TENTATIVE

XV-Z1E/A

SERVICE MANUAL

SERVICE-ANLEITUNG

PAL/SECAM/NTSC SYSTEM

LCD PROJECTOR

LCD PROJEKTOR

MODELS

MODELLE

XV-Z1E/A

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

SHARP CORPORATION

1

XV-Z1E/A

CONTENTS

Page

• NOTE TO SERVICE PERSONNEL.................... 3

• SPECIFICATIONS...............................................4

• OPERATION MANUAL ...................................... 6

• REMOVING OF MAJOR PARTS........................ 9

• CONTROLLING THE TOTAL

OPERATING HOURS OF THE LAMP.............. 14

• RESETTING THE LAMP

OPERATING HOUR COUNTER ...................... 15

• THE OPTICAL UNIT OUTLINE ........................ 16

• CONVERGENCE AND

FOCUS ADJUSTMENT.................................... 17

• ELECTRICAL ADJUSTMENT .......................... 21

• TROUBLESHOOTING TABLE ......................... 29

INHALT

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 43

• TECHNISCHE DATEN..................................... 44

• BEDIENUNGSANLEITUNG ............................. 46

• ENTFERNEN DER HAUPTTEILE.................... 49

• KONTROLL DER GESAMTBETRIE

BSSTUNDEN DER LAMPE ............................. 54

• RÜCKSTELLUNG DES

LAMPEN-BETRIEBSSTUNDENZÄHLERS...... 55

• ÜBERSICHT DER OPTIKEINHEIT .................. 56

• EINSTELLUNG VON KONVERGENZ

UND BRENNPUNKT........................................ 57

• ELEKTRISCHE EINSTELLUNG....................... 61

• STÖRUNGSSUCHTABELLE ........................... 69

Page

• CHASSIS LAYOUT ........................................ 123

• BLOCK DIAGRAM ..........................................125

• OVERALL WIRING DIAGRAM....................... 127

• DESCRIPTION OF SCHEMATIC DIAGRAM... 129

• WAVEFORMS .................................................130

• SCHEMATIC DIAGRAM................................. 131

• PRINTED WIRING BOARD ASSEMBLIES.... 167

• P ARTS LIST

ELECTRICAL PARTS ............................... 177

CABINET AND MECHANICAL PARTS ..... 204

ACCESSORIES PARTS ............................211

P ACKING PARTS ......................................211

• PACKING OF THE SET ................................. 212

SeiteSeite

• CHASSIS-ANORDNUNG............................... 123

• BLOCKSCHAL TBILD ..................................... 125

• GESAMTSCHAL TPLAN................................. 127

• BESCHREIBUNG DES SCHEMATISCHEN

SCHALTPLANS...............................................129

• WELLENFORMEN ..........................................130

• SCHEMATISCHER SCHALTPLAN ................ 131

• LEITERPLATTENEINHEITEN........................ 167

• ERSATZTEILLISTE

ELEKTRISCHE BAUTEILE ...................... 177

CEHÄUSE UND MECHANISCHE

BAUTEILE .................................................204

ZUBEHÖRTEILE .......................................211

VERPACKUNGSTEILE .............................211

• VERPACKEN DES GERÄTS ......................... 212

• ..........................................................................83

• ..........................................................................84

• ..........................................................................86

• ..........................................................................89

• ..........................................................................94

• ..........................................................................95

• ..........................................................................96

• ..........................................................................97

• ........................................................................101

• ........................................................................109

• ........................................................................123

• ....................................................................... 125

• ........................................................................127

• ........................................................................129

• ........................................................................130

• ........................................................................131

• ........................................................................167

•

...................................................................177

...................................................................204

................................................................... 211

................................................................... 211

• ........................................................................212

2

XV-Z1E/A

2

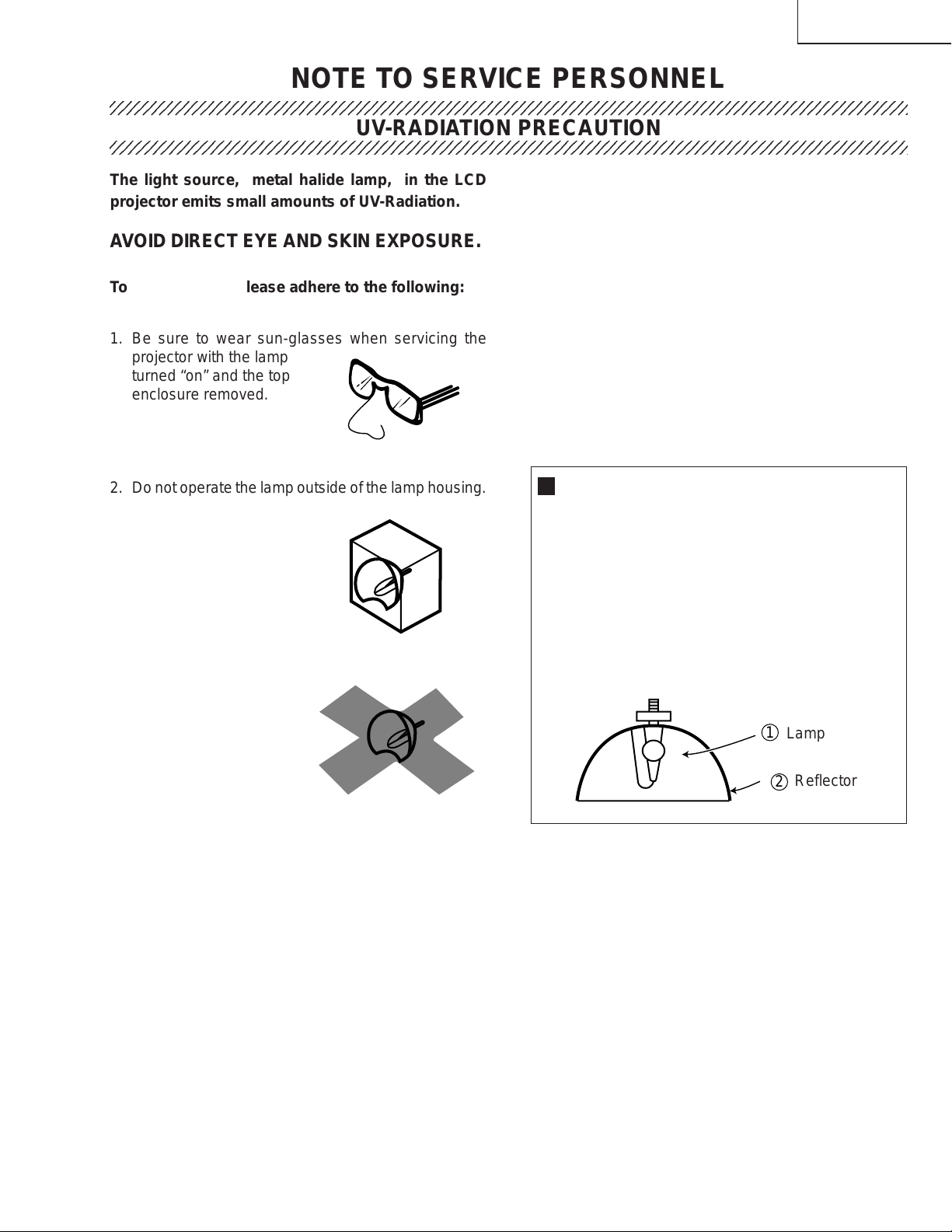

NOTE TO SERVICE PERSONNEL

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0042DE01 rated 75V/265W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

1

Lamp

Reflector

2

DANGER ! –– Never turn the power on without

the lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

3

XV-Z1E/A

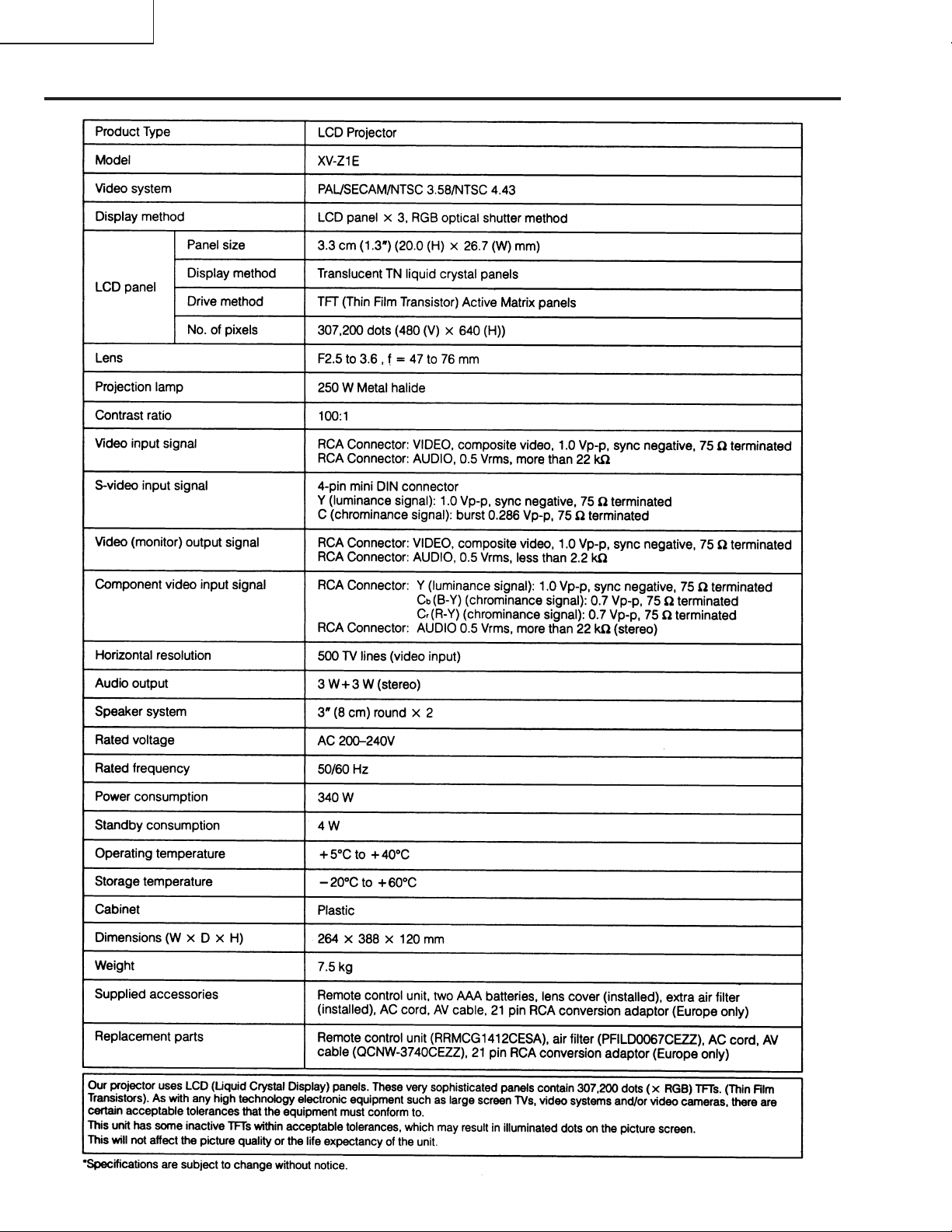

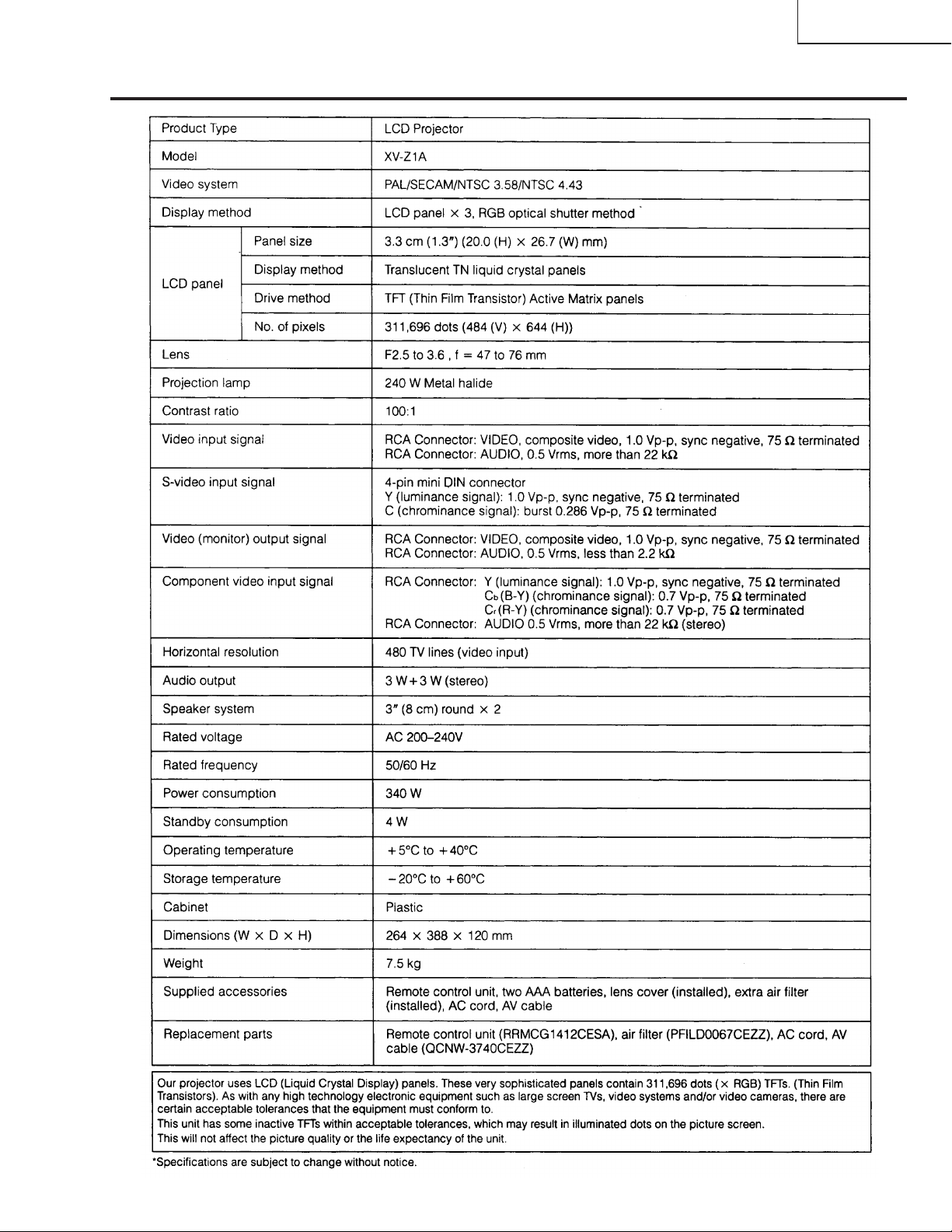

Specifications

4

Specifications

XV-Z1E/A

5

XV-Z1E/A

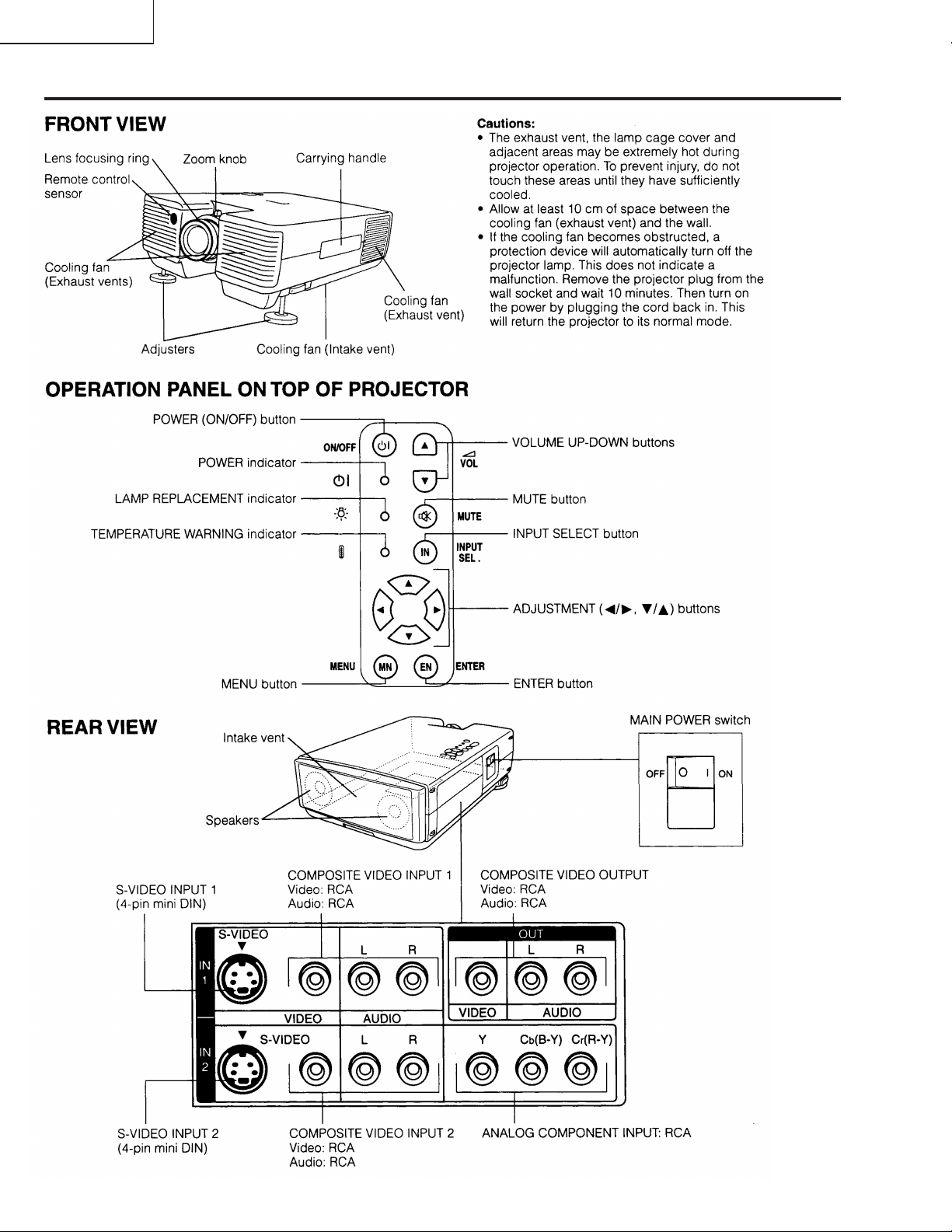

Location of Controls

6

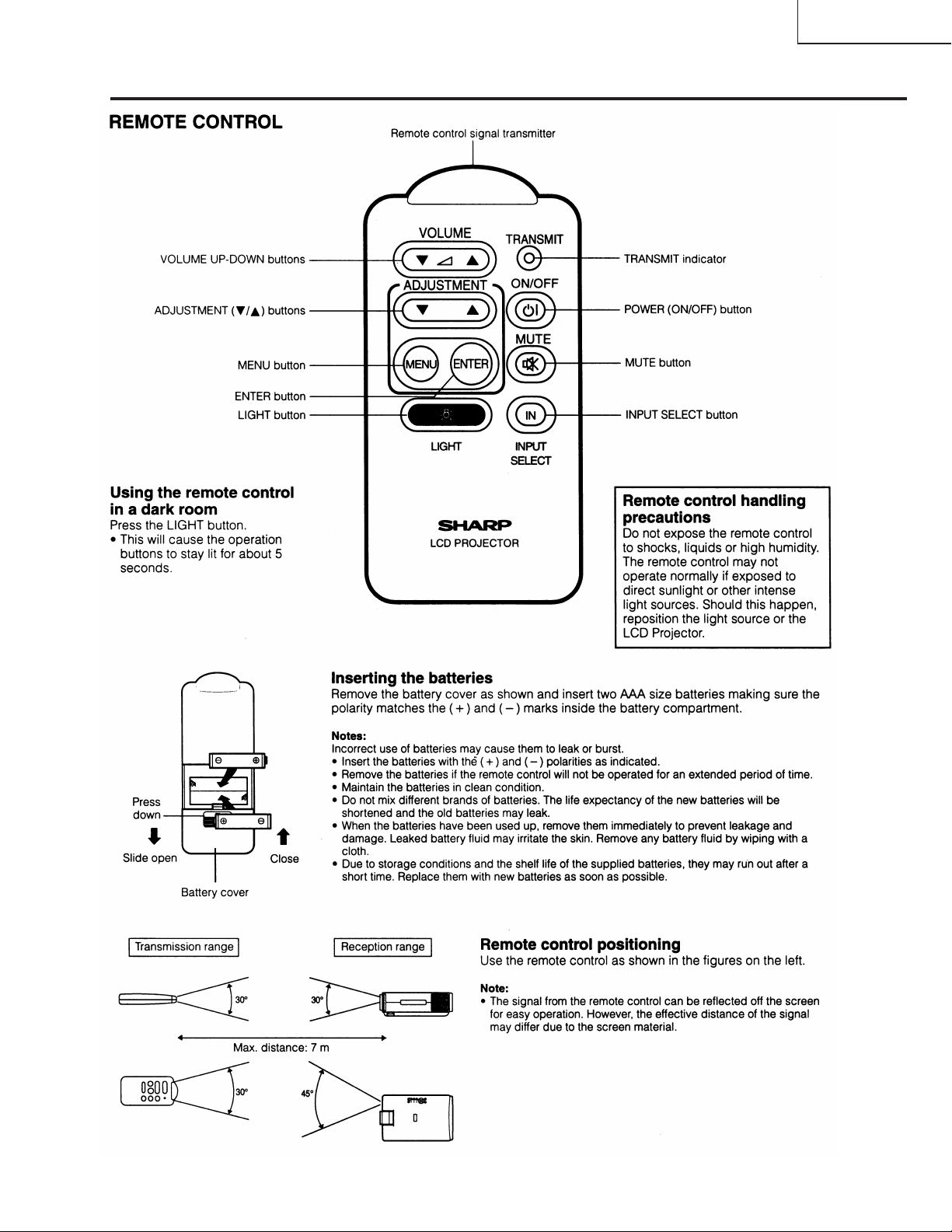

Operating the Wireless Mouse Remote Control

XV-Z1E/A

7

XV-Z1E/A

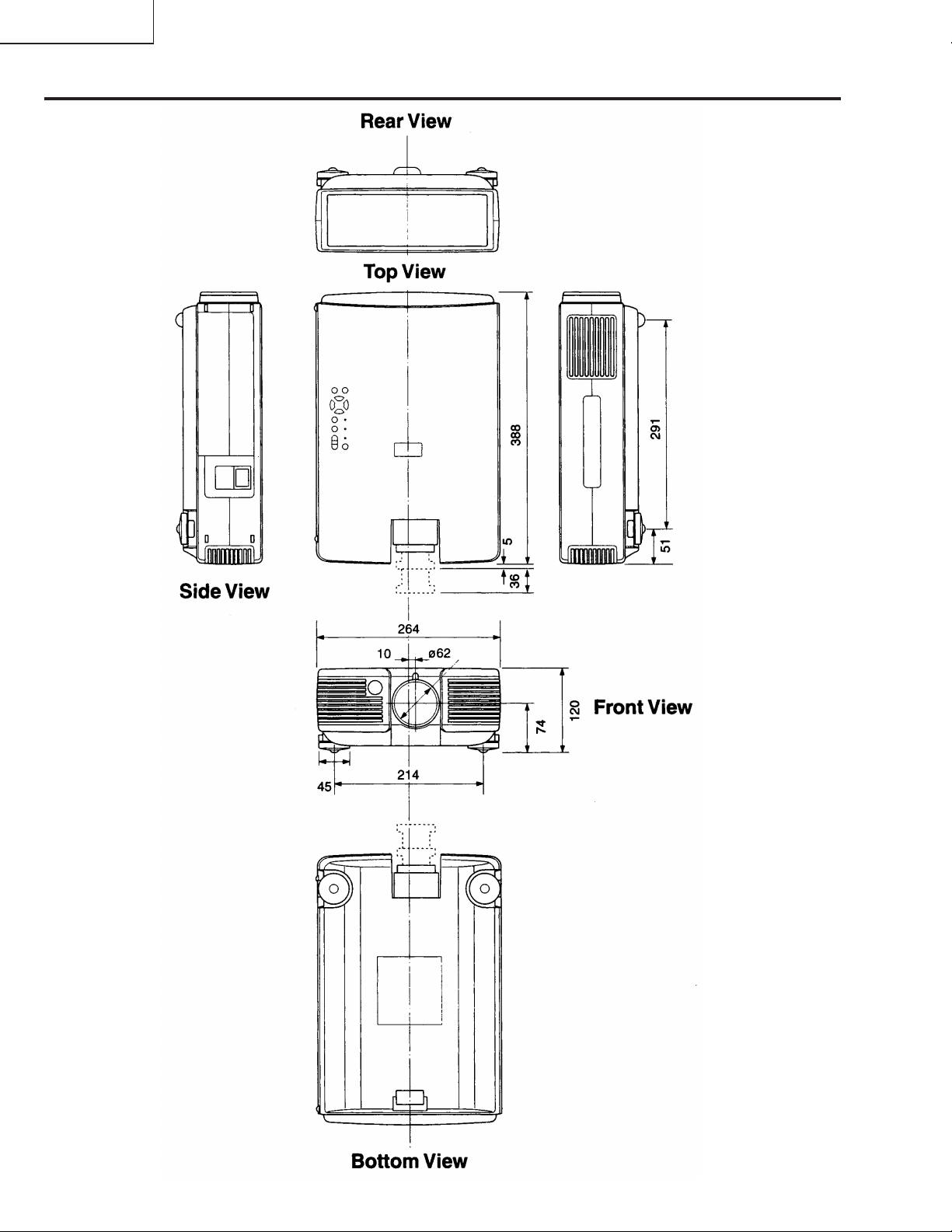

Demensions

[Units: mm]

8

XV-Z1E/A

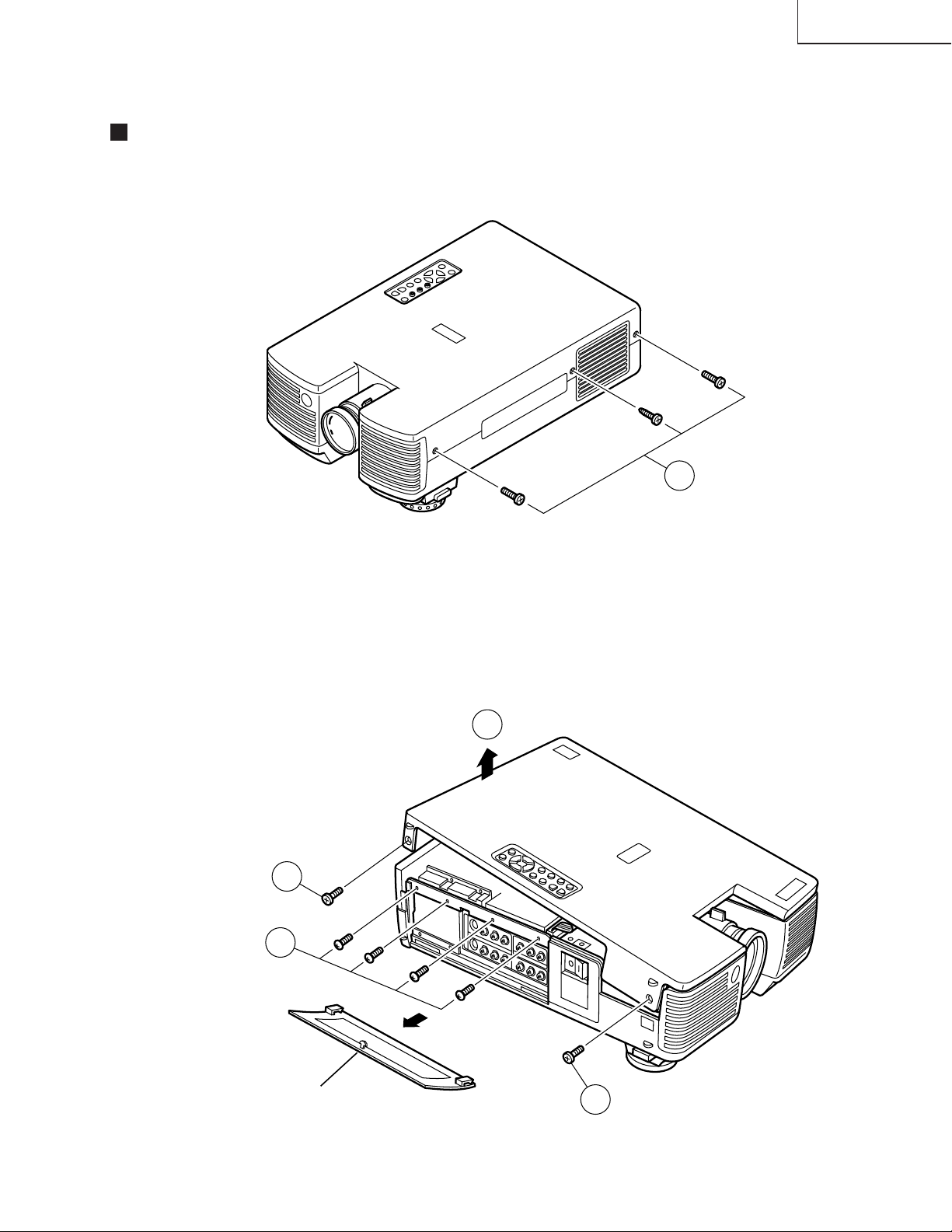

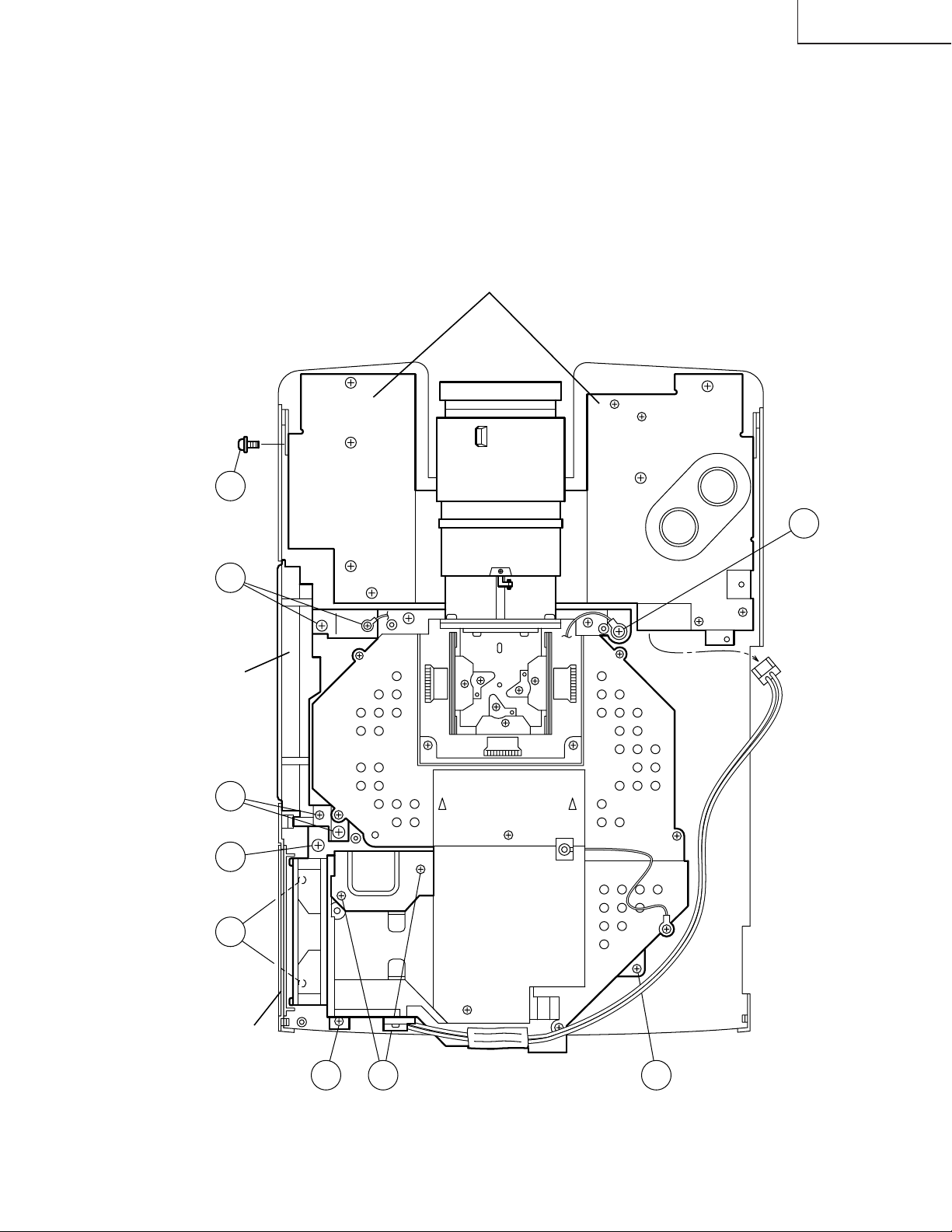

REMOVING OF MAJOR PARTS

Before starting this job, detach the lamp cage unit and the filter cover.

1.Removing the top cabinet

1-1. Remove the three screws at the carrying handle side.

1-1

1-2. Remove the two screws at the terminals side.

1-3. Detach the terminal door, and remove the four screws off the terminal cover.

1-4. Slowly lift the back of the top cabinet and disconnect the operation key unit connector (KY). Pull up and away

the top cabinet.

1-5. Place the top cabinet upside down. Remove the four screws off the operation key unit. T ake out the operation

key unit.

1-4

Top Cabinet

1-2

(KY)

1-3

Terminal Door

1-2

9

XV-Z1E/A

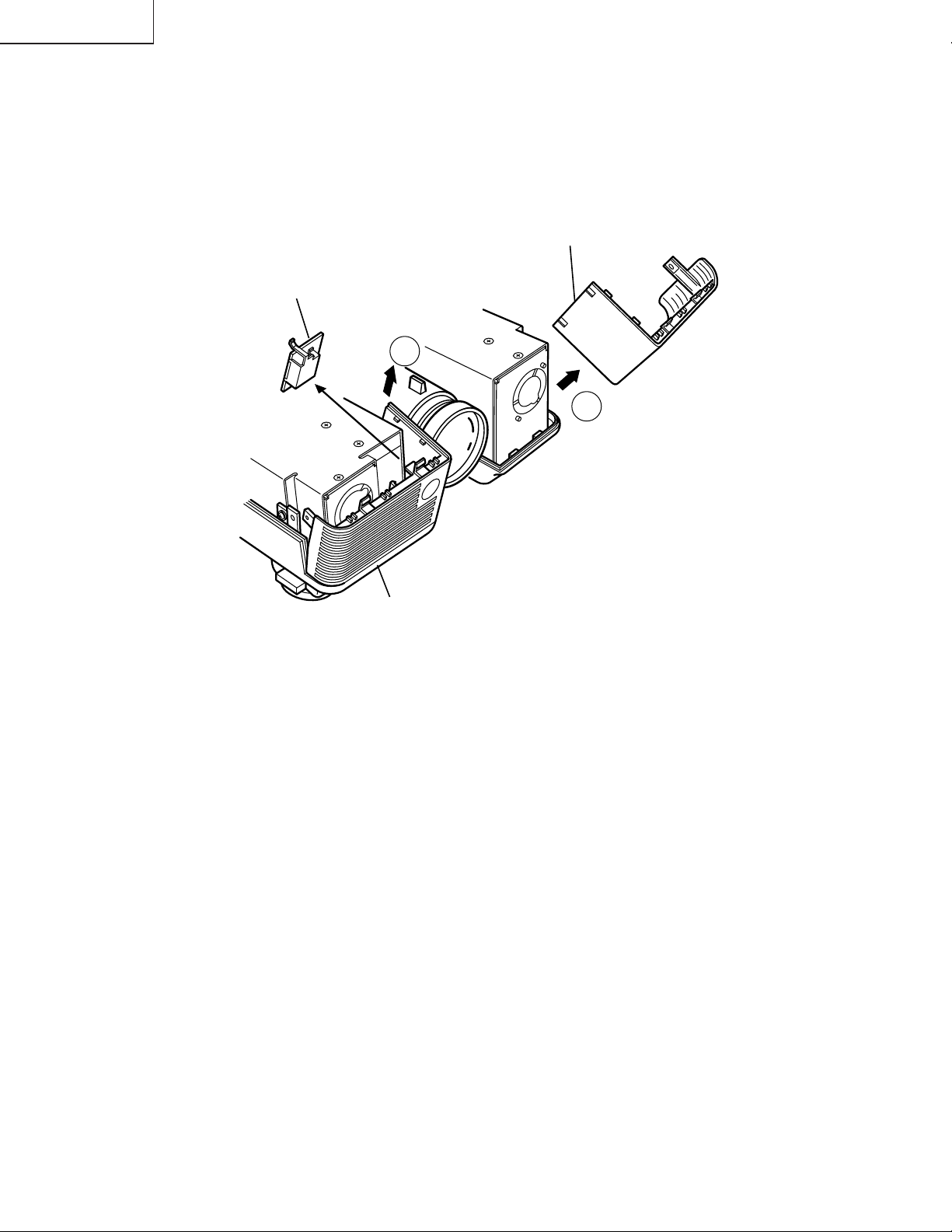

2.Removing the front cabinets

2-1. Tilt the front-right cabinet forward. Pull it up out of position.

2-2. Tilt the front-left cabinet forward. Disconnect the infrared R/C receiver unit. Pull up the cabinet out of position.

Front-right Cabinet

Infrared R/C Receiver Unit

2-2

2-1

Front-left Cabinet

10

XV-Z1E/A

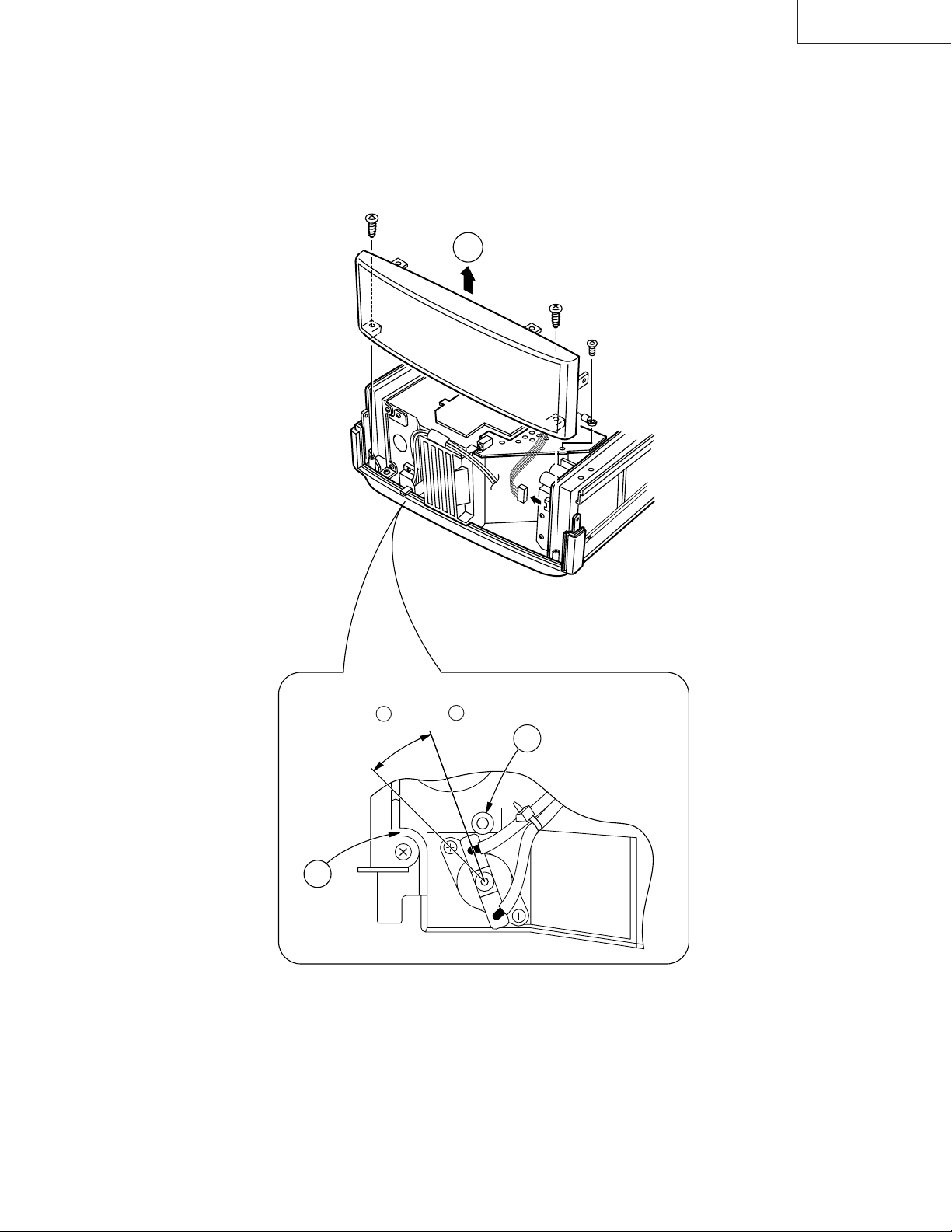

3.Removing the rear cabinet and video terminal cover

3-1. Remove the two screws off the rear cabinet and the screw from the static ground lead. Pull up the cabinet

and disconnect the speaker connector (SP). Now the rear cabinet is free.

3-2. Remove the four screws off the video terminal cover. Detach the cover.

3-1

Rear Cabinet

(SP)

Make sure the bimetal lead terminals are at the bottom

of the boss a and rib b .

Boss

a

b

Rib

11

XV-Z1E/A

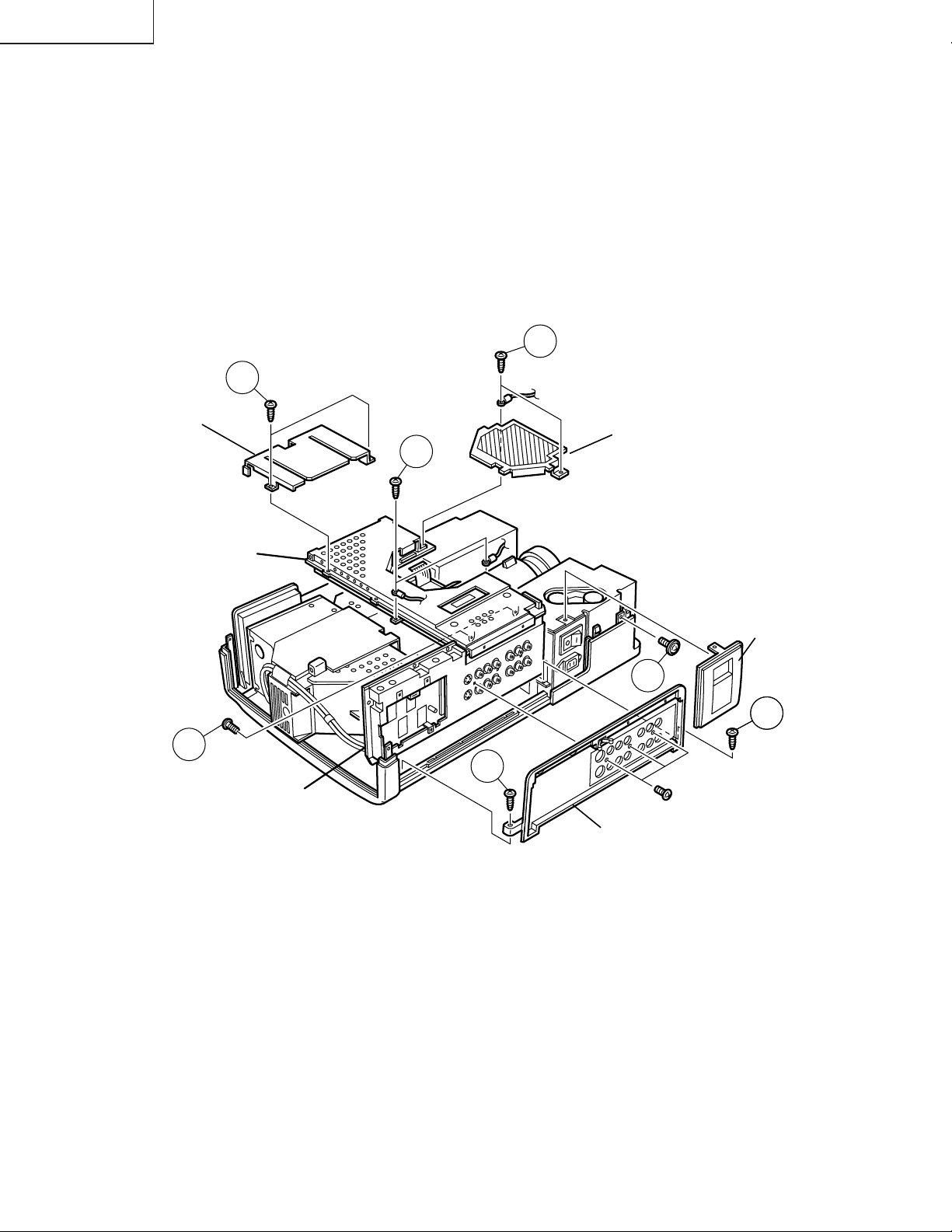

4.Removing the PWBs

4-1. Remove the two screws that fix the PC terminal cover to the bottom cabinet.

4-2. Remove the two screws off the output shield. Take out the output shield and disconnect the R-LCD, G-LCD

and B-LCD connectors (RP, GP, and BP).

4-3. Remove the four screws off the output unit. Disconnect the insulating barrier, the ground leads and the

connectors (FN, Q, LL, FF, LF, BL, RC and EA). Pull up and away the output unit and the signal/Video Input

terminal unit.

4-4. Remove the screw off the back of the output unit. Separate this unit from the signal/PC terminal unit.

4-5. Remove the screw off the bottom cabinet and the screw off the power panel. Now take out the power panel.

4-2

4-3

Insulating

Barrier

Output Unit

4-4

Signal/Video Input

terminal Unit

4-3

4-1

Output Shield

Power Panel

4-5

Video Input Terminal Cover

4-1

4-1

12

XV-Z1E/A

5.Removing the optics mechanism assembly

5-1. Remove the two screws off the angles A and B of the carrying handle. Detach the carrying handle.

5-2. Remove the two screws off the lamp socket holder. Take out the lamp socket.

5-3. Disconnect the bimetal connector (BA). Remove the four screws off the optics mechanism assembly , and pull

up and away this assembly.

5-4. Remove the two screws off the exhaust panel. Separate the panel from the bottom cabinet.

5-5. Remove the screw off the power/ballast unit assembly. Pull up and away the unit.

Power/Ballast Unit

5-5

5-1

Carrying

Handle

5-1

5-3

5-4

5-3

(BA)

Optics

Mechanism

Ass'y

Exhaust

Panel

5-3 5-2 5-3

13

XV-Z1E/A

CONTROLLING THE TOTAL OPERATING HOURS OF THE LAMP

The following control is carried out when the lamp has been used for 1900 hours and 2000

hours.

1. After 1900-hour use

When the power is turned on, "LAMP" appears in the on-screen display for about 1 minute (flashing in yellow)

and the lamp LED indicator lights up in red. When the 1,900-hour point comes up during use of the unit, the

"LAMP" display starts flashing in yellow on the screen for 1 minute at the very 1,900-hour point. Now the lamp

LED indicator changes from green to red.

2. After 2000-hour use

When the power is turned on, "LAMP" appears in the on-screen display for about 5 minutes (flashing in red) and

the lamp LED indicator lights up in red. Five minutes thereafter, the power turns itself of f and the unit is interrupted.

When the 2000-hour point comes up during use of the unit, the "LAMP" display starts flashing in red on the

screen for 5 minutes at the very 2000-hour point. Five minutes later, the power turns itself off and the unit is

interrupted. (The lamp LED indicator stays red since the 1900-hour point.)

If you try to turn on the power three times after the 2000-hour point, the unit remains off.

3. When the 2000-hour point comes up, take the following steps.

Replace the lamp with new one. While holding down both the "VOL."" and "ADJ."" keys on the unit, turn on the

main power switch (located on the side of the unit). The lamp operating hourmeter is now reset to zero. T urn on

the unit and make sure the time display shows "0000H".

4. Displaying the total operating hours of the lamp (used to check the total time)

Change the STATUS3 data settings: PICTURE at 0, BRIGHT at MAX, COLOR at MIN, TINT at MIN, and

SHARPNESS at MAX. Hold down the SOUND DOWN and ENTER keys for longer than 3 seconds. By doing

this, the total operating hours will be displayed on the screen.

TIME

000H

TOTAL TIME

000H

14

XV-Z1E/A

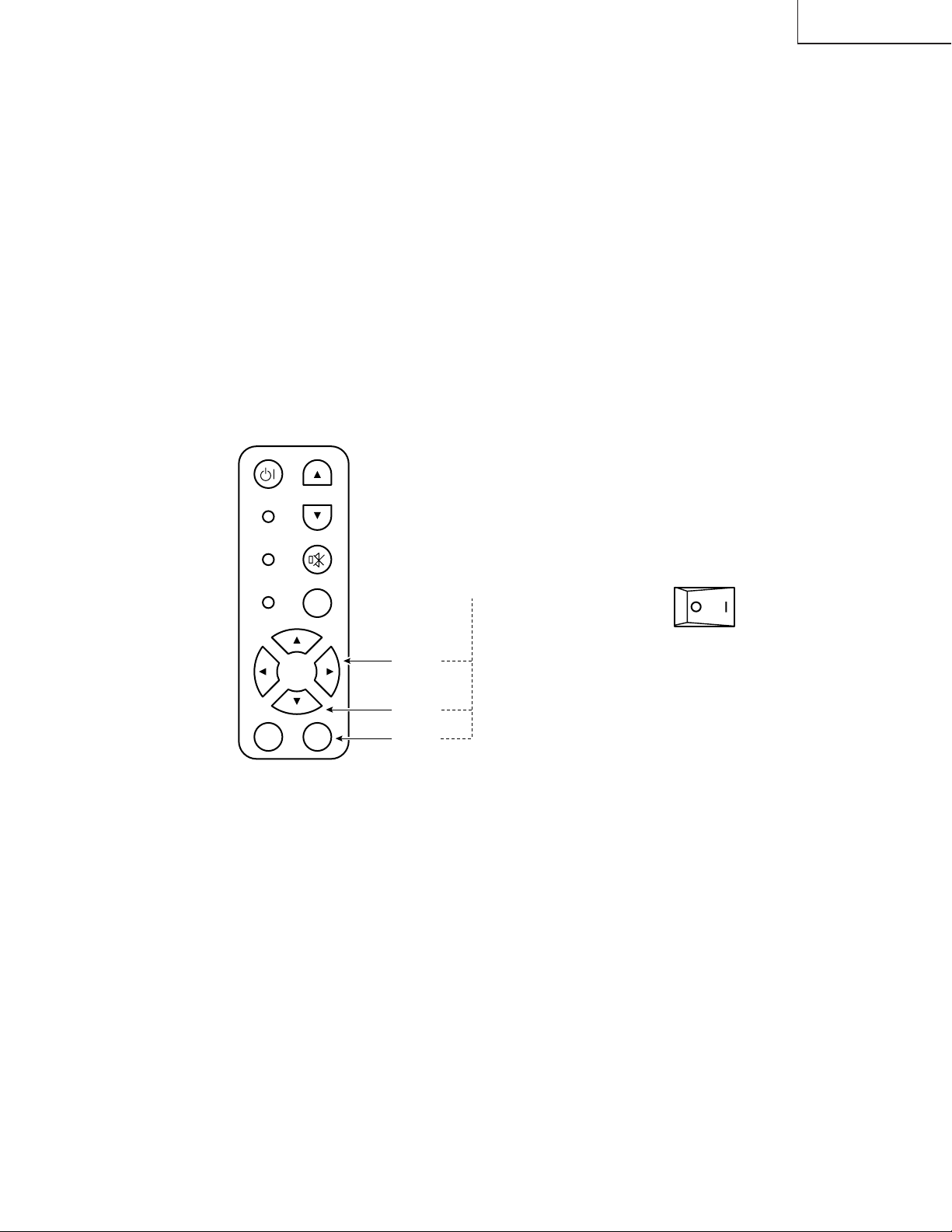

RESETTING THE LAMP OPERATING HOUR COUNTER

The unit is designed to keep its power off when the lamp has been used for 1900 and 2000

hours. This is to protect the lamp fixture. Replace the lamp with new one and take the

following resetting procedure.

Resetting the lamp operating hour counter

1. Hold down the “ENTER”, “ADJ."” and “ADJ.|” buttons on the unit, and turn on the main power switch

(located above the AC inlet).

2. Now the unit is turned on and the lamp operating hour counter is reset to zero. “000H” appears on the

screen.

Hold down the “ADJ.|”, “ADJ."”

and “ENTER” keys at once.

IN

MN EN

(To be held down

*

ADJ.|

ADJ."

ENTER

at once)

Turn on the main power switch

(located above the AC inlet)

OFF ON

15

XV-Z1E/A

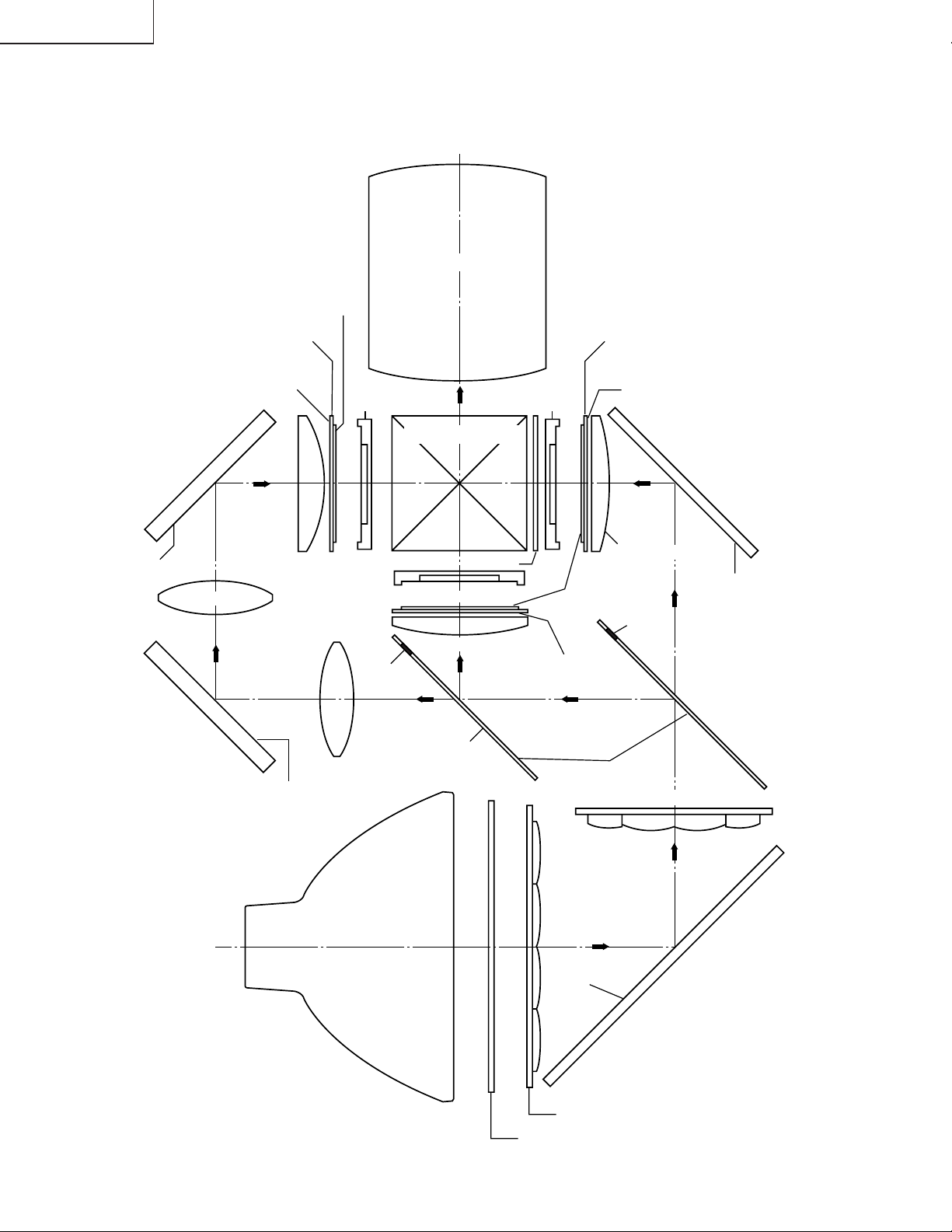

THE OPTICAL UNIT OUTLINE

Layout of the optical system

Note: Layout for positioning the optical system.

Polarizer film

Projection Lens

Dichroic coating

(B reflection)

Incident polarizer plate B

Dichroic coating

(B transmission)

M6

B reflector

Relay lens 2

AL-coated mirror B

M4

BLUE

Relay lens 3

AL-deposited face

B-LCD

G-LCD R-Filter

Incident polarizer plate G

Marking

Relay lens 1

Cross dichroic prism

Condenser lens G

GREEN

BLUE

G reflector

* M3

R-LCD

Polarizer film

AR-coated face

Dichroic coating

Incident polarizer plate R

Dichroic coating

(R transmission)

AL-coated mirror R

M5

Condenser lens R

AL-deposited face

RED

Marking

M2

B/G reflector

Fly-eye lens (outgoing light)

* The M3 mirrors have a coating

wedge (for different film thickness). Set up these mirrors, with

their markings positioned as

shown above, so that their

coated faces and both sides be

in the correct directions.

Metal-halide lamp

(Light source)

16

AL-deposited

face

Fly-eye lens (incoming light)

UV cut filter

M1

AL-coated mirror W

XV-Z1E/A

CONVERGENCE AND FOCUS ADJUSTMENT

» Start the convergence and focus adjustments with the top cabinet and the signal shield

removed but the power on. Use the remote control gun to adjust the image. Take the

following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the panels with new ones. But until the focus has been completely readjusted, be careful not to

change the distance between the set and the screen, nor to move the projection lens focus and zoom

rings.

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE, for example) may get

(

out of the focus range, or a long-distance image (300 WIDE, for example) may come out of focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

distance between the set and the screen, nor to move the projection lens focus and zoom rings.

(If the distance has been changed or the projection lens readjusted, repeat the above steps 1 and 2.)

)

2. Adjusting the G-LCD panel

(A) Focus adjustment. (Make this adjustment on the white-only screen.)

1. Right-and-left focus adjustment (θY direction) .

Loosen the lock screws "b" and "c" and insert the eccentric screwdriver into the notch and hole "b". Turn

the screwdriver until the right and left halves on the screen get into focus.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

(

below.

2. Top-center-bottom focus adjustment (θX and Z directions).

Loosen the lock screws "a" and "c" and insert the eccentric screwdriver into the notch and hole "a" or "c".

Turn the screwdriver until the top, center and bottom on the screen get into focus. In adjusting this top-tobottom focus, temporarily tighten the lock screw "b" to fix the θY direction adjustment.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Note :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

(B) Convergence adjustment

» The G-LCD panel has no convergence adjustment mechanism. Use this panel as convergence adjustment

reference.

3. B-LCD panel adjustment (the same for the R-LCD panel)

(A) Focus adjustment

» T ake the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is small

in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels, roughly adjust

the convergence first and then the focus.

(B) Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-colour and the relevant colour.

(1) Loosen the convergence lock screw "d".

(2) With the G-LCD panel’s screen center as reference, adjust the B-LCD panel in the X, Y and θZ directions.

(3) Finally tighten up the convergence lock screw "d".

)

17

XV-Z1E/A

Note :

1 The eccentric cam is used for convergence adjustment. This means that the cam’s turning and the linear

movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the dichroic prism

is used for image formation. When the LCD panels all get into the best focus, the images are almost

completely converged.

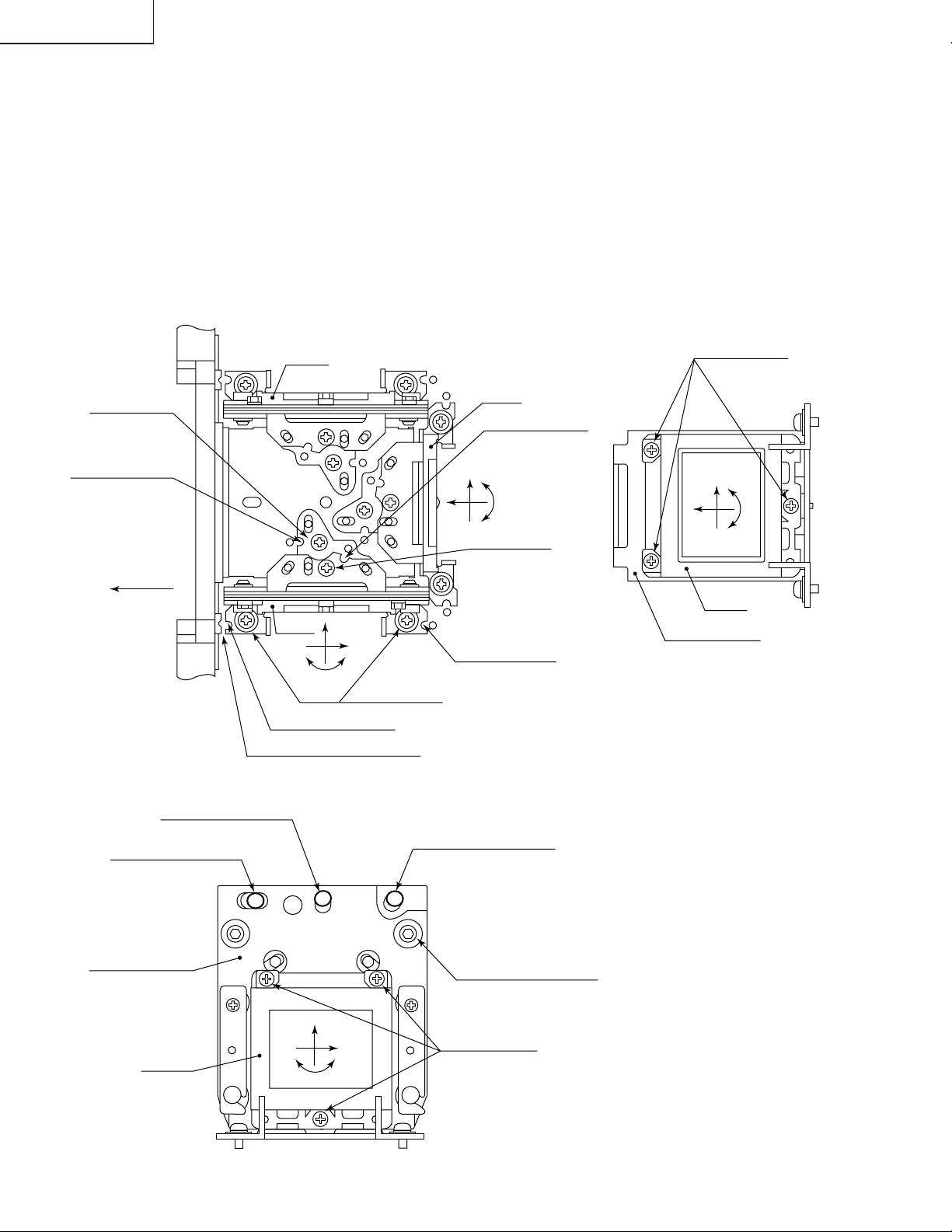

Convergence and Focus Adjustments Mechanism

TOP VIEW

Lock screw "a"

Notch and hole "a"

(Use an eccentric

screwdriver.)

FRONT

R-LCD

B-LCD

Notches and holes "c"

(Use an bladed screwdriver.)

Z

X

θY

Lock screws "c"

G-LCD

Notch and hole "b"

(Use an eccentric

screwdriver.)

X

θY

Z

Lock screw "b"

(θY direction)

Notches and

holes "c"

(Use on eccentric

screwdriver.)

SIDE VIEW

G-LCD panel

mounting screws

X

θZ

Y

G-LCD

G adjusting plate

SIDE VIEW

Eccentric cam

(X direction adjustment)

Eccentric cam

(Y direction adjustment)

R•B adjusting plate

R•B-LCD

Eccentric cam

(θZ direction adjustment)

Lock screw "d"

(convergence adjustment)

Y

X

θZ

R•B-LCD panel

mounting screws

18

2

5

(16)

(R2)

(50)

CUT

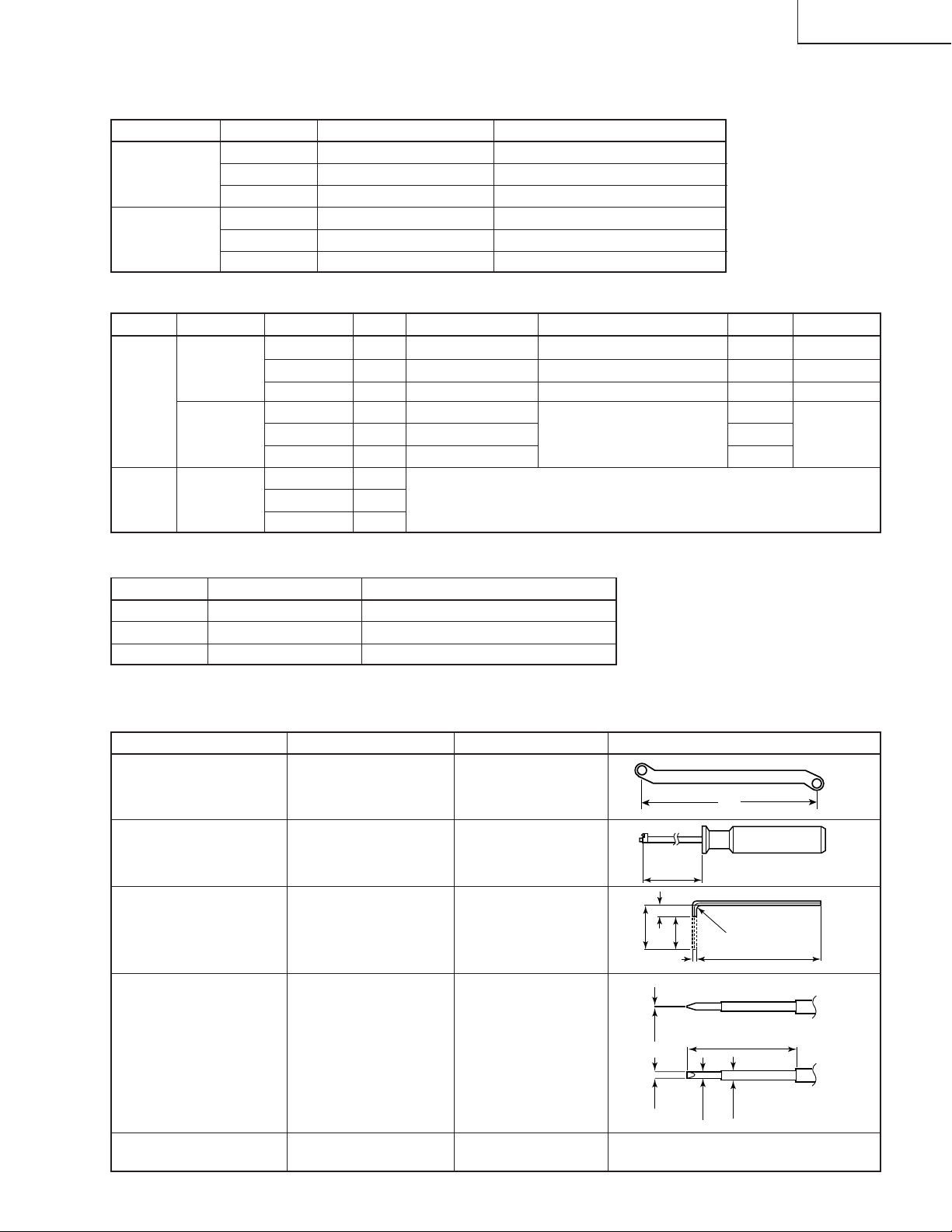

Convergence and Focus Adjustments at a Glance

Adjustment directions

Adjustment Direction Definition Direction of LCD panel

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the XV-Z1 Optical Mechanism

XV-Z1E/A

Colour Adjustment Direction

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colours Z direction ±0.8mm

Focus θX direction ±1°

θY direction ±1°

Z direction ±0.2mm

G colour Focus θX direction ±1° Same as for R and B colours

θY direction ±1°

Movement

Position Adjusting tool

Notch and hole "a" & "c"

Notch and hole "a" & "c"

Notch and hole "b" & "c"

Eccentric screwdriver, a, c Phillips

Bladed screwdriver a, c screwdriver

Lock screw

b, c

Tightening tool

Focus Adjustments the Other Way

Lock screw Position Related direction

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

Tool Specific or General Tool code Configuration

Eccentric cam

adjusting wrench

Specific 9DASPN-XGNV1U

80

Eccentric screwdriver Specific 9EQDRiVER-NV1A

100

Hex wrench General (redesigned) 9EQLNC-XGNV1U

0.5

Bladed screwdriver General 9EQDRiVER-NV1B

3.5

(ø3.5)

85min

ø5

Phillips screwdriver General — For M2.6 pan-head machine screw

19

XV-Z1E/A

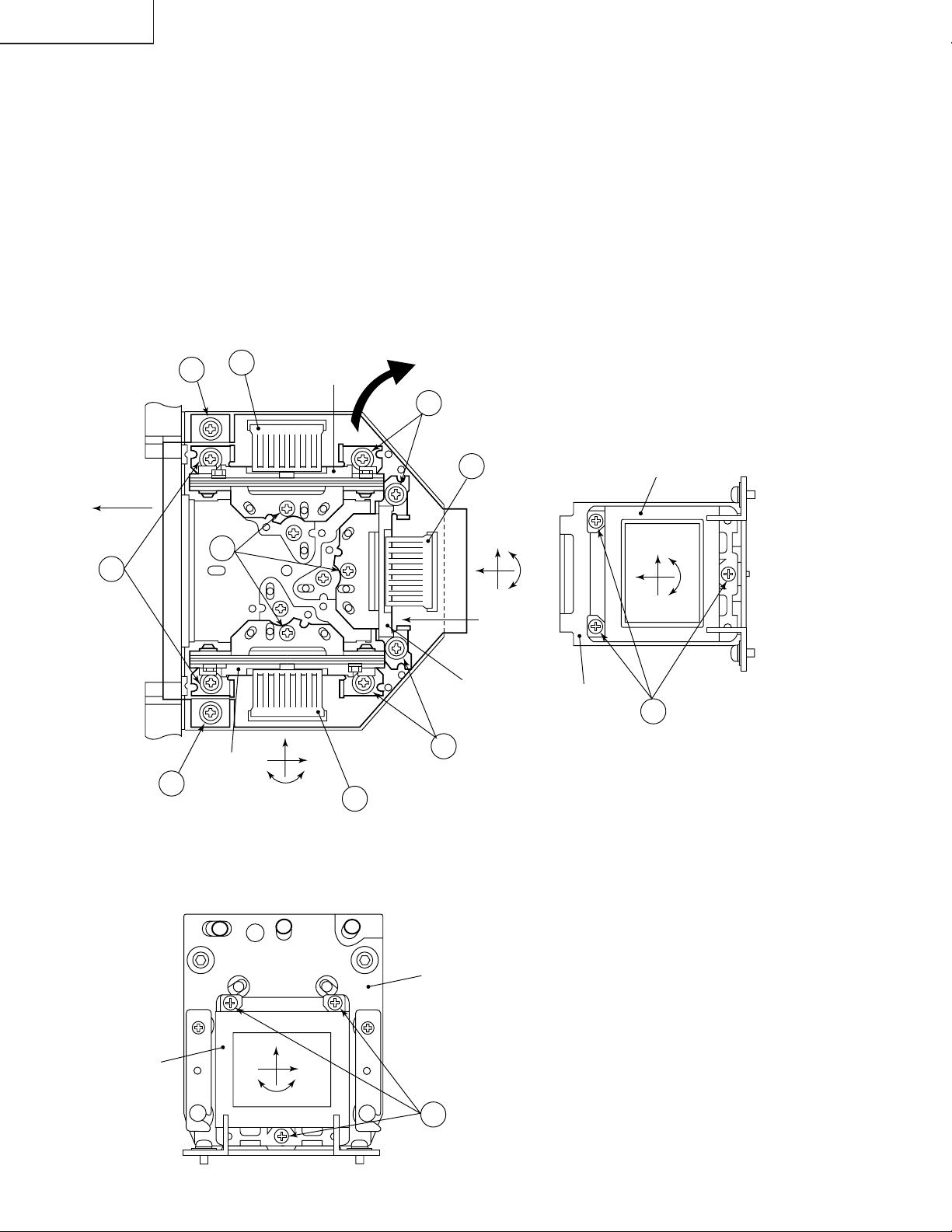

Replacing the LCDs

With the top cabinet removed

(1)Remove the output shield.

(2)Disconnect the LCD flat cable from the output PWB connector.

(3)Remove the lock screws "b" and "c". Detach the R/B adjusting plate or the G adjusting plate together with the LCD

panel.

(4)Separate the LCD panel from the adjusting plate.

(5)Mount a new LCD panel in the reverse order of the above steps (1), (2), (3) and (4).

~ Readjust the convergence and focus. Note that the G LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

TOP VIEW

FRONT

3

Lock

screws "c"

1

1

Lock

screws "b"

3

B-LCD

2

R-LCD

Lock screws "c"

3

SIDE VIEW

2

X

θY

Z

~

G-LCD

Z

X

θY

Lock screws "c"

3

G-LCD

G adjusting plate

X

θZ

Y

G-LCD panel

4

mounting screws

2

SIDE VIEW

R•B-LCD

R•B adjusting plate

Y

X

θZ

R•B-LCD panel

4

mounting screws

20

Loading...

Loading...