Sharp XV-Z1U Service Manual

I

SHARP SERVICE MANUAL

S88V9XV-Zl U//

PAL/SECAM/NTSC SYSTEM

LCD PROJECTOR

MODEL xv-z1 u

of user-safety (Required by safety regulations in some countries) the set should be re-

condition and only parts identical to those specified should be used.

-xv-z1 u

I

/

. SPECIFICATIONS

. INPORTANT SERVICE SAFETY NOTES ..........

. NOTE TO SERVICE PERSONNEL ....................

. OPERATION MANUAL

. REMOVING OF MAJOR PARTS

l CONTROLLING THE TOTAL

OPERATING HOURS OF THE LAMP .............. 15

l RESETTING THE LAMP

OPERATING HOUR COUNTER

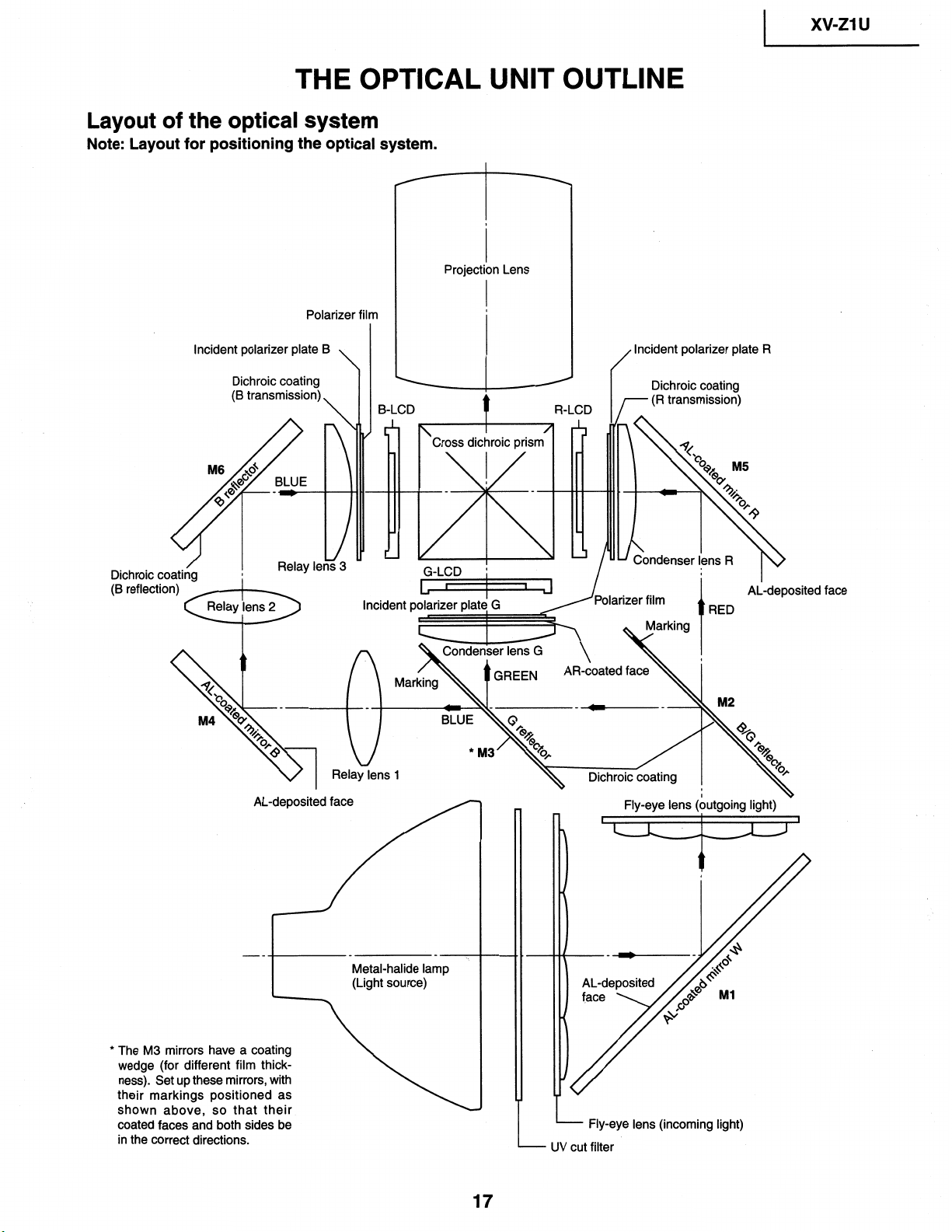

. THE OPTICAL UNIT OUTLINE

l CONVERGENCE AND

FOCUS ADJUSTMENT

. ELECTRICAL ADJUSTMENT

. TROUBLESHOOTING TABLE

...............................................

.......................................

......................

...................... 16

........................ 17

....................................

..........................

..........................

CONTEN--

Page

2

3

4

7

10

18

22

30

is

Page

CHASSIS LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLOCK DIAGRAM

OVERALL WIRING

DESCRIPTION OF SCHEMATIC DIAGRAM . . . . . 41

1

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC DIAGRAM

PRINTED WIRING BOARD ASSEMBLIES . . . . . . 79

PARTS LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

n ELECTRICAL PARTS . . . . . . . . . . . . . . . . . ..*.............

n CABINET AND MECHANICAL PARTS . . . . . 113

n ACCESSORIES PARTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . 122

n PACKING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PACKING OF THE SET . . . . . . . . . . . . . . . . . . . . . ..*..........

35

37

39

42

43

89

122

123

SHARP CORPORATlON

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

xv=21 u

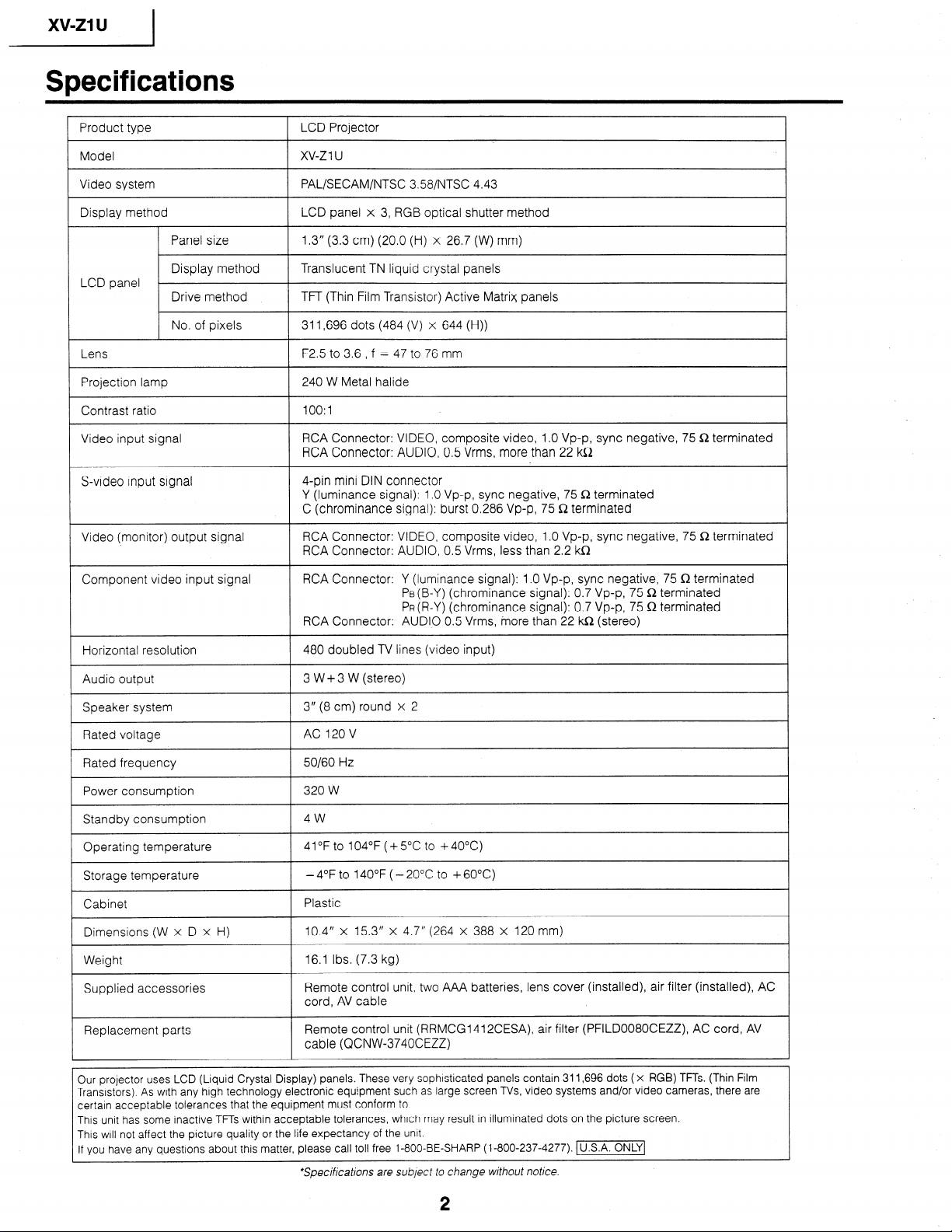

Specifications

1 Product type 1 LCD Projector

Model xv-z 1 u

Video system PAL/SECAM/NTSC 358/NTSC 4.43

Display method LCD panel x 3, RGB optical shutter method

Panel size 1.3” (3.3 cm) (20.0 (H) x 26.7 (W) mm)

LCD panel

Display method Translucent TN liquid crystal panels

Drive method TFT (Thin Film Transistor) Active Matrix panels

No. of pixels 311,696 dots (484 (V) x 644 (H))

Lens

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Video (monitor) output signal

Component video input signal

Audio output

Speaker system

F2.5 to 3.6 , f = 47 to 76 mm

240 W Metal halide

lOO:l

RCA Connector: VIDEO, composite video, 1 .O Vp-p, sync negative, 75 Q terminated

RCA Connector: AUDIO, 0.5 Vrms, more than 22 kQ

4-pin mini DIN connector

Y (luminance signal): 1 .O Vp-p, sync negative, 75 Q terminated

C (chrominance signal): burst 0.286 Vp-p, 75 Q terminated

RCA Connector: VIDEO, composite video, 1 .O Vp-p, sync negative, 75 Q terminated

RCA Connector: AUDIO, 0.5 Vrms, less than 2.2 kS2

RCA Connector: Y (luminance signal): 1 .O Vp-p, sync negative, 75 Q terminated

PB(B-Y) (chrominance signal): 0.7 Vp-p, 75 R terminated

PR (R-Y) (chrominance signal): 0.7 Vp-p, 75 Q terminated

RCA Connector: AUDIO 0.5 Vrms, inore than 22 kR (stereo)

480 doubled TV lines (video input)

3 W + 3 W (stereo)

3” (8 cm) round x 2

Rated voltage

/ Rated frequency

Standby consumption

I_

Operating temperature

Storage temperature

Weight

Supplied accessories

Replacement parts

Our projector uses LCD (Liquid Crystal Display) panels. These very sophisticated panels contain 311,696 dots ( x RGB) TFTs. (Thin Film

Transistors). As with any high technology electronic equipment such as large screen TVs, video systems and/or video cameras, there are

certain acceptable tolerances that the equipment must conform to.

This unit has some inactive TFTs within acceptable tolerances, which may result in illuminated dots on the picture screen.

This will not affect the picture quality or the life expectancy of the unit.

If you have any questions about this matter, please call toll free 1-800-BE-SHARP (l-800-237-4277). (U.S.A.]

AC 120 V

50160 Hz

320 W

4w

/ 41°F to 104°F (+5”C to +4O”C)

- 4°F to 140°F ( - 20°C to + 60°C)

Plastic

10.4” x 15.3” x 4.7” (264 x 388 x 120 mm)

16.1 Ibs. (7.3 kg)

Remote control unit, two AAA batteries, lens cover (installed), air filter (installed), AC

cord, AV cable

Remote control unit (RRMCG1412CESA) air filter (PFILD0080CEZZ), AC cord, AV

cable (QCNW-3740CEZZ)

*Specifications are subject to change without notice.

2

) xv-ZlU

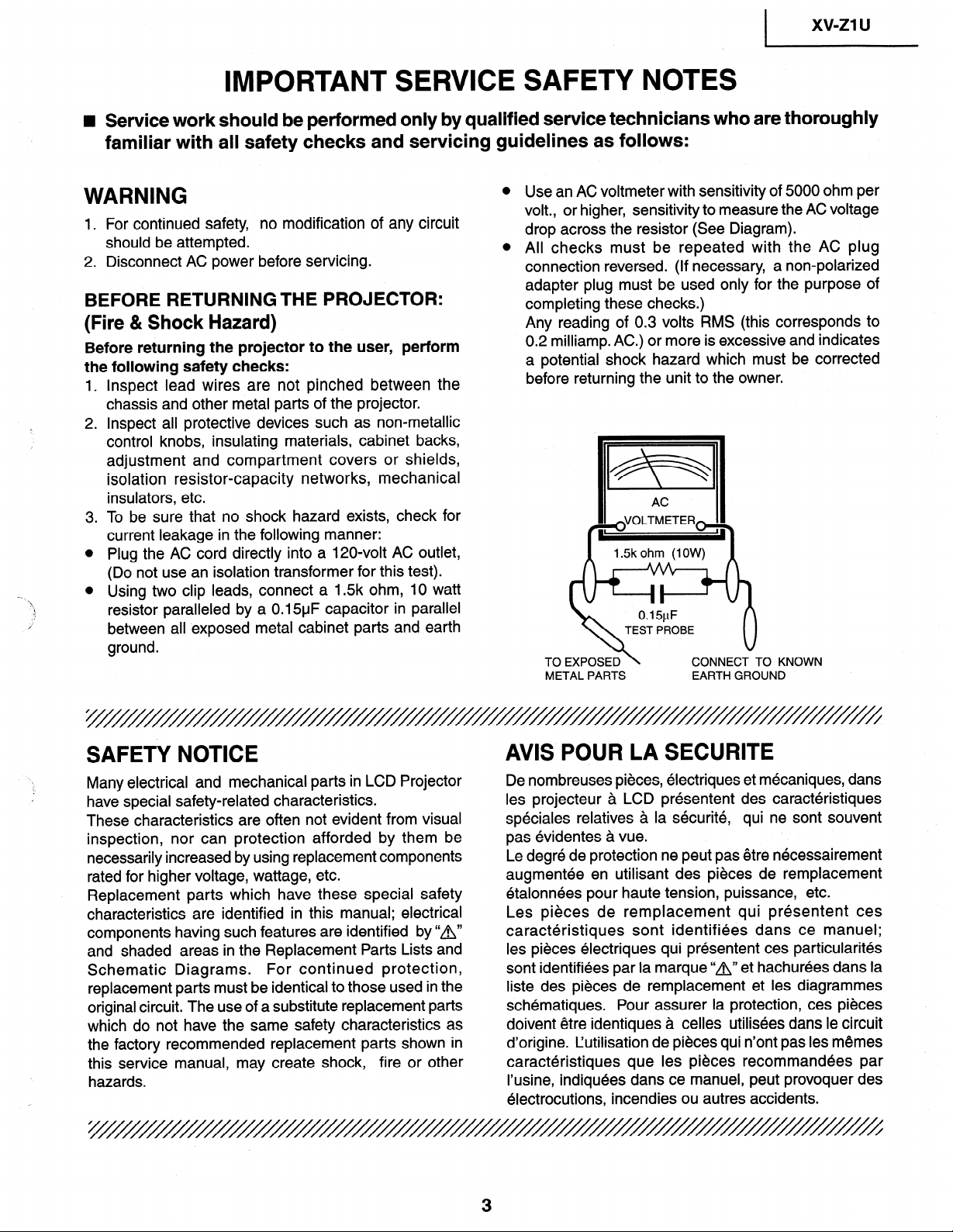

IMPORTANT SERVICE SAFETY NOTES

n Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1 .

Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2 .

Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

.

To be sure that no shock hazard exists, check for

3

current leakage in the following manner:

Plug the AC cord directly into a 120,volt AC outlet,

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15uF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “A”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

For continued protection,

AVIS POUR LA SECURITE

De nombreuses pieces, electriques et mecaniques, dans

les projecteur a LCD presentent des caracteristiques

speciales relatives a la securite, qui ne sont souvent

pas evidentes a vue.

Le degre de protection ne peut pas etre necessairement

augmentee en utilisant des pieces de remplacement

etalonnees pour haute tension, puissance, etc.

Les pieces de remplacement qui presentent ces

caracteristiques sont identifiees dans ce manuel;

les pieces electriques qui presentent ces particularites

sont identifiees par la marque “A” et hachurees dans la

liste des pieces de remplacement et les diagrammes

schematiques. Pour assurer la protection, ces pieces

doivent etre identiques a celles utilisees dans le circuit

d’origine. Cutilisation de pieces qui n’ont pas les memes

caracteristiques que les pieces recommandees par

I’usine, indiquees dans ce manuel, peut provoquer des

electrocutions, incendies ou autres accidents.

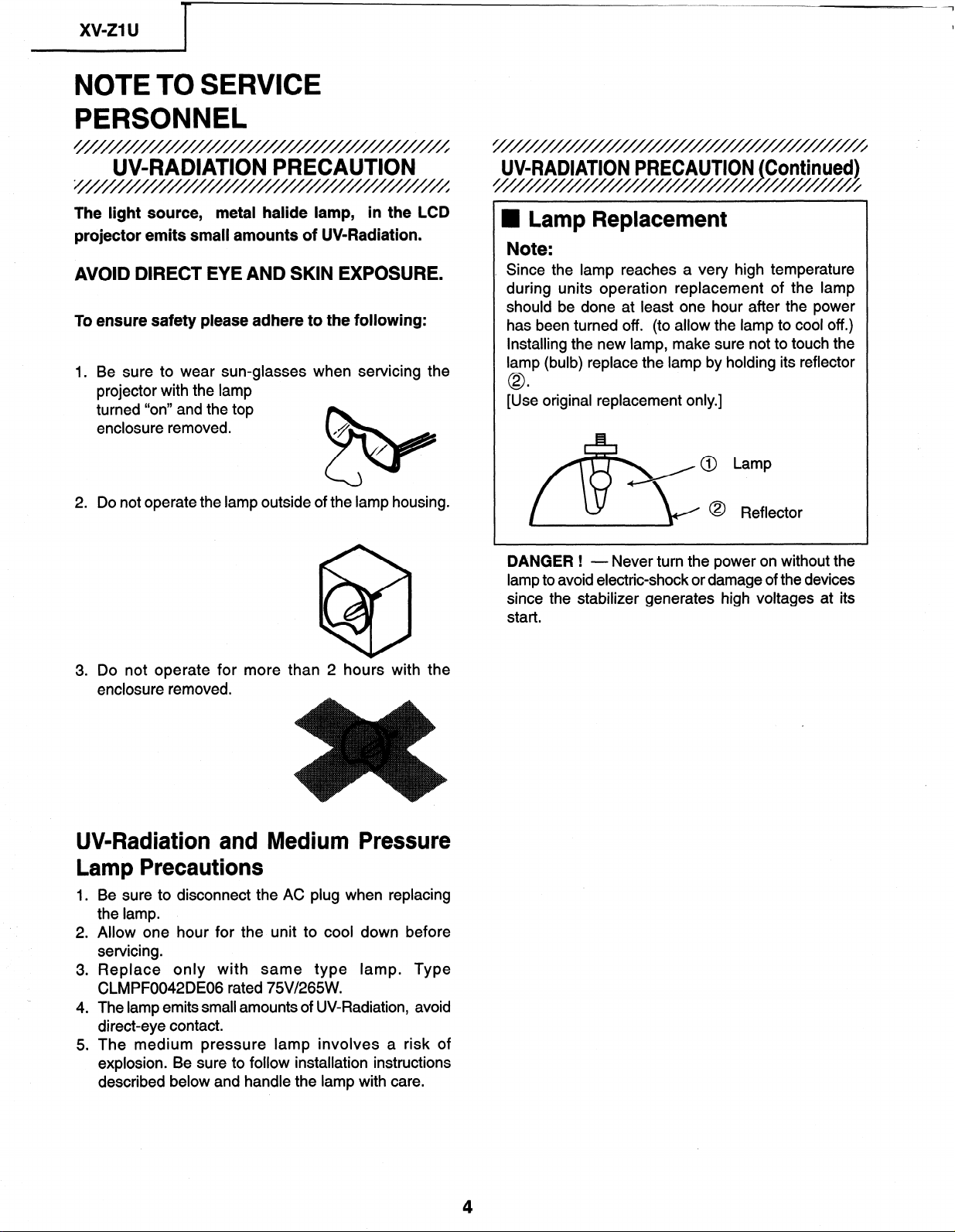

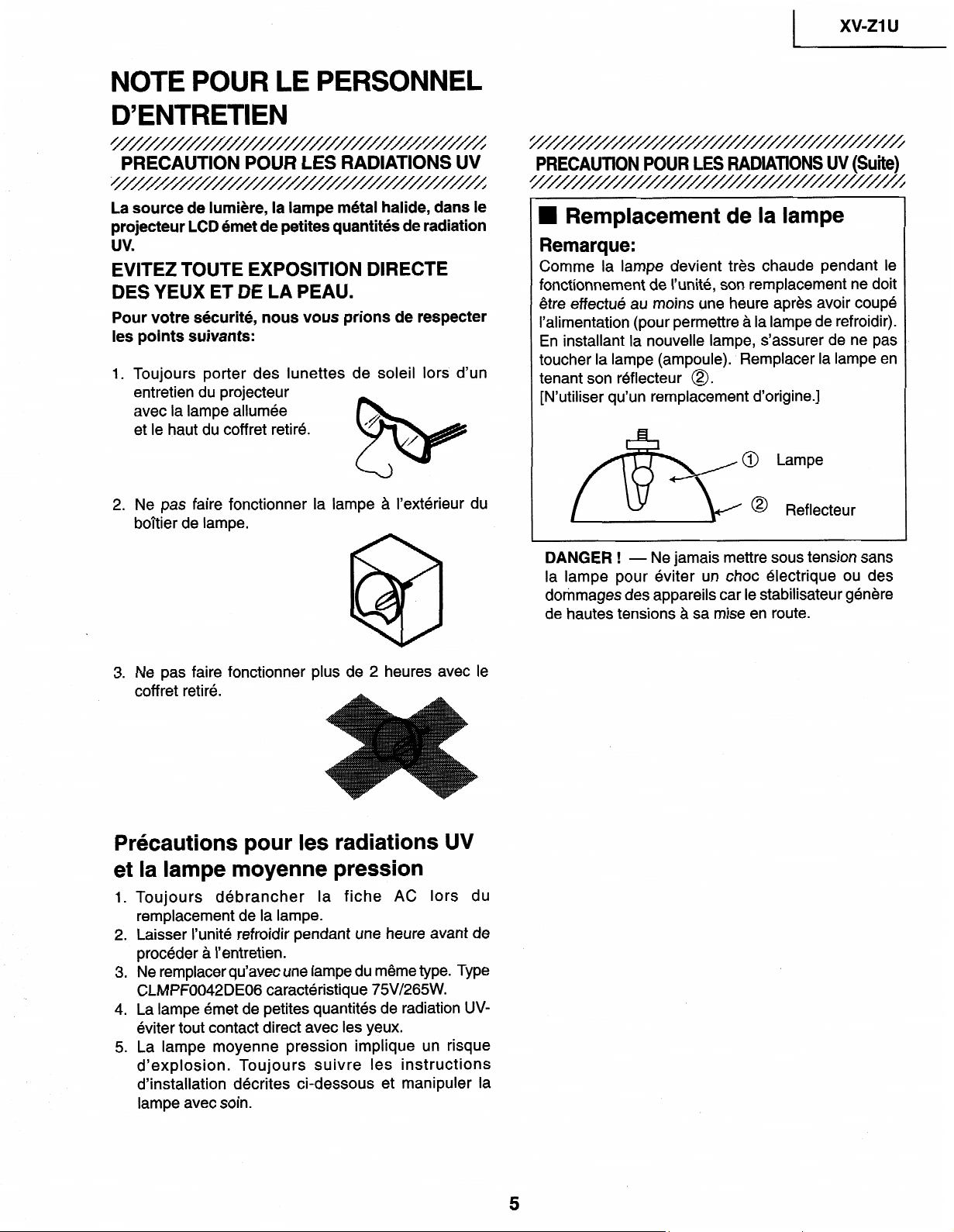

NOTE TO SERVICE PERSONNEL

////////////////////////////////////////

UV-RADIATION PRECAUTION

;///////////////////

The light source,

projector emits small amounts of UV-Radiation.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

metal halide lamp, in the LCD

/

/

&

UV-RADIATION PRECAUTION

I////////////

Continued)

/’

U Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

0

[Use original replacement only.]

@ Lamp

@ Reflector

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1 .

Be sure to disconnect the AC plug when replacing

the lamp.

.

Allow one hour for the unit to cool down before

2

servicing.

Replace only with same type lamp. Type

.

3

CLMPF0042DE06 rated 75V/265W.

The lamp emits small amounts of UV-Radiation, avoid

4 .

direct-eye contact.

The medium pressure lamp involves a risk of

.

5

explosion. Be sure to follow installation instructions

described below and handle the lamb with care.

DANGER !

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its

start.

- Never turn the power on without the

4

D’ENTRETIEN

////////////////////////////////////////

PRECAUTION POUR LES RADIATIONS UV

;///////////////////

La

source de

projecteur LCD 6met de

uv

EiTEZ TOUTE EXPOSITION DIRECTE

DES

YEUX ET DE LA PEAU.

Pour votre sbcurit6, nous vous prions de respecter

les points suivants:

1. Toujours porter des

entretien du projecteur

avec la

et le haut

lumi&e,

lampe allumee

du

coffret

la

retire.

lampe

petites

lunettes de soleil lors d’un

metal

halide, dans le

quantitbs de

radiation

L %

I

xv-z1

3

PRECAUTION POUR LES RADlATlONS UV (Suite)

I

n

Remplacement de la lampe

Remarque:

Comme

fonctionnement de I’unite,

etre effect& au moins une heure apres avoir

I’alimentation (pour permettre

En

toucher

tenant

[N’utiliser

la

lampe devient tres chaude

son remplacement ne doit

a la lampe

installant la

la lampe (ampoule). Remplacer la lampe en

son

nouvelle lampe,

reflecteur

qu’un remplacement d’origine.]

0.

s’assurer

@ Lampe

pendant le

de

coupe

refroidir).

de

ne pas

u

2. Ne pas faire fonctionner la lampe a I’exterieur du

boltier de lampe.

3. Ne pas faire fonctionner plus de 2 heures avec le

coff ret retire.

Prkautions pour les radiations UV

et la lampe moyenne pression

.

Toujours debrancher la fiche AC lors du

1

remplacement de la lampe.

Laisser I’unite refroidir pendant une heure avant de

2 .

proceder a I’entretien.

Ne remplacer qu’avec une lampe du meme type. Type

3 *

CLMPF0042DE06 caracteristique 75V/265W.

.

La lampe emet de petites quantites de radiation UV-

4

eviter tout contact direct avec les yeux.

.

La lampe moyenne pression implique un risque

5

d’explosion. Toujours suivre les instructions

d’installation d&rites ci-dessous et manipuler la

lampe

avec soin.

0

Reflecteur

DANGER ! - Ne jamais mettre sous tension sans

la

lampe pour eviter

dommages des appareils car le stabilisateur genere

de hautes tensions a sa

un choc electrique ou des

mise en route.

5

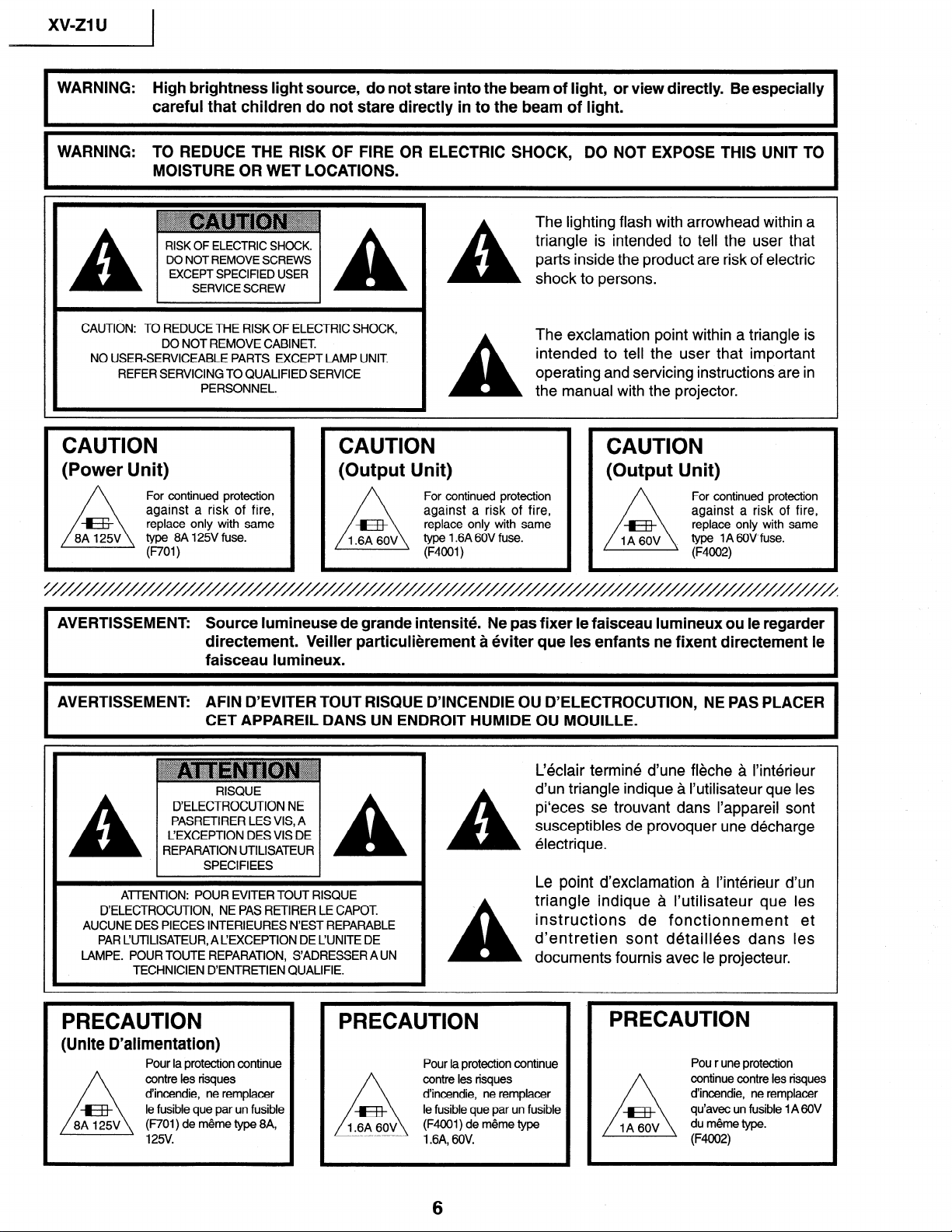

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

I

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

careful that children do not stare directly in to the beam of light.

MOISTURE OR WET LOCATIONS.

The lighting flash with arrowhead within a

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

A

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT

CAUTION

(Power Unit)

AVERTISSEMENT: Source lumineuse de grande intensite. Ne pas fixer le faisceau lumineux ou le regarder

AVERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

I

A

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

DO NOT REMOVE CABINET

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

CAUTION

(Output Unit)

For continued protection

against a risk of fire,

replace only with same

type 8A l25V fuse.

(ROl)

directement. Veiller particulierement a eviter que les enfants ne fixent directement le

faisceau lumineux.

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

TECHNICIEN D’ENTRETIEN QUALIFIE.

A

A

For continued protection

against a risk of fire,

replace only with same

type 1.6A 60V fuse.

(F4OOl)

A

A

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(Output Unit)

For continued protection

against a risk of fire,

replace only with same

type 1 A 6OVfuse.

(F4002)

C&lair termine d’une fleche a l’interieur

d’un triangle indique a I’utilisateur que les

pi‘eces se trouvant dans I’appareil sont

susceptibles de provoquer une decharge

electrique.

Le point d’exclamation a I’interieur d’un

triangle indique a I’utilisateur que les

instructions de fonctionnement et

d’entretien sont detaillees dans les

documents fournis avec le projecteur.

I

PRECAUTION PRECAUTION

(Unite D’alimentation)

Pour la protection continue

contre les risques

d’incendie, ne remplacer

le fusible que par un fusible

(F701) de meme type 8A,

l25V.

Pour la protection continue

contre les risques

d’incendie, ne remplacer

le fusible que par un fusible

(F4001) de meme type

1.6A, 60V.

6

PRECAUTION

Pou r une protection

continue contre les risques

d’incendie, ne remplacer

qu’avec un fusible 1 A 60V

du meme type.

(F4002)

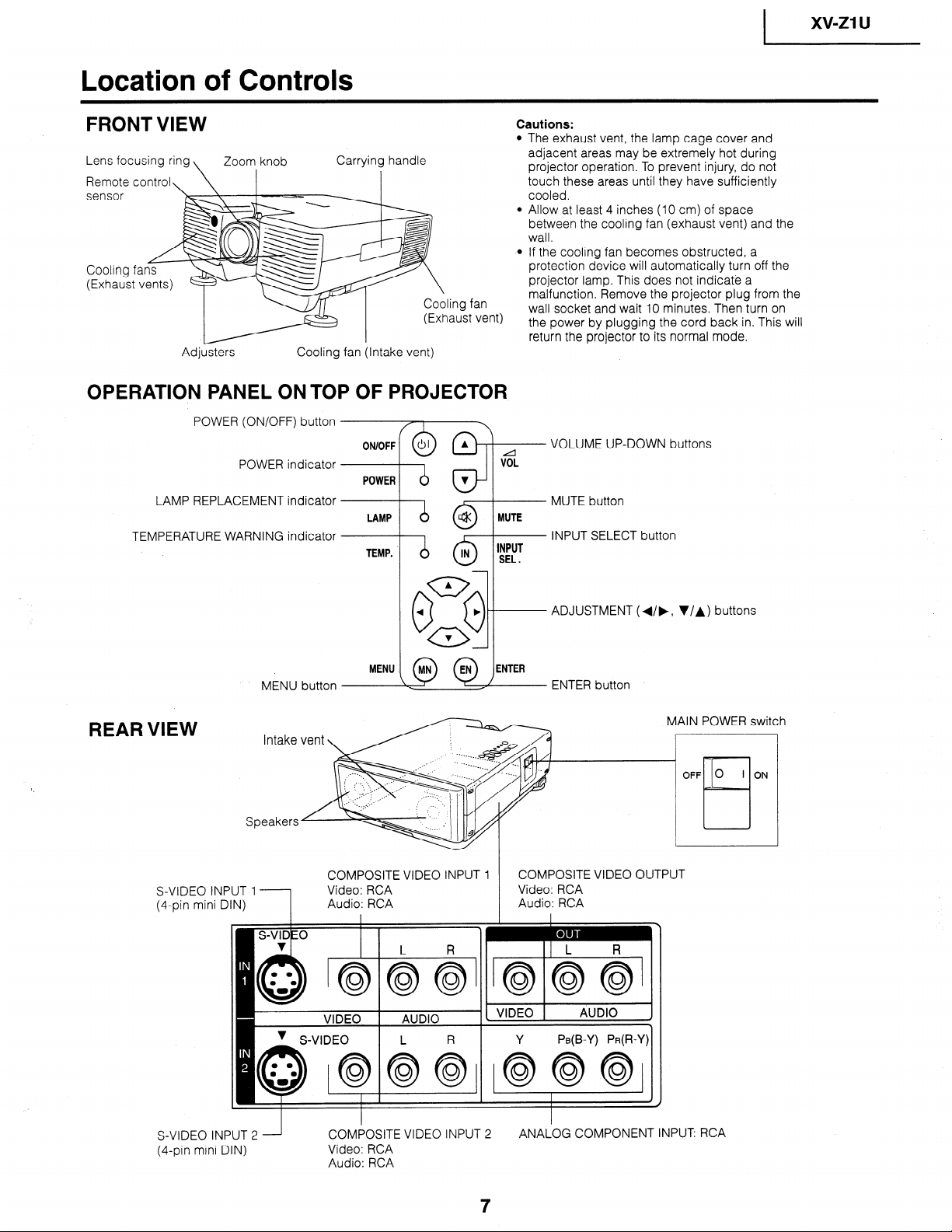

Location of Controls

I

xv-z1 u

FRONT VIEW

Lens focusing ring

Remote control,

sensor

Cooling f

(Exhaust

\ Zoom, knob Carry in! handle

ing fan

aust vent)

Adjusters Cooling fan (Intake vent)

OPERATION PANEL ON TOP OF PROJECTOR

POWER (ON/OFF) button

ON/OFF

POWER indicator

LAMP REPLACEMENT indicator

TEMPERATURE WARNING indicator

POWER

Cautions:

The exhaust vent, the lamp cage cover and

adjacent areas may be extremely hot during

projector operation. To prevent injury, do not

touch these areas until they have sufficiently

cooled.

Allow at least 4 inches (10 cm) of space

between the cooling fan (exhaust vent) and the

wall.

If the cooling fan becomes obstructed, a

protection device will automatically turn off the

projector lamp. This does not indicate a

malfunction. Remove the projector plug from the

wall socket and wait 10 minutes. Then turn on

the power by plugging the cord back in. This will

return the projector to its normal mode.

VOLUME UP-DOWN buttons

MUTE button

INPUT SELECT button

REAR VIEW

S-VIDEO INPUT 1

(4pin mini DIN)

MENU button

Intake

Speakers

1

COMPOSITE VIDEO INPUT 1

Video: RCA

Audio: RCA

ADJUSTMENT (4/b, V/A) buttons

ENTER button

COMPOSITE VIDEO OUTPUT

Video: RCA

Audio: RCA

I IjL R

Y PB(B-Y) PR(R-Y)

MAIN POWER switc

h

S-VIDEO INPUT 2

(4-pin mini DIN)

COMPOSITE VIDEO INPUT 2

Video: RCA

Audio: RCA

ANALOG COMPONENT INPUT RCA

xv-ZlU 1

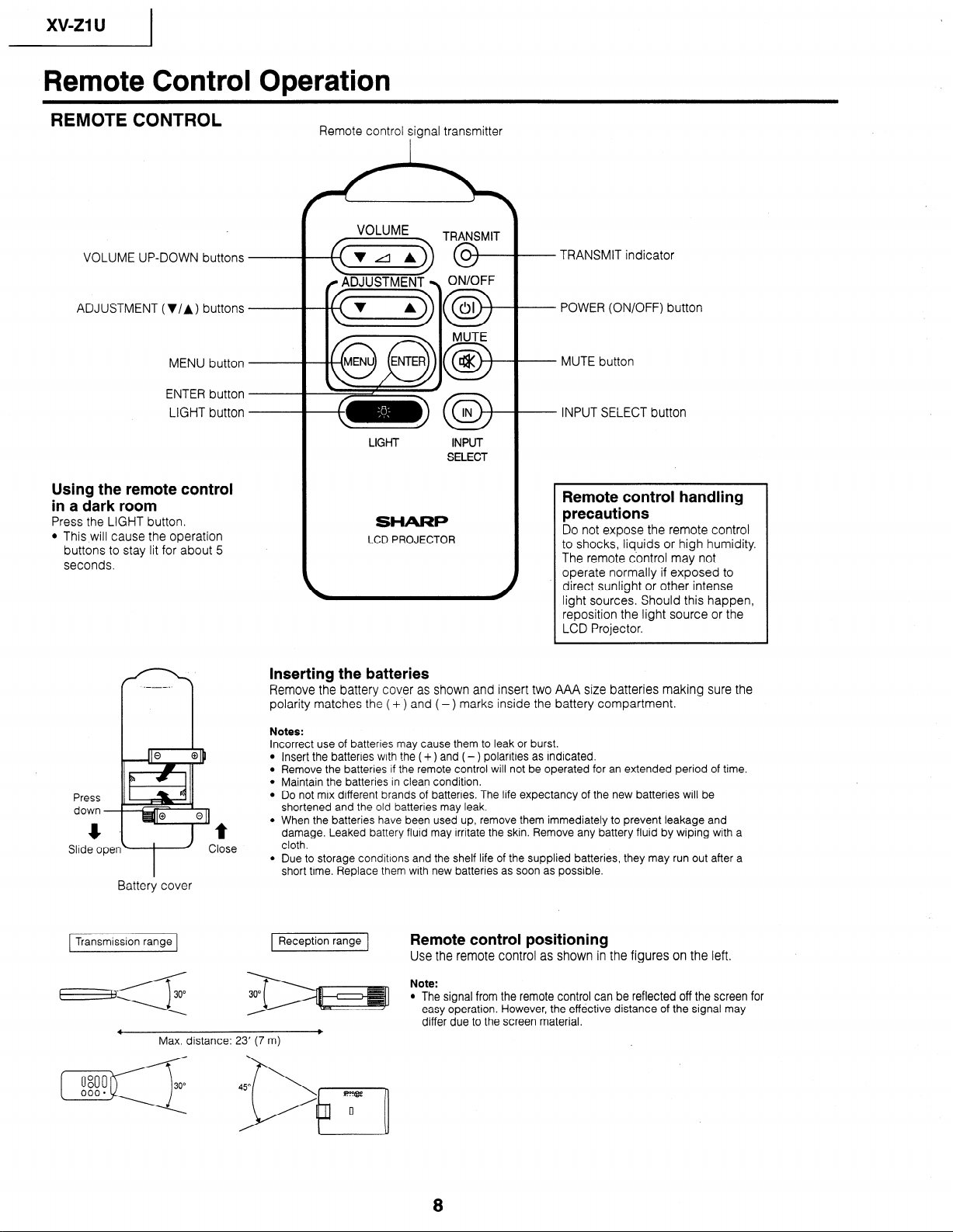

Remote Control Operation

REMOTE CONTROL

VOLUME UP-DOWN buttons

ADJUSTMENT (V/A) buttons

MENU button

ENTER button

LIGHT button

Using the remote control

in a dark room

Press the LIGHT button.

l This will cause the operation

buttons to stay lit for about 5

seconds.

Remote control sianal transmitter

VOLUME

aTRF

LIGHT INPUT

ON/OFF

01

a

MUTE

a

0-

SELECT

SHARP

LCD PROJECTOR

- TRANSMIT indicator

- POWER (ON/OFF) button

- MUTE button

- INPUT SELECT button

Remote control handling

precautions

Do not expose the remote control

to shocks, liquids or high humidity.

The remote control may not

operate normally if exposed to

direct sunlight or other intense

light sources. Should this happen,

reposition the light source or the

LCD Projector.

L

Press

down -

Slide oper

Battery cover

1 Transmission range 1

Max. distance: 23’ (7 m)

t

Zlose

Inserting the batteries

Remove the battery cover as shown and insert two AAA size batteries making sure the

polarity matches the ( + ) and (-) marks inside the battery compartment.

Notes:

Incorrect use of batteries may cause them to leak or burst.

Insert the batteries with the ( +) and (- ) polarities as indicated.

Remove the batteries if the remote control will not be operated for an extended period of time.

Maintain the batteries in clean condition.

Do not mix different brands of batteries. The life expectancy of the new batteries will be

shortened and the old batteries may leak.

When the batteries have been used up, remove them immediately to prevent leakage and

damage. Leaked battery fluid may irritate the skin. Remove any battery fluid by wiping with a

cloth.

Due to storage conditions and the shelf life of the supplied batteries, they may run out after a

short time. Replace them with new batteries as soon as possible.

Reception range

Remote control positioning

Use the remote control as shown in the figures on the left.

Note:

l The signal from the remote control can be reflected off the screen for

easy operation. However, the effective distance of the signal may

differ due to the screen material.

-

8

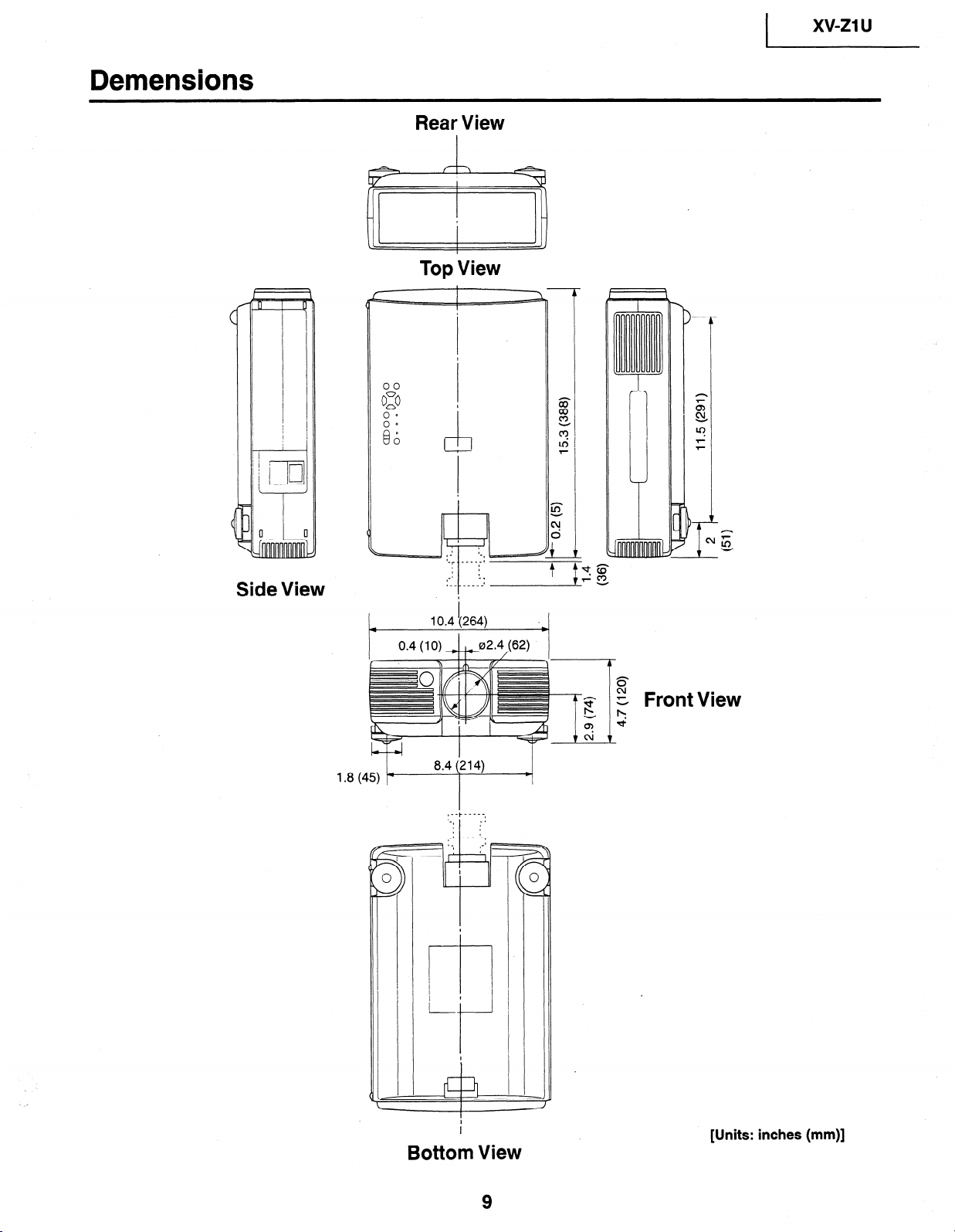

Demensions

1 xv-mu

Rear View

Top View

t-----

I

Side View

Front View

__!L

1.8 (45)

14

Bottom View

9

[Units: inches (mm)]

xv-21

u

I

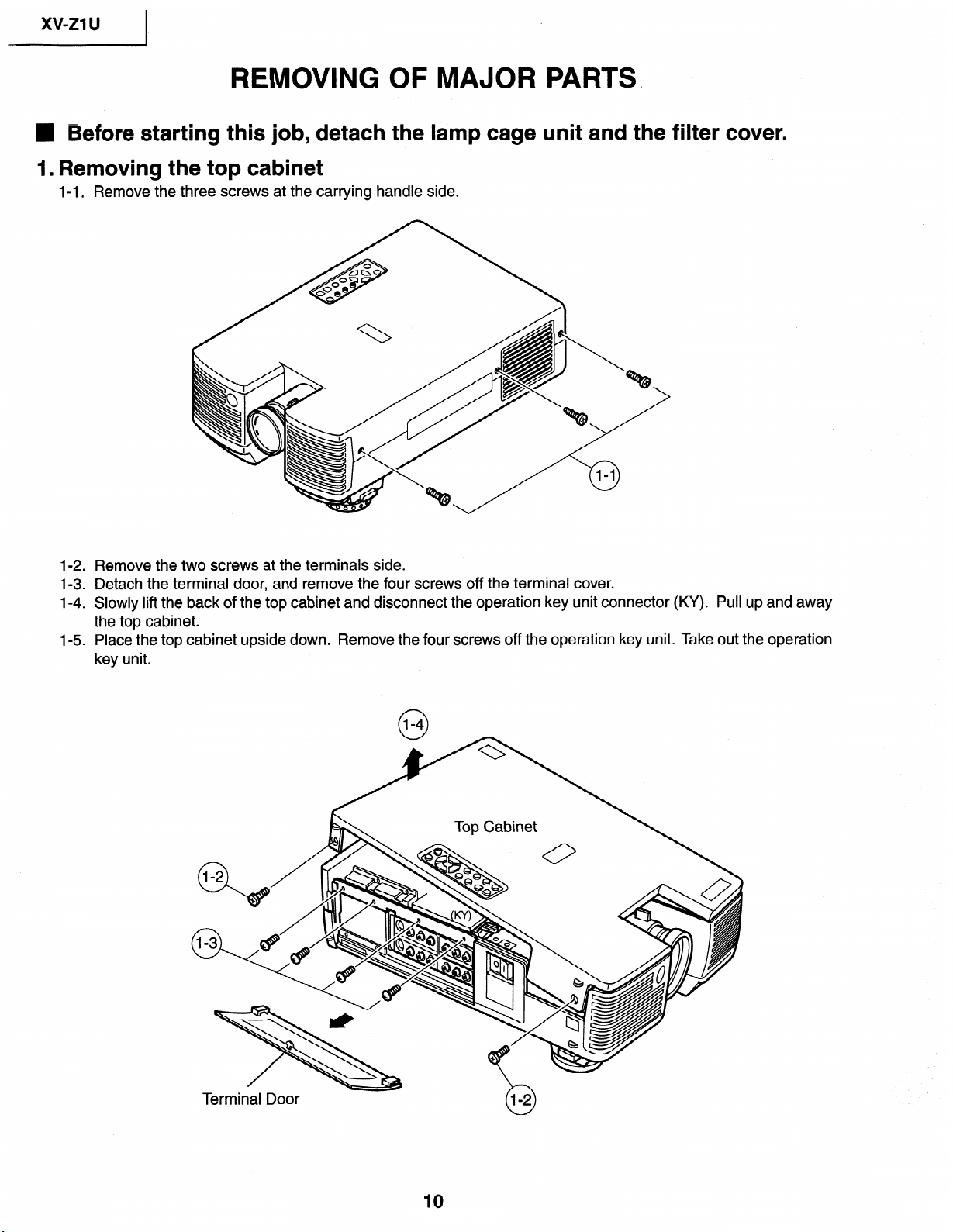

REMOVING OF MAJOR

PARTS>

n Before starting this job, detach the lamp cage unit and the filter cover.

1. Removing the top cabinet

l-l

. Remove the three

screws at the carrying

handle side.

Remove the two screws at the terminals side.

1-2

.

Detach the terminal door, and remove the four screws off the terminal cover.

.

1-3

Slowly lift the back of the top cabinet and disconnect the operation key unit connector (KY).

1-4 .

the top cabinet.

Place the top cabinet upside down. Remove the four screws off the operation key unit. Take out the operation

.

l-5

key unit.

Pull up and away

Terminal Door

10

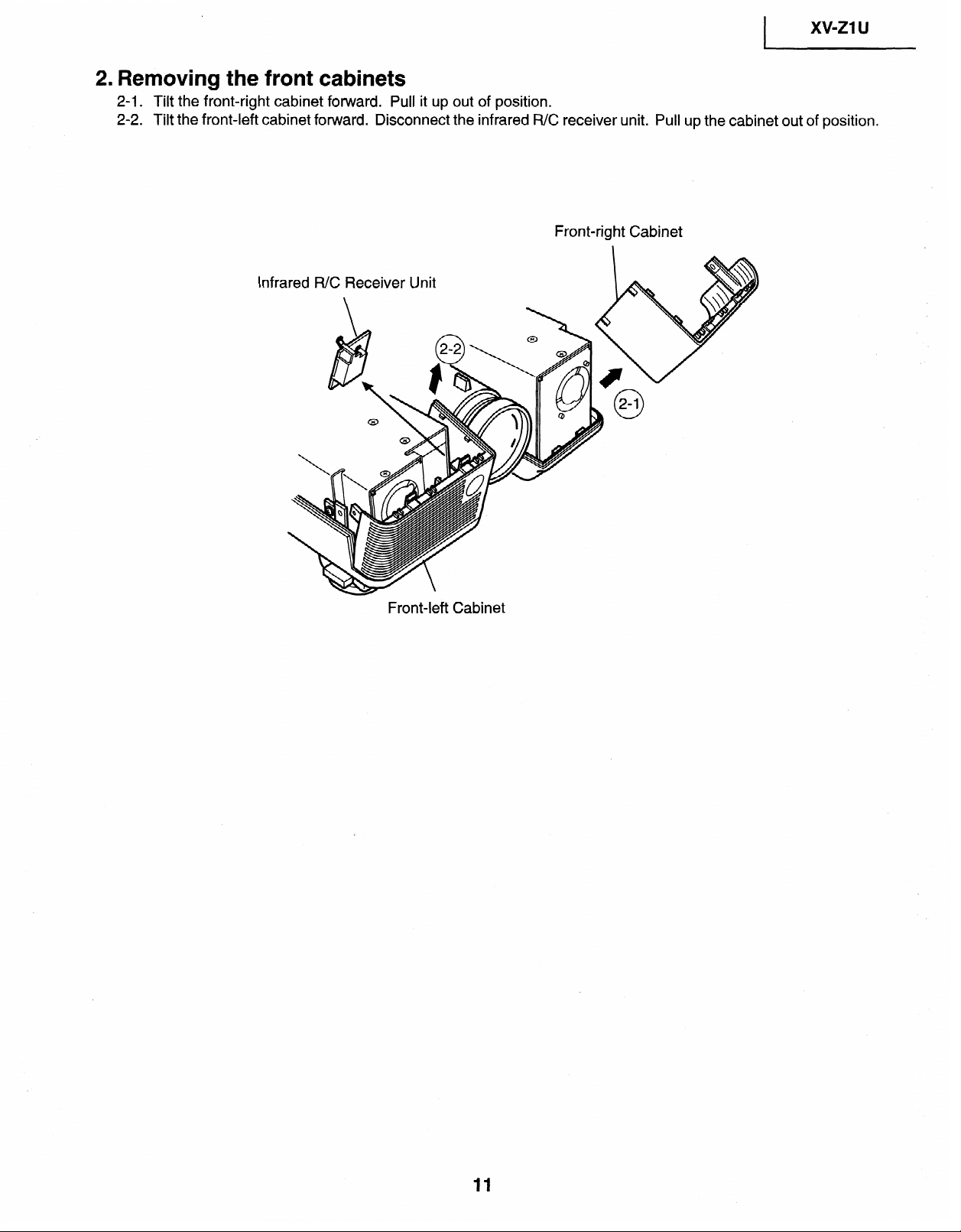

2. Removing the front cabinets

2-1. Tilt the front-right cabinet forward. Pull it up out of position.

Tilt the front-left cabinet

2-2.

lnfra

forward. Disconnect the infrared R/C receiver unit. Pull up

Front-right Cabinet

I

the cabinet out of position.

xv-z1

u

Front-left Cabinet

11

xv-21 u

I

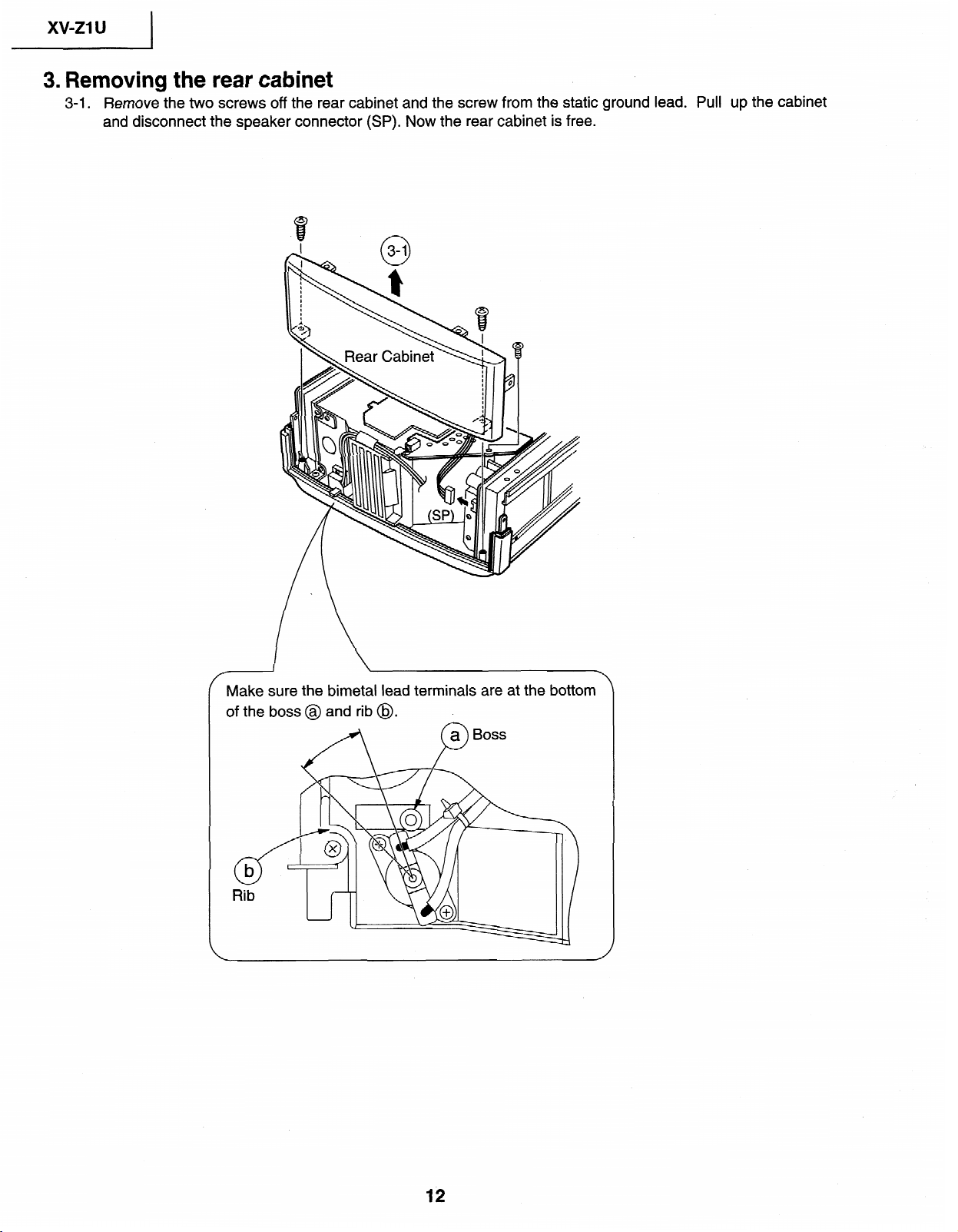

3. Removing the rear cabinet

3-1. Remove the two

and

disconnect

screws

the

off the rear

speaker connector (SP). Now

cabinet

and

the

the

screw

rear

from

the static ground lead. Pull up the cabinet

cabinet

is free.

Make sure the bimetai lead terminals are at the

of the boss@ and

rib @.

bottom

12

1 xv-ZlU

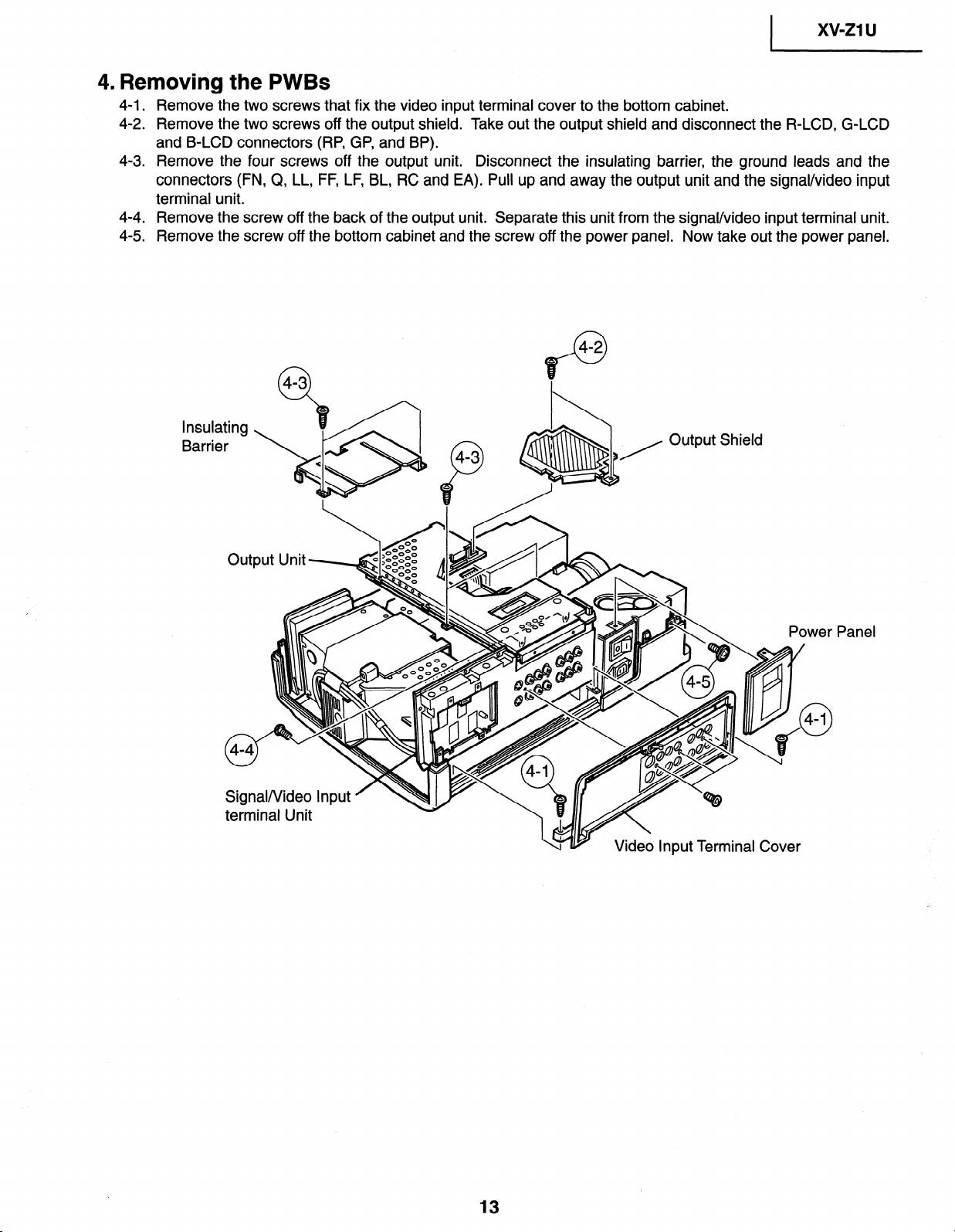

4. Removing the PWBs

4-1 .

Remove the two screws that fix the video input terminal cover to the bottom cabinet.

.

4-2

Remove the two screws off the output shield. Take out the output shield and disconnect the R-LCD, G-LCD

and B-LCD connectors (RP, GP, and BP).

4-3 .

Remove the four screws off the output unit. Disconnect the insulating barrier, the ground leads and the

connectors (FN, Q, LL, FF, LF, BL, RC and EA). Pull up and away the output unit and the signal/video input

terminal unit.

4-4 . Remove the screw off the back of the output unit. Separate this unit from the signal/video input terminal unit.

4-5 . Remove the screw off the bottom cabinet and the screw off the power panel. Now take out the power panel.

lnsula

Barrie

ting

r

Output Shield

Signal/Video Input

terminal Unit

Panel

13

xv-z1 u

I

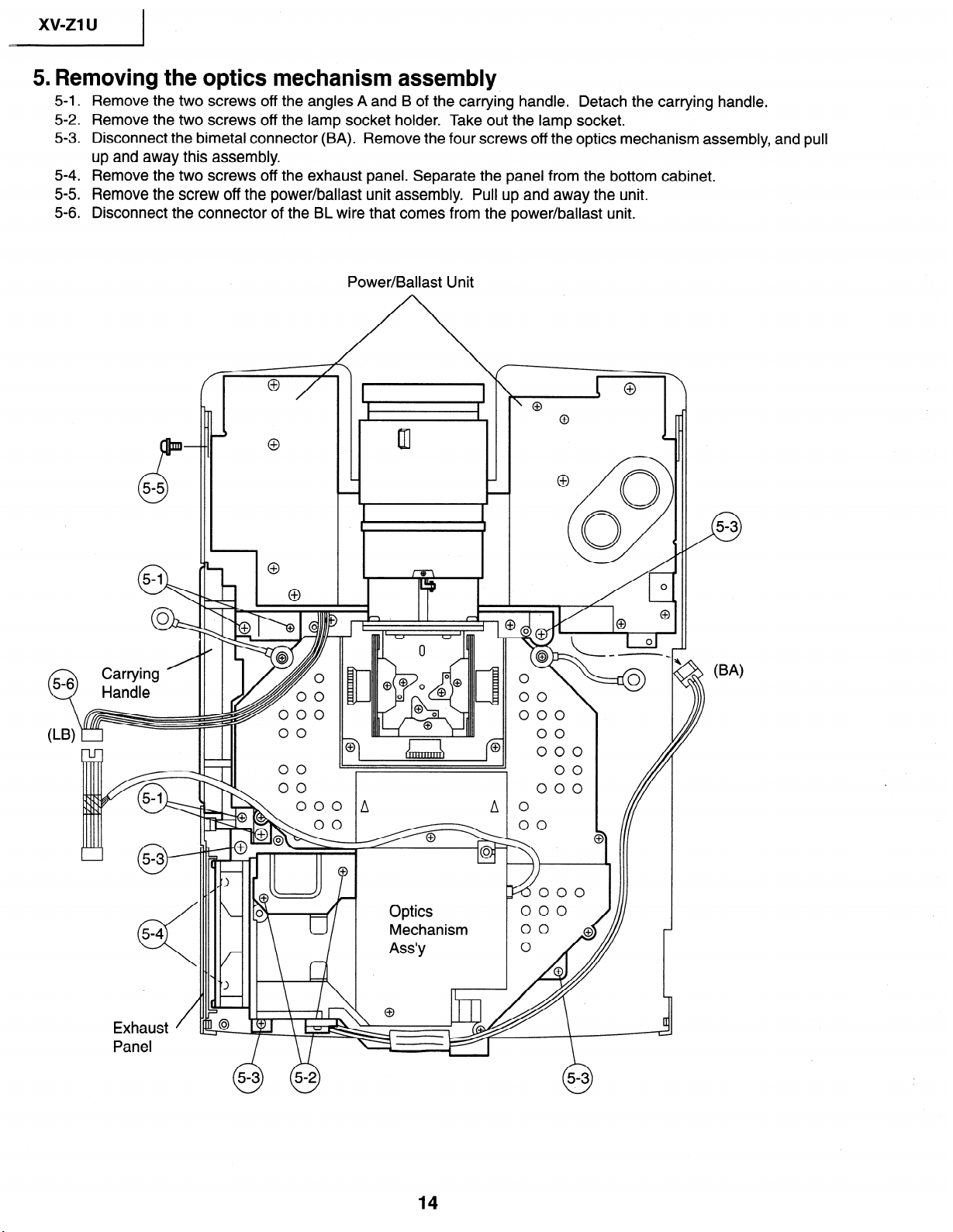

5. Removing the optics mechanism assembly

.

5-l

Remove the two screws off the angles A and B of the carrying handle.

.

5-2

Remove the two screws off the lamp socket holder. Take out the lamp socket.

5-3 .

Disconnect the bimetal connector (BA).

up and away this assembly.

5-4

.

Remove the two screws off the exhaust panel. Separate the panel from the bottom cabinet.

5-5 .

Remove the screw off the power/ballast unit assembly. Pull up and away the unit.

.

5-6

Disconnect the connector of the BL wire that comes from the power/ballast unit.

Remove the four screws off the optics mechanism assembly, and pull

Power/Ballast Unit

Detach the carrying handle.

5-6

Q

Exhaust

Panel

/

14

xv-z1 u

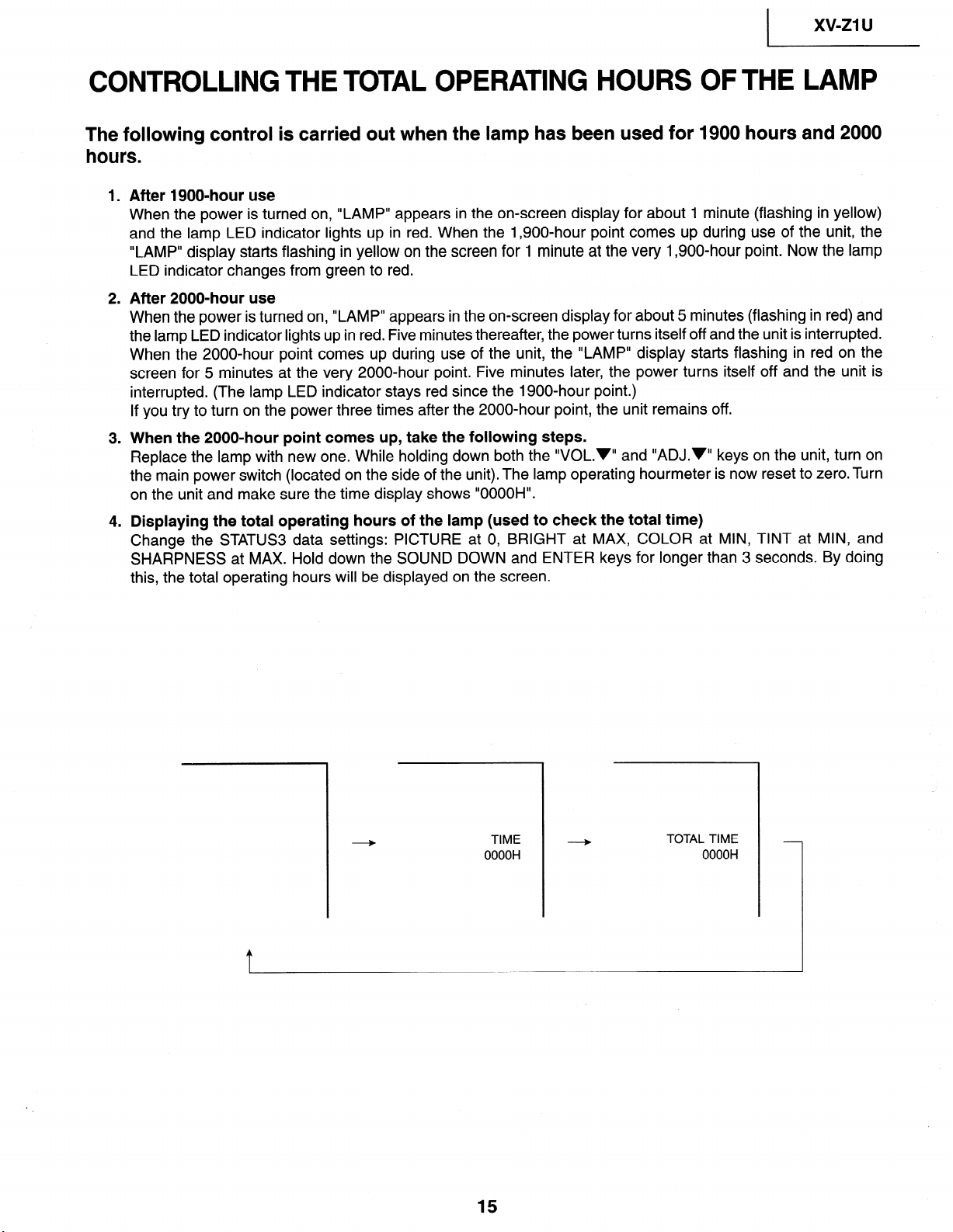

CONTROLLING THE TOTAL OPERATING HOURS OF THE LAMP

The following control is carried out when the lamp has been used for 1900 hours and 2000

hours.

1 .

After 1900-hour use

When the power is turned on, “LAMP” appears in the on-screen display for about 1 minute (flashing in yellow)

and the lamp LED indicator lights up in red. When the 1,900-hour point comes up during use of the unit, the

“LAMP” display starts flashing in yellow on the screen for 1 minute at the very 1,900-hour point. Now the lamp

LED indicator changes from green to red.

2 .

After 2000-hour use

When the power is turned on, “LAMP” appears in the on-screen display for about 5 minutes (flashing in red) and

the lamp LED indicator lights up in red. Five minutes thereafter, the power turns itself off and the unit is interrupted.

When the 2000-hour point comes up during use of the unit, the “LAMP” display starts flashing in red on the

screen for 5 minutes at the very 2000-hour point. Five minutes later, the power turns itself off and the unit is

interrupted. (The lamp LED indicator stays red since the 1900-hour point.)

If you try to turn on the power three times after the 2000-hour point, the unit remains off.

3 .

When the 2000-hour point comes up, take the following steps.

Replace the lamp with new one. While holding down both the “V0L.v” and “ADJY” keys on the unit, turn on

the main power switch (located on the side of the unit). The lamp operating hourmeter is now reset to zero. Turn

on the unit and make sure the time display shows “OOOOH”.

4 .

Displaying the total operating hours of the lamp (used to check the total time)

Change the STATUS3 data settings: PICTURE at 0, BRIGHT at MAX, COLOR at MIN, TINT at MIN, and

SHARPNESS at MAX. Hold down the SOUND DOWN and ENTER keys for longer than 3 seconds. By doing

this, the total operating hours will be displayed on the screen.

15

1 xv-ZlU

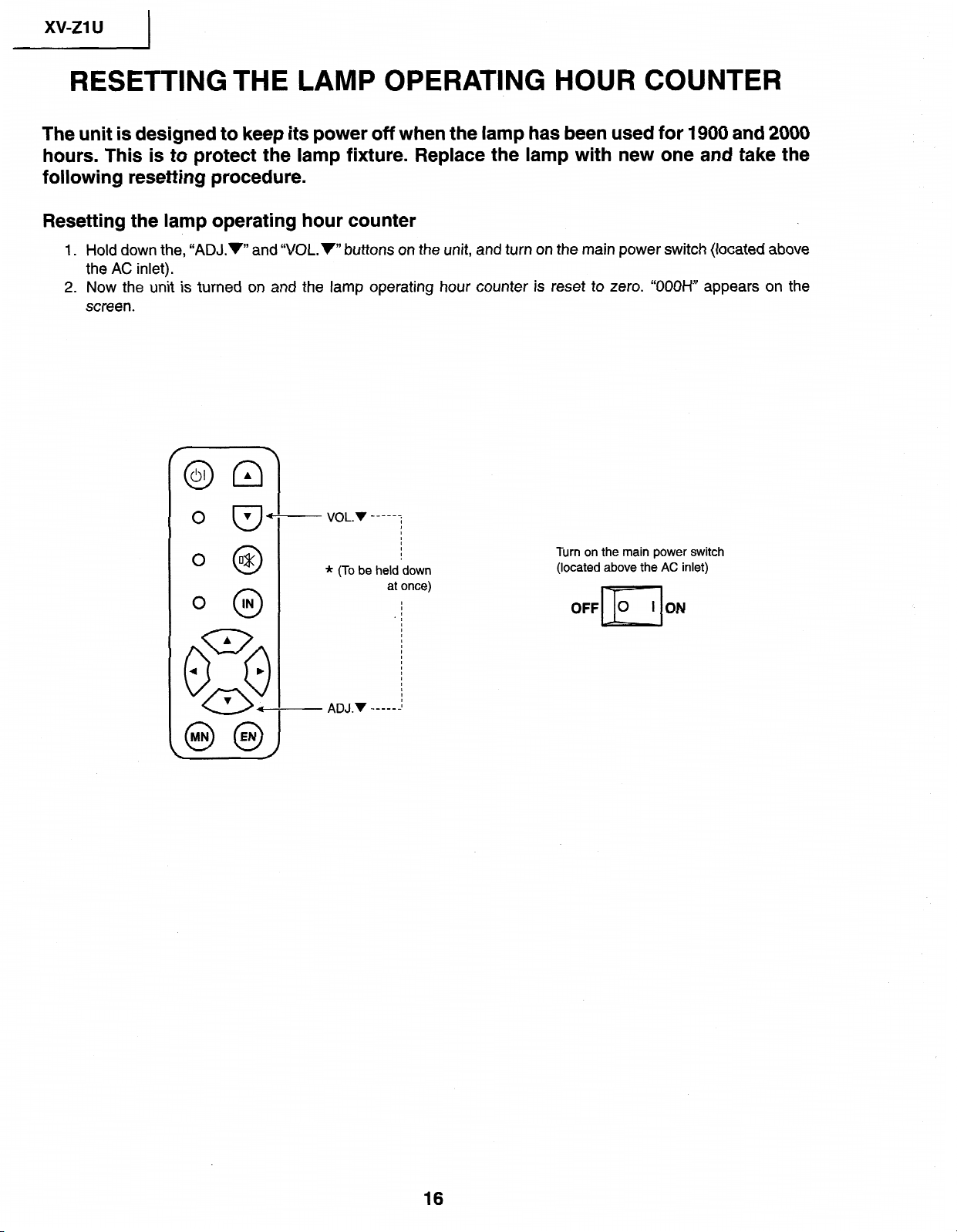

RESETTING THE LAMP OPERATING HOUR COUNTER

The unit is designed to keep its power off when the

hours.

This is to protect the lamp fixture. Replace the lamp with new one and take the

following resetting procedure.

Resetting the lamp operating hour counter

1.

Hold down the, “ADJ.v” and “V0L.v” buttons on the unit, and

the AC inlet).

2. Now the

screen.

unit is

turned on and the

0 @

0 @

lamp operating hour counter

* (To be held down

at once)

I

I

I

’

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ADJ.v _____s.~

lamp has been

turn

on the main power

is reset to zero. “OOOH” appears on

Turn on the main power switch

(located above the AC inlet)

used for

switch (located above

1900

and

2000

the

16

_ xv-ZlU

1

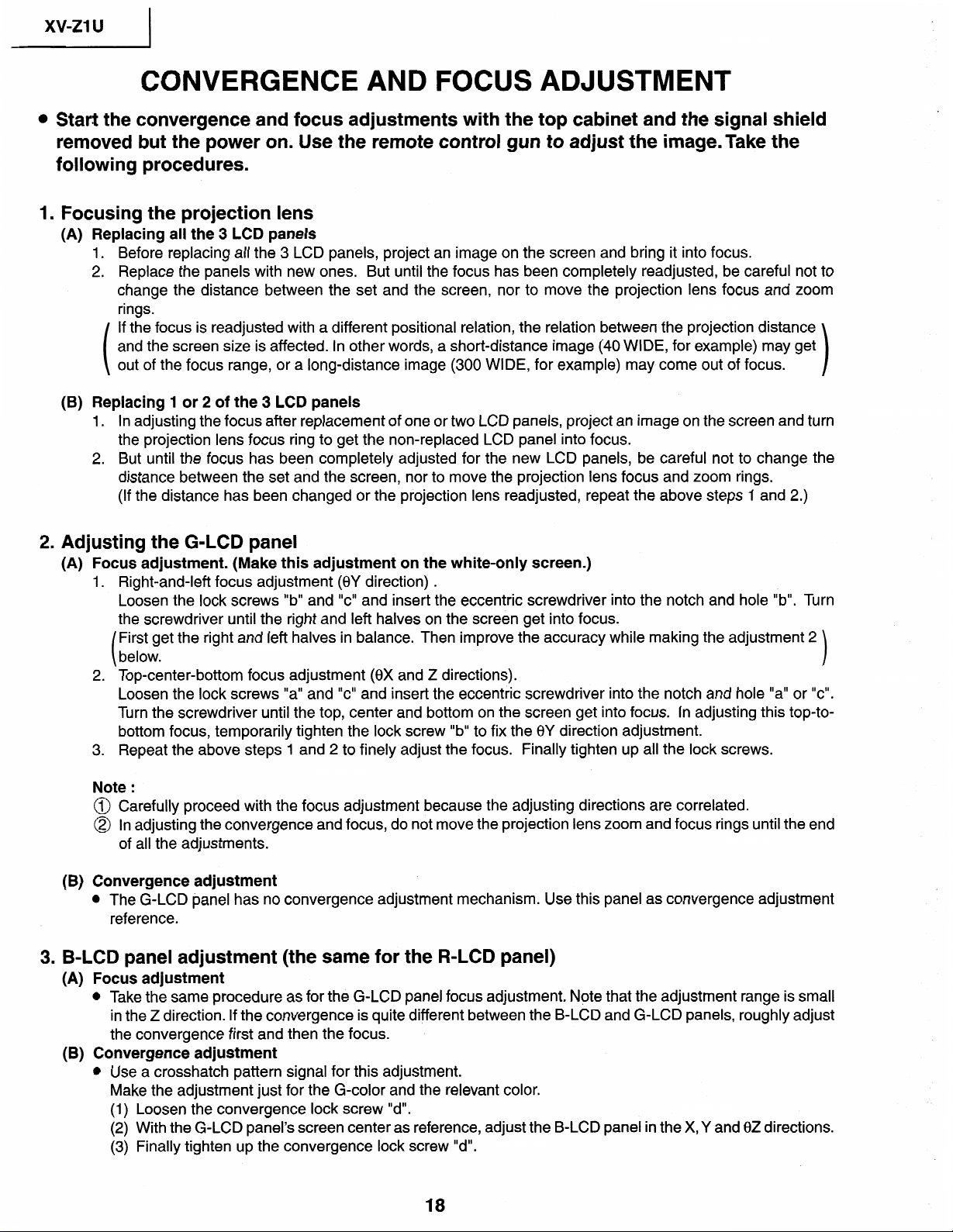

CONVERGENCE AND FOCUS ADJUSTMENT

l

Start the convergence

removed but the power on. Use the remote control gun to adjust the image.Take the

following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1.

Before

2. Replace the

change the distance between the set and the

rings.

If

and the screen size is affected. In

out of the focus range, or a

replacing all the 3 LCD panels,

panels with

the

focus

is

and focus adjustments with the top cabinet and the signal shield

project an image on the screen and bring it into focus.

new

ones. But

readjusted with a different positional relation, the relation between the projection

long-distance

until

the focus

screen, nor to move

other words, a short-distance image (40 WIDE, for example) may

image (300

has been completely readjusted,

the projection

WIDE,

for example) may come out of focus.

lens focus and zoom

be

careful not to

distance

get

(B) Replacing

1. In adjusting

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If

1 or 2 of the 3 LCD panels

the focus after replacement of one or two LCD

the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

panels, project

2. Adjusting the G-LCD panel

(A) Focus adjustment. (Make this adjustment on the white-only screen.)

1. Right-and-left focus adjustment (0Y direction) .

Loosen the lock screws “b” and “c” and insert the eccentric screwdriver into the notch and hole ‘lb”. Turn

the screwdriver until the right and left halves on the screen get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

‘Top-center-bottom focus adjustment (0X and Z directions).

2 .

Loosen the lock screws “a” and “c”

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this top-tobottom focus, temporarily tighten the lock screw “b” to fix the 8Y direction adjustment.

Repeat the above steps 1 and 2 to finely adjust the focus.

.

3

Note

:

@ Carefully proceed with the focus adjustment because the adjusting directions are correlated.

@ In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

and insert the eccentric screwdriver into the notch and hole “a” or “c”.

Finally tighten up all the lock screws.

an image on the screen and turn

(B) Convergence adjustment

l

The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

l Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is small

in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels, roughly adjust

the convergence first and then the focus.

(B) Convergence adjustment

l Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-color and the relevant color.

Loosen the convergence lock screw “d”.

(1)

With the G-LCD panel’s screen center as reference, adjust the B-LCD panel in the X, Y and 8Z directions.

(2)

Finally tighten up the convergence lock screw I’d”.

(3)

18

1 xv-ZllJ

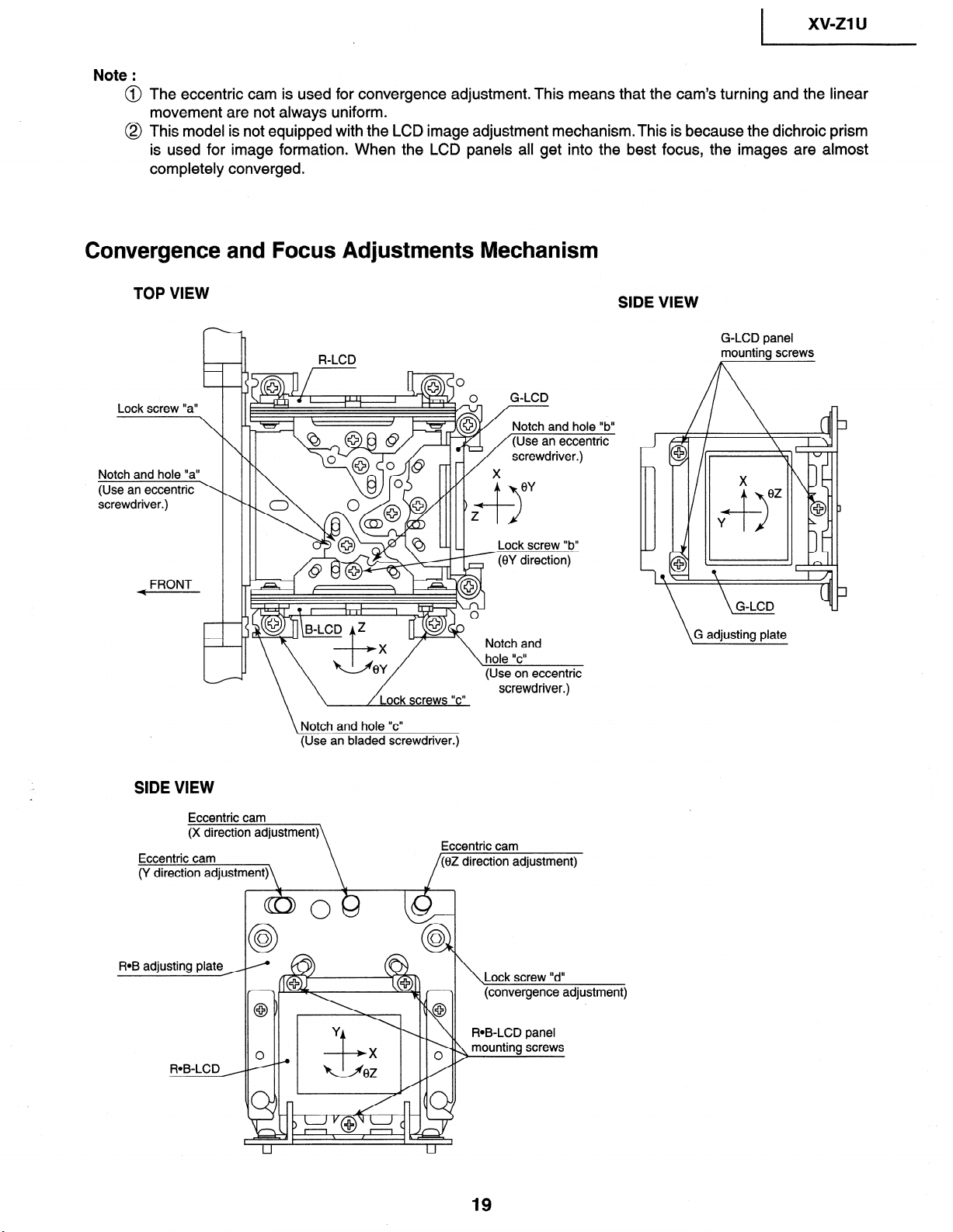

Note :

@ The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

@ This model is not equipped with the LCD image adjustment mechanism.This is because the dichroic prism

is used for image formation. When the LCD panels all get into the best focus, the images are almost

completely converged.

Convergence and Focus Adjustments Mechanism

TOP VIEW

Lock screw “a”

Notch and hole “a”

(Use an eccentric \

screwdriver.)

FRONT

r

-r-I

h

R-LCD

\ Notch and hole “c”

(Use an bladed screwdriver.)

SIDE VIEW

G-LCD panel

mounting screws

0 G-LCD

Lock screw “b”

(0Y direction)

\G adjusting plate

Eccentric cam

Eccentnc cam

(y direct.;\

ROB adjusting plate ,

Lock screw “d”

(convergence adjustment)

xv-ZlU 1

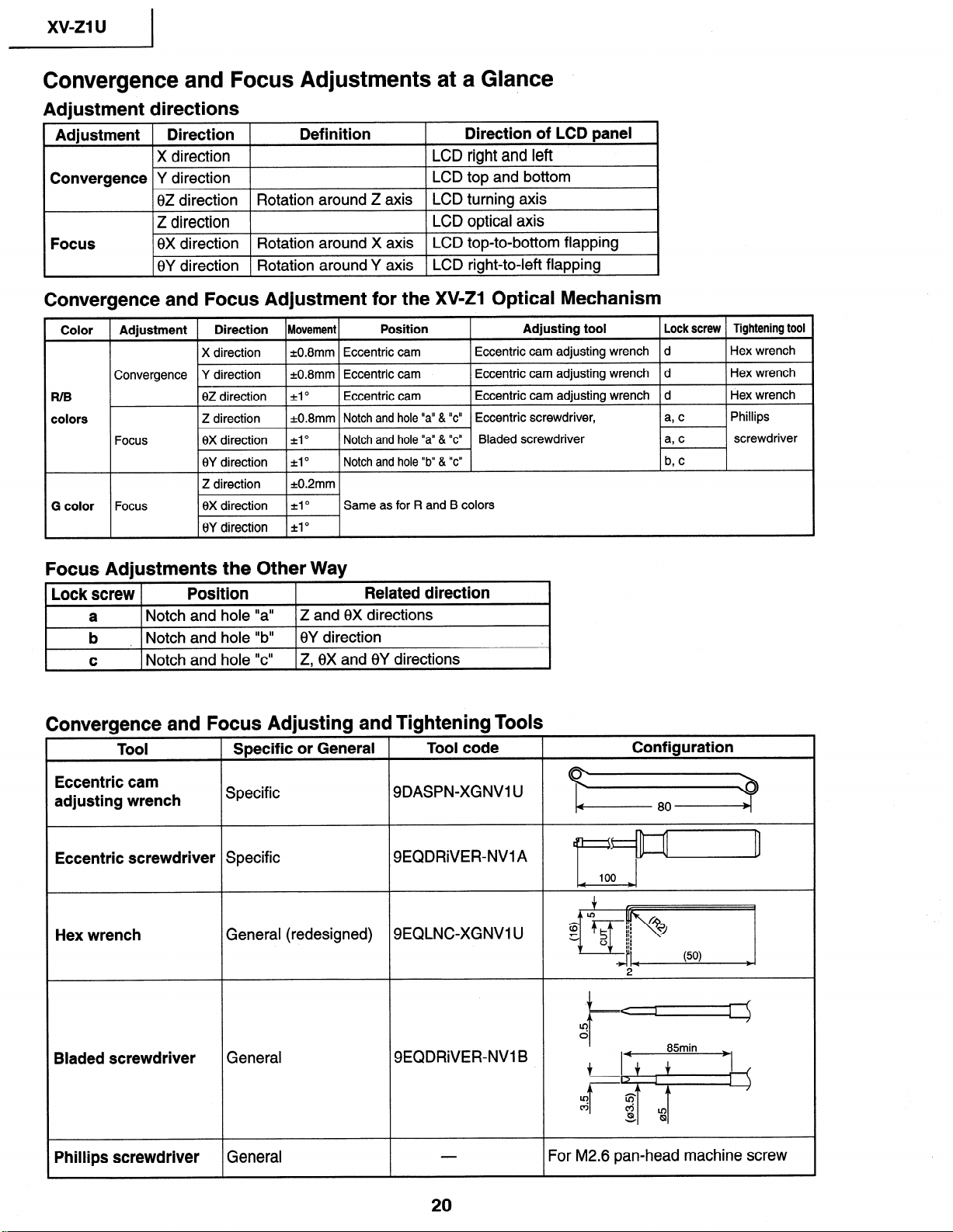

Convergence and Focus Adjustments at a Glance

Adjustment directions

Adjustment Direction

Definition

X direction

Convergence Y direction

0Z direction

Rotation around Z axis LCD turning axis

Z direction

Focus

,

8X direction Rotation around X axis LCD top-to-bottom flapping

8Y direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the XV-Z1 Optical Mechanism

Direction of LCD panel

LCD right and left

LCD top and bottom

LCD optical axis

Color Adjustment Direction Movement

X direction *0.8mm Eccentric cam

Convergence Y direction k0.8mm Eccentric cam

R/B

colors

Focus

G color

0Z direction

Z direction =t0.8mm Notch and hole “a” & “c” Eccentric screwdriver,

0X direction A0

8Y direction ~1”

=tl O

Position

Eccentric cam adjusting wrench

Eccentric cam adjusting wrench d

Eccentric cam

Notch and hole “a” & “c” Bladed screwdriver

Notch and hole “b” & “c”

Same as for R and B colors

Eccentric cam adjusting wrench

Adjusting tool Lock screw Tightening tool

Focus Adjustments the Other Way

Lock screw Posit ion

Notch and hole “a” Z and 6X directions

1 Notch and hole “b” I8Y direction

I---

a

b

Related direction

I C 1 Notch and hole “c” 1 Z, 0X and 8Y directions

Convergence and Focus Adjusting and Tightening Tools

Tool

Specific or General

-

-

Tool code

. I

d

d

a, c

a’ c

b, c

I

Hex wrench

Hex wrench

Hex wrench

Phillips

screwdriver

Configuration

Eccentric cam

adjusting wrench

Specific

Eccentric screwdriver Specific

Hex wrench

Bladed screwdriver

General (redesigned)

General

Phillips screwdriver General

9DASPN-XGNVl U

SEQDRiVER-NVlA

SEQLNC-XGNVl U

SEQDRiVER-NV1 B

TT?

2

,LL

Lc!

t f

j=$+j-

For M2.6 pan-head machine screw

85min +,

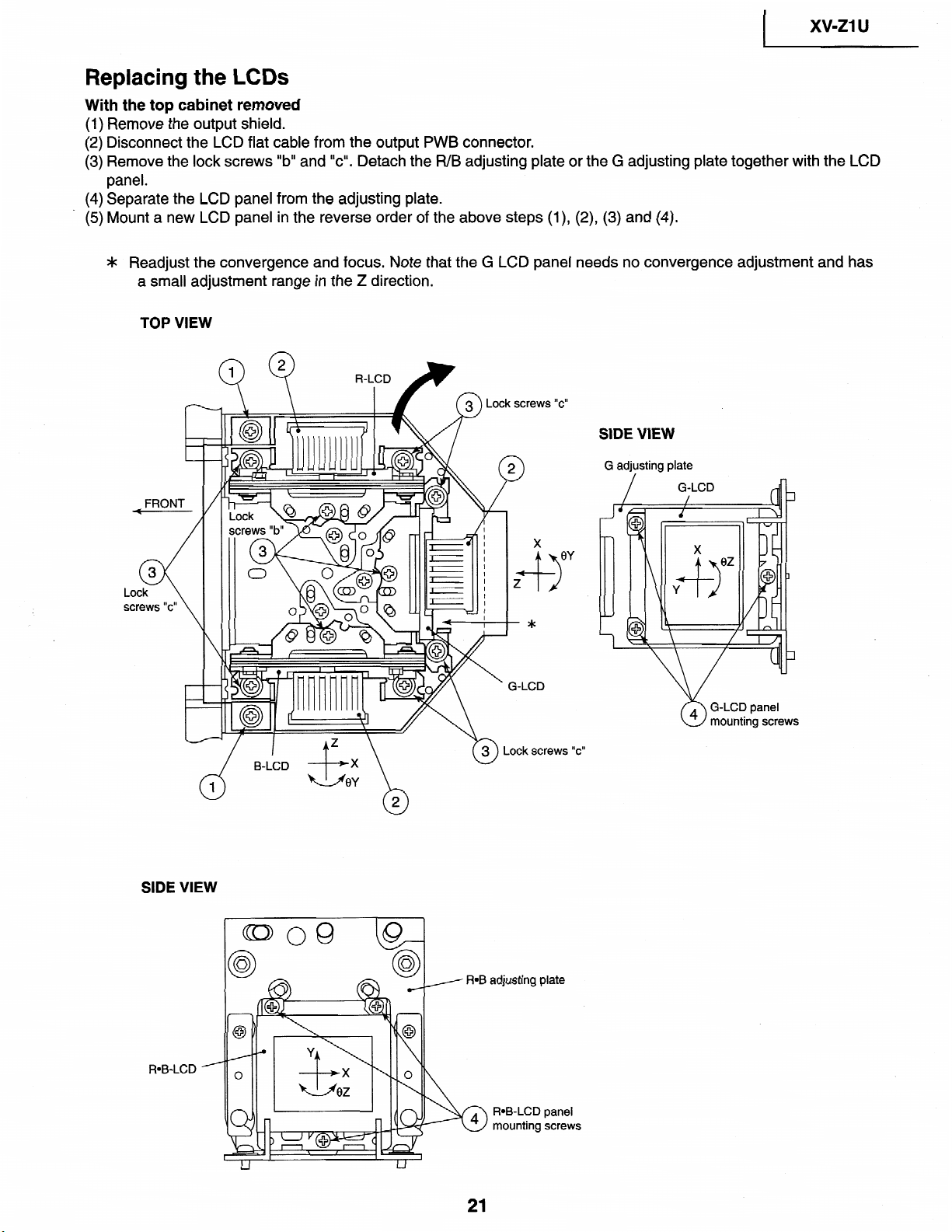

Replacing the LCDs

With the top cabinet removed

(1) Remove the output shield.

(2) Disconnect the LCD flat cable from the output PWB connector.

(3) Remove the lock screws “b” and

panel.

(4) Separate the LCD panel from the adjusting plate.

* (5) Mount a new LCD panel in

“c”. Detach the R/B adjusting plate or the G adjusting plate together with the LCD

the reverse order of the above steps (l), (2), (3) and (4).

I

xv-21

u

* Readjust the convergence and

a small adjl

_rstment range in the Z direction.

TOP VIEW

focus. Note that the G LCD

panel

pews

.CD

needs

“C”

no convergence adjustment

SIDE VIEW

G adjusting plate

G-LCD

/

and has

1

d

SIDE VIEW

ROB-LCD

B-LCD

fz \

m Lock screws “c”

adjusting plate

ROB-LCD panel

mounting screws

xv-21

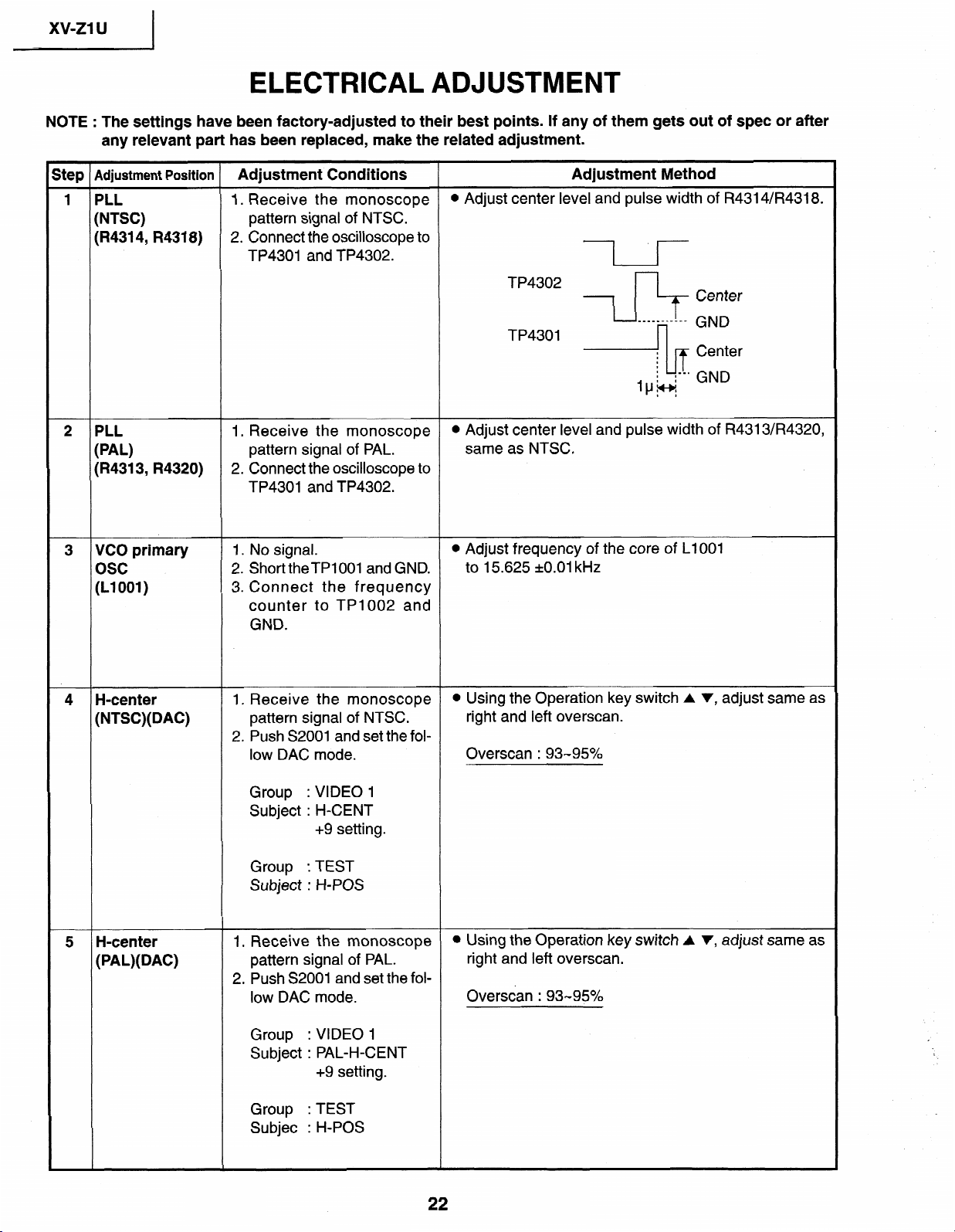

NOTE :

u

I

The settings

any relevant

ELECTRICAL ADJUSTMENT

have been factory-adjusted to their

part has been

replaced, make

the

best

points.

If any of them gets out of

related adjustment.

spec

or after

Adjustment

Step

1 PLL

(NTSC)

(R4314,

PLL

2

(PAL)

(I?431 3, R4320)

VCO primary

3

osc

(Ll 001)

Position Adjustment

1. Receive the monoscope

pattern signal of NTSC.

R4318)

2. Connect the oscilloscope to

TP4301 and

1. Receive the monoscope

pattern signal

Connect the oscilloscope to

2.

TP4301 and TP4302.

1. No signal.

2. Short theTPlOO1 and GND.

3. Connect the frequency

counter to TP1002 and

GND.

Conditions

TP4302.

of PAL.

Adjustment Method

Adjust center level

l

TP4302

TP4301

Adjust

l

same as NTSC.

l Adjust frequency of the core

to 15.625 kO.01 kHz

center

and pulse width of R4314/R4318.

x

.+

level and pulse width of R4313/R4320,

I

I

of LlOOl

Center

iinIer

H-center

4

(NTSC)( DAC)

H-center

5

(PAL)( DAC)

1. Receive the

pattern signal of NTSC.

2. Push S2001 and set the fol-

low DAC mode.

Group

Subject : H-CENT

Group

Subject : H-POS

1. Receive the monoscope

pattern signal of PAL.

2. Push S2001 and set the follow DAC mode.

Group

Subject : PAL-H-CENT

Group : TEST

Subjec : H-POS

monoscope

: VIDEO

+9 setting.

: TEST

: VIDEO 1

+9 setting.

1

Using the Operation key switch A ‘I, adjust same as

l

right and left overscan.

Overscan : 93-95%

Using the Operation key switch A v, adjust same as

l

right and left overscan.

Overscan : 93-95%

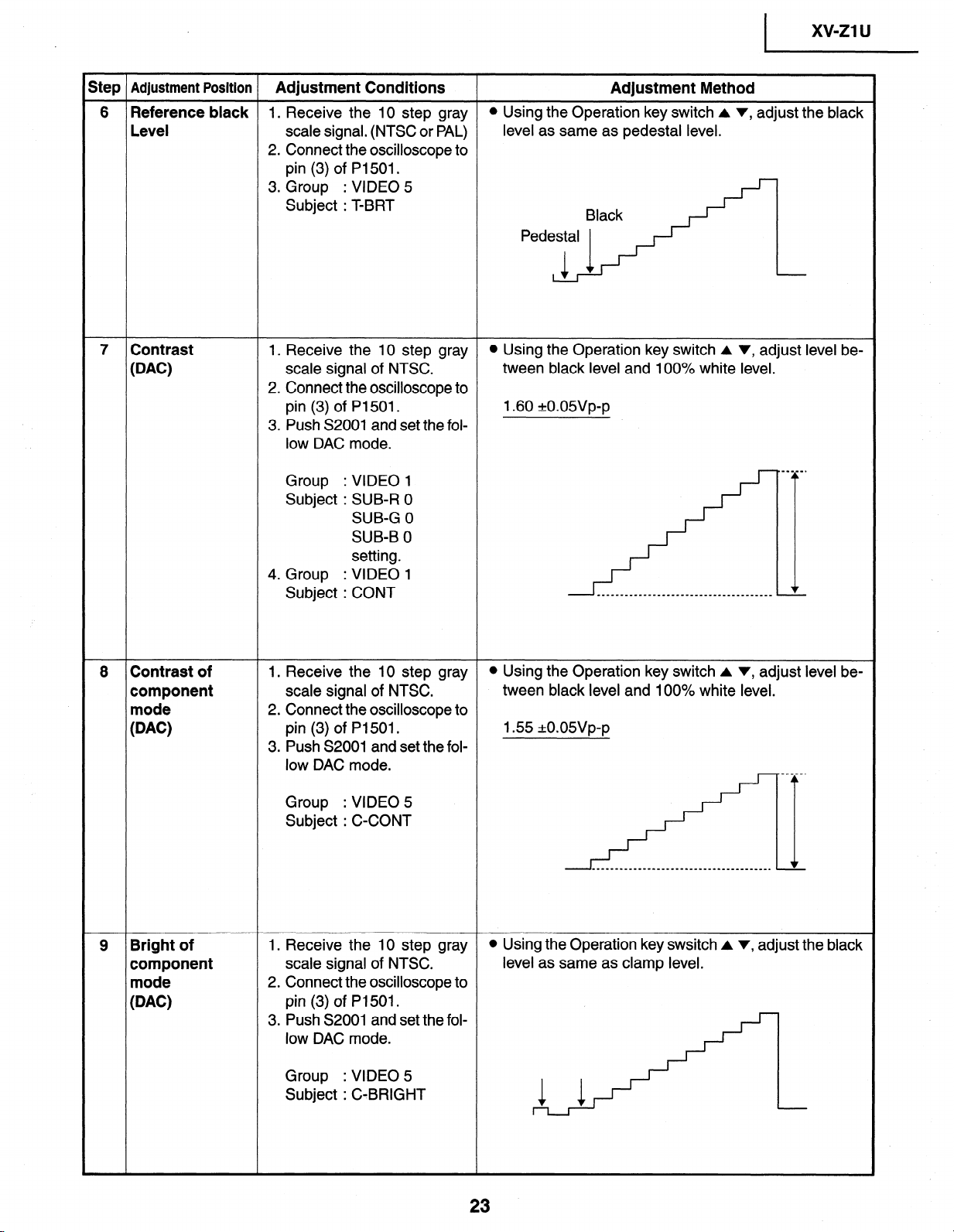

1 xv-ZlU

Step Adjustment Position

Adjustment Conditions

6 Reference black 1. Receive the 10 step gray

Level scale signal. (NTSC or PAL)

2. Connect the oscilloscope to

pin (3) of P1501.

3. Group : VIDEO 5

Subject : T-BRT

7 Contrast

WC)

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (3) of P1501.

3. Push S2001 and set the follow DAC mode.

Group : VIDEO 1

Subject : SUB-R 0

SUB-G 0

SUB-B 0

setting.

4. Group : VIDEO 1

Subject : CONT

Adjustment Method

l Using the Operation key switch A v, adjust the black

level as same as pedestal level.

Ped;?: .:,’

l Using the Operation key switch A v, adjust level be-

tween black level and 100% white level.

1.60 kO.OWp-p

8 Contrast of

component

mode

WC)

9 Bright of

component

mode

WC)

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (3) of P1501.

3. Push S2001 and set the follow DAC mode.

Group : VIDEO 5

Subject : C-CONT

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (3) of P1501.

3. Push S2001 and set the follow DAC mode.

Group

Subject : C-BRIGHT

: VIDEO 5

l Using the Operation key switch A v, adjust level be-

tween black level and 100% white level.

1.55 -r-o.o5vp-p

l Using the Operation key swsitch A v, adjust the black

level as same as clamp level.

I

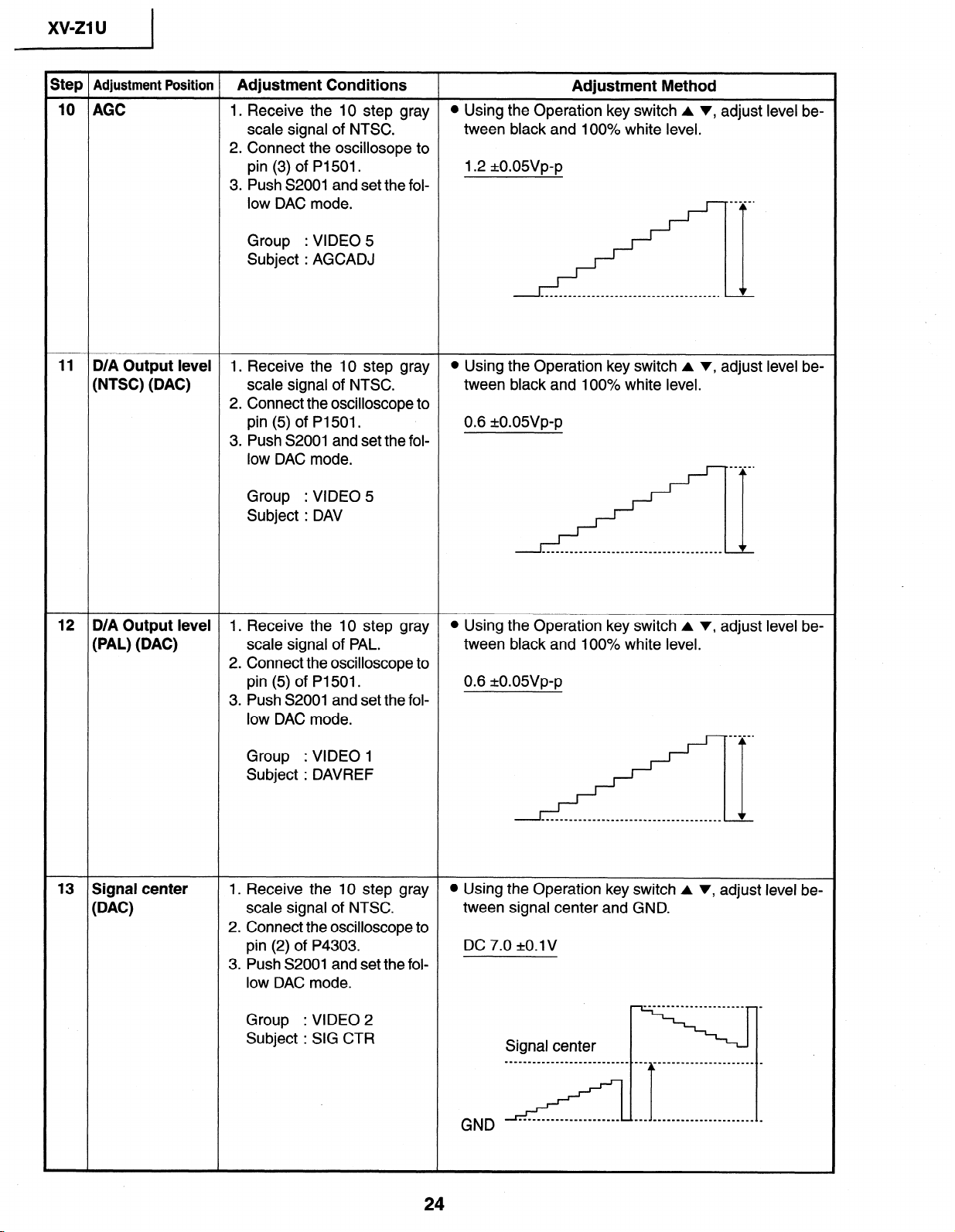

Step Adjustment Position Adjustment Conditions

10 AGC I. Receive the IO step gray

scale signal of NTSC.

2. Connect the oscillosope to

pin (3) of PI 501.

3. Push S2001 and set the follow DAC mode.

Group : VIDEO 5

Subject : AGCADJ

Adjustment Method

l Using the Operation key switch A v, adjust level be-

tween black and 100% white level.

1.2 *O.OWp-p

_------_______________________________I

‘i

11 D/A Output level

I. Receive the 10 step gray

(NTSC) (DAC) scale signal of NTSC.

2. Connect the oscilloscope to

pin (5) of Pl501.

3. Push S2001 and set the follow DAC mode.

Group : VIDEO 5

Subject : DAV

12 D/A Output level 1. Receive the 10 step gray

(PAL) (DAC)

scale signal of PAL.

2. Connect the oscilloscope to

pin (5) of PI 501.

3. Push S2001 and set the follow DAC mode.

Group

Subject : DAVREF

: VIDEO 1

l Using the Operation key switch A v, adjust level be-

tween black and 100% white level.

0.6 +-O.OSVp-p

l Using the Operation key switch A v, adjust level be-

tween black and 100% white level.

0.6 kO.O5Vp-p

13 Signal center

WC)

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (2) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : SIG CTR

: VIDEO 2

0 Using the Operation key switch A v, adjust level be-

tween signal center and GND.

DC 7.0 1t0.lV

Signal center

----________________--~~~--.--~

GND

24

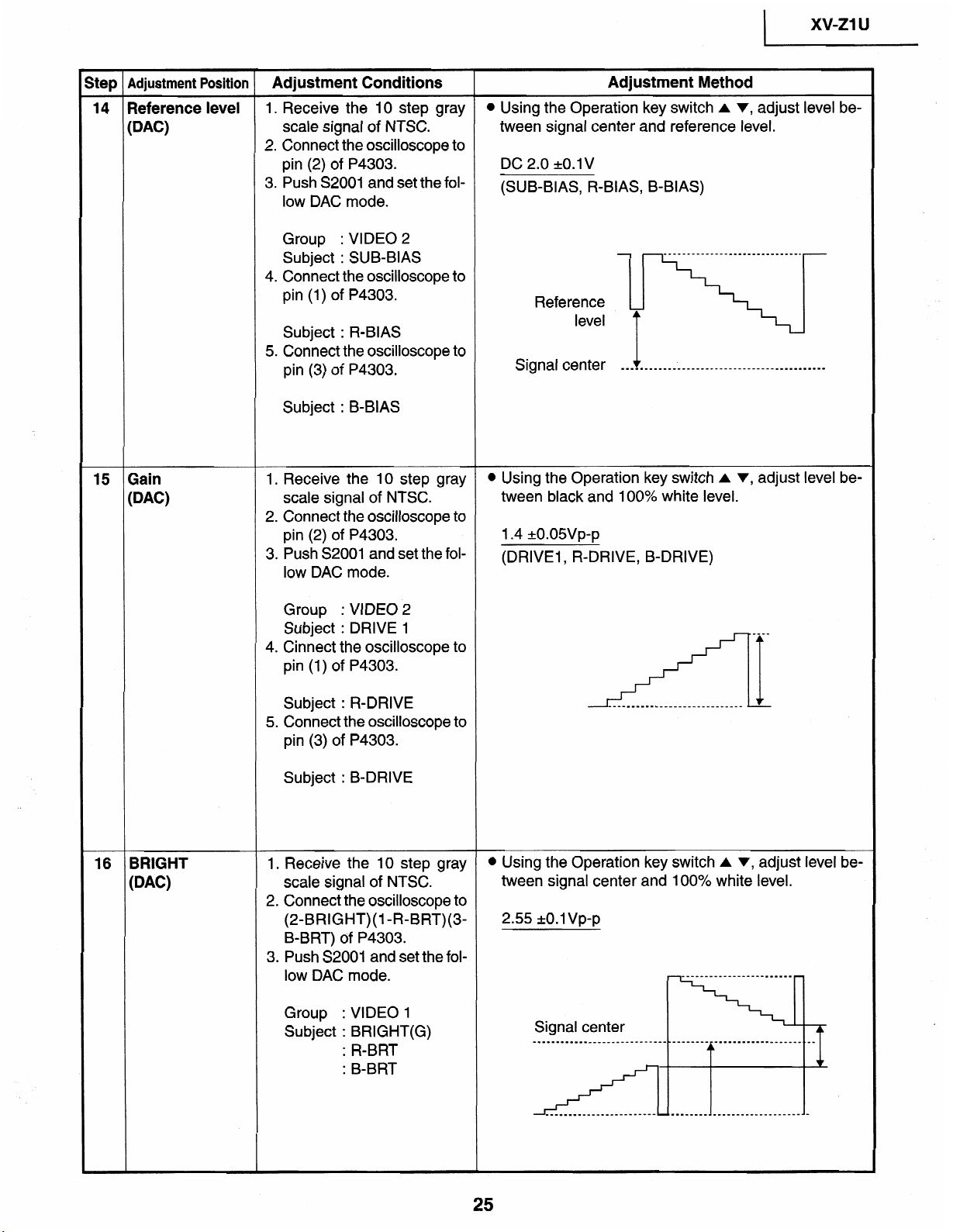

Step

Adjustment Position

14 Reference level

WC)

Adjustment Conditions

1.

Receive the 10

scale signal

2. Connect the oscilloscope to

pin

(2) of P4303.

3. Push

S2001 and set the fol-

low

DAC mode.

step

of NTSC.

gray

xv-z1

I

Adjustment Method

l

Using the Operation key switch A v, adjust level between signal center and reference level.

DC 2.0

(SUB-BIAS, R-BIAS, B-BIAS)

+O.lV

u

15

Gain

WC)

Group

Subject

4. Connect the oscilloscope to

pin

Subject

5. Connect the oscilloscope to

pin (3) of P4303.

Subject

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (2) of P4303.

3. Push S2001 and set the fol-

low DAC mode.

Group

Subject : DRIVE

4. Cinnect the oscilloscope to

pin (1) of P4303.

: VIDEO

: SUB-BIAS

(1) of P4303.

:

R-BIAS

: B-BIAS

: VIDEO 2

2

1

______-_____________---------.

Reference

level

+

Signal

0 Using the Operation key switch A v, adjust level be-

tween black and 100% white level.

1.4 *O.OWp-p

(DRIVEl, R-DRIVE, B-DRIVE)

center -

________________________________________----

16

BRIGHT

WC)

Subject : R-DRIVE

5. Connect the oscilloscope to

pin (3) of P4303.

Subject : B-DRIVE

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

(2=BRIGHT)(l -R=BRT)(3-

B-BRT) of P4303.

3. Push S2001 and set the follow DAC mode.

Group : VIDEO 1

Subject : BRIGHT(G)

: R-BRT

: B-BRT

l

Using the Operation key switch A v, adjust level be-

tween signal center and 100% white level.

2.55 ~0.1 Vp-p

Signal center

____--______________---------.-------

xv-21 u

I

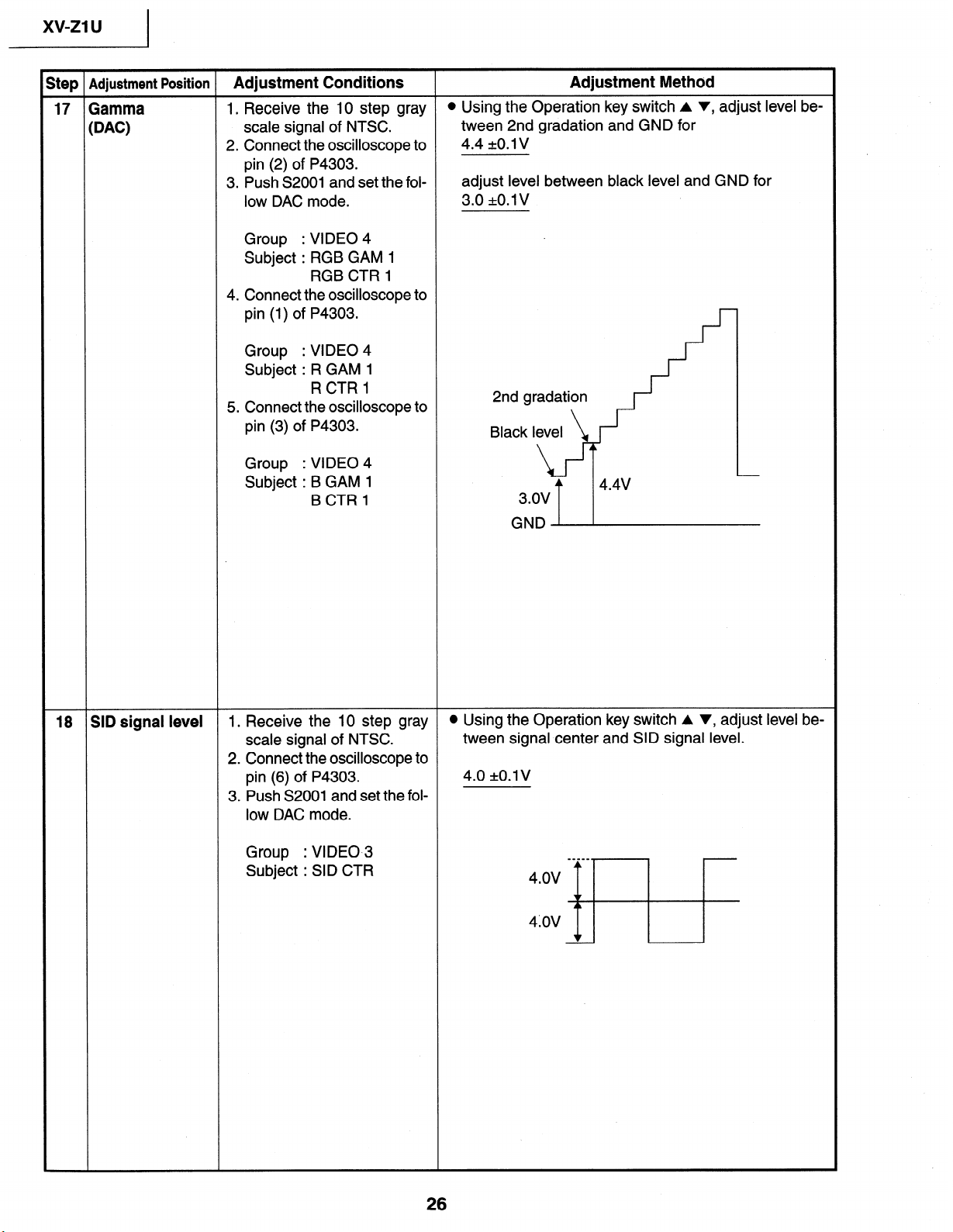

Step Adjustment Position Adjustment Conditions

17 Gamma

WC)

1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (2) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : RGB GAM 1

4. Connect the oscilloscope to

pin (1) of P4303.

Group

Subject : R GAM 1

5. Connect the oscilloscope to

pin (3) of P4303.

Group

Subject : B GAM 1

: VIDEO 4

RGB CTR 1

: VIDEO 4

RCTRl

: VIDEO 4

BCTRl

Adjustment Method

l Using the Operation key switch A v, adjust level be-

tween 2nd gradation and GND for

4.4 kO.1 v

adjust level between black level and GND for

3.0 &O.lV

4

3.ov

GND

4.4v

18 SID signal level 1. Receive the 10 step gray

scale signal of NTSC.

2. Connect the oscilloscope to

pin (6) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : SID CTR

: VIDEO.3

l Using the Operation key switch A v, adjust level be-

tween signal center and SID signal level.

4.0 *O.lV

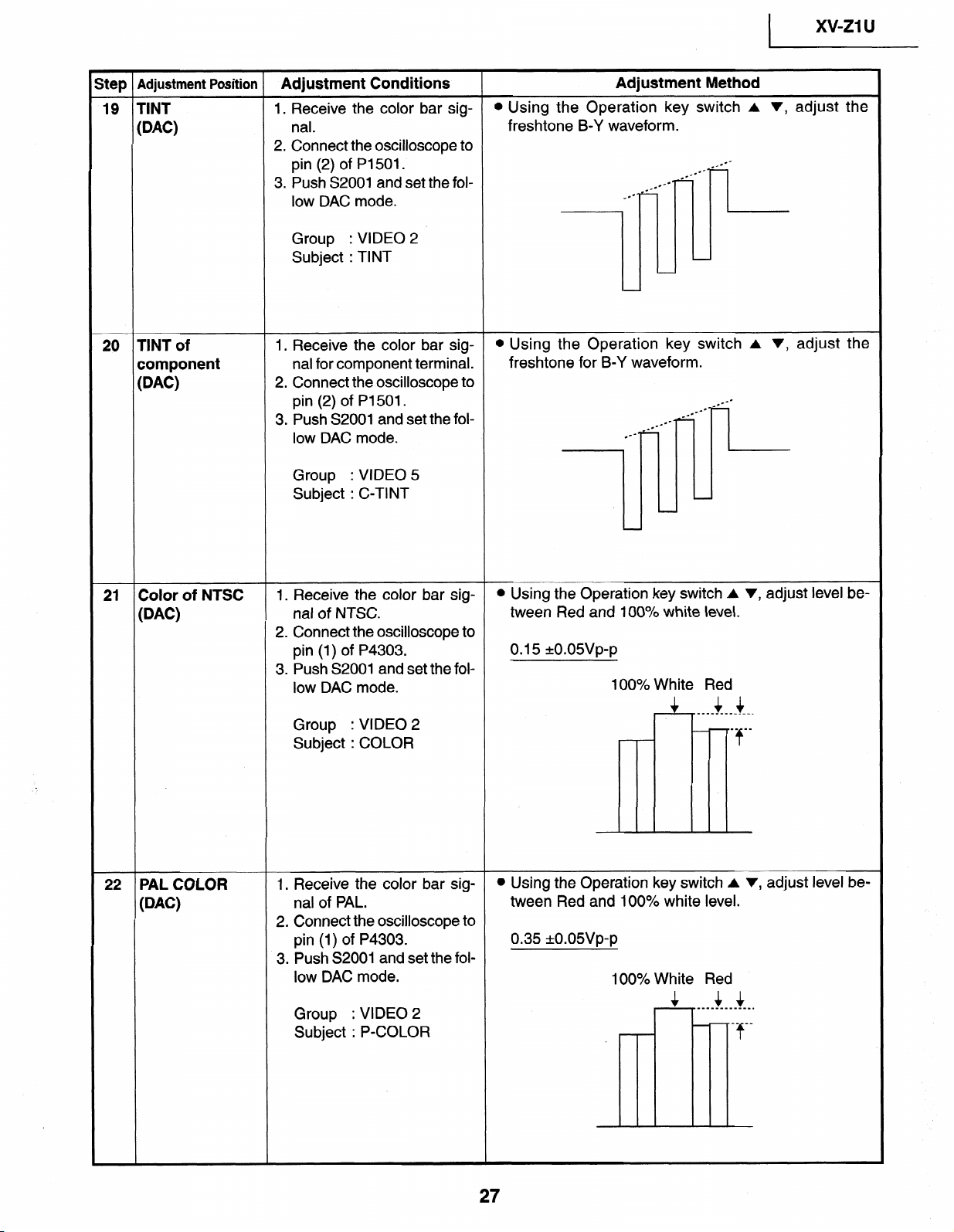

step

Adjustment Position

19 TINT

(DAC)

Adjustment Conditions Adjustment Method

l

1.

Receive the

nal.

2.

Connect the oscilloscope

pin

(2)

3. Push

S2001

low DAC mode.

color

of P1501.

and set the fol-

bar

sig-

to

Using the Operation key switch A

freshtone B-Y waveform.

v, adjust the

20

TINT of

component

@AC)

21 Color

@AC)

of NTSC

Group : VIDEO

Subject : TINT

1. Receive the

nal for

component terminal.

2.

Connect

pin

3. Push S2001 and set the follow DAC mode.

Group

Subject : C-TINT

1. Receive the color bar signal of NTSC.

2. Connect the oscilloscope to

pin (1) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : COLOR

the oscilloscope to

(2)

of P1501.

: VIDEO 5

: VIDEO 2

color

2

bar

sig-

l

Using

freshtone for

l

tween Red and 100% white level.

0.15 +o.osvp-p

the Operation key switch A v,

B-Y waveform.

c

_e--

c--

Using the Operation key switch A v, adjust level be-

100% White Red

$_ 44

_________M__.

__ -_

-’

*f

adjust the

22 PAL COLOR

@AC)

1. Receive the color bar sig-

nal of PAL.

2. Connect the oscilloscope to

pin (1) of P4303.

3. Push S2001 and set the fol-

low DAC mode.

Group

Subject : P-COLOR

: VIDEO 2

l Using the Operation key switch A v, adjust level be-

tween Red and 100% white level.

0.35 *o.o5vp-p

100% White Red

&_ $4

____________.

__ -_

- -f

27

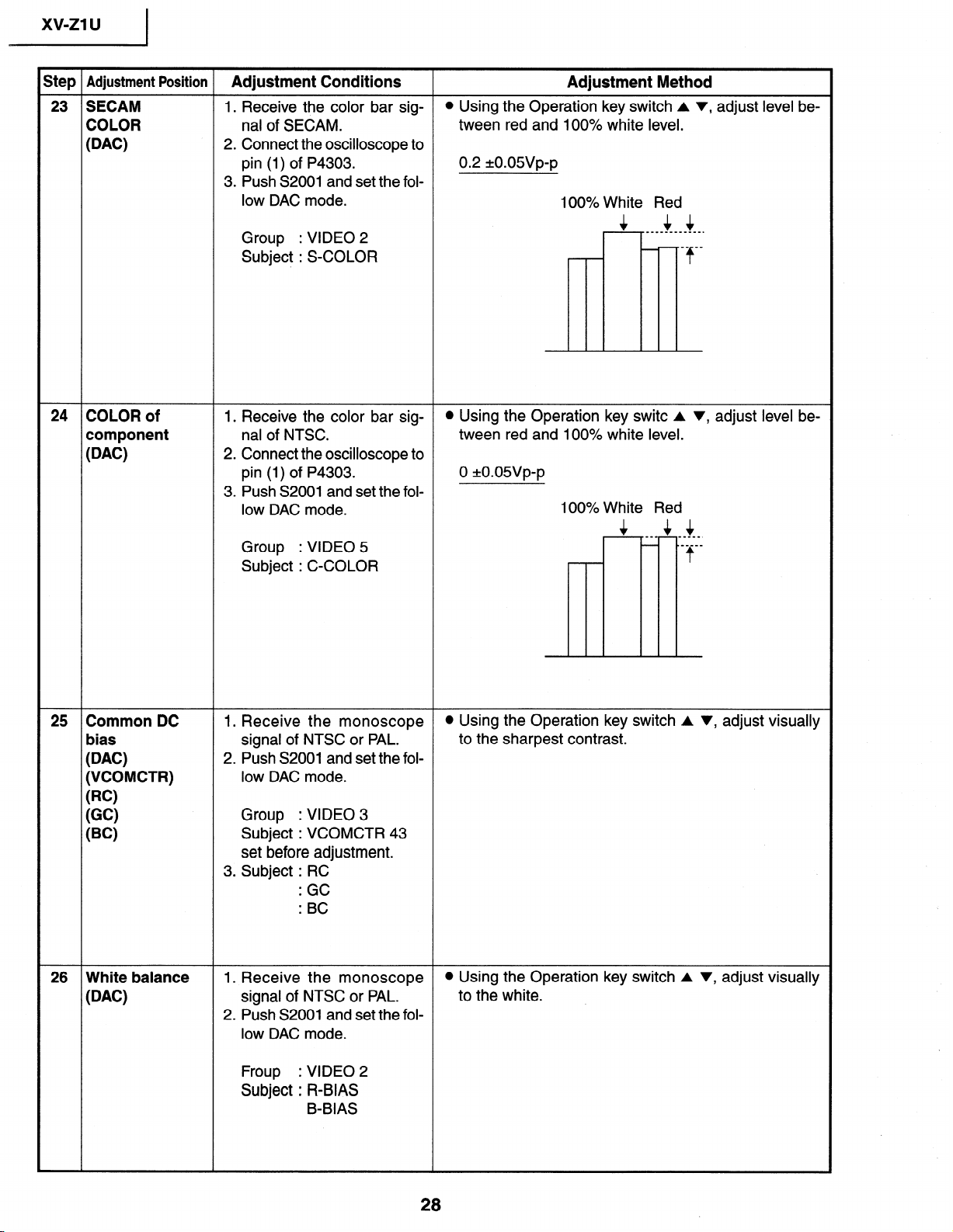

xv-z1 u

I

Step Adjustment Position Adjustment Conditions Adjustment Method

23 SECAM 1. Receive the color bar sig-

COLOR nal of SECAM.

(DAC)

2. Connect the oscilloscope to

pin (1) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : S-COLOR

: VIDEO 2

l Using the Operation key switch A v, adjust level be-

tween red and 100% white level.

0.2 *o.o5vp-p

100% White Red

,A $4

____________.

__ __

- @f

24 COLOR of

component

@AC)

25 Common DC

bias

(DAC)

(VCOMCTR)

(RC)

(GC)

(BC)

1. Receive the color bar signal of NTSC.

2. Connect the oscilloscope to

pin (1) of P4303.

3. Push S2001 and set the follow DAC mode.

Group

Subject : C-COLOR

1. Receive the monoscope

signal of NTSC or PAL.

2. Push S2001 and set the fol-

low DAC mode.

Group

Subject : VCOMCTR 43

set before adjustment.

3. Subject : RC

: VIDEO 5

: VIDEO 3

=

.

GC

.

.

BC

l Using the Operation key switc A v, adjust level be-

tween red and 100% white level.

0 *o.o5vp-p

100% White Red

A&

$4

--_

-____.

- ._____

t

l Using the Operation key switch A v, adjust visually

to the sharpest contrast.

26 White balance

(DAC)

1. Receive the monoscope

signal of NTSC or PAL.

2. Push S2001 and set the follow DAC mode.

Froup

Subject : R-BIAS

: VIDEO 2

B-BIAS

l Using the Operation key switch A v, adjust visually

to the white.

28

1

xv-ZlU X’

step Adjustment Position

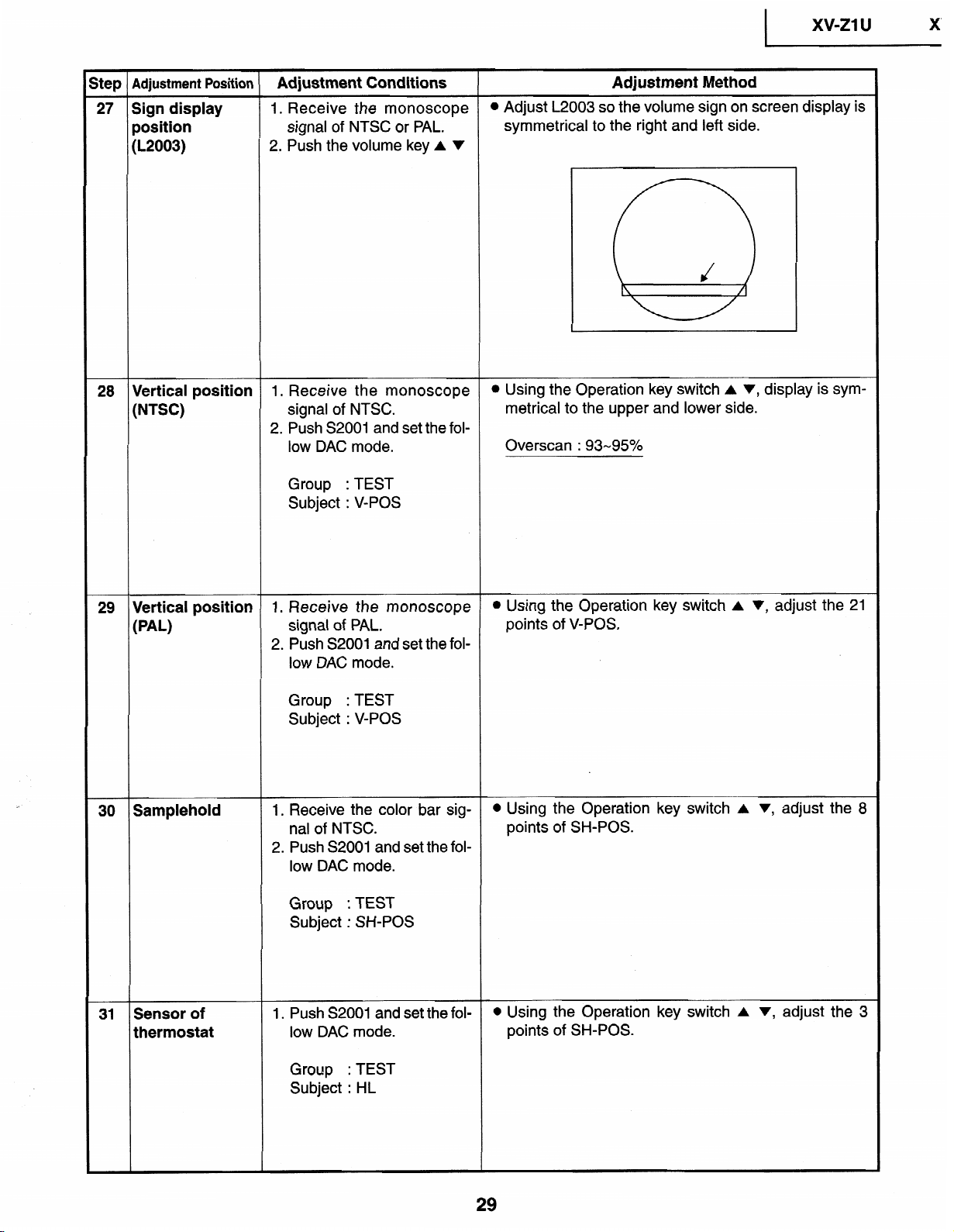

27 Sign display

position

(L2003)

28

Vertical

position

(NTSC)

Adjustment

1. Receive

signal of NTSC or PAL.

2.

Push the

1.

Receive the monoscope

signal of NTSC.

2. Push S2001 and set

low DAC mode.

Group

Subject :

Conditions Adjustment Method

the

monoscope

volume key A

: TEST

V-POS

v

the fol-

l

Adjust L2003

symmetrical

l

Using

the

metrical to the upper

Overscan : 93-95%

so

to the

Operation

the volume sign on screen

right and

key switch

and

left side.

A v, display is

lower

side.

display is

sym-

29

Vertical position

(PAL)

30

Samplehold

31 Sensor of

thermostat

1.

Receive the monoscope

signal of PAL.

2. Push S2001 and set the fol-

low DAC mode.

Group :

Subject : V-POS

1, Receive the color bar sig-

nal of NTSC.

2. Push S2001 and set the fol-

low DAC mode.

Group : TEST

Subject : SH-POS

1. Push S2001 and set the follow DAC mode.

TEST

l

Using the Operation key switch A v, adjust the 21

points of V-POS.

l

Using the Operation key switch A v, adjust the

points of SH-POS.

l

Using the Operation key switch A V, adjust the 3

points of SH-POS.

8

Group : TEST

Subject : HL

Loading...

Loading...