Page 1

XV-C100A/M/E

SERVICE MANUAL

SERVICE-ANLEITUNG

!

S99O9XV-C100A

LCD PROJECTOR

LCD PROJEKTOR

!"

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

XV-C100A/M/E

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet werden.

!"#$%=E !"#$%&'($)*F= !"#$%&'()*+,-./0123456

OUTLINE

The power unit and ballast unit of this model have been modified as follows in the course of production.

This Service Manual covers the processes before and after the power and ballast units have been modified.

ERLÄUTERUNG

Die Netzeinheit und Vorschalteinheit dieses Modells wurden im Laufe der Produktion modifiziert, wie nachstehend

erläutert.

Diese Service-Anleitung enthält die Vorgehensweisen, die vor und nach der Modifikation von der Netzeinheit

und der Vorschalteinheit anzuwenden sind.

====

!"#$%&'()*+,-.-/01234-/0156789

!"#$%&'(')*+,-.')*+/0123014/567

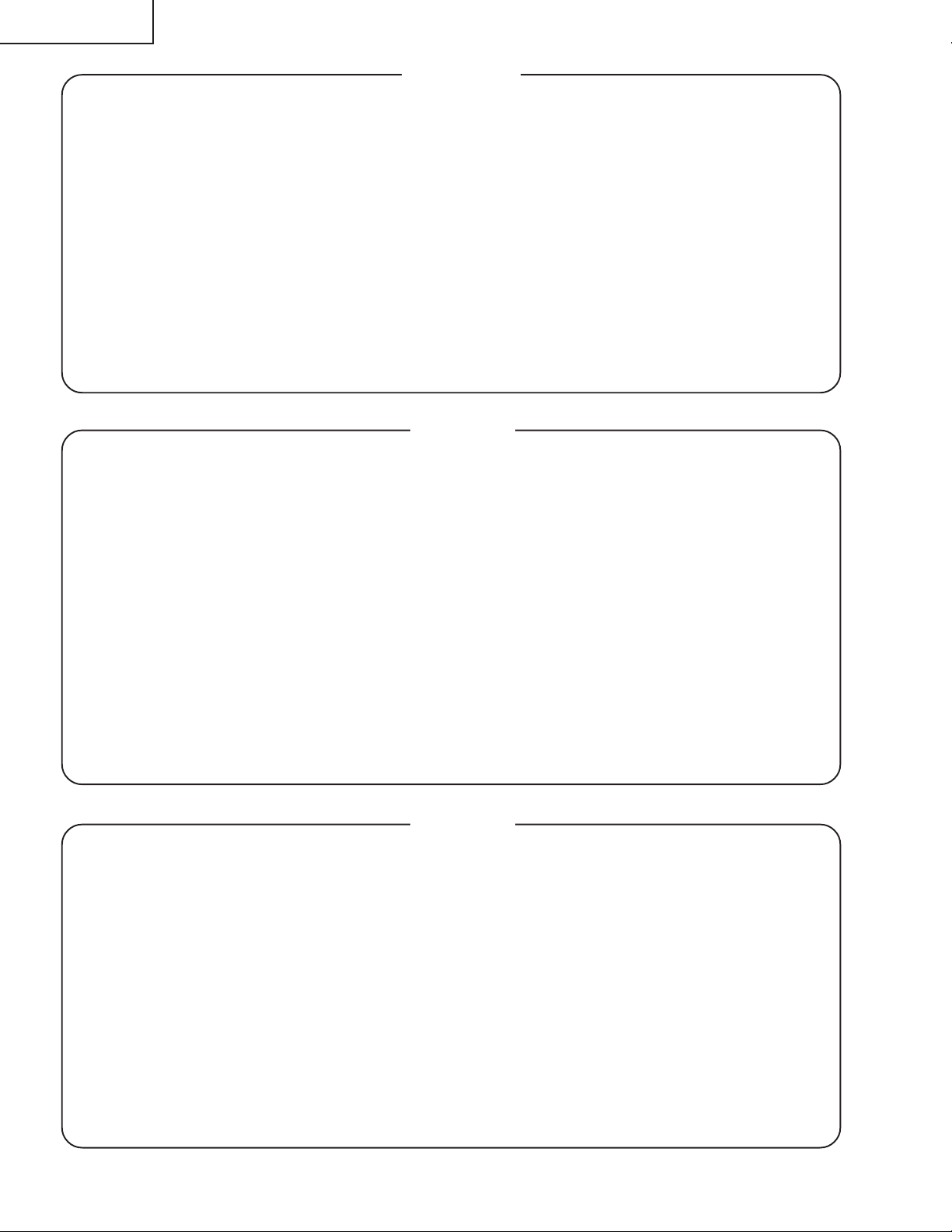

MODEL & UNIT OLD NEW NUMBERS OF UNITS PRODUCED

MODELL & EINHEIT AL T NEU

!"# !"#

XV-C100A

POWER UNIT DUNTKA001WEV2 ← 1~ NEW

BALLAST UNIT DUNTKA009WEV0 ←

XV-C100M

POWER UNIT RDENC0266CEZZ DUNTKA001WEV2 1~134 OLD

BALLAST UNIT RDENC0265CEZZ DUNTKA009WEV0 135~ NEW

XV-C100E

POWER UNIT RDENC0266CEZZ DUNTKA001WEV2 1~28 OLD

BALLAST UNIT RDENC0262CEZZ DUNTKA009WEV1 29~ NEW

ANZAHL DER PRODUZIERTEN EINHEITEN

SHARP CORPORATION

1

Page 2

XV-C100A/M/E

• SPECIFICATIONS ............................................. 3

• NOTE TO SERVICE PERSONNEL ................... 4

• OPERATION MANUAL ...................................... 5

• REMOVAL OF MAJOR COMPONENTS ........... 8

• OPTICAL SYSTEM .......................................... 12

• ADJ. IN FUNCTION .......................................... 14

• ELECTRICAL ADJUSTMENT.......................... 17

• TROUBLE SHOOTING TABLE........................ 23

• CHASSIS LAYOUT .......................................... 78

• OVERALL WIRING DIAGRAM ........................ 80

• DESCRIPTION OF SCHEMATIC DIAGRAM .... 82

• TECHNISCHE DATEN.....................................28

•

HINWEIS FÜR DAS WARTUNGSPERSONAL ...

• BEDIENUNG ANLEITUNG .............................. 30

•

ENTFERNEN DER HAUPTKOMPONENTEN .....

• OPTIKSYSTEM ...............................................37

• FUNKTION ADJ IN ..........................................39

• ELEKTRISCHE EINSTELLUNG ...................... 42

• STÖRUNGSSUCHTABELLE...........................48

• CHASSISANORDNUNG..................................78

• GESAMTSCHALTPLAN...................................80

• BESCHREIBUNG DES SCHEMATISCHEN

SCHALTPLANS ............................................ 82

CONTENTS

• WAVEFORMS .................................................. 83

• SCHEMATIC DIAGRAM .................................. 84

• PRINTED WIRING BOARD ASSEMBLIES ... 107

• P ARTS LIST

Ë

Ë

Ë

Ë

• PACKING OF THE SET ................................. 135

INHALT

• WELLENFORMEN...........................................83

29

33

• SCHEMATISCHER SCHALTPLAN.................. 84

• LEITERPLATTENEINHEITIN.........................107

• ERSATZTEILLISTE

Ë

Ë

Ë

Ë

• VERPACKEN DES GERÄTS .........................135

PagePage

ELECTRICAL PARTS .................................114

CABINET AND MECHANICAL PARTS ...... 128

ACCESSORIES PARTS ............................ 134

PACKING PARTS ...................................... 134

SeiteSeite

ELEKTRISCHETEILE ................................ 114

GEHÄUSE UND MECHANISCHE

BAUTEILE...............................................128

ZUBEHÖRTEILE .......................................134

VERPACKUNGSTEILE..............................134

• KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 53

• !"#$ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 54

• !" KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 55

• !"#$ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 58

• ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 62

• ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 64

• ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 67

• !" KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 73

• !"#$% KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 78

• !"#$ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 80

• !"#$% KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 82

========

• KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 83

• !" KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 84

• !"#$ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 107

•

Ë ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 114

Ë !"#$%&'( KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 128

Ë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 134

Ë ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 134

• ! KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK 135

2

Page 3

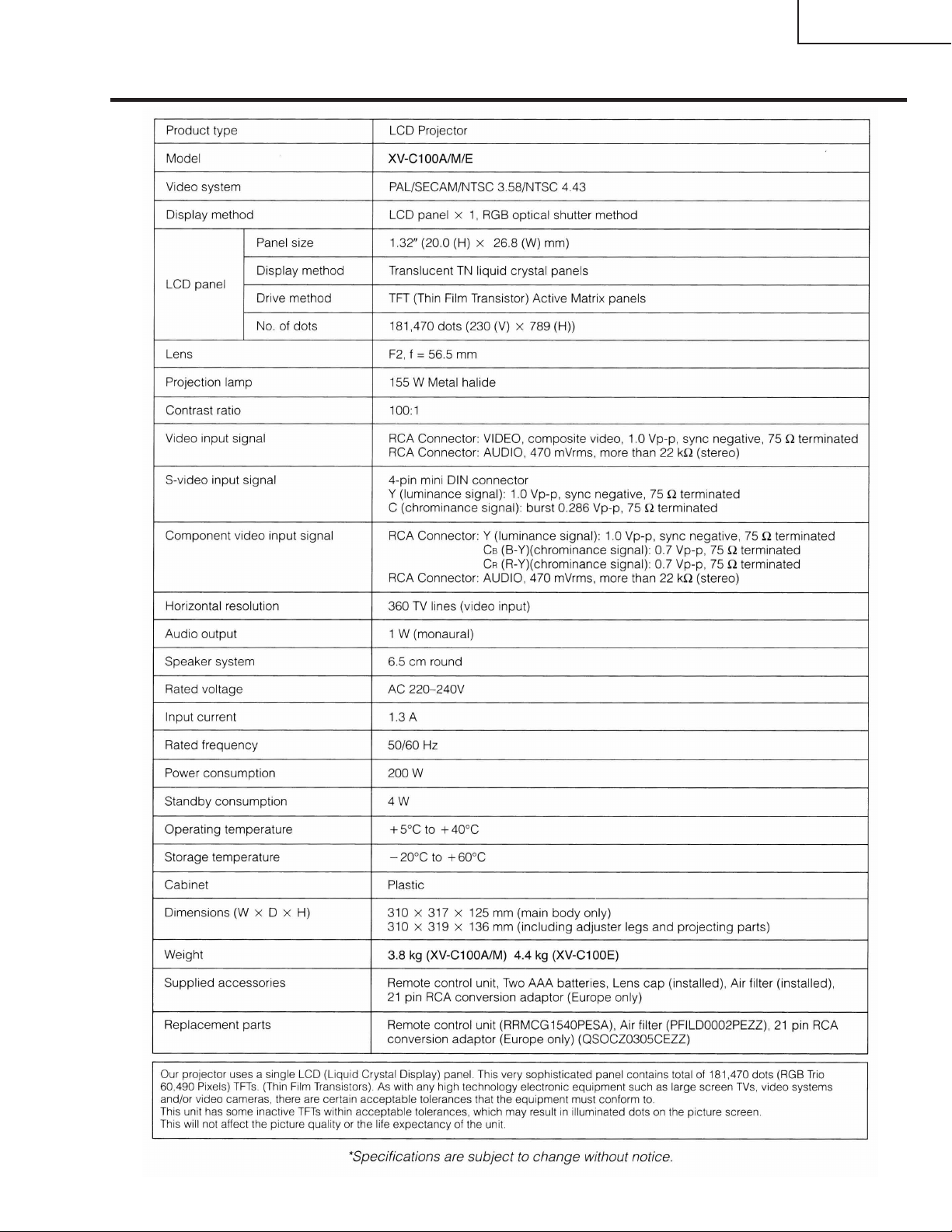

Specifications

XV-C100A/M/E

3

Page 4

XV-C100A/M/E

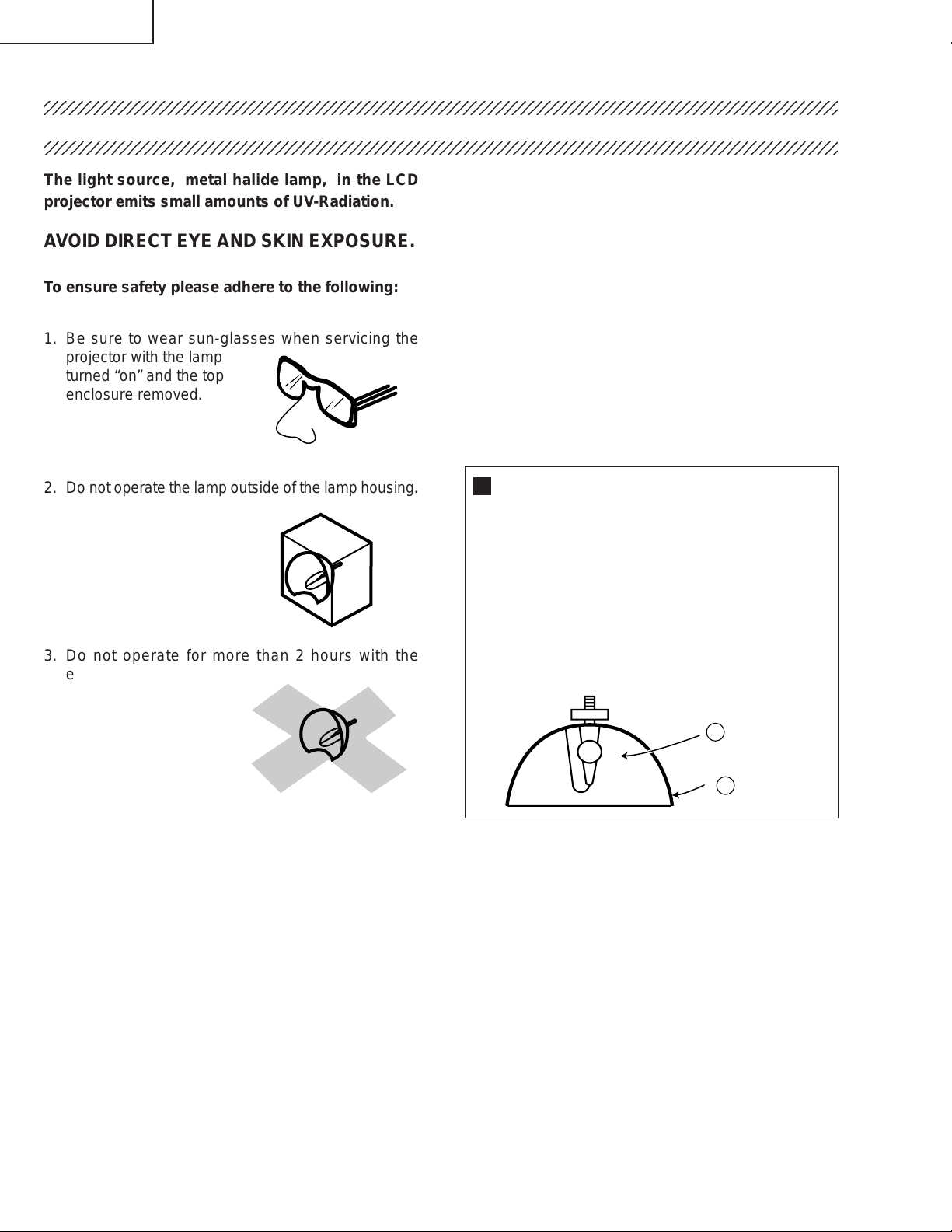

NOTE TO SERVICE PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0053DE03 rated 65V/155W.

4. The lamp emits small amounts of UV-Radiation,

avoid direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp should

be done at least one hour after the power has been

turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without

the lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

4

Page 5

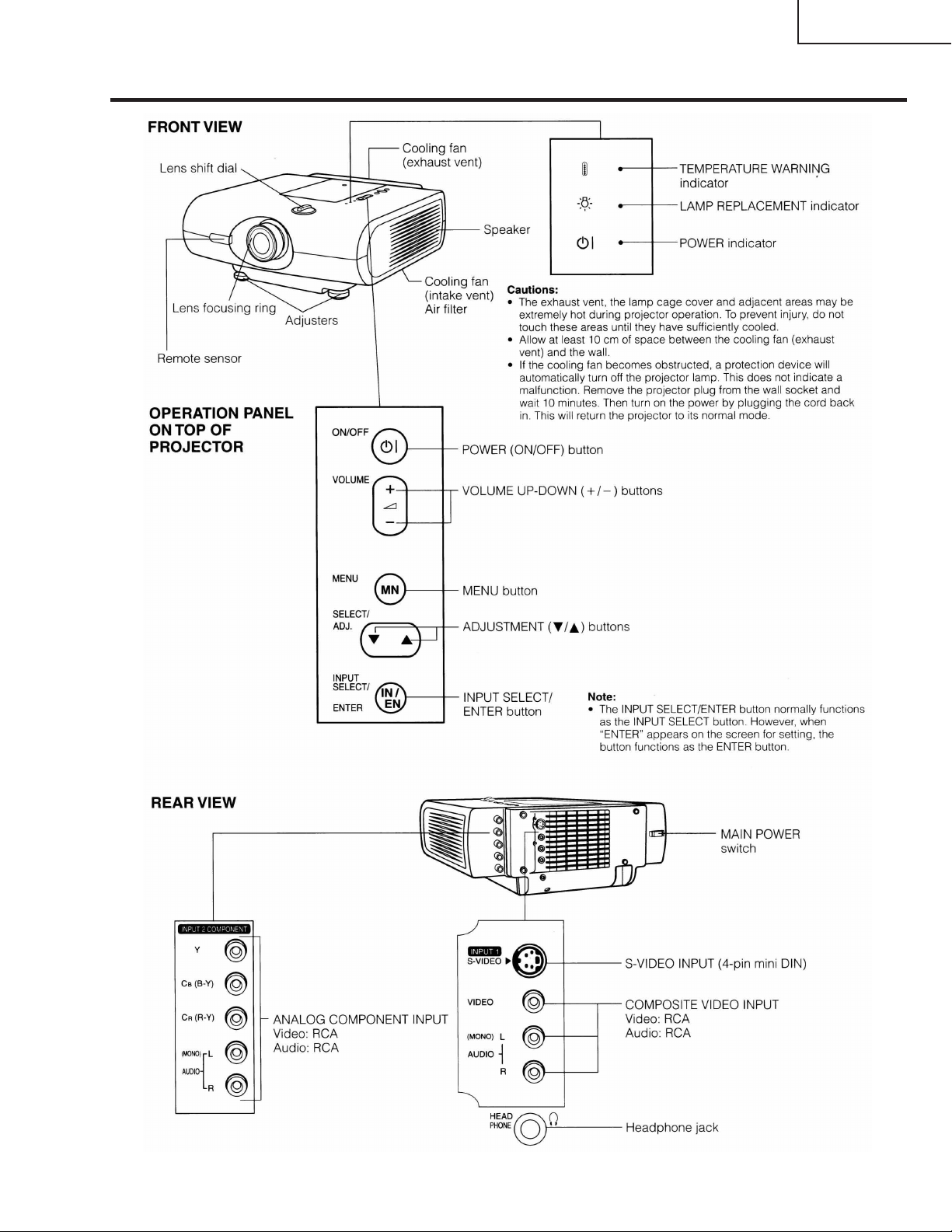

Location of Controls

XV-C100A/M/E

5

Page 6

XV-C100A/M/E

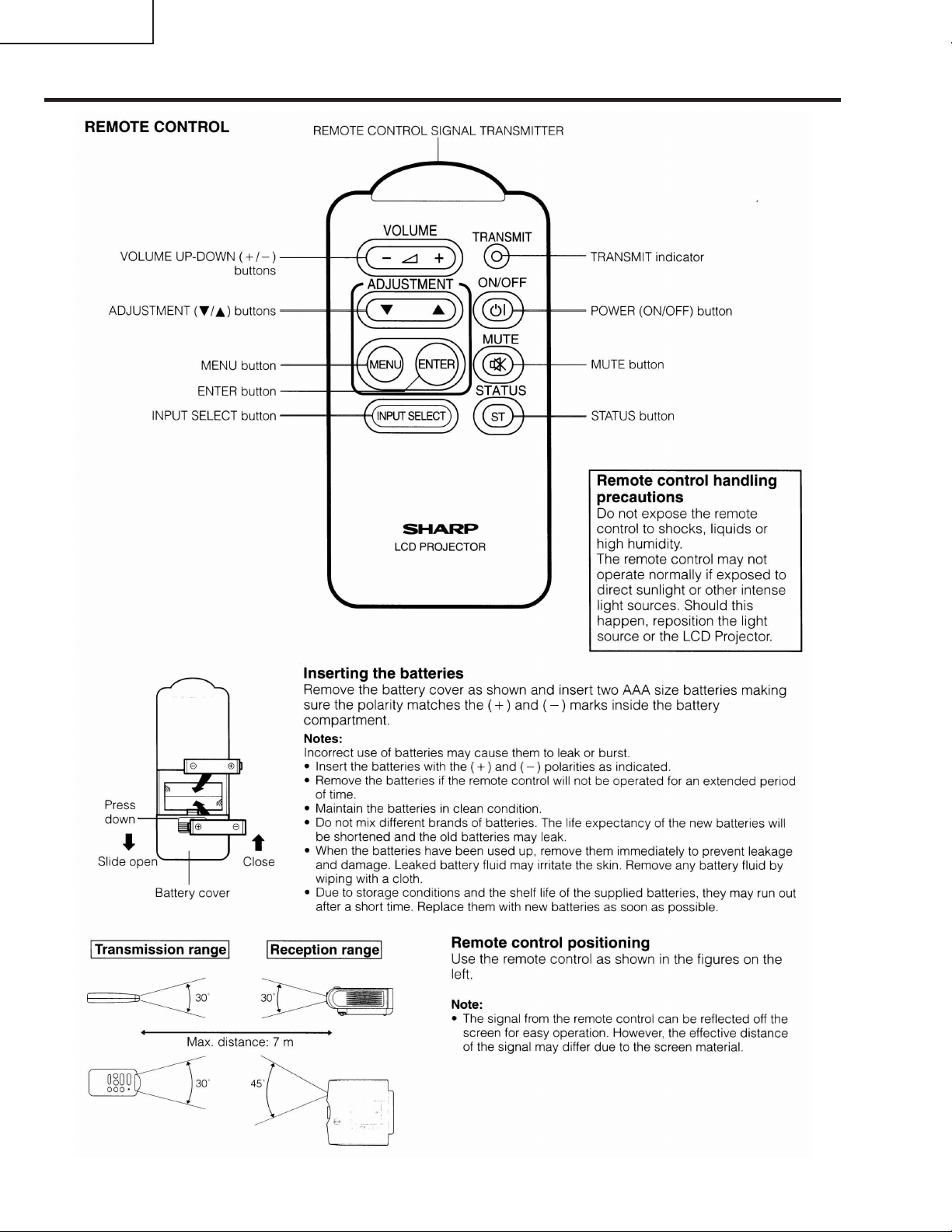

Remote Control Operation

6

Page 7

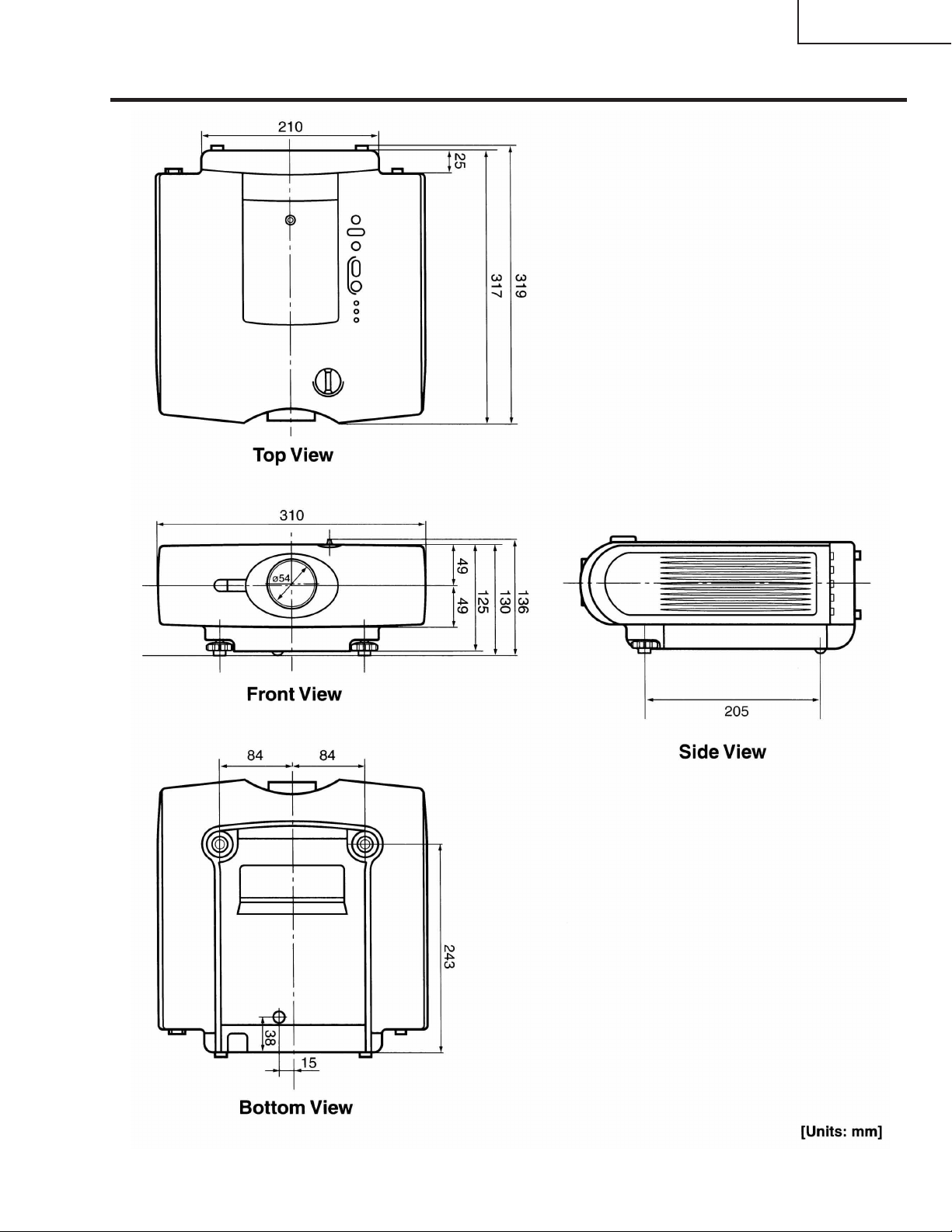

Dimensions

XV-C100A/M/E

7

Page 8

XV-C100A/M/E

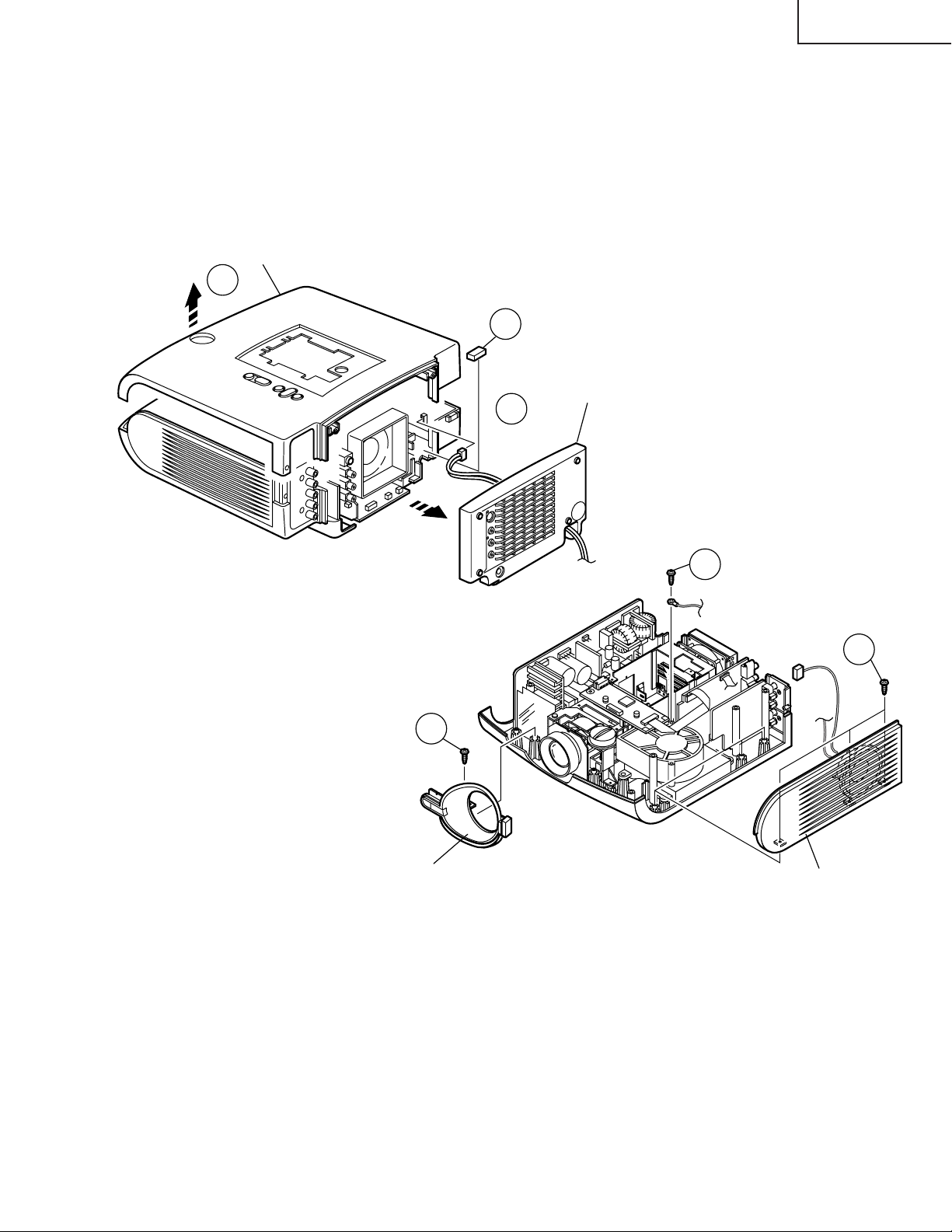

Rear Cabinet

1-4

1-5

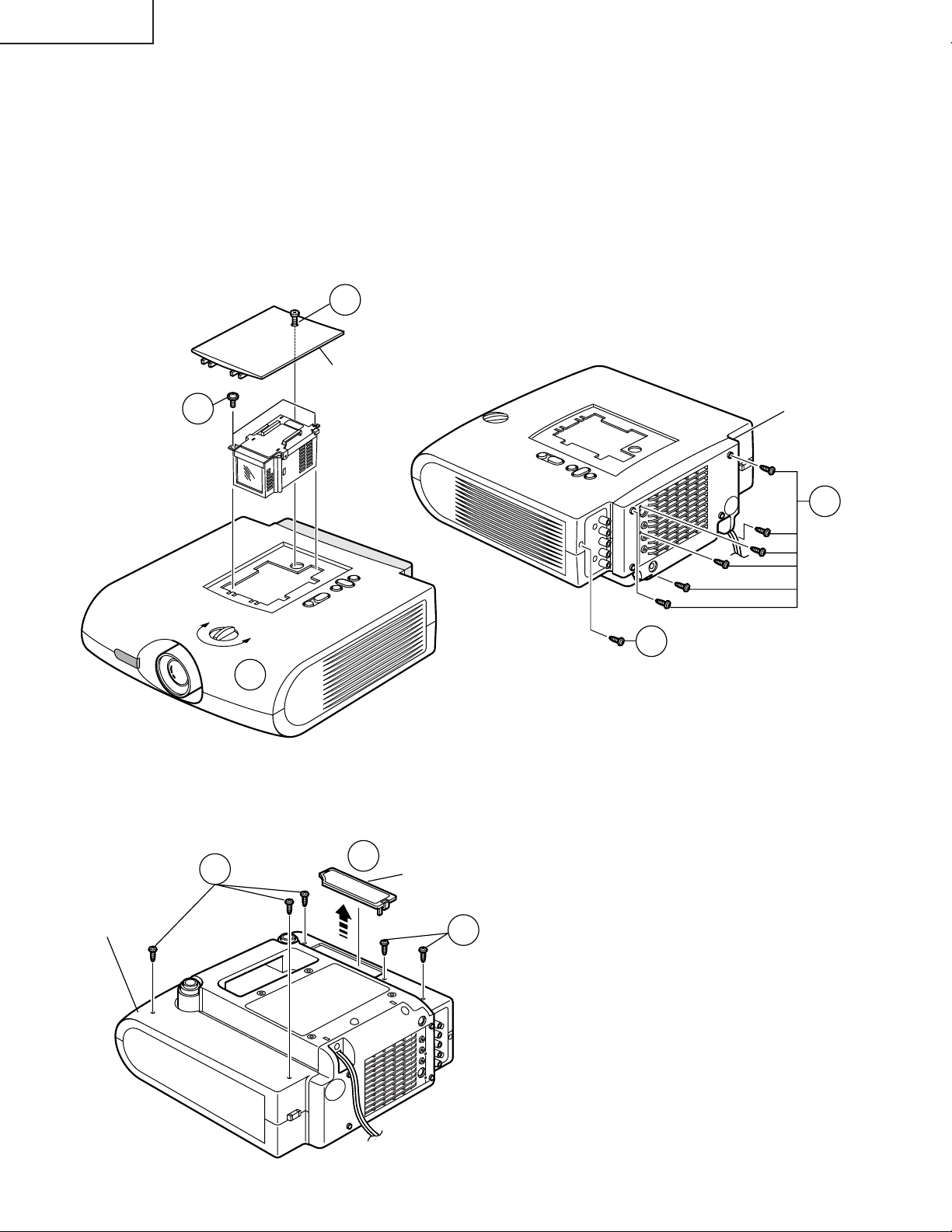

REMOVAL OF MAJOR COMPONENTS

1. Removing the cabinets

1-1. Remove the screw and detach the lamp cage cover.

1-2. Remove the two lock screws (two 4-mm screws) off the lamp/cage module unit.

1-3. Turn the lens shift dial until the lens comes to almost the center of the lens hole in the front cabinet.

1-4. Remove the six screws (six 3-mm tapping screws) off the rear cabinet.

1-5. Remove the M3 tapping screw off the sub unit cover.

1-1

Lamp Cage Cover

1-2

Lamp/Cage Module Unit

1-3

1-6. Remove the air filter cover.

1-7. Remove the five tapping screws off the bottom cabinet.

1-7

Bottom Cabinet

1-6

Air Filter Cover

1-7

8

Page 9

Top Cabinet

1-8

XV-C100A/M/E

1-8. Now lift the top cabinet further up and

disconnect the leaf switch connectors (LL) as

well as the operation key unit flat cable (KE).

The top cabinet is now free.

1-9. Disconnect the connector (PE) of the AC cord

(that runs through the rear cabinet) from the

ballast unit. Detach the rear cabinet.

1-10. Remove the spacer.

1-11. Remove the screws off the lens Cover.

1-12. Disconnect the speaker connector (SP) and

remove the three lock screws. Remove the

screw off the ground lead. Now detach the side

cover.

1-10

Rear Cabinet

1-9

(PE)

1-12

1-11

Lens Cover

Reassembling procedure

1. Fit the lens cover and the side cover to the bottom panel. Tighten up the related screws.

2. Set the top cabinet over the bottom cabinet.

(SP)

Side Cover

1-12

3. Tighten up the M3 tapping screw into the sub unit cover.

4. Press the rear cabinet against the top and bottom cabinets to fit them together.

5. Tighten up the screws into the rear cabinet. Use the six 3-mm tapping screws.

6. Tighten up the tapping screws to fix the top and bottom cabinets.

7. Put the lamp/cage module unit into position. Tighten up the two 4-mm screws.

8. Place the lamp cage cover and tighten up the screws.

9

Page 10

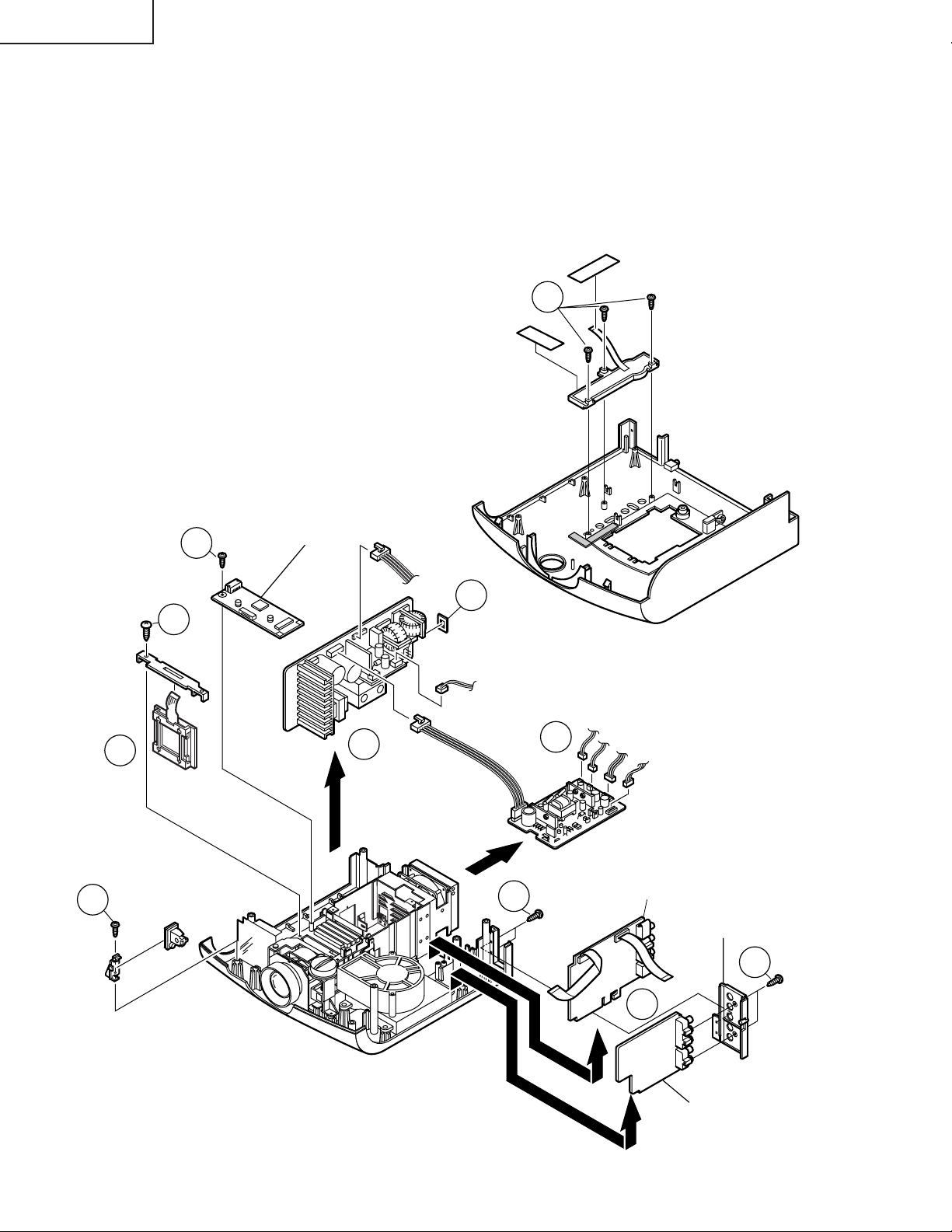

XV-C100A/M/E

2. Removing the PWBs

2-1. Slide out the power unit, ballast unit, main unit in their directions of arrow. Disconnect the connectors.

2-2. Remove the three screws, peel off the two pieces of tape, and take out the operation key unit.

2-3. Remove the screw off the control unit and R/C Receiver unit and sub unit. Disconnect the connectors.

2-4. Remove the button cover.

3. Removing the LCD module unit

3-1. Remove the screw off the panel cover. Take out the panel cover.

3-2. Pull up the LCD module unit slowly out of position.

2-2

Operation Key Unit

Panel Cover

3-2

2-3

2-3

3-1

LCD

Module Unit

R/C Receiver

Unit

Control Unit

2-1

2-4

Ballast Unit

2-3

Top Cabinet

2-1

Power Unit

Main Unit

Sub Unit Cover

2-3

10

2-1

Sub Unit

Page 11

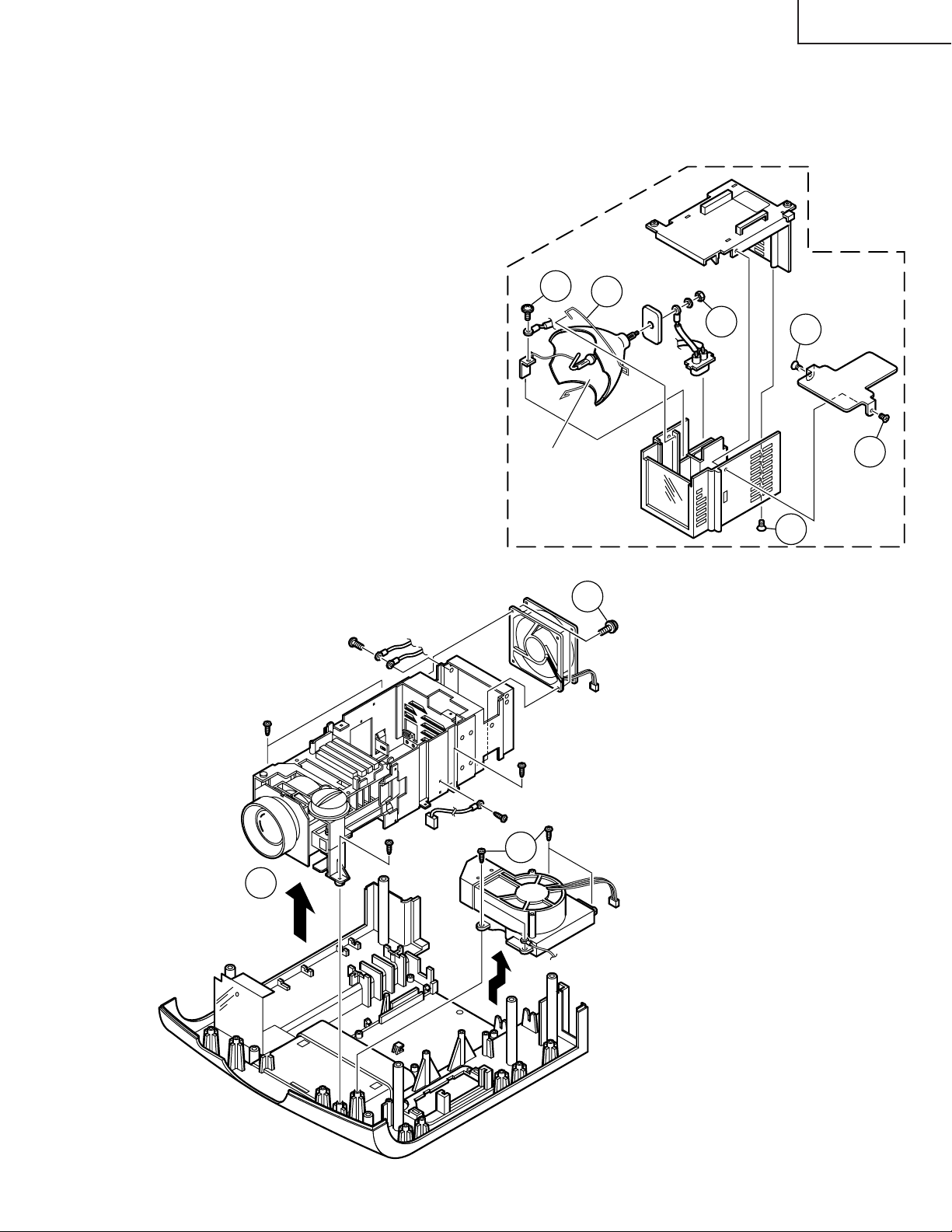

XV-C100A/M/E

4. Removing the optics mechanism assembly

4-1. Remove the four screws off the optics mechanism assembly. Detach the assembly from the bottom cabinet.

4-2. Remove the four screws off the intake duct assembly. Detach the intake duct assembly from the bottom

cabinet.

4-3. Remove the two screws off the cooling fan.

5.Removing the lamp

5-1. Remove the three countersunk lock screws off

the upper and lower lamp cases.

5-2. Remove the lock screw and the nut off the lamp

terminal.

5-3. Release the lamp lock spring off the hook below

the lower lamp case. Take out the lamp/mirror

assembly.

5-2

Lamp/Mirror

Ass'y

Lower Lamp Case

5-3

4-3

5-2

Lamp/Cage

Module Unit

Upper Lamp

Case

5-1

5-1

5-1

Optics Mecha

Ass'y

Bottom Cabinet Ass'y

Cooling Fan

(Exhaust Vent)

4-2

4-1

Intake Duct Ass'y

11

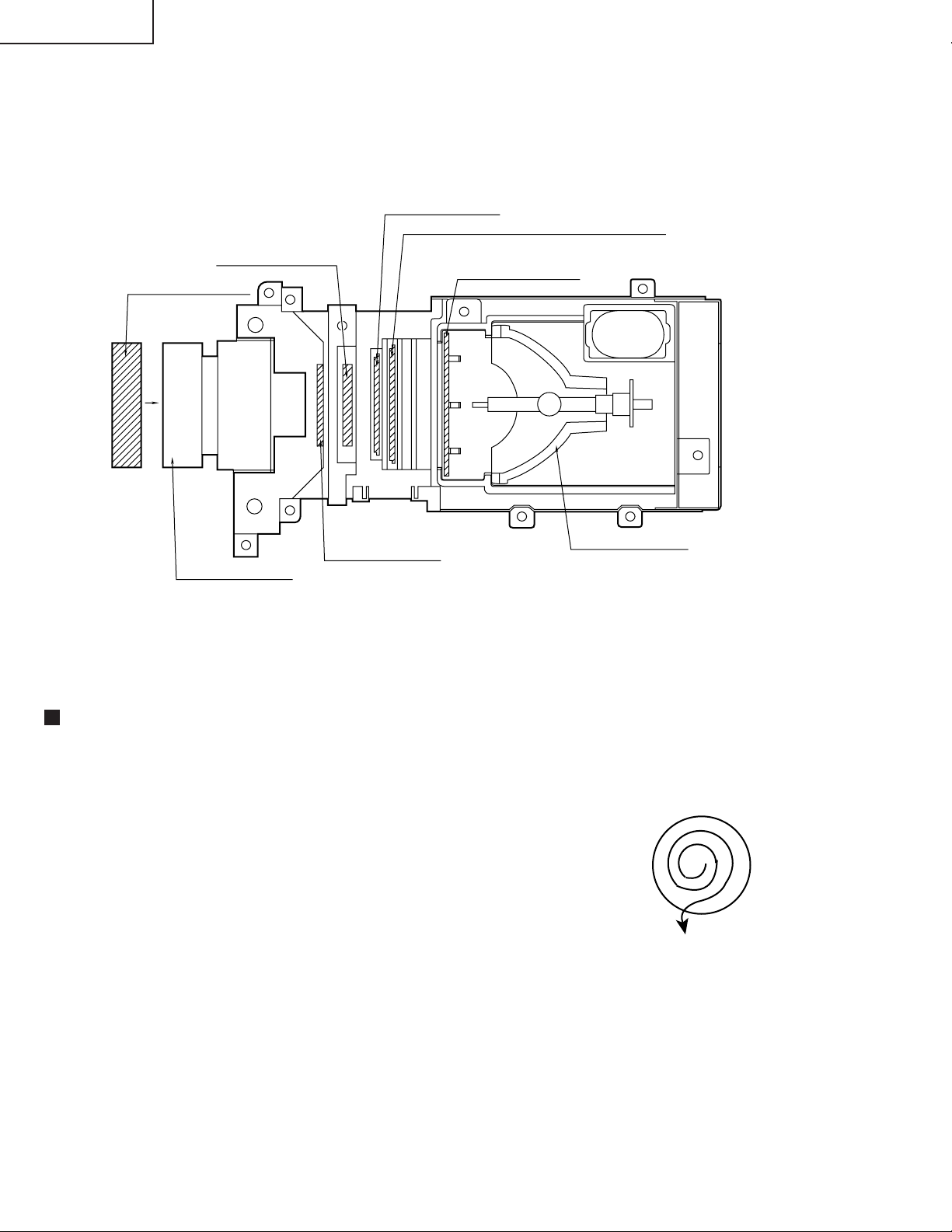

Page 12

XV-C100A/M/E

Optical unit

RLCDP0088CEZZ

PCAPH1061CESB

Lens cap

LCD

OPTICAL SYSTEM

Polarizer Input plate

PFiLW0164CEZZ

PFiLW0202CEZZ

PFiLW0194CEZZ

UV/IR filter

Heat Management plate

PFiLW0200CEZZ

PLNS-0124CEZZ

Projection lens

Diffraction grating

Cleaning the lenses and reflectors

1. Lens cleaner

• Cleaning liquid:

Change the mixture ratio of alcohol and ether depending on ambient

temperatures. Make sure that the liquid evaporates from the lens

surface immediately after you rub it: This is the best ratio. The more

ether is used, the quicker the liquid evaporates.

• Method:

Use well-washed bleached cotton cloth or cleaning paper available

on the market. Damp the bleached cotton cloth with the liquid, and

hold the lens sandwiched in the cloth with your thumb and the index

finger. Turn the lens and wipe the surface clean from the center

outward to collect dust. Be careful not to rub the coated surface too

strong.

CLMPF0053DE03

Lamp/Mirror Ass'y

12

Page 13

Ë

Controlling the total operating hours of the lamp

The following control is carried out when the lamp has been used for 1,900 hours and 2,000 hours.

1. After 1900-hour use

When the power is turned on, "LAMP" appears in the on-screen display for about 1 minute (flashing in yellow)

and the lamp LED indicator lights up in red.

When the 1,900-hour point comes up during use of the unit, the "LAMP" display starts flashing in yellow on the

screen for 1 minute at the very 1,900-hour point.

Now the lamp LED indicator changes from green to red.

2. After 2000-hour use

When the power is turned on, "LAMP" appears in the on-screen display for 5 minutes (flashing in red) and the

lamp LED indicator lights up in red. Five minutes thereafter, the power turns itself of f and the unit is interrupted.

When the 2,000-hour point comes up during use of the unit, the "LAMP" display starts flashing in red on the

screen for 5 minutes at the very 2,000-hour point. Five minutes later, the power turns itself off and the unit is

interrupted. (The lamp LED indicator stays red since the 1,900-hour point.)

If you try to turn on the power twice after the 2,000-hour point, the unit remains off.

3. When the 2,000-hour point comes up, take the following steps.

Replace the lamp with new one. While holding down both the "VOLUME "" and "SELECT/ADJ "" Keys on the

unit, turn on the main power switch (located on the back of the unit). The lamp operating hourmeter is now reset

to zero. Turn on the unit and make sure the time display shows "0000H".

XV-C100A/M/E

4. Displaying the total operating hours of the lamp

Change the STATUS3 data settings: PICTURE at 0, BRIGHT at MAX, COLOR at MIN, TINT at MIN, and

SHARPNESS at MAX. Hold down the SOUND DOWN and ENTER keys for longer than 2 seconds. By doing

this, the total operating hours will be displayed on the screen.

TIME

0000H

TOTAL TIME

0000H

13

Page 14

XV-C100A/M/E

ADJ. IN (adjustment input) FUNCTION

1. Keys used for the adjustments

On the sub PWB: S2001

Control keys: [ENTER], [MENU], [SELECT/ADJ.'], [SELECT/ADJ."], [VOLUME+]

2. Operation

Press S2001 to call up the ADJ IN mode.

Use the [SELECT/ADJ. '] and [SELECT/ADJ."] keys to select an adjustment group, and press the

[ENTER] key.

Use the [SELECT/ADJ. '] and [SELECT/ADJ."] keys again to select an adjustment subject, and

press the [ENTER] key.

The [SELECT/ADJ. '] and [SELECT/ADJ."] keys are also used to make adjustments.

Each time the [ENTER] key is pressed on the ADJ IN screen, the adjustment subjects of a group are

changed one by one. (Pressing the [VOLUME + ] key changes the subjects in the reverse order.)

When the [MENU] key is pressed, the previous group appears on the screen.

Press S2001 again to go out of the ADJ IN mode.

Group

Adjustment

subjects

VIDEO 1

H-CENT

P-H-CENT

CONT

BRIGHT

SUB-R

SUB-G

SUB-B

VIDEO 2

SUB-BIAS

R-BIAS

B-BIAS

R-DRIVE

B-DRIVE

TINT

COLOR

P-COLOR

S-COLOR

VIDEO 3

GAMMA1

GAMMA2

AGCADJ

T-BRT

VIDEO 4

C-CONT

C-BRIGHT

C-COLOR

C-TINT

C-H-CENT

C-PH-CENT

SET

HL

The adjustment group "LINE" is not used here.

Do not feed the signal when the adjustment group "N • W" is used.

N • W

RED

GREEN

BLUE

N • W

LINE

AUTO

OFF TIMER

TEMP1

TEMP2

FACTORY SET4

TEST

TIME1

TIME2

14

Page 15

3. Adjustment subjects

VIDEO 1

H-CENT NTSC horizontal position adjustment

P-H-CENT P AL horizontal position adjustment

CONT Sub-contrast adjustment

BRIGHT Brightness adjustment

SUB-R Not used, just to be 0 (zero)

SUB-G Not used, just to be 0 (zero)

SUB-B Not used, just to be 0 (zero)

VIDEO 2

SUB-BIAS Sub-bias adjustment

R-BIAS White balance (red), bias adjustment

B-BIAS White balance (blue), bias adjustment

R-DRIVE White balance (red), drive adjustment

B-DRIVE White balance (blue), drive adjustment

TINT TINT adjustment

COLOR Colour level adjustment

P-COLOR PAL colour level adjustment

S-COLOR SECAM colour level adjustment

XV-C100A/M/E

VIDEO 3

GAMMA1 Gamma correction 1

GAMMA2 Gamma correction 2

AGC ADJ AGC adjustment

T-BRT Chroma IC brightness adjustment

VIDEO 4

C-CONT Component input contrast adjustment

C-BRIGHT Component input brightness adjustment

C-COLOR Component input colour level adjustment

C-TINT Component input tint adjustment

C-H-CENT Component input NTSC horizontal position adjustment

C-PH-CENT Component input PAL horizontal position adjustment

SET

HL Temperature detection level setting

N • W (Single-colour display)

RED Red

GREEN Green

BLUE Blue

N • W Not used

TEST

TIME1 1-hour increment setting for total lamp timer

TIME2 1899H-1999H-0H-1899H setting for total lamp timer

15

Page 16

XV-C100A/M/E

0

SUB-B

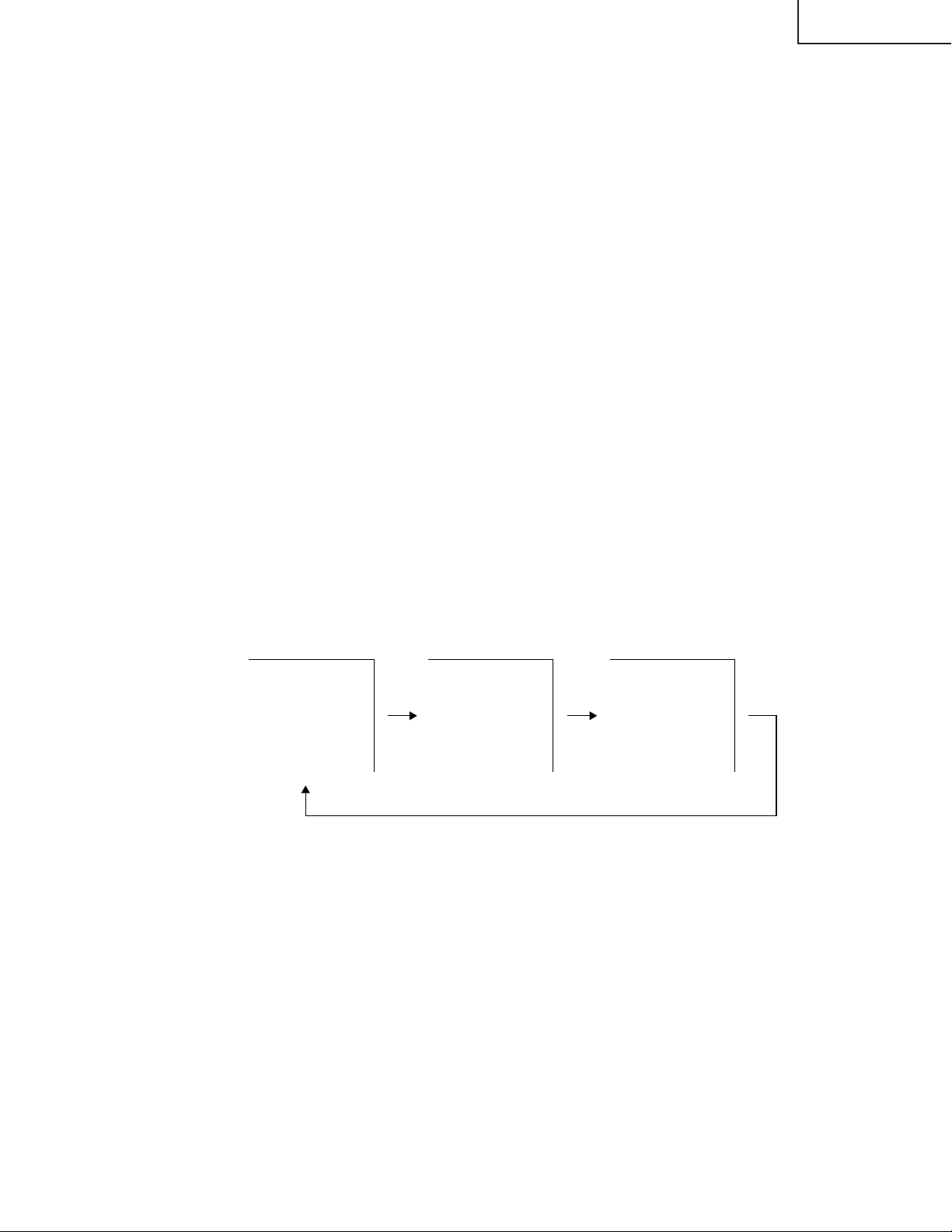

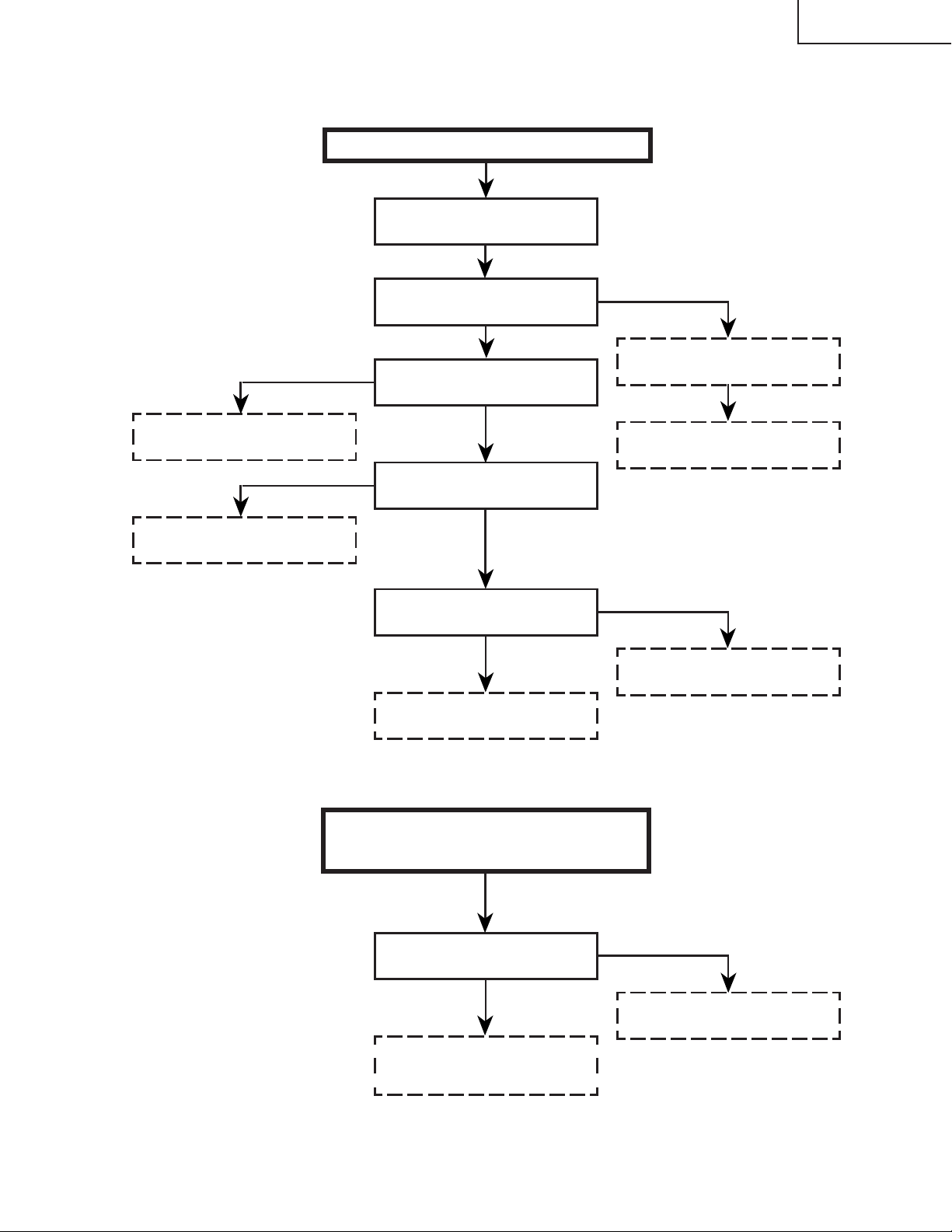

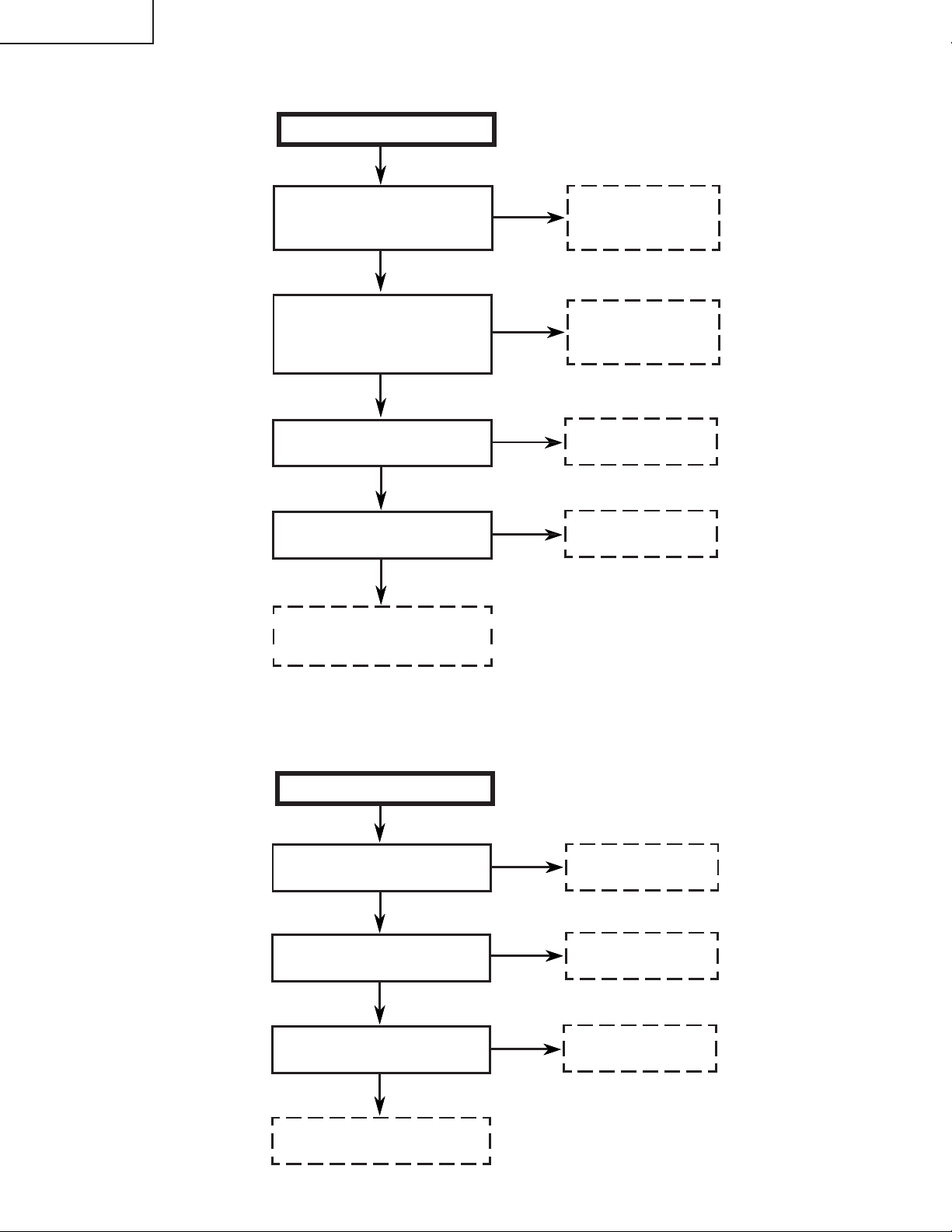

FLOWCHART OF ADJUSTMENT

–4

S-COLOR

–6

P-COLOR

+7

C-PH-CENT

HL

2

0

SUB-G

0

SUB-R

–3

BRIGHT

+6

CONT

0

P-H-CENT

64

B-DRIVE

64

R-DRIVE

74

B-BIAS

74

R-BIAS

COLOR

TINT

T-BRT

ADJ

AGC

GAMMA2

–4

–3

–30

0

0

+5

C-H-CENT

+9

C-TINT

+7

C-COLOR

+5

C-BRIGHT

Not used

0000

TIME2

ENTER

H-CENT SUB-R

VIDEO1

H-CENT

MENU

P-H-CENT SUB-G

CONT SUB-B

–3

BRIGHT

SUB-BIAS

MENU

ENTER

TINT

COLOR

P-COLOR

SUB-BIAS

R-BIAS

B-BIAS

VIDEO2

User mode screen

64

S-COLOR

R-DRIVE

B-DRIVE

S2001

ENTER

ENTER

MENU

VIDEO1 SET

VIDEO2 N • W

ADJ IN

255

GAMMA1

MENU

GAMMA1

GAMMA2

AGC ADJ

VIDEO3

VIDEO3 LINE

VIDEO4 TEST

T-BRT

ENTER

C-PH-CENT

C-CONT

C-BRIGHT

VIDEO4

–4

C-CONT

MENU

C-COLOR

C-TINT

C-H-CENT

16

ENTER

N • W

RED

R G B N • W

MENU

GREEN

BLUE

N • W

LINE

AUTO

OFF TIMER

TEMP1

TEMP2

ENTER

Not used

FACTORY SET 4

TEST

TIME1

MENU

TIME1

TIME2

0001

Page 17

XV-C100A/M/E

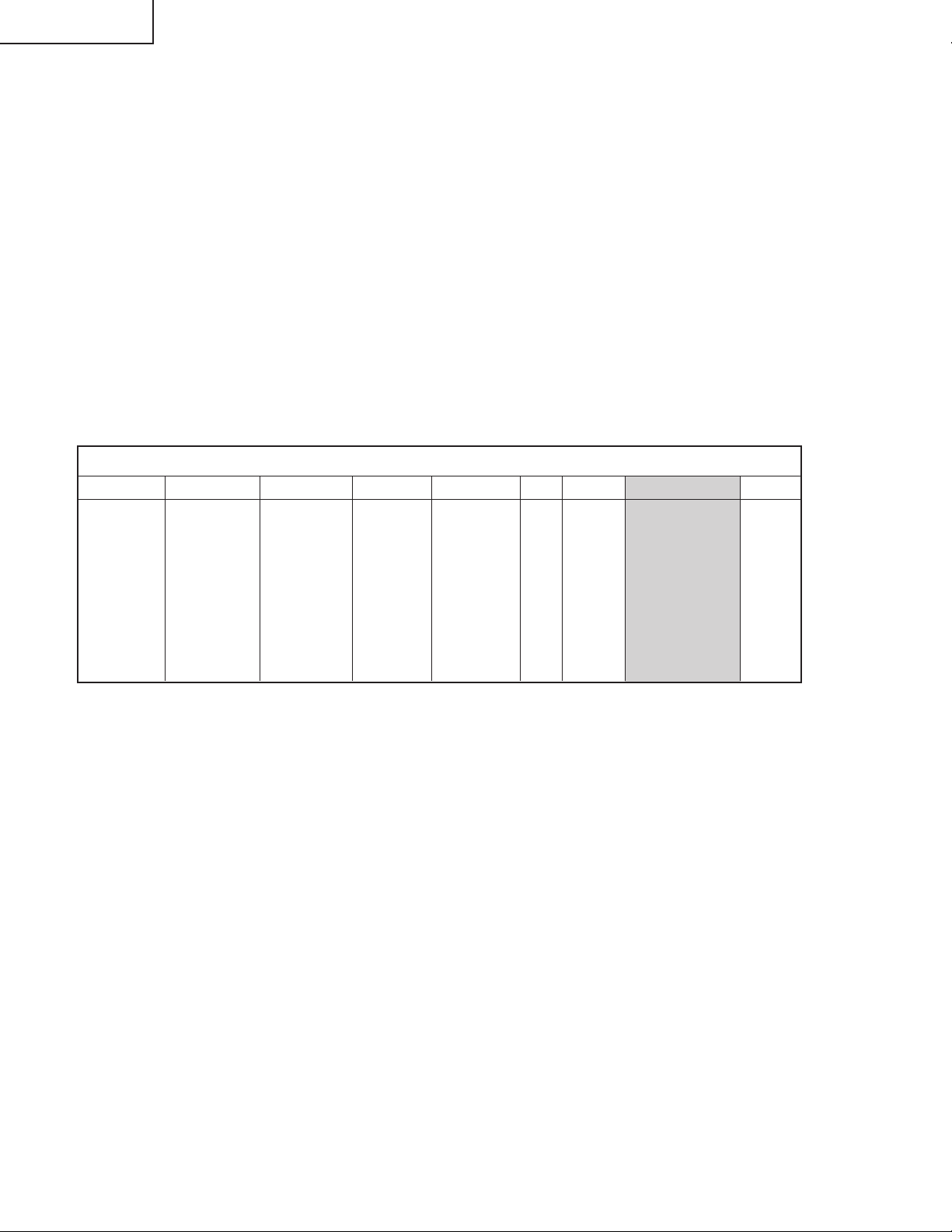

ELECTRICAL ADJUSTMENT

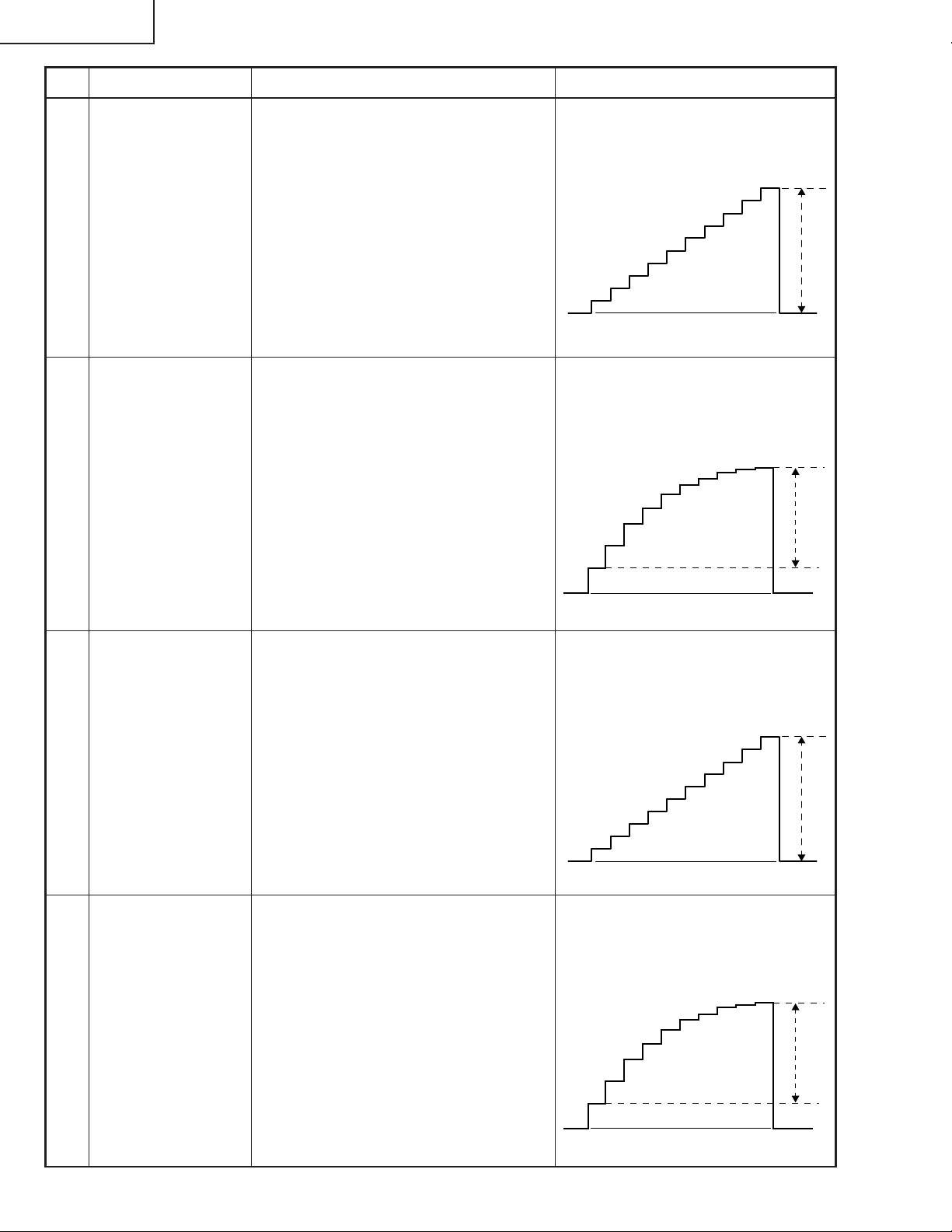

No. Adjustment Item Adjustment Conditions Adjustment Procedure

1

NTSC freerunning

frequency

(R1616)

2

PAL freerunning

frequency

(R1602)

3

Horizontal

center (NTSC)

(DAC)

4

Horizontal

center (PAL)

(DAC)

1.Receive the NTSC monoscope pattern

signal.

2.Hold down S801.

1. Receive the PAL monoscope pattern

signal.

2. Hold down S801.

1. Receive the NTSC monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 1

Subject: H-CENT

1. Receive the PAL monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 1

Subject: P-H-CENT

• Turn R1616 until the image appears

as specified.

• Turn R1602 until the image appears

as specified.

• Using the ' and " keys, make the

overscan just the same at right and

left.

Overscan: 91-97%

• Using the ' and " keys, make the

overscan just the same at right and

left.

Overscan: 91-97%

5

Contrast (DAC)

(gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect a dual-beam oscilloscope

between pin (2) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: SUB-BIAS

4. Using the ' and " keys, put the

waveform to its proper shape.

5. Press S2001 again to call up the ADJ

IN mode and select the following

subject.

Group: VIDEO 1

Subject: SUB-R, SUB-G, SUB-B

Make sure all these subjects have an

entry of 0 (zero).

6. Adjust R861 to get the highest gain.

7. Finally select the following subject.

Group: VIDEO 1

Subject: CONT

• Using the ' and " keys, adjust the

difference between the tenth-step

level and the pedestal level to

6.0±0.15 Vp-p.

10

17

Page 18

XV-C100A/M/E

No. Adjustment Item Adjustment Conditions Adjustment Procedure

6

Automatic gain

control: R861

(gamma

correction off)

7

Brightness

(DAC)

(gamma

correction on)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P1401 and GND.

3. Select the following subject.

Group: VIDEO 1

Subject: CONT

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 1

Subject: BRIGHT

• Turn R861 so that the difference

between the 100% white level and the

pedestal level be 4.8±0.05 Vp-p.

10

• Using the ' and " keys, adjust the

difference between the first-step

level and the tenth-step level to

2.0±0.05 Vp-p.

10

1

8

Component

contrast (DAC)

(gamma

correction off)

9

Component

brightness

(DAC)

(gamma

correction on)

1. Feed the NTSC 10-step pattern signal

to the component terminal.

2. Connect the dual-beam oscilloscope

between pin (2) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-CONT

1. Feed the NTSC 10-step pattern signal

to the component terminal.

2. Connect the dual-beam oscilloscope

between pin (2) of P1402 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-BRIGHT

• Using the ' and " keys, adjust the

difference between the 100% white

level and the pedestal level be

4.8±0.05 Vp-p.

10

• Using the ' and " keys, adjust the

difference between the first-step

level and the tenth-step level to

2.0±0.05 Vp-p.

10

1

18

Page 19

XV-C100A/M/E

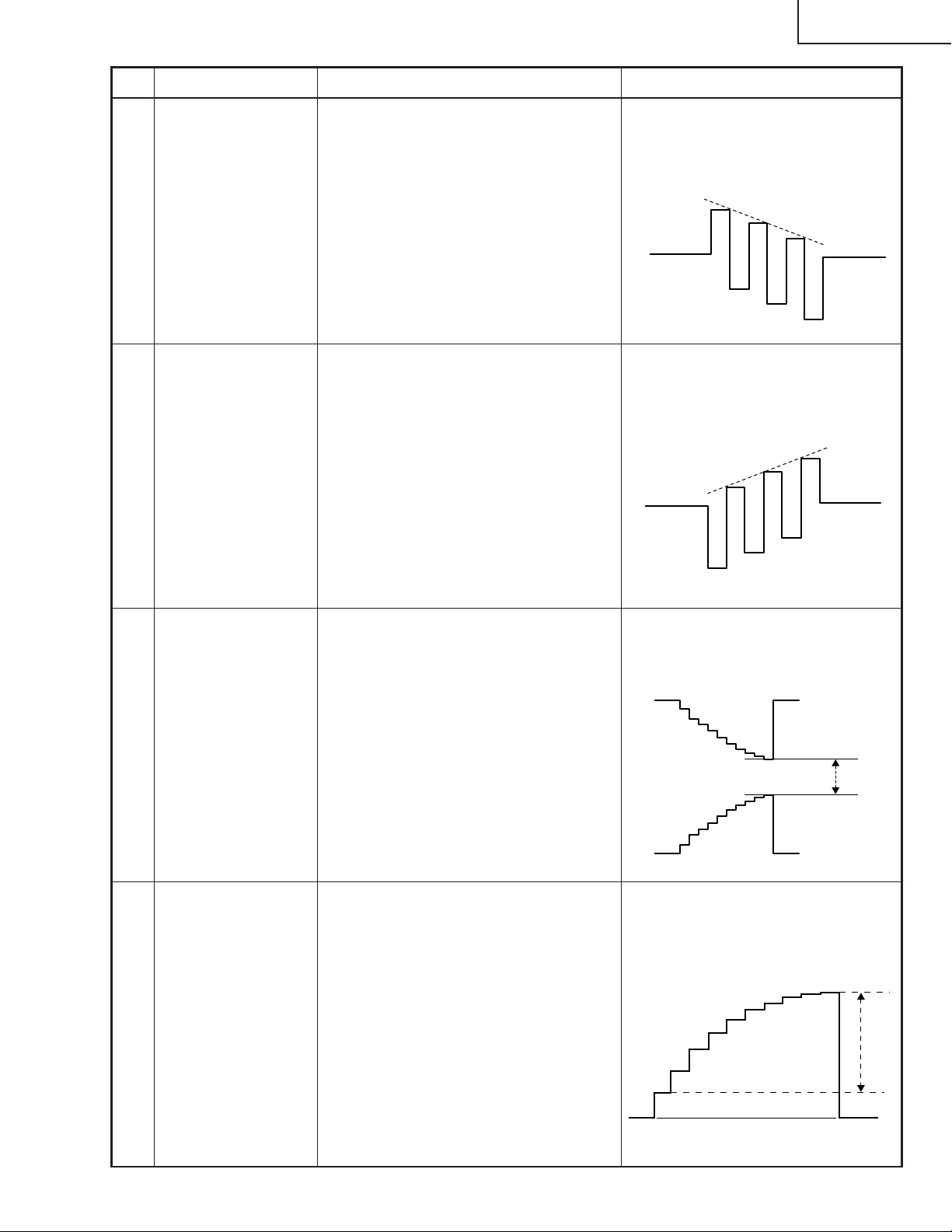

No. Adjustment Item Adjustment Conditions Adjustment Procedure

10

Tint (DAC)

11

Component tint

(DAC)

1. Receive the NTSC half-colour bar

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: TINT

3. Connect the dual-beam oscilloscope

between pin (5) of P803 and GND.

1. Feed the NTSC half-colour bar signal

to the component terminal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-TINT

3. Connect the dual-beam oscilloscope

between pin (3) of P803 and GND.

• Using the ' and " keys, adjust the

(B-Y) signal waveform to slope down

straight.

• Using the ' and " keys, adjust the

(B-Y) signal waveform to slope down

straight.

12

Sub-bias (DAC)

(gamma

correction on)

13

R-drive

B-drive

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: SUB-BIAS

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (3)(R) (or pin (1)(B)) of

P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: R-DRIVE, B-DRIVE

• Using the ' and " keys, adjust the

difference between the white levels

to 3.0±0.05 Vp-p.

• Using the ' and " keys, adjust the

difference between the first-step

level and the tenth-step level to

2.0±0.05 Vp-p.

19

Page 20

XV-C100A/M/E

No. Adjustment Item Adjustment Conditions Adjustment Procedure

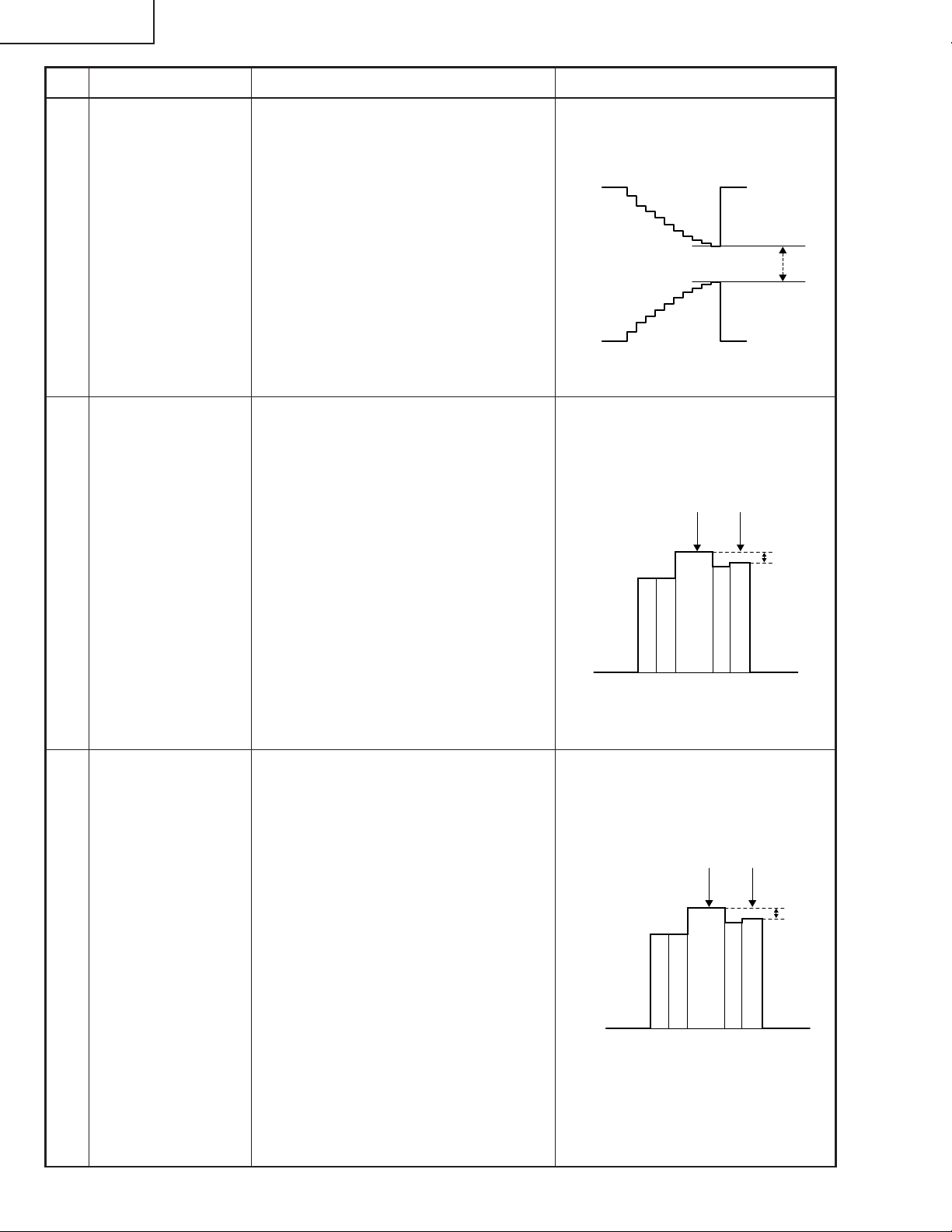

14 • Using the ' and " keys, adjust the

R-bias

B-bias

15

NTSC colour

(DAC) (gamma

correction on)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (3)(R) (or pin (1)(B)) of

P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: R-BIAS, B-BIAS

1. Receive the NTSC half-colour bar

signal.

2. Connect the dual-beam oscilloscope

between pin (3) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: COLOR

difference between the white levels

to 3.0±0.05 Vp-p.

• Using the ' and " keys, adjust the

difference between the 100% white

level and the primary red level to

0±0.05 Vp-p.

100% white

Primary red

16

PAL colour

(DAC) (gamma

correction on)

1. Receive the P AL half-colour bar signal.

2. Connect the dual-beam oscilloscope

between pin (3) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: P-COLOR

20

• Using the ' and " keys, adjust the

difference between the 100% white

level and the primary red level to

0.10±0.05 Vp-p.

100% white

Primary red

Page 21

XV-C100A/M/E

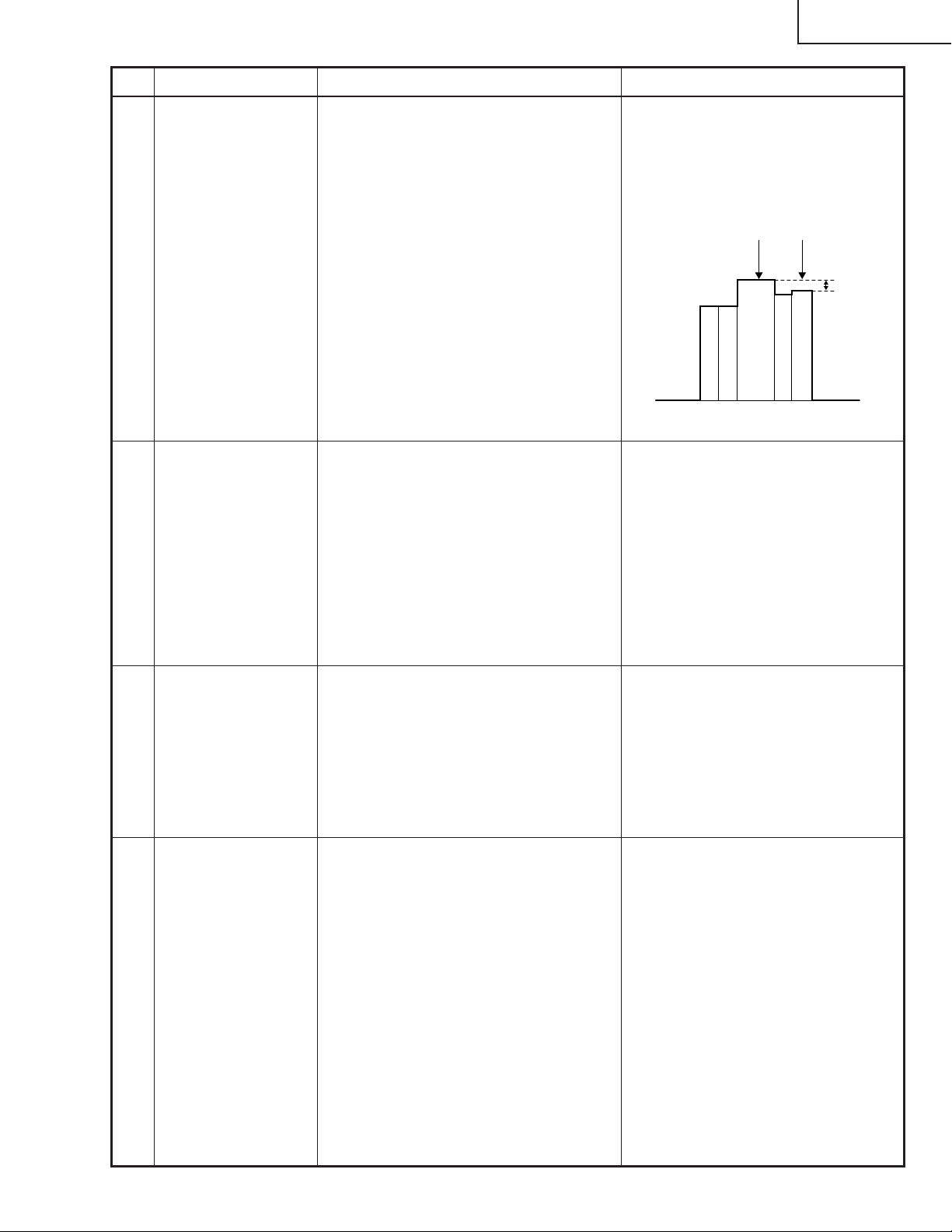

No. Adjustment Item Adjustment Conditions Adjustment Procedure

17

SECAM colour

(DAC) (gamma

correction on)

18

Component

colour (DAC)

1. Receive the SECAM half-colour bar

signal.

2. Connect the dual-beam oscilloscope

between pin (3) of P1401 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: S-COLOR

1. Feed the NTSC half-colour bar signal

to the component terminal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-COLOR

• Using the ' and " keys, adjust the

difference between the 100% white

level and the red level to 0.10±0.05

Vp-p.

100% white

• Make sure that the setting is 12.

Primary red

19

Counter-bias

(R1402)

20

White balance

(DAC)

1. Receive the NTSC monoscope pattern

signal.

1. Receive the NTSC monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 2

Subject: R-BIAS, B-BIAS

• Turn R1402 until the best contrast

is achieved.

• Using the ' and " keys, visually

adjust the white balance to best

position.

21

Page 22

XV-C100A/M/E

No. Adjustment Item Adjustment Conditions Adjustment Procedure

21

On-screen

display position

check (L2003)

22

Temperature

sensor setting

check

1. Receive the NTSC monoscope pattern

signal.

2. Press the SOUND UP/DOWN keys to

get the sound volume display bar on

the screen.

1. Press S2001 to call up the ADJ IN

mode and select the following group.

Group: SET

Subject: HL

• Turn L2003 so that the display bar

be well centered on the screen.

• Make sure that the setting is 2.

23

Component

horizontal

center (NTSC)

(DAC)

24

Component

horizontal

center (PAL)

(DAC)

1. Receive the NTSC monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-H-CENT

1. Receive the PAL monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group: VIDEO 4

Subject: C-PH-CENT

• Using the ' and " keys, make the

overscan just the same at right and

left.

Overscan : 91-97%

• Using the ' and " keys, make the

overscan just the same at right and

left.

Overscan : 91-97%

22

Page 23

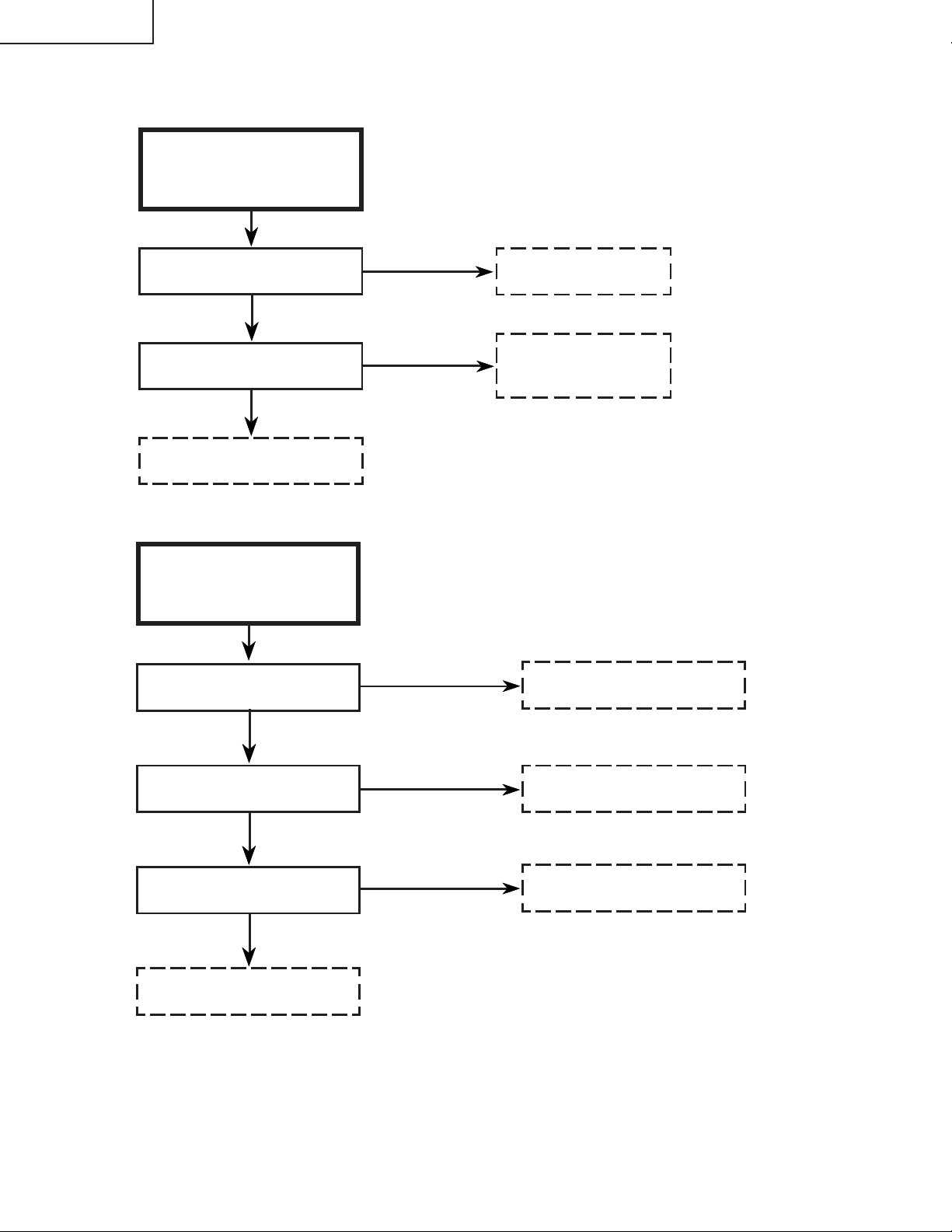

TROUBLE SHOOTING TABLE

Checking the video system

No picture

XV-C100A/M/E

Check the power unit.

Check IC401, DL401 and their

peripheral circuits.

No

No

Is the lamp on?

Yes

Is voltage applied at the EA

and EB connectors?

Yes

Is there signal at pins (21) and

(29) of IC801?

Yes

Is there signal at pins (1), (2) and (3)

of P803?

Yes

Go to "Checking the IC1501

interface circuit".

No

Check the lamp.

Check the ballast unit circuit.

No

Check IC801, IC804, Q801, Q802,

Q803 and their peripheral circuits.

No colour or poor tint with

NTSC signal

Is there chroma signal input at pin

(20) of IC801?

Yes

Check IC801, IC802, IC804 and their

peripheral circuits (X801 and C810 in

particular).

23

No

Check DL401, IC401, Q401 and their

peripheral circuits.

Page 24

XV-C100A/M/E

TROUBLE SHOOTING TABLE (Continued)

No colour or poor

tint with PAL

signal

Is there video signal input at pin (29)

of IC801?

Yes

Are R-Y and B-Y signals put out of

pins (45) and (46) of IC801?

Yes

Check IC802, IC804 and their

peripheral circuits.

No colour or poor

tint with SECAM

signal

Is there chroma signal input at pin

(20) of IC803?

No

No

No

Check IC401 and its

peripheral circuits.

Check IC801 and its

peripheral circuits (X802 and

C811 in particular).

Check IC401 and its peripheral

circuits.

Yes

Are there R-Y and B-Y signal outputs

at pins (11) and (12) of IC803?

Yes

Is voltage of over 4V fed to pin (49)

of IC801?

Yes

Check IC801, IC802, IC804 and their

peripheral circuits.

No

No

Check IC803 and its peripheral

circuits.

Check IC803 and its peripheral

circuits.

24

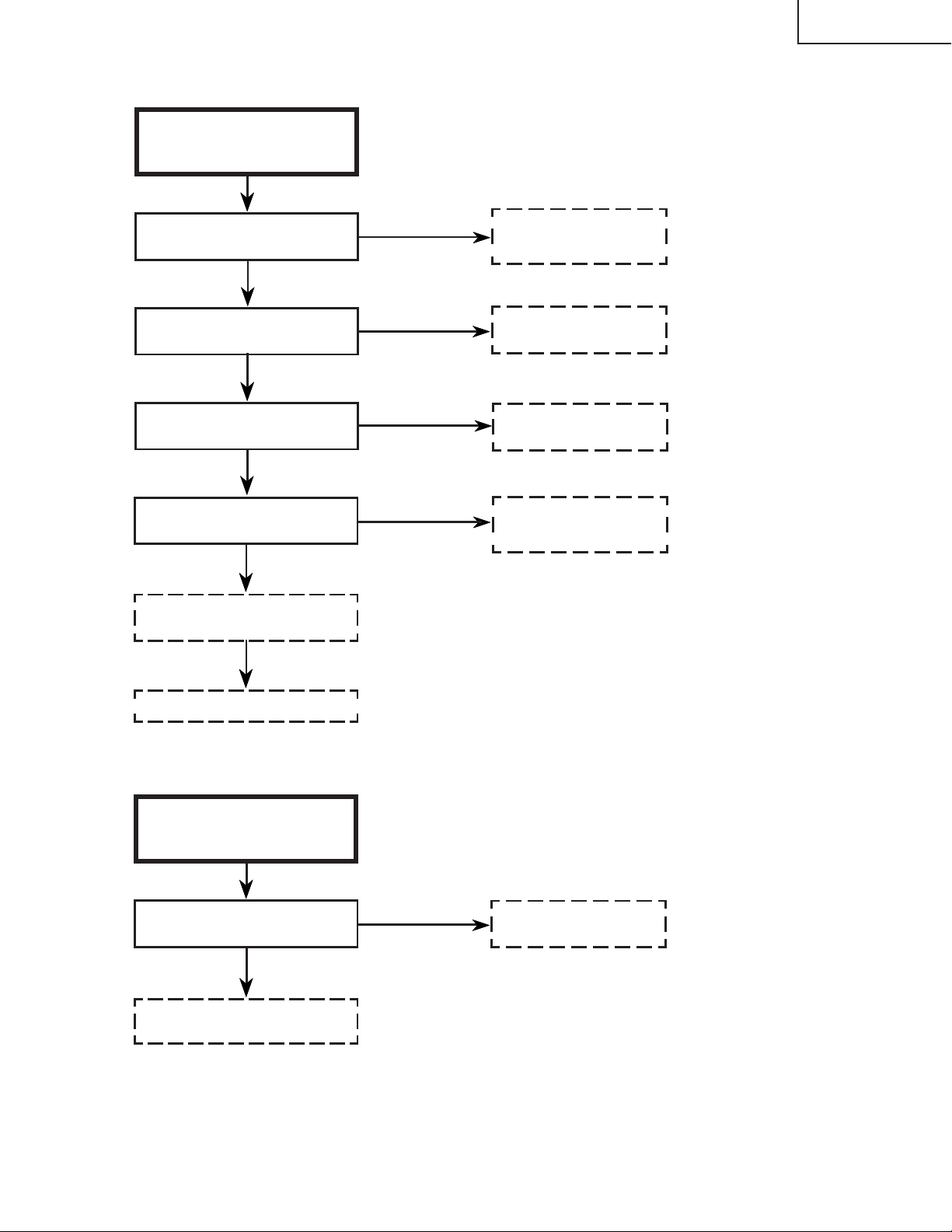

Page 25

TROUBLE SHOOTING TABLE (Continued)

No component

picture

XV-C100A/M/E

Is there Y signal input at pin (35) of

IC3003?

Yes

Are there signal inputs at pins (13)

and (14) of IC3003?

Yes

Are there signal outputs at pins (44),

(45) and (46) of IC3003?

Yes

Are there signal inputs at pins (35),

(36) and (37) of IC801?

Yes

Check IC801 and its peripheral

circuits.

No

No

No

No

Check Q3001, Q3020,

Q3021 and their peripheral

circuits.

Check IC2001 and its

peripheral circuits.

Check IC3003 and its

peripheral circuits.

Check C830, C831, C832

and their peripheral circuits.

Check the IC1501 interface circuit.

No component

colour

Are there signal inputs at pins (33)

and (34) of IC3003?

Yes

Check IC3003 and its peripheral

circuits.

No

Check Q3006 thru Q3013

and Q3007 thru Q3010.

25

Page 26

XV-C100A/M/E

TROUBLE SHOOTING TABLE (Continued)

No horizontal sync

Is there horizontal drive signal output

at pin (56) of IC801?

Yes

Are video signal at pin (21) or (29) of

IC801 and horizontal drive signal at

pin (58) of IC801 in sync with each

other?

Yes

Is there horizontal sync signal output

at pin (10) of IC503?

Yes

Is there composite sync signal output

at pin (4) of IC504?

Yes

Check IC1603, IC1607, IC1608 and

all located on the control PWB. Check

also their peripheral parts.

No

No

No

No

Check pins (17) and (18)

of IC801, IC501 and their

peripheral circuits.

Check pins (58) and

(59) of IC801 and their

peripheral parts.

Check IC503 and its

peripheral circuits.

IC504 defective.

No vertical sync

Is there vertical sync signal output at

pin (4) of IC801?

Yes

Is there vertical sync signal input at

pin (11) of IC502?

Yes

Is there vertical sync signal output at

pin (10) of IC502?

Yes

Check IC1606 and its peripheral

parts.

26

No

No

No

Check IC801 and its

peripheral circuits.

Check Q827.

Check IC502 and its

peripheral parts.

Page 27

TROUBLE SHOOTING TABLE (Continued)

Checking the IC1501

interface circuit

XV-C100A/M/E

Are there video signal outputs at pins

(32), (34) and (36) of IC1501?

Yes

Check Q1501, Q1502, Q1503,

Q1504, Q1505 and Q1506.

Lamp Failure to Light Up

Remove Q1701. Does F1701 break

down again?

No

No

Check the voltages of all the

IC1501 pins. Check also their

peripheral circuits.

Yes

Power unit in trouble.

No problem with fuse

Is discharging sound heard?

Replace

T1702 or

lamp.

Check trigger

circuit.

Ballast unit in trouble.

No

Fuse blown-out

Do Q1701 and L1701 break down in

the short-circuit mode?

NoYesYes

Replace

Q1701 and

L1701.

Check Q1701,

L1701 and their

peripheral circuits.

27

Page 28

XV-C100A/M/E

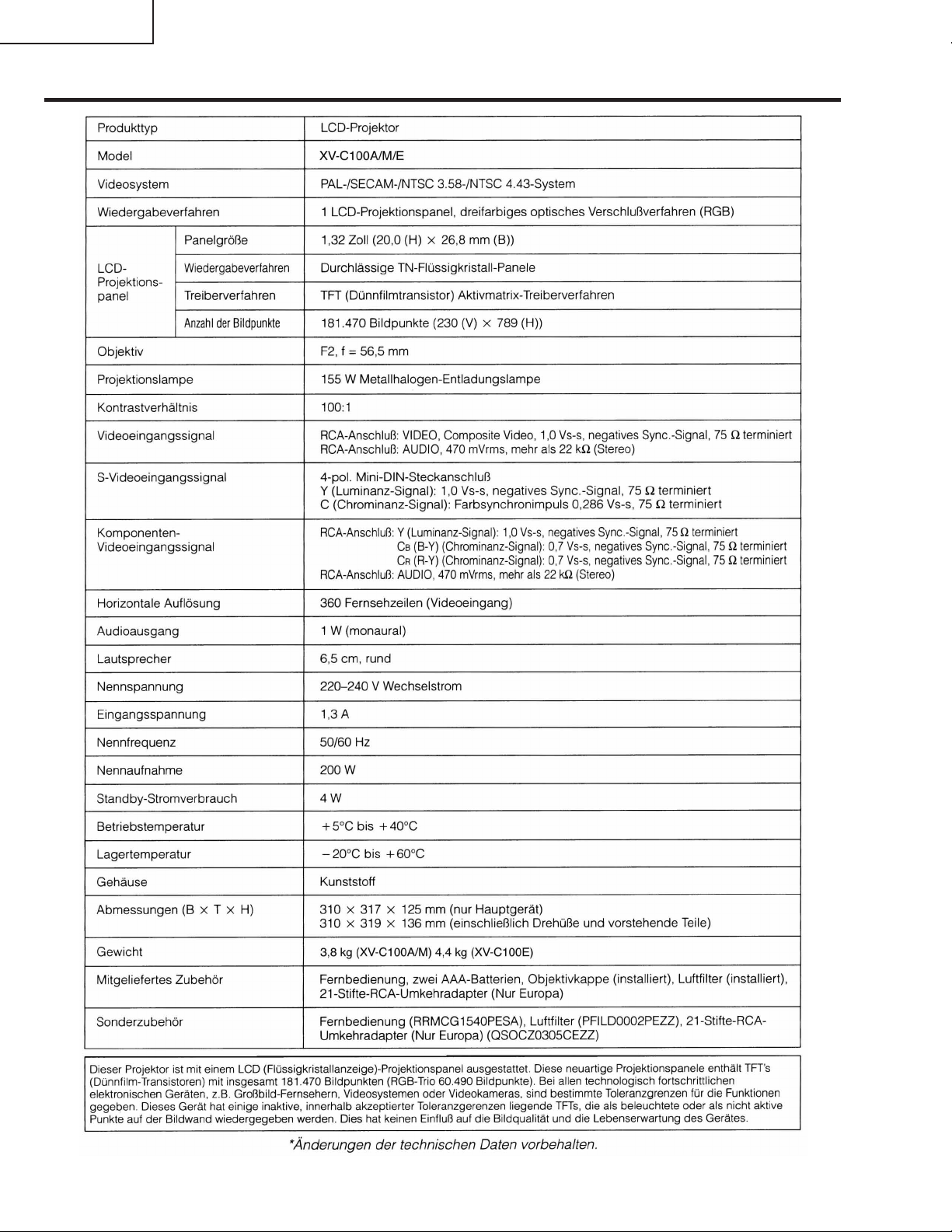

Technische Daten

28

Page 29

HINWEIS FÜR DAS WARTUNGSPERSONAL

ACHTUNG: UV-STRAHLUNG

XV-C100A/M/E

Die Lichtquelle im LCD-Projektor, eine MetallHalogen-Lampe, gibt eine geringe UV-Strahlung ab.

DIREKTE BESTRAHLUNG AUF AUGEN

UND HAUT MUSS VERMIEDEN WERDEN.

Zur Gewährleistung der Sicherheit muß folgendes

beachtet werden:

1. Bei Arbeiten am Projektor bei eingeschalteter

Lampe und abgenommenem oberen Gehäuse

muß unbedingt eine Sonnenbrille getragen

werden.

2. Die Lampe darf nicht außerhalb des

Lampengehäuses eingeschaltet werden.

3. Betrieb für länger als 2 Stunden bei

abgenommenem Gehäuse ist nicht zulässig.

Zur Beachtung bei UV-Strahlung

und Mitteldruck-Lampen

1. Vor dem Auswechseln der Lampe muß der

Netzstecker gezogen werden.

2. Vor Durchführung von Wartungsarbeiten muß das

Gerät eine Stunde abkühlen.

3. Die Lampe darf nur gegen eine der gleichen Art

ausgewechselt werden. Typ CLMPF0053DE03,

bemessen für 65V/155W.

4. Die Lampe gibt eine geringe UV-Strahlung ab,

daher muß direkter Augenkontakt vermieden

werden.

5. Die Mitteldruck-Lampe weist ein Explosionsrisiko

auf. Daher müssen die nachstehenden

Installationsanweisungen beachtet werden, und

die Lampe muß vorsichtig behandelt werden.

ËAuswechseln der Lampe

Hinweis:

Da die Lampe während des Betriebs sehr heiß wird,

sollte die Lampe erst ausgewechselt werden, nachdem

das Gerät mindestens eine Stunde ausgeschaltet war,

damit die Lampe ausreichend abkühlen kann.

Beim Installieren der neuen Lampe muß darauf

geachtet werden, die Lampe selbst (Glaskolben)

nicht zu berühren. Vielmehr muß die Lampe am

Reflektor 2 gehalten werden.

[Es darf nur ein Original-Ersatzteil verwendet

werden.]

Lampe

1

2

GEFAHR! — Niemals die Spannungsversorgung

einschalten, ohne daß eine Lampe vorhanden ist,

um elektrische Schläge und Schäden am Gerät zu

vermeiden, da der Stabilisator anfangs hohe

Spannungen erzeugt.

29

Reflektor

Page 30

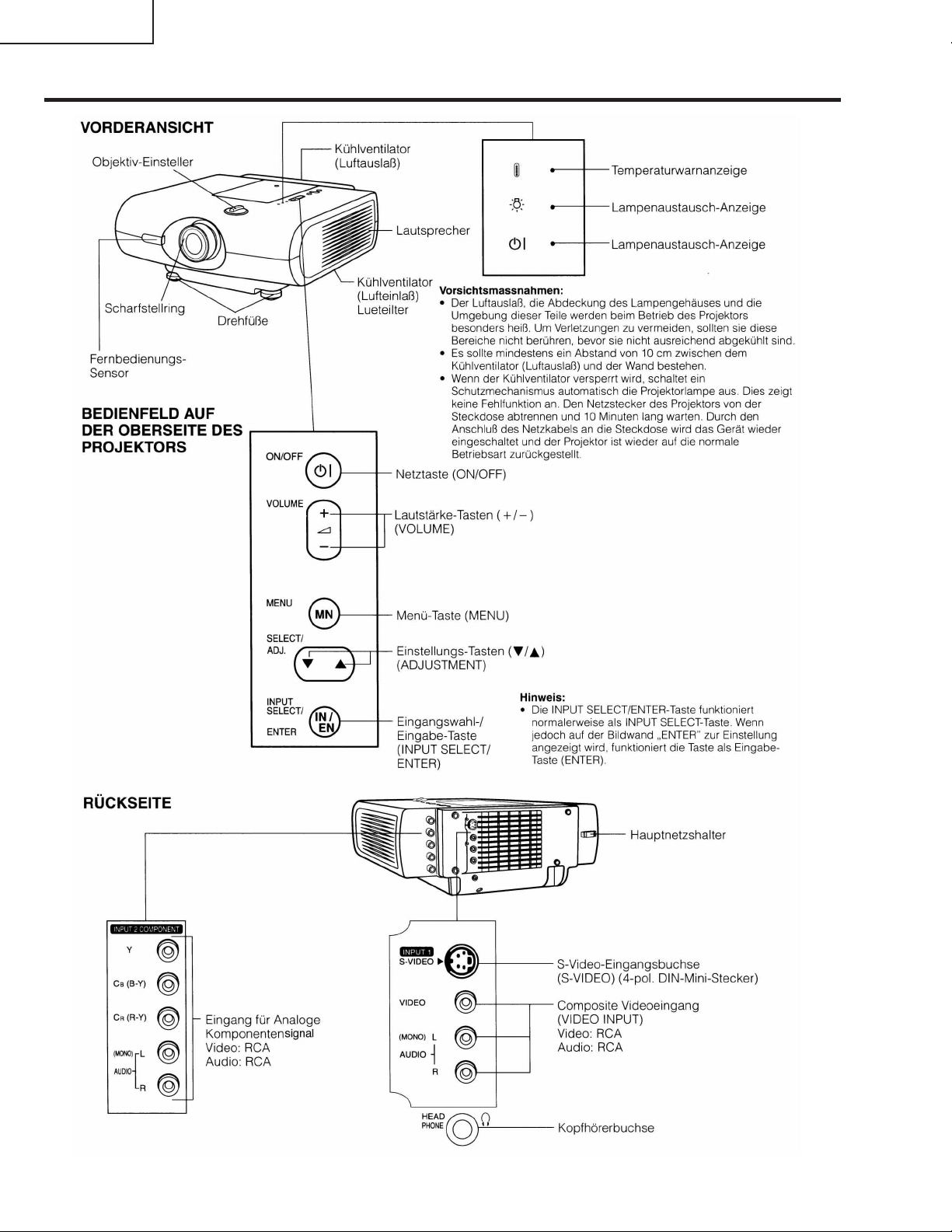

XV-C100A/M/E

Lage der Bedienelemente

30

Page 31

Fernbedienter Betrieb

XV-C100A/M/E

31

Page 32

XV-C100A/M/E

Abmessungen

32

Page 33

XV-C100A/M/E

ENTFERNEN DER HAUPTKOMPONENTEN

1. Entfernen der Gehäuse

1-1. Die Schraube herausdrehen, dann die Abdeckung des Glühlampengehäuses abnehmen.

1-2. Die beiden Sicherungsschrauben (zwei 4-mm-Schrauben) aus dem Glühlampen-/Gehäusemodul

herausdrehen.

1-3. D en O bjektiv-Schaltregler soweit verstellen, bis das Objektiv fast bis an die Mitte der Objektivöffnung im

vorderen Gehäuse heranreicht.

1-4. Die sechs Schrauben (sechs 3 mm Gewindeschneidschrauben) vom hinteren Gehäuse entfernen.

1-5. Die M3-Blechschraube aus der Zusatzeinheit-Abdeckung herausdrehen.

1-1

Glühlampengehäuse

1-2

Lampen/Käfig-Moduleinheit

Hinteres Gehäuse

1-3

1-6. Die Abdeckung des Luftfilters entfernen.

1-7. Die fünf Schneidschrauben von der Bodenplatte losdrehen.

1-7

Unteres Gehäuse

1-6

Luftfilterabdeckung

1-4

1-5

1-7

33

Page 34

XV-C100A/M/E

Oberes Gehäuse

1-8

1-8. Nun das obere Gehäuse weiter anheben und die Blattschalter-

Steckverbinder (LL) sowie den Flachkable-Steckverbinder (KE) der

Betriebseinheit abtrennen. Damit ist das obere Gehäuse frei.

1-9. Den Steckverbinder (PE) des Wechselstromkabels (das durch das

hintere Gehäuse vom Vorschaltelement verläuft) abtrennen. Das

hintere Gehäuse abnehmen.

1-10. Das Abstandsstück entfernen.

1-11. Die Schrauben von dem Lensenabdeckung losdrehen.

1-12.Den Stecker des Lautsprechers (SP) abziehen, dann die drei

Sicherungsschrauben entfernen. Die Schraube des Massekabels

herausdrehen; danach die Seitenabdeckung abnehmen.

1-10

Hinteres Gehäuse

1-9

(PE)

1-12

(SP)

1-11

Lensenabdeckung

1-12

Seitliche Abdeckung

Einbauverfahren

1. Die Lensenabdeckung und die Seitenabdeckung auf die Bodenplatte einpassen. Die erforderliche Schrauben

festziehen.

2. Das obere Gehäuse auf dem unteren Gehäuse aufsetzen.

3. Die M3-Blechschraube an der Zusatzeinheit-Abdeckung wieder festziehen.

4. Danach das hintere Gehäuse gegen das obere und untere Gehäuse drücken, um diese anzupassen.

5. Die Schrauben am hinteren Gehäuse festziehen. Die vier 3-mm-Blechschräuben und eine M2.5Maschinenschraube benutzen. Niemals Blechschrauben in das M2.5-Schraubenloch eindrehen. Die

Schraubenwindungen Können dadurch zerstört werden.

6. Die Blechschrauben für die Befestigung des oberen und unteren Gehäuses festziehen.

7. Das Glühlampen-/Gehäusemodul einsetzen; danach die beiden 4-mm-Schrauben festziehen.

8. Die Abdeckung des Glühlampengehäuses anbringen und die Schrauben festziehen.

34

Page 35

XV-C100A/M/E

2. Entfernen der gedruckten Leiterplatten-

2-1. Die Netzeinheit, die Ballasteinheit, die Haupteinheit und die in Richtung der entsprechenden Pfeile herausziehen.

Die Steckverbinder abtrennen.

2-2. Die drei Schrauben herausdrehen, die beiden Klebebänder abziehen, dann die Bedienungstasten-Einheit

herausnehmen.

2-3. Die Schrauben von der Ausgangseinheit, Bedienungstasteneinheit sowie Fernbedienungseinheit losdrehen.

Die Steckverbinder trennen.

2-4. Die Tastenabdeckung entfernen.

3. Entfernen der Flüssigkristalldisplay-Moduleinheit

3-1. Die Schraube von der Tafel-Abdeckung entfernen. Die T afel-

Abdeckung herausnehmen.

3-2. Die Flüssigkristalldisplay-Moduleinheit langsam aus ihrer

Position hochziehen.

Bedientasteneinheit

2-2

TafelAbdeckung

3-2

2-3

2-3

3-1

LCDModuleinheit

InfrarotEmpfängereinheit

Steuereinheit

2-1

2-4

Ballasteinheit

2-3

Oberes Gehäuse

2-1

Netzeinheit

Haupteinheit

Signaleinheit

2-3

35

2-1

Untereinheit

Page 36

XV-C100A/M/E

4. Entfernen der Optikmechanismus-Baugruppe

4-1. Die fünf Schrauben von der Optikmechanismus-Baugruppe entfernen. Die Baugruppe vom unteren Gehäuse

abnehmen.

4-2. Die vier Schrauben an der Lufteinlaßführung herausdrehen. Die Lufteinlaßführung vom unteren Gehäuse

abnehmen.

4-3. Die beiden Schrauben vom Kühlgebläse entfernen.

5.Ausbau der Lampe

5-1. Die drei Versenkschrauben von den oberen und

unteren Lampengehäusen losdrehen.

5-2. Die Arretierschraube und die Mutter vom

Lampenanschluß losdrehen.

5-3. Die Lampen-Arretierfeder aus dem Haken unter

dem Lampengehäuse lösen. Nun die Lampen/Spiegeleinheit herausnehmen.

5-2

Lampen-/

Spiegeleinheit

Unteres Lampengehäuse

5-3

4-3

5-2

Lampen/KäfigModuleinheit

Oberes

Lampengehäuse

5-1

5-1

5-1

Optikmechanismus-

Bau gruppe

Untere GehäuseBaugruppe

Kühlgebläse

(Entlüftungsöfnung)

4-2

4-1

Einlaßkanal-Baugruppe

36

Page 37

Optikeinheit

PCAPH1061CESB

Objektivdeckel

Flüssigkristalldisplay

RLCDP0088CEZZ

OPTIKSYSTEM

Polarisator-Eingangsplatte

PFiLW0164CEZZ

PFiLW0202CEZZ

PFiLW0194CEZZ

Ultraviolett-/Infrarotfilter

Wärmesenke

XV-C100A/M/E

PFiLW0200CEZZ

PLNS-0124CEZZ

Projektionsobjektiv

Beugungsgitter

Reinigung der Objektive und Reflektoren

1. Objektivreiniger

• Reinigungsflüssigkeit:

Das Mischverhältnis von Alkohol und Äther entsprechend der

Umgebungstemperatur wählen. Sicherstellen, daß die Flüssigkeit

unmittelbar nach dem Wischen von der Oberfläche der Linsen

verdampft, dieses ist dann das beste Verhältnis. Je mehr Äther

verwendet wird, desto schneller verdampft die Flüssigkeit.

• Methode:

Ein gut gespültes, gebleichtes Baumwolltuch oder im Fachhandel

erhältliches Reinigungspapier verwenden. Das gebleichte

Baumwolltuch mit der Flüssigkeit befeuchten, und die Linse im Tuch

zwischen Daumen und Zeigefinger halten. Die Linse drehen, und

seine Oberfläche von der Mitte nach außen wischen, um Staub zu

entfernen. Darauf achten, die vergütete Oberfläche nicht zu stark zu

reiben.

CLMPF0053DE03

Lampe/Reflektor-Baugruppe

37

Page 38

XV-C100A/M/E

Ë

Kontrolle der Gesamtbetriebsstunder der Lampe

Die folgende Kontrolle wird durchgeführt, wenn die Lampe 1900 Stunden und 2000 Stunden verwendet wurde.

1. Nach 1900 Stunden Verwendung

Beim Einschalten der Spannungsversorgung erscheint "LAMP" für etwa 1 Minute (blinkt gelb) auf der BildschirmAnzeige, und die Lampen-LED leuchtet rot.

Wenn die Betriebszeit von 1900 Stunden während der V erwendung des Geräts erreicht wird, blinkt die Anzeige

"LAMP" gelb auf dem Bildschirm für 1 Minute genau zur Betriebszeit von 1900 Stunden.

Dann wechselt die Lampen-LED von grün zu rot.

2. Nach 2000 Stunden Verwendung

Wenn die Spannungsversorgung eingeschaltet wird, erscheint "LAMP" für 5 Minuten (blinkt rot) auf der BildschirmAnzeige, und die Lampen-LED leuchtet rot. Fünf Minuten danach wird die Spannungsversorgung automatisch

ausgeschaltet und der Betrieb des Geräts unterbrochen. Wird die Betriebszeit von 2000 Stunden während der

Verwendung des Geräts erreicht, blinkt "LAMP" für 5 Minuten rot auf dem Bildschirm genau zur Betriebszeit von

2000 Stunden. Fünf Minuten später wird die Spannungsversorgung automatisch ausgeschaltet und der Betrieb

des Geräts unterbrochen. (Die Lampen-LED leuchtet seit dem Erreichen der Betriebszeit von 1900 Stunden

ständig rot.)

Wenn nach der 2000-Stunden-Betriebszeit zweimal versucht wird, die Spannungsversorgung einzuschalten,

bleibt das Gerät ausgeschaltet.

3. Bei Erreichen der 2000-Stunden-Betriebszeit die folgenden Schritte durchführen.

Die Lampe gegen eine neue auswechseln. Beide Tasten "VOLUME "" und "SELECT/ADJ "" am Gerät gedrückt

halten und dabei den Hauptnetzschalter (an der Rückseite des Geräts) einschalten. Dadurch wird der LampenBetriebsstundenzähler auf null zurückgestellt. Das Gerät einschalten und sicherstellen, daß "0000H" auf der

Zeit-Anzeige angezeigt wird.

4. Anzeige der Gesamtbetriebsstunden der Lampe

Die ST ATUS3-Dateneinstellungen ändern: PICTURE auf 0, BRIGHT auf MAX, COLOR auf MIN, TINT auf MIN

und SHARPNESS auf MAX. Die Tasten SOUND DOWN und ENTER für mindestens 2 Sekunden gedrückt

halten. Dadurch werden die Gesamtbetriebsstunden auf dem Bildschirm angezeigt.

ZEIT

0000H

GESAMTZEIT

0000H

38

Page 39

XV-C100A/M/E

FUNKTION ADJ IN (Eingangseinstellung)

1. Tasten für die Einstellung

An der Neben-Leiterplatte: S2001

Steuertasten: [ENTER], [MENU], [SELECT/ADJ.'], [SELECT/ADJ."], [VOLUME+],

2. Bedienung

S2001 drücken, um den ADJ IN-Modus abzurufen.

Mit den Tasten [SELECT/ADJ. '] und [SELECT/ADJ."] eine Einstellungsgruppe wählen, dann die

Taste [ENTER] drücken.

Erneut mit den Tasten [SELECT/ADJ. '] und [SELECT/ADJ."] ein Einstellungselement wählen, dann

wieder die Taste [ENTER] drücken.

Die Tasten [SELECT/ADJ. '] und [SELECT/ADJ."] dienen außerdem zum Durchführen der

Einstellungen.

Bei jeder Betätigung der Taste [ENTER] am ADJ IN-Bildschirm werden die Einstellungselemente einer

Gruppe nacheinander gewechselt. (Durch Drücken der Taste [VOLUME +] werden die Elemente in

umgekehrter Reihenfolge durchlaufen.)

Wenn die Taste [MENU] key is pressed, gedrückt wird, erscheint die vorherige Gruppe am Bildschirm.

S2001 erneut drücken, um den ADJ IN-Modus zu verlassen.

Gruppe

Einstellung

-selemente

VIDEO 1

H-CENT

P-H-CENT

CONT

BRIGHT

SUB-R

SUB-G

SUB-B

VIDEO 2

SUB-BIAS

R-BIAS

B-BIAS

R-DRIVE

B-DRIVE

TINT

COLOR

P-COLOR

S-COLOR

VIDEO 3

GAMMA1

GAMMA2

AGCADJ

T-BRT

VIDEO 4

C-CONT

C-BRIGHT

C-COLOR

C-TINT

C-H-CENT

C-PH-CENT

SET

HL

N • W

RED

GREEN

BLUE

N • W

Die Einstellgruppe “LINE” wird hier nicht verwendet.

Kein Signal zuführen, wenn die Einstellungsgruppe “N • W” verwendet wird.

LINE

AUTO

OFF TIMER

TEMP1

TEMP2

FACTORY SET4

TEST

TIME1

TIME2

39

Page 40

XV-C100A/M/E

3. Einstellelemente

VIDEO 1

H-CENT Einstellung der Horizontalposition für NTSC

P-H-CENT Einstellung der Horizontalposition für PAL-System

CONT Einstellung des Unterkontrastes

BRIGHT Einstellung der Helligkeit

SUB-R Nicht belegt, auf 0 (null) eingestellt

SUB-G Nicht verwendet, muß 0 (null) sein

SUB-B Nicht verwendet, muß 0 (null) sein

VIDEO 2

SUB-BIAS Einstellung der Unter-Vormagnetisierung

R-BIAS Weißbalance (rot), Einstellung der Vormagnetisierung

B-BIAS Weißbalance (blau), Einstellung der Vormagnetisierung

R-DRIVE Weißbalance (rot), Einstellung der Ansteuerung

B-DRIVE Weißbalance (blau), Einstellung der Ansteuerung

TINT TINT-Einstellung

COLOR Farbpegel-Einstellung

P-COLOR Farbpegel-Einstellung für PAL-System

S-COLOR Farbpegel-Einstellung für SECAM-System

VIDEO 3

GAMMA1 Gamma-Korrektur 1

GAMMA2 Gamma-Korrektur 2

AGC ADJ AGC-Einstellung

T-BRT Chroma-IC-Helligkeitseinstellung

VIDEO 4

C-CONT Kontrasteinstellung für Komponenten-Eingangssignal

C-BRIGHT Helligkeitseinstellung für Komponenten-Eingangssignal

C-COLOR Farbpegel-Einstellung für Komponenten-Eingangssignal

C-TINT Tönungseinstellung für Komponenten-Eingangssignal

C-H-CENT Einstellung der Horizontalposition für Komponenten-Eingangssignal am NTSC-System

C-PH-CENT Einstellung der Horizontalposition für Komponenten-Eingangssignal am PAL-System

SET

HL Einstellung des Temperaturerfassungspegels

N • W (Einfarbige Anzeige)

RED Rot

GREEN Grün

BLUE Blau

N • W Nicht verwendet

TEST

TIME1 Einstellung in 1-Stunden-Schritten für Gesamt-Glühlampen-Timer

TIME2 Einstellung 1899 h - 1999 h - 0 h - 1899 h für Gesamt-Glühlampen-Timer

40

Page 41

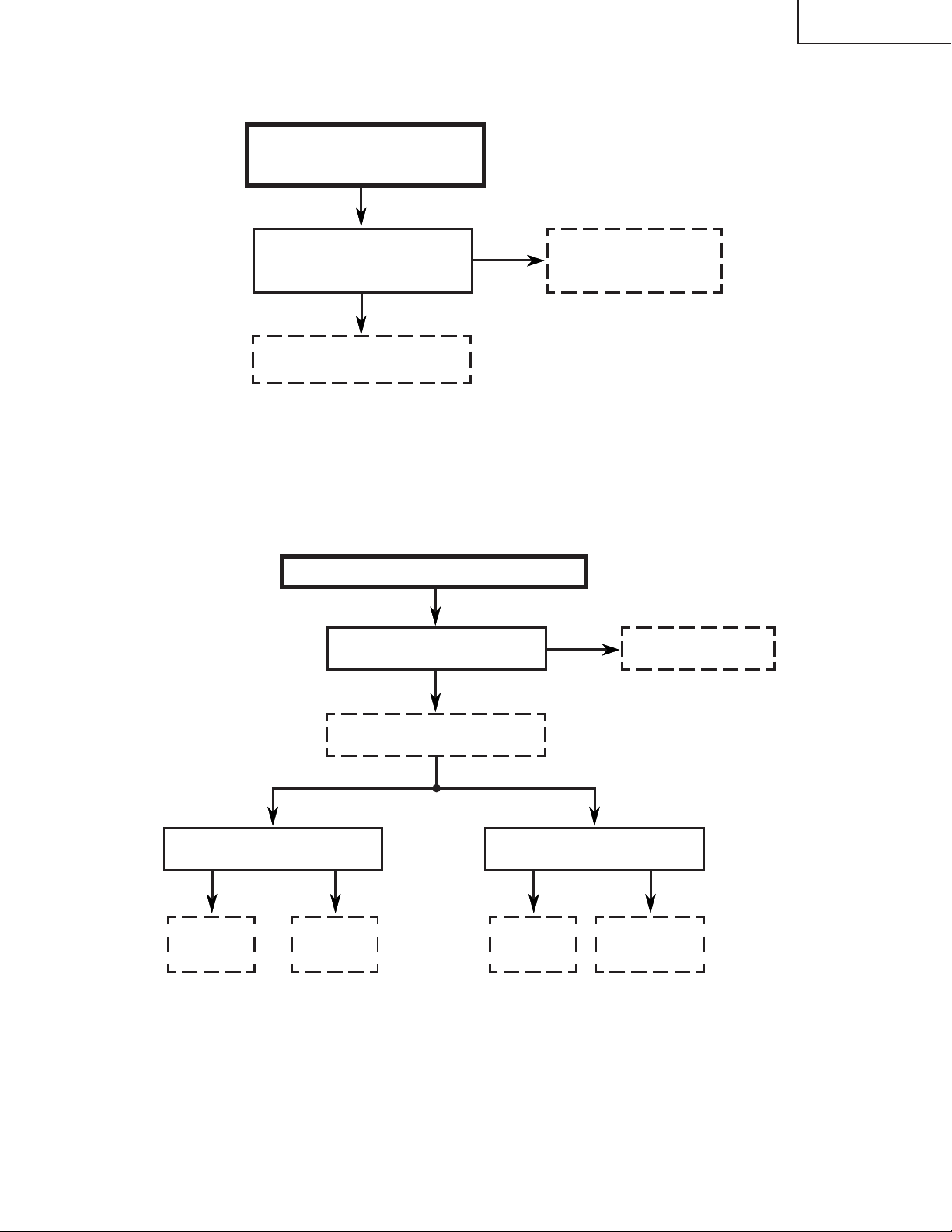

FLIESSDIAGRAMM DER EINSTELLUNGEN

–4

S-COLOR

–6

0

SUB-B

P-COLOR

+7

C-PH-CENT

HL

2

XV-C100A/M/E

0

SUB-G

0

SUB-R

–3

BRIGHT

+6

CONT

0

P-H-CENT

64

B-DRIVE

64

R-DRIVE

74

B-BIAS

74

R-BIAS

COLOR

TINT

T-BRT

ADJ

AGC

GAMMA2

–4

–3

–30

0

0

+5

C-H-CENT

+9

C-TINT

+7

C-COLOR

+5

C-BRIGHT

Not used

0000

TIME2

ENTER

H-CENT SUB-R

VIDEO1

H-CENT

MENU

P-H-CENT SUB-G

CONT SUB-B

–3

BRIGHT

64

SUB-BIAS

MENU

ENTER

TINT

COLOR

P-COLOR

S-COLOR

SUB-BIAS

R-BIAS

B-BIAS

VIDEO2

Anwendermodus-

R-DRIVE

Bildschirm

B-DRIVE

ENTER

S2001

ENTER

MENU

VIDEO1 SET

VIDEO2 N • W

ADJ IN

255

GAMMA1

MENU

GAMMA1

GAMMA2

AGC ADJ

VIDEO3

VIDEO3 LINE

VIDEO4 TEST

T-BRT

ENTER

C-PH-CENT

C-CONT

C-BRIGHT

VIDEO4

–4

C-CONT

MENU

C-COLOR

C-TINT

C-H-CENT

41

ENTER

N • W

R G B N • W

MENU

RED

GREEN

BLUE

N • W

LINE

AUTO

OFF TIMER

TEMP1

TEMP2

FACTORY SET 4

ENTER

Nicht belegt

TEST

TIME1

MENU

TIME1

TIME2

0001

Page 42

XV-C100A/M/E

ELEKTRISCHE EINSTELLUNG

Nr. Einstellgegenstand Einstellbedingungen Einstellverfahren

1

NTSCFreilauffrequenz

(R1616)

2

PALFreilauffrequenz

(R1602)

3

NTSCHorizontalzentrierung

(Digital/AnalogWandler)

4

PAL-Horizontalzentrierung

(Digital/AnalogWandler)

1. Das NTSC-Monoskopsignal

empfangen.

2. S801 gedrückt halten.

1. Das P AL-Monoskopsignal empfangen.

2. S801 gedrückt halten.

1. Das NTSC-Monoskopsignal

empfangen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 1

Element: H-CENT

1. Das P AL-Monoskopsignal empfangen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 1

Element: PAL-H-CENT

• R1616 drehen, bis das Bild nach

Spezifikation erscheint.

• R1602 drehen, bis das Bild nach

Spezifikation erscheint.

• Mit den Tasten ' und " die

Nutzflächenüberschreitung rechts

und links gleich einstellen.

Overscan: 91 - 97%

• Mit den Tasten ' und " die

Nutzflächenüberschreitung rechts

und links gleich einstellen.

Overscan: 91 - 97%

5

Kontrast

(Digital/AnalogWandler)

(Gammakorrektur

eingeschaltet)

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: S-BIAS

4. Mit den Tasten ' und " die

Wellenform auf die richtige Form

einstellen.

5. S2001 noch einmal drücken, um den

ADJ IN-Modus zu aktivieren, dann die

nachfolgende Position wählen.

Gruppe: VIDEO 1

Element: SUB-R, SUB-G, SUB-B

Sicherstellen, daß diese Elemente alle

den Eintrag 0 (null) aufweisen.

6. R861 so einstellen, daß die größte

Verstärkung erhalten wird.

7. Gruppe: VIDEO 1

Element: CONT

• Mit den Tasten ' und " den

Unterschied zwischen dem 10Stufenpegel und dem Austastpegel

auf 6,0 ±0,15 Vs-s einstellen.

10

42

Page 43

Nr. Einstellgegenstand Einstellbedingungen Einstellverfahren

XV-C100A/M/E

6

Automatische

Verstärkungsregelung: R861

(Gammakorrektur

ausgeschaltet)

7

Kontrast (D/AWandler)

(Gammakorrektur

aus)

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1401 und GND

anschließen.

3. Den nachfolgenden Gegendstand

wählen.

Gruppe: VIDEO 1

Gegenstand: CONT

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 1

Element: BRIGHT

• R861 drehen, so daß die Differenz

zwischen dem 100 % Weißpegel und

dem Austastpegel auf 4,8 ±0,05 Vss

beträgt.

• Mit den Tasten ' und " die

Differenz zwischen dem Pegel der

ersten Stufe und dem 100 %

Weißpegel auf 2,0 ±0,05 Vss

einstellen.

1

10

10

8

KomponentensignalKontrast (DAC)

(Gammakorrektur

aus)

9

KomponentensignalHelligkeit (DAC)

(Gammakorrektur

aus)

1. Ein NTSC-10-Stufen-Testbildsignal

dem Komponentensignal-Anschluß

zuführen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 4

Element: C-CONT

1. Ein NTSC-10-Stufen-Testbildsignal

dem Komponentensignal-Anschluß

zuführen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1402 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 4

Element: C-BRIGHT

• Mit den Tasten ' und " die

Differenz zwischen dem 100 %

Weißpegel und dem Austastpegel

auf 4,8 ±0,05 einstellen.

10

• Mit den Tasten ' und " die

Differenz zwischen dem Pegel der

ersten Stufe und dem 100 %

Weißpegel auf 2,0 ±0,05 Vss

einstellen.

1

10

43

Page 44

XV-C100A/M/E

Nr.

Einstellgegenstand Einstellbedingungen Einstellverfahren

10

Farbton (Digital/

AnalogWandler)

11

KomponentensignalTönung

(DAC)

1. Das NTSC-Halbfarbbalkensignal

empfangen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: TINT

3. Das Doppelstrahl-Oszilloskop

zwischen Stift (5) von P803 und GND

anschließen.

1. Ein NTSC-Halbfarbbalkensignal dem

Komponentensignal-Anschluß

zuführen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 4

Element: C-TINT

3. Das Doppelstrahl-Oszilloskop

zwischen Stift (3) von P803 und GND

anschließen.

• Mit den Tasten ' und " die

Signalwellenform (B-Y) auf eine

gerade Abwärtsflanke einstellen.

• Mit den Tasten ' und " die

Signalwellenform (B-Y) auf eine

gerade Abwärtsflanke einstellen.

12

UnterVormagnetisierung (Digital/

AnalogWandler)

(Gammakorrektur

eingeschaltet)

13

R-Ansteuerung

B-Ansteuerung

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (2) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: SUB-BIAS

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Ein Doppelstrahl-Oszilloskop zwischen

Stift (3) (R) [oder Stift (1) (B)] von

P1401 und der Masse (GND)

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: R-DRIVE, B-DRIVE

• Mit den Tasten ' und " die

Differenz zwischen den Weißpegeln

auf 3,0 ±0,05 Vss einstellen.

• Mit den Tasten ' und " die

Differenz zwischen dem Pegel der

ersten Stufe und dem Weißpegel

auf 2,0 ±0,05 Vss einstellen.

44

Page 45

Nr. Einstellgegenstand Einstellbedingungen Einstellverfahren

XV-C100A/M/E

14 • Mit den Tasten ' und " die

R-Vormagnetisierung

B-Vormagnetisierung

15

NTSC-Farbe

(Digital/AnalogWandler)

(Gammakorrektur

eingeschaltet)

1. Das 10stufige NTSC-Mustersignal

empfangen.

2. Ein Doppelstrahl-Oszilloskop zwischen

Stift (3) (R) [oder Stift (1) (B)] von

P1401 und der Masse (GND)

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: R-BIAS, B-BIAS

1. Das NTSC-Halbfarbbalkensignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (3) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: COLOR

Differenz zwischen den Weißpegeln

auf 3.0 ±0,05 Vss einstellen.

• Mit den Tasten ' und " die

Differenz zwischen dem 100 %

Weißpegel und dem Rotpegel auf

0±0,05 Vss einstellen.

100 % weiß

Primärrot

16

PAL-Farbe

(Digital/AnalogWandler)

(Gammakorrektur

eingeschaltet)

1. Das PAL-Halbfarbbalkensignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (3) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: P-COLOR

45

• Mit den Tasten ' und " die

Differenz zwischen dem 100 %

Weißpegel und dem Rotpegel auf

0,10 ±0,05 Vss einstellen.

100 % weiß

Primärrot

Page 46

XV-C100A/M/E

Nr. Einstellgegenstand Einstellbedingungen Einstellverfahren

17

SECAM-Farbe

(Digital/AnalogWandler)

(Gammakorrektur

eingeschaltet)

18

Farbe des

Komponentensignals (DAC)

1. Das SECAM-Halbfarbbalkensignal

empfangen.

2. Das Doppelstrahl-Oszilloskop

zwischen Stift (3) von P1401 und GND

anschließen.

3. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: S-COLOR

1. Ein NTSC-Halbfarbbalkensignal dem

Komponentensignal-Anschluß

zuführen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 4

Element: C-COLOR

• Mit den Tasten ' und " die

Differenz zwischen dem 100 %

Weißpegel und dem Rotpegel auf

0,10 ±0,05 Vss einstellen.

100 % weiß

• Sich vergewissern, daß der Wert auf

“12” gesetzt ist.

Primärrot

19

GegenVormagnetisierung (R1402)

20

Weißbalance

(DAC)

1. Das NTSC-Monoskopsignal

empfangen.

1. Das NTSC-Monoskopsignal

empfangen.

2. S2001 drücken, um in den Modus ADJ

IN zu schalten, und das folgende

Element wählen.

Gruppe: VIDEO 2

Element: R-BIAS, B-BIAS

• R1402 so drehen, daß der beste

Kontrast erhalten wird.

• Unter Verwendung der ' und "

T asten den W eißabgleich visuell auf

die optimale Position einstellen.

46

Page 47

Nr. Einstellgegenstand Einstellbedingungen Einstellverfahren

XV-C100A/M/E

21

Prüfung der

Bildschirmanzeigeposition

(L2003)

22

Überprüfung der

T emperatursensorEinstellung

1. Das NTSC-Monoskopsignal

empfangen.

2. Die Tasten SOUND UP/DOWN

drücken, um den Lautstärkebalken auf

den Bildschirm zu rufen.

1. S2001 drücken, um in den Modus ADJ

IN zu schalten, und die folgende

Gruppe wählen.

Gruppe: SET

Element: HL

• L2003 drehen, so daß der Balken

gut auf dem Bildschirm zentriert ist.

• Sich vergewissern, daß der Wert auf

“2” gesetzt ist.

23

Horizontale Mitte

des

Komponentensignals (NTSC)

(DAC)

24

Horizontale Mitte

des

Komponentensignals (PAL)

(DAC)

1. Das NTSC-Testbildsignal zuführen.

2. S2001 drücken, um den ADJ IN-Modus

zu aktivieren, dann die folgende

Position wählen.

Gruppe: VIDEO 4

Element: C-H-CENT

1. Das PAL-Testbildsignal zuführen.

2. S2001 drücken, um den ADJ IN-Modus

zu aktivieren, dann die folgende

Position wählen.

Gruppe: VIDEO 4

Element: C-PH-CENT

• Unter Verwendung der ' und "

T asten den Abtastbereich rechts und

links auf die genau gleiche Distanz

einstellen.

Abtastbereich: 91 - 97%

• Unter Verwendung der ' und "

T asten den Abtastbereich rechts und

links auf die genau gleiche Distanz

einstellen.

Abtastbereich: 91 - 97%

47

Page 48

XV-C100A/M/E

TABELLE FÜR STÖRUNGSSUCHE

Prüfung des Videosystems

Kein Bild

Das Netzteil prüfen.

IC401, DL401 und ihre

Peripheriekreise prüfen.

Nein

Nein

Leuchtet die Lampe?

Ja

Liegt Spannung an den

Steckverbindern EA und EV an?

Ja

Liegt ein Signal an den Stiften

(21) und (29) von IC801 an?

Ja

Liegt ein Signal an den Stiften (1), (2)

und (3) von P803 an?

Ja

Mit “Prüfung des IC1501

Schnittstellenkreises” weitermachen.

Nein

Die Lampe prüfen.

Den Stromkreis des

Vorschaltelements prüfen.

Nein

IC801, Q801, Q804, Q802, Q803

und ihre Peripheriekreise prüfen.

Keine Farbe oder schlechter

Farbton bei NTSC-Signal

Liegt ein Chromasignaleingang an

Stift (20) von IC801 an?

Ja

IC801, IC801, IC804 und seine

Peripheriekreise prüfen

(insbesondere X801 und C810).

48

Nein

DL401, IC401, Q401 und ihre

Peripheriekreise prüfen.

Page 49

TABELLE FÜR STÖRUNGSSUCHE (fortgesetzt)

Keine Farbe oder

schlechter Farbton bei

PAL-Signal

XV-C100A/M/E

Liegt ein Videosignaleingang an Stift

(29) von IC801 an?

Ja

Werden die Signale R-Y und B-Y an

den Stiften (45) und (46) von IC801

ausgegeben?

IC802, IC804 und seine

Peripheriekreise prüfen.

Keine Farbe oder

schlechter Farbton bei

SECAM-Signal

Liegt ein Chromasignaleingang an

Stift (20) von IC803 an?

Nein

Nein

Nein

IC401 und seine

Peripheriekreise prüfen.

IC801 und seine

Peripheriekreise prüfen

(insbesondere X801 und C811).

IC401 und seine Peripheriekreise

prüfen.

Ja

Liegen an den Stiften (11) und (12)

von IC803 R-Y- und

B-Y-Ausgangssignale an?

Ja

Wird Spannung von über 4 V an Stift

(49) von IC801 zugeführt?

Ja

IC801, IC802, IC804 und seine

Peripheriekreise prüfen.

Nein

Nein

IC803 und seine Peripheriekreise

prüfen.

IC803 und seine Peripheriekreise

prüfen.

49

Page 50

XV-C100A/M/E

Kein KomponentensignalBild

TABELLE FÜR STÖRUNGSSUCHE (fortgesetzt)

Liegt an Stift (35) von IC3003 ein

Y-Eingangssignal an?

Ja

Liegen an den Stiften (13) und (14)

von IC3003 Eingangssignale an?

Ja

Liegen an den Stiften (44), (45) und

(46) von IC3003 Ausgangssignale

an?

Ja

Liegen an den Stiften (35), (36) und

(37) von IC801 Eingangssignale an?

Ja

IC801 und die

Peripherie-Schaltkreise überprüfen.

Nein

Nein

Nein

Nein

Q3001, Q3020, Q3021 und

die Peripherie-Schaltkreise

überprüfen.

IC2001 und die

Peripherie-Schaltkreise

überprüfen.

IC3003 und die

Peripherie-Schaltkreise

überprüfen.

C830, C831 und C832 sowie

die Peripherie-Schaltkreise

überprüfen.

Den Schnittstellen-Schaltkreis von

IC1501 überprüfen.

Keine KomponentensignalFarbe

Liegen an den Stiften (33) und (34)

von IC3003 Eingangssignale an?

Ja

IC3003 und die

Peripherie-Schaltkreise überprüfen.

Nein

Q3006 bis Q3013 sowie

Q3007 bis Q3010 überprüfen.

50

Page 51

TABELLE FÜR STÖRUNGSSUCHE (fortgesetzt)

Keine horizontale

Synchronisierung

Ja

XV-C100A/M/E

Liegt ein horizontaler

Ansteuerungssignalausgang an Stift

(56) von IC801 an?

Ja

Sind das Videosignal an Stift (21)

oder (29) von IC801 und das

horizontale Ansteuerungssignal an

Stift (58) von IC801 miteinander

synchronisiert?

Ja

Liegt ein horizontaler

Synchronisierungssignalausgang an

Stift (10) von IC503 an?

Ja

Liegt ein BASSynchronisierungssignalausgang an

Stift (4) von IC504 an?

Ja

IC1603, IC1607 und IC1608, die alle

auf der Steuerung-Leiterplatte

angeordnet sind, prüfen. Außerdem

ihre Peripherieteile prüfen.

Nein

Nein

Nein

Nein

Die Stifte (17) und (18)

von IC801, IC501 und die

Peripherie-Schaltkreise

überprüfen.

Stifte (58) und (59)

von IC801 und ihre

Peripherieteile prüfen.

IC503 und seine

Peripheriekreise prüfen.

IC504 defekt.

Keine vertikale

Synchronisierung

Ja

Liegt ein vertikaler

Synchronisierungssignalausgang an

Stift (4) von IC801 an?

Ja

Liegt ein vertikaler

Synchronisierungssignaleingang an

Stift (11) von IC502 an?

Ja

Liegt ein vertikaler

Synchronisierungssignalausgang an

Stift (10) von IC502 an?

Ja

IC1606 und seine Peripherieteile

prüfen.

Nein

Nein

Nein

IC801 und seine

Peripheriekreise prüfen.

Q804 und Q805 prüfen.

IC502 und seine

Peripherieteile prüfen.

51

Page 52

XV-C100A/M/E

TABELLE FÜR STÖRUNGSSUCHE (fortgesetzt)

Prüfung des IC1501

Schnittstellenkreises

Ja

Liegen Videosignalausgänge an den

Stiften (32), (34) und (36) von IC1501

an?

Ja

Q1501, Q1502, Q1503, Q1504,

Q1505 und Q1506 prüfen.

Lampe leuchtet nicht

Q1701 entfernen. Fällt F1701 wieder

aus?

Nein

Nein

Die Spannungen aller Stifte

von IC1501 prüfen.

Außerdem ihre

Peripheriekreise prüfen.

Ja

Problem bei

Spannungseinheit.

Sicherung in Ordnung

Wird Entladungston gehört?

T1702 oder

Lampe

ersetzen.

Triggerschaltkreis

überprüfen.

Problem bei Vorschalteinheit

NeinJa

Sicherung durchgebrannt

Fallen Q1701 und L1701 im

Kurzschlußmodus aus?

Ja

Q1701 und

L1701

ersetzen.

Q1701, L1701 und ihre

Peripherieschaltkreise

überprüfen.

Nein

52

Page 53

XV-C100A/M/E

53

Page 54

XV-C100A/M/E

!"#$%

!"#$%&

!"#$%&'()*+,-./01

!"#$%&'

!"#$%

!

!"# !"#$%&'=

NK !"#$%&'()*+,-.*/

! !

!"

OK !"#$%&'(()*+,

PK !"#$%&'()*+,- O

!"#$%&

!"

NK !"#$ !"#$%&

OK !"#$%& !"#$%&'

PK !"#$%&'()*

`ijmcMMRPabMP SRsLNRRt

QK !"#$%&'()*+,-

!"#

RK !"#$%&'() !

!"#$%&'()*

Ë

== !"#$%

!"#$%&'()* !"

!"#$%&'()* !"#$

!"#$% !"#$%&'2

! !"#$%&'(

!"#$%&'()*+

1

2

!" !"#$% !"#

!"#$% !"#$%&'()

!"#$

!"#$%&'(

54

Page 55

!"#$

XV-C100A/M/E

55

Page 56

XV-C100A/M/E

!"#$%

56

Page 57

!

XV-C100A/M/E

57

Page 58

XV-C100A/M/E

1-4

1-5

!"#$

1-1

1-2

1-7

1-3

1-6

1-7

58

Page 59

1-8

XV-C100A/M/E

1-10

1-9

(PE)

1-11

1-12

(SP)

1-12

59

Page 60

XV-C100A/M/E

2-2

2-3

3-2

3-1

2-3

2-1

2-4

2-1

2-3

2-3

60

2-1

Page 61

XV-C100A/M/E

5-2

4-3

5-3

5-2

5-1

5-1

5-1

4-1

4-2

61

Page 62

XV-C100A/M/E

!

!

PFiLW0164CEZZ

PFiLW0202CEZZ

RLCDP0088CEZZ

PCAPH1061CESB

PLNS-0124CEZZ

PFiLW0200CEZZ

PFiLW0194CEZZ

CLMPF0053DE03

Ë

!"#$%

62

Page 63

Ë

XV-C100A/M/E

0000H

0000H

63

Page 64

XV-C100A/M/E

!"#$%& '()LINE。

!"#N·W !"#$%

64

Page 65

XV-C100A/M/E

65

Page 66

XV-C100A/M/E

0

SUB-B

!"#

–4

S-COLOR

–6

P-COLOR

+7

C-PH-CENT

HL

2

0

SUB-G

0

SUB-R

–3

BRIGHT

+6

CONT

0

P-H-CENT

64

B-DRIVE

64

R-DRIVE

74

B-BIAS

74

R-BIAS

COLOR

TINT

T-BRT

ADJ

AGC

GAMMA2

–30

0

0

–4

+5

C-H-CENT

–3

+9

C-TINT

+7

C-COLOR

+5

C-BRIGHT

0000

TIME2

ENTER

H-CENT SUB-R

VIDEO1

H-CENT

MENU

P-H-CENT SUB-G

CONT SUB-B

–3

BRIGHT

ENTER

TINT

SUB-BIAS

VIDEO2

SUB-BIAS

MENU

COLOR

P-COLOR

R-BIAS

B-BIAS

64

S-COLOR

R-DRIVE

B-DRIVE

S2001

ENTER

ENTER

MENU

VIDEO1 SET

VIDEO2 N • W

ADJ IN

255

GAMMA1

MENU

GAMMA1

GAMMA2

AGC ADJ

VIDEO3

VIDEO3 LINE

VIDEO4 TEST

T-BRT

ENTER

C-PH-CENT

C-CONT

C-BRIGHT

VIDEO4

–4

C-CONT

MENU

C-COLOR

C-TINT

C-H-CENT

66

ENTER

N • W

RED

R G B N • W

MENU

GREEN

BLUE

N • W

LINE

AUTO

OFF TIMER

TEMP1

TEMP2

ENTER

FACTORY SET 4

TEST

TIME1

MENU

TIME1

TIME2

0001

Page 67

!

XV-C100A/M/E

67

10

Page 68

XV-C100A/M/E

10

10

1

10

68

10

1

Page 69

XV-C100A/M/E

69

Page 70

XV-C100A/M/E

70

Page 71

XV-C100A/M/E

71

Page 72

XV-C100A/M/E

!"#$kqp`

!a^`

!"#Em^i

FEa^`F

1. kqp` !"#$%&'

2. pOMMN !"^ag=fk

!"#$%&'()

・ !sfablQ

・ !`JeJ`bkq

1. m^i !"#$%&'

2. pOMMN !"^ag=fk

!"#$%&'()

・ !sfablQ

・ !`JmeJ`bkq

・'

!"

!VNVT

・'

!"

!VNVT

"

"

!"#$%&'(

!"#$%&'(

72

Page 73

!"

XV-C100A/M/E

73

Page 74

XV-C100A/M/E

!"#$%&'

74

Page 75

!"#$%&'

XV-C100A/M/E

75

Page 76

XV-C100A/M/E

!"#$%&'

76

Page 77

!"#$%&'

XV-C100A/M/E

77

Page 78

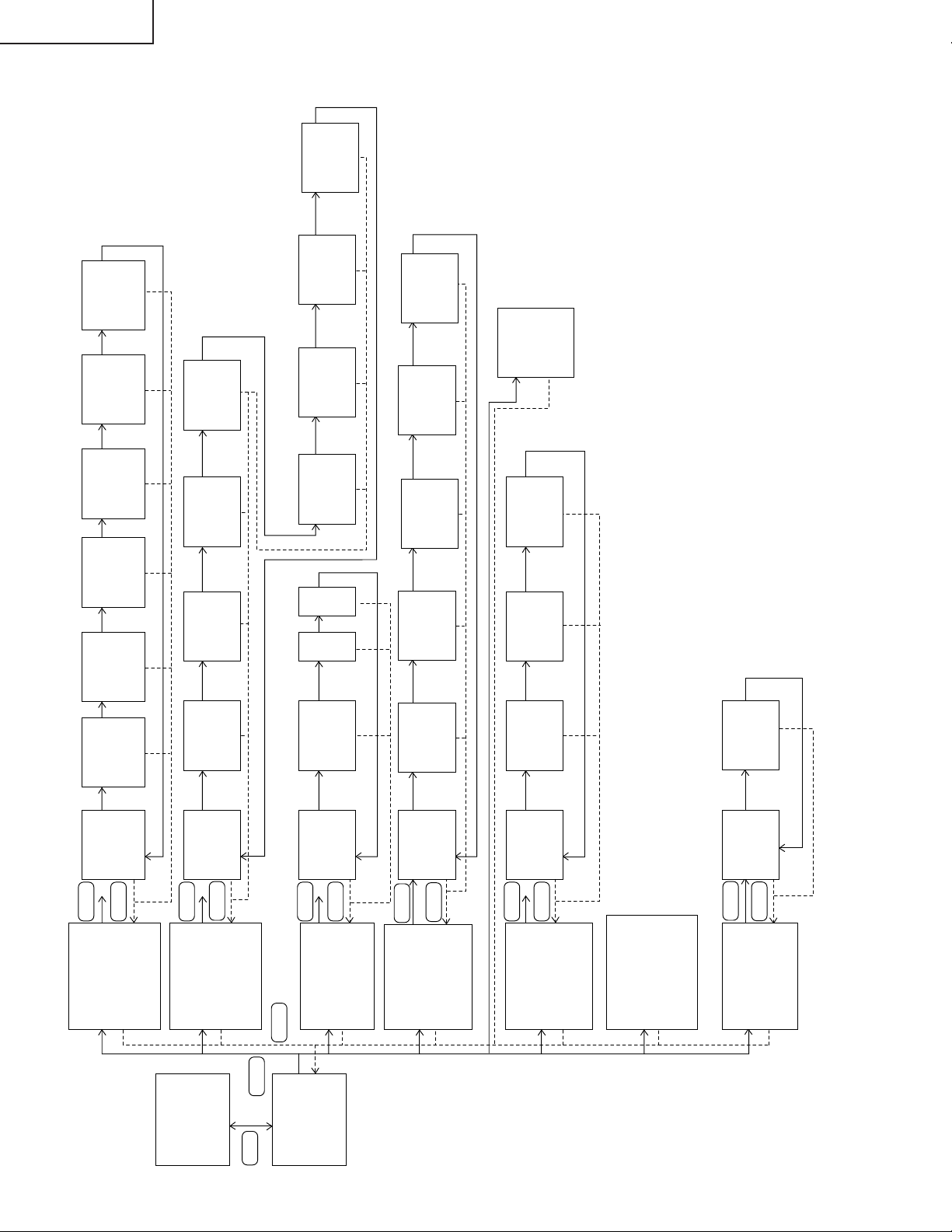

CHASSIS LAYOUT / CHASSIS-ANORDNUNG

!"#$%

H

R/C UNIT

DUNTK9004WEV0/V1/V4

G

F

BALLAST UNIT

RDENC0265CEZZ/DUNTKA009WEV0

RDENC0262CEZZ/DUNTKA009WEV1

XV-C100A/M/E

POWER UNIT

RDENC0266CEZZ/DUNTKA001WEV2

CONTROL UNIT

DUNTK9003WEV0/V1/V4

E

D

C

MAIN UNIT

DUNTK9001WEV0/V1/V4

SUB UNIT

DUNTK9002WEV0/V1/V4

B

OPERATION KEY UNIT

RUNTK0624CEZZ

A

121110987654321

78

79

Page 79

OVERALL WIRING DIAGRAM / GESAMTSCHALTPLAN

!"#$

H

G

F

XV-C100A/M/E

E

D

C

B

A

121110987654321

80

81

Page 80

XV-C100A/M/E

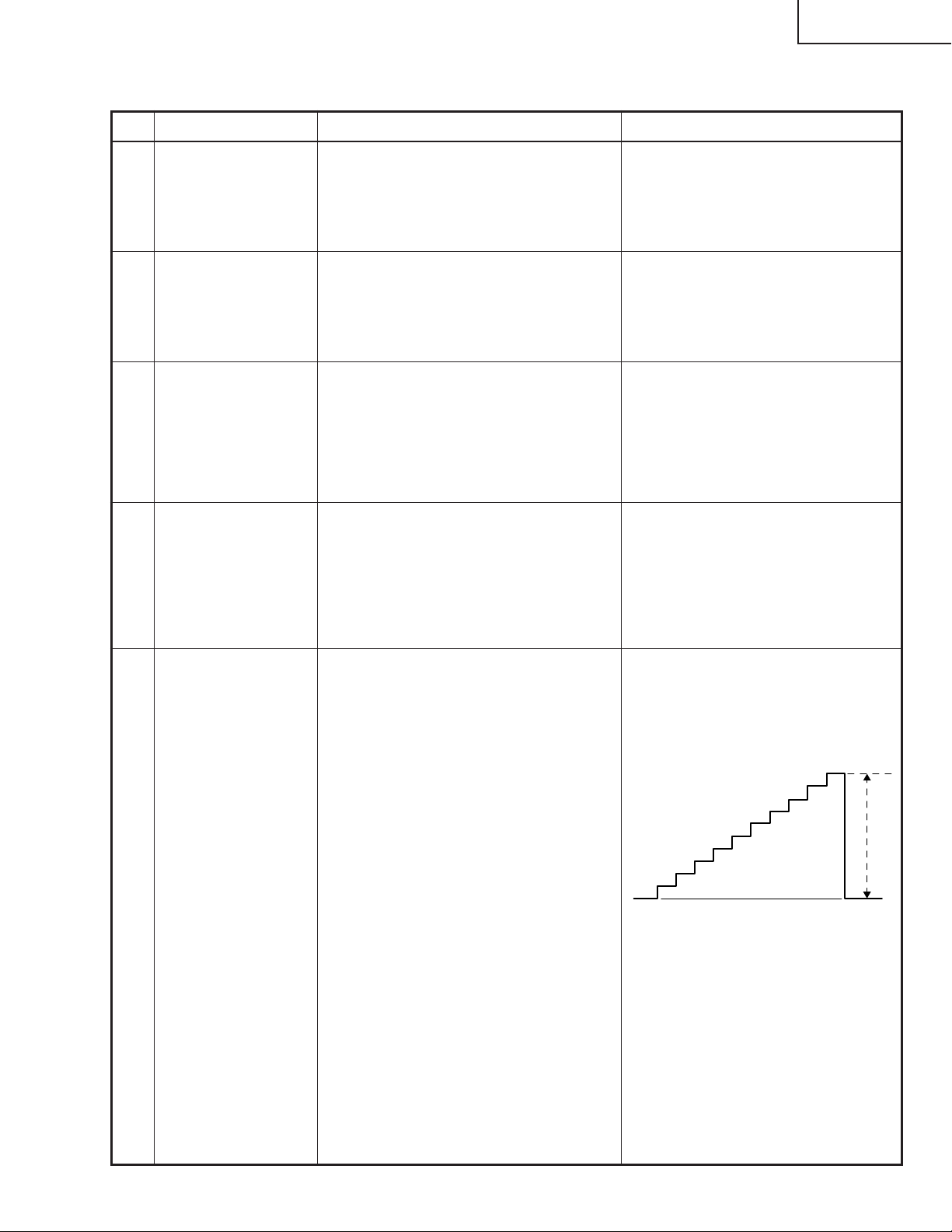

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the supply voltage of AC 220V. Signals

are fed by a colour bar signal generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

H

WAVEFORM MEASUREMENT CONDITION:

1. Waveforms at test points are observed at the supply voltage of AC 220V.

Signals are fed by a colour bar signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise noted.

C : Solid W : Cement

S : Oxide Film T : Special

N : Metal Coating

G

F

BESCHREIBUNG DES SCHEMATISCHEN SCHALTPLANS

SPANNUNGSMESSUNGEN:

1. Spannungen an den Prüfpunkten werden bei einer Netzspannung von 220V

gemessen, Signale werden für die Wartung mit einem Farbbalken-Signal

generator zugeführt, und Spannungen werden mit einem Meßinstrument

(20 kΩ/V) ermittelt.

SIGNALFORMMESSUNGEN:

1. Die Wellenformen an den Testpunkten werden bei einer Netzspannung von

220V verfolgt. Signale werden für die Wartung mit einem Farbbalken-Signal

generator zugeführt.

BEZEICHNUNG DES WIDERSTANDS UND

KONDENSATORS:

WIDERSTAND

1. Die Widerstandseinheit “Ω” wird weggelassen.

(K=kΩ=1000 Ω, M=MΩ).

2. Alle Widerstände haben ± 5%, sofern nicht anders angegeben.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. Alle Widerstände haben 1/16W, sofern nicht anders angegeben.

4. Alle Widerstände sind Kohletyp, sofern nicht anders angegeben.

C : Fest W : Zement

S : Oxidfilm T : Spezial

N : Metallüberzug

E

D

C

!"#$%

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise noted.