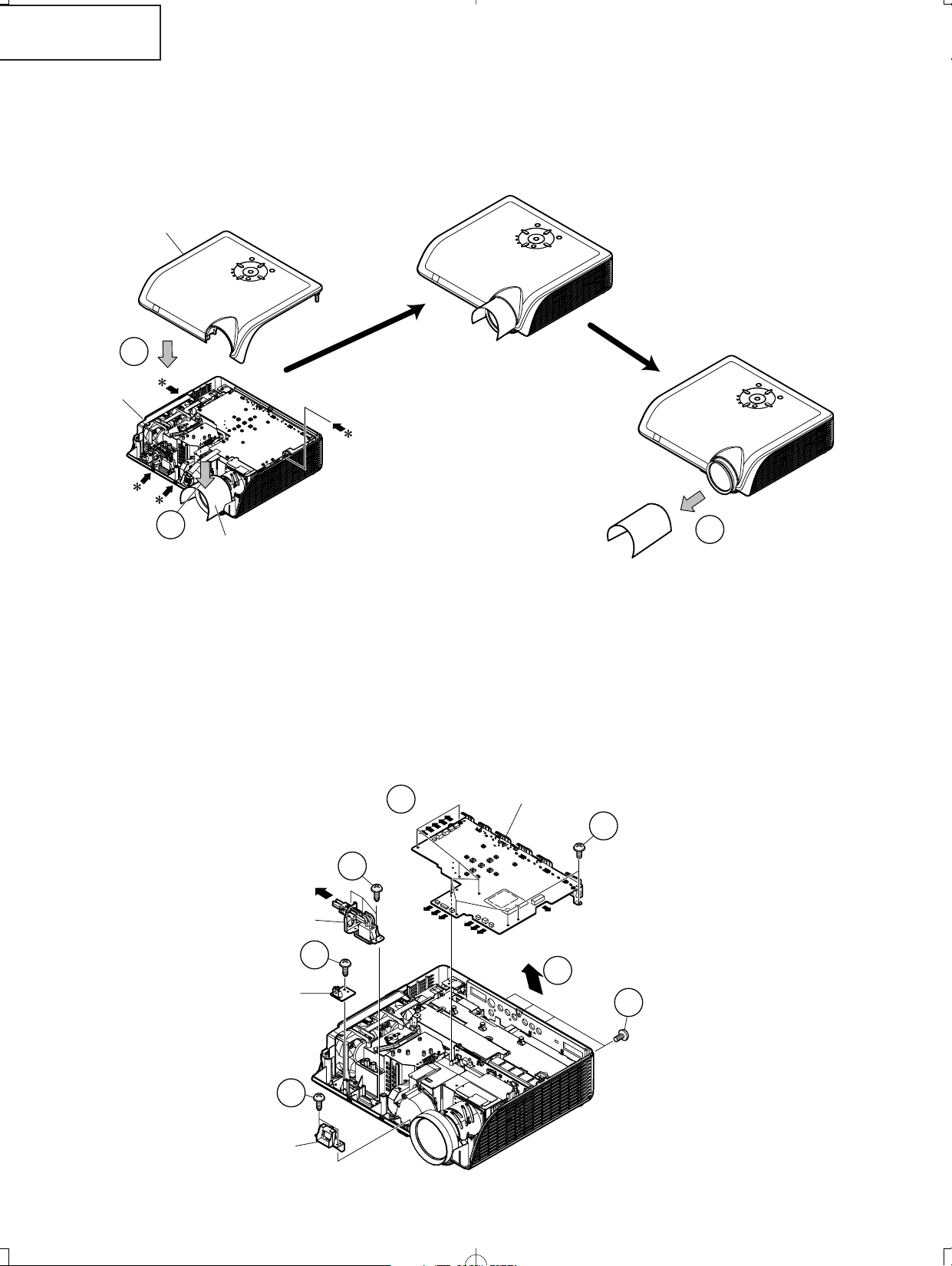

Lamp Unit Cover

Lamp Unit

1-2

1-3

2-4

2-3

2-1

Thick paper such as a postcard.

To protect the lens barrel

against scratches.

Short side

(10cm)

Long side

(15cm)

Top Body

Bottom Body

2-2

2-2

DT-400

REMOVING OF MAJOR PARTS

1. Removing the lamp unit cover and the lamp unit

1-1. Loosen the lamp unit cover fixing screw, slide the lamp unit cover in allow direction and lift off the lamp unit

cover.

1-2. Loosen 2 lamp unit fixing screws and lift off the lamp unit.

2. Removing the top body

2-1. Insert thick paper such as a postcard under the lens barrel.

2-2. Remove 7 fixing screws for the top and bottom bodies.

2-3. Press and hold the areas (marked with *) and disengage the claws on the top body to remove the top body.

2-4. Draw out a postcard.

17

Page 18

XV-Z2000

4-1

4-4

4-5

4-6

4-2

4-7

4-3

Main PWB

Button Holder

Switch Bracket

Front-R/C Unit

Top Body

Bottom Body

Thick paper such as postcard

3-2

3-1

3-3

DT-400

3. Attaching the top body (For the screws to apply, refer back to "2. Removing

the top body".)

3-1. Place the postcard over the lens barrel.

3-2. Place the top body in position. Make sure the four hooks are tightly caught.

3-3. Draw out the postcard.

4. Removing the main PWB unit and the peripheral units

4-1. Remove 4 main PWB fixing screws (terminal side).

4-2. Remove 9 main PWB fixing screws.

4-3. Remove 12 connectors from the main PWB.

4-4. Pull out the switch bracket connector and remove 3 fixing screws.

4-5. Remove the fixing screw for the front R/C PWB.

4-6. Remove 2 fixing screws for the button holder unit.

4-7. Lift off the main PWB in an oblique direction from the optical mechanism unit side.

18

Page 19

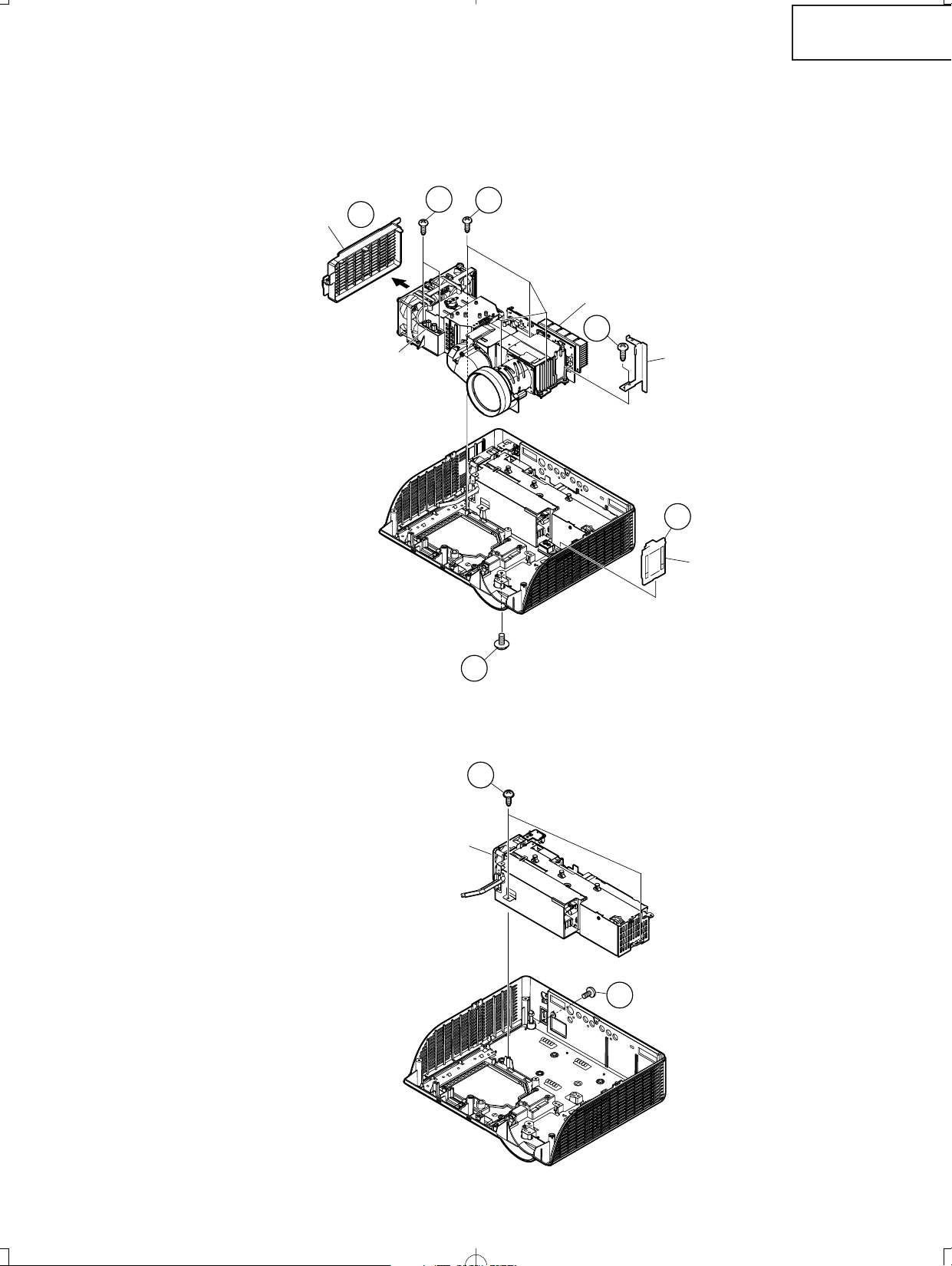

Power/Ballast Unit

6-1

6-1

5. Removing the optical mechanism unit

Duct

Optical Mechanism Unit

5-3

5-3

5-2

5-4

Ballast Output Socket

5-1

PWB Bracket

Speaker Cover

5-5

5-1. Remove the fixing screw from the PWB bracket.

5-2. Remove 2 fixing screws for the ballast output socket, and remove the ballast output socket.

5-3. Remove 5 fixing screws for the optical mechanism unit, and remove the optical mechanism unit.

5-4. Remove the duct, pulling up the optical mechanism unit.

5-5. Remove the speaker cover.

XV-Z2000

DT-400

6. Removing the power/ballast unit

6-1. Remove 3 fixing screws for the power/ballast unit.

19

Page 20

XV-Z2000

Bracket-A

Bracket-B

Front Adjuster Foot

Front Adjuster Holder

Height Adjust Button

8-1

8-2

Power Unit

Fan

Air Flow

Ballast Unit

Ballast PWB

Rear-R/C PWB

Power PWB

Edge saddle

7-1

7-2

7-2

7-4

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-2

DT-400

7. Removing the power/ballast unit

7-1. Remove the fixing screw for the rear-R/C PWB.

7-2. Remove 4 fixing screws, 4 WH bosses and the edge saddle for the ballast unit.

7-3. Remove 11 fixing screws and 5 WH bosses for the power unit.

7-4. Remove 4 fixing screws for the fan.

8. Removing the peripheral units

8-1. Remove 4 fixing screws for the front adjuster foot.

8-2. Remove 8 bracket fixing screws and remove the bracket-A and bracket-B.

20

Page 21

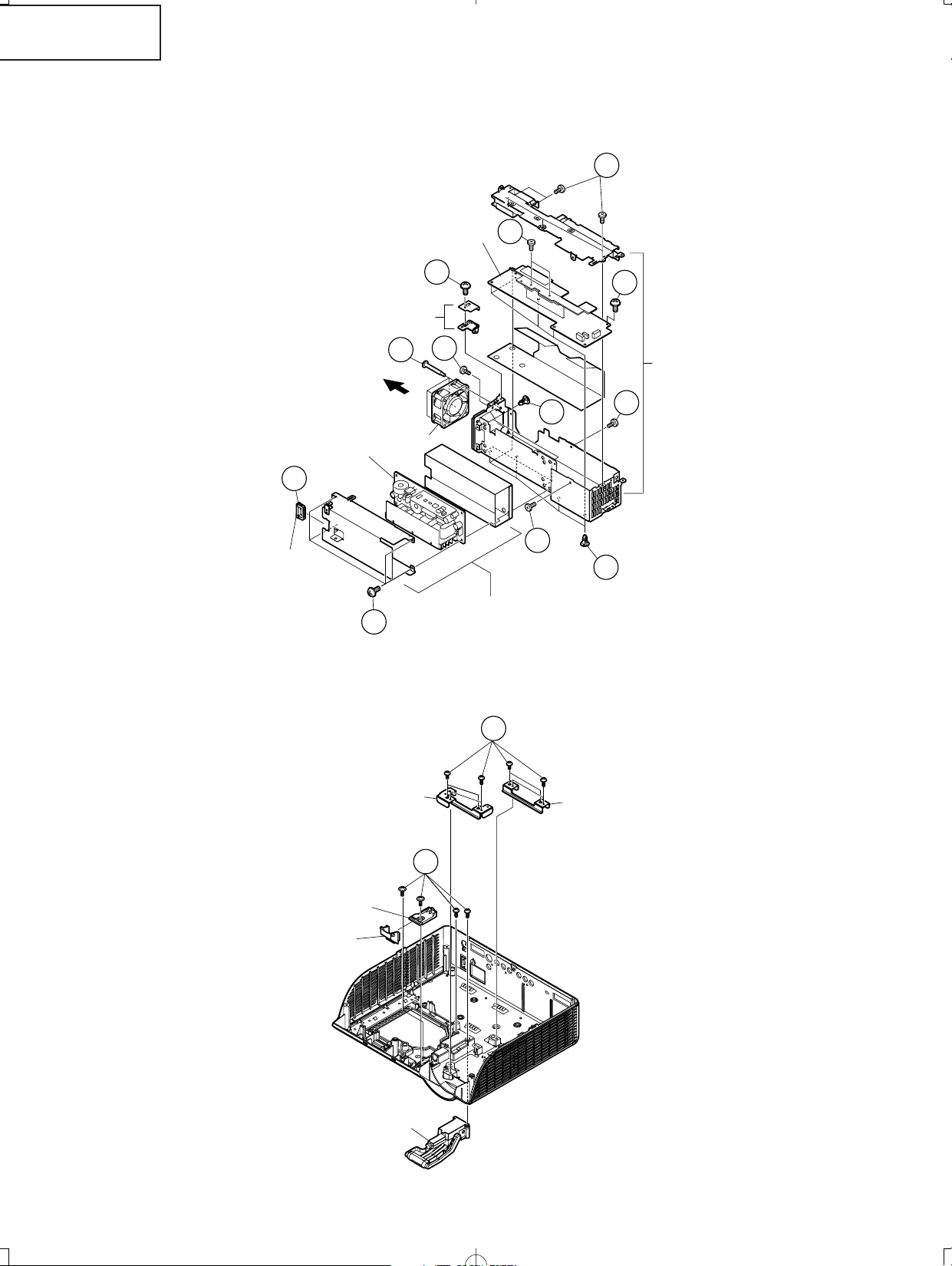

9-3

Earth Shield (L)

M4 screw (4 locations)

9-7

Earth Shield (S)

9-6

Reinforcement

(Bracket-B)

9-4

Reinforcement

(Bracket-A)

9-2

Melt the 17 pins.

Precaution

*Melt the pins with a soldering

iron to fix the earth shield.

Finally check for loosenes.

9-8

M3 screw (4 locations)

9-5

Nut (4 locations)

9-1

9. Fixing the earth shield

9-1. Install the four nuts.

9-2. Fit the reinforcement (bracket-A) in position.

9-3. Place the earth shield (L) as specified.

9-4. Fit the reinforcement (bracket-B) in position.

9-5. Tighten up the four M3 screws.

9-6. Tighten up the four M4 screws.

9-7. Place the earth shield (S) as specified.

9-8. Melt the 17 pins of the earth shield.

XV-Z2000

DT-400

21

Page 22

XV-Z2000

Power indicator

Lamp indicator

Temperature warning indicator

Maintenance Indicators

About the temperature warning indicator

If the temperature inside the projector increases, due to blockage of the air vents, or the setting location,

“ ” will illuminate in the lower left corner of the picture. If the temperature keeps on rising, the lamp will

turn off and the temperature warning indicator will blink, the cooling fan will run for a further 90 seconds, and

then the projector will enter the standby mode. After “

” appears, ensure to perform the measures

described on operation manual.

Info

• Make sure to reset the lamp timer only

when replacing the lamp. If you reset the

lamp timer and continue to use the same

lamp, this may cause the lamp to become

damaged or explode.

1 Connect the power cord.

• Plug the power cord into the AC socket

of the projector.

2 Reset the lamp timer.

• Press

, , ,

\\

\\

\,

and

||

||

| on the

projector in order, and then press

on

the projector.

•

“LAMP 0000H” is displayed on the lower

left of the screen, indicating that the lamp

timer is reset.

AC socket

\/|

buttons

ON button

ENTER button

UNDO button

INPUT button

DT-400

RESETTING THE TOTAL LAMP TIMER

● Resetting the total lamp timer

When replacing the lamp, reset the total lamp timer in the procedure below.

Lamp

■ It is recommended that the lamp (sold separately) be replaced when the remaining lamp life becomes 5% or less,

or when you notice a significant deterioration in the picture and color quality. The lamp life (percentage) can be

checked with the on-screen display.

■ Purchase a replacement lamp of type AN-K2LP from your place of purchase, nearest Sharp Projector Dealer or

Service Center.

■ The warning lights (ON/STANDBY button, lamp indicator and temperature warning indicator) on the projector

indicate problems inside the projector.

■ If a problem occurs, either the temperature warning indicator or the lamp indicator will illuminate red, and the

projector will enter the standby mode. After the projector has entered the standby mode, follow the procedures

given below.

22

Page 23

XV-Z2000

Maintenance indicator

Problem

Cause Possible solution

Temperature

warning

indicator

Normal

Abnormal

Off

Red on

(Standby)

The internal

temperature is

abnormally high.

Abnormal

•

Blocked air intake

•

Relocate the projector to an area

with proper ventilation

•

Cooling fan breakdown

•

Internal circuit failure

•

Clogged air intake

•

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

•

Clean the exhaust and intake

vents.

Lamp

indicator

Red on

(Standby)

The lamp does

not illuminate.

•

Burnt-out lamp

•

Lamp circuit failure

•

Carefully replace the lamp.

•

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Centerfor repair.

•

Please exercise care when

replacing the lamp.

Red on

Time to change

the lamp.

•

Remaining lamp life

becomes 5% or less.

Green on

Green blinks

when the lamp

is warming up

or shutting

down.

Info

•

If the temperature warning indicator illuminates and the projector enters the standby mode, check whether

any of the ventilation holes are blocked and then try turning the power back on. Wait until the projector has

cooled down completely before plugging in the power cord and turning the power back on.

(At least 10 minutes.)

•

If the power is turned off for a brief moment due to power outage or some other cause while using the

projector, and the power supply recovers immediately after that, the lamp indicator will illuminate in red

and the lamp may not be lit. In this case, unplug the power cord from the AC outlet, replace the power

cord in the AC outlet and then turn the power on again.

•

Do not unplug the power cord after the projector has entered the standby mode and while the cooling fan

is running. The cooling fan runs for about 90 seconds.

The lamp does

not illuminate.

•

The lamp is shut

down abnormally.

•

Disconnect the power cord from

the AC outlet, and then connect it

again.

DT-400

23

Page 24

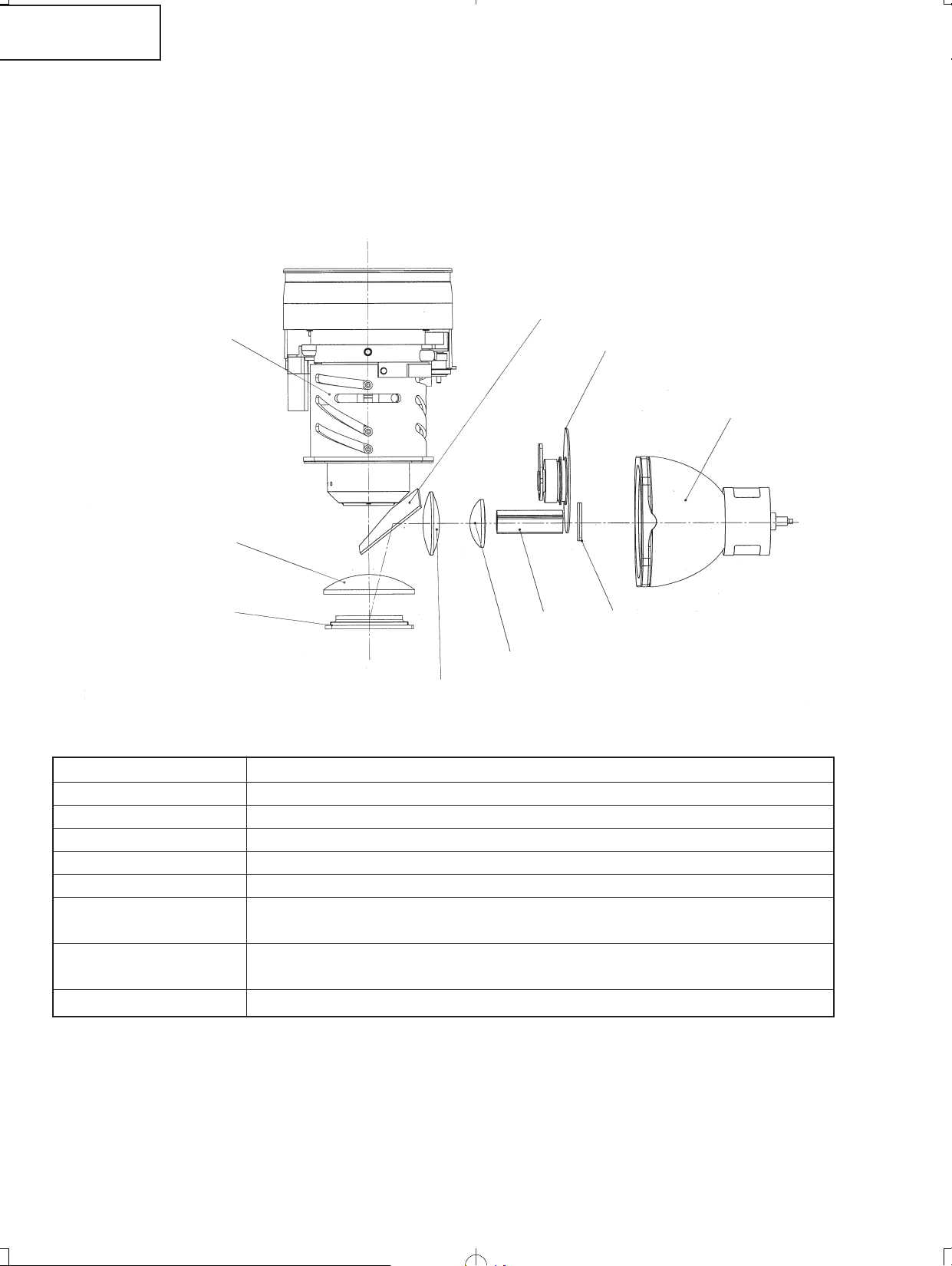

XV-Z2000

DT-400

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

(Schematic diagram)

Reflection mirror

Projection lens

Field lens

DMD

Rod

Illumination lenses 1

Illumination lenses 2

Item Function

Lamp Light source. DC high-pressure mercury lamp.

Color wheel Splits light from the light source into R, G, B and W through a color filter.

Rod Assures uniform light ray.

Illumination lenses Focus light from the rod on DMD.

Reflection mirror Reflects light from the illumination lenses toward DMD.

Field lens Focuses light from the reflection mirror on DMD and then the light from DMD to

the projection lens.

DMD Turns the internal micromirror ON/OFF at the rate of color component of each dot

of the input source to reflect light.

Projection lens Enlarges light from DMD and projects it on a screen.

Color wheel

Lamp

UV Filter

24

Page 25

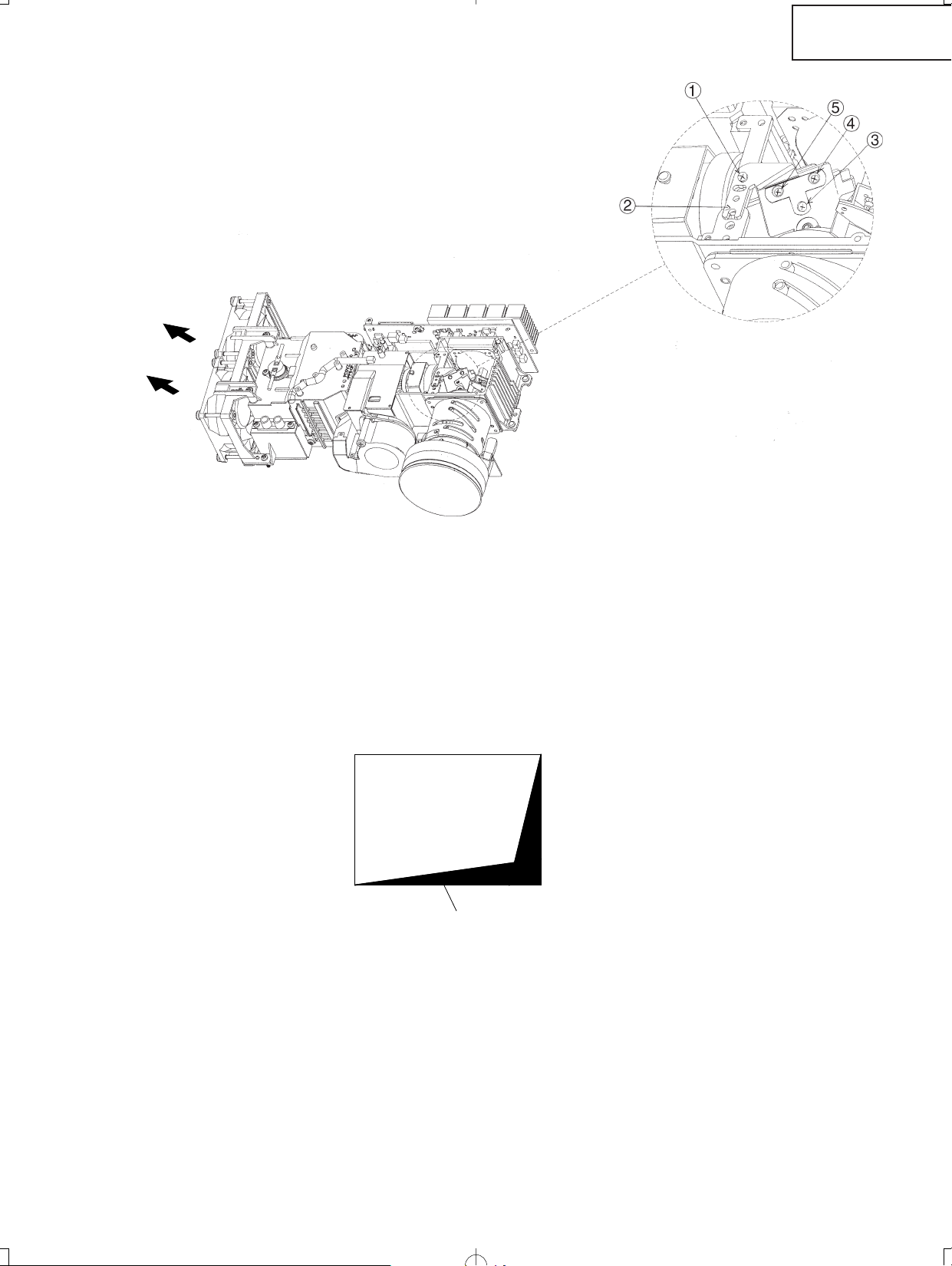

XV-Z2000

Air Flow

DT-400

After replacing the DMD, if shading is present on the screen as shown in Figure 1, adjust the lighting area of the

DMD by turning the adjustment screws for the optical engine.

1. Loosen the fixing screw for the adjustment lever 1. Adjust the lighting area by adjustment lever 2 and

then tighten the fixing screw for the adjustment lever 1.

2. If the lightening area cannot be adjusted after the above procedure, loosen the fixing screw 3, adjust the

area with adjustment screws 4 and 5, and then tighten the fixing screw 3.

Shading

Fig. 1

25

Page 26

XV-Z2000

R

G

B

DT-400

ELECTRICAL ADJUSTMENT

No. Adjusting point Adjusting conditions Adjusting procedure

1 Initialization of

EEPROM

2 Adjustment of

CW index

3-1 R-Bright / R-

Contrast

1. Turn on the power (the

lamp lights up) and warm

up the system for 15 minutes.

1. Input the gradation pattern of RGB.

(SVGA60Hz or XGA)

2. Select the following

group and subject.

Group: DLP

Subject: INDEX DELAY

1. Group: AD

Subject: R-BRIGHT

(Black level)

R-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) R signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 5 RGB input

1. Carry out the following setting.

Using the remote controller or press S2002 to

enter the process mode, and execute SS2 on SS

menu.

1. Select subject and make adjustment so that the

lamp gradation patterns of R, G and B should be

smooth without noise.

1. Observe the 0% window pattern chromaticity on

CA100.

2. Starting with a bit dropout screen, vary the RBright setting until the bright red "x" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

3. Observe the 91% R signal chromaticity on CA100.

4. Starting with a bit dropout screen, vary the RContrast setting until the bright red "x" setting

turns toward the black tone and stays there. Now

raise the setting by one point and adjust to the

point where the first bit dropout is encountered

(the setting changes over 5/1000).

3-2 G-Bright / G-

Contrast

1. Group: AD

Subject: G-BRIGHT

(Black level)

G-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) G signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 5 RGB input

1. Observe the 0% window pattern chromaticity on

CA100.

2. Starting with a bit dropout screen, vary the GBright setting until the bright green "y" setting

turns toward the black tone and stays there. Now

raise the setting by one point and adjust to the

point where the first bit dropout is encountered

(the setting changes over 5/1000).

3. Observe the 91% G signal chromaticity on CA100.

4. Starting with a bit dropout screen, vary the RContrast setting until the bright green "y" setting turns toward the black tone and stays there.

Now raise the setting by one point and adjust to

the point where the first bit dropout is encountered (the setting changes over 5/1000).

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z2000

DT-400

3-3 B-Bright / B-

Contrast

4-1 DTV Bright/

Contrast

Adjustment

4-2 DTV R-Bright/

Contrast

Adjustment

1. Group: AD

Subject: B-BRIGHT

(Black level)

B-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) B signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 5 RGB input

1. Group: DTV

Subject: BRIGHT

(Black level)

CONTRAST

(White level)

1. Group: DTV

Subject: R-BRIGHT

(Black level)

R-CONTRAST

(White level)

(Process/GAMMA interaction Input5 Color difference input)

1. Observe the 0% window pattern chromaticity on

CA100.

2. Starting with a bit dropout screen, vary the BBright setting until the bright blue "y" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

3. Observe the 91% G signal chromaticity on CA100.

4. Starting with a bit dropout screen, vary the BContrast setting until the bright blue "y" setting

turns toward the black tone and stays there. Now

raise the setting by one point and adjust to the

point where the first bit dropout is encountered

(the setting changes over 5/1000).

1. Check the fixed value.

Contrast: 5

Bright: 55

1. Observe the 0%black window pattern chromaticity on CA100.

2. Starting with a bit dropout screen, vary the Bright

setting until the bright red "x" setting turns toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

3. Observe the 100% W window pattern chromaticity on CA100.

4. Starting with a bit dropout screen, vary the Contrast setting until the bright red "x" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

4-3 DTV G-Bright/

Contrast

Adjustment

1. Group: DTV

Subject:G-BRIGHT

(Black level)

G-CONTRAST

(White level)

(Process/GAMMA interaction Input5 Color difference input)

1. Observe the 0%black window pattern chromaticity on CA100.

2. Starting with a bit dropout screen, vary the Bright

setting until the bright green "y" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

3. Observe the 100% W window pattern chromaticity on CA100.

4. Starting with a bit dropout screen, vary the Contrast setting until the bright green "y" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

27

Page 28

XV-Z2000

DT-400

No. Adjusting point Adjusting conditions Adjusting procedure

4-4 DTV B-Bright/

Contrast

Adjustment

5 DTV Tint 1. Group: DTV

6 DTV Color

Saturation

Level

1. Group: DTV

Subject: B-BRIGHT

(Black level)

B-CONTRAST

(White level)

(Process/GAMMA interaction Input5 Color difference input)

Subject: Tint

1. Group: DTV

Subject: Color

1. Observe the 0%black window pattern chromaticity on CA100.

2. Starting with a bit dropout screen, vary the Bright

setting until the bright blue "y" setting turns toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

3. Observe the 100% W window pattern chromaticity on CA100.

4. Starting with a bit dropout screen, vary the Contrast setting until the bright blue "y" setting turns

toward the black tone and stays there. Now raise

the setting by one point and adjust to the point

where the first bit dropout is encountered (the

setting changes over 5/1000).

1. Check the fixed value.

Tint: 8

1. Check the fixed value.

Color: 4

7 DVD Bright/

Contrast

Adjustment

8 DVD Tint 1. Check the fixed value.

9 DTV Color

Saturation Level

10 Video Bright/

Contrast

Adjustment

11 VIDEO Tint 1. Group: VIDEO

1. Group: DVD

Subject: BRIGHT

(Black level)

CONTRAST

(White level)

1. Group: DVD

Subject: Tint

1. Group: DVD

Subject: Color

1. Group: VIDEO

Subject: BRIGHT

(Black level)

CONTRAST

(White level)

Subject: N-Tint

P-Tint

S-Tint

1. Check the fixed value.

Contrast: 5

Bright: 55

Tint: 4

1. Check the fixed value.

Color: 5

1. Check the fixed value.

Contrast: 5

Bright: 55

1. Check the fixed values.

N-Tint: 8

P-Tint: 4

S-Tint: 4

12 VIDEO Color

Saturation Level

1. Group: VIDEO

Subject: N-Color

P-Color

S-Color

1. Check the fixed values.

N-Color: 7

P-Color: 4

S-Color: 7

28

Page 29

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z2000

DT-400

13 DVD White

balance

(Auto

adjustment)

14 DLP voltage

adjustment

15 Factory setting

1. Feed the component 75%

gray scale signal.

2. Group: PIXEL

Subject:R-GAIN (R)

B-GAIN (B)

Input 5 Color

difference input

1. Read the DLP-listed volt-

age rank.

2. Make the switch setting

corresponding to the readout rank.

(on the Formatter PWB)

1. Adjust the white balance by controlling R-GAIN and

B-GAIN.

(Adjust x=298 and y=319.)

1. Make this adjustment when the DLP chip has

been replaced or the combination of DLP chip

and Formatter PWB has been changed.

Ranking: D E

1. Make the following settings.

Destination Process adjustment

Europe SS3 Factory setting 3

North America SS4 Factory setting 4

Remote controller setting

29

29

Page 30

XV-Z2000

*1272-6bbc

CHXXXX

LLLLL

YYYYYYY

L LLL LM

TI Intenal Numbering

TI Intenal Numbering

2-Dimensional Matrix Code

(DMD Part Number and

Serial Number)

Part 1 of Serial Number

(7 characters)

Part 2 of Serial Number

(6 or 7 characters)

DMD Part Number

The last alphabet letter indicates the

Bin voltage setting (D. E).

1

DT-400

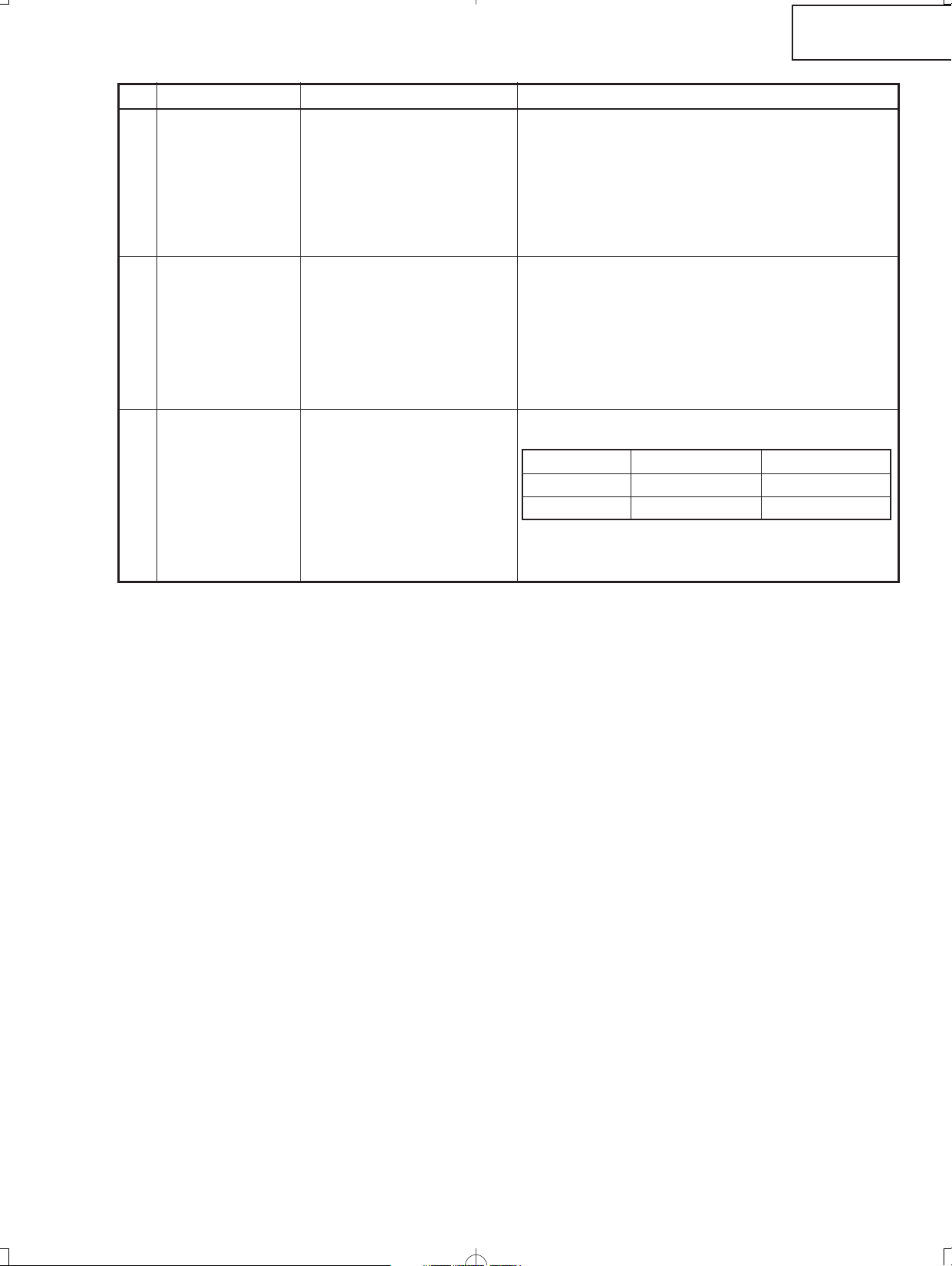

* Precautions in setting up the DMD (Digital Micromirror Device) unit

Before connecting the formatter PWB to the optical engine, take the following steps. Look at the voltage rank marking

that is on the DMD itself. Referring to this marking, set the DIP switches on the formatter PWB. And connect this PWB

to the optical engine. Wrong settings will adversely affect the system performance.

Set the formatter PWB switches according to the Bin voltage shown on the back face of the DMD.

2Based on Bin voltage, switch is set up as follows.

D:

E:

30

Page 31

XV-Z2000

DT-400

Calling and quitting the process mode with the control keys on this model.

∗ Although it is possible for the process OUT to exit using the process menu, the IN/OUT toggle command is also

available considering the existing specification.

1. Calling and quitting

With the menu not displayed, press the "'", "'", """, """, "|", "\" and "ENTER" keys on main unit.

2. Others

Press the S2002 process key (toggle) on the main PWB to call and quit the process menu.

Note: When adjusting in the process mode, set a signal with a vertical frequency of 60 Hz or no signal. (May not be

properly adjusted with other signals.)

» Adjustment mode process menu

Adjustment mode process menu 1

* Adjust only the shaded items below.

Adjustment Process Menu

First layer DTV VERSION

DVD SS

VIDEO TEMP

AD OPTION

DLP PATTERN

VIDEO1 LAMP

PIXEL LINE

Pedestal EXIT

second layer Initial Value

DTV Contrast 5

Tint 8

Color 4

Sharpness 1

Bright 55

R-Bright 20

G-Bright 20

B-Bright 20

R-Contrast 120

G-Contrast 120

B-Contrast 120

EXIT

DVD Contrast 5

Tint 4

Color 5

Sharpness 1

CTi-Level 1

LTi-Level 0

CB-Offset 7

CR-Offset 7

Bright 55

B-DRIVE 41

R-DRIVE 41

EXIT

VIDEO Contrast 5

N-Tint 7

P-Tint 4

S-Tint 4

N-Color 7

P-Color 4

S-Color 7

Sharpness 2

CTi-Level 1

LTi-Level 0

CB-Offset 7

CR-Offset 7

Bright 55

B-DRIVE 41

R-DRIVE 41

EXIT

31

Page 32

XV-Z2000

DT-400

Adjustment mode process menu 2

second layer Initial Value

AD R-Bright 40

G-Bright 40

B-Bright 40

R-Contrast 120

G-Contrast 120

B-Contrast 120

EXIT

DLP Index Delay 325

R-Bright 128

G-Bright 128

B-Bright 128

R-Contrast 100

G-Contrast 100

B-Contrast 100

EXIT

VIDEO1 N-Contrast 14

P-Contrast 14

S-Contrast 15

Color 17

NT3.58Delay 0

NT4.43Delay 1

PAL Delay 5

SECAM Delay 0

Shapness2 1

EXIT

PIXEL R-GAIN 128

G-GAIN 128

B-GAIN 128

EXIT

Pedestal R-Bright -10

G-Bright -10

B-Bright -10

R-Contrast +10

G-Contrast +10

B-Contrast +10

EXIT

second layer Initial Value

VERSION Build

Boot Code

Config

RomCode

GUI

DLP

EXIT

SS SS2

SS3 EU

SS4 US

SS5 JPN

SS6 CHIN

EXIT

TEMP Temp1 Parameter of sensor1

Temp2 Parameter of sensor2

Temp3

Temp4

EXIT

OPTION

PATTERN Cross Hatch

LAMP Current Time Current time of use

LINE OFF

PW365 Gamma

DLP Gamma 8

EXIT

Color bar

EXIT

History1 One Earlier

History2 Two Earlier

History3 Three Earlier

History4 Four Earlier

TOTAL TIME Total operating hours

EXIT

LED CHECK

EXIT

Standard VIDEO

32

Page 33

Checking the basic operation

Does the power LED light up or flash in

red or green?

Go to "Checking the power supply system"

and "Checking the power unit".

Does the set function with its keys or the

remote controller?

Go to "Checking the peripheral circuits of

the microprocessor".

Does the cooling fan rotate, and the lamp

turn on?

Go to "Checking the lamp light-up".

Is the user menu displayed?

Go to "Checking the peripheral circuits of

the formatter".

Does the analog RGB input function

normally?

Go to "Checking the RGB input".

Does the component input function

normally?

Go to "Checking the component".

Does the VIDEO input function normally?

Go to "

Checking of

VIDEO input ".

Does the DVI input function normally?

Check the DVI circuit and its peripheral

circuits.

Does the RS-232C function?

Go to "Checking RS-232C".

Does the autofocus function?

Go to "Checking the IRIS, FOCUS and

ZOOM motors".

End.

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

XV-Z2000

DT-400

TROUBLESHOOTING TABLE

33

Page 34

XV-Z2000

Checking the power supply system

Is 13V outputted to pins (9) and (11) of

P1707?

Is 6V outputted to pins (1) and (3) of

P1707?

Go to "Checking the power unit".

Go to "Checking the power unit".

Is the connector of P1707 fully inserted?

Is the voltage of 6V applied to both ends?

Replace the thermal fuse.

Is B+5VA outputted from IC1707?

Check IC1707 and its peripheral circuits.

Is Bu+5V outputted from IC1701?

Check IC1701 and its peripheral circuits.

Is Bu+3.3V outputted from IC1702?

Check IC1702 and its peripheral circuits.

Is Bu+2.5V outputted from IC1703?

Check IC1703 and its peripheral circuits.

Go to "Checking the peripheral circuits of

the microprocessor".

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

YES

NO

DT-400

34

Page 35

XV-Z2000

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

ABNORMAL

YES

YES

Checking the power unit

Is each connector of the power unit

fully inserted?

Securely insert the connectors.

Is the lamp door closed completely?

Fix the lamp door with screws.

Is the bimetal broken?

Replace the bimetal switch or restore

by pressing the red button.

Is AC voltage applied to both AC input

ends of DB701?

Replace F701. If other parts are

damaged, replace them.

Is DC voltage of approx. 6.25V

outputted to both ends of C726?

Check D707 and the peripheral circuits

of IC702 on the primary side. If

defective, replace them.

Is DC voltage of approx. 370V

outputted to the cathode of D701?

Replace the subunit or check the

primary side circuit.

if defective, replace them.

Replace the ballast power supply.

Is the specified voltage outputted to

each output terminal of EA701?

Check the secondary-side circuits of

T701. If defective, replace them.

Check the PWB circuits on each output

side.

DT-400

35

Page 36

XV-Z2000

Checking the peripheral circuits of the

microprocessor

Are the voltages of approx. 3.3V and 2.5V

applied to both ends of C8001 and C8056

respectively?

Go to "Checking the power supply

system".

Are the oscillations of 133MHz and

74.25MHz outputted from pin (3) of

X8003 and pin (3) of X8007 respectively?

Check X8001, X8003 and their peripheral

circuits.

Does each terminal of R8038, R8039,

R8041, R8042 and R8050 change?

Check IC8202 or IC8001 is defective.

Do pins (15) and (16) of IC2002 change?

Check IC8203 or IC2002 is defective. The

I2C bus does not function normally.

Do pins (46) to (49) and (4) to (7) of

IC2002 change when any key is

operated?

IC2002 is defective. The keys do not

function normally.

When the power button is pressed, does

the voltage of pin (7) of IC8006 become

3.3V?

IC8001 is defective.

Do pulse-shaped waveforms appear at

pins (1), (2), (5) and (6) of IC8006?

IC8006 is defective.

Does the voltage of pins (3) and (6) of

IC8003 change?

IC8003 is defective.

Is the voltage of pin (2) of Q8002 5V?

Q8002 is defective.

Does the fan rotate?

Check the power supply circuit or fan

circuit on the main circuit.

Go to "Checking the lamp light-up".

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

DT-400

36

Page 37

XV-Z2000

Checking the lamp light-up

Does each cooling fan

function?

Check the power supply circuit

or fan circuit on the main circuit.

Is the rotating sound of the

color wheel heard?

Check Q9401 to Q9403,

IC9401(motor driver IC)

and their peripheral circuits.

Go to "Checking the

peripheral circuits of

the formatter".

Replace the color wheel.

Is the discharging sound

heard?

Is the lamp tight in the

socket?

Replace the lamp.

Securely insert the

connectors.

Is DC voltage of approx.

370V applied to both ends

of the ballast power supply?

Is pin (2) of P1707 at the

"H" level?

Go to "Checking the

power unit".

Go to "Checking the

peripheral circuits of the

formatter".

Check Q8002, Q8006 and

their peripheral circuits.

NO

YES

NO

ABNORMAL

YES

NORMAL

YES NO

YES

NO

NO YES

YES

NO

DT-400

37

Page 38

XV-Z2000

Adjustment by "Process

Menu"

→

"DLP"

→

"INDEX". The failure state

remains unchanged.

Display in trouble

Screen with spectral

colors

Color production of R,

G and B is not correct.

Black screen

Are the sockets SC2001

and SC9001 connected

correctly?

Are the socket SC2001

and SC9001 connected

correctly?

Are the contact terminals

of the DMD, formatter

PWB and cLGA dirty?

Are the SC2001 and

SC9001 connected

correctly?

Does the color wheel

turn?

Does P9402 have the

correct motor drive

voltage waveform?

Is the waveform at pins

(18) and (20) of IC9202

the 400MHz sine wave?

IC9202, IC9101, X9101

or their peripheral

circuits are faulty.

Does the pin (3) of

IC9201 have the correct

voltage +1.8V?

Are the signals fed to the

terminating resistance

(39W) of RDRAM

(IC9203)?(DQA8 and

DQB8 are unused.)

Re-assemble the DMD,

the optical mechanism

and the formatter unit.

Do the colors return to

correct colors when the

process menu is

entered?

Poor adjustment should

be a likely cause.

Perform readjustment

according to the

adjustment method.

Color wheel is faulty.

IC2002 is faulty.

IC9401 or its peripheral

circuits are faulty.

Is the lamp lit on?

Check the color wheel

sensor unit.

IC2001, IC2007 or their

peripheral circuits are

faulty.

Is the correct voltage is

supplied to the each

connector of power and

ballast unit?

Check the ballast unit

and the power unit.

Does pin (2) of P2004

have 150Hz pulse signal

in no-signal state?

Does pin (9) of IC9301

have the correct voltage

(+23~+26V)?

Is pulse wave in voltage

at pin (14) of P1701?

IC9301 or its peripheral

circuits are faulty.

Miscellaneous

Equally spaced white or

black vertical stripes

Black horizontal band

IC9203, IC9101 or their

peripheral circuits are

faulty.

IC2007, IC2002 or their

peripheral circuits are

faulty.

Does pin (13) of IC9301

have the correct voltage

(-26V)?

Does pin (49) of IC9301

have the correct voltage

(+7V)?

Is the fan rotating?

Check the fan circuit.

Double-check DMD and

cLGA units.

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

DT-400

» Formatter Unit Troubleshooting

38

Page 39

XV-Z2000

Input the digital signal from INPUT5.

Select digital with the keys on the main body or the

remote control.

Check the Formatter unit.

Is the picture disturbed?

Is picture outputted?

Is the signal coming to pins (10)(77) of IC502?

YES NO

Check between the input terminals

and IC502.

NO

NO

YES

YES

Is the signal coming to pins (26)(54) and (66)-(94) of SC2001?

Check IC8001 and its peripheral

circuits.

NO

YES

Checking the digital input

End.

1

Input the analog RGB signal from INPUT5.

Select INPUT5 with the keys on the main body or the

remote control.

Check IC3102 and its peripheral

circuits.

Are pins (76), (77) and (78) of

IC3102 outputting and the signals

inputted to pins (73), (74) and (75)?

Is the picture disturbed?

Is picture outputted?

YES NO

NO

YES

NO

Is the picture signal coming to

pins (3), (4) and (5) of IC3102?

Check between the input terminals

and IC3102.

NO

YES

YES

Checking the analog RGB input

End.

1

3

DT-400

39

Page 40

XV-Z2000

YES

NO

Check IC3102, IC3106 and

their peripheral circuits.

Check IC3104 and its

peripheral circuits.

Check IC3102 and its

peripheral circuits.

NO

NO

Check IC6004 and its

peripheral circuits.

NO

Check IC8001 and its

peripheral circuits.

NO

Checking the Component

Send component signals to

INPUT1 or INPUT2. Use keys

on the main unit or remote

control to select INPUT1 or

INPUT2.

Is video signal inputted into

pins (3) to (5) of IC3102 at the

time of INPUT1 selection, and

is inputted into pins (15) to

(17), respectively at the time of

INPUT2 selection?

Are video signals inputted to

pins (1), (3) and (5) of

IC3104?

YES

Are video signals inputted to

pins (43), (48) and (54) of

IC6004?

YES

Are video signals outputted

from pins (2)-(9), (12)-(19)

and (70)-(77) of IC6004?

YES

Is signal outputted to each

even number pin of pins (21)(54) and (66)-(94) of SC2001?

YES

Check Formatter unit again.

YES

DT-400

40

Page 41

Feed the composite video signal to

INPUT 4. Select INPUT 4 using the

set's key or the remote controller.

Does the picture appear? Is the picture disturbed?

End.

YES

YES

NO

NO

Is the video signal inputted to the

pin (1) of IC3105?

YES

Check the VIDEO-IN signal

line of Q3505.

NO

Is there any input to pins (1), (3) and (5) of IC3104?

YES

Check IC3102 and its peripheral circuits.

NO

Is there any output from pins (16), (18) and (20) of IC3104?

YES

Check IC3104 and its peripheral circuits.

NO

Is the video signal inputted to pins (43), (48) and (54) of

IC6004 and the synchronized signal inputted to pins (30)

and (31)?

YES

Check IC3104, IC6001, IC6002 and their

peripheral circuits.

NO

Is each digital output coming on pins (64), (65), (66) and

(67) of IC6004?

YES

Check IC6004 and its peripheral circuits.

NO

Is there any output from IC8001 (DPORT)?

Check the formatter PWB.

YES

Check IC8001 and its peripheral circuits.

NO

YES

Check IC3501 and its

peripheral circuits.

YES

Checking the Video Input

Check IC3102 and its

peripheral circuits.

1

3

NOYES

Is synchronized signal

coming to pins (28) and

(29) of IC3102?

2

Memo

The composite video signal is Y/C-separated by IC3506 (3 Line

COM) and the resulting signals are inputted to pins (39) and

(41) of IC3105.

The video signal is outputted from color-difference pins (21),

(22) and (23) of IC3105.

Are the video signals inputted to

pins (39) and (41) of IC3105?

YES

YES

Is the video signal outputted from

pins (21), (22) and (23) of IC3105

inputted to pins (67), (68) and (69)

of IC3102?

Check IC3504, IC3506 and

their peripheral circuits.

XV-Z2000

DT-400

41

Page 42

XV-Z2000

Checking the SOG Circuit

Measure the pin (7) of IC5001

with an oscilloscope.

This is the failure of the SOG

synchronization separator circuit.

Is there the Y signal including sync

signal?

Measure the pin (2) of Q5001

with an oscilloscope.

Is the composite synchronized

signal regenerated at proper timing?

NO

Is there any output from the pin

(25) of IC3102?

NO

The SOG circuit is normal.

End.

YES

YES YES

Check Q3110 and its

peripheral circuits.

NO

DT-400

42

Page 43

XV-Z2000

Input the S terminal (Y, C) signal to

INPUT 3. Select INPUT 3 with the

keys on the main body or the

remote controller.

Does the picture appear? Is the picture disturbed? End.

Is the video signal inputted to the

pins (43) and (44) of IC3105?

YES NO

NO

NO YES

NO

YES

Check the input side and its

peripheral circuits.

Check the Y,C signal line.

Checking the S terminal input.

Check IC3105 and its

peripheral circuits.

1

YES

3

Is the video signal outputted

from pins (21), (22) and (23)

of IC3105 inputted into pins

(67), (68) and (69) of IC3102?

DT-400

43

Page 44

XV-Z2000

Checking the Sync Signal

Is the horizontal synchronized

signal on pin (6) of IC6003?

Is the vertical synchronized signal

on pin (6) of IC6009?

Is the synchronized signal

outputted from IC5009, IC5005,

IC5006, IC5007 and IC5008?

Are the timing of both vertical and

horizontal synchronized signals

correct?

Is the horizontal synchronized

signal on pin (30) of IC6004?

Is the vertical synchronized signal

on pin (31) of IC6004?

The sync signal is normal.

End of checking.

YES

NO

Check the of the signal input part.

NO

YES

YES

YES

YES

NO

YES

Check each IC and their peripheral

circuits.

NO

Check IC6001, IC6002 and their

peripheral circuits.

NO

Set the signal source appropriately.

NO

2

Is the signal generator (input

source) correct?

YES

IC8001 and its periphery is

defective.

NO

Is the horizontal synchronized

signal on pin (66) of IC6004?

Is the vertical synchronized signal

on pin (64) of IC6004?

YES

YES

NO

Failure of IC6004 and its

peripheral circuit.

NO

DT-400

44

Page 45

Checking RS-232C

Communication is disabled even though

connecting the control PC and projector

with a RS-232C cable.

Is the connecting cable connected

correctly? (cross cable)

Replace the connecting cable.

Is there any signal at pin (8) of IC8002?

Check SC3501, R2039 and their peripheral circuits.

Is there any signal at pin (106) of IC2201? Check IC2006 and its peripheral circuits.

Check IC2002 and its peripheral circuits.

NO

YES

NO

YES

NO

YES

XV-Z2000

DT-400

45

Page 46

XV-Z2000

Checking the IRIS, FOCUS and

ZOOM motors

Do all the motors function?

Check the optical mechanism.

YES

YES

YES

YES

YES

NO

NO

YES

YES

NO

NO